Abstract

In this paper, a novel hybrid approach is proposed for predicting peak particle velocity (PPV) due to bench blasting in open pit mines. The proposed approach is based on the combination of adaptive neuro-fuzzy inference system (ANFIS) and particle swarm optimization (PSO). In this approach, the PSO is used to improve the performance of ANFIS. Furthermore, a model is developed based on support vector regression (SVR) approach. The models are trained and tested based on actual data compiled from 120 blast rounds in Sarcheshmeh copper mine. To determine the accuracy and efficiency of ANFIS–PSO and SVR models, a statistical model (USBM equation) is applied. According to the obtained results, both techniques can be used to predict the PPV, but the comparison of models shows that the ANFIS–PSO model provides better results. Root mean square error (RMSE), variance account for (VAF), and coefficient of determination (R 2) indices were obtained as 1.83, 93.37 and 0.957 for ANFIS–PSO model, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Although blasting is one of the important basic operations for production cycle in mines, this operation has always been accompanied by some undesirable effects. Ground vibration is one of these destructive effects, which has been the main concern of environmentalists. In fact, ground vibration is acoustic waves that propagate through the ground [1–3]. When an explosive charge detonates in the blasthole, intense dynamic stresses are set up around it due to sudden acceleration of the rock mass by detonating gas pressure on blasthole wall. The strain waves transmitted to the surrounding rock set up a wave motion in the ground [4, 5]. The strain energy carried out by these strain waves fragments the rock mass due to different breakage mechanisms such as crushing, radial cracking, and reflection breakage in the presence of a free face. The crushed zone and radial fracture zone encompass a volume of permanently deformed rock. When the stress wave intensity diminishes to the level where no permanent deformation occurs in the rock mass (i.e., beyond the fragmentation zone), strain waves propagate through the medium as the elastic waves, oscillating the particles through which they travel. These waves in the elastic zone are known as ground vibration, which closely conform to the visco-elastic behavior. The wave motion spreads concentrically from the blast site in all directions and gets attenuated due to spreading of fixed energy over a greater mass of material and away from its origin [6]. Even though, the ground vibration attenuates exponentially with distance but due to large quantity of explosive, it can still be high enough to threaten the safety and stability of surrounding structures because of dynamic stresses that exceed material strength [7]. This phenomenon can create great socioeconomic problems for the mine management as well as for people residing in the vicinity of the mine. High level of ground vibration has harmful effects on the structural integrity, ground water, and ecology of the nearby area. To minimize these harmful effects, mining and blasting engineers should monitor and assess the ground vibration phenomenon, carefully. Peak particle velocity (PPV) is the most practical indicator for assessment of this phenomenon. Many researchers have suggested several criteria for evaluation of blast-induced damage based on this indicator [5–12].

During past years, several empirical equations have been presented for PPV prediction (Table 1). The most widely used predictor equation for PPV is square-root scaling proposed by the United States Bureau of Mines (USBM equation). Two main disadvantages of these equations are: (1) the empirical equations are site specific and are not suitable for other sites, and (2) these equations are based on only two parameters, maximum charge per delay and distance from blast location, and do not include other effective parameters [22].

Recently, new approaches have attracted the attention of researchers for prediction of PPV, which are based on soft computing techniques. The studies indicate that the efficiency and accuracy of these approaches is more than empirical methods by a wide margin. Thus, nowadays these approaches are applied extensively for PPV prediction. For example, artificial neural network (ANN) [4, 23–40], fuzzy logic (FL) [22, 28, 41], adaptive neuro-fuzzy inference system (ANFIS) [42–47], support vector regression (SVR) [48–54], genetic algorithm (GA) [55], hybrid artificial neural network and imperialist competitive algorithm (ANN-ICA) [56], and hybrid artificial neural network and particle swarm optimization (ANN-PSO) [57, 58] have been applied for this purpose successfully.

The study presented herein aims to predict the PPV based on two soft computing techniques; hybrid adaptive neuro-fuzzy inference system and particle swarm optimization (ANFIS–PSO) and support vector regression (SVR). For this purpose, a database compiled from Sarcheshmeh copper mine was used and the models were developed based on major blasting parameters.

In spite of being applied in various fields widely, the literature surveys show that there is no study about the application of ANFIS–PSO in the field of mining [59–64]. Hence, an effort has been made in this paper to make use of ANFIS–PSO for PPV prediction. As mentioned before, recently some models have been developed for PPV prediction due to bench blasting based on SVR approach [48–54]. In most of these models, the PPV value is estimated considering only two parameters, i.e., charge weight per delay and distance from blast location, whereas this study not only considers these two parameters but also other effective parameters on ground vibration, such as burden, spacing, stemming and number of blastholes per delay.

To assess the performances of ANFIS–PSO and SVR models, the prediction capacity of these models is compared with USBM empirical equation developed based on Sarcheshmeh copper mine database.

This paper is organized as follows: the mine description and the structure of database are explained in Sect. 2. In Sects. 3, 4, and 5, ANFIS–PSO, SVR and USBM models are constructed for PPV prediction in Sarcheshmeh copper mine, respectively. The performances of proposed models are examined and compared with each other in Sect. 6 and finally, the paper is concluded in Sect. 7.

2 Description of database

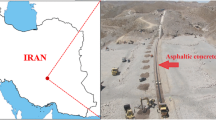

As mentioned before, a database compiled from Sarcheshmeh copper mine is used in this study. Sarcheshmeh copper mine is the biggest open pit porphyry copper mine in Iran which is located 160 km southwest of Kerman [22, 29]. In this mine, blasting operation is performed for rock excavation. ANFO is used as the main explosive material and dynamite cartridges are used as primer with bottom hole positioning. The blasting system is non-electric and detonating cord is applied for initiation. Blastholes are drilled vertically in a staggered pattern and drilling cuttings are used as stemming materials. The diameter and depth of blastholes are 215 mm and 15 m, respectively.

The database is composed of 120 blast events and includes 8 parameters (see Table 2). Burden, spacing, stemming, number of blastholes per delay, maximum charge per delay, distance from blast location to monitoring point, and PPV were recorded in each blast event. Burden, spacing and stemming were measured by a tape meter and number of blastholes per delay by controlling each blasting pattern. The distance from the blasting location to the monitoring point was measured carefully by means of a hand-held GPS (global positioning system) and the amount of maximum charge per delay was recorded for each blast by controlling the blasthole charge. Furthermore, the amount of dynamite used as priming was considered for determining the maximum charge per delay. PPV was measured by digital seismograph of PDAS-100 (Portable Data Acquisition System), which measures PPV in three orthogonal directions. The dynamic range of this seismograph is more than 96 dB, with frequency range between 2 and 250 Hz, sampling rate of 300 sample per second, and trigger levels of 0.1–250 mm/s.

It should be mentioned that in all of recorded blasts, diameter of blastholes, depth of blastholes and delay time between blastholes are constant and equal to 152 mm, 15 m and 50 ms, respectively. The range of collected data is summarized in Table 2.

For developing the proposed models, the database was divided into two groups randomly: one group for developing predictive models including 80 % of the cases (i.e., 96 blasts) and the other group including the rest of the cases (i.e., 24 blasts) for testing the models’ performances.

3 Development of ANFIS–PSO model

The adaptive neuro-fuzzy inference system (ANFIS) is a learning algorithm which was first introduced by Jang [65]. Furthermore, particle swarm optimization (PSO) is a heuristic global optimization method developed originally by Kennedy and Eberhart [66] based on the research of bird and fish flock movement behavior. Since the details about the algorithm and mathematical of ANFIS and PSO can be found in numerous literatures [65–69], they are not explained in this paper.

In this section, a PPV estimation model is developed using a novel hybrid approach. In this model, the ANFIS framework is optimized by PSO to improve the performance of ANFIS. In fact, ANFIS provides the search space and employs PSO for finding the best solution by tuning the membership functions required to achieve lower error rates. The error between the model output and the actual training data can reach a minimum value through the iteration of the PSO algorithm.

The ANFIS–PSO approach was coded with Matlab software package. ANFIS–PSO approach is developed to estimate PPV based on major blasting parameters; burden, spacing, stemming, number of blastholes per delay, maximum charge per delay, and distance from blast location to monitoring point. The membership functions considered in this study are Gaussian shaped. Furthermore, the main PSO parameters are given in Table 3. These parameters represent number of particles, maximum number of iterations, initial inertia weight, final inertia weight, personal learning coefficient and global learning coefficient. These parameters are determined by trial and error procedure and are the optimum values for this case study.

4 Development of SVR model

Support vector regression (SVR) is a universal learning algorithm proposed by Vapnik et al. [70] and has been regarded as one of the most significant achievements in machine learning in the last decades. SVR has a strong ability to address nonlinear issues and has been successfully used in a wide range of fields [71–75]. More details about the SVR and its mathematics are given in Vanpik [76].

The SVR model, like ANFIS–PSO model, includes six inputs (burden, spacing, stemming, number of blastholes per delay, maximum charge per delay, and distance from blast location to monitoring point) and one output (PPV). LIBSVM toolbox developed by Chang and Lin [77] was used for constructing the SVR model. The LIBSVM, an integrated software tool for SVR, was run in the Matlab environment. Gaussian radial basis function kernel was selected as the kernel function because of its superiority over the other kernel functions. The form of this kernel function is as follows:

where g is the deviation (width) of the RBF kernel.

The main parameters for model development are the penalty factor C, and the radial basis function kernel deviation g. The values of these two parameters greatly affect the training and generalization capability of the SVR. In LIBSVM software, C and g are obtained via a grid searching method coupled with cross validation [77].

5 Development of USBM equation

As mentioned previously, the USBM equation is the most common empirical equation that is used in blasting operations to estimate PPV. As can be seen in Table 1, this equation contains two site constants, K and B, which can be determined by regression analysis. In this section, these constants for Sarcheshmeh copper mine are determined using regression analysis on training datasets in SPSS 16 software. The final form of USBM equation for Sarcheshmeh copper mine is shown below:

6 Performance assessment of models

In this section, performances of constructed models (ANFIS–PSO, SVR, and USBM) are evaluated using 24 blast events (testing datasets), which were not incorporated in the models. Figure 1 and Table 4 show the comparison of predicted PPV values using the ANFIS–PSO, SVR and USBM models and measured (actual) PPV values. It can be seen from Table 2 that the predicted PPV by ANFIS–PSO model is closer to the measured PPV in comparison to the SVR and USBM models. The error range of ANFIS–PSO varies between −5.17 and +2.96, for SVR varies between −5.61 and +3.56, and for USBM varies between −8.77 and +8.41; this indicates that the prediction of PPV using ANFIS–PSO model is more accurate than that of the SVR and USBM models.

To evaluate the accuracy of the mentioned models, two criteria are used: root mean square error (RMSE; Eq. (3)) and variance account for (VAF; Eq. (4)). A predictive model is accepted as excellent when RMSE is 0 and VAF is 100 %.

where A i and P i are the measured (actual) and predicted values of PPV, respectively, and m is the number of blasting event.

The values of performance indices (RMSE and VAF) for ANFIS–PSO, SVR and USBM models are listed in Table 5. As can be seen, the USBM shows the lowest prediction capacity, whereas two other models can predict PPV with acceptable error rates, but the ANFIS–PSO model exhibits lower error rates than the SVR model.

The coefficient of determination (R 2) between the measured and predicted values is a good indicator to check the prediction performance of each model. R 2 is a positive number that can only take values between zero and one. A value for R 2 close to one shows a good fit of the forecasting model and a value close to zero presents a poor fit. Figure 2 shows the relationship between measured and predicted values, with good determination coefficient, obtained from three predictive models. As can be seen, between developed models, the ANFIS–PSO model shows a higher prediction performance.

The findings of this section reveal that ANFIS–PSO and SVR are efficient and useful techniques for PPV prediction due to bench blasting. These two approaches have some advantages and disadvantages in comparison with each other. The main advantages and disadvantages of these techniques are presented in Table 6.

7 Conclusions

This study proposes a novel hybrid approach based on ANFIS framework, optimized by PSO for estimation of PPV. Tuning parameters of ANFIS formulation were obtained through searching mechanism of PSO which results in an optimized ANFIS model. The application of the ANFIS–PSO model in field of mining and blasting engineering is both novel and effective. The ANFIS–PSO as a soft computing method showed acceptable prediction capacity. The performance of the ANFIS–PSO and SVR models against the USBM model indicated that both intelligent models are suitable and practical techniques and can be used effectively for PPV prediction with acceptable error rates. Furthermore, the comparison of two models revealed that the ANFIS–PSO model was more successful and produced more reliable predictions than the SVR model. Based on testing datasets, the error range of ANFIS–PSO varies between −5.17 and +2.96 and for SVR varies between −5.61 and +3.56. The RMSE, VAF and R 2 values were obtained as 1.83, 93.37 and 0.957 for the ANFIS–PSO, respectively, whereas these values were obtained as 2.40, 89.49, and 0.924 for SVR model.

Finally, it should be noted that the developed models in this study are specific to Sarcheshmeh copper mine. The application of these models directly in other mines is not recommended and some modifications are necessary based on blasting and mining conditions.

References

Jimeno CL, Jimeno EL, Carcedo FJA (1995) Drilling and blasting of rocks. Balkema, Rotterdam

Bhandari S (1997) Engineering rock blasting operations. Balkema, Rotterdam

Pal Roy P (2005) Rock blasting effects and operations. Balkema, Rotterdam

Khandelwal M, Singh TN (2007) Evaluation of blast-induced ground vibration predictors. Soil Dynam Earthquake Eng 27:116–125

Duvall WI, Petkof BB (1959) Spherical propagation of explosion generated strain pulses in rock. US Bur Mines, RI 5483

Dowding CH (1985) Blast vibration monitoring and control. Prentice-Hall, Englewoods Cliffs

Siskind DE, Stagg MS, Kopp JW, Dowding CH (1980) Structure response and damage produced by ground vibration from surface mine blasting. US Bur Mines, RI 8507

Duvall WI, Fogelson DE (1962) Review of criteria for estimating damage to residences from blasting vibration. US Bur Mines, RI 5968

Edwards AT, Northwood TD (1960) Experimental study of effects of blasting on structures. Engineering 210:539–546

Nicholls HR, Johnson CF, Duvall WI (1971) Blasting vibrations and their effects on structures. US Bur Mines, RI 656

German Institute of Standards (1986) Vibration of building-effects on structures. DIN 4150, Vol 3, pp 1–5

Siskind DE (2000) Vibrations from blasting. ISEE Publication, Cleveland

Duvall WI, Petkof BB (1959) Spherical propagation of explosion generated strain pulses in rock. US Bur Mines, RI 5483

Langefors U, Kihlstrom B (1963) The modern technique of rock blasting. Wiley, New York

Davies B, Farmer IW, Attewell PB (1964) Ground vibrations from shallow sub-surface blasts. Engineering 217:553–559

Ambraseys NN, Hendron AJ (1968) Dynamic behavior of rock masses. In: Stagg KG, Zienkiewicz OC (eds) Rock mechanics in engineering practices. Wiley, London, pp 203–227

Indian Standard Institute (1973) Criteria for safety and design of structures subjected to underground blast. ISI Bull No 6922

Ghosh A, Daemen JK (1983) A simple new blast vibration predictor (based on wave propagation laws). In: Proceedings of the 24th US symposium on rock mechanics, Texas, USA, pp 151–161

Gupta RN, Pal Roy P, Singh B (1987) On a blast induced blast vibration predictor for efficient blasting. In: Proceedings of the 22nd international conference on safety in mines research institute, Beijing, China, pp 1015–1021

Pal Roy P (1991) Vibration control in an opencast mine based on improved blast vibration predictors. Min Sci Tech 12(2):157–165

Rai R, Singh TN (2004) A new predictor for ground vibration prediction and its comparison with other predictors. Indian J Eng Mater Sci 11(3):178–184

Ghasemi E, Araei M, Hashemolhosseini H (2012) Development of a fuzzy model for predicting ground vibration caused by rock blasting in surface mining. J Vib Contr 19(5):755–770

Singh TN (2004) Artificial neural network approach for prediction and control of ground vibrations in mines. Mining Technol 113(4):251–256

Singh TN, Singh V (2005) An intelligent approach to predict and control ground vibration in mines. Geotech Geol Eng 23(3):249–262

Khandelwal M, Singh TN (2006) Prediction of blast induced vibrations and frequency in opencast mine: a neural network approach. J Sound Vib 289:711–725

Khandelwal M, Singh TN (2009) Prediction of blast-induced ground vibration using artificial neural network. Int J Rock Mech Min Sci 46(7):1214–1222

Khandelwal M, Kumar DL, Yellishetty M (2011) Application of soft computing to predict blasting-induced ground vibration. Eng Comput 27(2):117–125

Mohamed MT (2011) Performance of fuzzy logic and artificial neural network in prediction of ground and air vibrations. Int J Rock Mech Min Sci 48(5):845–851

Bakhshandeh Amnieh H, Mozdianfard MR, Siamaki A (2010) Predicting of blasting vibrations in Sarcheshmeh copper mine by neural network. Saf Sci 48(3):319–325

Monjezi M, Ahmadi M, Sheikhan M, Bahrami A, Salimi AR (2010) Predicting blast-induced ground vibration using various types of neural networks. Soil Dynam Earthquake Eng 30(11):1233–1236

Dehghani H, Ataee-pour M (2011) Development of a model to predict peak particle velocity in a blasting operation. Int J Rock Mech Min Sci 48(1):51–58

Kamali M, Ataei M (2011) Prediction of blast induced vibrations in the structures of Karoun III power plant and dam. J Vib Contr 17(4):541–548

Monjezi M, Ghafurikalajahi M, Bahrami A (2011) Prediction of blast-induced ground vibration using artificial neural networks. Tunn Undergr Space Technol 26:46–50

Monjezi M, Hasanipanah M, Khandelwal M (2013) Evaluation and prediction of blast-induced ground vibration at Shur River Dam, Iran, by artificial neural network. Neural Comput Appl 22:1637–1643

Saadat M, Khandelwal M, Monjezi M (2014) An ANN-based approach to predict blast-induced ground vibration of Gol-E-Gohar iron ore mine, Iran. J Rock Mech Geotech Eng 6:67–76

Vasovic D, Kostic S, Ravilic M, Trajkovic S (2014) Environmental impact of blasting at Drenovac limestone quarry (Serbia). Environ Earth Sci 72:3915–3928

Alvarez-Vigil AE, Gonzalez-Nicieza C, Gayarre Lopez F, Alvarez-Fernandez MI (2012) Predicting blasting propagation velocity and vibration frequency using artificial neural network. Int J Rock Mech Min Sci 55:108–116

Gorgulu K, Arpaz E, Demirci A, Kocaslan A, Dilmac MK, Yuksek AG (2013) Investigation of blast-induced ground vibrations in the Tulu boron open pit mine. Bull Eng Geol Environ 72:555–564

Gorgulu K, Arpaz E, Uysal O, Duruturk YS, Yuksek AG, Kocaslan A, Dilmac MK (2015) Investigation of the effects of blasting design parameters and rock properties on blast-induced ground vibrations. Arab J Geosci 8:4269–4278

Ghoraba S, Monjezi M, Talebi N, Moghadam MR, Jahed Armaghani D (2015) Prediction of ground vibration caused by blasting operations through a neural network approach: a case study of Gol-E-Gohar Iron Mine, Iran. J Zhejiang Univ Sci A. doi:10.1631/jzus.A1400252

Fisne A, Kuzu C, Hudaverdi T (2011) Prediction of environmental impacts of quarry blasting operation using fuzzy logic. Environ Monit Assess 174(1–4):461–470

Iphar M, Yavuz M, Ak H (2008) prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neuro-fuzzy inference system. Environ Geol 56(1):97–107

Rao YS, Rao KM (2009) Prediction of ground vibrations and frequency in opencast mine using neuro-fuzzy technique. J Sci Ind Res 68:292–295

Mohammadi SS, Bakhshandeh Amnieh H, Bahadori M (2011) Prediction ground vibration caused by blasting operations in Sarcheshmeh copper mine considering the charge type by adaptive neuro-fuzzy inference system (ANFIS). Arch Min Sci 56(4):701–710

Ataei M, Kamali M (2013) Prediction of blast-induced vibration by adaptive neuro-fuzzy inference system in Karoun 3 power plant and dam. J Vib Contr 19(12):1906–1914

Jahed Armaghani D, Momeni E, Khalil Abad SVAN, Khandelwal M (2015) Feasibility of ANFIS model for prediction of ground vibrations resulting from quarry blasting. Environ Earth Sci 74:2845–2860

Jahed Armaghani D, Hajihassani M, Monjezi M, Mohamad ET, Marto A, Moghaddam MR (2015) Application of two intelligent systems in predicting environmental impacts of quarry blasting. Arab J Geosci 8:9647–9665

Mohammadnejad M, Gholami R, Ramazanzadeh A, Jalali ME (2012) Prediction of blast-induced vibrations in limestone quarries using Support Vector Machine. J Vib Contr 18(9):1322–1329

Khandelwal M (2010) Evaluation and prediction of blast-induced ground vibration using support vector machine. Int J Rock Mech Min Sci 47:509–516

Khandelwal M (2011) Blast-induced ground vibration prediction using support vector machine. Eng Comput 27:193–200

Verma AK, Singh TN (2013) Comparative study of cognitive systems for ground vibration measurements. Neural Comput Appl 22:341–350

Verma AK, Singh TN, Maheshwar S (2014) Comparative study of intelligent prediction models for pressure wave velocity. J Geosci Geomatic 2(3):130–138

Dindarloo SR (2015) Peak particle velocity prediction using support vector machines: a surface blasting case study. J S Afr Inst Min Metall 115:637–643

Hasanipanah M, Monjezi M, Shahnazari A, Jahed Armaghani D, Farazmand A (2015) Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 75:289–297

Verma AK, Singh TN (2011) Intelligent systems for ground vibration measurement: a comparative study. Eng Comput 27(3):225–233

Hajihassani M, Jahed Armaghani D, Marto A, Mohamad ET (2015) Ground vibration prediction in quarry blasting through an artificial neural network optimized by imperialist competitive algorithm. Bull Eng Geol Environ 74:873–886

Jahed Armaghani D, Hajihassani M, Mohamad ET, Marto A, Noorani SA (2014) Blasting-induced flyrock and ground vibration prediction through an expert artificial neural network based on particle swarm optimization. Arab J Geosci 7:5383–5396

Hajihassani M, Jahed Armaghani D, Monjezi M, Mohamad ET, Marto A (2015) Blast-induced air and ground vibration prediction: a particle swarm optimization-based artificial neural network approach. Environ Earth Sci 74:2799–2817

Dutta S (2010) Obstacle avoidance of mobile robot using PSO based neuro fuzzy technique. Int J Comput Sci Eng 2:30–304

Pousinho HMI, Mendes VMF, Catalao JPS (2011) A hybrid PSO-ANFIS approach for short-term wind power prediction in Portugal. Energ Convers Manag 52:397–402

Jiang HM, Kwong CK, Ip WH, Wong TC (2012) Modeling customer satisfaction for new product development using PSO-based ANFIS approach. Appl Soft Comput 12:726–734

Chen MY (2013) A hybrid ANFIS model for business failure prediction utilizing particle swarm optimization and subtractive clustering. Inform Sci 220:180–195

Djavareshkian MH, Esmaeili A (2014) Heuristic optimization of submerged hydrofoil using ANFIS-PSO. Ocean Eng 92:55–63

Basser H, Karami H, Shamshirband S, Akib S, Amirmojahedi M, Ahmad R, Jahangirzadeh A, Javidnia H (2015) Hybrid ANFIS–PSO approach for predicting optimum parameters of a protective spur dike. Appl Soft Comput 30:642–649

Jang JSR (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23:665–685

Kennedy J, Eberhart RC (1995) Particle swarm optimization, In: Proceedings of IEEE international conference on neural networks, Perth, Australia, pp 1942–1948

Jang JSR, Sun CT, Mizutani E (1997) Neuro-fuzzy and soft computing: a computational approach to learning and machine intelligence. Prentice Hall, Upper Saddle River

Sumathi S, Paneerselvam S (2010) Computational intelligence paradigms: theory and applications using Matlab. CRC Press, New York

Engelbrecht AP (2007) Computational intelligence: an introduction. Wiley, Chichester

Cortes C, Vapnik V (1995) Support-vector networks. Mach Learn 20:273–297

Venkoba Rao B, Gopalakrishna SJ (2009) Hardgrove grindability index prediction using support vector regression. Int J Miner Process 91:55–59

Azamathulla HM, Ghani AA, Chang CK, Hasan ZA, Zakaria NA (2010) Machine learning approach to predict sediment load—a case study. CLEAN Soil Air Water 38:969–976

Suganyadevi MV, Babulal CK (2014) Support vector regression model for the prediction of loadability of a power system. Appl Soft Comput 24:304–315

Yao B, Hu P, Zhang M, Jin M (2014) A support vector machine with the tabu search algorithm for freeway incident detection. Int J Appl Math Comput Sci 24:397–404

Tan P, Zhang C, Xia J, Fang QY, Chen G (2015) Estimation of higher heating value of coal based on proximate analysis using support vector regression. Fuel Process Tech 138:298–304

Vapnik VN (1999) An overview of statistical learning theory. IEEE Trans Neural Network 10(5):988–999

Chang CC, Lin CJ (2011) LIBSVM: a library for support vector machines. ACM Trans Intell Syst Technol 2(3):21–27

Acknowledgments

The authors would like to thank two anonymous reviewers for their critical reviews and constructive comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghasemi, E., Kalhori, H. & Bagherpour, R. A new hybrid ANFIS–PSO model for prediction of peak particle velocity due to bench blasting. Engineering with Computers 32, 607–614 (2016). https://doi.org/10.1007/s00366-016-0438-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-016-0438-1