Abstract

Most flavonoids are glycosylated and the nature of the attached sugar can strongly affect their physiological properties. Although many flavonoid glycosides have been synthesized in Escherichia coli, most of them are glucosylated. In order to synthesize flavonoids attached to alternate sugars such as glucuronic acid and galactoside, E. coli was genetically modified to express a uridine diphosphate (UDP)-dependent glycosyltransferase (UGT) specific for UDP-glucuronic acid (AmUGT10 from Antirrhinum majus or VvUGT from Vitis vinifera) and UDP-galactoside (PhUGT from Petunia hybrid) along with the appropriate nucleotide biosynthetic genes to enable simultaneous production of their substrates, UDP-glucuronic acid and UDP-galactose. To engineer UDP-glucuronic acid biosynthesis, the araA gene encoding UDP-4-deoxy-4-formamido-L-arabinose formyltransferase/UDP-glucuronic acid C-4″ decarboxylase, which also used UDP-glucuronic acid as a substrate, was deleted in E. coli, and UDP-glucose dehydrogenase (ugd) gene was overexpressed to increase biosynthesis of UDP-glucuronic acid. Using these strategies, luteolin-7-O-glucuronide and quercetin-3-O-glucuronide were biosynthesized to levels of 300 and 687 mg/L, respectively. For the synthesis of quercetin 3-O-galactoside, UGE (encoding UDP-glucose epimerase from Oryza sativa) was overexpressed along with a glycosyltransferase specific for quercetin and UDP-galactose. Using this approach, quercetin 3-O-galactoside was successfully synthesized to a level of 280 mg/L.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

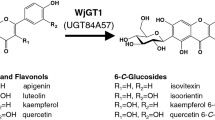

Flavonoids are plant secondary metabolites derived from the amino acids, phenylalanine, and tyrosine via the phenylpropanoid pathway (Winkel-Shirely 2001). Most flavonoids exist as O-glycosylated forms, but some plants produce C-glycosylated flavonoids (Bowles et al. 2006). O-Glycosylation reactions occur at hydroxyl groups during the final stage of flavonoid biosynthesis (Vogt and Jones 2001) while C-glycosylation occurs during flavonoid biosynthesis (Brazier-Hicks et al. 2009). Flavonoids can be glycosylated with various sugars. Sugars commonly linked to flavonoids include arabinose, galactose, glucose, rhamnose, glucuronic acid, and xylose (Bowles et al. 2006).

The biosynthesis of flavonoid-O-glycosides is mediated by nucleotide diphosphate-dependent glycosyltransferases (UGTs) (Vogt and Jones 2001), most of which use uridine diphosphate sugars as sugar donors, although thymidine derivatives can also be used (Lim et al. 2006). Thus, the biosynthesis of nucleotide sugars is a prerequisite to the formation of flavonoid-O-glycosides. Nucleotide sugar biosynthesis has been extensively studied in plants due to its role in cell wall biosynthesis (Seifert 2004). UDP-glucose is eventually converted into UDP-galactose, UDP-glucuronic acid, or UDP-rhamnose. UDP-glucuronic acid serves as a precursor to UDP-xylose, UDP-adipose, and UDP-arabinose. GDP-sugars such as GDP-mannose, GDP-galactose, GDP-fucose, and GDP-glucose are also found in plants. Most of the genes involved in nucleotide sugar biosynthesis in plants have been characterized (Reiter 2008). Furthermore, genes regulating nucleotide sugar biosynthesis in plants and microorganisms have been successfully expressed in heterologous systems such as Escherichia coli and Saccharomyces cerevisiae (Oka and Jigami 2006; Yang et al. 2011). These systems serve as host that provide sugar donors for the synthesis of secondary metabolite-glycosides, including flavonoid glycosides.

The biosynthesis of phytochemicals in E. coli has been widely studied. The flavonoid biosynthesis pathway has been a good model for biosynthesis of phytochemicals in E. coli (Horinouchi 2008; Flower and Koffas 2009; Du et al. 2010). Simple modification reactions, semi-synthesis, and total synthesis have been performed by introducing flavonoid biosynthetic genes into E. coli. Although flavonoids have been successfully synthesized from glucose in E. coli (Santos et al. 2011; Kim et al. 2013a, b), there is an advantage to introducing simple modifications into flavonoids through biotransformation (Kim et al. 2005; 2006). Biotransformation of flavonoids using E. coli harboring UGT has been used successfully to produce flavonoid glucosides (Lim et al. 2006; Ko et al. 2006). E. coli provides the sugar donors (nucleotide sugars) necessary to synthesize flavonoid glycosides using exogenous flavonoids. E. coli synthesizes diverse nucleotide sugars for polysaccharide biosynthesis, which serve as sugar donors. To date, several flavonoid glycosides have been synthesized through biotransformation in E. coli. These include flavonoid-O-glucoside (Ko et al. 2006: Lim et al. 2004), flavonoid-O-xyloside (Pandey et al. 2013; Han et al. 2014), flavonoid-O-rhamnoside (Kim et al. 2012a; 2013a, b), flavonoid-O-(N-acetylglucosamine) (Kim et al. 2012b), flavonoid-O-(6-deoxytalose) (Yoon et al. 2012), and flavonoid-3-O-(4-deoxy-4-formamido-L-arabinose) (flavonoid-3-O-Ara4FN) (Kim et al. 2010). Although naringenin 7-O-glucuronide was synthesized previously, the final yields were not reported (Simkhada et al. 2010).

Flavonoid-O-galactoside and flavonoid-O-glucuronide, whose synthesis has not been extensively attempted in E. coli, have diverse biological activities. For example, quercetin-3-O-galactoside (hyperoside) has antidepressant effects (Zheng et al. 2012) and anti-inflammatory activity (Kim et al. 2011). Quercetin-3-O-glucuronide (miquelianin) also has antidepressant effects (Juergenliemk et al. 2003) and can prevent Alzheimer’s disease and hypertension (Ho et al. 2013; Balasuriya and Rupasinghe 2012). Luteolin-7-O-glucuronide has anti-genotoxic and choleretic effects (Orhan et al. 2013; Benedek et al. 2006). In the present study, we synthesized flavonoid-O-glucuronide (luteolin-7-O-glucuronide and quercetin-3-O-glucuronide) and flavonoid-O-galactoside (quercetin-3-O-galactoside) in E. coli. We expressed specific UGTs for either UDP-glucuronic acid or UDP-galactose in E. coli and engineered its nucleotide sugar metabolism. Using this approach, we could achieve yield of more than 280 mg/L for flavonoid-O-galactoside and flavonoid-O-glucuronides.

Materials and methods

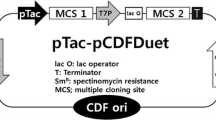

Nucleic acid manipulation

UGT from Antirrhinum majus (AmUGT10; Gene ID AB362988; Noguchi et al. 2009), which was used for the production of luteolin-7-O-glucuronide, was cloned using reverse transcription polymerase chain reaction (RT-PCR). Total RNA was isolated from the flower of A. majus using the Qiagen Plant Total RNA Isolation kit (Qiagen, Hilden, Germany). cDNA was synthesized using Omniscript reverse transcriptase with oligo dT as a primer. The primers for AmUGT10 are listed in Table 1. AmUGT10 was subcloned into the EcoRI/NotI site of pETDuet-1 (Novagen), and the resulting construct was named pE-AmUGT (Table 1). To synthesize quercetin-3-O-galactoside, UGT from Petunia hybrid (PhUGT, GenBank ID; AF165148; Miller et al. 1999) was cloned by polymerase chain reaction (PCR) using cDNA as template. The resulting PCR product was digested with EcoRI/NotI and subcloned into the corresponding sites of pGEX 5X-3 (pG-PhUGT in Table 1). OsUGE (UDP-glucose epimerase from Oryza sativa; GenBank ID; NP_001062869.1) (Kim et al. 2009) was subcloned into the EcoRI/NotI site of pCDFDuet (pC-OsUGE in Table 1). UDP-glucose 4-epimerase (galE, GenBank ID; 945354) from E. coli DH5α was subcloned into the EcoRI/NotI site of pCDFDuet (pC-galE in Table 1). UGT from Vitis vinifera (VvUGT; GenBank ID XM_002280887; Ono et al., 2010), which was used for the production of quercetin-3-O-glucuronide, was cloned using RT-PCR. Total RNA was isolated from the leaves for V. vinifera, and cDNA was synthesized as described above. The PCR product was subcloned into the EcoRI/NotI site of pGEX 5X-3 (pG-VvUGT in Table 1). UDP-glucose dehydrogenase (ugd; Gene ID, 946571) from E. coli was cloned using PCR using E. coli genomic DNA as a template. The resulting PCR product was sequenced and subcloned into the NdeI/XhoI site of pE-AmUGT (pE-AmUGT-Ecugd in Table 1). Ugds from Arabidopsis thaliana (Gene ID, AT3G29360) and Glycine max (Gene ID, U53418) were cloned using RT-PCR. The resulting PCR products were subcloned into the NdeI/KpnI site of pE-AmUGT for AtUgd (pE-AmUGT-AtUgd) and into the NdeI/XhoI site of pE-AmUGT for GmUgd (pE-AmUGT-GmUgd). Primers used are listed in Table 1.

Gene deletion in E. coli BL21 (DE3) was carried out using the Quick & Easy Conditional Knock Out Kit (Gene Bridges, Heidelberg, Germany). The arnA deletion mutant was developed as described in Kim et al. (2010).

Biotransformation of flavonoid using E. coli

An overnight culture of E. coli harboring specific genes was inoculated into 50 mL fresh of LB medium containing appropriate antibiotics. The cells were grown until the OD600 reached 0.8. Genes in the E. coli expression vector were induced by adding isopropyl β-D-1-thiogalactopyranoside (IPTG) to a final concentration of 1 mM. The transformants were grown for an additional 20 h at 18 °C. Cells were harvested by centrifugation and resuspended in fresh M9 medium containing 2 % glucose and antibiotics and 1 mM IPTG. To compare the production of luteolin-7-O-glucuronide among different E. coli strains (B500-B507, Table 1), the cell density was adjusted to an OD600 value of 2. The total reaction volume was 2 mL in a test tube (14 mm × 145 mm). One hundred micromoles of luteolin was added, and the reaction mixture was incubated at 25 °C for 1.5 h. Then, an additional 100 μM luteolin was added, and the mixture was incubated for an additional 1.5 h. To determine the optimum cell concentration, 200 μM of luteolin was added. After 2 h, an additional 200 μM luteolin was added, and the reaction mixture was incubated for 2 h. To compare the production of quercetin-3-O-glucuronide among different E. coli strains, the cell densities were adjusted to an OD600 value of 3, and the reactions were carried out for 2 h after addition of 200 μM quercetin.

The effect of EcgalE and OsUGE on the production of quercetin-3-O-galactoside in E. coli BL21 (DE3) was tested using strains B510 and B511 (Table 1). Each strain was cultured as described above. One hundred micromoles of quercetin was added, and the mixture was incubated at 30 °C for 1.5 h with shaking.

To analyze quercetin-3-O-galactoside, the culture supernatant was harvested, extracted twice with an equal volume of ethyl acetate and dried in a vacuum. The dried sample was dissolved in dimethyl sulfoxide (DMSO) and analyzed by high-performance liquid chromatography (HPLC) using a Varian HPLC equipped with a photodiode array (PDA) detector and a Varian C18 reverse-phase column (Varian, 4.60 × 250 mm, 3.5 μm particle size). Cell growth was monitored by determining the absorbance at 600 nm. For analysis of flavonoid-O-glucuronic acid, the reaction supernatant was boiled for 3 min and centrifuged for 10 min at 13,000g. The supernatant was analyzed with HPLC.

The mean and standard error of the mean were calculated from three experiments. Analysis of variance (ANOVA) was carried out using Tukey’s method with a significance level of P = 0.01. Statistical analyses were performed using Microsoft Office Excel 2010.

The molecular masses of the reaction products were determined by mass spectrometry as described previously (Lee et al. 2007). The structures of the reaction products were determined using nuclear magnetic resonance (NMR) spectroscopy as described previously (Kim et al. 2004). The following data were obtained. Quercetin-3-O-galactoside: 1H NMR (400 MHz, DMSO-d 6 ) δ (ppm) 7.67 (dd, J = 8.5, 2.2 Hz, 1H, H-6′), 7.54 (d, J = 2.2 Hz, 1H, H-2′), 6.83 (d, J = 8.5 Hz, 1H, H-5′), 6.41 (d, J = 2.0 Hz, 1H, H-8), 6.21 (d, J = 2.0 Hz, 1H, H-6), 5.38 (d, J = 7.7 Hz, 1H, H-1″), 3.66 (d, J = 3.1 Hz, 1H, H-4″), 3.58 (m, 1H, H-2″), 3.47 (dd, J = 9.6, 5.2 Hz, 1H, H-6″), 3.39 (dd, J = 9.5, 3.3 Hz, 1H, H-3″), 3.33 (d, J = 2.9 Hz, 1H, H-5″), 3.31 (m, 1H, H-6″); 13C NMR (100 MHz, DMSO-d 6 ) δ (ppm) 177.4 (C-4), 164.2 (C-7), 161.2 (C-5), 156.3 (C-2), 156.2 (C-9), 148.4 (C-4′), 144.8 (C-3′), 133.4 (C-3), 121.1 (C-1′), 122.0 (C-6′), 115.9 (C-2′), 115.2 (C-5′), 103.9 (C-10), 101.8 (C-1″), 98.7 (C-6), 93.5 (C-8), 75.8 (C-5″), 73.2 (C-3″), 71.2 (C-2″), 67.9 (C-4″), 60.1 (C-6″). Quercetin-3-O-glucuronic acid: 1H NMR (CD3OD, 400 MHz): δ 7.61–7.65 (m, 2H), 6.85 (d, J = 8.4 Hz, 1H), 6.39 (d, J = 2.0 Hz, 1H), 6.20 (d, J = 2.1 Hz, 1H), 5.34 (d, J = 7.6 Hz, 1H), 3.74 (d, J = 9.7 Hz, 1H), 3.60 (d, J = 8.8 Hz, 1H), 3.56 (d, J = 3.1 Hz, 1H), 3.45–3.53 (m, 3H); 13C NMR (CD3OD, 100 MHz): δ 178.7, 165.4, 162.4, 158.4, 157.9, 149.3, 148.3, 145.4, 134.8, 122.8, 122.2, 116.6, 115.4, 105.0, 103.6, 99.3, 94.1, 77.0, 76.6 74.8, 72.3. Luteolin-7-O-glucuronic acid: 1H NMR (400 MHz, DMSO-d 6 ) δ (ppm) 7.44 (d, J = 8.0 Hz, 1H), 7.43 (s, 1H), 6.90 (d, J = 8.0 Hz, 1H), 6.81 (d, J = 2.0 Hz, 1H), 6.75 (s, 1H), 6.45 (d, J = 2.0 Hz, 1H), 5.26 (d, J = 6.8 Hz, 1H), 4.00 (d, J = 9.2 Hz, 1H), 3.38 (t, J = 9.2 Hz, 1H), 3.33 (t, J = 9.0 Hz, 1H), 3.29 (t, J = 7.2 Hz, 1H); 13C NMR (100 MHz, DMSO-d 6 ) δ (ppm) 181.85, 170.38, 164.45, 162.49, 161.10, 156.91, 149.92, 145.75, 121.27, 119.12, 115.96, 113.49, 105.37, 103.10, 99.35, 99.13, 94.48, 75.65, 75.15, 72.74, 71.29.

Results

Production of flavonoid-O-glucuronides

We planned to use E. coli to synthesize flavonoid glucuronide. E. coli synthesizes UDP-glucuronic acid but does not contain a UGT specific for luteolin and UDP-glucuronic acid. AmUGT10 uses UDP-glucuronic acid as a sugar donor and luteolin as the optimal sugar acceptor to make luteolin-7-O-glucuronide (Noguchi et al. 2009). E. coli harboring pE-AmUGT (B500 in Table 1) was used for biotransformation of luteolin, and analysis of the reaction product with HPLC showed a new peak at 462 Da (Fig. 1a), whose molecular mass was consistent with that of a glucuronic acid attached to luteolin (Fig. 1d). In addition, the reaction product differed in retention time from luteolin-7-O-glucoside (Fig. 1c). MS/MS analysis of the reaction product revealed a compound with a molecular mass of 286 Da (Fig. 1d), which corresponded to the molecular weight of luteolin. Thus, we concluded that E. coli harboring pE-AmUGT synthesized luteolin-7-O-glucuronic acid from luteolin. Furthermore, NMR revealed the structure of the biotransformation product to be luteolin-7-O-glucuronide (see “Materials and methods”).

a HPLC profile of the reaction product (P1) obtained from E. coli strain B500 supplemented with luteolin (S1); b luteolin-7-O-glucose standard (S2); c mixture of the reaction product and luteolin-7-O-glucose standard; d MS/MS analysis of the reaction product (P1). The mass spectrometer was operated in negative mode

To increase the production of luteolin-7-O-glucuronide, it was necessary to increase the supply of UDP-glucuronic acid in E. coli because luteolin was supplied exogenously, but UDP-glucuronic acid was synthesized by the E. coli itself. UDP-glucuronic acid is synthesized from UDP-glucose by UDP-glucose dehydrogenase (ugd) and is then converted into UDP-4″-ketose by UDP-L-Ara4N formyltransferase/UDP-GlcA C-4″-decarboxylase (arnA), which is involved in the biosynthesis of outer membrane lipopolysaccharides (Breazeale et al. 2005). Thus, in order to increase the supply of UDP-glucuronic acid, arnA was first deleted in E. coli (B-araA in Table 1), and B-arnA was transformed with pE-AmUGT. The resulting strain B504 produced 31.1 mg/L of luteolin-7-O-glucuronide, which is approximately 121 % more than B500 (14.1 mg/L) (Fig. 2).

In order to increase the supply of UDP-glucuronic acid, ugd, which encodes a protein converting UDP-glucose to UDP-glucuronic acid, was overexpressed in E. coli. Three ugd genes from E. coli, A. thaliana, and G. max were tested in two different E. coli strains (wild type and B-araA). The product of biotransformation of luteolin for each strain (B500∼B507 in Table 1) was analyzed using HPLC. E. coli transformants containing ugd produced more luteolin-7-O-glucuronide than E. coli transformants not containing ugd. The ugd of E. coli (Ecugd) was the most efficient followed by those of A. thaliana and G. max (Fig. 2). Strain B505 (B-araA harboring pE-AmUGT-Ecugd) produced 197 % more luteolin-7-O-glucuronide (92 mg/L) than strain B504 (B-araA harboring only pE-AmUGT, 31.1 mg/L). Thus, an increased supply of UDP-glucuronic acid by ugd overexpression is required to increase the production of luteolin-7-O-glucuronide. As shown above, the B-araA strain produced more luteolin-7-O-glucuronide than BL21 for all constructs. B500, in which only AmUGT was overexpressed in wild type E. coli BL21 (DE3), synthesized approximately 14 mg/L luteolin-7-O-glucuronic acid while B505, in which both AmUGT and Ecugd were overexpressed in B-araA, produced approximately 92 mg/L of luteolin-7-O-glucuronide.

We employed another UGT (VvUGT) to synthesize quercetin-3-O-glucuronide from quercetin in E. coli. Strain B508 (Table 1) was used for biotransformation of quercetin, and the biotransformation product was analyzed. A new peak was observed at 478 Da (Fig. 3a), the molecular mass corresponding to that of quercetin-3-O-glucuronide. The structure of the reaction product was determined to be quercetin-3-O-glucuronide by NMR (see “Materials and methods”). Similar to the synthesis of luteolin-7-O-glucuronide, the production of quercetin-3-O-glucuronide increased in the araA deletion strain (B-araA) and overexpressing Ecugd. Strain B508 (E. coli BL21 [DE3] harboring pG-VvUGT) produced approximately 38 mg/L quercetin-3-O-glucuronide, while strain B509 (B-ara harboring pG-VvUGT and pA-Ecugd) produced approximately 62 mg/L quercetin-3-O-glucuronide. Therefore, the engineered E. coli strain produced approximately 1.6-fold as much quercetin-3-O-glucuronide as wild type E. coli strain.

HPLC analysis of the reaction product obtained with strain B508 supplemented with quercetin as a substrate. a The reaction product obtained with E. coli BL21 harboring empty vector, 5X-3; b HPLC profile and MS analysis of the reaction product obtained with strain B508. The mass spectrometer was operated in negative mode

The production of luteolin-7-O-glucuronide was optimized with strain B505. First, we determined the optimal cell density. After induction, the cell density was adjusted to OD600 values of 1, 1.5, 2.0, 2.5, 3.0, 3.5, 4, 5, and 7. Initially, 200 μM (57.2 mg/L) luteolin was added. After incubation of the reaction mixture at 25 °C for 2 h, an additional 200 μM of luteolin was added, and the reaction mixture was incubated 25 °C for 6 h. In the reaction mixture containing cells at an OD600 value of 3.5, 320 μM (148 mg/L) luteolin-7-O-glucuronide was produced, which was the highest yield among the cell densities tested. The production of luteolin-7-O-glucuronide was monitored. The cell density of strain B505 was 3.5 at 600 nm. One hundred micromolar of luteolin (28.6 mg/L) was added at 0, 2, 4, 6, 8, 10, and 12 h (the final concentration was 700 μM [200.4 mg/L]) because the solubility of luteolin is low and a high concentration might cause cell lysis. The mixture was incubated at 25 °C for 48 h. The reaction mixture was collected periodically and analyzed by HPLC. The production of luteolin-7-O-glucuronide continued to increase until 24 h. At this point, 300.5 mg/L of luteolin-7-O-glucuronide (approximately 650 μM) was produced (Fig. 4a). The conversion yield from luteolin to luteolin-7-O-glucuronide was 92.8 %.

Production of luteolin-7-O-glucuronide using strain B505 (a) and quercetin-3-O-glucuronide using B509 (b). Data are mean values ± SD from three independent experiments. For the synthesis of luteolin-7-O-glucuronide, 100 μM luteolin was added at 0, 2, 4, 6, 8, 10, and 12 h (total 700 μM luteolin was added). For the synthesis of quercetin-3-O-galactoside, 200 μM quercetin was added every 2 h up to 12 h and then at 24 h (total 1.4 mM quercetin was added). Sample was taken at each time point, and the product was analyzed using HPLC

The production of quercetin-3-O-glucuronide was also monitored for 48 h in strain B509. Quercetin (100 μM = 30.2 mg/L) was added every hour up to 12 h and then at 24 h. Therefore, the final amount of quercetin added was 1.4 mM (422.8 mg/L). The initial cell density was set to an OD600 value of 3. The production of quercetin-3-O-glucuronide increased rapidly for 12 h, and then the rate of increase slowed. After 48 h, 659.6 mg/L of quercetin-3-O-glucuronide (1.38 mM) was produced (Fig. 4b). The conversion yield was 98.5 %.

Production of quercetin-3-O-galactoside

PhUGT, flavonol-3-O-galactosyltransferase, was used to produce quercetin-3-O-galactoside (Miller et al. 1999). E. coli BL21 (DE3), which is a generally used host for expressing foreign genes that was transformed with pG-PhUGT (Table 1). However, galE, which is a UDP-glucose 4-epimerase and catalyzes the interconversion of UDP-glucose and UDP-galactose, is absent in E. coli BL21 (DE3), and this strain no longer synthesizes UDP-galactose. Therefore, biotransformation of quercetin using E. coli BL21 (DE3) harboring pG-PhUGT did not produce any reaction product (Fig. 5a). It clearly showed that UDP-galactose is absent from E. coli BL21 (DE3) due to the absence of galE. On the other hand, E. coli DH5α harboring pG-PhUGT produced a new reaction product from quercetin, which was predicted to be quercetin-3-O-galactoside, because E. coli DH5α contains an intact copy of galE. Thus, both galE and PhUGT are required to synthesize quercetin-3-O-galactoside in E. coli BL21 (DE3). We decided to use E. coli BL21 (DE3) instead of DH5α because this strain is commonly used to express foreign genes.

HPLC profile of the reaction product obtained with strain B511 supplemented with quercetin as a substrate. a Reaction product obtained with E. coli BL21 harboring PhUGT; b HPLC profile and MS analysis of the reaction product obtained from strain B510 supplemented with quercetin as a substrate. The mass spectrometer was operated in negative mode

In order to provide UDP-galactose to E. coli BL21, two genes, EcgalE and OsUGE, were tested. Both EcgalE and OsUGE interconvert UDP-glucose and UDP-galactose. E. coli BL21 (DE3) was transformed with pC-galE or pC-OsUGE along with pG-PhUGT (Table 1). The production of quercetin-3-O-galactoside in strains, B510 and B511 (Table 1) were compared. Strain B511 produced 38 mg/L quercetin-3-O-galactoside, which was 1.9-fold as much as that produced by strain B510 (20 mg/L). This indicated that OsUGE more effectively converted UDP-glucose to UDP-galactose. The structure of the biotransformation product was determined to be quercetin-3-O-galactoside by NMR (see “Materials and methods”).

Using strain B511, we monitored the production of quercetin-3-O-galactoside. The initial cell density was set to OD600 value of 3. Quercetin (100 μM = 30.2 mg/L) was added at 0, 3, 6, 9, 13, 24, and 36 h (total 700 μM [211.5 mg/L] quercetin was added). Quercetin-3-O-galactoside was rapidly produced until 24 h. After 36 h, its production did not increase substantially. Approximately 280.4 mg/L quercetin-3-O-galatoside (approximately 603 μM) was produced after 60 h of biotransformation (Fig. 6). The conversion yield was 86.1 %.

Discussion

UDP-glucose is a substrate for the synthesis of UDP-galactose, UDP-glucuronic acid, and UDP-Ara4FN in E. coli. UDP-galactose is not synthesized in E. coli BL21 (DE3) because it lacks galE, which encodes the enzyme that converts UDP-glucose into UDP-galactose. Introducing galE into E. coli BL21 (DE3) resulted in the production of UDP-galactose, which served as a substrate for the production of quercetin 3-O-galactoside. For the production of flavonoid-O-glucuronide, we also overexpressed ugd to enhance the conversion of UDP-glucose to UDP-glucuronic acid. This increased in luteolin-7-O-glucuronic acid production from 14 to 65 mg/L. Furthermore, an E. coli strain in which a gene (arnA) for a protein converting UDP-glucuronic acid to UDP-Ara4FN produced more luteolin-7-O-glucuronic acid (30 mg/L) than wild type (14 mg/L). Finally, E. coli strain, in which ugd was overexpressed and arnA was deleted, was the most effective for the production of luteolin-7-O-glucuronic acid (92 mg/L).

Two flavonoid-O-glucuronides (luteolin-7-O-glucuronide and quercetin-3-O-glucuronide) and quercetin-3-O-galactoside were synthesized in E. coli via biotransformation of exogenously supplied luteolin and quercetin, respectively. The UGTs that used (namely, AmUGT10, VvUGT, and PhUGT) have both sugar donor specificity and acceptor specificity (Miller et al. 1999; Noguchi et al. 2009; Ono et al., 2010). In regard to sugar acceptors, AmUGT10 could use flavonoids having a 7-hydroxy group such as naringenin, apigenin, and quercetin. Therefore, it is possible to make naringenin-7-O-glucuronide, apigenin-7-O-glucuronide, and quercetin-7-O-glucuronide. Kaempferol, which also has a 3-hydroxy group, serves as a substrate for PhUGT and VvUGT for the synthesis of kaempferol-3-O-galactoside and kaempferol-3-O-glucuronide, respectively.

Flavonoid-O-glucuronides and flavonoid-O-galactose have not been synthesized previously in E. coli. Most research on flavonoid glycosylation has been about the regioselective glucosylation of flavonoids, although glucuronylation and galactosylation of flavonoids in plants are also common (Xiao et al. 2014). The reason that glucosylation of flavonoids is common is because most UGTs use UDP-glucose as a sugar donor. In this study, we chose UGTs that use either UDP-glucuronic acid or UDP-galatose as a sugar donor. In addition, we engineered E. coli to provide higher levels of the appropriate sugar donors to enhance synthesis of flavonoid-O-glucuronides and flavonoid-O-galactosides. The E. coli strains which nucleotide biosynthesis pathways have been engineered could be used to attach glucuronic acid and galactose to other secondary metabolites.

Flavonoid glucosides were the most prevalent flavonoid glycosides synthesized using biotransformation. The final yield of quercetin- O-glucoside ranged from 1 to 10 mg/L (Lim et al. 2004). Using a controlled fermentation system, yields of approximately 100 mg/L were obtained (Lim et al. 2004). E. coli harboring isoflavone glucosyltransferase gave yields ranging from 10 to 20 mg/L genistein-7-O-glucoside or biochanin A-7-O-glucoside (He et al. 2008). These studies were performed using endogenous UDP-glucose as a substrate donor. In this study, 300 mg/L of luteolin-7-O-glucuronide, 687 mg/L of quercetin-3-O-glucuronide, and 280 mg/L of quercetin-3-O-galactoside were obtained This was achieved by engineering the nucleotide pathway of E. coli. Quercetin-3-O-rhamnoside and kaempferol-3-O-rhamnoside were also synthesized (150 to 200 mg/L) in E. coli strain with an engineered nucleotide synthesis pathway (Kim et al. 2012a, b). Thus, engineering the nucleotide pathway in E. coli is critical to increasing the yield of flavonoid glycosides.

We tested functionally identical genes from different organisms in order to identify the one with the highest productivity. For the synthesis of luteolin-3-O-glucuronide, ugd from E. coli was more effective than those from plants such as A. thaliana and G. max. On the other hand, OsUGE from rice was more effective than that from E. coli in the synthesis of quercetin-3-O-galactoside. Although we did not measure in vitro catalytic efficiency of the individual enzymes encoded by each gene, the most efficient enzyme was selected by comparing the final yield. Furthermore, in vitro catalytic efficiency is always not correlated with in vivo biotransformation efficiency (Lim et al. 2011). Thus, the overall balance of several reaction intermediates and the concentration of enzymes must be modulated in order to maximize the productivity.

References

Balasuriya N, Rupasinghe HP (2012) Antihypertensive properties of flavonoid-rich apple peel extract. Food Chem 135:2320–2325

Benedek B, Geisz N, Jäger W, Thalhammer T, Kopp B (2006) Choleretic effects of yarrow (Achillea millefolium sl) in the isolated perfused rat liver. Phytomedicine 13:702–706

Bowles D, Lim E-K, Poppenberger B, Vaistij FE (2006) Glycosyltransferases of lipophilic small molecules. Annu Rev Plant Biol 57:567–597

Brazier-Hicks M, Evans KM, Gershater MC, Puschmann H, Steel PG, Edwards R (2009) The C-glycosylation of flavonoids in cereals. J Biol Chem 284:17926–17934

Breazeale SD, Riberio AA, McClerren AL, Raetz CRH (2005) A formyltransferase required for polymyxin resistance in Escherichia coli and the modification of lipid A with 4-amino-4-deoxy-L-arabinose. J Biol Chem 280:14154–14167

Du H, Huang Y, Tang Y (2010) Genetic and metabolic engineering of isoflavonoid biosynthesis. Appl Microbiol Biotechnol 86:1293–1312

Flower ZL, Koffas MA (2009) Biosynthesis and biotechnological production of flavanones: current state and perspectives. Appl Microbiol Biotechnol 83:799–808

Han SH, Kim B-G, Yoon JA, Chong Y, Ahn J-H (2014) Synthesis of flavonoid O-pentosides by Escherichia coli through engineering nucleotide sugar synthesis pathway and glycosyltransferase. Appl Env Microbiol 80:2754–2762

He X-Z, Li W-S, Blount JW, Dixon RA (2008) Regioselective synthesis of plant (iso)flavone glycosides in Escherichia col. Appl Microbiol Biotechnol 80:252–260

Ho L, Ferruzzi MG, Janle EM, Wang J, Gong B, Chen TY, Lobo J, Cooper B, Wu QL, Talcott ST, Percival SS, Simon JE, Pasinetti GM (2013) Identification of brain-targeted bioactive dietary quercetin-3-O-glucuronide as a novel intervention for Alzheimer’s disease. FASEB J 27:769–781

Horinouchi S (2008) Combinatorial biosynthesis of non-bacterial and unnatural flavonoids, stilbenoids, and curcuminoids by microorganisms. J Antibiot 6:709–728

Juergenliemk G, Boje K, Huewel S, Lohmann C, Galla HJ, Nahrstedt A (2003) In vitro studies indicate that miquelianin (quercetin 3-O-beta-D-glucuronopyranoside) is able to reach the CNS from the small intestine. Planta Med 69:1013–1017

Kim DH, Kim B-G, Lee Y, Ryu JY, Lim Y, Hur H-G, Ahn J-H (2005) Regiospecific methylation of naringenin to ponciretin by soybean O-methyltransferase expressed in Escherichia coli. J Biotech 115:155–162

Kim BG, Kim H, Hur HG, Lim Y, Ahn J-H (2006) Regioselectivity of 7-O-methyltransferase of poplar to flavones. J Biotech 138:155–162

Kim S-K, Kim DH, Kim BG, Jeon YM, Hong BS, Ahn J-H (2009) Cloning and characterization of the UDP glucose/galactose epimerases of Oryza sativa. J Kor Soc Appl Biol Chem 52:315–320

Kim B-G, Jung NR, Joe EJ, Hur H-G, Lim Y, Chong Y, Ahn J-H (2010) Bacterial synthesis of a flavonoid deoxyaminosugar conjugate in Escherichia coli expressing a glycosyltransferase of Arabidopsis thaliana. ChemBioChem 11:2389–2392

Kim SJ, Um JY, Lee JY (2011) Anti-inflammatory activity of hyperoside through the suppression of nuclear factor-κB activation in mouse peritoneal macrophages. Am J Chin Med 39:171–181

Kim BG, Kim HJ, Ahn J-H (2012a) Production of bioactive flavonol rhamnosides by expression of plant genes in Escherichia coli. J Agr Food Chem 60:11143–11148

Kim B-G, Sung SH, Ahn J-H (2012b) Biological synthesis of quercetin 3-O-N-acetylglucosamine conjugate using engineered Escherichia coli expressing UGT78D2. Appl Microbiol Biot 93:2447–2453

Kim MJ, Kim B-G, Ahn J-H (2013a) Biosynthesis of bioactive O-methylated flavonoids in Escherichia coli. Appl Microbiol Biot 97:7195–7204

Kim HJ, Kim BG, Ahn J-H (2013b) Regioselective synthesis of flavonoid bisglycosides using Escherichia coli harboring two glycosyltransferases. Appl Microbiol Biot 97:5275–5282

Ko JH, Kim BG, Ahn J-H (2006) Glycosylation of flavonoids with a glycosyltransferase from Bacillus cereus. FEMS Microbiol Lett 258:263–268

Lee YJ, Jeon Y, Lee JS, Kim BG, Lee CH, Ahn J-H (2007) Enzymatic synthesis of phenolic CoAs using 4-coumarate:coenzyme A ligase (4CL) from rice. Bull Kor Chem Soc 28:365–366

Lim E-K, Ashford DA, Hou B, Jackson RG, Bowles DJ (2004) Arabidopsis glycosyltransferases as biocatalysts in fermentation for regioselective synthesis of diverse quercetin glucosides. Biotech Bioeng 87:623–631

Lim E-K, Ashford DA, Bowles DJ (2006) The synthesis of small-molecule rhamnosides through the rational design of a whole-cell biocatalysis system. ChemBioChem 7:1181–1185

Lim CG, Fowler ZL, Hueller T, Schaffer S, Koffas MAG (2011) High-yield resveratrol production in engineered Escherichia coli. Appl Env Microbiol 77:3451–3460

Miller KD, Guyon V, Evans JN, Shuttleworth WA, Taylor LP (1999) Purification cloning and heterologous expression of a catalytically efficient flavonol 3-O-galactosyltransferase expressed in the male gametophyte of Petunia hybrid. J Biol Chem 274:34011–34019

Noguchi A, Horikawa M, Fukui Y, Fukuchi-Mizutani M, Luchi-Okada A, Ishiguro M, Kiso Y, Nakayama T, Ono E (2009) Local differentiation of sugar donor specificity of flavonoid glycosyltransferase in Lamiales. Plant Cell 21:1556–1572

Oka T, Jigami Y (2006) Reconstruction of de novo pathway for synthesis of UDP-glucuronic acid and UDP-xylose from intrinsic UDP-glucose in Sacchromyces cerevisiae. FEBS J 273:2645–2657

Orhan F, Gulluce M, Ozkan H, Alpsoy L (2013) Determination of the antigenotoxic potencies of some luteolin derivatives by using a eukaryotic cell system Saccharomyces cerevisiae. Food Chem 141:366–372

Pandey RP, Malla S, Simkhada B, Kim B-G, Sohng JG (2013) Production of 3-O-xylosyl quercetin in Escherichia coli. Appl Microbiol Biotechnol 97:1889–1901

Reiter W-D (2008) Biochemical genetics of nucleotide sugar interconversion reactions. Cur Opin Plant Biol 11:236–243

Santos CN, Koffas M, Stephanopoulos G (2011) Optimization of a heterologous pathway for the production of flavonoids from glucose. Met Eng 13:392–400

Seifert GJ (2004) Nucleotide sugar interconversion and cell wall biosynthesis: how to bring the inside to the outside. Cur Opin Plant Biol 7:277–284

Simkhada D, Kurumbang NP, Lee HC, Sohng JK (2010) Exploration of glycosylated flavonoids from metabolically engineered E coli. Biotech Biopro Eng 15:754–760

Vogt T, Jones P (2001) Glycosyltransferases in plant natural product synthesis: characterization of a supergene family. Trends Plant Sci 5:380–386

Winkel-Shirely B (2001) Flavonoid biosynthesis. a colorful model for genetics, biochemistry, cell biology, and biotechnology. Plant Physiol 126:485–493

Xiao J, Muzashvilli TS, Georgiev MI (2014) Advances in the biotechnological glycosylation of valuable flavonoids. Biotech Advan 32:1145–1156

Yang T, Bar-Peled Y, Smith JA, Glushka J, Bar-Peled M (2011) In-microbe formation of nucleotide sugars in engineered Escherichia coli. Anal Biochem 421:691–698

Yoon J-A, Kim B-G, Lee WJ, Lim Y, Chong Y, Ahn J-H (2012) Production of a novel quercetin glycoside through metabolic engineering of Escherichia coli. Appl Env Microbiol 78:4256–4262

Zheng M, Liu C, Pan F, Shi D, Zhang Y (2012) Antidepressant-like effect of hyperoside isolated from Apocynum venetum leaves: possible cellular mechanisms. Phytomedicine 19:145–149

Acknowledgments

This work was supported by a grant from the Next-Generation BioGreen 21 Program (PJ00948301), Rural Development Administration, Basic Science Research Program (NRF-2013R1A1A2057804), and Priority Research Centers Program through the National Research Foundation of Korea funded by the Ministry of Education, Science and Technology 2009–0093824).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.Y., Lee, H.R., Park, Ks. et al. Metabolic engineering of Escherichia coli for the biosynthesis of flavonoid-O-glucuronides and flavonoid-O-galactoside. Appl Microbiol Biotechnol 99, 2233–2242 (2015). https://doi.org/10.1007/s00253-014-6282-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6282-6