Abstract

Two bioactive O-methylflavonoids, sakuranetin (7-O-methylnaringenin) and ponciretin (7-O-methylnaringenin), were synthesized in Escherichia coli. Sakuranetin inhibits germination of Magnaporthe grisea, and ponciretin is a potential inhibitor of Helicobacter pylori. To achieve this, we reconstructed the naringenin biosynthesis pathway in E. coli. First, the shikimic acid pathway, which leads to the biosynthesis of tyrosine, was engineered in E. coli to increase the amount of available tyrosine. Second, several genes for the biosynthesis of ponciretin and sakuranetin such as tyrosine ammonia lyase (TAL), 4-coumaroyl CoA ligase (4CL), chalcone synthase (CHS), and O-methyltransferase (OMT) were overexpressed. In order to increase the supply the Coenzyme A (CoA), one gene (icdA, isocitrate dehydrogenase) was deleted. Using these strategies, we synthesized ponciretin and sakuranetin from glucose in E. coli at the concentration of 42.5 mg/L and 40.1 mg/L, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural compounds, particularly secondary metabolites from plants, are valuable sources for development of nutraceuticals, medicinal foods, and drugs (Raskin et al. 2002; Brandt et al. 2004; Newman and Cragg 2007). Flavonoids are one of the most well-known plant secondary metabolites and exert diverse pharmacological functions such as anti-oxidant, anti-cancer, anti-aging, and antimicrobial activities (Tapas et al. 2008). Despite their pharmaceutical usefulness, most flavonoids are obtained by extraction from plants. This makes stable and uniform production of useful flavonoids difficult. Thus, the development of efficient microbial processes for the production of flavonoids has been a goal of metabolic engineering for the past several years (Pirie et al. 2013).

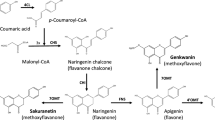

The basic structure of flavonoids contains an aromatic ring and flavonoid biosynthesis derives from an aromatic amino acid, tyrosine. l-Tyrosine is converted into naringenin via several catalytic steps. First, tyrosine ammonia lyase (TAL) converts l-tyrosine to a phenylpropanoic acid, p-coumaric acid. Once p-coumaric acid is generated, 4-coumarate CoA ligase (4CL) mediates the formation of its corresponding CoA ester, p-coumaroyl-CoA. Coumaroyl-CoA is condensed with three malonyl-CoA units by the sequential action of the type III polyketide synthase, chalcone synthase (CHS), to form naringenin chalcone, which becomes naringenin by chalcone isomerase (CHI) (Fig. 1; Winkel-Shirley 2001). In order to synthesize naringenin in Escherichia coli, at least three genes, TAL, 4CL, and CHS, are required. However, availability of tyrosine is a limiting factor for increasing the yield of naringenin. Thus, the tyrosine biosynthesis pathway in E. coli also needs to be manipulated. Supply of tyrosine or p-coumaric acid is an alternative approach, but results in increased cost of production cost compared to glucose.

Two bioactive flavonoids, ponciretin and sakuranetin, and their biosynthetic pathways starting with glucose. ppsA phosphoenolpyruvate synthetase, tktA transketolase, tyrR phenylalanine DNA-binding transcription repressor, aroG deoxyphosphoheptonate aldolase, aroC chorismate synthase, tyrA prephenate dehydrogenase, pheA prephenate dehydratase, tyrB phenylalanine aminotransferase, TAL tyrosine ammonia lyase, 4CL 4-coumaroyl-CoA ligase, CHS chalcone synthase, CHI chalcone isomerase, SOMT2 soybean O-methyltransferase, NOMT naringenin O-methyltransferase

Several reports have been published concerning production of flavonoids in E. coli. Most previous studies used p-coumaric acid as the starting point to synthesize flavonoids (Watts et al. 2004; Malla et al. 2012). In two different studies, supplementing an engineered E. coli strain with p-coumaric acid resulted in production of 0.27 μg/L and 20.8 mg/L of naringenin (Hwang 2003; Watts et al. 2004). Because p-coumaric acid is relatively expensive, the synthesis of flavonoids from glucose is an attractive approach. To date, in only one study, naringenin was produced from glucose using tyrosine-overproducing E. coli mutant (Santos et al. 2011). For the production of naringenin from glucose, an E. coli strain that overproduced tyrosine was used, and the yield of naringenin was 29 mg/L (Santos et al. 2011). Although this study demonstrated production of naringenin, the potential to improve productivity remained. In addition, some naringenin derivatives are more biologically active than naringenin. Previous studies have shown production of naringenin from glucose or p-coumaric acid (Watts et al. 2004; Santos et al. 2011). In addition, biosynthesis of naringenin derivatives from phenylpropanoid acid in Saccharomyces cerevisiae (Leonard et al. 2005; Yan et al. 2005) and E. coli (Miyahisa et al. 2006) has been demonstrated. Naringenin itself is a building block for synthesis of other flavonoids including flavones, flavonols, and isoflavones. Several modification reactions such as O-methylation, glycosylation, and malonylation occur during flavonoid biosynthesis (Winkel-Shirley 2001). Among these, O-methylation, which is mediated by O-methyltransferase (OMT), confers novel biological activity, and O-methylated flavonoids have several specific biological functions (Kim et al. 2010). For example, 4′-O-methylnaringenin (ponciretin) shows antibacterial activity against Helicobacter pylori (Kim et al. 1999) and 7-O-methylnaringenin (sakuranetin) inhibits germination of the rice blast fungus, Magnaporthe grisea (Kodama et al. 1992). Here, we engineered the tyrosine biosynthesis pathway in E. coli to increase production of tyrosine and introduced flavonoid biosynthetic genes to produce two bioactive O-methylated flavonoids, sakuranetin and ponciretin. Using this approach, we synthesized approximately 40 mg/L of sakuranetin and ponciretin.

Materials and methods

Construction of E. coli expression vectors

The genes aroG (2-dehydro-3-deoxyphosphoheptonate aldolase, AM946981.2), tyrA (chorismate mutase/prephenate dehydrogenase, AM946981.2), tktA (transketolase A, AM946981.2), and ppsA (phosphoenolpyruvate synthetase, AM946981.2) were cloned by polymerase chain reaction (PCR) using E. coli BL21 (DE3) genomic DNA. The PCR product of tyrA was digested with NdeI/KpnI and subcloned into the corresponding sites of the E. coli expression vector pACYCDuet (Novagen). The resulting construct was called pA-tyrA. The PCR product of aroG was digested with EcoRI/SalI and cloned into the corresponding sites of pA-tyrA. This construct was designated pA-tyrA-aroG. SeTAL (tyrosine ammonia lyase, DQ357071.1) was amplified from genomic DNA of Saccharothrix espanaensis (ATCC 51144) obtained from the Korean Collection for Type Cultures, and the resulting PCR product was cloned into the EcoRI/HindIII sites of pACYCDuet. The resulting construct was designated pA-SeTAL. SeTAL containing the T7 promoter was amplified using pA-SeTAL as a template. The resulting PCR product was digested with XhoI/HindIII, and then finally cloned into the corresponding sites of pA-tyrA-aroG. The resulting construct was named pA-aroG-SeTAL-tyrA.

aroGfbr and tyrAfbr, neither of which is inhibited by the end product, tyrosine, were produced by site-directed mutagenesis. aroGfbr was mutated at D146N and tyrAfbr was mutated at M531I and A354V (Lütke-Eversloh and Stephanopoulos 2007). The tyrA fbr gene was subcloned into NdeI/KpnI of pACYCDuet, and the EcoRI/SalI digest of the resulting construct was ligated with the EcoRI/SalI digest of aroGfbr. The ppsA and tktA genes were subcloned following aroGfbr. Each of the two genes contained ribosomal binding site (RBS) without a promoter. The SeTAL gene, which contained the T7 promoter, was subcloned between tktA and tyrA fbr. The resulting construct was named pA-aroGfbr-ppsA-tktA-SeTAL-tyrAfbr.

Three 4CL genes, from Petroselinum crispum [Mill.] Nyman (Pc4CL, X13325.1), Oryza sativa L. cv. Nakdong (Os4CL, Lee et al. 2007), and Streptomyces coelicolor A3(2) (Sc4CL, AL939119.1), were subcloned into the first multiple cloning site of pCDFDuet. Two CHS genes from Populus euramericana Guinier (PeCHS, Kim et al. 2012, EF147137.1) and Petunia × hybrida cv. Surfinia Hot Pink (PhCHS, S80857.1) were subcloned into the second multiple cloning site of pCDFDuet, which already contained a 4CL gene in the first multiple cloning site. Thus, six different constructs were produced. Table 1 lists the primers used.

SOMT-2 (C6TAY1.1) from Glycine max cv. Paldal, which transfers a methyl group to 4′-hydroxyl group of naringenin, was cloned previously (Kim et al. 2005). NOMT (NM_001073009.2) from Oryza sativa L. cv. Nakdong was cloned based on the published sequence (Shimizu et al. 2012) using reverse transcription polymerase chain reaction (RT–PCR) with rice cDNA as the template. Primers of NOMT-2 are listed in Table 1.

Deletion of the ΔtyrR, ΔpheA, and ΔicdA genes

Three genes tyrR (DNA binding transcriptional dual regulator), pheA (chorismate mutase/prephenate dehydratase), and icdA (isocitrate dehydrogenase) were inactivated in E. coli BL21(DE3) using the Quick and Easy Conditional Knockout Kit (Gene Bridges, Heidelberg, Germany). Briefly, the tyrR gene of E. coli BL21 (DE3) was inactivated using the ΔtyrR FRT-PGK-gb2-neo-FRT cassette generated by PCR and FRT-PGK-gb2-neo-FRT as a template. Luria–Bertani (LB) medium containing 50 μg/mL kanamycin was used to select positive colonies. Positive clone of the tyrR mutation was verified by colony PCR. The tyrR deletion mutant strain was named BtyrR. To generate ΔtyrR and ΔpheA double mutant, the BtyrR strain was used. First, the kanamycin cassette in BtyrR was removed with a 708-FLPe expression plasmid encoding FLPe recombinase. Removal of the kanamycin cassette was verified by colony PCR. Using the kanamycin cassette-free E. coli BtyrR as a host, the pheA gene was replaced by the ΔpheA FRT-PGK-gb2-neo-FRT cassette. The tyrR and pheA deletion mutant strain was designated BpheA-tyrR. Finally, a BpheA-tyrR-icdA triple mutant was produced using the BpheA-tyrR strain as a host. Deletion of the kanamycin cassette was performed as described above. The icdA gene was replaced by the ΔicdA Tn5-neo cassette.

Synthesis of naringenin, ponciretin, and sakuranetin from glucose in E. coli

To compare the production of naringenin from p-coumaric acid among E. coli strains containing different 4CL and CHS, each E. coli transformant was grown overnight at 37 °C and transferred into new LB medium containing 50 μg/mL of spectinomycin. Cells were grown until OD600 reached 0.8. IPTG was added to the final concentration of 1 mM and the culture continued to grow for 18 h at 18 °C. The cultured cells were collected by centrifugation and then washed briefly with M9 medium. The cells adjusted to OD600 of 3.0, were resuspended in a test tube containing 2 mL of M9 medium supplemented with 2 % glucose, 50 μg/mL of spectinomycin, 1 mM IPTG, and 300 μM p-coumaric acid. Biotransformation was conducted at 30 °C for 24 h. After 24 h of culture, 200 μL of the culture medium was extracted with 800 μL of ethyl acetate, dried, dissolved in 100 μL DMSO, and analyzed by HPLC.

For the synthesis of ponciretin and sakuranetin, a seed culture of the transformant was grown in LB medium containing 50 μg/mL of ampicillin, spectinomycin, and chloramphenicol. The seed culture was inoculated into 3 mL of fresh LB containing 50 μL/mL of ampicillin, spectinomycin, and chloramphenicol. The culture was grown until absorbance at 600 nm reached 1.0. The cells were harvested via centrifugation and resuspended in YM9 medium (pH 7.0) containing 50 μg/mL of ampicillin, spectinomycin, and chloramphenicol, 1 mM IPTG, 2 % glucose, 43 g/L of MOPS [3-(N-morpholino)propanesulfonic acid], and 0.1 % yeast extract, respectively. The mixture was incubated for 48 h at 30 °C. And 200 μL samples were extracted with ethyl acetate. After vortexing and centrifugation, the top organic layer was separated and evaporated to dryness, and the remaining residue was resolubilized with 60 μL DMSO. Samples were analyzed using an HPLC system. A Varian HPLC equipped with a photo diode array detector and an Agilent Polaris 5 C18-A column (250 mm × 4.6 mm) was used for analysis of the reaction products. The mobile phases consisted of 0.1 % formic acid in water and acetonitrile. The program was as follows: 20 % acetonitrile at 0 min, 45 % acetonitrile at 10 min, 80 % acetonitrile at 20 min, 90 % acetonitrile at 20.1 min, 90 % acetonitrile at 25 min, 20 % acetonitrile at 25.1 min, and 20 % acetonitrile at 30 min. The flow rate was 1 mL/min and UV detection was dually performed at 290 nm and 310 nm.

Results

Production of sakuranetin and ponciretin in E. coli

Ponciretin and sakuranetin are O-methylated naringenin and synthesized from naringenin. Therefore, naringein synthesis is important for production of more ponciretin and sakuranetin. Two genes, 4CL and CHS, were tested to find the best combination of 4CL and CHS for the production of naringenin. We tested the production of naringenin from p-coumaric acid in E. coli BL21(DE3) containing different combinations of 4CL and CHS. Three 4CL genes from O. sativa (Os4CL), S. coelicolor (Sc4CL), and P. crispum (Pc4CL), and two CHS genes from P. hybrida (PhCHS) and P. euramericana (PeCHS) were used. Six different combinations of 4CL and CHS were tested for the production of naringenin from p-coumaric acid. E. coli containing Os4CL and PeCHS showed the highest productivity (59 mg/L) after 24 h of incubation followed by E. coli containing Os4CL and PhCHS (48 mg/L) (Fig. 2). The E. coli containing either Se4CL and PeCHS or Sc4CL and PeCHS produced only small amounts of naringenin (less than 5 mg/L, Fig. 2). These results indicated that there was optimum combination of 4CL and CHS and balanced gene combination is important for the higher amount of naringenin production. We used Os4CL and PeCHS as the best combination for naringenin production. The E. coli strain containing Os4CL and PeCHS was designated B201 (Table 1).

Comparison of production of naringenin from p-coumaric acid using different combination of 4CL and CHS. 1 PeCHS and Pc4CL in pCDFDuet, 2 PeCHS and Os4CL in pCDFDuet, 3 PeCHS and Sc4CL in pCDFDuet, 4 PtCHS and Pc4CL in pCDFDuet, 5 PtCHS and Os4CL in pCDFDuet, 6 PtCHS and Sc4CL in pCDFDuet. Error bars indicate mean values ± SD from three independent experiments

Using the strain B201, we tested the production of ponciretin and sakuranetin from p-coumaric acid by transforming the B201 with either pG-S2 (for the production of ponciretin) or pG-N (for the production of sakuranetin) to know if the two constructs, pC-Os4CL-PeCHS and pG-S2 or pC-Os4CL-PeCHS and pG-N, worked properly. The resulting strain B202 and B203 were fed with p-coumaric acid and the production of ponciretin (B202) or sakuranetin (B203) was examined. Ponciretin was successfully synthesized by B202 and sakuranetin was produced by B203 (Fig. 3). These results indicated that ponciretin and sakuranetin could be synthesized from p-coumaric acid in E. coli carrying three genes.

HPLC analysis of reaction product. a S1 authentic p-coumaric acid, S2 authentic naringenin, S3 authentic sakuranetin, S4 authentic ponciretin. b HPLC analysis of reaction products from strain B301S. M, E. coli metabolite; P1, ponciretin. c HPLC analysis of reaction product from strain B301N. M, E. coli metabolite; P1, sakuranetin

Synthesis of ponciretin and sakuranetin from glucose requires TAL, which converts tyrosine into p-coumaric acid. TAL was cloned from S. espanaensis (Berner et al. 2006; Kang et al. 2012). Both strain B202 and B203 were transformed with pA-SeTAL and the resulting strains B-301N and B-301S were examined for production of ponciretin or sakuranetin, respectively, from glucose. The reaction mixture from strain B-301N produced a new product, which had the same retention time and molecular mass with ponciretin (Fig. 3); B-301S also produced sakuranetin, based on the HPLC retention time and molecular mass. Additional peaks shown in Fig. 3, turned out to be p-coumaric acid and naringenin intermediates of ponciretin and sakuranetin. Using four genes, TAL, 4CL, CHS, and OMT, we synthesized 2.5 mg/L of ponciretin and 16.3 mg/L of sakuranetin in wild-type E. coli.

Engineering of E. coli to increase the production of ponciretin and sakuranetin

Although two O-methylated flavonoids were synthesized from glucose using the E. coli strain containing several genes for O-methylated flavonoid biosynthesis, yields were low. Therefore, E. coli was engineered to increase the production of two bioactive O-methylflavonoids, ponciretin and sakuranetin, from glucose. Two strategies were used: the first was to increase the pool of tyrosine and the second one was to increase the supply of CoA for the production of p-coumaroyl-CoA and malonyl-CoA.

The amino acid tyrosine is the substrate of TAL, which is the entry point of flavonoid biosynthesis (Fig. 1). Several studies have shown an increase in the production of tyrosine in E. coli (Lütke-Eversloh and Stephanopoulos 2007; Juminaga et al. 2012). Two genes, tyrR and pheA, were deleted. The tyrR is the transcription regulatory protein, which is feedback-inhibited by tyrosine. Deletion of tyrR increased tyrosine production in E. coli (Lütke-Eversloh and Stephanopoulos 2007; Muñoz et al. 2011). The pheA competes for prephenate with tyrA. Therefore, deletion of these two genes resulted in an increase in tyrosine (Lütke-Eversloh and Stephanopoulos 2007; Juminaga et al. 2012). As a second target for increase in tyrosine production, two genes, ppsA and tktA, both of which are at the entry point of the shikimic acid pathway (Fig. 1), were overexpressed to increase the substrates phosphoenolpyruvate and erythrose 4-phosphate, both of which are the first substrates to be converted by aroG into 3-deoxy-d-arabinoheptulosonate-7-phosphate in shikimic acid pathway (Fig. 1; Patnaik and Liao 1994; Yi et al. 2002). Two additional two genes, aroG fbr and tyrA fbr, were also overexpressed. aroGfbr is a mutant form of aroG that is not inhibited by the end product, tyrosine. The tyrA was also altered to generate a mutant protein (tyrAfbr), which was not inhibited by the end product, tyrosine (Lütke-Eversloh and Stephanopoulos 2007). Second, a supply of CoA was engineered. The icdA gene, which encodes isocitrate dehydrogenase, was deleted. It was reported that deletion of icdA led to an increase in the amount of CoA in E. coli (Lee et al. 2009). It was expected that increasing the amount of CoA would accelerate the production of p-coumaroyl-CoA. Three E. coli strains, BL21 (wild type), B-TP (tyrA/pheA double mutant), and B-TPI (tyrR/pheA/icdA triple mutant), were used along with three different vector sets, pA-SeTAL, pA-aroG-SeTAL-tyrA, and pA-aroGfbr-ppsA-tktA-SeTAL-tyrAfbr (Table 1). Therefore, nine different strains, comprising three E. coli strains harboring three different constructs, were compared for ponciretin production (Fig. 4).

Effect of different gene combinations and E. coli mutants on the production of ponciretin. A—pA-SeTAL, pC-Os4CL-PeCHS, and pG-S2; B—pA-aroG-SeTAL-tyrA, pC-Os4CL-PeCHS, and pG-S2; C—pA-aroGfbr-ppsA-tktA-SeTAL-tyrAfbr, pC-Os4CL-PeCHS, and pG-S2. Error bars indicate mean values ± SD from three independent experiments

The production of ponciretin was examined in each E. coli strain. In wild-type E. coli BL21, the strain harboring pA-aroGfbr-ppsA-tktA-SeTAL-tyrAfbr produced much greater amount of ponciretin (11.5 mg/L) than did strains harboring pA-SeTAL (2.5 mg/L) or pA-aroG-SeTAL-tyrA (3.2 mg/L). However, the effect of pA-aroGfbr-ppsA-tktA-SeTAL-tyrAfbr in strain B-TP and B-TPI was not as significant as in wild type (Fig. 4). Strain B-TPI was more productive than other strains such as wild type and B-TP. Mutation of icdA led to an increase in the production of ponciretin from 17.2 mg/L (strain B-TP-303N) to 32.7 mg/L (strain B-TPI-303N). Overall, by engineering E. coli, we increased ponciretin production from 2.5 mg/L (strain B-301N) to 32.7 mg/L (strain B-TPI-303N), a 13-fold difference.

Using the B-TPI-303 strain, we optimized the cell concentration and the reaction temperature. First, we optimized the reaction temperature. The cells were incubated at 25 °C, 30 °C, and 37 °C. Cells grown at 30 °C produced 18.2 mg/L ponciretin for 24 h. However, cells grown at 25 °C produced only 6.4 mg/L, and cells grown at 37 °C did not produce any detectable amount of ponciretin. It is likely that cells grown at 25 °C did not provide sufficient cofactor such as S-adenosylmethionine for O-methylation and/or did not express enough proteins for the production of ponciretin from glucose due to the low growth temperature. However, cells grown at 37 °C are likely to produce high amounts of protein, which may form inclusion bodies.

We also optimized cell concentration. Cell concentration was adjusted to 0.5, 1, 1.5, 2, and 2.5 at OD600. The optimal cell concentration was 1 at OD600, at which approximately 18.2 mg/L ponciretin was produced. However, cells at lower and higher concentrations produced less ponciretin. Subsequently, production of ponciretin using strain B-TPI-303 was monitored for 72 h. Production of naringenin was detected at 3 h whereas production of ponciretin was first detected at 12 h. However, production of naringenin continued to decrease after 3 h. It seems that conversion of naringenin to ponciretin occurs from 3 to 12 h. Notably, production of p-coumaric acid continued to increase after 24 h. The final yield of ponciretin was approximately 42.5 mg/L after 60 h of incubation (Fig. 5a), after which the amount of ponciretin was decreased.

Based on the results for ponciretin, we used the same E. coli strain, B-TPI with pA-SeTAL-aroGfbr-ppsA-tktA-tyrAfbr, pC-Os4CL-PeCHS, and pG-Ss (Strain B-TP1-304S), to examine the production of sakuranetin. Unlike the production of ponciretin, sakuranetin was produced after 12 h of incubation, and its production reached a maximum at 48 h, both of which were 12 h earlier than ponciretin production. The yield of sakuranetin was approximately 40.1 mg/L (Fig. 5b), which is 2.46-fold greater than the productivity of strain B-301S (Table 1), which contained pA-SeTAL, pC-Os4CL-PeCHS, and pG-S1.

Discussion

By manipulation of the tyrosine biosynthesis pathway and the coenzyme A supply, we achieved the production of greater than 40 mg/L of two bioactive flavonoids, ponciretin and sakuranetin. Previously, ponciretin and sakuranetin were synthesized using bioconversion from naringenin using E. coli harboring naringenin O-methyltransferase. The yield of ponciretin was approximately 42.5 mg/L (Kim et al. 2005), which was similar to the yield in this study. However, the yield of sakuranetin (40.1 mg/L) in this study was much greater than that obtained by bioconversion of naringenin using E. coli harboring SaOMT-2 (16.3 mg/L, Kim et al. 2006). The OMT used in the present study was from rice instead of Streptomyces avermitilis. Differences in catalytic efficiency between two OMTs may have caused the difference in sakuranetin production.

The overexpression of aroG fbr and tyrA fbr along with ppSA and tktA led to a significant increase in the production of ponciretin from 2.5 mg/L to 11.2 mg/L in the wild-type strain. However, its effect in strains B-TP and B-TPI was not significant. In B-TPI, use of SeTAL alone achieved ponciretin production of 26.6 mg/L, which is approximately 81 % of that achieved by coexpression of aroG fbr and tyrA fbr along with ppsA and tktA (32.7 mg/L). It is likely that the major bottleneck in wild E. coli was the amount of tyrosine, which was supplemented by overexpression of ppsA, tktA, aroG fbr, and tyrA fbr. However, in B-TP and B-TPI, supplementation of tyrosine could be achieved by mutation in tyrR and tyrA. Therefore, the effect of overexpression of ppsA, tktA, aroG fbR, and tyrA fbr was marginal. In addition, once tyrosine supplementation is sufficient, the supply of CoA became important. B-TP-303N produced approximately 17 mg/L, whereas B-TPI-303N, in which the icdA gene from B-TP has been deleted in order to increase the supply of CoA (Lee et al. 2009), produced 32.7 mg/L.

Sakuranetin production occurred 12 h sooner than ponciretin production (Fig. 4). Precursors such as p-coumaric acid and naringenin accumulated in greater amounts during ponciretin production than during sakuranetin production, probably due to the different catalytic properties of SOMT and NOMT. NOMT converted naringenin more efficiently than SOMT, which resulted in less accumulation of the precursors.

p-Coumaric acid did not accumulate at the initial stage, but continued to accumulate thereafter. It appears that p-coumaric acid was converted into p-coumaroyl-CoA, which was eventually converted into naringenin at the initial stage. However, during the later stages, due to the lack of energy source, because we used minimal medium, the supply of CoA and/or malonyl-CoA were insufficient for the conversion of p-coumaric acid into next stage products. These results coincided with the results of a previous study that showed that the p-coumaric acid supplied was not converted to naringenin after optimization of production of malonyl-CoA (Xu et al. 2011).

Sakuranetin was originally considered to be a phytoalexin against Magnaporthe oryzae (Kodama et al. 1992), although it was first isolated from cherry tree (Asahina 1908). Subsequently, sakuranetin has been isolated from various plants, and various biological activities have been documented, including anti-inflammatory activity (Zhang et al. 2006), anti-mutagenic activity (Miyazawa et al. 2003), and anti-bacterial activity against H. pylori (Zhang et al. 2008). Development of an efficient method for production of sakuranetin as well as ponciretin will make it possible to explore their other biological activities, which has not been possible due to their limited supply. Engineered E. coli could be used to produce other biologically active flavonoids in addition to sakuranetin and ponciretin.

References

Asahina Y (1908) Ueber das sakuranin, ein neues Glykosid der Rinde von Prunus pseudo-cerasus Lindl. var. Sieboldi Maxim. Arch Pharm 246:259–272

Berner M, Krug D, Bihlmaier C, Vente A, Müller R, Bechthold A (2006) Genes and enzymes involved in caffeic acid biosynthesis in the actinomycete Saccharothrix espanaensis. J Bacteriol 188:2666–2673

Brandt K, Christensen LP, Hansen-Møllerd J, Hansen SL, Haraldsdottir J, Jespersen L, Purup S, Kharazmi A, Barkholt V, Frøkiær H, Kobæk-Larsen M (2004) Health promoting compounds in vegetables and fruits: a systematic approach for identifying plant components with impact on human health. Trends Food Sci Tech 15:384–393

Hwang EI, Kaneko M, Ohnishi Y, Horiniuchi S (2003) Production of plant-specific flavanones by Escherichia coli containing an artificial gene cluster. Appl Environ Microbiol 69:2699–2706

Juminaga D, Baidoo EE, Redding-Johanson AM, Batth TS, Burd H, Mukhopadhyay A, Petzold CJ, Keasling JD (2012) Modular engineering of L-tyrosine production in Escherichia coli. Appl Environ Microbiol 78:89–98

Kang SY, Choi O, Lee JK, Hwang BY, Uhm TB, Hong YS (2012) Artificial biosynthesis of phenylpropanoic acids in a tyrosine overproducing Escherichia coli strain. Microb Cell Factories 11:153

Kim BG, Jung B-R, Lee Y, Hur H-G, Lim Y, Ahn J-H (2006) Regiospecific flavonoid 7-O-methylation with Streptomyces avermitilis O-methyltransferase expressed in Escherichia coli. J Agric Food Chem 54:823–828

Kim B-G, Lee E-R, Ahn J-H (2012) Analysis of flavonoid contents and expression of flavonoid biosynthetic genes in Populus euramericana Guinier in response to abiotic stress. J Korean Soc Appl Biol Chem 55:141–145

Kim B-G, Sung SH, Chong Y, Lim Y, Ahn J-H (2010) Plant flavonoid O-methyltransferases: substrate specificity and application. J Plant Biol 53:321–329

Kim D-H, Bae E-A, Han MJ (1999) Anti-Helicobacter pylori activity of the metabolites of poncirin from Poncirus trifoliate by human intestinal bacteria. Biol Pharm Bull 22:422–424

Kim DH, Kim B-G, Lee Y, Ryu JY, Lim Y, Hur H-G, Ahn J-H (2005) Regiospecific methylation of naringenin to ponciretin by soybean O-methyltransferase expressed in Escherichia coli. J Biotechnol 115:155–162

Kodama O, Miyakawa J, Akatsuka T, Kiyosawa S (1992) Sakuranetin, a flavanone phytoalexin from ultraviolet-irradiated rice leaves. Phytochemistry 31:3807–3809

Lee EG, Yoon SH, Das A, Lee SH, Li C, Kim JY, Choi MS, Oh DK, Kim SW (2009) Directing vanillin production from ferulic acid by increased acetyl-CoA consumption in recombinant Escherichia coli. Biotechnol Bioeng 102:200–208

Lee Y-J, Jeon Y, Lee JS, Kim B-G, Lee CH, Ahn J-H (2007) Enzymatic synthesis of phenolic CoAs using 4-coumarate:coenzyme A ligase (4CL) from rice. Bull Korean Chem Soc 28:365–366

Leonard E, Yan Y, Lim KH, Koffas MAG (2005) Investigation of two distinct flavone synthase for plant-specific flavone biosynthesis in Saccharomyces cerevisiae. Appl Environ Microbiol 71:8241–8248

Lütke-Eversloh T, Stephanopoulos G (2007) L-Tyrosine production by deregulated strains of Escherichia coli. Appl Microbiol Biotechnol 75:103–110

Malla S, Koffas MAG, Kazlauskas R, Kim B-G (2012) Production of 7-O-methyl aromadendrin, a medicinally valuable flavonoid, in Escherichia coli. Appl Environ Microbiol 78:684–694

Miyahisa I, Funa N, Ohnishi Y, Martens S, Moriguchi T, Horinouchi S (2006) Combinatorial biosynthesis of flavones and flavonols in Escherichia coli. Appl Microbiol Biotechnol 71:53–58

Miyazawa M, Kinoshita H, Okuno Y (2003) Antimutagenic activity of sakuranetin from Prunus jamasakura. J Food Sci 68:52–56

Muñoz AJ, Hernández-Chávez G, de Anda R, Martínez A, Bolívar F, Gosset G (2011) Metabolic engineering of Escherichia coli for improving L-3,4-dihydroxyphenylalanine (L-DOPA) synthesis from glucose. J Ind Microbiol Biotechnol 38:1845–1852

Newman DJ, Cragg GM (2007) Natural products as sources of new drugs over the last 25 years. J Nat Prod 70:461–477

Patnaik R, Liao JC (1994) Engineering of Escherichia coli central metabolism for aromatic metabolite production with near theoretical yield. Appl Environ Microbial 60:3903–3908

Pirie CM, Mey MD, Prather KLJ, Ajikumar PK (2013) Integrating the protein and metabolic engineering toolkits for next-generation chemical biosynthesis. ACS Chem Biol 8:662–672

Raskin I, Ribnicky DM, Komarnytsky S, Ilic N, Poulev A, Borisjuk N, Brinker A, Moreno DA, Ripoll C, Yakoby N, O'Neal JM, Cornwell T, Pastor I, Fridlender B (2002) Plants and human health in the twenty-first century. Trends Biotechnol 20:522–531

Santos CNS, Koffas M, Stephanopoulos (2011) Optimization of a heterologous pathway for the production of flavonoids from glucose. Met Eng 13:392–400

Shimizu T, Lin F, Hasegawa M, Okada K, Nojiri H, Yamane H (2012) Purification and identification of naringenin 7-O-methyltransferase, a key enzyme in biosynthesis of flavonoid phytoalexin sakuranetin in rice. J Biol Chem 287:19315–19325

Tapas AR, Sakarkar DM, Kakde RB (2008) Flavonoids as nutraceuticals: a review. Trop J Pharm Res 7:1089–1099

Watts KT, Lee PC, Schmidt-Dannert C (2004) Exploring recombinant flavonoid biosynthesis in metabolically engineered Escherichia coli. ChemBioChem 5:500–507

Winkel-Shirley B (2001) Flavonoid biosynthesis. A colorful model for genetics, biochemistry, cell biology, and biotechnology. Plant Physiol 126:485–493

Xu P, Ranganathan S, Fowler Z, Maranas CD, Koffas MAG (2011) Genome-scale metabolic network modeling results in minimal interventions that cooperatively force carbon flux towards malonyl-CoA. Met Eng 13:578–587

Yan Y, Kohli A, Koffas MAG (2005) Biosynthesis of natural flavones in Saccharomyces cerevisiae. Appl Envrion Microbiol 71:5610–5613

Yi J, Li K, Draths KM, Frost JW (2002) Modulation of phosphoenolpyruvate synthase expression increases shikimate pathway product yields in E. coli. Biotechnol Prog 18:1141–1148

Zhang X, Hung TM, Phuong PT, Ngoc TM, Min BS, Song KS, Seong YH, Bae K (2006) Anti-inflammatory activity of flavonoids from Populus davidiana. Arch Pharm Res 29:1102–1108

Zhang L, Kong Y, Wu D, Zhang H, Wu J, Chen J, Ding J, Hu L, Jiang H, Shen X (2008) Three flavonoids targeting the β-hydroxyacyl-acyl carrier protein dehydratase from Helicobacter pylori: crystal structure characterization with enzymatic inhibition assay. Protein Sci 17:1971–1978

Acknowledgments

This work was supported by a grant from the Next-Generation BioGreen 21 Program (PJ00948301), Rural Development Administration, Republic of Korea, and by the Priority Research Centers Program through the National Research Foundation of Korea funded by the Ministry of Education, Science and Technology (2012-0006686).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, MJ., Kim, BG. & Ahn, JH. Biosynthesis of bioactive O-methylated flavonoids in Escherichia coli . Appl Microbiol Biotechnol 97, 7195–7204 (2013). https://doi.org/10.1007/s00253-013-5020-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5020-9