Abstract

Terminal modification of peptides is frequently used to improve their hydrophobicity. While N-terminal modification with fatty acids (lipidation) has been reported previously, C-terminal lipidation is limited as it requires the use of linkers. Here we report the use of a biocatalyst for the production of an unnatural fatty amino acid, (S)-2-aminooctanoic acid (2-AOA) with enantiomeric excess > 98% ee and the subsequent use of 2-AOA to modify and improve the activity of an antimicrobial peptide. A transaminase originating from Chromobacterium violaceum was employed with a conversion efficiency 52–80% depending on the ratio of amino group donor to acceptor. 2-AOA is a fatty acid with amino functionality, which allowed direct C- and N-terminal conjugation respectively to an antimicrobial peptide (AMP) derived from lactoferricin B. The antibacterial activity of the modified peptides was improved by up to 16-fold. Furthermore, minimal inhibitory concentrations (MIC) of C-terminally modified peptide were always lower than N-terminally conjugated peptides. The C-terminally modified peptide exhibited MIC values of 25 μg/ml for Escherichia coli, 50 μg/ml for Bacillus subtilis, 100 μg/ml for Salmonella typhimurium, 200 μg/ml for Pseudomonas aeruginosa and 400 μg/ml for Staphylococcus aureus. The C-terminally modified peptide was the only peptide tested that showed complete inhibition of growth of S. aureus.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During reductive amination, a transaminase (TA) transfers an amino group from a donor to an acceptor via a pyridoxal-5`-phosphate (PLP)-dependent mechanism to generate a chiral amine (Ghislieri and Turner 2013; Humble et al. 2012). TAs are widely used in the production of chiral amino compounds such as the antidiabetic drug sitagliptin (Savile et al. 2010). Enantiopure amino compounds can have bioactivity, or they can be used as building blocks for the synthesis of bioactive compounds (Breuer et al. 2004; Panke et al. 2004). Approximately 80% of the pharmaceuticals currently produced are chiral amines (Breuer et al. 2004).

Unnatural (nonproteinogenic) amino acids are receiving increasing attention as building blocks for pharmaceuticals, agrochemicals and other value added products (Mathew and Yun 2012). Biocatalysts such as TAs offer an option for the “green” production of these chiral compounds. The unnatural amino acids are structurally and functionally diverse, and therefore can have multiple different applications. l-tert-leucine, a building block of a protease inhibitor acting on the HIV virus, has been synthesised in a process employing a TA from Escherichia coli (Seo 2011). The enantiomerically pure unnatural amino acid l-homoalanine was asymmetrically synthesised using an ω-TA, and it is a key intermediate for the production of pharmaceutical compounds such as antiepileptic and antituberculosis drugs (Shin and Kim 2009; Zhang et al. 2010). One of the applications of unnatural amino acids is the synthesis of antimicrobial peptides (AMPs). The incorporation of unnatural amino acids in AMPs leads to increased bioactivity and stability when compared with naturally occurring peptides (Bhonsle et al. 2013).

AMPs are biomaterials evolved in virtually every class of organisms as a host defence mechanism (Bhonsle et al. 2013; Yeaman and Yount 2003). Increased interest in AMPs in recent years is due to their activity towards a wide range of bacteria, including some antibiotic-resistant strains, different fungi, viruses and parasites (Ageitos et al. 2017; Hancock 2001). AMPs are usually selective and efficient (Fosgerau and Hoffmann 2015) and unlike conventional antibiotics, they exhibit dual activity: disrupt targeted cell membranes and modulate the immune system (Hancock and Sahl 2006). Bacterial resistance to AMP would require severe rearrangements of the membrane structure, which would significantly delay the emergence of the resistance (Aoki and Ueda 2013; Chen et al. 2014). Thus, AMPs are promising candidates for the treatment of resistant infections.

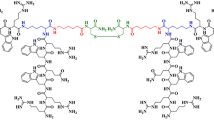

The modification of naturally occurring peptide sequences to develop synthetic AMPs with desired properties has previously been reported (Bhonsle et al. 2013; Goodwin et al. 2012; Malina and Shai 2005; Reinhardt and Neundorf 2016). Terminal modification of peptides frequently adds hydrophobic moieties to increase the hydrophobicity of peptides (Chu-Kung et al. 2010). It was demonstrated that increasing hydrophobicity of a peptide via lipidation, either internally (Lee et al. 2002) or terminally (Chen et al. 2016), increased the antimicrobial activity. The modification of the N-terminus by fatty acids has been reported previously (Chicharro et al. 2001). However, the C-terminal modification of peptides is limited due to the need for an amino function which is absent in fatty acids. The synthesis of unnatural amino acids with the hydrophobic tail of fatty acids allows the N- and C-terminal modification of peptides offering a greater diversity of modifications.

Here we demonstrate the production of an unnatural amino acid, 2-aminooctanoic acid (2-AOA), which was subsequently used for the modification of N- and C-termini of a lactoferricin-like peptide. An ω-TA from Chromobacterium violaceum DSM3019 was used for the production of 2-AOA. The product was purified from the biotransformation reaction using Fmoc-Cl derivatisation, which demonstrates the possibility to directly apply the derivatised amino acid for peptide synthesis. Furthermore, we demonstrated improved antimicrobial activity of a lactoferricin-like AMP modified with 2-AOA, with the highest improvement (16-fold for E. coli) though C-terminal modification.

Materials and methods

Reagents

The amino group donor (S)-(-)1-phenylethylamine (1-PEA) and the amino group acceptor 2-oxooctanoic acid (2-OOA), racemic (R, S)-2-aminooctanoic acid (AOA) and the cofactor PLP were purchased from Sigma-Aldrich (Dublin, Ireland). (S)-Fmoc-2-AOA was obtained from Eurogentec (Liege, Belgium). Trifluoroacetic acid (TFA), isopropyl-b-D-thiogalactopyranoside (IPTG) and imidazole were obtained from Fisher Scientific (UK). Restriction enzymes, BamHI and HindIII, were obtained from Thermo Scientific (UK). The oligonucleotide primers were synthesised by Sigma Genosys (Dublin, Ireland). BugBuster® was purchased from Merck Chemicals (Nottingham, UK). All other chemicals were from Sigma-Aldrich (Dublin, Ireland).

Cloning and expression of the CV_TA

Standard recombinant DNA techniques were performed as previously described (Sambrook et al. 1989). In brief, the CV_2025 gene (kegg.jp) was amplified by PCR from the genomic DNA of Chromobacterium violaceum DSM30191 using the primers listed in Table 1 and ligated into an expression vector pET-45b(+) (Table 1).

The CV_TA construct was introduced into E. coli BL21 (DE3) to give E. coli CV_TA. The recombinant strain was grown in LB medium supplemented with carbenicillin (50 μg/ml). For CV_TA expression, 1 ml of overnight culture was inoculated in 400 ml LB medium with carbenicillin (50 μg/ml) and grown at 37 °C, 200 rpm until an OD600 of 0.5 was reached. The culture was then cooled for 30 min at 4 °C, followed by the induction with 0.5 mM IPTG and the CV_TA was expressed for an additional 4 h. The cells were harvested by centrifugation 6000 rpm (Sorvall RC-5, refrigerated floor centrifuge) for 10 min at 4 °C and the pellet was washed twice with 400 ml of 100 mM potassium phosphate buffer (pH 7). The protein was purified from the cells as described previously (Hume et al. 2009) using HisTrap FF 1 mL column (Amersham Biosciences/GE Healthcare, England) and ÄKTAprime chromatography system (Amersham Biosciences/GE Healthcare, England). The fractions (2 ml volume) were collected and analysed by 8% SDS-PAGE under denaturing conditions (Laemmli 1970). The purified protein concentration was determined by bicinchoninic acid (BCA) assay (Smith et al. 1985).

Analysis of the activity of CV_TA towards 2-OOA

The activity of purified CV_TA was tested by a spectrophotometric assay (Schatzle et al. 2009). The biotransformation was carried out in 200 μl total reaction volume in microtiter plate (Greiner UV-Star® 96 well plates, Sparks) and contained in 100 mM phosphate buffer pH 7: 2.5 mM 1-PEA, 2.5 mM 2-OOA or pyruvate, 0.25% DMSO, 22 μg/ml (0.43 μM) CV_TA pre-incubated with 0.2 mM PLP for 10 min at 4 °C. The conversion of 1-PEA to acetophenone was monitored over 60 min at 30 °C spectrophotometrically at 245 nm (SPECTROstar Nano, BMG LABTECH). CV_TA activity was expressed as nmoles/min/mg. When CV_TA activity between two different substrates was compared, relative activity (%) was used, and it was calculated as the percentage of the activity with its native substrate, pyruvate.

The activity of CV_TA was characterised using 10 mM 1-PEA and 2-OOA concentrations ranging from 0.1 to 20 mM. The course of the reaction was followed spectrophotometrically as described in the previous paragraph, and the activity was calculated from the initial rates using the molar extinction coefficient of acetophenone (ε = 7.03 mM−1 cm−1). The kinetic parameters were determined by non-linear regression analysis, (Enzfitter for Windows 2.0.18.0 (Elsevier, Biosoft®, UK)).

Optimum pH and temperature for the synthesis of 2-AOA

To determine the optimal conditions for the production of 2-AOA, the reaction was tested in 100 mM phosphate buffers pH range 6 to 8. The temperature optimum was determined in 100 mM phosphate buffer pH 7 at a temperature range from 25 to 55 °C.

Optimisation of the production of 2-AOA

Different donor:acceptor ratios (mol:mol) 1-PEA:2-OOA = 4:1, 1.7:1, 1.5:1 and 1.3:1 were employed to find the optimal ratio for the production of 2-AOA. The reaction was performed in 10 ml of 100 mM potassium phosphate buffer pH 7, at 45 °C and with 44 μg/ml (0.86 μM) of CV_TA pre-incubated with 0.2 mM PLP. Aliquots (0.5 ml) were sampled at times 0 and then every 15 min until the end of the reaction (180 min) and mixed with the same volume of 0.2% TFA to stop the reaction, followed by tenfold dilution with potassium phosphate buffer (100 mM, pH 7) and subjected to HPLC analysis after derivatisation.

A sequential addition of the donor and acceptor was attempted in order to improve the yield of 2-AOA. The reaction was performed in 10 ml total volume for 6 h at 45 °C using the donor:acceptor ratio of 4:1. The samples (0.5 ml) were retrieved at 90, 180 and 270 min of the reaction. The concentration of the produced AP was measured spectrophotometrically as described in section 2.3. Based on the estimated 1-PEA and 2-OOA consumption, the donor and the acceptor were added to reach 10 and 2.5 mM concentration while maintaining the reaction volume (10 ml). Finally, using a donor:acceptor ratio of 1.7:1, the production of 2-AOA was tested in a 100 ml reaction volume at optimal conditions.

Derivatisation of the amino compounds and HPLC analysis

The biotransformation mixture and standard solutions of 1-PEA and 2-AOA were derivatised with 9-fluorenylmethyloxycarbonyl chloride (Fmoc-Cl) by mixing 150 μl of a standard/reaction mixture with 150 μl of 400 mM borate buffer pH 9 and 300 μl of 20 mM Fmoc-Cl dissolved in acetonitrile (Jambor and Molnar-Perl 2009). The reaction was incubated at room temperature for 20 min and stopped by the addition of 25 μl of 100 mM heptylamine (HEPA). The mixture was incubated for additional 3 min at room temperature, centrifuged at 13000 rpm (Centrifuge 5430 R, Eppendorf) for 1 min, followed by the filtration of the supernatant through 0.45 μm filter (Mini-UniPrep, GE Healthcare).

The supernatants were analysed by a modified HPLC method (Fabiani et al. 2002), using a C18 ACE 5 reverse phase column (150 mm × 4.6 mm, particle size 5 μm; Advance Chromatography Technologies, Aberdeen, UK) with the detector set at 263 nm. The samples (20 μl) were injected at a flow rate of 1 ml/min using 50 mM acetate buffer (pH 4.2) as eluent A and acetonitrile as eluent B. The amino compounds were separated with the following linear gradient elution: (min/A%): 0/40, 10/0, 13/0, 14/40, 18/40.

Purification and characterisation of 2-AOA

To purify Fmoc-2-AOA, the fractions eluted between 6.4 and 7.2 min were collected using the program described above, and the purity of samples was verified by HPLC. Accurate mass measurements were obtained with a LCT time-of-flight mass spectrometer (Waters Corp., Dublin, Ireland).

Chiral HPLC

To determine the enantiomeric excess of the produced 2-AOA, the commercial (S)-Fmoc-2-AOA (Eurogentec, Belgium) and purified Fmoc-2-AOA were analysed by normal phase HPLC (Agilent 1200 Series) using a CHIRALPACK IC column and with the detector set at 254 nm. The sample (5 μl) was injected at a flow rate of 1 ml/min using 95% heptane to 5% ethanol.

Optical activity

The 1 mg/ml solutions of the standard (S)-Fmoc-2-AOA (Eurogentec, Belgium) and Fmoc-2-AOA purified from the biotransformation mixture were prepared in methanol (Fisher Chemical, HPLC grade, Ireland). The rotation of polarised light [α]D was recorded using a single wavelength polarimeter (Polarimeter Model 343, PerkinElmer, USA).

Antimicrobial peptides (AMP) synthesis and antimicrobial activity testing

The core sequence of lactoferricin B (LFcin B) RRWQWRMKK (Wakabayashi et al. 1999) and an acylated derivative (2-AOA)-RRWQWRMKK and amidated derivative RRWQWRMKK-(2-AOA) were chemically synthesised in Eurogentec (Liege, Belgium).

The antimicrobial activity of the synthesised peptides was assayed with two Gram-positive bacteria, Bacillus subtilis (ATCC 6633) and Staphylococcus aureus (ATCC 25923), and three Gram-negative bacteria, Escherichia coli (NCTC 9001), Pseudomonas aeruginosa (ATCC 27853) and Salmonella typhimurium (NCTC 12023). The minimal inhibitory concentrations (MIC) of the peptides were determined using the standard microdilution method (EUCAST 2003). The bacterial strains were grown for 16 h in LB broth with decreased NaCl (0.1%), followed by dilution with LB (0.1% NaCl). A dilution series of synthesised AMPs were prepared in 40% DMSO to give peptide stock concentrations from 0.125 to 4 mg/ml. The assay was performed in 96-well polypropylene microtiter plate (96 well cell culture cluster, Costar) and it consisted of 20 μl of AMP at the appropriate concentration, 100 μl of diluted bacterial cultures (5 × 105 CFU/ml) and 80 μl of LB. The assay allowed bacterial growth for 18 h at 35 °C and 200 rpm, and the growth was measured as A600 (JENWAY 6300 spectrophotometer). The appropriate controls were included: growth of the strains in LB (0.1% NaCl), LB (0.1% NaCl) with the addition of 4% DMSO, as well as non-inoculated LB. MIC was defined as the lowest concentration of AMP at which no bacterial growth was observed. All samples were assayed in triplicates.

Results

Gene cloning, expression and purification of CV_2025

The N-terminally histidine tagged protein CV_TA, expressed in E. coli BL21 (DE3), was purified to homogeneity using a nickel-chelating column and an imidazole step gradient from 0 to 100%. The purity of CV_TA was analysed using SDS-PAGE 8% denaturing gel (Fig. 1a). The majority of CV_TA eluted in three fractions (Fig. 1a), which combined, gave 2.5 mg/ml of pure protein.

a SDS-PAGE analysis of His-tagged CV_TA as it appears at ~ 50 kDa. Lane 1: PageRuler Pre-stained Protein Ladder (Fisher BioReagent); lane 2: cell free extract; lanes 3–6: fractions containing pure protein after affinity chromatography purification. b Comparison of the reaction rates of CV_TA towards 2.5 mM 2-OOA and pyruvate as amino acceptors and 2.5 mM of 1-PEA as amino donor with 22 μg purified protein/ml at 30 °C

CV_TA activity towards non-native amino group acceptor 2-OOA

We have tested the production of 2-aminooctanoic acid (2-AOA) using the purified CV_TA as a biocatalyst, (S)-(-)1-phenylethylamine (1-PEA) as an amino donor and 2-oxooctanoic acid (2-OOA) as an amino group acceptor using a donor:acceptor ratio of 1:1. Using 1-PEA as a donor allows monitoring of the reaction spectrophotometrically, as the deamination product, acetophenone (AP), absorbs in the UV spectrum (A245).

The CV_TA produced the desired product, 2-AOA, which was confirmed by HPLC. However, the rate of the reaction with 2-OOA was 1.7-fold lower compared with pyruvate (Fig. 1b), considered the native substrate of CV_TA (Sayer et al. 2007).

The affinity of CV_TA towards 2-OOA is 14-fold lower than the affinity towards pyruvate, the native substrate of the enzyme (Table 2). This contributes significantly to a 29-fold lower catalytic efficiency towards 2-OOA compared to pyruvate. Despite this lower catalytic efficiency, 45% conversion of the acceptor into 2-AOA was observed in 60 min.

The optimal pH for the conversion of 2-OOA into 2-AOA is pH 7 (Fig. 2a) while the optimal temperature is 45 °C (Fig. 2b).

Effect of pH (a) and temperature (b) on the activity of purified CV_TA. The optimum pH and temperature were determined in 100 mM potassium phosphate buffer. Activity was tested across the pH range at 30 °C and across the temperature range at pH 7.0. CV_TA activity was determined by measuring acetophenone formation at A245. Data is the average of triplicates (SD < 5%)

Optimisation of 2-AOA production through alteration of the amino donor to recipient ratio

An excess of the amino group donor is usually supplied to a transaminase catalysed reaction, in order to drive the reaction towards product formation (Koszelewski et al. 2010). Different ratios of the donor, 1-PEA and the acceptor, 2-OOA were applied in order to find the optimal donor:acceptor ratio for the production of 2-AOA (Table 3). The biotransformation was performed in a total reaction volume of 10 ml with 44 μg/ml (0.86 μM) of CV_TA at 45 °C and pH 7. The consumption of 1-PEA and formation of 2-AOA were quantified by HPLC, which required a derivatisation of the amino compounds using Fmoc-Cl (see section 2.6).

While the highest conversion efficiency of 2-OOA into 2-AOA (84%) was achieved when a donor:acceptor ratio of 4:1 was applied (Table 3), the conversion of 2-OOA into 2-AOA at a ratio of 1.7:1 (entry 2) resulted in twice as much product as the reaction with 4:1 ratio (Table 3). A further decrease in donor:acceptor ratio decreased product yield further (Table 3). Increasing the concentration of 1-PEA (donor) to 15 mM and 2-OOA (recipient) to 10 mM resulted in the highest concentration of 2-AOA but at a lower efficiency of conversion compared to the same ratio but with 10 mM donor and 6 mM acceptor. We therefore scaled-up the reaction to 100 ml employing the donor:acceptor ratio of 1.7:1 with 10 mM donor and 6 mM acceptor, which produced 62.2 mg (4.1 mM) of 2-AOA (Supplemental information, Fig. S1).

A sequential addition of the substrates was investigated in order to further improve the reaction (Supplemental information, Fig. S2). The acceptor and the donor were added to the reaction to maintain the initial concentrations, i.e. 10 and 2.5 mM while maintaining the volume of the reaction. However, the highest achieved concentration of 2-AOA was only 2.8 mM (Supplemental information, Fig. S2), most likely due the inhibition of CV_TA (Kaulmann et al. 2007; Park et al. 2013b).

Purification and characterisation of Fmoc-2-AOA

After the optimal donor:acceptor ratio for the conversion of 2-OOA into 2-AOA was determined, the biotransformation was performed under optimal conditions in order to allow product purification and characterisation. After 180 min of the biotransformation, the reaction was stopped with 0.25% TFA and subjected to derivatisation with Fmoc-Cl. The derivatised amino compounds were separated from the rest of the reaction mixture by HPLC and the fraction containing the derivatised Fmoc-2-AOA collected. The collected fraction was lyophilised, resuspended in water and re-run on HPLC to verify the purity (Supplemental information, Fig. S3). High-resolution mass spectrometry confirmed the presence of purified Fmoc-2-AOA (ESI-TOF) m/z: [M + Na]+ Calcd for C23H27NO4Na 404.1838; Found 404.1848. The sample of Fmoc-2-AOA purified from the biotransformation mixture was then analysed using a chiral HPLC column (CHIRALPACK IC). A standard for (S)-Fmoc-2-AOA (Eurogentec, Belgium) is > 98% ee and elutes from the column at 12.035 min (Fig. 3b). The Fmoc-2-AOA purified from the biotransformation mixture eluted at time 11.985 (Fig. 3a). A trace of dibenzofulvene, Fmoc cleavage product is observed in the purified sample, suggesting a low level of cleavage (Fig. 3a, c). The observed rotation of the commercial and produced and purified Fmoc-2-AOA was − 22°. Chiral analysis and specific rotation strongly suggest that the produced compound is the S-enantiomer with > 98% ee.

C- and N-terminal modification of a nine amino acid core of lactoferricin B with 2-AOA and testing of antimicrobial activity

The antimicrobial activity of LFcin B against a range of Gram-positive and Gram-negative bacteria is known (Ulvatne et al. 2001). This peptide likely exhibits its antimicrobial activity via membrane perturbation (Haukland et al. 2001); however, the mechanism is not completely understood. A region of the LFcin B rich with cationic amino acids, RRWQWRMKK (Wakabayashi et al. 1999), is important for the antimicrobial activity of LFcin B (Ulvatne et al. 2001) and was modified by the addition of 2-AOA on either N- or C- terminus. The antibacterial activities of the modified peptides were tested against Gram-positive bacteria (Bacillus subtilis and Staphylococcus aureus) and Gram-negative bacteria (E. coli, Pseudomonas aeruginosa and Salmonella typhimurium) using the standard microdilution method (EUCAST 2003). The MIC values, which are defined as the lowest concentration that inhibits the growth of microorganisms after 18 h of incubation with a peptide, are summarised in Table 4.

Both N- and C-terminal modifications of the nonameric peptide showed improved antimicrobial activity towards the tested bacterial strains (Table 4, Fig. 4). The most profound effect was observed with RRWQWRMKK-2-AOA, with MICs determined for all tested strains, while unmodified peptide inhibited only the growth of E. coli at 400 μg/ml (Table 4). Only the C-terminally modified peptide exhibited a bactericidal effect on S. aureus at 400 μg/ml (Table 4). The N-terminal modified peptide inhibited growth of E. coli, S. typhymirium and B. subtilis at 100, 200 and 400 μg/ml, respectively (Table 4). Furthermore, even concentrations below the MIC for C- and N-terminally modified peptides reduced growth of the tested strains up to fourfold when compared to the growth in the presence of the unmodified peptide (Fig. 4).

The inhibitory effect of different concentrations of LFcin B (RRWQWRMKK), C-terminally modified LFcin B (RRWQWRMKK-2-AOA) and N-terminally modified LFicin B (2-AOA-RRWQWRMKK) on growth of Escherichia coli (a), Salmonella typhimirium (b), Bacillus subtilis (c), Pseudomonas aeruginosa (d) and Staphylococcus aureus (e). The controls (LB with 4% DMSO) reached OD600 of 1.7 for E. coli, 1.9 for S. typhimirium, 1.9 for B. subtilis, 2.1 for P. aeruginosa, and 2.1 for S. aureus

Discussion

For the first time, we demonstrate the process encompassing the synthesis of an enantiomerically pure unnatural amino acid 2-aminooctanoic acid (2-AOA), its subsequent purification by HPLC and use to terminally modify and improve the activity of an antimicrobial peptide. Unnatural amino acids are a valuable toolbox for drug creation, particularly in peptide research. Microbial transaminases (TAs) are well established for the synthesis of chiral amines such as amino acids (Mathew and Yun 2012; Park et al. 2013a). We have demonstrated here the potential to use an ω-TA form Chromobacterium violaceum to synthesise a lipophilic unnatural amino acid, 2-AOA using 2-oxooctanoic acid (2-OOA) as an acceptor in a reductive amination reaction. The transamination reaction is reversible, and the desired product formation is therefore determined by the thermodynamic equilibrium constant and the initial concentrations of substrates (Tufvesson et al. 2011). The kinetics of a TA-catalysed reaction could be changed by employing an amino donor such as 1-phenyethylamine (1-PEA) in excess (Busto et al. 2014; Tufvesson et al. 2011). The optimal donor:acceptor ratio seems to be dependent on the transaminase and substrates used. Recently identified transaminases named pQR118 and pQR1114 showed the best conversion yield at 1-PEA:cyclohexanecarboxaldehyde 5:1 ratio, while pQR1113 showed the same conversion yield at 2:1, 3:1 and 5:1 ratios (Baud et al. 2017). The best conversion of the acceptor into 2-AOA employing CV_TA was obtained with a 1-PEA:2-OOA ratio of 4:1 (Table 3). However, to reduce the amount of unused donor, we have tested the effect of decreasing 1-PEA:2-OOA ratio. The highest production of 2-AOA with 46% conversion of the donor into acetophenone and 68% efficiency in conversion of 2-OOA to 2-AOA was observed with 1-PEA:2-OOA 1.7:1 ratio (Table 3, entry 2). Increasing the concentration of both donor and acceptor while maintaining the 1.7:1 ratio however resulted in decreased conversion yield for both 1-PEA and 2-OOA to 42 and 62%, respectively (Table 3, entry 5). It has been reported that high concentration of substrates and products could inhibit the TA activity (Malik et al. 2012; Shin and Kim 2002). To avoid the potential inhibition of CV_TA by high starting concentrations of 1-PEA and 2-OOA, we have tested the sequential addition of the substrates. However, this strategy still resulted in the inhibition of CV_TA activity by substrates/products (Supplemental information, Fig. S2).

Derivatisation of amino compounds present in the reaction mixture with Fmoc-Cl allowed separation and purification of Fmoc-2-AOA, which could subsequently be used for peptide synthesis (O’Connor et al. 2013). The incorporation of unnatural amino acids in the sequence of an antimicrobial peptides (AMP) can alter the physicochemical properties of the peptide, increasing its activity, metabolic stability and selectivity (Bhonsle et al. 2013). AMPs are attractive as they offer a viable alternative to antibiotics due to their broad spectrum antimicrobial activity and the mechanism of action which reduces the possibility of acquired resistance (Aoki and Ueda 2013; Chen et al. 2014). The net positive charge and amphipathicity of AMPs are the most important characteristics determining the nature of AMP—bacterial cell interaction (Bhonsle et al. 2013). The molecular interactions between AMP and the cell are important for binding selectivity and the outcome of an antibacterial treatment (Ciumac et al. 2017). Cationic AMPs are positively charged peptides which show specific folding with the positively charged residues grouped on one side of the molecule and hydrophobic residues on the opposite side (Oren and Shai 1998).

N-terminal lipidation of peptides has been usually employed to modify the activity and selectivity of the peptide (Chu-Kung et al. 2010; Krishnakumari and Nagaraj 2015; Wakabayashi et al. 1999). Lipidation of a C-terminus however is rarely reported. C-terminal lipidation requires a linker, such as lysine (Albada et al. 2012), which has to be additionally modified. Our biocatalytic platform for the production of amino fatty acids offers the possibility to directly introduce a lipid tail at the C-terminus without the need for a linker, using standard techniques of peptide synthesis. Hydrophobicity is viewed as a highly desirable feature of AMPs, as it improves the interaction with bacterial membranes (Albada et al. 2012; Findlay et al. 2010; Wenzel et al. 2016).

Lactoferricin B (LFcin B) is a 25-mer formed by pepsin digestion of bovine lactoferrin and it has demonstrated antimicrobial activity against a range of bacteria (Bellamy et al. 1992; Gifford et al. 2005; Wakabayashi et al. 1999). The cationic region of LFcin B corresponding to residues R4-K12 is part of an α-helix (Hwang et al. 1998) and was modified with 2-AOA. This core nonamer of LFcin B is particularly interesting as it shows good anti-bacterial activity and low haemolytic activity (Liu et al. 2011). In the current study, C-terminal modification of the cationic region of LFcin B inhibited growth of all tested bacterial strains, showing the highest activity towards E. coli (MIC 25 μg/ml; Table 4). C-terminal modification of LFcin B has not been reported previously. Interestingly, N-terminally modified peptide exhibited lower activity compared with the C-terminally modified peptide but the N-terminal modification was not inhibitory as the latter exhibited better activity than the unmodified peptide (Table 4). For example, N-terminally modified peptide inhibited growth of E. coli at fourfold lower concentration compared with the unmodified peptide, and it also inhibited growth of S. typhimirium and B. subtilis at 200 and 400 μg/ml, respectively. S. aureus was the most resistant strain among tested bacteria, with only C-terminally modified peptide completely inhibiting its growth at 400 μg/ml (Table 4). The hydrophobic interactions between the peptides modified with 2-AOA and bacterial membranes were the likely reason for their increased antimicrobial activity (Dathe and Wieprecht 1999; Dathe et al. 1997; Wieprecht et al. 1997). Albada and co-workers reported that no significant difference in antimicrobial activity was observed when a short peptide was modified on either C- or N-terminus via acylated lysine residue (Albada et al. 2012). Our results demonstrate that C-terminal modification has a more profound effect on the antimicrobial activity but the reasons for this are not known. Increasing the hydrophobicity at C- rather than N-terminus has been reported to improve peptide and peptidomimetic selectivity (Dorner and Lienkamp 2013; Kragol et al. 2002).

In conclusion, CV_TA can be employed as a biocatalyst for the synthesis of an unnatural amino acid, 2-aminooctanoic acid. Both C- and N-terminal modifications of a cationic region of a known antimicrobial peptide lactoferricin B significantly improved the activity against Gram-positive and Gram-negative strains tested in this study, with C-terminal modification having a greater positive impact on antibacterial activity of the peptide. This study demonstrates the potential of the product of a transaminase catalysed reaction to be directly used for lipidation of C- and N-termini for the improvement of the activity of antimicrobial peptides.

References

Ageitos JM, Sanchez-Perez A, Calo-Mata P, Villa TG (2017) Antimicrobial peptides (AMPs): ancient compounds that represent novel weapons in the fight against bacteria. Biochem Pharmacol 133:117–138. https://doi.org/10.1016/j.bcp.2016.09.018

Albada HB, Prochnow P, Bobersky S, Langklotz S, Schriek P, Bandow JE, Metzler-Nolte N (2012) Tuning the activity of a short arg-trp antimicrobial peptide by lipidation of a C- or N-terminal lysine side-chain. ACS Med Chem Lett 3(12):980–984. https://doi.org/10.1021/ml300148v

Aoki W, Ueda M (2013) Characterization of antimicrobial peptides toward the development of novel antibiotics. Pharmaceuticals (Basel) 6(8):1055–1081. https://doi.org/10.3390/ph6081055

Baud D, Jeffries JWE, Moody TS, Ward JM, Hailes HC (2017) A metagenomics approach for new biocatalyst discovery: application to transaminases and the synthesis of allylic amines. Green Chem 19(4):1134–1143. https://doi.org/10.1039/c6gc02769e

Bellamy W, Takase M, Wakabayashi H, Kawase K, Tomita M (1992) Antibacterial spectrum of lactoferricin B, a potent bactericidal peptide derived from the N-terminal region of bovine lactoferrin. J Appl Bacteriol 73(6):472–479. https://doi.org/10.1111/j.1365-2672.1992.tb05007.x

Bhonsle JB, Clark T, Bartolotti L, Hicks RP (2013) A brief overview of antimicrobial peptides containing unnatural amino acids and ligand-based approaches for peptide ligands. Curr Top Med Chem 13(24):3205–3224. https://doi.org/10.2174/15680266113136660226

Breuer M, Ditrich K, Habicher T, Hauer B, Kesseler M, Sturmer R, Zelinski T (2004) Industrial methods for the production of optically active intermediates. Angew Chem Int Ed Engl 43(7):788–824. https://doi.org/10.1002/anie.200300599

Busto E, Simon RC, Grischek B, Gotor-Fernández V, Kroutil W (2014) Cutting short the asymmetric synthesis of the ramatroban precursor by employing ω-transaminases. Adv Synt Catal 356(9):1937–1942. https://doi.org/10.1002/adsc.201300993

Chen C, Hu J, Zeng P, Chen Y, Xu H, JR L (2014) High cell selectivity and low-level antibacterial resistance of designed amphiphilic peptide G(IIKK)(3)I-NH(2). ACS Appl Mater Interfaces 6(19):16529–16536. https://doi.org/10.1021/am504973d

Chen C, Hu J, Yang C, Zhang Y, Wang F, Mu Q, Pan F, Xu H, JR L (2016) Amino acid side chains affect the bioactivity of designed short peptide amphiphiles. J Mater Chem B 4(13):2359–2368. https://doi.org/10.1039/c6tb00155f

Chicharro C, Granata C, Lozano R, Andreu D, Rivas L (2001) N-terminal fatty acid substitution increases the Leishmanicidal activity of CA(1-7)M(2-9), a cecropin-melittin hybrid peptide. Antimicrob Agents Chemother 45(9):2441–2449. https://doi.org/10.1128/aac.45.9.2441-2449.2001

Chu-Kung AF, Nguyen R, Bozzelli KN, Tirrell M (2010) Chain length dependence of antimicrobial peptide fatty acid conjugate activity. J Colloid Interface Sci 345(2):160–167. https://doi.org/10.1016/j.jcis.2009.11.057

Ciumac D, Campbell RA, Xu H, Clifton LA, Hughes AV, Webster JRP, JR L (2017) Implications of lipid monolayer charge characteristics on their selective interactions with a short antimicrobial peptide. Colloids Surf B Biointerfaces 150:308–316. https://doi.org/10.1016/j.colsurfb.2016.10.043

Dathe M, Wieprecht T (1999) Structural features of helical antimicrobial peptides: their potential to modulate activity on model membranes and biological cells. Biochim Biophys Acta Biomembr 1462(1-2):71–87. https://doi.org/10.1016/S0005-2736(99)00201-1

Dathe M, Wieprecht T, Nikolenko H, Handel L, Maloy WL, MacDonald DL, Beyermann M, Bienert M (1997) Hydrophobicity, hydrophobic moment and angle subtended by charged residues modulate antibacterial and haemolytic activity of amphipathic helical peptides. FEBS Lett 403(2):208–212. https://doi.org/10.1016/s0014-5793(97)00055-0

Dorner F, Lienkamp K (2013) Polymer-based synthetic mimics of antimicrobial peptides (SMAMPs)—a new class of nature-inspired antimicrobial agents with low bacterial resistance formation potential. In: Muñoz-Bonilla A, Cerrada M, Fernández-García M (eds) Polymeric materials with antimicrobial activity : from synthesis to applications, 1st edn. RSC, Cambridge, UK pp 97–138, DOI: https://doi.org/10.1039/9781782624998-00097

EUCAST (2003) Determination of minimum inhibitory concentrations (MICs) of antibacterial agents by broth dilution. vol 9. Clinical Microbiology and Infection, CMI, p 1-7

Fabiani A, Versari A, Parpinello GP, Castellari M, Galassi S (2002) High-performance liquid chromatographic analysis of free amino acids in fruit juices using derivatization with 9-Fluorenylmethyl-Chloroformate. J Chromatogr Sci 40(1):14–18. https://doi.org/10.1093/chromsci/40.1.14

Findlay B, Zhanel GG, Schweizer F (2010) Cationic amphiphiles, a new generation of antimicrobials inspired by the natural antimicrobial peptide scaffold. Antimicrob Agents Chemother 54(10):4049–4058. https://doi.org/10.1128/AAC.00530-10

Fosgerau K, Hoffmann T (2015) Peptide therapeutics: current status and future directions. Drug Discov Today 20(1):122–128. https://doi.org/10.1016/j.drudis.2014.10.003

Ghislieri D, Turner NJ (2013) Biocatalytic approaches to the synthesis of enantiomerically pure chiral amines. Top Catal 57(5):284–300. https://doi.org/10.1007/s11244-013-0184-1

Gifford JL, Hunter HN, Vogel HJ (2005) Lactoferricin: a lactoferrin-derived peptide with antimicrobial, antiviral, antitumor and immunological properties. Cell Mol Life Sci 62(22):2588–2598. https://doi.org/10.1007/s00018-005-5373-z

Goodwin D, Simerska P, Toth I (2012) Peptides as therapeutics with enhanced bioactivity. Curr Med Chem 19(26):4451–4461. https://doi.org/10.2174/092986712803251548

Hancock RE (2001) Cationic peptides: effectors in innate immunity and novel antimicrobials. Lancet Infect Dis 1(3):156–164. https://doi.org/10.1016/s1473-3099(01)00092-5

Hancock RE, Sahl HG (2006) Antimicrobial and host-defense peptides as new anti-infective therapeutic strategies. Nat Biotechnol 24(12):1551–1557. https://doi.org/10.1038/nbt1267

Haukland H, Ulvatne H, Sandvik K, Vorland LH (2001) The antimicrobial peptides lactoferricin B and magainin 2 cross over the bacterial cytoplasmic membrane and reside in the cytoplasm. FEBS Lett 508(3):389–393. https://doi.org/10.1016/S0014-5793(01)03100-3

Humble MS, Cassimjee KE, Hakansson M, Kimbung YR, Walse B, Abedi V, Federsel HJ, Berglund P, Logan DT (2012) Crystal structures of the Chromobacterium violaceum ω-transaminase reveal major structural rearrangements upon binding of coenzyme PLP. FEBS J 279(5):779–792. https://doi.org/10.1111/j.1742-4658.2012.08468.x

Hume AR, Nikodinovic-Runic J, O'Connor KE (2009) FadD from Pseudomonas putida CA-3 is a true long-chain fatty acyl coenzyme A synthetase that activates phenylalkanoic and alkanoic acids. J Bacteriol 191(24):7554–7565. https://doi.org/10.1128/JB.01016-09

Hwang PM, Zhou N, Shan X, Arrowsmith CH, Vogel HJ (1998) Three-dimensional solution structure of lactoferricin B, an antimicrobial peptide derived from bovine lactoferrin. Biochem J 37(12):4288–4298. https://doi.org/10.1021/bi972323m

Jambor A, Molnar-Perl I (2009) Amino acid analysis by high-performance liquid chromatography after derivatization with 9-fluorenylmethyloxycarbonyl chloride: literature overview and further study. J Chromatogr A 1216(15):3064–3077. https://doi.org/10.1016/j.chroma.2009.01.068

Kaulmann U, Smithies K, Smith MEB, Hailes HC, Ward JM (2007) Substrate spectrum of ω-transaminase from Chromobacterium violaceum DSM30191 and its potential for biocatalysis. Enzym Microb Technol 41(5):628–637. https://doi.org/10.1016/j.enzmictec.2007.05.011

Koszelewski D, Tauber K, Faber K, Kroutil W (2010) ω-Transaminases for the synthesis of non-racemic alpha-chiral primary amines. Trends Biotechnol 28(6):324–332. https://doi.org/10.1016/j.tibtech.2010.03.003

Kragol G, Hoffmann R, Chattergoon MA, Lovas S, Cudic M, Bulet P, Condie BA, Rosengren KJ, Montaner LJ, Otvos L (2002) Identification of crucial residues for the antibacterial activity of the proline-rich peptide, pyrrhocoricin. Eur J Biochem 269(17):4226–4237. https://doi.org/10.1046/j.1432-1033.2002.03119.x

Krishnakumari V, Nagaraj R (2015) N-terminal fatty acylation of peptides spanning the cationic C-terminal segment of bovine beta-defensin-2 results in salt-resistant antibacterial activity. Biophys Chem 199:25–33. https://doi.org/10.1016/j.bpc.2015.02.005

Laemmli UK (1970) Cleavage of structural protein during the assembly of the head of bacteriophage T4. Nature 227(5259):680–685. https://doi.org/10.1038/227680a0

Lee DG, Kim HM, Park Y, Kim HK, Choi BH, Choi C, Hahm K (2002) Design of novel analogue peptides with potent antibiotic activity based on the antimicrobial peptide, HP (2–20), derived from N-terminus of Helicobacter pylori ribosomal protein L1. Biochim Biophys Acta 1598(1-2):185–194. https://doi.org/10.1016/S0167-4838(02)00373-4

Liu Y, Han F, Xie Y, Wang Y (2011) Comparative antimicrobial activity and mechanism of action of bovine lactoferricin-derived synthetic peptides. Biometals 24(6):1069–1078. https://doi.org/10.1007/s10534-011-9465-y

Malik MS, Park ES, Shin JS (2012) Features and technical applications of ω-transaminases. Appl Microbiol Biotechnol 94(5):1163–1171. https://doi.org/10.1007/s00253-012-4103-3

Malina A, Shai Y (2005) Conjugation of fatty acids with different lengths modulates the antibacterial and antifungal activity of a cationic biologically inactive peptide. Biochem J 390(Pt 3):695–702. https://doi.org/10.1042/BJ20050520

Mathew S, Yun H (2012) ω-Transaminases for the production of optically pure amines and unnatural amino acids. ACS Catal 2(6):993–1001. https://doi.org/10.1021/cs300116n

O’Connor S, Szwej E, Nikodinovic-Runic J, O’Connor A, Byrne AT, Devocelle M, O’Donovan N, Gallagher WM, Babu R, Kenny ST, Zinn M, Zulian QR, O’Connor KE (2013) The anti-cancer activity of a cationic anti-microbial peptide derived from monomers of polyhydroxyalkanoate. Biomaterials 34(11):2710–2718. https://doi.org/10.1016/j.biomaterials.2012.12.032

Oren Z, Shai Y (1998) Mode of action of linear amphipathic α-helical antimicrobial peptides. Biopolymers 47(6):451–463. https://doi.org/10.1002/(SICI)1097-0282(1998)47:6<451::AID-BIP4>3.0.CO;2-F

Panke S, Held M, Wubbolts M (2004) Trends and innovations in industrial biocatalysis for the production of fine chemicals. Curr Opin Biotechnol 15(4):272–279. https://doi.org/10.1016/j.copbio.2004.06.011

Park ES, Dong JY, Shin J-S (2013a) Biocatalytic asymmetric synthesis of unnatural amino acids through the cascade transfer of amino groups from primary amines onto keto acids. ChemCatChem 5(12):3538–3542. https://doi.org/10.1002/cctc.201300571

Park ES, Dong JY, Shin JS (2013b) ω-Transaminase-catalyzed asymmetric synthesis of unnatural amino acids using isopropylamine as an amino donor. Org Biomol Chem 11(40):6929–6933. https://doi.org/10.1039/c3ob40495a

Reinhardt A, Neundorf I (2016) Design and application of antimicrobial peptide conjugates. Int J Mol Sci 17(5):701–722. https://doi.org/10.3390/ijms17050701

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual, 2nd edn. Cold Spring Harbor Laboratory, New York

Savile CK, Janey JM, Mundorff EC, Moore JC, Tam S, Jarvis WR, Colbeck JC, Krebber A, Fleitz FJ, Brands J, Devine PN, Huisman GW, Hughes GJ (2010) Biocatalytic asymmetric synthesis of chiral amines from ketones applied to sitagliptin manufacture. Science 329(5989):305–309. https://doi.org/10.1126/science.1188934

Sayer C, Isupov MN, Littlechild JA (2007) Crystallization and preliminary X-ray diffraction analysis of omega-amino acid:pyruvate transaminase from Chromobacterium violaceum. Acta Crystallogr Sect F Struct Biol Cryst Commun 63(2):117–119. https://doi.org/10.1107/S1744309107000863

Schatzle S, Hohne M, Redestad E, Robins K, Bornscheuer UT (2009) Rapid and sensitive kinetic assay for characterization of ω-transaminases. Anal Chem 81(19):8244–8248. https://doi.org/10.1021/ac901640q

Seo Y-M (2011) Enzymatic synthesis of L-tert-leucine with branched chain aminotransferase. J Microbiol Biotechnol 21(10):1049–1052. https://doi.org/10.4014/jmb.1105.05049

Shin JS, Kim BG (2002) Exploring the active site of amine:pyruvate aminotransferase on the basis of the substrate structure-reactivity relationship: how the enzyme controls substrate specificity and stereoselectivity. J Org Chem 67(9):2848–2853. https://doi.org/10.1021/jo016115i

Shin JS, Kim BG (2009) Transaminase-catalyzed asymmetric synthesis of L-2-aminobutyric acid from achiral reactants. Biotechnol Lett 31(10):1595–1599. https://doi.org/10.1007/s10529-009-0057-7

Smith PK, Krohn RI, Hermanson GT, Mallia AK, Gartner FH, Provenzano MD, Fjjimoto EK, Goeke NM, Olson BJ, Klenk DC (1985) Measurement of protein using bicinchoninic acid. Anal Biochem 150(1):76–85. https://doi.org/10.1016/0003-2697(85)90442-7

Tufvesson P, Lima-Ramos J, Jensen JS, Al-Haque N, Neto W, Woodley JM (2011) Process considerations for the asymmetric synthesis of chiral amines using transaminases. Biotechnol Bioeng 108(7):1479–1493. https://doi.org/10.1002/bit.23154

Ulvatne H, Haukland HH, Olsvik O, Vorland LH (2001) Lactoferricin B causes depolarization of the cytoplasmic membrane of Escherichia coli ATCC 25922 and fusion of negatively charged liposomes. FEBS Lett 492(1-2):62–65. https://doi.org/10.1016/S0014-5793(01)02233-5

Wakabayashi H, Matsumoto H, Hashimoto K, Teraguchi S, Takase M, Hayasawa H (1999) N-Acylated and D enantiomer derivatives of a nonamer core peptide of lactoferricin B showing improved antimicrobial activity. Antimicrob Agents Chemother 43(5):1267–1269

Wenzel M, Schriek P, Prochnow P, Albada HB, Metzler-Nolte N, Bandow JE (2016) Influence of lipidation on the mode of action of a small RW-rich antimicrobial peptide. Biochim Biophys Acta 1858(5):1004–1011. https://doi.org/10.1016/j.bbamem.2015.11.009

Wieprecht T, Dathe M, Beyermann M, Krause E, Maloy WL, MacDonald DL, Bienert M (1997) Peptide hydrophobicity controls the activity and selectivity of magainin 2 amide in interaction with membranes. Biochem J 36(20):6124–6132. https://doi.org/10.1021/bi9619987

Yeaman MR, Yount NY (2003) Mechanisms of antimicrobial peptide action and resistance. Pharmacol Rev 55(1):27–55. https://doi.org/10.1124/pr.55.1.2

Zhang K, Li H, Cho KM, Liao JC (2010) Expanding metabolism for total biosynthesis of the nonnatural amino acid L-homoalanine. Proc Natl Acad Sci U S A 107(14):6234–6239. https://doi.org/10.1073/pnas.0912903107

Funding

Sarah A. Almahboub and this work were supported by Ministry of education of Kingdom of Saudi Arabia, King Abdullah scholarship program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain any studies with human participants or animals performed by any of the author.

Conflict of interest

The authors declare that they have no conflict of interests

Electronic supplementary material

ESM 1

(PDF 438 kb).

Rights and permissions

About this article

Cite this article

Almahboub, S.A., Narancic, T., Devocelle, M. et al. Biosynthesis of 2-aminooctanoic acid and its use to terminally modify a lactoferricin B peptide derivative for improved antimicrobial activity. Appl Microbiol Biotechnol 102, 789–799 (2018). https://doi.org/10.1007/s00253-017-8655-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8655-0