Abstract

In the current report, characteristics of the propagated wave in a sandwich structure with a soft core and multi-hybrid nanocomposite (MHC) face sheets are investigated. The higher-order shear deformable theory (HSDT) is applied to formulate the stresses and strains. Rule of the mixture and modified Halpin–Tsai model are engaged to provide the effective material constant of the multi-hybrid nanocomposite face sheets of the sandwich panel. By employing Hamilton’s principle, the governing equations of the structure are derived. Via the compatibility rule, the bonding between the composite layers and a soft core is modeled. Afterward, a parametric study is carried out to investigate the effects of the CNTs' weight fraction, core to total thickness ratio, various FG face sheet patterns, small radius to total thickness ratio, and carbon fiber angel on the phase velocity of the FML panel. The results show that the sensitivity of the phase velocity of the FML panel to the \({W}_{\rm{CNT}}\) and different FG face sheet patterns can decrease when we consider the core of the panel more much thicker. It is also observed that the effects of fiber angel and core to total thickness ratio on the phase velocity of the FML panel are hardly dependent on the wavenumber. The presented study outputs can be used in ultrasonic inspection techniques and structural health monitoring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Up to now, huge research is proved that the compositionally structures have a marvelous thermo-electro-mechanical property [1,2,3] and this issue is being an important reason to take the attention of all engineering fields for having efficient productions with the aid of composite structure, especially carbon-based nanofillers reinforced structure [4,5,6,7,8,9,10]. In addition to what is mentioned owing to the wide applications of wave propagation analysis in structural health monitoring, most recently, an interesting field of research has been started in scholar which is called wave propagation response [11,12,13]. In addition, the properties of reinforcements make them an appropriate choice to be used in chemistry, physics, electrical engineering [14,15,16,17,18,19,20,21,22,23,24,25,26], materials science [10], and engineering applications [27,28,29,30,31,32,33,34,35].

By considering the mentioned necessities and in the field of wave propagation in composite beams and plates, Ebrahime et al. [36] could present a paper to investigate the wave propagation of the sandwich plate in which the structure is embedded in a nonlinear foundation. Also, they considered a magnetic environment in their model and used the classical theory for doing their computational formulation. Based on their result, as the magnetic layer will play the most important role on the wave response of the sandwich plate [37]. presented a comprehensive formulation on the wave dispersion of a high speed rotating 2D-FG nanobeam. They used nonlocal theory for consideration of the couple stress in the nanomechanics effect on the wave response of the structure. They could solve their complex formulation via an analytical method and they reported that the rotating speed is the most effective parameter. By employing the new version couple stress theory, Global matrix, and Legendre orthogonal polynomial methods, and, Liu et al. [38] had a try for reporting the characteristics of the propagated wave in a micro FG plate. They reported that by controlling the couple stress, we will have the grater phase velocity in the aspect of wave propagation. Ebrahimi et al. [39] succeeded in publishing a paper in which a computational framework is developed for investigation wave behavior in a thermally affected nonlocal beam which is made by FG materials. One of their assumptions was that the nanobeam is under high-speed rotation and is located in a thermal environment. They presented a lot of results but the most significant one was that changing the rotating speed can provide some novel results on the wave propagation in the nanostructure. In a novel work, Barati [40] showed the behavior of propagated wave in the porous nanobeam with attention to the nonlocality via strain–stress gradient theory. Gao et al. [41] could report a mathematical framework to analyze the propagated wave in a GPLs reinforced porous FG plate via a well-known mixture method. Based on their result, porosity and GPLs weight fraction are two important parameters in the field of structural health monitoring via wave propagation method. Ebrahimi et al. [42] were able to provide results on the characteristics propagated waves in a compositionally nonlocal plate in which the structure located in a high-temperature environment. Also, they consider the shear deformation in each element of the structure. They found that without doubt the nonlocal effect has a bolded role on the characteristics of propagated waves. Safaei et al. [43] tried to report characteristics of the propagated waves in a CNTs reinforced FG thermoelastic plate via the high order ready plat theory and Mori–Tanaka method. Their important achievement was that the thermal stress and adding small amount of CNTs can make a remarkable effect on the wave velocity in the structure. The static and dynamic stabilities of the reinforced nanocomposite structures are presented in some researches [44,45,46,47,48,49,50] by having attention to the impacts of honeycomb core, porosity distributions, and transverse dynamic loads via higher-order theories. Many researchers [51,52,53,54,55,56] studied the behavior and stability of the FG multilayer composite and isotropic materials.

In the field of characteristics propagated waves in the shell, Bakhtiari et al. [57] provided some results on the wave propagation of the FG shell in which fluid flow through the shell is considered. Ebrahimi et al. [58] studied the wave response in a high-speed rotating nanoshell with a GPLs reinforced compositionally core and patched piezoelectric face sheet. They claimed that if the rotating should be controlled for improving the phase velocity of the nanoshell. The dispersion behavior of the wave in the MHC reinforced shell is investigated by Ebrahimi et al. [59]. They used the lowest order shear deformation theory and eigenvalue problem for providing their formulation and results. They found out that the impact of nanosize reinforcements is more effective than the macro size reinforcements for improving the phase velocity of the compositionally shell. Karami et al. [60] developed a mathematical model for literature in which wave dispersion in an imperfect nanoshell via NSG and HSD theories is analyzed. They provided some evidences that sensitivity of the prospected waves to the nonlocal effects, temperature, and humidity in the porous material should be considered. The vibration and buckling/post-buckling responses of the curved structures are investigated in some researches [61,62,63,64,65,66,67]. A key issue in various engineering field is that the prediction of the properties, behavior, and performance of different systems is an important aspect [68,69,70,71,72,73,74,75,76,77]. Also, some researchers tried to predict the static and dynamic properties of different structures and materials via neural network solution [78,79,80,81,82,83,84]. In addtion, many studies reported the application of applied soft computing method for prediction of the behavior of complex system [85,86,87,88,89,90,91,92].

In the field of analysis, the wave propagation in the smart structure, Li et al. [93] succeeded in publishing an article in which they examined the wave propagation of a smart plate via a semi-analytical method. They modeled a GPLs reinforced plate which is covered with a piezoelectric actuator. They used the Reissner–Mindlin plate theory and Hamilton’s principle for developing their computational approach and did the formulation. The application of their result is that GPLs in a matrix can play a positive role in structural health monitoring and improve wave propagation in the structures, especially smart structures. Ebrahimi et al. [94] developed a mathematical model for literature in which wave dispersion of a smart sandwich nanoplate by considering the nanosize effect via nonlocal strain gradient theory and the sandwich structure is made of ceramic face sheets and magnetostrictive core. Abad et al. [95] published an article in which they presented a formulation about the wave propagation problem of a somewhat sandwich thick plate. They smarted the plate by patching a piezoelectric layer on the top face of the structure and they considered Maxwell's assumptions in their computational approach. Habibi et al. [96] studied the wave response in a nanoshell with a GPLs reinforced compositionally core and patched piezoelectric face sheet. When they compared their result with molecular simulation, it can be seen that the nonlocality should be considered via NSGT. As a practical outcome they reported that the thickness of the smart layer will have more effect on the characteristics propagated waves in the nanoshell.

Based on the extremely detailed exploration in the literature by the authors, no one can claim that there is a study on the wave propagation of the doubly curved panel.

Therefore, characteristics of the propagated wave in a sandwich structure with a soft core and multi-hybrid nanocomposite face sheets are investigated. The HSDT is applied to formulate the stresses and strains. Rule of the mixture and modified Halpin–Tsai model are engaged to provide the effective material constant of the multi-hybrid nanocomposite face sheets of the sandwich panel. By employing Hamilton’s principle, the governing equations of the structure are derived. Via the compatibility rule, the bonding between the smart layer and the soft core is modeled. The results show that, CNT’s weight fraction, core to total thickness ratio, various FG face sheet patterns, small radius to total thickness ratio, and carbon fiber angel have an important role in the phase velocity of the FML panel.

2 Mathematical modeling

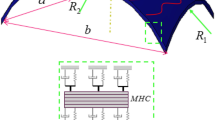

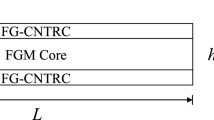

Figure 1 shows a sandwich doubly curved panel. The effective thickness (hb + hc + ht) and the middle surface radius of the doubly curved panel are presented by heff and R, respectively. Besides, hb hc, and hp are the thickness of the multi-hybrid nanocomposite reinforcement at the top layer, the core layer, and the multi-hybrid nanocomposite reinforcement at the bottom layer, respectively.

2.1 MHC reinforcement

The procedure of homogenization is made of two main steps based upon the Halpin–Tsai model together with a micromechanical theory. The first stage is engaged with computing the effective characteristics of the composite reinforced with CF as following [97]:

Here, elasticity modulus, mass density, Poisson’s ratio, and shear modulus are symbolled via \(\rho ,\,\,E,\,\,G\) and \(\nu\). The superscripts of the matrix and fiber are NCM and F, respectively. Add the carbon fiber volume fraction ( \(V_{\rm{F}}\)) to the nanocomposite matrix volume fraction ( \(V_{\rm{NCM}}\)) is one.

The second step is organized to obtain the effective characteristics of the nanocomposite matrix reinforced with CNTs with the aid of the extended Halpin–Tsai micromechanics as follows [97]:

Here, \(\beta_{dd}\) and \(\beta_{dl}\) would be computed as the following expression:

volume fraction, thickness, length, elasticity modulus, weight fraction, and diameter of CNTs are \(V_{\rm{CNT}}\), \(t^{CNT}\), \(l^{CNT}\), \(E^{CNT}\),\(W_{\rm{CNT}}\), and \(d^{CNT}\). Also, the volume fraction of the matrix and elasticity modulus of the matrix are \(V_{M}\) and \(E^{M}\). So, The CNTs volume fraction can be formulated as below:

Also, the effective volume fraction of CNTs can be formulated as follows:

where \(\xi_{j} = \left( {\frac{1}{2} + \frac{1}{{2N_{t} }} - \frac{j}{{N_{t} }}} \right)h{\text{ j = 1,2,}}...{,}N_{t}\). Furthermore, the sum of \(V_{M}\) and \(V_{\rm{CNT}}\) as the two constituents of the nanocomposite matrix is equal to 1.

Also, Poisson’s ratio, mass density, and shear modulus will be calculated as

2.2 Kinematic relations

The displacement fields of the core can be given by [98]

The strain components can be given by [98, 99]

Also, the strain–stress equations of the metal structure can be given as

In the Eq. (17) \(E_{c}\), and \(\nu_{c}\) are Young’s module and poison ratio of the metal, respectively.

2.3 Face sheets

In the present structural model for the sandwich panel, the HSDT is adopted for the face sheets. Hence, the displacement components of the top and bottom face sheets (j = t, b) are represented as

The strain components can be given by

Also, the strain–stress equations of the metal structure can be given as [9, 104,105,106,107,108,109,110,111,112,113,114,115,116,117,118]

where [119]

The terms involved in Eq. (21) would be obtained as [114, 120,121,122,123]

Therefore, the face sheets are assumed as in-plane flexible and transversely rigid panels. Also, the core is assumed as an in-plane and transversely flexible layer. Finally, in this model, there are fifteen displacement unknowns: five unknowns for each face sheet and five unknowns for the core.

2.4 Compatibility equations

The compatibility conditions assuming perfect bonding between the core and the composite layers that can be defined as follows:

2.5 Extended Hamilton’s principle

For obtaining the governing equation and associated boundary conditions, we can apply extended Hamilton’s principle as follows [24,25,26, 98, 124,125,126]:

The components of strain energy can be expressed as below:

which

where \(\lambda = b,\,t,\,c\).

Also, the kinetic energy [4,5,6, 8, 127,128,129,130,131,132] of each layer of the structure can be defined as bellow:

Finally, the motion equations are derived as follows:

Also, the motion equations for the nanocomposite face sheets are as follows:

It is worth mentioning that, according to compatibility equations (Eq. 22), the numbers of unknown variables are decreased from 15 to 9. Therefore, the total number of unknowns in the core and the face sheet is reduced to 9.

2.6 Solution procedure

Displacement fields for investigation the wave propagation analysis of the structure defined as follow [24,25,26, 109]:

where s and n are wave number along with the directions of x and y, respectively, also \(\omega\) is called frequency. With replacing Eq. (28) into governing equations achieve to [133,134,135,136,137]:

where

Also, the phase velocity of wave dispersion can be calculated by Eq. (29):

In the Eq. (31), c and s are called phase velocity and wavenumber of a laminated nanocomposite cylindrical shell. These parameters are propagation speeds of the particles in a sandwich panel.

2.7 Validation

The obtained results for the perfect panel are compared with the results of Refs.[138, 139]. These results are listed in Table 1 and 2. From these tables, it can be seen that the present results have a good agreement with the obtained results in the literature. Note that, the dimensionless form of the frequency can be calculated using the below relation:

For more verification, the fundamental frequencies of the FML moderately thick plates resting on partial elastic foundations are calculated by the free vibration Eq. (21) as an eigenvalue problem. In Table 2, non-dimensional fundamental frequencies of the symmetrically laminated cross-ply plate \(({0}^{^\circ },{90}^{^\circ },9{0}^{^\circ },{0}^{^\circ })\) are shown as compared for different E1/E2.

3 Results

In this part, a comprehensive investigation is carried out to demonstrate the effects of various parameters on the phase velocity response of a multi-hybrid nanocomposite doubly curved panel. The geometrical and material characteristics of constituent materials would be presented in Table 3.

With pay attention to Fig. 1 can find an investigation about the impacts of the various CNTs weight fraction (\({W}_{\rm{CNT}}\)) and core to total thickness ratio (\({h}_{c}/h\)) of the FML panel on the wave responses of the doubly carved panel.

As stated by Fig. 2, the impact of \({W}_{\rm{CNT}}\) on the phase velocity is obvious and considerable if the \({h}_{c}/h\) is less than 0.8. in another word for \({0\le h}_{c}/h\le 0.8\), the phase velocity can improve due to increasing the CNTs' weight fraction and this enhancement will be weakened by increasing the core thickness of the FML panel. Also, when the thickness of the core is small, the phase velocity falling down owning to increasing the \({h}_{c}/h\), but if we consider the thicker core, we can find an indirect relation between \({h}_{c}/h\) and phase velocity. Accordingly, the sensitivity of the phase velocity of the FML panel to the \({W}_{\rm{CNT}}\) can decrease when we consider the core of the panel thicker.

From Fig. 3, we can find research about the effects of the various FG face sheet patterns and core to total thickness ratio (\({h}_{c}/h\)) of the FML panel on the wave responses of the MHC reinforced doubly carved panel.

The most obvious result in Fig. 3 is that for having an impact from FG face sheet patterns on the phase velocity we should consider the \({h}_{c}/h\) less than 0.2. As another explanation, considering different FG face sheet patterns will be ineffective at the higher value of the \({h}_{c}/h\). As a practical result, according to Fig. 3, it can be stated that the sensitivity of the phase velocity of the FML panel to the different FG face sheet patterns can decrease when the thickness of the core of the FML panel increases. Generally, for each \({h}_{c}/h\), when the face sheet is made by Pattern 1 and Pattern 3, we can see the lowest and highest phase velocity in the sandwich panel.

With the aid of Fig. 4, presented the effects of the wavenumber and small radius to total thickness ratio (\({R}_{1}/h\)) of the FML panel on the wave responses of the FML reinforced doubly carved panel.

The most evident outcome in Fig. 4 is that boosting the wave number can be an encouragement for improving the phase velocity of the FML panel and this impact from wavenumber on the wave propagation of the sandwich structure will change to be ineffective when the wavenumber is more than 11e4. As a practical result, if the small radius of the FML doubly curved panel is rising, the phase velocity of the system can increase and this impact will be ineffectual at the higher value of the wavenumber.

With attention to Fig. 5 can see an investigation for analysis the impacts of the various CNTs weight fraction (\({W}_{\rm{CNT}}\)) and wavenumber on the wave responses of the FML doubly carved panel.

The apparent and the most important result in Fig. 5 is that if there is more distribution of CNTs in the matrix of the face sheet of the FML panel, we will find that the phase velocity or wave response of the system can improve and without a doubt, this issue is considerable at the higher wavenumber.

Presented diagrams in Fig. 6 are drawn to have an explanation about the effects of the wavenumber and different FG face sheet patterns of the FML panel on the wave responses of the FML reinforced doubly carved panel.

The bolded result in Fig. 6 is that boosting the wave number can be an encouragement for improving the phase velocity of the FML panel and this impact from wavenumber on the wave propagation of the sandwich structure will change to be ineffective in the higher value of the wavenumber. As a practical result and at the lower wavenumber, when the face sheet is made by Pattern 1 and Pattern 3, we can see the lowest and highest phase velocity in the sandwich panel. Also, the wave propagation response of the FML panel with Pattern 2, 3, and 4 is similar when the wavenumber is great enough.

With the aid of Fig. 7, the effects of the fibers angel and different FG face sheet patterns on the wave responses of the FML reinforced doubly carved panel are presented.

The most general result in Fig. 7 is that for each FG face sheet patterns when the fibers angel is less than \(\pi /2\), the phase velocity is decreasing and this trend will be revers for the fibers angel more than \(\pi /2\). As the most interesting result from Fig. 7 is that when the fiber angel is \(0.3\le \theta /\pi \le 0.7\), employing different FG patterns for making the FML cannot provide any change on the phase velocity of the structure. As another explanation, if the fibers are distributed in the matrix vertically, changing the FG patterns cannot play any roles on the wave response of the FML panel and as the fibers become horizontal, the effect of the FG patterns on the phase velocity becomes more dramatic. Reported data in Fig. 8 are shown to have a deep presentation about the effects of the wavenumber, fibers angel of the FML panel, and small radius to total thickness ratio (\({R}_{1}/h\)) of the FML panel on the wave responses of the doubly carved panel.

If we have excellent attention to Fig. 8, it could be seen that within a certain range of the core to total thickness ratio, there is no effect from the small radius to total thickness ratio of the FML panel on the phase velocity, and this range will be wider if the wave number rises. Also, for the lower wavenumber, when the fiber angel is 0 and 1 radians, the pick of the phase velocity of the system will happen but as the wave number increases, the maximum value of the phase velocity will be seen at 0.25 and 0.75 radians.

With the aid of Fig. 9, the effects of the fibers angel and weight fraction of CNTs (\({W}_{\rm{CNT}}\)) on the wave responses of the FML doubly carved panel are presented.

The most interesting result from Fig. 9 is that when the fiber angel is \(0.4\le \theta /\pi \le 0.6\), increasing \({W}_{\rm{CNT}}\) cannot provide any change on the phase velocity of the structure. As another explanation, if the fibers are distributed in the matrix vertically, changing the \({W}_{\rm{CNT}}\) cannot play any roles on the wave response of the FML panel and as the fibers become horizontal, the effect of \({W}_{\rm{CNT}}\) on the phase velocity becomes more dramatic. With pay attention to Fig. 10, we can see a study about the effects of the fibers angel and core to total thickness ratio (\({h}_{c}/h\)) of the FML panel on the wave responses of the doubly carved panel.

as stated by Fig. 10 when the fiber angel is 0 \(\le \theta /\pi \le\) 0.42 and 0.58 \(\le \theta /\pi \le\) 1, the phase velocity will be improved by having each decline in the core to total thickness ratio but this relation between fiber angel and \({h}_{c}/h\) change to direct as the fibers angel is 0.42 \(<\theta /\pi <\) 0.58. The reported 3D diagram in Figs. 11 and 12 are shown to have a comparative study about the effects of the wavenumber, core to total thickness ratio (\({h}_{c}/h\)) of the FML panel, and fiber angle on the wave responses of the doubly carved panel.

The most principal and evident result in Figs. 11 and 12 are that as the wave number increases, the changes in phase velocity of the MHC reinforced sandwich panel which is caused by increasing the fibers angel and core to total thickness ratio become much more dramatic. In the simpler word, the effects of fibers angel and core to total thickness ratio on the phase velocity of the FML panel are highly dependent on the wavenumber.

4 Conclusion

Wave propagation characteristics of a sandwich structure with the soft core and multi-hybrid nanocomposite face sheets is investigated. The stresses and strains are obtained using HSDT. Rule of the mixture and modified Halpin–Tsai model are engaged to provide the effective material constant of the multi-hybrid nanocomposite face sheets of the sandwich panel. Via the compatibility rule, the bonding between the smart layer and a soft core is modeled. Finally, the most bolded results of this paper are as follow:

-

it is true that when the thickness of the core is small, the phase velocity falling down owning to increasing the \({h}_{c}/h\), but if we consider the thicker core, we can find an indirect relation between \({h}_{c}/h\) and phase velocity;

-

the sensitivity of the phase velocity of the FML panel to the \({W}_{\rm{CNT}}\) and different FG face sheet patterns can decrease when we consider the core of the panel thicker;

-

boosting the wave number can be an encouragement for improving the phase velocity of the FML panel and this impact from wavenumber on the wave propagation of the sandwich structure will change to be ineffective when the wavenumber is more than 11e4;

-

as a practical result, if the small radius of the FML doubly curved panel is rising, the phase velocity of the system can increase and this impact will be ineffectual at the higher value of the wavenumber;

-

if the fibers are distributed in the matrix vertically, changing the FG patterns cannot play any role on the wave response of the FML panel and as the fibers become horizontal, the effect of the FG patterns on the phase velocity becomes more dramatic;

-

when the fiber angel is 0 and 1 radians, the pick of the phase velocity of the system will happen but as the wave number increases, the maximum value of the phase velocity will be seen at 0.25 and 0.75 radians;

-

when the fiber angel is 0 \(\le \theta /\pi \le\) 0.42 and 0.58 \(\le \theta /\pi \le\) 1, the phase velocity will be improved by having each decline in the core to total thickness ratio but this relation between fiber angel and \({h}_{c}/h\) changes to direct as the fiber angel is 0.42 \(<\theta /\pi <\) 0.58;

-

the effects of fibers angel and core to total thickness ratio on the phase velocity of the FML panel is hardly dependent on the wavenumber.

References

Ghayesh MH (2018) Dynamics of functionally graded viscoelastic microbeams. Int J Eng Sci 124:115–131

Ghayesh MH (2019) Nonlinear oscillations of FG cantilevers. Appl Acoust 145:393–398

Ghayesh MH (2018) Nonlinear vibration analysis of axially functionally graded shear-deformable tapered beams. Appl Math Model 59:583–596

Ghabussi A, Habibi M, NoormohammadiArani O, Shavalipour A, Moayedi H, Safarpour H (2020) Frequency characteristics of a viscoelastic graphene nanoplatelet–reinforced composite circular microplate. J Vib Control 1:1077546320923930

Safarpour M, Ghabussi A, Ebrahimi F, Habibi M, Safarpour H (2020) Frequency characteristics of FG-GPLRC viscoelastic thick annular plate with the aid of GDQM. Thin-Walled Struct 150:106683

Cheshmeh E, Karbon M, Eyvazian A, Jung D, Tran T, Habibi M et al Buckling and vibration analysis of FG-CNTRC plate subjected to thermo-mechanical load based on higher-order shear deformation theory. Mech Based Des Struct Mach

Shariati A, Mohammad-Sedighi H, Żur KK, Habibi M, Safa M (2020) Stability and dynamics of viscoelastic moving Rayleigh beams with an asymmetrical distribution of material parameters. Symmetry 12:586

Oyarhossein MA, Alizadeh AA, Habibi M, Makkiabadi M, Daman M, Safarpour H et al (2020) Dynamic response of the nonlocal strain-stress gradient in laminated polymer composites microtubes. Sci Rep 10:5616

Habibi M, Taghdir A, Safarpour H (2019) Stability analysis of an electrically cylindrical nanoshell reinforced with graphene nanoplatelets. Compos B Eng 175:107125

Chen S, Hassanzadeh-Aghdam M, Ansari R (2018) An analytical model for elastic modulus calculation of SiC whisker-reinforced hybrid metal matrix nanocomposite containing SiC nanoparticles. J Alloy Compd 767:632–641

Ebrahimi F, Habibi M, Safarpour H (2019) On modeling of wave propagation in a thermally affected GNP-reinforced imperfect nanocomposite shell. Eng Comput 35:1375–1389

Li C, Han Q (2020) Analyzing wave propagation in graphene-reinforced nanocomposite annular plates by the semi-analytical formulation. Mech Adv Mater Struct 1:1–14

Aminipour H, Janghorban M, Li L (2020) Wave dispersion in nonlocal anisotropic macro/nanoplates made of functionally graded materials. Waves Random Complex Media 1:1–45

Zhang X, Zhang Y, Liu Z, Liu J (2020) Analysis of heat transfer and flow characteristics in typical cambered ducts. Int J Therm Sci 150:106226

Hu X, Ma P, Wang J, Tan G (2019) A hybrid cascaded DC–DC boost converter with ripple reduction and large conversion ratio. IEEE J Emerg Sel Top Power Electron 8:761–770

Hu X, Ma P, Gao B, Zhang M (2019) An integrated step-up inverter without transformer and leakage current for grid-connected photovoltaic system. IEEE Trans Power Electron 34:9814–9827

Wu X, Huang B, Wang Q, Wang Y (2020) High energy density of two-dimensional MXene/NiCo-LDHs interstratification assembly electrode: understanding the role of interlayer ions and hydration. Chem Eng J 380:122456

Guo L, Sriyakul T, Nojavan S, Jermsittiparsert K (2020) Risk-based traded demand response between consumers’ aggregator and retailer using downside risk constraints technique. IEEE Access 8:90957–90968

Cao B, Zhao J, Lv Z, Gu Y, Yang P, Halgamuge SK (2020) Multiobjective evolution of fuzzy rough neural network via distributed parallelism for stock prediction. IEEE Trans Fuzzy Syst 28:939–952

Wang G, Yao Y, Chen Z, Hu P (2019) Thermodynamic and optical analyses of a hybrid solar CPV/T system with high solar concentrating uniformity based on spectral beam splitting technology. Energy 166:256–266

Liu Y, Yang C, Sun Q (2020) Thresholds based image extraction schemes in big data environment in intelligent traffic management. IEEE Trans Intell Transport Syst

Liu J, Liu Y, Wang X (2019) An environmental assessment model of construction and demolition waste based on system dynamics: a case study in Guangzhou. Environ Sci Pollut Res 31:1–23

Xu W, Qu S, Zhao L, Zhang H (2020) An improved adaptive sliding mode observer for a middle and high-speed rotors tracking. In: IEEE transactions on power electronics

Nadri S, Xie L, Jafari M, Bauwens MF, Arsenovic A, Weikle RM (2019) Measurement and extraction of parasitic parameters of quasi-vertical schottky diodes at submillimeter wavelengths. IEEE Microwave Wirel Compon Lett 29:474–476

Nadri S, Xie L, Jafari M, Alijabbari N, Cyberey ME, Barker NS et al (2018) A 160 GHz frequency quadrupler based on heterogeneous integration of GaAs Schottky diodes onto silicon using SU-8 for epitaxy transfer. IEEE/MTT-S Int Microwave Sympos-IMS 2018:769–772

Weikle RM, Xie L, Nadri S, Jafari M, Moore CM, Alijabbari N et al (2019) Submillimeter-wave Schottky diodes based on heterogeneous integration of GaAs onto silicon. In: 2019 United States National Committee of URSI National Radio Science Meeting (USNC-URSI NRSM), pp 1–2

Cao L, Tu C, Hu P, Liu S (2019) Influence of solid particle erosion (SPE) on safety and economy of steam turbines. Appl Therm Eng 150:552–563

Wang Y, Cao L, Hu P, Li B, Li Y (2019) Model establishment and performance evaluation of a modified regenerative system for a 660 MW supercritical unit running at the IPT-setting mode. Energy 179:890–915

Zhu B, Zhou X, Liu X, Wang H, He K, Wang P (2020) Exploring the risk spillover effects among China's pilot carbon markets: a regular vine copula-CoES approach. J Clean Product 242:118455

Liu X, Zhou X, Zhu B, He K, Wang P (2019) Measuring the maturity of carbon market in China: an entropy-based TOPSIS approach. J Clean Product 229:94–103

Zhu B, Ye S, Jiang M, Wang P, Wu Z, Xie R et al (2019) Achieving the carbon intensity target of China: a least squares support vector machine with mixture kernel function approach. Appl Energy 233:196–207

Zhu B, Su B, Li Y (2018) Input-output and structural decomposition analysis of India’s carbon emissions and intensity, 2007/08–2013/14. Appl Energy 230:1545–1556

Cao Y, Li Y, Zhang G, Jermsittiparsert K, Nasseri M (2020) An efficient terminal voltage control for PEMFC based on an improved version of whale optimization algorithm. Energy Rep 6:530–542

Liu Y-X, Yang C-N, Sun Q-D, Wu S-Y, Lin S-S, Chou Y-S (2019) Enhanced embedding capacity for the SMSD-based data-hiding method. Signal Process Image Commun 78:216–222

Quan Q, Hao Z, Xifeng H, Jingchun L (2020) Research on water temperature prediction based on improved support vector regression. Neural Comput Appl 1:1–10

Ebrahimi F, Sedighi SB (2020) Wave dispersion characteristics of a rectangular sandwich composite plate with tunable magneto-rheological fluid core rested on a visco-Pasternak foundation. Mech Based Des Struct Mach 1–14

Faroughi S, Rahmani A, Friswell M (2020) On wave propagation in two-dimensional functionally graded porous rotating nano-beams using a general nonlocal higher-order beam model. Appl Math Model 80:169–190

Liu C, Yu J, Xu W, Zhang X, Zhang B (2020) Theoretical study of elastic wave propagation through a functionally graded micro-structured plate base on the modified couple-stress theory. Meccanica 1–15

Ebrahimi F, Barati MR, Haghi P (2017) Thermal effects on wave propagation characteristics of rotating strain gradient temperature-dependent functionally graded nanoscale beams. J Therm Stresses 40:535–547

Barati MR (2017) On wave propagation in nanoporous materials. Int J Eng Sci 116:1–11

Gao W, Qin Z, Chu F (2020) Wave propagation in functionally graded porous plates reinforced with graphene platelets. Aerosp Sci Technol 105860

Ebrahimi F, Barati MR, Dabbagh A (2016) A nonlocal strain gradient theory for wave propagation analysis in temperature-dependent inhomogeneous nanoplates. Int J Eng Sci 107:169–182

Safaei B, Moradi-Dastjerdi R, Qin Z, Behdinan K, Chu F (2019) Determination of thermoelastic stress wave propagation in nanocomposite sandwich plates reinforced by clusters of carbon nanotubes. J Sandwich Struct Mater 1099636219848282

Barati MR, Zenkour AM (2019) Analysis of postbuckling of graded porous GPL-reinforced beams with geometrical imperfection. Mech Adv Mater Struct 26:503–511

Shahverdi H, Barati MR, Hakimelahi B (2019) Post-buckling analysis of honeycomb core sandwich panels with geometrical imperfection and graphene reinforced nano-composite face sheets. Mater Res Express 6:095017

Barati MR, Shahverdi H (2020) Finite element forced vibration analysis of refined shear deformable nanocomposite graphene platelet-reinforced beams. J Braz Soc Mech Sci Eng 42:33

Mirjavadi SS, Forsat M, Hamouda A, Barati MR (2019) Dynamic response of functionally graded graphene nanoplatelet reinforced shells with porosity distributions under transverse dynamic loads. Mater Res Express 6:075045

Mirjavadi SS, Afshari BM, Barati MR, Hamouda A (2019) Nonlinear free and forced vibrations of graphene nanoplatelet reinforced microbeams with geometrical imperfection. Microsyst Technol 25:3137–3150

Barati MR, Zenkour AM (2019) Analysis of postbuckling behavior of general higher-order functionally graded nanoplates with geometrical imperfection considering porosity distributions. Mech Adv Mater Struct 26:1081–1088

Liu W, Zhang X, Li H, Chen J Investigation on the deformation and strength characteristics of rock salt under different confining pressures. Geotech Geol Eng 1–15

Eyvazian A, Hamouda AM, Tarlochan F, Mohsenizadeh S, Dastjerdi AA (2019) Damping and vibration response of viscoelastic smart sandwich plate reinforced with non-uniform graphene platelet with magnetorheological fluid core. Steel Compos Struct 33:891

Motezaker M, Eyvazian A (2020) Post-buckling analysis of mindlin cut out-plate reinforced by FG-CNTs. Steel Compos Struct 34:289

Motezaker M, Eyvazian A (2020) Buckling load optimization of beam reinforced by nanoparticles. Struct Eng Mech 73:481–486

Derazkola HA, Eyvazian A, Simchi A (2020) Modeling and experimental validation of material flow during FSW of polycarbonate. Mater Today Commun 22:100796

Eyvazian A, Hamouda A, Tarlochan F, Derazkola HA, Khodabakhshi F (2020) Simulation and experimental study of underwater dissimilar friction-stir welding between aluminium and steel. J Mater Res Technol

Eyvazian A, Habibi MK, Hamouda AM, Hedayati R (2014) Axial crushing behavior and energy absorption efficiency of corrugated tubes. Mater Des 1980–2015(54):1028–1038

Bakhtiari M, Tarkashvand A, Daneshjou K (2020) Plane-strain wave propagation of an impulse-excited fluid-filled functionally graded cylinder containing an internally clamped shell. Thin-Walled Struct 106482

Ebrahimi F, Mohammadi K, Barouti MM, Habibi M (2019) Wave propagation analysis of a spinning porous graphene nanoplatelet-reinforced nanoshell. Waves Random Complex Media 1–27

Ebrahimi F, Seyfi A (2019) Wave propagation response of multi-scale hybrid nanocomposite shell by considering aggregation effect of CNTs. Mech Based Des Struct Mach 1–22

Karami B, Shahsavari D, Janghorban M, Dimitri R, Tornabene F (2019) Wave propagation of porous nanoshells. Nanomaterials 9:22

Ebrahimi F, Barati MR (2016) Magneto-electro-elastic buckling analysis of nonlocal curved nanobeams. Eur Phys J Plus 131:346

Ebrahimi F, Barati MR (2018) Vibration analysis of piezoelectrically actuated curved nanosize FG beams via a nonlocal strain-electric field gradient theory. Mech Adv Mater Struct 25:350–359

Ebrahimi F, Barati MR (2016) On nonlocal characteristics of curved inhomogeneous Euler-Bernoulli nanobeams under different temperature distributions. Appl Phys A 122:880

Ebrahimi F, Barati MR (2017) Size-dependent dynamic modeling of inhomogeneous curved nanobeams embedded in elastic medium based on nonlocal strain gradient theory. Proc Inst Mech Eng Part C J Mech Eng Sci 231:4457–4469

Ebrahimi F, Barati MR, Mahesh V (2019) Dynamic modeling of smart magneto-electro-elastic curved nanobeams. Adv Nano Res 7:145

Mirjavadi SS, Forsat M, Barati MR, Hamouda A (2020) Post-buckling of higher-order stiffened metal foam curved shells with porosity distributions and geometrical imperfection. Steel Compos Struct 35:567–578

Mirjavadi SS, Forsat M, Barati MR, Hamouda AS (2020) Geometrically nonlinear vibration analysis of eccentrically stiffened porous functionally graded annular spherical shell segments. Mech Based Des Struct Mach 1–15

Qu S, Zhao L, Xiong Z (2020) Cross-layer congestion control of wireless sensor networks based on fuzzy sliding mode control. Neural Comput Appl 1–16

Zhang H, Qu S, Li H, Luo J, Xu W (2020) A moving shadow elimination method based on fusion of multi-feature. IEEE Access 8:63971–63982

Pang R, Xu B, Kong X, Zou D (2018) Seismic fragility for high CFRDs based on deformation and damage index through incremental dynamic analysis. Soil Dyn Earthq Eng 104:432–436

Pang R, Xu B, Zhou Y, Zhang X, Wang X (2020) Fragility analysis of high CFRDs subjected to mainshock-aftershock sequences based on plastic failure. Eng Struct 206:110152

Guo J, Zhang X, Gu F, Zhang H, Fan Y (2020) Does air pollution stimulate electric vehicle sales? Empirical evidence from twenty major cities in China. J Clean Product 249:119372

Zeng H-B, Teo KL, He Y, Wang W (2019) Sampled-data-based dissipative control of TS fuzzy systems. Appl Math Model 65:415–427

Gao N-S, Guo X-Y, Cheng B-Z, Zhang Y-N, Wei Z-Y, Hou H (2019) Elastic wave modulation in hollow metamaterial beam with acoustic black hole. IEEE Access 7:124141–124146

Chen H, Zhang G, Fan D, Fang L, Huang L (2020) Nonlinear lamb wave analysis for microdefect identification in mechanical structural health assessment. Measurement 108026

Gao N, Wei Z, Hou H, Krushynska AO (2019) Design and experimental investigation of V-folded beams with acoustic black hole indentations. J Acoust Soc Am 145:EL79–EL83

Song Q, Zhao H, Jia J, Yang L, Lv W, Gu Q et al (2020) Effects of demineralization on the surface morphology, microcrystalline and thermal transformation characteristics of coal. J Anal Appl Pyrol 145:104716

Moayedi H, Hayati S (2018) Applicability of a CPT-based neural network solution in predicting load-settlement responses of bored pile. Int J Geomech 18

Moayedi H, Bui DT, Foong LK (2019) Slope stability monitoring using novel remote sensing based fuzzy logic. Sensors (Switzerland) 19

Moayedi H, Bui DT, Kalantar B, Osouli A, Gör M, Pradhan B et al (2019) Harris hawks optimization: a novel swarm intelligence technique for spatial assessment of landslide susceptibility. Sensors (Switzerland) 19

Moayedi H, Mu’azu MA, Kok Foong L (2019) Swarm-based analysis through social behavior of grey wolf optimization and genetic programming to predict friction capacity of driven piles. Eng Comput

Moayedi H, Osouli A, Nguyen H, Rashid ASA (2019) A novel Harris hawks’ optimization and k-fold cross-validation predicting slope stability. Eng Comput

Yuan C, Moayedi H (2019) The performance of six neural-evolutionary classification techniques combined with multi-layer perception in two-layered cohesive slope stability analysis and failure recognition. Eng Comput

Yuan C, Moayedi H (2019) Evaluation and comparison of the advanced metaheuristic and conventional machine learning methods for the prediction of landslide occurrence. Eng Comput

Zhao X, Li D, Yang B, Ma C, Zhu Y, Chen H (2014) Feature selection based on improved ant colony optimization for online detection of foreign fiber in cotton. Appl Soft Comput 24:585–596

Wang M, Chen H (2020) Chaotic multi-swarm whale optimizer boosted support vector machine for medical diagnosis. Appl Soft Comput 88:105946

Zhao X, Zhang X, Cai Z, Tian X, Wang X, Huang Y et al (2019) Chaos enhanced grey wolf optimization wrapped ELM for diagnosis of paraquat-poisoned patients. Comput Biol Chem 78:481–490

Xu X, Chen H-L (2014) Adaptive computational chemotaxis based on field in bacterial foraging optimization. Soft Comput 18:797–807

Shen L, Chen H, Yu Z, Kang W, Zhang B, Li H et al (2016) Evolving support vector machines using fruit fly optimization for medical data classification. Knowl-Based Syst 96:61–75

Wang M, Chen H, Yang B, Zhao X, Hu L, Cai Z et al (2017) Toward an optimal kernel extreme learning machine using a chaotic moth-flame optimization strategy with applications in medical diagnoses. Neurocomputing 267:69–84

Xu Y, Chen H, Luo J, Zhang Q, Jiao S, Zhang X (2019) Enhanced Moth-flame optimizer with mutation strategy for global optimization. Inf Sci 492:181–203

Chen H, Zhang Q, Luo J, Xu Y, Zhang X (2020) An enhanced Bacterial Foraging Optimization and its application for training kernel extreme learning machine. Appl Soft Comput 86:105884

Li C, Han Q, Wang Z, Wu X (2020) Analysis of wave propagation in functionally graded piezoelectric composite plates reinforced with graphene platelets. Appl Math Model

Ebrahimi F, Dabbagh A (2018) Thermo-magnetic field effects on the wave propagation behavior of smart magnetostrictive sandwich nanoplates. Eur Phys J Plus 133:97

Abad F, Rouzegar J (2019) Exact wave propagation analysis of moderately thick Levy-type plate with piezoelectric layers using spectral element method. Thin-Walled Struct 141:319–331

Habibi M, Mohammadgholiha M, Safarpour H (2019) Wave propagation characteristics of the electrically GNP-reinforced nanocomposite cylindrical shell. J Braz Soc Mech Sci Eng 41:221

Tornabene F, Bacciocchi M, Fantuzzi N, Reddy J (2019) Multiscale approach for three-phase CNT/polymer/fiber laminated nanocomposite structures. Polym Compos 40:E102–E126

Karimiasl M, Ebrahimi F, Vinyas M (2019) Nonlinear vibration analysis of multiscale doubly curved piezoelectric composite shell in hygrothermal environment. J Intell Mater Syst Struct 30:1594–1609

Shariati A, Mohammad-Sedighi H, Żur KK, Habibi M, Safa M (2020) On the vibrations and stability of moving viscoelastic axially functionally graded nanobeams. Materials 13:1707

Batou B, Nebab M, Bennai R, Atmane HA, Tounsi A, Bouremana M (2019) Wave dispersion properties in imperfect sigmoid plates using various HSDTs. Steel Compos Struct 33:699

Pham Q-H, Pham T-D, Trinh QV, Phan D-H (2019) Geometrically nonlinear analysis of functionally graded shells using an edge-based smoothed MITC3 (ES-MITC3) finite elements. Eng Comput 1–14

Salah F, Boucham B, Bourada F, Benzair A, Bousahla AA, Tounsi A (2019) Investigation of thermal buckling properties of ceramic-metal FGM sandwich plates using 2D integral plate model. Steel Compos Struct 33:805

Ebrahimi F, Nouraei M, Dabbagh A (2019) Thermal vibration analysis of embedded graphene oxide powder-reinforced nanocomposite plates. Eng Comput 1–17

Moayedi H, Darabi R, Ghabussi A, Habibi M, Foong LK (2020) Weld orientation effects on the formability of tailor welded thin steel sheets. Thin-Walled Struct 149:106669

Shariati A, Habibi M, Tounsi A, Safarpour H, Safa M Application of exact continuum size‑dependent theory for stability and frequency analysis of a curved cantilevered microtubule by considering viscoelastic properties

Moayedi H, Habibi M, Safarpour H, Safarpour M, Foong L Buckling and frequency responses of a graphen nanoplatelet reinforced composite microdisk. Int J Appl Mech

Moayedi H, Aliakbarlou H, Jebeli M, Noormohammadiarani O, Habibi M, Safarpour H et al (2020) Thermal buckling responses of a graphene reinforced composite micropanel structure. Int J Appl Mech 12:2050010

Ghabussi A, Ashrafi N, Shavalipour A, Hosseinpour A, Habibi M, Moayedi H et al (2019) Free vibration analysis of an electro-elastic GPLRC cylindrical shell surrounded by viscoelastic foundation using modified length-couple stress parameter. Mech Based Des Struct Mach 1–25

Habibi M, Mohammadi A, Safarpour H, Shavalipour A, Ghadiri M (2019) Wave propagation analysis of the laminated cylindrical nanoshell coupled with a piezoelectric actuator. Mech Based Des Struct Mach 1–19

Ghazanfari A, Soleimani SS, Keshavarzzadeh M, Habibi M, Assempuor A, Hashemi R (2019) Prediction of FLD for sheet metal by considering through-thickness shear stresses. Mech Based Des Struct Mach 1–18

Mohammadi A, Lashini H, Habibi M, Safarpour H (2019) Influence of viscoelastic foundation on dynamic behaviour of the double walled cylindrical inhomogeneous micro shell using MCST and with the aid of GDQM. J Solid Mech 11:440–453

Habibi M, Payganeh G (2018) Experimental and finite element investigation of titanium tubes hot gas forming and production of square cross-section specimens

Fazaeli A, Habibi M, Ekrami A (2016) Experimental and finite element comparison of mechanical properties and formability of dual phase steel and ferrite-pearlite steel with the same chemical composition. Metall Eng 19(2):84–93

Shokrgozar A, Ghabussi A, Ebrahimi F, Habibi M, Safarpour H (2020) Viscoelastic dynamics and static responses of a graphene nanoplatelets-reinforced composite cylindrical microshell. Mech Based Des Struct Mach 1–28

Adamian A, Safari KH, Sheikholeslami M, Habibi M, Al-Furjan M, Chen G (2020) Critical temperature and frequency characteristics of GPLs-reinforced composite doubly curved panel. Appl Sci 10:3251

Ghadiri M, Shafiei N, Safarpour H (2017) Influence of surface effects on vibration behavior of a rotary functionally graded nanobeam based on Eringen’s nonlocal elasticity. Microsyst Technol 23:1045–1065

Habibi M, Hashemi R, Tafti MF, Assempour A (2018) Experimental investigation of mechanical properties, formability and forming limit diagrams for tailor-welded blanks produced by friction stir welding. J Manuf Process 31:310–323

Habibi M, Hashemi R, Sadeghi E, Fazaeli A, Ghazanfari A, Lashini H (2016) Enhancing the mechanical properties and formability of low carbon steel with dual-phase microstructures. J Mater Eng Perform 25:382–389

Reddy JN (2003) Mechanics of laminated composite plates and shells: theory and analysis. CRC Press, London

Shamsaddini Lori E, Ebrahimi F, Elianddy Bin Supeni E, Habibi M, Safarpour H (2020) The critical voltage of a GPL-reinforced composite microdisk covered with piezoelectric layer. Eng Comput

Moayedi H, Ebrahimi F, Habibi M, Safarpour H, Foong LK (2020) Application of nonlocal strain–stress gradient theory and GDQEM for thermo-vibration responses of a laminated composite nanoshell. Eng Comput

Safarpour M, Ebrahimi F, Habibi M, Safarpour H (2020) On the nonlinear dynamics of a multi-scale hybrid nanocomposite disk. Eng Comput 1–20

Ebrahimi F, Supeni EEB, Habibi M, Safarpour H (2020) Frequency characteristics of a GPL-reinforced composite microdisk coupled with a piezoelectric layer. Eur Phys J Plus 135:144

Ghayesh MH (2019) Viscoelastic mechanics of Timoshenko functionally graded imperfect microbeams. Compos Struct 225:110974

Ghayesh MH (2012) Subharmonic dynamics of an axially accelerating beam. Arch Appl Mech 82:1169–1181

Kazemirad S, Ghayesh MH, Amabili M (2013) Thermo-mechanical nonlinear dynamics of a buckled axially moving beam. Arch Appl Mech 83:25–42

Shariati A, Ghabussi A, Habibi M, Safarpour H, Safarpour M, Tounsi A et al (2020) Extremely large oscillation and nonlinear frequency of a multi-scale hybrid disk resting on nonlinear elastic foundation. Thin-Walled Struct 154:106840

Al-Furjan M, Habibi M, Safarpour H (2020) Vibration control of a smart shell reinforced by graphene nanoplatelets. Int J Appl Mech

Habibi M, Safarpour M, Safarpour H (2020) Vibrational characteristics of a FG-GPLRC viscoelastic thick annular plate using fourth-order Runge-Kutta and GDQ methods. Mech Based Des Struct Mach 1–22

Liu Z, Su S, Xi D, Habibi M (2020) Vibrational responses of a MHC viscoelastic thick annular plate in thermal environment using GDQ method. Mech Based Des Struct Mach 1–26

Al-Furjan M, Safarpour H, Habibi M, Safarpour M, Tounsi A (2020) A comprehensive computational approach for nonlinear thermal instability of the electrically FG-GPLRC disk based on GDQ method. Eng Comput 1–18

Jermsittiparsert K, Ghabussi A, Forooghi A, Shavalipour A, Habibi M, won Jung D et al (2020) Critical voltage, thermal buckling and frequency characteristics of a thermally affected GPL reinforced composite microdisk covered with piezoelectric actuator. Mech Based Des Struct Mach 1–23

Ghayesh MH (2019) Resonant vibrations of FG viscoelastic imperfect Timoshenko beams. J Vib Control 25:1823–1832

Ghayesh MH, Amabili M (2013) Nonlinear vibrations and stability of an axially moving Timoshenko beam with an intermediate spring support. Mech Mach Theory 67:1–16

Ghayesh MH, Amabili M (2013) Nonlinear dynamics of an axially moving Timoshenko beam with an internal resonance. Nonlinear Dyn 73:39–52

Ghayesh MH (2012) Nonlinear dynamic response of a simply-supported Kelvin-Voigt viscoelastic beam, additionally supported by a nonlinear spring. Nonlinear Anal Real World Appl 13:1319–1333

Ghayesh MH (2019) Mechanics of viscoelastic functionally graded microcantilevers. Eur J Mech-A/Solids 73:492–499

Ebrahimi F, Dabbagh A (2019) Vibration analysis of multi-scale hybrid nanocomposite plates based on a Halpin-Tsai homogenization model. Compos B Eng 173:106955

Wattanasakulpong N, Chaikittiratana A (2015) Exact solutions for static and dynamic analyses of carbon nanotube-reinforced composite plates with Pasternak elastic foundation. Appl Math Model 39:5459–5472

Khdeir A (1988) Free vibration and buckling of symmetric cross-ply laminated plates by an exact method. J Sound Vib 126:447–461

Thinh TI, Nguyen MC, Ninh DG (2014) Dynamic stiffness formulation for vibration analysis of thick composite plates resting on non-homogenous foundations. Compos Struct 108:684–695

Funding

National Natural Science Foundation of China (51675148). The Outstanding Young Teachers Fund of Hangzhou Dianzi University (GK160203201002/003). National Natural Science Foundation of China (51805475). This research was supported by the 2020 scientific promotion funded by Jeju National University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Furjan, M.S.H., Habibi, M., Jung, D.w. et al. A computational framework for propagated waves in a sandwich doubly curved nanocomposite panel. Engineering with Computers 38, 1679–1696 (2022). https://doi.org/10.1007/s00366-020-01130-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-020-01130-8