Abstract

Colloidal crystallization of copolymer-grafted silica containing ferrocenyl groups in organic solvents and effects of ferrocenyl groups on effective refractive index of colloidal crystal systems were investigated. Poly(ferrocenyl metharylate (FeMA)-co-methyl methacrylate (MMA)-grafted silica gave colloidal crystallization in dimethylformamide and acetonitrile. The colloidal crystals exhibited characteristic coloration due to cooperative effects of specific absorption at 400–500 nm by ferrocenyl group and transmission of 700–800-nm light through the crystals. It was observed that effective refractive index of colloidal crystals systems of poly(FeMA-co-MMA)-grafted silica was higher than that of poly(MMA)-grafted silica. Normalized effective refractive index of the system linearly increased with mole fraction of FeMA in grafted copolymer. However, poly(FeMA-block-MMA) did not bring effective increase of the index because of bias formation of ferrocenyl group on silica.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, three-dimensional (3D) particle array structure, interparticle space of which is corresponding to visible light wave length, has been receiving great attention for promising application to optical devices, such as wave guide, sensor, and so on [1–8]. So far, there are many approaches for fabrication of the particle array structure [1–35]. One of the approaches is the fabrication of 3D array structure employing colloidal crystal, which is classified by two categories, hard type and soft type. The hard-type colloidal crystals are usually formed by deposition or ordering during drying of colloidal suspension and have an advantage for making large size of single crystal [18–24]. However, the hard-type crystal gives blunt Bragg reflection due to direct affects of particle size distribution on particle array structure. On the other hand, soft-type colloidal crystals are formed in deionized aqueous solution through electrostatic repulsion between the particles [36, 37]. The soft-type crystals usually exhibit a sharp and clear Bragg reflection; challenging of photonic crystal fabrication from the crystals formed in suspension was carried out by solidification of colloidal crystals in hydrogels [13, 16, 25–31, 34, 35]. Moreover, the soft-type colloidal crystals have the advantage for controlling intersphere distance by changing volume fraction of particles, which is fairly attractive for application to photonic devices in spite of polycrystalline. In cases of soft-type systems, colloidal crystallization in aqueous solution has been examined employing monodisperse colloidal silica, polystyrene, or poly(methyl methacrylate (MMA)) latexes because of easy availability and stability. Especially, colloidal silica is fairly favorable to make stable colloidal crystallization in aqueous solution due to high surface charge.

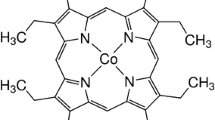

In order to fabricate photonic devices composed of 3D arrayed structure, it is obviously essential to immobilize or solidify colloidal crystals in polymer matrixes. In this respect, we have successfully achieved colloidal crystallization of polymer-grafted silica in organic solvents [38–40] and then immobilization in polymer gels [41–44]. However, there are major problems for fabrication of photonic devices employing colloidal crystals from silica or polymer latexes because of comparatively low refractive index and/or dielectric constant. On improvement of shortcomings, Ashrit et al. have fabricated photonic crystal of WO3 by using inverse colloidal crystals of polystyrene latex [8]. So far, incorporation of heavy atoms or high electron density substituent groups into polymer was widely investigated to increase the refractive index [45, 46]. In this study, colloidal crystallization of colloidal silica modified with copolymer of ferrocenyl metharylate (FeMA) and MMA group in organic solvent and effects of ferrocenyl group on effective refractive index (n eff) of colloidal crystal system were investigated. Increasing ionic strength in colloidal suspension generally disturbs colloidal crystallization in solution because of decreasing electric double layer on the surface of particles. Thus, we chose zero-valence Fe(0) complex of ferrocenyl group as a functional group for increasing refractive index.

Experimental

Materials

Colloidal silica, of 150 nm in diameter, suspended in ethanol was kindly offered by JGC Catalysts and Chemicals, Ltd., Japan. 3-Aminopropyltriethoxysilane (APTS), N,N′-dicyclohexylcarbodiimide (DCC), N,N,N′,N″,N″-pentamethyldiethylene triamine (PMDETA), and N,N′-azobis(4-cyanovaleric acid) (ACVA) were pursed from Wako Pure Chemical Industries, Ltd., Japan. 2-Bromo-2-methylpropionic acid was pursed from Tokyo Chemical Industry Co. Ltd., Japan.

Measurements

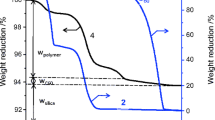

Particle size was determined by a dynamic light scattering (DLS) on DLS-7000DL Otsuka Electronics Co. Ltd., Japan using a He–Ne laser at measurement angle of 90°. Molecular weight of polymer was evaluated by a gel permeation chromatography on series-connected columns, PL-gel MIEXED-C and PL-gel MIEXED-D with a differential refract meter and THF eluent of 0.8 ml/min. Amounts of grafted polymer was determined by a thermal gravimetric analysis on TG-50, Shimadzu Co. Ltd., Japan under nitrogen atmosphere in elevating temperature up to 800 at heating rate 10 °C/min. 1H nuclear magnetic resonance (1H NMR) spectra were recorded on AVNACE400, Bruker, Germany at 440 MHz. Reflection spectra of colloidal crystals were recorded on NAR-2T Atago Co. Ltd., Japan. Transmission electron microscopy (TEM) observation was conducted on H-9000NAR, Hitachi Ltd., Japan.

Preparation of carboxyl-terminated poly(FeMA-co-MMA)

The polymer was synthesized by radical copolymerization of FeMA and MMA in tetrahydrofuran (THF; Scheme 1). In Table 1, recipe in radical copolymerization of FeMA and MMA using an initiator of ACVA and molecular weight of resulting copolymers are shown. In this copolymerization, carboxyl-terminated copolymers of FeMA/MMA mole ratio from 1:3 to 1:12 in the molecular weight range from 9,600 to 19,500 were obtained.

Preparation of triethoxysilyl-terminated poly(FeMA-co-MMA)

The polymer was synthesized according to previous paper [39]. In a 50-ml flask, 0.622-g carboxyl-terminated poly(FeMA-co-MMA), 2.1 mg DCC, and 0.02 ml APTS in 10-ml chloroform were put, and the mixture was stirred at 0 °C in N2 atmosphere for 30 min. Evaporation of solvent and drying under reduced pressure gave 0.47 g copolymer silane.

Grafting of copolymer silane on colloidal silica

In a 100-ml flask, 0.12 g copolymer silane and 15 ml colloidal silica ethanol suspension, containing 3.0 g SiO2 and 40 ml 1,2-dimethoxyethane, were put, and the mixture was sonicated for 30 min at room temperature. After the suspension was stirred at 90 °C to remove 30 ml of solvent azeotropically, 10 ml THF was then added to the suspension, followed by heating at 70 °C for 12 h. After washing with THF using centrifugation, drying under reduced pressure gave about 2.5 g poly(FeMA-co-MMA)-grafted silica.

Synthesis of 3-(2-bromo-2-methylbutyloyl)aminopropyl triethoxysilane

A mixture of 1.2 g 2-bromo-2-methylpropionic acid, 1.4 g DCC, and 10 ml chloroform was stirred at 0 °C for 30 min. After addition of 1.4 g APTS to the mixture, the solution was stirred at room temperature for 5 h. Filtration, evaporation of solvent, and drying under reduced pressure gave 2.81 g product. 1H NMR (CDCl3); 0.6 (q, CH2-Si), 1.2 (q, CH3), 1.7 (q, CH2), 2.0 (s, (CH3)2), 3.3 (t, CH2), 7.0 (s, NH) ppm.

Preparation of poly(FeMA-block-MMA)-grafted silica

Grafting of block copolymer on colloidal silica was carried out by an atom transfer radical polymerization (Scheme 2). Introduction of initiator group on silica was conducted by the reaction of 3-(2-bromo-2-methylbutyloyl)aminopropyl triethoxysilane with colloidal silica by the same method as described above.

Into a test tube, a mixture of 0.7 g initiator-grafted silica, 0.53 g FeMA, 22 mg CuBr, 32 μl PMDETA, 3 ml dimethylformamide (DMF), and 0.04 ml 1-(2-bromo-2-methylbuloyl) aminobutane as a free initiator was put. The test tube was purged with nitrogen through freeze-pump-thaw and heated at 70 °C for 24 h. After cooling down, the particles were separated by centrifugation and washed with DMF. Drying under reduced pressure gave 0.7 g poly(FeMA)-grafted silica; amount of grafted polymer 20 mg/g, molecular weight of polymer obtained from a free initiator 2,700. A DLS analysis of resulting particles showed achieving polymer grafting without aggregation during the polymerization.

Successive polymerization of MMA on poly(FeMA)-grafted silica was carried out by the same manner as the first one. The mixture of 0.7 g poly(FeMA)-grafted silica, 3.25 ml MMA, 29 mg CuBr, 43 µl PMDETA, 0.075 ml free initiator, and 3 ml dimethylformamide (DMF) was purged with nitrogen and then stirred at 70 °C for 2 days. The polymerization gave 0.5 g poly(FeMA-block-MMA)-grafted silica: amount of grafted polymer, 136 mg/g; molecular weight of grafted polymer, 184,000; average size of the particles, 216 nm.

Determination of effective refractive index

Effective refractive index (n eff) of colloidal crystal system was determined from angle-resolved reflection spectra according to Bragg equation on assumption of face centered cubic closed packing [22]:

where λ max is wavelength of reflection peak, θ is incident angle, and d is neighboring particle distance. Actually, n eff was estimated from fitting plots of θ vs λmax by putting appropriate d value in Eq. 1.

Determination of interparticle distance

Neighboring interparticle distance (d) was estimated by following equation [37]:

where λ is peak top wavelength on reflection spectrum recorded at incident angle 90°, and n ave is average refraction index of the suspension system calculated by following equation:

where n silica and n sol are refractive indices of silica and solvent, respectively, and ϕ is volume fraction of silica.

Results and discussion

Grafting of poly(FeMA-co-MMA) on colloidal silica

Grafting of poly(FeMA-co-MMA) on silica was carried out by the reaction of colloidal silica with corresponding polymer silane in 1,2-dimethoxyethane under refluxing. Amounts of grafted polymer were in the range from 14 to 36 mg/g (Table 2). These particles were well dispersed in organic solvents, such as THF and acetonitrile.

Colloidal crystallization

When poly(FeMA-co-MMA)-grafted silica was dispersed in DMF and acetonitrile, colloidal crystallization was observed. In Table 2, critical volume fraction for colloidal crystallization of poly(FeMA-co-MMA)- and poly(MMA)-grafted silica was shown. The critical volume fraction (ϕ o) is the minimal fraction of colloidal particles to form colloidal crystals. Therefore, low ϕ o values are attributable to strong electrostatic interaction, and ϕ o values are sometimes employed as an index of stability of colloidal crystals. The values of ϕ o for copolymer-grafted silica in DMF were in the range from 0.081 to 0.094, higher than those, 0.029 to 0.048, in acetonitrile. Probably, high polarity of DMF disturbs the crystallization due to decreasing electrostatic repulsion between the particles. Also, ϕ o values for copolymer-grafted silica in DMF and acetonitrile were fairly higher than those for poly(MMA)-grafted silica. The reason for low ϕ o values in colloidal crystallization of the present copolymer-grafted silica is still unclear. It might come from increasing π–π interaction between ferrocenyl groups in grafted polymer chains to disturb electrostatic repulsion between the particles. On the other hand, poly(FeMA-block-MMA)-grafted silica exhibited relative high ϕ value for colloidal crystallization in DMF and acetonitrile. In this case, the crystallization probably takes place based on steric repulsion between grafted polymer chains on silica particles [47]. Therefore, relatively high ϕ o values presumably come from low polymer graft density on silica surface.

In Fig. 1, typical pictures of colloidal crystals are shown. Interestingly, in the front side view against light irradiation, colloidal crystallites were observed in green solution, and transmission light in the rear side was colored reddish. The coloration in colloidal crystallization of polymer-grafted silica containing diene iron(0) tricarbonyl complex in organic solvent was observed previously, coming from cooperative effects of specific absorption of 400–500-nm light by iron(0) complex moiety and transmission of 700–800-nm light through the crystals [48].

Effective refractive index

In Fig. 2a, angle-resolved reflection spectra of colloidal crystals of poly(FeMA-co-MMA)-grafted SiO2 in DMF at incident angle from 20° to 44° were shown. Typical fitting plotting between θ and λ max in Eq. 1 for optimizing interparticle distance (d colloid) and effective refractive index (n eff) was shown in Fig. 2b. In Table 3, n eff and d values estimated by fitting plots for colloidal crystals systems of poly(FeMA-co-MMA)-grafted SiO2 in DMF were listed along with average refractive index (n ave) and interparticle distances (d) derived by Eqs. 2 and 3, respectively. Consequently, the value of n ave is simply estimated from the ones of silica and solvent without taking into account grafted polymer. As can be seen in Table 3, d values were well coincident with d colloid within 5% deviation. Therefore, it was suggested that n eff values were reasonable and relatively precise. The values of n eff slightly increased with increasing mole fraction of FeMA in grafted polymer. However, these values changed with volume fraction of polymer-grafted silica and mole fraction of FeMA in the copolymer. Thus, differential effective refractive indices (∆n/ϕ), which were normalized by average refractive index (n ave) and volume fraction of particles (ϕ), were proposed: ∆n = n eff − n ave. Here, it is important to notify that n eff implies contribution of grafted copolymer involved with Fe(0) complex to refractive index. In Fig. 3, plots of mole fraction of FeMA in grafted polymer vs ∆n/ϕ were shown. The normalized values proportionally increased with mole fraction of FeMA and reached 0.27, which was 50% higher as compared with that of poly(MMA)-grafted silica. Those results showed that introduction of ferrocenyl group in grafted copolymer on silica effectively enhanced refractive index of polymer-grafted silica suspension systems.

Angle-resolved reflection spectra of colloidal crystals of poly(MMA-co-FeMA) (m/n = 1/5)-grafted silica in DMF (a) and fitting curve between θ and λ peak in Eq. 1 (b)

In the above cases, the particles were modified with random copolymer of FeMA and MMA, and then ferrocenyl groups in grafted copolymer were probably considered to exist in relatively homogeneous distribution around particle surface. If the ferrocenyl groups could be effectively condensed near the surface of the particles, the groups could efficiently contribute to increasing refractive indices. Therefore, we studied colloidal crystallization of poly(FeMA-block-MMA)-grafted silica in organic solvents and effective refractive index of suspension system. The ϕ o values of poly(FeMA-block-MMA)-grafted silica for the crystallization in DMF and acetonitrile was to be 0.24 and 0.106, respectively, which were fairly higher than those of poly(FeMA-co-MMA)- and poly(MMA)-grafted silica. In this case, therefore, effective refractive index was estimated using colloidal crystals system of poly(FeMA-block-MMA)-grafted silica in acetonitrile because of low stability of colloidal crystals in DMF. In Table 3, n eff and ∆n/ϕ of poly(FeMA-block-MMA)–, poly(FeMA-co-MMA)-, and poly(MMA)-grafted silica colloidal crystal systems in acetonitrile were listed. These values of poly(FeMA-co-MMA)-grafted silica system were clearly higher than those of poly(MMA)-grafted silica. Unexpectedly, ∆n/ϕ of poly(FeMA-block-MMA)-grafted silica colloidal crystals system was relatively low as compared with poly(MMA)- and poly(FeMA-co-MMA)-grafted silica systems, in spite of higher grafting amount of ferrocenyl methacrylate moiety. The reason for low distribution of block copolymer to effective refraction index is discussed below.

TEM observation of copolymer-grafted silica

Figure 4 shows the TEM images of poly(MMA)-, poly(FeMA-co-MMA)-, and poly(FeMA-block-MMA)-grafted silica. It was observed that the surface of poly(FeMA-co-MMA)-grafted silica was smooth and homogeneous, as well as that of poly(MMA)-grafted silica, while the surface of block copolymer-grafted silica was heterogeneous and spotty area. The area was possibly assigned to aggregates of ferrocenyl methacrylate moiety, formed due to π–π or nonpolar–nonpolar interaction between ferrocenyl groups. Therefore, low effectiveness of ferrocenyl group in block copolymer-grafted silica on enlargement of refractive index probably stemmed from bias formation of ferrocenyl groups on silica surface.

Conclusions

Colloidal silica modified with copolymer tethering ferrocenyl group, poly(FeMA-co-MMA), and poly(FeMA-block-MMA), brought colloidal crystallization in DMF and acetonitrile. Characteristic coloration of colloidal crystals was observed due to cooperative effects of specific absorption at 400–500 nm by ferrocenyl group and transmission of 700–800-nm light through the crystals. Normalized effective refractive index by volume fraction of the particles increased with mole fraction of FeMA in copolymer. This result suggested that introduction of ferrocenyl group into grafted copolymer led to enlargement of refractive index of colloidal silica systems.

References

Holtz JH, Asher SA (1997) Nature 389:829

Reese CE, Mikhonin AV, Kamenjicki M, Tikhonov A, Asher SA (2004) J Am Chem Soc 126:1493

Muscatello MMW, Stunja LE, Asher SA (2009) Anal Chem 81:4978

Muscatello MMW, Stunja LE, Thareja P, Wang L, Bohn JJ, Velankar SS, Asher SA (2009) Macromolecules 21:4403

Xia Y, Gates B, Yin Y, Lu Y (2000) Adv Mater 12:693

Lawrence JR, Ying Y, Yiang P, Foulger SH (2006) Adv Mater 18:300

Park JH, Ohoi WS, Koo HY, Kim DY (2005) Adv Mater 17:879

Kuai SL, Bader G, Ashrit PV (2005) Appl Phys Lett 86:22110

Cong H, Cao W (2004) Langmuir 20:8049

Nagao D, Anzai N, Kobayashi Y, Gu S, Konno M (2006) J Colloid Interface Sci 298:232

Hong SH, Moon JH, Lim JM, Kim SH, Yang SM (2005) Langmuir 21:10416

Zheng N, Fan J, Stucky GD (2006) J Am Chem Soc 128:6550

Zhou J, Cai T, Tang S, Marquez M, Hu Z (2006) Langmuir 22:863

Li Y, Kunitake T, Fujikawa S, Ozasa K (2007) Langmuir 23:9101

Zhou Z, Yan Q, Li Q, Zhao XS (2007) Langmuir 23:1473

Hosein ID, Lindell CM (2007) Langmuir 23:2892

Weekes SM, Ogrin FY, Murray WA, Keatley PS (2007) Langmuir 23:1057

Jiang P, Bertone JF, Hwang KS, Colvin VL (1999) Chem Mater 11:2132

Lyon AL, Debord JD, Debord SB, Jones CD, McGrath JG, Serpe MJ (2004) J Phys Chem B 108:19099

Fudouzi H, Xia Y (2003) Langmuir 19:9653

Camargo PH, Lee YH, Jeong U, Zou Z, Xia Y (2007) Langmuir 23:2985

Nakamura H, Ishii M, Tsukigase A, Harada M, Nakano H (2006) Langmuir 22:1268

Ishii M, Nakamura H, Nakano H, Tsukigase A, Harada M (2005) Langmuir 21:5367

Nakamura H, Shii M, Tsukigase A, Harada M, Nakano H (2005) Langmuir 21:8918

Nakamura H, Ishii M (2005) Langmuir 21:11578

Nakamura H, Mitsuoka T, Ishii M (2006) J Appl Polym Sci 102:2308

Takeoka Y, Watanabe M (2003) Langmuir 19:9554

Kumada M, Watanabe M, Takeoka Y (2006) Langmuir 22:4403

Sakai T, Takeoka Y, Seki T, Yoshida R (2007) Langmuir 23:8651

Sawada T, Suzuki Y, Toyotama A, Iyi N (2001) Jpn J Appl Phys 40:1226

Yamanaka J, Murai M, Iwayama Y, Yonese M, Ito K, Sawada T (2004) J Am Chem Soc 126:7156

Murai M, Yamada H, Yamanaka J, Onda S, Yonese M, Ito K, Sawada T, Uchida F, Ohki Y (2007) Langmuir 23:7510

Toyotama A, Kanai T, Sawada T, Yamanaka J, Ito K, Kitamura K (2005) Langmuir 21:10268

Toyotama A, Yamanaka J, Shinohara M, Onda S, Sawada T, Yonese M, Uchida F (2009) Langmuir 25:589

Evanoff DD, Hayes SE, Ying Y, Shim GH, Carroll LJR, JB RRD, Houchins JM, Huebner CF, Foulger SH (2009) Adv Mater 19:3507

Okubo T (1986) Acc Chem 82:3163

Okubo T (1996) Colloid Surf A 109:97

Yoshinaga K, Chiyoda M, Yoneda A, Nishida H, Komatsu M (1999) Colliod Polym Sci 28:481

Yoshinaga K, Chiyoda M, Ishiki H, Okubo T (2002) Colloid Surf A 204:285

Yoshinaga K, Shigeta M, Komune S, Mouri E, Nakai A (2007) Colloids Surf B 54:10

Yoshinaga K, Fujiwara K, Tanaka Y, Nakanishi M, Takesue M (2003) Chem Lett 32:1082

Yoshinaga K, Mouri E, Ogawa J, Nakai A, Ishii M, Nakamura H (2004) Colloid Polym Sci 283:340

Yoshinaga K, Fujiwara K, Mouri E, Ishii M, Nakamura H (2005) Langmuir 21:4471

Yoshinaga K, Satoh S, Mouri E, Nakai A (2006) Colloid Polym Sci 284:694

Arsenault A, Miguez H, Kitaev V, Ozin GA, Manners I (2003) Chem Mater 15:503

Paquet C, Cyr PW, Kumacheva E, Manners I (2004) Chem Mater 16:5250

Ohno K, Morinaga T, Takeno S, Tsujii Y, Fukuda T (2006) Macromolecules 39:1245

Yoshinaga K, Mouri E (2007) Proceedings SPIE 676701:676708

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, Z., Watanabe, M., Mouri, E. et al. Effects of ferrocenyl group on refractive index of colloidal crystal system formed by polymer-grafted silica in organic solvent. Colloid Polym Sci 288, 519–525 (2010). https://doi.org/10.1007/s00396-009-2143-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-009-2143-8