Abstract

Although conventional oil refining process like hydrodesulfurization (HDS) is capable of removing sulfur compounds present in crude oil, it cannot desulfurize recalcitrant organosulfur compounds such as dibenzothiophenes (DBTs), benzothiophenes (BTs), etc. Biodesulfurization (BDS) is a process of selective removal of sulfur moieties from DBT or BT by desulfurizing microbes. Therefore, BDS can be used as a complementary and economically feasible technology to achieve deep desulfurization of crude oil without affecting the calorific value. In the recent past, members of biodesulfurizing actinomycete genus Gordonia, isolated from versatile environments like soil, activated sludge, human beings etc. have been greatly exploited in the field of petroleum refining technology. The bacterium Gordonia sp. is slightly acid-fast and has been used for unconventional but potential oil refining processes like BDS in petroleum refineries. Gordonia sp. is unique in a way, that it can desulfurize both aliphatic and aromatic organosulfurs without affecting the calorific value of hydrocarbon molecules. Till date, approximately six different species and nineteen strains of the genus Gordonia have been recognized for BDS activity. Various factors such as enzyme specificity, availability of essential cofactors, feedback inhibition, toxicity of organic pollutants and the oil–water separations limit the desulfurization rate of microbial biocatalyst and influence its commercial applications. The current review selectively highlights the role of this versatile genus in removing sulfur from fossil fuels, mechanisms and future prospects on sustainable environment friendly technologies for crude oil refining.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The third most abundant heteroatom in crude oil is sulfur which contributes approximately 10% of the total crude oil chemical composition. It is estimated that 50–95% of the sulfur content in petroleum and its derivative fractions is in the form of thiophenic sulfur where alkylated derivatives of dibenzothiophenes (DBTs) comprise the predominant form of polyaromatic sulfur hydrocarbons [1, 2].

Biodesulfurization of organosulfur compounds by microbes has attracted a lot of attention in the recent past due to its economical, ecological and environmentally benign bioprocess. However, further investigations are required to enhance and remodel the process to make it more suitable for use in industry [3].

Research in biotechnology and petroleum microbiology suggests that strains of Gordonia sp. have the potential to break down refractory crude oil pollutants like polycyclic aromatic hydrocarbons (PAHs) and organosulfur compounds due to long chain hydrophobic mycolic acids located in their cell wall [4]. Gordonia, is a gram positive, non-motile, catalase-positive, aerobic bacterium. This versatile genus has been retrieved from different land and water ecosystems for its deterioration capability of oil pollutants [5, 6]. Several examples illustrate the potentiality of this genus in degrading wide variety of organic pollutants. Two strains of G. rubripertincta; strain SBUG 1971 and SUBG 1972 have been reported to degrade twenty four n-alkanes, twenty two n-alkylcyclohexanes, twenty branched chain alkanes, thirteen alkylbenzenes, four n-alkyl-substituted naphthalenes, three n-alkyl-substituted biphenyls and many other oil components in traces [7]. Further, long chain hydrocarbon decomposing G. amicalis strain LH3, showed 17.8% of paraffin degradation and 44.7% of oil viscosity reduction [8]. Gordonia amicalis IEGMT was identified as a reliable and homogeneous strain on par with the well-studied Rhodococci model having a 4S metabolic pathway for DBT desulfurization [9]. There are about six species and nineteen strains of Gordonia sp. known to show biodesulfurization (BDS) activity (Table 1) [10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37].

Few researchers have reviewed the potential biotechnological prospects of the Gordonia sp. [4, 6, 38, 39]. Arenskötter et al. [38] reviewed the biological significance of the genus with emphasis on its role in various biotechnological fields in regards to catabolic and metabolic abilities of genus Gordonia. Drzyzga [4] highlighted the strengths and weaknesses of the genus in regards to various industrial applications as well as its pathogenic role in causing disease in humans. A review of Gordonia shows the clinical significance of this versatile genus, both in healthy and immune compromised patients [39]. The ecological significance, diversity and adaptability of Gordonia sp. in relevance to different metabolites were highlighted by Sowani et al. [6]. Several species of the genus have been reported to have catabolic adaptations, for bioremediation purposes such as bioaugmentation [40]. Many factors including enzyme specificity, cofactor (FMNH2) availability, feedback inhibition, oil–water separation and toxicity of organic pollutants affect the desulfurization rate of microbial biocatalyst and influence its commercial applications. Therefore, strategies to optimize industrial scale BDS processes are needed for oil refineries. The present review will provide insights into the role of Gordonia sp. in a novel biorefining process known as BDS. In this paper, mechanisms and pathways involved, recent technological developments, as well as genetic engineering opportunities for enhancing the BDS process are explained.

Gordonia sp. as Potential Biodesulfurizing Bacteria

Hydrodesulfurization vs Biodesulfurization

Emissions of SOx from vehicular exhaust pose a dire threat to the environment. Therefore, to limit the sulfur content in the emissions, governing authorities of many developing countries have recommended petroleum refineries to adopt deep desulfurization of crude oil [41]. The recommended limit of sulfur content set by the Environmental Protection Agency (EPA) of USA for gasoline is 15 ppm and diesel is 30 ppm [42]. Desulfurization is a key step in the pre-processing of fossil fuels to achieve compliance with these regulations [43]. Hydrodesulfurization (HDS) is the standard, traditional process routinely accepted in oil industries for cutting back the sulfur components present in crude oil and petroleum refining purposes. However, HDS suffer from major setbacks as it is dependent on severe operating conditions like that of extremely high pressure (1–18 MPa), and high temperature (200–240 °C) to fulfil the stringent EU sulfur regulations (500 to < 10 ppm) [44, 45]. Sulfides, mercaptans, thiophenes and their derivatives such as DBTs are the forms of sulfur found in liquid fuels [46]. The removal of these refractory compounds by conventional but sophisticated HDS has made the process both expensive and energy- exhaustive. Moreover, expensive catalysts used in the process constitute a greater problem of disposal as they are hazardous in nature. In addition to this, HDS is not efficient in attaining the reduced contents of sulfur limited by the Environmental Protection Agency, EPA [47, 48].

The major obstacle in petroleum desulfurization has been overcome through an alternative, emerging microbial process of BDS that exhibit a lot of potential for refining crude oils. Apart from being environmentally friendly, the major advantage of the technology is that it can work at ambient conditions [49, 50]. The following are some general conclusions drawn about BDS from previous studies (a) various factors such as the amount and accumulation of reduced cofactors, enzyme activity, movement of substrate and intermediates across cell membranes do not affect the rate of biodesulfurization; (b) Competitive enzyme inhibition is the best model for explaining the mechanism of biodesulfurization and its transition states; (c) The number of substituent’s of DBT determines the biodesulfurization rate which is specified by depletion in inhibition constant and the increase in Michaelis–Menten constant [46].

Metabolic Pathways of Biodesulfurization

Microorganisms have the tendency to extract sulfur from different sources to fulfill their nutrient needs through their metabolic pathways. Thiophenic compounds like DBT and benzothiophenes (BT) can be consumed by certain microorganisms, leading to a decrease in sulfur content in fossil fuels. While HDS results in increased amount of H2S due to reduction of sulfur moieties, BDS is based on oxidative pathways, making it a promising and less-demanding technology under ambient conditions [51]. There are two principle pathways that have been reported for DBT utilization such as ring-destructive (degradation) i.e. Kodama pathway and sulfur specific (desulfurization) pathway i.e. 4S metabolic pathway [52].

The Kodama pathway of DBT degradation is comparable to the naphthalene degradation, which is among the most common path for oxidative cleavage of C–C bond [52, 53]. This destructive oxidative C–C bond scission mechanism is rather undesired and is not commercially exploited due to fragmentation of phenyl ring by sequential degradation/ oxidation of C–C bonds, and the reduced calorific value of the fuels (Fig. 1) [47, 54].

The key features in the pathway are addition of hydroxyl group (hydroxylation) followed by breakage of C–C bonds which lead to the disruption of the aromatic ring and finally hydrolysis [42]. Diverse groups of microorganisms are known to follow this destructive pathway. The microbial cleavage of DBT following the Kodama pathway was tested by growing Pseudomonas jianii DDC279 in a DBT rich minimal salt medium where five water-soluble products were obtained among which 3-hydroxy-2-formyl-benzothiophene was accounted for the maximum quantity [55]. The Kodama pathway prefers to catalyze unsubstituted homocyclic rings of DBTs over their methylated derivatives [53]. The reactive steps in the pathway begins with addition of oxygen to the DBT compound resulting in cleavage of the aromatic ring and accumulation of an unstable, water-soluble end product, 3-hydroxy-2-formyl -benzothiophene (HFBT). The number of carbon atoms in HFBT is lower than that of DBT, thereby halting the desulfurizing process altogether [52].

Contrary to Kodama pathway, the 4S metabolic pathway does not disrupt the DBT aromatic ring. It specifically attacks the C–S bond, removing the sulfur entity from the ring through successive oxidation steps. As the DBT is oxidized, the following products are formed: dibenzothiophene sulfoxide, dibenzothiophene sulfone, 2-hydroxybiphenl sulfinate and finally 2-hydroxybiphenyl (2-HBP) and other water-soluble sulfates (Fig. 2). The 4S metabolic pathway does not affect the oil’s combustion value which is recognized as the most valuable potential application pathway [36, 56]. There are several reports that suggest an expanded account of the 4S pathway where 2-methoxybiphenyl (2-MBP), 2,2-dihydroxybipheny or biphenyl are the end product instead of 2-HBP. However, their level of toxicity and inhibition of desulfulrizing capacity of the bacteria is yet to be explored [57]. The 4S metabolic pathway is divided into three major stages: (a) cleavage of the sulfur component by oxidation which results in activation of the thiophene ring; (b) cleavage of thiophenic ring which results in sulphinate, an aromatic compound and (c) eradication of sulfinate group.

There are 22 identified bacterial genera and several other unidentified bacteria are reported to utilize the 4S metabolic pathway, but most of the research is focused on Rhodococcus sp. [58]. Application of muti-enzymatic 4S metabolic pathway has suggested to be adopted as an alternative technology in oil production fields and refineries. It is therefore necessary to promote the commercialization of BDS in large scale industrial applications by deepening our understanding of the mechanism, genes involved and inhibitory nature of the end products [3, 36]. The US Company, Energy BioSystems Corporation undertook one such industrial BDS project and used three bioreactors to lower sulphur concentration from 5 barrels of oil per day [59].

Genetics of Biodesulfurization

DBT metabolism involves several catabolic genes known as dsz, bds, mds, sox and tds. Among these genes, “sox” designation for DBT desulfurization has been now dismissed as numerous independent unlinked genes have also designated as sox (Mohebali and Ball 2016) [58]. BDS of organosulfur compounds like DBT is carried out by activity of three enzymes encoded by dszA, dszB and dszC genes. Rhodococcus erythropolis IGTS8 has a linear megaplasmid with size of 120–150 kb which bears these three genes arranged and expressed in a 4 kb fragment of the megaplasmid in the same orientation. All the three dsz genes are regulated by a dsz operon [34, 59,60,61]. Rhodococcus erythropolis IGTS8 is a model bacterium and is among the first strains reported to be DBT-BDS where DBT is successfully transformed into 2-HBP following the 4S pathway. 4-S metabolic pathway of R. erythropolis IGTS8 involves DszC (45-kDa protein) and DszA (50-kDa protein) monooxygenases enzymes and a desulfinase enzyme, DszB (40-kDa protein) [58, 62].

DBT is degraded into 2-HBP through successive oxidative step wherein the first catalyzing step is regulated by dszC gene and the enzyme encodes for this is a monooxygenase, DBT-monooxygenase. This enzyme oxidizes DBT to DBT-sulfoxide and DBT- sulfoxide to DBT- sulfone. Second gene, dszA encodes a monooxygenase, called DBT sulfone monooxygenase, which acts on DBT-sulfone converting it further into 2-hydroxybiphenyl-2-sulfinic acid. Further oxidative step is catalyzed by a desulfinase enzyme, 2-hydroxybiphenyl sulfinate desulfinase encoded by dszB gene. During this step, 2-hydroxybiphenyl-2-sulfinic acid is converted to 2-hydroxybiphenyl and sulfite [63]. DszC and DszA are flavin-dependent monooxygenases that require reductive flavin nucleotides (FMNH2) as cofactors for their catalytic activities. Studies indicates an additional presence of chromosomal gene, dszD encodes protein DszD, reduced nicotinamide adenine dinucleotide (NADH) or flavin mononucleotide (FMN) or simply flavin reductase. However, various factors such as enzyme specificity, limited availability of enzyme and essential cofactor (FMNH2), feedback inhibition, toxicity of organic pollutants and the oil–water separations limits the desulfurization rate of microbial biocatalyst and influence its commercial applications [59, 64].

Diverse bacterial genera isolated from various environments possess dsz genes which support the assumption that these genes are horizontally transferred and have only a few differences in their sequences. Six different types of organization in dszABC genes nucleotide sequences were reported. Type 2 (dszABC-type-2) has been reported from Gordonia alkanivorans 1B whereas type -3 (dszABC-type-3) was detected from G. amicalis strain F.5.25.8. The homology of dszABC-type-2 and dszABC-type-3 with that of dszABC-type-1 found in Rhodococcus sp. IGTS8 is 90% and 84% respectively. Similarly, dszABC-type-3 and type-4 have been found from thermophilic Bacillus subtilis and Paenibacillus sp. respectively. Type-5 and type-6 organizations were described from Mycobacterium sp. [65]. The size of dszA, dszB and dszC range from 1362 to 1425 bp, 1062–1098 bp and 1245–1254 bp respectively [58, 65]. The expression patterns of dszA, dszB, and dszC genes in Gordonia species were found to be in the same orientation under the control of a single promoter [58]. Sequencing studies indicated a 10 bp gap between dszC and dszB genes along with a 67 bp overlap between initiation codon of dszB and the termination codon of dszA [65]. Removal of the overlap between dszA and dszB gens in dsz operon can substantially improve the biodesulfurization activity of Gordonia species [58]. Shavandi et al. [13] discussed that rearrangement of dszABC operon into dszBAC would facilitate a higher biodesulfurization activity. Further, results of Southern blot and pulsed field gel electrophoresis specify that, dsz operon of G. alkanivorans RIPI90A is located on bacterial chromosome where as dsz operon of Rhodococcus strain IGTS8 is located on 120 kb megaplasmid [13]. Although there is a higher homology of dsz operons between strain RIPI90A and strain IGTS8, the homology between promoter sequences of both strains is minimal (> 52.5%) [13].

Taxonomy, Diversity and Cultural Characteristics of Gordonia sp.

The bacterial genus, Gordonia is very versatile for its ability to convert and decompose a wide range of compounds, including polyaromatic sulfur heterocycles (PASHs) that are present in fossil fuels. There are several strains in this diverse catabolic genus which are capable of desulfurizing not only DBT, but also benzothiophene (BT) and other thiophenic compounds, which most common Rhodococci strains cannot do [43]. A comparative characteristic of the efficiency of Gordonia species in fuel desulfurization showed that strains CYKS1, SYKS1 were capable of desulfurizing middle distillate unit feed (1500 ppm), light gas oil (3000 ppm) and diesel fuel (250 ppm) of oil fractions with 50–70% and 35–76% of degree of desulfurization respectively [51]. Table 2 summarizes the desulfurization efficiency of various strains of Gordonia sp. [10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37].

Tsukamura, in1971 proposed Gordona as a new genus of coryneform bacteria isolated from sputa of patients with pulmonary disease and from soil [66]. In order to pay tribute to an eminent American bacterial taxonomist, Ruth E. Gordon, the name Gordona for this genus was proposed. The genus was later renamed as Gordonia based on biochemical, molecular and 16S ribosomal RNA sequence evaluation. The cell wall composition of Gordonia sp. consists of high molecular weight, long-chained fatty acids like mycolic-acid with an average carbon atom number of 50–60 and a range of 0–5 double bonds, as well as MK-9-(H) menaquinone [67, 68]. Phylogenetic analysis places this genus in the family Gordoniacea, suborder Corynebacterineae, and order Actinomycetales [6, 69].

Phylogenetic relationships based on 16S rRNA gene analyses of 39 Gordonia species isolated from soil, rhizosphere, waste water, marine animals, activated sludge and human beings has been published [6]. Seven strains of Gordonia sp. isolated from soil and sludge samples have shown siderophore production, lignin, xenobiotic, thermo-halotolerant alkane degradation and metabolism of organo sulfur compounds. G. desulfuricans, G. terrae, G. amicalis, and G. alkanivorans are thoroughly studied Gordonia species for their role in crude oil component degradation. Twenty four Gordonia species isolated from diverse environments have shown a potential role in biodegradation of hydrocarbons and pollutants. Among these, ten species, whose roles are unclear, have been found to be associated with marine fauna, and three species, G. aichiensis, G. sputa, and G. otitidis, have been linked to human pathologies [6, 40].

Various phenotypic, biochemical, chemotaxonomic and molecular results distinguish Gordonia from other members of the Actinobacteria group. Members of this genus are partially acid-fast, arylsulfatase-negative, bacilli or cocci in shape, sensitive to lysozyme, hydrolyses urea, and shows positive nitrate reduction. Their gram character is positive to variable. Few members of Gordonia are known to produce pigmented colonies with a broad range of colors including orange to orange-red, pale grey, white, peach, yellow, tannish to deep pink and also bear shiny, slimy, smooth to rough and uneven surfaces. One of the best methods for identifying this genus is to observe its growth in medium containing carbohydrates, amino acids and different concentrations of sodium chloride at different temperatures [4, 6, 39, 40, 69,70,71]. Depending on the type of medium used for growth, the colony characteristics may vary within one species [72].

16S rRNA gene sequence analysis helps to identify Gordonia species, however, for species level identification a reference laboratory is required [73, 74]. The homology of 16S rRNA gene sequences among different Gordonia species is found to be very high. It ranges 99.9% between G. alkanivorans and G. nitida; and 94.8% in between G. amarae and Gordonia sihwensis. The intrageneric DNA–DNA closeness varies from 3.7% (shared by G. amarae and Gordonia nitida) to 52% (shared by G. rubripertincta and G. alkanivorans) and the G + C% ratio of Gordonia genome extends from 63 to 69 mol% [38].

Biodesulfurization Potential of Gordonia sp.

Gordonia species are recognized as an effective biocatalyst, capable of degrading as well as transforming organosulfur pollutants from oil contaminated soil and water. In the recent past, Gordonia sp has been recognized as a potential biodesulfurizing bacteria as it can degrade both aromatic and aliphatic hydrocarbons [75]. Some of the sulfur compounds that are degraded by different Gordonia strains are mentioned in the following.

Thiols, sulphides, thiophenes and its substituted derivatives constitute the major portion among the 200 types of organosulfur compounds found in crude oils. According to a study of the thiophenic compounds found in crude oil from Texas, 70 percent of the sulfur is in the form of DBT and its alkylated form [76]. Many other reports in the last few decades also share a similar background. Therefore, DBT has been exploited as a model compound in biodesulfurizing research.

The genus Gordonia comprises of many species which are capable of using DBT as a sole source of sulfur, e.g. G. amicalis strain IEGMT [9], G. alkanivorans RIPI90A [10,11,12,13], G. amicalis F.5.25.8 [18, 19], G. alkanivorans 1B [14,15,16], G. nitida CYKSI [22, 23], G. rubripertincta ICP172 [25], and Gordonia sp. strain TM414 [30].

Gordonia sp. IITR100 is a robust, aerobic bacterium that can desulfurize a broad range of organosulfur compounds such as thiophenic (DBT, benzonaphthothiophene) and non-thiophenic (thiathrene). The presence of a nucleotide sequence of 11.5 kb region (GenBank accession number KC693733.1) containing the dszABC operon in Gordonia sp IITR100 shown > 99% sequence similarity with that of Gordonia strains 1B, RIPI90A and CYKS2. The size of the dsz genes are 1425, 1098 and 1251 for dszA, dszB and dszC respectively [32, 65]. Draft-genome sequence of Gordonia sp. strain IITR100 reported the presence of five genes involved in the BDS process, which includes 2-hydroxybiphenyl-2-sulfinate desulfinase, dibenzothiophene (DBT) desulfurization enzyme, DBT monooxygenase, sulfite reductase, and flavin reductase [77]. Another study reports strain IITR100 as one of the pioneer strains among the members of Gordonia genus showing remarkable biodesulfurizing capacity of heavy and hydrodesulfurized oil by reducing its sulfur quantity by 76% and 70–98% (70– < 2 ppm) respectively. Since the bacterium can also degrade aliphatic C–S bonds, 31% of viscosity reduction was observed until 6 days of incubation after which hydrocarbon framework of C–C bonds were disturbed [35].

Gordonia alkanivorans RIPI90A is widely used organism in BDS experiments conducted till date as it has the advantage of desulfurizing alkylated derivatives of DBT such as 4-dimethyldibenzothiophene (4-MDBT), 4, 6-dimethyldibenzothiophene (4, 6-DMDBT) etc. when used as sulfur sources and not as carbon sources. However, the strain prefers 4-MDBT over DBT and 4, 6-DMDBT, DBT sulfone over DBT and cannot desulfurize BT. In another study, DBT biodesulfurizing potential of G. alkanivorans RIPI90A was reported to be repressed by amino acids methionine, cysteine and sulfate. This was however controlled by adopting G. alkanivorans RIPI90A transformants with a stable plasmid pRSG43 harbouring a sulfate non-repressible, inducible lac promoter where dszABC genes were cloned and expressed for efficient BDS process with higher specific activity. Analytical studies for alternative promoters in effective expression of dszABC operon in Gordonia have also been done [10, 12, 13].

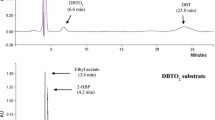

Repression effect of desulfurization by sulfate has been described to be characteristic of the 4S metabolic pathway [14]. A major hurdle in mass production of desulfurizing resting cells is repression of BDS by presence of sulfate. The problem can be tackled by replacement of sulfate by DBT as the main substrate for the 4S pathway. However, in practical purpose it is not possible. Therefore, dimethyl sulfoxide (DMSO) was used as the sulfur source for mass production of desulfurizing bacterium G. alkanivorans RIPI90A, [11].

The first report on the utilization of alternative raw materials as substitutes for refined substrates (namely glucose) in biodesulfurization studies was done by using G. alkanivorans strain 1B [15]. Since the 4S pathway is a multienzymatic metabolic pathway, it depends on both reducing cofactors and the nutrient composition. The effect of various metal ions was observed on the growth and BDS activity of G. alkanivorans strain 1B, a potential BDS bacterium. Among all the nutrients, zinc showed the most significant effect, probably acting on DszA (DBT sulfone monooxygenase) and improved the production of 2HBP by 26% when its concentration was increased from 1 to 10 mg L−1 [16]. Although the pathways for DBT desulfurization and BT desulfurization varies, G. alkanivorans strain 1B has been reported to desulfurize both DBT and BT simultaneously [14]. A study on the effect of different carbon sources on BDS activity of the strain revealed the affinity of the strain towards fructose, producing 9.29 mM/hour of 2HBP from DBT [78].

DBT-desulfurizing bacterium, G. amicalis F.5.25.8 is highly stable, resistant to high temperature (42 °C) and mutagens. However, the remarkable and unique property of this strain lies on its location of the dsz genes. Unlike Rhodococcal BDS strains which have dszABC genes arranged on plasmid, G. amicalis F.5.25.8 and G. alkanivorans RIPI90A are reported to have these genes on the chromosome. PCR amplification based on Rhodococcus designed primers was only able to yield dszA and dszB genes. G. amicalis F.5.25.8 showed a high degree of BDS at a rate of 73% [18]. Characterization of entire DNA sequences, promoter region along with the dszABC genes as well as highly conserved regions of the strain F.5.25.8 showed 85% homology with dsz genes of G. alkinovorans 1B [19].

G. nitida CYKS1, another oil-desulfurizing biocatalyst adopted a unique strategy for its production and DBT-BDS rate. Two separate sulfur sources were used for the purpose. In a two-stage fermentation model, magnesium sulfate was used as the first sulfur source during the cell growth stage which was replaced by DBT in the desulfurization activity induction stage. The result generated a highly capable deep desulfurizing biocatalyst which can give rise to exceedingly low-sulfur petroleum oils. The level of sulfur in diesel oil was reported to have decreased to 61 mg-sulfur L-oil-1 in 20 h from 250 mg-sulfur L- oil−1 [22]. CYKS1 was found to take sulfur molecules from organic sulfur compounds for its growth [23]. Desulfurization activity of nocardioform bacteria, Gordonia sp.TM414 was increased by introducing dsz expression vector into the strain TM414 for practical application [30].

Apart from the studies on the metabolic pathways and varying desulfurizing rate of different Gordonia strains, reports on the studies of the genome sequences are also present which will give a platform of possibilities for exploitation of this genus ability in biotechnological applications. Draft genome sequence analysis of Gordonia sp. 1D showed that apart from genes involved in gentisate–naphthalene, salicylate, and alkane degradation, it also contain genes for DBT metabolism. The thermotolerant strain 1D is unique its ability to oxidize hydrocarbons found in crude oil at temperature of 45–50 °C. The strain is a kind of prototypical of Gordonia amicalis and effective in exploiting long chains of alkane group (upto C36). At 45 °C, magnitude of crude oil degeneration in liquid medium and soil is 38% and 40% respectively [20].

G. alkanivorans strain CGMCC6845 (GenBank accession number AYXO00000000) is a DBT desulfurizing halotolerant bacterium which can also degrade other thiophenes like BTs. From the draft genome sequence analysis, it was found that the strain has 9 hydrocarbon degrading genes, and only 1 dibenzothiophene desulfurizing gene [17]. The biodesulfurization pathway involved in BT desulfurization is not yet fully understood but is proposed to be having of four intermediates of sulfur containing compounds. The bdsABC operon in the pathway shares a low degree of similarity with that of DBT desulfuring enzymes of 4S metabolic pathway [79].

There are number of BT desulfurizing genes which play an important role in BT biodesulfurization pathways. The first three steps in the proposed biodesulfurizing pathway of BT involve five genes that encode for FMNH2-dependent monooxygenase and alkanesulfonate monooxygenase. A desulfinase gene along with transport proteins were also assumed to play catalyzing role in the last step of hydrolyzation of benzene sulphonate or benzene sulfinate to sulphonate or sulfinate [6]. There are several reports on desulfurization of benzothiophene by Gordonia species. The genetic analysis of G. terrae C-6 revealed presence of 135 genes up-regulated with BT desulfurization. Out of these, three genes arranged in a chromosomal operon, bdsABC, was reported to have a high percentage of similarity with that of DBT dszABC operon [26].

G. desulfuricans, 213E was established as the first BT-desulfurizing bacterium which uses BT and fructose as sulfur and carbon sources respectively. The strain was able to desulfurize BT in absence of sulfates forming four intermediates, where 2-(2’-Hydroxyphenyl) ethan-l-al (HPEal) got accumulated as the final product. Coincidently, the first three steps in the BT metabolizing pathway were homologous to 4S metabolic pathway of DBT biodesulfurization suggesting presence of enzyme similar to that of DszC [27].

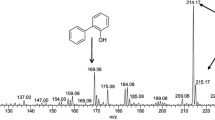

However, BT-desulfurizing pathway of G. rubropertinctus strain T08 differed from previously reported pathway by Gilbert et al. [27]. The metabolites produced by the strain were identified and based on them, a new BT-desulfurizing pathway was designed. The proposed catabolic sequence is BT → BTO (Benzothiophene S-oxide) → BTO2 (Benzothiophene S, S-dioxide) → BT-sultine → BT-sultone → o-hydroxystyrene → (coumaran) → coumaranone → (coumaranone derivative). Coumaran and coumaranone derivative were not detected in the study (Fig. 3) [24].

Earlier studies showed that the type of sulfur compounds present in crude oil can be used to predict the desulfurization technology needed for its degradation. Nevertheless, recent evidence points to other factors affecting the technology, such as the degree of substitution of groups in the sulfur ring and the amount of aromatic compounds of three rings in the crude oil. DBT and its methylated derivatives progressively inhibits desulfurization of other thiophenic compounds like that of benzo[b]naphtho[2,1-d]thiophene (BNT) [80].

Gordonia sp. IITR100 is one of the striking examples of BNT-desulfurizing strains, which degrades BNT using enzymes analogous to the 4S pathway of DBT biodesulfurization and forms intermediate metabolites such as BNT-sulfone, BNT-sulfinate, and BNT-hydroxide (Fig. 4). The strain prefers to degrade DBT over BNT during the first four days of incubation, and will only desulfurize BNT if it is the sole surface source [34].

Studies on the desulfurization of sulfide compounds are limited and one of such examples is the desulfurization of dibenzyl sulfide (DBS) by a newly identified strain, Gordonia sp. IITR100. The pathway proceeds via formation of metabolites such as DBS sulfoxide, DBS sulfone and benzoic acid. The strain shows immense potentiality to degrade DBS and can be used in petroleum biodesulfurization as it is capable of desulfurizing both thiophenic and sulfidic compounds [33].

Metabolic pathway for the degradation of non-thiophenic sulfur compound, thianthrene, by Gordonia sp. IITR100 has found to be similar to that of 4S metabolic pathway. The strain exhibited exceptional thianthrene (TA) desulfurization in comparison to DBT indicating a substantial acceptance of TA by the biodesulfuring enzymes [32].

Genetic Engineering Approaches in Gordonia sp. for Enhanced Biodesulfurization

Biotechnological potential of Gordonia sp. have not attained a huge success as exploitation in genetic tools such as obtaining a new plasmids or electroporation protocols developed so far have been limited. The availability of E.coli/Gordonia shuttle vectors for transformation works in the genus are very limited and are all based on origin of replication of plasmids belonging to Rhodococcus genus. Few examples include E.coli/Rhodococcus (Gordonia) shuttle vectors such as pNC9501, pNC9503; pBBRKmNC903 and pOpaCOS contain a common pNC903 ori, and kanamycin resistance gene [4, 81].

Another example, pRSG43 have been recently exploited for carrying out gene transfer and expression studies of dszABC genes in the Gordonia alkanivorans RIPI90A by adopting electroporation protocols. The recombinant strain was capable of increasing the desulfurizing activity by 2.67-fold under the regulation of lac promoter. However, the same shuttle vector did not produce any transformants in the case of Gordonia sp. IITR 100 (Genbank accession number GU084407), and therefore electroporation protocol for the genus was revised. A new, optimized protocol was suggested which required presence of glycine and a stronger permeabilizing reagent like Tween80. This protocol can be exploited for genetic manipulation studies in different species of the genera for enhancement of biodesulfurization [12, 82].

E. coli (SG13009) cells have been utilized as an expression host for dszAB genes of G. alkanivorans strain 1B. The recombinant strain could desulfurize DBTs in LB medium containing other sulfur compounds such as sulfates, showing no sulfate repression of the dszAB genes expression [83]. DBT biodesulfurization activity of G. alkanivorans RIPI90A was studied by conducting an intensive analysis of the promoter involved in the dsz operon. The study showed that regardless of high similarity in dsz upstream sequences with that of R. erythropolis IGST8, dsz promoter of the strain RIPI90A varied greatly in its sequences and location. A PCR-walking method was validated for cloning and sequencing of the dsz regulatory genes. Using Gordonia-specific primers, dszABC genes were amplified and it was reported that alterations in the orientation of dszABC operon by deletion of overlapping sequences may bring about remarkable increase in desulfurizing activity [13]. In a previous study, heterologus expression of hpaC oxidoreductase from Escherichia coli W was able to supply required FMNH2 to the Dsz monooxygenases [60] and significantly improved the DBT desulfurization.

With a demand in studies of degradation, synthesis and transformation of numerous compounds by Gordonia sp., a new strong, stationary phase and auto inducible promoter was characterized from a biodesulfurizing bacterium, Gordonia sp. IITR100, which could also perform well in E. coli cells. The aim of the study was to tackle the screening process more efficiently, so that positive constructs can be easily electroporated in IITR100 cells. One of the merits of this promoter is overexpression of heterologous proteins that do not lead to changes in the physiology of the bacterial cells which can prove beneficial in expression studies considering the rising demand in biotechnological field [84].

Even now in the field of biodesulfurization, vectors availability for knock-out mutants or transposon mutagenes for Gordonia sp. is are very limited. However, the increasing number of projects on whole genome sequencing will pave a way in the upcoming years for the genus to succeed in establishment of their metabolic as well as biotechnological prospects [4] (Table 3) [17, 20, 77, 85, 86].

Conclusions and Future Perspectives

It has been decades since attempts have been made to implement BDS in oil refining industries, but difficulties in achieving satisfactory results led researchers to seek new knowledge about this novel bioprocess. It is evidenced that successful commercialization of biodesulfurization process depends on various factors such as enzymatic activity of microorganisms, toxicity of the end product (2-HBP), and separation of microbial biomass/oil during BDS process [59]. However, this could be addressed with the rapid advent of computational analysis and modern genetic engineering technologies.

The commercialization of the BDS process will require genetically engineered microorganisms and novel biocatalysts as the desulfurizing rate of known BDS microorganisms is very low (55 fold lower than required) [87]. Molecular regulation of metabolic genes involved BDS pathways is still poorly understood. Therefore, further studies are required to understand metabolic gene expression and their regulation in the host cell during BDS pathways [58]. One possible way to achieve this is to regulate the BDS metabolic mechanisms from the available genome sequences of desulfurizing biocatalysts [88]. The available draft genome sequences of five different Gordonia spp. with desulfurizing activity (G. alkanivorans CGMCC6845 [17], G. amicalis 1D [20], G. amicalis CCMA-559 [85], G. terrae C-6 [86], Gordonia sp. IITR100 [77]) provide insight on the genes which are responsible for regulation of the BDS pathway.

The low solubility and adsorption of high molecular weight DBT and its hydrocarbons derivatives limits their availability to microorganisms and affects the biocatalysts ability. The difference in the interfacial tension between water and oil volume ratio is among the prominent drawback in the development of petroleum biotechnological processes. To control and cutback the operational costs linked with water dissociation and disposal, the interfacial tension should be preferably reduced [89]. This problem could be solved by application of suitable biosurfactants without effecting the biocatalyst cellular growth.

It has been observed that the presence of high number of disulfide bonds in proteins make them tolerant to various factors such as pH, solvents and temperature. Therefore, modifications in desulfurizing enzymes by incorporation of cysteine in its framework can have potential implications in industrial mass production of BDS biocatalysts. Further, the highly stable cysteine-rich desulfurizing enzymes will make the bacterial cells to have higher demand for sulfur and may even provide better tolerance against end products like 2-HBP. This will selectively enhance the desulfurization efficiency of the organism [57]. Investigations on efficient bioreactor systems for dealing with multiphase liquid mixture like air-lift reactor operation with immobilized cells can provide important information on the future development of BDS processes for deep desulfurization of fossil fuels [23]. Studies on purification and characterization of desulfurizing enzymes in Gordonia sp. can provide new avenues in petroleum biotechnology [16].

The BDS process alone should not be viewed as a complete replacement technology for oil refining processes, but rather as an interdependent complementary technology to conventional HDS. Integration of BDS systems along with HDS technology to eliminate recalcitrant components existing in fossil fuels shows a greater possibility of success in the nearest future for oil industries [58].

The present review summarizes relevant details of desulfurizing potentialities of Gordonia species that can be utilized and exploited in the field of petroleum biotechnology for the improvement of biorefining of crude oils. Draft genome sequencing data of the Gordonia species further enhanced our understanding of genetics behind biodesulfurization of organosulfur aliphatic and aromatic compounds in crude oils. Comprehensive understanding of different gene clusters involved in BDS pathways would enable us to go forward in strain improvement programmes and genetic manipulation studies for further enhancement of the process [6]. This genus could possibly play a significant role in petroleum biorefining process in the near future.

Data Availability

The original data compiled for the article will be maintained by the corresponding author.

References

Blumberg KO, Walsh MP, Pera C (2003) Low-sulfur gasoline and diesel: the key to lower vehicle emission. In: Prepared for the May 30, 2003 meeting in Napa, California, of the International Council on Clean Transportation (ICCT). https://theicct.org/sites/default/files/publications/Low-Sulfur_ICCT_2003.pdf. Accessed May 30, 2003.

Kilbane JJ, Le Borgne S (2004) Petroleum biorefining: the selective removal of sulfur, nitrogen, and metals. Stud Surf Sci Catal 151:29–65. https://doi.org/10.1016/S0167-2991(04)80143-5

Xu P, Yu B, Li FL, Cai XF, Ma CQ (2006) Microbial degradation of sulfur, nitrogen and oxygen heterocycles. Trends Microbiol 14(9):398–405. https://doi.org/10.1016/j.tim.2006.07.002

Drzyzga O (2012) The strengths and weaknesses of Gordonia: a review of an emerging genus with increasing biotechnological potential. Crit Rev Microbiol 38:300–316. https://doi.org/10.3109/1040841X.2012.668134

Vidal C, Padilla E, Alcacer P, Campos E, Prieto F, Santos C (2014) Breast abscess caused by Gordonia bronchialis and the use of 16S rRNA gene sequence analysis for its definitive identification. JMM Case Rep. https://doi.org/10.1099/jmmcr.0.001248

Sowani H, Kulkarni M, Zinjarde S (2018) An insight into the ecology, diversity and adaptations of Gordonia species. Crit Rev Microbiol 44(4):393–413. https://doi.org/10.1080/1040841X.2017.1418286

Mikolasch A, Omirbekova A, Schumann P, Reinhard A, Sheikhany H, Berzhanova R, Mukasheva T, Schauer F (2015) Enrichment of aliphatic, alicyclic and aromatic acids by oil degrading bacteria isolated from the rhizosphere of plants growing in oil contaminated soil from Kazakhstan. Appl Microbiol Biotechnol 99:4071–4084. https://doi.org/10.1007/s00253-014-6320-4

Hao DH, Lin JQ, Song X, Lin JQ, Su YJ, Qu YB (2008) Isolation, identification, and performance studies of a novel paraffindegrading bacterium of Gordonia amicalis LH3. Biotechnol Bioproc E 13:61–68. https://doi.org/10.1007/s12257-007-0168-8

Kim SB, Brown R, Oldfield C, Gilbert SC, Iliarionov S, Goodfellow M (2000) Gordonia amicalis sp. nov., a novel dibenzothiophene-desulphurizing actinomycete. Int J Syst Evol Microbiol 50(6):2031–2036. https://doi.org/10.1099/00207713-50-6-2031

Mohebali G, Ball AS, Kaytash A, Rasekh B (2007) Stabilization of water/gas oil emulsions by desulfurizing cells of Gordonia alkanivorans RIPI90A. Microbiology 153:1573–1581. https://doi.org/10.1099/mic.0.2006/002543-0

Mohebali G, Ball AS, Kaytash A, Rasekh B (2008) Dimethyl sulfoxide (DMSO) as the sulfur source for the production of desulfurizing resting cells of Gordonia alkanivorans RIPI90A. Microbiology 154:878–885. https://doi.org/10.1099/mic.0.2007/013011-0

Shavandi M, Sadeghizadeh M, Zomorodipour A, Khajeh K (2009) Biodesulfurization of dibenzothiophene by recombinant Gordonia alkanivorans RIPI90A. Bioresour Technol 100:475–479. https://doi.org/10.1016/j.biortech.2008.06.011

Shavandi M, Sadeghizadeh M, Khajeh K, Mohebali G, Zomorodipour A (2010) Genomic structure and promoter analysis of the dsz operon for dibenzothiophene biodesulfurization from Gordonia alkanivorans RIPI90A. Appl Microbiol Biotechnol 87:1455–1461. https://doi.org/10.1007/s00253-010-2605-4

Alves L, Salgueiro R, Rodrigues C, Mesquita E, Matos J, Gírio FM (2005) Desulfurization of dibenzothiophene, benzothiophene, and other thiophene analogs by a newly isolated bacterium, Gordonia alkanivorans strain 1B. Appl Biochem Biotech 120:199–208. https://doi.org/10.1385/ABAB:120:3:199

Alves L, Marques S, Matos J, Tenreiro R, Gírio FM (2008) Dibenzothiophene desulfurization by Gordonia alkanivorans strain 1B using recycled paper sludge hydrolyzate. Chemosphere 70:967–973. https://doi.org/10.1016/j.chemosphere.2007.08.016

Alves L, Matos J, Tenreiro R, Gírio FM (2008) Evidence for the role of zinc on the performance of dibenzothiophene desulfurization by Gordonia alkanivorans strain 1B. J Ind Microbiol Biotechnol 35:69–73. https://doi.org/10.1007/s10295-007-0278-5

Wang X, Jin D, Zhou L, Wu L, An W, Zhao L (2014) Draft genome sequence of Gordonia alkanivorans strain CGMCC6845, a halotolerant hydrocarbon degrading bacterium. Genome Announc 2:e01274-e1313. https://doi.org/10.1128/genomeA.01274-13

Santos SC, Alviano DS, Alviano CS, Pádula M, Leitão AC, Martins OB, Ribeiro CM, Sassaki MY, Matta CP, Bevilaqua J, Sebastián GV, Seldin L (2006) Characterization of Gordonia sp. strain F.5.25.8 capable of dibenzothiophene desulfurization and carbazole utilization. Appl Microbiol Biotechnol 71:355–362. https://doi.org/10.1007/s00253-005-0154-z

Kilbane JJ, Robbins J (2007) Characterization of the dszABC genes of Gordonia amicalis F. 5.25.8 and identification of conserved protein and DNA sequences. Appl Microbiol Biotechnol 75(4):843–851. https://doi.org/10.1007/s00253-007-0895-y

Delegan YA, Valentovich LN, Shafieva SM, Ganbarov KG, Filonov AE, Vainstein MB (2019) Characterization and genomic analysis of highly efficient thermotolerant oil-degrading bacterium Gordonia sp 1D. Folia Microbiol 64(1):41–48. https://doi.org/10.1007/s12223-018-0623-2

Kim SB, Brown R, Oldfeld C, Gilbert SC, Goodfellow M (1999) Gordonia desulfuricans sp. nov., a benzothiophene-desulphurizing actinomycete. Int J Syst Bacteriol 49:1845–1851. https://doi.org/10.1099/00207713-49-4-1845

Chang JH, Kim YJ, Lee BH, Cho KS, Ryu HW, Chang YK, Chang HN (2001) Production of a desulfurization biocatalyst by two-stage fermentation and its application for the treatment of model and diesel oils. Biotechnol Prog 17:876–880. https://doi.org/10.1021/bp0100676

Lee IS, Bae HS, Ryu HW, Cho KS, Chang YK (2005) Biocatalyticndesulfurization of diesel oil in an air-lift reactor with immobilized Gordonia nitida CYKS1 cells. Biotechnol Prog 21:781–785. https://doi.org/10.1021/bp0496171

Matsui T, Onaka T, Maruhashi K, Kurane R (2001) Benzo[b]thiophene desulfurization by Gordonia rubropertinctus strain T08. Appl Microbiol Biotechnol 57:212–215. https://doi.org/10.1007/s002530100735

Acero J, Berdugo C, Mogollón L (2003) Biodesulfurization process evaluation with a Gordona rubropertinctus strain. CT F-Cienc Tecn Fut 2(4):43–54

Wang W, Ma T, Lian K, Zhang Y, Tian H, Ji K, Li G (2013) Genetic analysis of benzothiophene biodesulfurization pathway of Gordonia terrae strain C-6. PLoS ONE 8:e84386. https://doi.org/10.1371/journal.pone.0084386

Gilbert SC, Morton J, Buchanan S, Oldfield C, McRoberts A (1998) Isolation of a unique benzothiophene-desulphurizing bacterium, Gordona sp. strain 213E (NCIMB 40816), and characterization of the desulphurization pathway. Microbiology 144(9):2545–2553. https://doi.org/10.1099/00221287-144-9-2545

Li GQ, Li SS, Qu SW, Liu QK, Ma T, Zhu L, Liang FL, Liu RL (2008) Improved biodesulfurization of hydrodesulfurized diesel oil using Rhodococcus erythropolis and Gordonia sp. Biotechnol Lett 30:1759–1764. https://doi.org/10.1007/s10529-008-9748-8

Rhee SK, Chang JH, Chang YK, Chang HN (1998) Desulfurization of dibenzothiophene and diesel oils by a newly isolated Gordona strain, CYKS1. Appl Environ Microbiol 64:2327–2331. https://doi.org/10.1128/AEM.64.6.2327-2331.1998

Matsui T, Maruhashi K (2004) Isolation of carotenoid-defcient mutant from alkylated dibenzothiophene desulfurizing nocardioform bacteria, Gordonia sp. TM414. Curr Microbiol 48:130–134. https://doi.org/10.1007/s00284-003-4141-2

Li W, Wang MD, Chen H, Chen JM, Shi Y (2006) Biodesulfurization of dibenzothiophene by growing cells of Gordonia sp. in batch cultures. Biotechnol Lett 28:1175–1179. https://doi.org/10.1007/s10529-006-9070-2

Ahmad A, Chauhan AK, Javed S, Kumar A (2014) Desulfurization of thianthrene by a Gordonia sp. IITR100. Biotechnol Lett 36(11):2209–2214. https://doi.org/10.1007/s10529-014-1606-2

Ahmad A, Chauhan AK, Kushwaha HN, Javed S, Kumar A (2015) Preferential desulfurization of dibenzyl sulfide by an isolated Gordonia sp. IITR100. 3 Biotech 5(3):237–243. https://doi.org/10.1007/s13205-014-0221-1

Chauhan AK, Ahmad A, Singh SP, Kumar A (2015) Biodesulfurization of benzonaphthothiophene by an isolated Gordonia sp. IITR100. Int Biodeterior Biodegr 104:105–111. https://doi.org/10.1016/j.ibiod.2015.05.024

Adlakha J, Singh P, Ram SK, Kumar M, Singh MP, Singh D, Srivastava P (2016) Optimization of conditions for deep desulfurization of heavy crude oil and hydrodesulfurized diesel by Gordonia sp. IITR100. Fuel 184:761–769. https://doi.org/10.1016/j.fuel.2016.07.021

Feng S, Yang H, Zhan X, Wang W (2016) Enhancement of dibenzothiophene biodesulfurization by weakening the feedback inhibition effects based on a systematic understanding of the biodesulfurization mechanism by Gordonia sp. through the potential “4S” pathway. RSC Adv 6(86):82872–82881. https://doi.org/10.1039/C6RA14459D

Aminsefat A, Rasekh B, Ardakani MR (2012) Biodesulfurization of dibenzothiophene by Gordonia sp. AHV-01 and optimization by using of response surface design procedure. Microbiology 81(2):154–159. https://doi.org/10.1134/S0026261712020026

Arenskötter M, Bröker D, Steinbüchel A (2004) Biology of the metabolically diverse genus Gordonia. Appl Environ Microbiol 70(6):3195–3204. https://doi.org/10.1128/AEM.70.6.3195-3204.2004

Andalibi F, Fatahi-Bafghi M (2017) Gordonia: isolation and identification in clinical samples and role in biotechnology. Folia Microbiol 62(3):245–252. https://doi.org/10.1007/s12223-017-0491-1

Sowani H, Kulkarni M, Zinjarde S (2019) Harnessing the catabolic versatility of Gordonia species for detoxifying pollutants. Biotechnol Adv 37(3):382–402

Song C, Ma X (2003) New design approaches to ultra-clean diesel fuels by deep desulfurization and deep dearomatization. Appl Catal 41(1–2):207–238. https://doi.org/10.1016/S0926-3373(02)00212-6

Srivastava VC (2012) An evaluation of desulfurization technologies for sulfur removal from liquid fuels. Rsc Adv 2(3):759–783. https://doi.org/10.1039/C1RA00309G

Aggarwal S, Karimi IA, Ivan GR (2013) In silico modeling and evaluation of Gordonia alkanivorans for biodesulfurization. Mol BioSyst 9(10):2530–2540. https://doi.org/10.1039/C3MB70132H

Alves L, Paixão SM, Pacheco R, Ferreira AF, Silva CM (2015) Biodesulphurization of fossil fuels: energy, emissions and cost analysis. RSC Adv 5(43):34047–34057. https://doi.org/10.1039/C4RA14216K

Paixão SM, Arez BF, Roseiro JC, Alves L (2016) Simultaneously saccharification and fermentation approach as a tool for enhanced fossil fuels biodesulfurization. J Environ Manag 182:397–405. https://doi.org/10.1016/j.jenvman.2016.07.099

Agarwal M, Dikshit PK, Bhasarkar JB, Borah AJ, Moholkar VS (2016) Physical insight into ultrasound-assisted biodesulfurization using free and immobilized cells of Rhodococcus rhodochrous MTCC 3552. Chem Eng J 295:254–267. https://doi.org/10.1016/j.cej.2016.03.042

Bhatia S, Sharma DK (2012) Thermophilic desulfurization of dibenzothiophene and different petroleum oils by Klebsiella sp. 13T. Environ Sci Pollut Res 19(8):3491–3497. https://doi.org/10.1007/s11356-012-0884-2

Babich IV, Moulijn JA (2003) Science and technology of novel processes for deep desulfurization of oil refinery streams: a review. Fuel 82(6):607–631. https://doi.org/10.1016/S0016-2361(02)00324-1

Le Borgne S, Quintero R (2003) Biotechnological processes for the refining of petroleum. Fuel Process Technol 81(2):155–169. https://doi.org/10.1016/S0378-3820(03)00007-9

Bhasarkar JB, Chakma S, Moholkar VS (2013) Mechanistic features of oxidative desulfurization using sono-Fenton–peracetic acid (ultrasound/Fe2+–CH3COOH–H2O2) system. Ind Eng Chem Res 52(26):9038–9047. https://doi.org/10.1021/ie400879j

Sadare OO, Obazu F, Daramola MO (2017) Biodesulfurization of petroleum distillates-current status, opportunities and future challenges. Environments 4(4):85. https://doi.org/10.3390/environments4040085

Campos-Martin JM, Capel-Sanchez MDC, Perez-Presas P, Fierro JLG (2010) Oxidative processes of desulfurization of liquid fuels. J Chem Technol Biotechnol 85(7):879–890. https://doi.org/10.1002/jctb.2371

Gupta N, Roychoudhury PK, Deb JK (2005) Biotechnology of desulfurization of diesel: prospects and challenges. Appl Microbiol Biotechnol 66(4):356–366. https://doi.org/10.1007/s00253-004-1755-7

Bhasarkar JB, Dikshit PK, Moholkar VS (2015) Ultrasound assisted biodesulfurization of liquid fuel using free and immobilized cells of Rhodococcus rhodochrous MTCC 3552: a mechanistic investigation. Bioresour Technol 187:369–378. https://doi.org/10.1016/j.biortech.2015.03.102

Kodama K, Nakatini S, Umehara K, Shimizu K, Minoda Y, Yamada K (1970) Microbial conversion of petro-sulfur compounds. Part III. Isolation and identification of products from dibenzothiophene. Agric Biol Chem 34:1320–1324. https://doi.org/10.1271/bbb1961.34.1320

Kilbane JJ (1989) Desulfurization of coal: the microbial solution. Trends Biotechnol 7:97–101. https://doi.org/10.1016/0167-7799(89)90007-3

Kilbane JJ (2017) Biodesulfurization: how to make it work? Arab J Sci Eng 42(1):1–9. https://doi.org/10.1007/s13369-016-2269-1

Mohebali G, Ball AS (2016) Biodesulfurization of diesel fuels–past, present and future perspectives. Int Biodeterior Biodegr 110:163–180. https://doi.org/10.1016/j.ibiod.2016.03.011

Boniek D, Figueiredo D, dos Santos AFB, de Resende Stoianoff MA (2015) Biodesulfurization: a mini review about the immediate search for the future technology. Clean Technol Environ Policy 17(1):29–37. https://doi.org/10.1007/s10098-014-0812-x

Galan B, Diaz E, García JL (2000) Enhancing desulphurization by engineering a flavin reductase-encoding gene cassette in recombinant biocatalysts. Environ Microbiol 2(6):687–694. https://doi.org/10.1046/j.1462-2920.2000.00151.x

Raheb J, Memari B, Hajipour MJ (2011) Gene-manipulated desulfurizing strain Pseudomonas putida reduced energy consuming in the biodesulfurization process. Energy Sour A 33(21):2018–2026. https://doi.org/10.1080/15567030903515054

Denis-Larose C, Labbe D, Bergeron H, Jones AM, Greer CW, Al-Hawari J, Grossman MJ, Sankey BM, Lau PC (1997) Conservation of plasmid-encoded dibenzothiophene desulfurization genes in several rhodococci. Appl Environ Microbiol 63(7):2915–2919

Abbad-Andaloussi S, Lagnel C, Warzywoda M, Monot F (2003) Multi-criteria comparison of resting cell activities of bacterial strains selected for biodesulfurization of petroleum compounds. Enzyme Microb Technol 32(3–4):446–454. https://doi.org/10.1016/S0141-0229(02)00320-4

Soleimani M, Bassi A, Margaritis A (2007) Biodesulfurization of refractory organic sulfur compounds in fossil fuels. Biotechnol Adv 25:570–596. https://doi.org/10.1016/j.biotechadv.2007.07.003

Chauhan AK, Singh SP, Kumar A (2014) Cloning, sequencing and characterization of the ‘desulfurization gene cluster’ from an isolated strain Gordonia sp. IITR100. Cloning. https://doi.org/10.5296/jab.v2i2.6027

Tsukamura M (1971) Proposal of a new genus, Gordonia, for slightly acid-fast organisms occurring in sputa of patients with pulmonary disease and in soil. Microbiology 68(1):15–26. https://doi.org/10.1099/00221287-68-1-15

Stackebrandt E, Rainey FA, Ward-Rainey NL (1997) Proposal for a new hierarchic classification system, Actinobacteria classis nov. Int J Syst Evol Microbiol 7(2):479–491. https://doi.org/10.1099/00207713-47-2-479

Nishiuchi Y, Baba T, Yano I (2000) Mycolic acids from Rhodococcus, Gordonia, and Dietzia. J Microbiol Method 40(1):1–9. https://doi.org/10.1016/S0167-7012(99)00116-5

Goodfellow M, Maldonado LA (2006) The families Dietziaceae, Gordoniaceae, Nocardiaceae and Tsukamurellaceae. In: Dworkin F, Falkow S, Schleifer KH, Stackebrandt E (eds) The prokaryotes. Springer, NewYork, Berlin, Heidelberg, pp 843–888

Kummer C, Schumann P, Stackebrandt E (1999) Gordonia alkanivorans sp. nov., isolated from tar-contaminated soil. Int J Syst Evol Microbiol 49:1513–1522. https://doi.org/10.1099/00207713-49-4-1513

Xue Y, Sun X, Zhou P, Liu R, Liang F, Ma Y (2003) Gordonia paraffinivorans sp. nov., a hydrocarbon-degrading actinomycete isolated from an oil-producing well. Int J Syst Evol Microbiol 53(5):1643–1646. https://doi.org/10.1099/ijs.0.02605-0

Linos A, Berekaa MM, Steinbüchel A, Kim KK, Sproer C, Kroppenstedt RM (2002) Gordonia westfalica sp. nov., a novel rubber-degrading actinomycete. Int J Syst Evol Microbiol 52(4):1133–1139. https://doi.org/10.1099/00207713-52-4-1133

Linos A, Steinbüchel A, Spröer C, Kroppenstedt RM (1999) Gordonia polyisoprenivorans sp. nov., a rubber-degrading actinomycete isolated from an automobile tyre. Int J Syst Evol Microbiol 49(4):1785–1791. https://doi.org/10.1099/00207713-49-4-1785

Brust JC, Whittier S, Scully BE, McGregor CC, Yin MT (2009) Five cases of bacteraemia due to Gordonia species. J Med Microbiol 58(10):1376. https://doi.org/10.1099/jmm.0.010272-0

Van Hamme JD, Singh A, Ward OP (2003) Recent advances in petroleum microbiology. Microbiol Mol Biol Rev 67(4):503–549. https://doi.org/10.1128/MMBR.67.4.503-549.2003

Monticello DJ, Finnerty WR (1985) Microbial desulfurization of fossil fuels. Annu Rev Microbiol 39:371–389. https://doi.org/10.1146/annurev.mi.39.100185.002103

Jaishankar J, Singh P, Srivastava P (2017) Draft genome sequence of a biodesulfurizing bacterium, Gordonia sp. strain IITR100. Genome Announc 5(17):e00230-17. https://doi.org/10.1128/genomeA.00230-17

Alves L, Paixão SM (2014) Fructophilic behavior of Gordonia alkanivorans strain 1B during dibenzothiophene desulfurization process. New Biotechnol 31(1):73–79. https://doi.org/10.1016/j.nbt.2013.08.007

Akhtar N, Akhtar K, Ghauri MA (2018) Biodesulfurization of thiophenic compounds by a 2-hydroxybiphenyl-resistant Gordonia sp. HS126–4N carrying dszABC genes. Curr Microbiol 75(5):597–603. https://doi.org/10.1007/s00284-017-1422-8

Choudhary TV, Parrott S, Johnson B (2008) Unraveling heavy oil desulfurization chemistry: targeting clean fuels. Environ Sci Technol 42:1944–1947. https://doi.org/10.1021/es0720309

Arenskötter M, Baumeister D, Kalscheuer R, Steinbüchel A (2003) Identification and application of plasmids suitable for transfer of foreign DNA to members of the genus Gordonia. Appl Environ Microbiol 69(8):4971–4974. https://doi.org/10.1128/AEM.69.8.4971-4974.2003

Singh P, Srivastava P (2013) An improved protocol for electroporation in members of the genus Gordonia. J Microbiol Methods 95(2):114–116. https://doi.org/10.1016/j.mimet.2013.07.025

Alves L, Melo M, Mendonça D, Simoes F, Matos J, Tenreiro R, Girio FM (2007) Sequencing, cloning and expression of the dsz genes required for dibenzothiophene sulfone desulfurization from Gordonia alkanivorans strain 1B. Enzyme Microb Technol 40(6):1598–1603. https://doi.org/10.1016/j.enzmictec.2006.11.008

Singh P, Chachan S, Singhi D, Srivastava P (2016) Isolation and molecular characterization of a stationary phase promoter useful for gene expression in Gordonia. Gene 591(1):153–160. https://doi.org/10.1016/j.gene.2016.07.018

Domingos DF, Dellagnezze BM, Greenfield P, Reyes LR, Melo IS, Midgley DJ, Oliveira VM (2013) Draft genome sequence of the biosurfactant-producing bacterium Gordonia amicalis strain CCMA-559, isolated from petroleum impacted sediment. Genome Announc. https://doi.org/10.1128/genomeA.00894-13

Wang W, Ma T, Ren Y, Li G (2013) Draft Genome sequence of a benzothiophene-desulfurizing bacterium, Gordona terrae strain C-6. Genome Announc. https://doi.org/10.1128/genomeA.00381-13

Bhatia S, Sharma DK (2010) Mining of genomic databases to identify novel biodesulfurizing microorganisms. J Ind Microbiol Biotechnol 37(4):425–429. https://doi.org/10.1007/s10295-010-0697-6

Ma T (2010) The desulfurization pathway in Rhodococcus. Biology of Rhodococcus. Springer, Berlin, Heidelberg, pp 207–230. https://doi.org/10.1007/978-3-642-12937-7_8

Foght JM (2004) Whole-cell bio-processing of aromatic compounds in crude oil and fuels. Studies in surface science and catalysis, vol 151. Elsevier, Amsterdam, pp 145–175. https://doi.org/10.1016/S0167-2991(04)80146-0

Acknowledgements

The authors acknowledge Department of Science and Technology (DST), New Delhi, Govt. of India for financial support for this work under the grant YSS/2015/001541/LS. We thank Director, CMER&TI, Central Silk Board for consistent support and valuable guidance.

Author information

Authors and Affiliations

Contributions

The authors have made the following declaration about their contributions. Conceptualization: MK and GS; literature compilation and writing of the manuscript: MK and GS; Data curation, figures and tables preparation: MK and GS; Drafting and correction of the work: MC and DKJ; Edited and finalized the manuscript: GS.

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Ethical Approval

The work involves no plant, animal and human experiments. All prevailing local, national and international regulations and conventions and normal scientific ethical practices have also been respected.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kalita, M., Chutia, M., Jha, D.K. et al. Mechanistic Understanding of Gordonia sp. in Biodesulfurization of Organosulfur Compounds. Curr Microbiol 79, 82 (2022). https://doi.org/10.1007/s00284-022-02770-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00284-022-02770-3