Abstract

Taking advantage of the catalytic promiscuity of l-carbamoylase from Geobacillus stearothermophilus CECT43 (BsLcar) and N-succinyl-amino acid racemase from Geobacillus kaustophilus CECT4264 (GkNSAAR), we have evaluated the production of different optically pure l-α-amino acids starting from different racemic N-formyl- and N-carbamoyl-amino acids using a dynamic kinetic resolution approach. The enzymes were immobilized on two different solid supports, resulting in improved stability of the enzymes in terms of thermostability and storage when compared to the enzymes in solution. The bienzymatic system retained up to 80 % conversion efficiency after 20 weeks at 4 °C and up to 90 % after 1 week at 45 °C. The immobilization process also resulted in a great enhancement of the activity of BsLcar toward N-formyl-tryptophan, showing for the first time that substrate specificity of l-carbamoylases can be influenced by this approach. The system was effective for the biosynthesis of natural and unnatural l-amino acids (enantiomeric excess (e.e.) >99.5 %), such as l-methionine, l-alanine, l-tryptophan, l-homophenylalanine, l-aminobutyric acid, and l-norleucine, with a higher performance toward N-formyl-α-amino acid substrates. Biocatalyst reuse was studied, and after 10 reaction cycles, over 75 % activity remained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Optically pure amino acids are of great interest for the chemical industry and of considerable economic importance because of the broad spectrum of their industrial applications (Leuchtenberger et al. 2005). The increasing interest in unnatural amino acids is giving rise to a new discipline of study, as can be inferred from the appearance of a complete book on this topic (Pollegioni and Servi 2012). By way of example, l-homophenylalanine is a precursor for the preparation of angiotensin-converting enzyme (ACE) and renin inhibitors, such as enalapril, lisinopril, quinapril, ramipril, trandolapril, and benazepril, among others (Johnson et al. 1985). l-α-Aminobutyric acid (l-ABA, also known as l-homoalanine) is a key chiral intermediate for the synthesis of several important drugs, such as levetiracetam or brivaracetam (antiepileptic drugs) and ethambutol (antituberculosis drug) (Zhang et al. 2010). l-Norleucine (2-aminohexanoic acid) has recently been shown to present cytotoxic activity against human tumor cell lines (Fazary et al. 2011), and it is also a key chiral intermediate for the synthesis of several new lead compounds (Gutierrez et al. 2013; Simmons 2008). Despite the direct commercial applications of unnatural amino acids, in recent years, the possibility to incorporate unnatural amino acids site-specifically into proteins has had a major impact on protein engineering (Liu and Schultz 2010; Zhang et al. 2013). By removing the constraints imposed by nature on the number and properties of genetically encoded amino acids, this technique has proven very valuable to probe protein function and to improve protein function for medical and industrial applications (Liu and Schultz 2010; Zhang et al. 2013).

Biocatalysis has become an established technology for the industrial manufacture of fine chemicals (Breuer et al. 2004), and optically pure amino acid production is no exception (Leuchtenberger et al. 2005). Different methods have been described for the enzymatic production of l-amino acids, such as the hydantoinase (Altenbuchner et al. 2001), amidase (Asano 2007), or acylase processes (May et al. 2002). Given the progress made in this field, it is clear that biocatalysts were not merely a trend of the last decade, rather interest in them continues to grow (Kircher 2012; Gotor and Flitsch 2011).

Several of the above-described biotechnological methods rely on the use of at least one enantiospecific or highly enantioselective enzyme to achieve enantiopure (or highly enantiomeric enriched) amino acids, turning the process into a kinetic resolution (Huerta et al. 2001). Furthermore, since in most cases racemic mixtures are the starting point for these processes, an additional chemical or enzymatic racemization step of the nonhydrolyzed isomer turns the process into a dynamic kinetic resolution (DKR), allowing total conversion of the racemic substrates used in each case (Huerta et al. 2001; Altenbuchner et al. 2001; Asano 2007; May et al. 2002).

In previous works, we confirmed the substrate promiscuity of an l-carbamoylase from Geobacillus stearothermophilus CECT43 (BsLcar) and an N-succinyl-amino acid racemase from Geobacillus kaustophilus CECT4264 (GkNSAAR) toward different N-substituted amino acids (Pozo-Dengra et al. 2009, 2010). We further confirmed the effectiveness of coupling BsLcar and GkNSAAR as a DKR biotool using racemic mixtures of different N-acetyl-, N-carbamoyl-, and N-formyl-amino acids (Soriano-Maldonado et al. 2014). This bienzymatic system presented the highest efficiency for N-formyl-amino acids and allowed the production of different enantiopure l-α-amino acids (e.e. >99.5 %) due to the strict enantiospecificity of l-carbamoylases (Martínez-Rodríguez et al. 2010). In the present work, we aimed to enhance further the performance of the BsLcar/GkNSAAR tandem by using an immobilization approach, as this technique is known to alter properties such as catalytic activity or thermal stability (Garcia-Galan et al. 2011; Rodrigues et al. 2013). DKR has been carried out with the two fastest substrates (N-formyl- and N-carbamoyl-amino acids). In order to establish whether this approach might be of economic interest, reuse of the bienzymatic system has also been assayed.

Materials and methods

General protocols and reagents

Racemic mixtures and optically pure d- and l-amino acids were purchased from Sigma-Aldrich (Madrid, Spain). Sepabeads EC-HFA/S (Resindion, Rome, Italy) and Immobeads IB-A161 (ChiralVision, Leiden, The Netherlands) matrixes were used for enzyme immobilization. The N-carbamoyl- and N-formyl-amino acids used in this work were synthesized according to previous works (Boyd 1933; Hussenet et al. 2001; Soriano-Maldonado et al. 2014).

Expression and purification of BsLcar and GkNSAAR enzymes

Procedures for the purification and preparation of the enzymes were the same as those previously described using cobalt affinity chromatography (Clontech Laboratories Inc.) (Soriano-Maldonado et al. 2014). The purified enzymes were concentrated using Vivaspin concentrators (Sartorius), dialyzed against 100 mM borate-HCl pH 8.0 buffer, and stored at 4 °C until use. Protein concentrations were determined from the absorbance of coefficient extinction of tyrosine residues (ε = 43,430 and 58,900 M−1 cm−1 for BsLcar and GkNSAAR, respectively).

Preparation of immobilized enzymes

Immobilization of the purified enzymes was performed by mixing 0.1 g of Sepabeads EC-HFA/S (Resindion SRL) with 400 μL of BsLcar (0.5–0.7 mg mL−1) or GkNSAAR (7 mg mL−1) separately in 100 mM borate-HCl pH 8.0 buffer, following the manufacturer’s instructions, with slight modifications. The mixture was placed in a thermo shaker (TS-100, BOECO, Germany) for 12 h at 700 rpm and 20 °C. The matrixes with the immobilized enzymes were decanted and rinsed thoroughly with 400 μL of distilled water and treated with the same volume of 3 M glycine pH 8.2 for a further 12 h. The immobilized enzymes were then rinsed again with water and resuspended in 400 μL of the aforementioned borate-HCl buffer. The protocol for immobilization onto Immobead IB-A161 was very similar, except that the 12-h treatment with 3 M glycine pH 8.2 was not necessary for this matrix.

The concentration of immobilized enzymes was determined from the equation:

where (mg Enzyme)0 and (mg Enzyme)f correspond to the amount of enzyme in solution before and after the immobilization process, respectively. A medium-scale immobilization process was scaled up after optimization of the enzyme concentration used. For this purpose, both enzymes were separately immobilized on 1 g of matrix with 4 mL of enzyme at the previously established concentration and following the steps described above, but using 4 mL of distilled water, 3 M glycine pH 8.2, and 100 mM borate-HCl buffer.

Standard assay

The immobilized BsLcar or GkNSAAR enzymes (or both together) were mixed with 7.5 mM substrate (N-formyl-l-methionine for the free enzymes; N-carbamoyl- or N-formyl-d,l-methionine for the BsLcar/GkNSAAR tandem) in 100 mM borate-HCl pH 8.0, in the presence of 1 mM CoCl2 (reaction volume 1,010 μL). The reaction mixture was incubated at 45–55 °C with shaking (850 rpm), and aliquots of 75 μL were retrieved at different intervals. The reaction was stopped by the addition of 675 μL of 1 % H3PO4. After centrifugation (13,000 × g), the resulting supernatants were analyzed by high-performance liquid chromatography (HPLC) to measure the l-methionine produced (BsLcar and BsLcar/GkNSAAR mixtures, RP-HPLC) or N-formyl-d-methionine (GkNSAAR, chiral HPLC). The activities of the isolated immobilized enzymes were calculated as micromole of l-methionine (BsLcar) or N-formyl-d-methionine (GkNSAAR) formed per minute and milligram of immobilized protein, in order to allow comparison with the activity of the enzymes in solution.

Characterization of the immobilized enzymes

Based on the calculated activities of the enzymes under the immobilization conditions, we assayed different mixtures of immobilized BsLcar/GkNSAAR (w/w ratios 1:1 to 1:20), following the standard reaction (see above). After selection of a fixed w/w ratio of enzymes (10 mg BsLcar plus 20 mg GkNSAAR for EC-HFA/S; 25 mg BsLcar plus 50 mg GkNSAAR for IB-A161), pH and temperature studies were carried out following the standard reaction described above. pH studies were conducted using N-carbamoyl- and N-formyl-d,l-methionine as substrates. A pH range of 5.0 to 10.0 was assayed (sodium citrate pH 5.0–6.0; sodium cacodylate pH 6.5–7.5; borate-HCl 8.0–9.0; borate-NaOH 9.5–10.0). The effect of temperature on the conversion rate of the bienzymatic system was evaluated from 30 to 80 °C. The thermal stability of the two immobilized systems was also measured using two approaches, both in 100 mM borate-HCl pH 8.0, following the standard reaction; residual activity of the bienzymatic system was measured (a) after 18 h of preincubation at temperatures ranging from 30 to 80 °C and (b) after preincubation at 4 and 45 °C for several days.

Substrate specificity studies were performed with each different N-formyl- and N-carbamoyl-d,l-amino acid (7.5 mM) dissolved in 100 mM borate-HCl pH 8.0, 1 mM CoCl2 together with the immobilized enzymes (10 mg BsLcar plus 20 mg GkNSAAR for EC-HFA/S; 25 mg BsLcar plus 50 mg GkNSAAR for IB-A161). Different temperatures were used according to the optimal parameters found with the different reaction systems. Larger scale reactions were carried out with N-formyl-d,l-norleucine at 160 mM dissolved in 10 mM borate-HCl pH 8.0,Footnote 1 1 mM CoCl2 (1 and 10 mL final volume; 25 or 250 mg IB-A161-BsLcar plus 50 or 500 mg IB-A161-GkNSAAR, respectively) at pH 8.0 and 45 °C. In both the small- and large-scale reactions, 75 μL aliquots were retrieved at different reaction times, and the reaction was stopped by the addition of 675 μL of 1 % H3PO4. After centrifugation, the resulting supernatants were analyzed by HPLC as described below. Upon completion of the reaction, the reaction solution was separated from the immobilized enzymes by gentle centrifugation (1,800 rpm, 1 min, 4 °C) and subjected to evaporation using a rotary evaporator (RV 10 digital, IKA, Germany). The precipitate obtained was recrystallized twice using hot 30 % EtOH, filtered with a Buchner funnel, and then dried in a desiccator for 1 week. Solid l-norleucine purity was assayed by RP- and chiral HPLC and NMR. The specific rotation of the l-norleucine produced in water was measured by polarimetry (JASCO P-1030 polarimeter operating at the sodium D line) and compared with that of commercially available l-norleucine.

Chromatographic analysis

To determine the e.e. of different amino acids produced by the enzymatic tandem, chiral separations were carried out using the same HPLC system equipped with a chirobiotic T column (250 × 4.6 mm, 5 μm, Astec, Sigma-Aldrich). The mobile phase was 70:29.5:0.05 methanol/10 mM ammonium acetate/acetic acid, pumped at a flow rate of 0.3 mL min−1, and measured at 203 nm (Soriano-Maldonado et al. 2014). On the other hand, an HPLC system (LC2000Plus HPLC System, Jasco) equipped with a Zorbax C18 column (3.0 × 250 mm, Agilent Inc.) was used to detect N-formyl-amino acids, N-carbamoyl-amino acids, and the corresponding l-amino acids, as previously described (Soriano-Maldonado et al. 2014). The mobile phases contained H3PO4 20 mM pH 3.2 and methanol in different proportions (50:50 to 95:5, depending on the substrate), pumped at a flow rate of 0.2 to 1.0 mL min−1, and measured at 200–203 nm.

Reutilization of the immobilized enzymes

Reuse of the immobilized enzymes was assayed using mixtures of the different solid supports (10 mg BsLcar plus 20 mg GkNSAAR for EC-HFA/S; 50 mg BsLcar plus 100 mg GkNSAAR for IB-A161). The solid supports were incubated at 45 °C with 1 mL of 7.5 mM N-formyl-d,l-methionine in 100 mM borate-HCl pH 8.0 supplemented with 1 mM CoCl2. The supernatant was removed on completion of the reaction and analyzed by HPLC to quantify the amount of l-methionine produced. The solid supports were washed once with 1 mL of 100 mM borate-HCl pH 8.0, and 1 mL of 7.5 mM N-formyl-d,l-methionine in 100 mM borate-HCl pH 8.0 supplemented with 1 mM CoCl2 was added to a 2-mL tube containing the immobilized enzymes and incubated again at 45 °C. The same process was repeated for several cycles.

Results

Immobilization process

The amounts of BsLcar and GkNSAAR immobilized onto the EC-HFA/S support (HFA-BsLcar and HFA-GkNSAAR) were 0.4 ± 0.0 and 8.0 ± 0.7 μg prot mg−1 beads, respectively, whereas 2.6 ± 0.2 and 15.0 ± 1.2 μg prot mg−1 beads were obtained for the immobilization of BsLcar and GkNSAAR onto the IB-A161 support (A161-BsLcar and A161-GkNSAAR). These results show that IB-A161 proved more efficient in terms of the amount of immobilized enzyme. Under these immobilization conditions, both HFA-GkNSAAR and A161-GkNSAAR showed activities in the range of 0.4 ± 0.2 μmol mg prot−1 min−1 with N-formyl-l-methionine as substrate, i.e., slightly below the activity found previously with GkNSAAR in solution (1.6 ± 0.1 μmol mg prot−1 min−1; Soriano-Maldonado et al. 2014). On the other hand, HFA-BsLcar and A161-BsLcar showed activity values of 14.0 ± 4.0 and 8.5 ± 3.5 μmol mg prot−1 min−1, respectively, with N-formyl-l-methionine as substrate, which is very similar to the value found in solution (12.0 ± 5.5 μmol mg prot−1 min−1; Soriano-Maldonado et al. 2014). Thus, our results show that the immobilization process did not substantially alter the specific activity of the enzymes.

Effect of pH and temperature

Based on the specific activities of the enzymes under the immobilization conditions, we assayed different mixtures of immobilized BsLcar/GkNSAAR (w/w). When using the HFA-BsLcar/HFA-GkNSAAR mixture, total consumption was achieved after 420 min for a ratio of 1:20, whereas it took 540 min for a ratio of 1:2 (data not shown). The 1:2 (w/w) ratio was chosen for subsequent experiments (10 mg HFA-BsLcar/20 mg HFA-GkNSAAR), as the decrease in time in total consumption of the substrate did not outweigh the higher amounts of GkNSAAR used.Footnote 2 When assaying the A161-BsLcar/A161-GkNSAAR mixture, the minimum amount of support to be used was conditioned by the size of the solid support, which is larger and more difficult to handle.Footnote 3 Based on our results, a 1:2 (w/w) ratio was also selected (25 mg A161-BsLcar/50 mg A161-GkNSAAR).

Studies of pH and temperature dependence for the production of l-methionine when using both immobilized bienzymatic systems were similar to those previously described for the enzymes in solution (Soriano-Maldonado et al. 2014): The highest conversion rate for the biocatalyst proved to be 7.5–8.0 for both N-formyl- and N-carbamoyl-amino acid substrates. Temperature ranges with the fastest conversion were 40–55 °C for N-formyl-amino acids and 55–70 °C for N-carbamoyl-derivatives when using the HFA support (Fig. S1). The results with the A161 support varied slightly, and the highest conversion rates were obtained at 45–75 °C with N-formyl-amino acids and 65 °C with N-carbamoyl-derivatives. Thus, immobilization on the A161 support increased the temperature at which reactions could be carried out. On the other hand, these results suggest that the immobilization process did not substantially alter the enzymatic behavior when compared to the enzymes in solution (Soriano-Maldonado et al. 2014). Thermal stability of the system was studied by preincubation of the immobilized enzymes together for 18 h in 100 mM borate-HCl pH 8.0, at temperatures ranging from 30 to 80 °C. Conversion rates decreased when the immobilized enzymes were incubated at temperatures over 55 °C and were lost completely at over 70 °C for the HFA-BsLcar/HFA-GkNSAAR system (Fig. 1). Similar results were obtained when using the A161-BsLcar/A161-GkNSAAR tandem (Fig. 1), although this immobilized system still presented 30 % activity at 70 °C after 18 h of incubation. This value is slightly higher than that found with the enzymes in solution, when no conversion was observed after 10 h of incubation of the bienzymatic system at 70 °C (Soriano-Maldonado et al. 2014), thus showing that the A161 support slightly increased the thermal stability of the bienzymatic tandem. On the other hand, in view of the loss of activity at over 55 °C for both HFA- and A161-immobilized tandems (Fig. 1; mostly due to GkNSAAR denaturation as a result of prolonged incubation times, as previously shown (Pozo-Dengra et al. 2009; Soriano-Maldonado et al. 2014)), it was decided to carry out all the subsequent reactions at temperatures ≤55 °C.

Further studies of the system’s stability were carried out over prolonged times of storage/incubation. The immobilized BsLcar/GkNSAAR enzymes were found to maintain full activity after 4 weeks at 4 °C, retaining up to 80 % after 20 weeks at this temperature. These values are much higher than those obtained with the enzymes in solution, when 50 % of activity was lost after 4 weeks at the same temperature. Furthermore, the immobilized enzymes maintained 90 and 50 % of their activity after 7 and 14 days of incubation at 45 °C, respectively, which also improves on the results obtained previously for the enzymes in solution. The immobilization procedure therefore resulted in greater enzyme stability than using enzymes in solution, as has been observed for other enzymes immobilized on solid supports (Sheldon 2007; Garcia-Galan et al. 2011; Rodrigues et al. 2013).

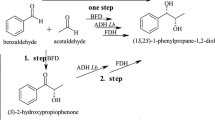

Bienzymatic production of enantiopure l-α-amino acids

HFA- and A161-immobilized tandems were assayed with different N-formyl- and N-carbamoyl-amino acid racemates. Both systems were effective for the production of methionine, alanine, norleucine, norvaline, ABA, homophenylalanine, phenylglycine, and ethionine (Tables 1 and 2), obtaining an e.e. of >99.5 % in all cases. On the other hand, they were not effective for tert-leucine production. The A161 tandem was also effective for the biosynthesis of l-tryptophan under the conditions assayed (Table 2). Interestingly enough, whereas the HFA-immobilized tandem showed a negligible conversion toward l-tryptophan (Table 1), similar to the results observed with the enzymes in solution, the conversion rate with N-formyl-l-tryptophan was greatly enhanced when using the A161 tandem (more than 500 times faster; Table 2). These results arose from an improvement in the hydrolysis of the substrate by BsLcar, which might be due to BsLcar structure distortion altering the catalytic center environment of the enzyme, as has been observed for the other enzymes (Garcia-Galan et al. 2011; Rodrigues et al. 2013). The l-enantiospecific character of the immobilized BsLcar was maintained after the immobilization process, allowing the production of these l-amino acids with an e.e. >99.5 %, as was observed previously for the enzymatic tandem in solution (Soriano-Maldonado et al. 2014). By way of example, the enantiomeric purity of homophenylalanine produced by the immobilized tandem is shown in Fig. 2.

Chiral HPLC chromatogram showing commercial d,l-homophenylalanine (dashed line) and a sample of a finished standard reaction of the bienzymatic system (continuous line), using racemic N-formyl-homophenylalanine as substrate. Optically pure l-homophenylalanine was produced by the enzymatic tandem (>95 % yield, e.e. >99.5 %)

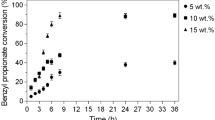

Operational stability of the immobilized enzymes and large-scale reaction

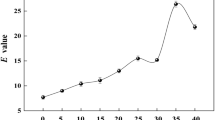

The relative activity of the A161-BsLcar/A161-GkNSAAR tandem decreased only slightly after each cycle, with an average of 3 % activity loss per cycle (Fig. 3), maintaining over 75 % of the initial activity after 10 cycles. However, the relative activity of the HFA-BsLcar/HFA-GkNSAAR tandem was almost totally lost after 4 cycles (Fig. 3). SDS-PAGE gels of the supernatant fractions of the different reaction cycles showed that protein was partially removed from the matrix after each reaction cycle (data not shown). The same experiment was carried out under the same conditions of pH and temperature, but in the absence of shaking, and it was observed that no protein was lost by SDS-PAGE. Furthermore, this effect was seen to be time and shake dependent, thus allowing us to conclude that the mechanical force was responsible for the loss of activity, as has been described for other immobilization processes (Garcia-Galan et al. 2011). This drawback considerably diminishes the likelihood of a putative industrial application of the HFA-BsLcar/HFA-GkNSAAR tandem. On the other hand, since our results showed that recycling of the A161-BsLcar/A161-GkNSAAR tandem was possible, it was decided to test the process on a larger scale, as its implementation at the industrial level depends on several factors, such as whether high concentrations of substrate/products inhibit the enzymatic reaction. The A161-BsLcar/A161-GkNSAAR tandem was therefore assayed for l-norleucine production using 160 mM of N-formyl-d,l-norleucine in 10 mM borate-HCl pH 8.0 at 45 °C. Total conversion was achieved after 11 h for both the 1-mL (Fig. 4) and 10-mL reactions. The productivity of the system was 16 ± 2 mmol norleu L −1 h−1. After recrystallization, 1.7 g of a white precipitate was obtained from the 10-mL solution. The nature of the product (l-norleucine) was confirmed by HPLC and RMN (Fig. S2), and its enantiomeric purity (>99.5 %) was checked by chiral HPLC. The specific rotation ([a]D 20) of the enzymatically produced and commercially available l-norleucine in water was +4.8° and +4.7° (±0.2°), respectively. The overall reaction yield for purified l-norleucine was 80 ± 5 %.

Achieved reaction completeness when reusing the immobilized HFA-BsLcar/GkNSAAR (gray bars) and A161-BsLcar/GkNSAAR (black bars) bienzymatic systems. Reactions were carried out in triplicate as described in the “Materials and methods”

Profile of conversion of 160 mM N-formyl-d,l-norleucine (filled triangle) into l-norleucine (filled circle) by the immobilized A161-BsLcar/GkNSAAR tandem (reaction volume 1 mL). The sum of both compounds is also shown (filled square). Reactions were carried out in triplicate in 10 mM borate-HCl pH 8.0, 1 mM CoCl2 at 45 °C, using 25 and 50 mg of immobilized BsLcar and GkNSAAR enzymes, respectively

Discussion

Optically pure amino acids are of great interest, since they are important building blocks in pharmaceutical and other industrial sectors. A wide range of these compounds have been synthesized by different enzymatic methods, such as the hydantoinase (Altenbuchner et al. 2001), amidase (Asano 2007), or acylase processes (May et al. 2002). Based on the acylase process, an alternative method to synthesize l-homophenylalanine using an l-carbamoylase and an N-succinyl-amino acid racemase was proposed by Hsu et al. (2007). We have further confirmed that BsLcar and GkNSAAR are highly promiscuous enzymes and can accept different N-substituted amino acids (Pozo-Dengra et al. 2009, 2010), allowing to couple both enzymes for the biosynthesis of different optically pure natural and unnatural amino acids (Soriano-Maldonado et al. 2014). Our results suggested that the industrially used “acylase process” could be named “amidohydrolase process” in a more general way, since substitution of l-acylase by l-carbamoylase increases the substrate spectrum to be used with this enzymatic process.

Enzyme immobilization has arisen as one of the common strategies to be used to increase enzymatic performance (Sheldon 2007; Garcia-Galan et al. 2011; Rodrigues et al. 2013). Whereas the immobilization process often results in enzymes with higher stability, it also often results in lower enzymatic activity if the proper support is not selected (Rodrigues et al. 2013). In this work, we have shown that the immobilization of BsLcar/GkNSAAR tandem resulted in conversion levels comparable to the enzymes in solution, but with enhanced stability, and allowed enzyme reuse. The system was more effective for the degradation of N-formyl-derivatives (Tables 1 and 2), as was observed previously with the enzymes in solution (Soriano-Maldonado et al. 2014). When comparing the performance of both systems, the HFA tandem might in principle seem slower than the A161 tandem (Tables 1 and 2). However, the effective amount of the enzymes in the reaction is different in both systems as a result of (a) the different immobilization effectiveness for both supports (see above) and (b) the different amounts of support used for each system. Indeed, the A161 tandem uses four times the amount of GkNSAAR used by the HFA tandem. Since it has previously been shown that the limiting step of the reaction in this process is the GkNSAAR enzyme (Soriano-Maldonado et al. 2014), reactions carried out with the A161 tandem should prove approximately four times faster than with the HFA tandem, and Tables 1 and 2 show that this is the case. Reuse of the HFA-BsLcar/HFA-GkNSAAR showed that enzymatic activity was almost totally lost after 4 cycles (Fig. 3). This drawback considerably diminishes the likelihood of a putative industrial application of this support. On the other hand, our results showed that recycling of the A161-BsLcar/A161-GkNSAAR tandem was possible, retaining more than 75 % of its conversion capability after 10 reaction cycles.

The immobilization of GkNSAAR resulted in approximately a fourfold decrease in its specific activity when compared to the enzyme in solution, but with an increased stability in terms of half-life. Similar results were obtained when Deinococcus radiodurans NSAAR (DraNSAAR) was immobilized, resulting in a 90 % decrease of its specific activity (Yen et al. 2010). Regarding l-carbamoylases, previous studies have shown that immobilization of the enzymes from Arthrobacer and Bacillus genera has resulted in a substantial decrease in their specific activity (Ragnitz et al. 2001a, b; Yen et al. 2010; Nandanwar et al. 2013), except in the case of a recombinant (Asp)6-tagged l-carbamoylase from Arthrobacter (AauBLcar), which maintained similar activities to the enzyme in solution (Ragnitz et al. 2001a, b). BsLcar could also be reused for several cycles as other Bacillus l-carbamoylases, maintaining similar significant half-lives (Nandanwar et al. 2013; Yen et al. 2010). Unexpectedly, BsLcar activity toward N-formyl-l-tryptophan was greatly enhanced (approx. 500 times; Table 2) when using the A161 support. Whereas this phenomenon has been observed for other biotechnologically relevant enzymes such as lipases (Rodrigues et al. 2013), this is the first evidence showing that the substrate spectrum of l-carbamoylases can be altered via immobilization. Thus, and although additional studies are mandatory to ascertain whether this property can be generalized to other l-carbamoylases, our results suggest that the substrate spectrum of l-carbamoylases could also be enhanced by an immobilization procedure.

Whereas alternative l-carbamoylase/NSAAR biocatalysts have been used only for the synthesis of l-homophenylalanine (Hsu et al. 2007; Yen et al. 2010; Nandanwar et al. 2013), the BsLcar/GkNSAAR tandem is the first l-carbamoylase/NSAAR biocatalyst shown to produce different optically pure amino acids (e.e. >99.5 %) starting from different racemic N-substituted amino acids (Tables 1 and 2). The immobilized system had a productivity of 16 mmol l-norleu L−1 h−1 (yield >99 %; e.e. >99.5 %), showing no inhibition at high concentrations of substrate or product (Fig. 4), which is a prerequisite to scale it up to an analytical or industrial scale. In this work, we also show that this amino acid can be readily crystallized with a reaction yield of over 80 %. This productivity is higher than that reported for the other l-carbamoylase/NSAAR systems (Hsu et al. 2007; Yen et al. 2010). Furthermore, the BsLcar/GkNSAAR tandem presents higher yields and enantiomeric excess than other methods used for l-homophenylalanine biosynthesis (Ahmad et al. 2010; Vaidya et al. 2012). l-ABA production also proved more simple and with similar or even higher productivity when compared to other methods using enzymatic cascades such as l-threonine deaminase/l-leucine dehydrogenase/formate dehydrogenase (Tao et al. 2013) or l-threonine deaminase/aromatic aminotransferase/acetolactate synthase/alanine racemase/d-amino acid oxidase (Zhu et al. 2011).

Whereas the economic aspects of the immobilization process need to be studied, in this work, we show an effective immobilized bienzymatic system for the biosynthesis of optically pure (e.e. >99.5 %) unnatural l-α-amino acids such as l-phenylglycine, l-homophenylalanine, l-aminobutyric acid, and l-norleucine, among others. Interestingly, the immobilization process resulted in a great enhancement of the activity of BsLcar toward N-formyl-tryptophan, enhancing the substrate spectrum to be used with this system. The shelf life of both enzymes was greatly enhanced when immobilized. Biocatalyst reuse was studied, and over 75 % of activity remained after 10 reaction cycles.

Notes

The pH of the solution was readjusted with NaOH after dissolution of the substrate.

The ratio of the immobilized BsLcar/GkNSAAR enzymes in terms of their activity was approximately 10:1.

Twenty-five milligrams of the A161 matrix was selected as the minimum amount to be used reproducibly.

References

Ahmad AL, Oh PC, Abd Shukor SR (2010) Synthesis of L-homophenylalanine via integrated membrane bioreactor: influence of pH on yield. Biochem Eng J 52:296–300

Altenbuchner J, Siemann-Herzberg M, Syldatk C (2001) Hydantoinases and related enzymes as biocatalysts for the synthesis of unnatural chiral amino acids. Curr Opin Biotechnol 12:559–563

Asano Y (2007) Enzymes acting on D-amino acid amides. In: Konno R, Brückner H, D’Aniello A, Fisher GH, Fujii N, Homma H (eds) D-amino acids: a new frontier in amino acid and protein research—practical methods and protocols. Nova Biomedical Books, New York, pp 579–589

Boyd WJ (1933) The isolation of amino-acids in the form of the corresponding carbamido-acids and hydantoins. Biochem J 27:1838–1848

Breuer M, Ditrich K, Habicher T, Hauer B, Kesseler M, Stürmer R, Zelinski T (2004) Industrial methods for the production of optically active intermediates. Angew Chem Int Ed Engl 43788-824

Fazary AE, Hernowo E, Angkawijaya AE, Chou T-C, Lin CH, Taha M, Ju Y-H (2011) Complex formation between ferric(III), chromium(III), and cupric(II) metal ions and (O, N) and (O, O) donor ligands with biological relevance in aqueous solution. J Solut Chem 40:1965–1986

Garcia-Galan C, Berenguer-Murcia A, Fernandez-Lafuente R, Rodrigues RC (2011) Potential of different enzyme immobilization strategies to improve enzyme performance. Adv Synth Catal 353:2885–2904

Gotor V, Flitsch S (2011) Increasing the diversity of biocatalytic reactions. Curr Opin Chem Biol 15:185–186

Gutierrez M, Choi MH, Tian B, Xu J, Rho JK, Kim MO, Cho YH, Yoon SC (2013) Simultaneous inhibition of rhamnolipid and polyhydroxyalkanoic acid synthesis and biofilm formation in Pseudomonas aeruginosa by 2-bromoalkanoic acids: effect of inhibitor alkyl-chain-length. PLoS One 8:e73986. doi:10.1371/journal.pone.0073986

Hsu S, Lo H, Lin W, Chen I, Kao C, Hsu W (2007) Stereoselective synthesis of L-homophenylalanine using the carbamoylase method with in situ racemization via N-acylamino acid racemase. Process Biochem 42:856–862

Huerta FF, Minidis ABE, Bäckvall J-E (2001) Racemisation in asymmetric synthesis. Dynamic kinetic resolution and related processes in enzyme and metal catalysis. Chem Soc Rev 30:321–331

Hussenet P, Le Goff P, Sennyeey G, Vincent CH (2001) Process for producing N-formylleucine of high purity. US Patent 6294692.

Johnson AL, Price WA, Wong PC, Vavala RF, Stump JM (1985) Synthesis and pharmacology of the potent angiotensin-converting enzyme inhibitor N-[1(S)-(ethoxycarbonyl)-3-phenylpropyl]-(S)-alanyl-(S)-pyroglutamic acid. J Med Chem 28:1596–1602

Kircher M (2012) How to turn industrial biotechnology into reality. New Biotechnol 29:243–247

Leuchtenberger W, Huthmacher K, Drauz K (2005) Biotechnological production of amino acids and derivatives: current status and prospects. Appl Microbiol Biotechnol 69:1–8

Liu CC, Schultz PG (2010) Adding new chemistries to the genetic code. Annu Rev Biochem 79:413–444

Martínez-Rodríguez S, Martínez-Gómez AI, Rodríguez-Vico F, Clemente-Jiménez JM, Las Heras-Vázquez FJ (2010) N-Carbamoyl-D- and L-amino acid amidohydrolases: characteristics and applications in biotechnological processes. Appl Microbiol Biotechnol 85:441–458

May O, Verseck S, Bommarius A, Drauz K (2002) Development of dynamic kinetic resolution processes for biocatalytic production of natural and nonnatural L-amino acids. Org Process Res Dev 6:452–457

Nandanwar HS, Vohra RM, Hoondal GS (2013) Enhanced stability of newly isolated trimeric L-methionine-N-carbamoylase from Brevibacillus reuszeri HSN1 by covalent immobilization. Biotechnol Appl Biochem 60:305–315

Pollegioni L, Servi S (2012) Unnatural amino acids: methods and protocols. Methods in molecular biology 794. Humana Press

Pozo-Dengra J, Martínez-Gómez AI, Martínez-Rodríguez S, Clemente-Jiménez JM, Rodríguez-Vico F, Las Heras-Vázquez FJ (2009) Racemization study on different N-acetylamino acids by a recombinant N-succinylamino acid racemase from Geobacillus kaustophilus CECT4264. Process Biochem 44:835–841

Pozo-Dengra J, Martínez-Gómez AI, Martínez-Rodríguez S, Clemente-Jiménez JM, Rodríguez-Vico F, Las Heras-Vázquez FJ (2010) Evaluation of substrate promiscuity of an L-carbamoyl amino acid amidohydrolase from Geobacillus stearothermophilus CECT43. Biotechnol Prog 26:954–959

Ragnitz K, Pietzsch M, Syldatk C (2001a) Immobilization of the hydantoin cleaving enzymes from Arthrobacter aurescens DSM 3747. J Biotechnol 92:179–186

Ragnitz K, Syldatk C, Pietzsch M (2001b) Optimization of the immobilization parameters and operational stability of immobilized hydantoinase and L-N-carbamoylase from Arthrobacter aurescens for the production of optically pure L-amino acids. Enzyme Microb Technol 28:713–720

Rodrigues RC, Ortiz C, Berenguer-Murcia Á, Torres R, Fernández-Lafuente R (2013) Modifying enzyme activity and selectivity by immobilization. Chem Soc Rev 42:6290–6307

Sheldon RA (2007) Enzyme immobilization: the quest for optimum performance. Adv Synth Catal 349:1289–1307

Simmons WH (2008) Thio-containing inhibitors of aminopeptidase P, and compositions thereof. US Patent 7390789:B2

Soriano-Maldonado P, Rodríguez-Alonso MJ, Hernández-Cervantes C, Rodríguez-García I, Clemente-Jiménez JM, Rodríguez Vico F, Martínez-Rodríguez S, Las Heras-Vázquez FJ (2014) Amidohydrolase process: expanding the use of L-N-carbamoylase/N-succinnyl-amino acid racemase tandem for the production of different optically pure L-amino acids. Process Biochem. doi:10.1016/j.procbio.2014.04.013

Tao R, Jiang Y, Zhu F, Yang S (2013) A one-pot system for production of L-2-aminobutyric acid from L-threonine by L-threonine deaminase and a NADH-regeneration system based on L-leucine dehydrogenase and formate dehydrogenase. Biotechnol Lett. doi:10.1007/s10529-013-1424-y

Vaidya BK, Kuwar SS, Golegaonkar SB, Nene SN (2012) Preparation of cross-linked enzyme aggregates of L-aminoacylase via co-aggregation with polyethyleneimine. J Mol Catal B Enzym 74:184–191

Yen M-C, Hsu W-H, Lin S-C (2010) Synthesis of L-homophenylalanine with immobilized enzymes. Process Biochem 45:667–674

Zhang KH, Li K, Cho M, Liao JC (2010) Expanding metabolism for total biosynthesis of the nonnatural amino acid L-homoalanine. Proc Natl Acad Sci U S A 107:6234–6239

Zhang WH, Otting G, Jackson CJ (2013) Protein engineering with unnatural amino acids. Curr Opin Struct Biol 23:581–587

Zhu L, Tao R, Wang Y, Jiang Y, Lin X, Yang Y, Zheng H, Jiang W, Yang S (2011) Removal of L-alanine from the production of L-2-aminobutyric acid by introduction of alanine racemase and D-amino acid oxidase. Appl Microbiol Biotechnol 90:903–910

Acknowledgments

This work was supported by the Spanish Ministry of Education and Science, the European Social Fund (ESF), and the European Regional Development Fund (ERDF), through project BIO2011-27842, by the Andalusian Regional Council of Innovation, Science and Technology, through project TEP-4691, and by the European Cooperation in Science and Technology (COST) Action CM1303. P.S.-M. was supported by the University of Almería. S.M.-R. was supported by the Spanish Ministry of Science and Innovation. We thank Andy Taylor for critical discussion of the manuscript and Pedro Madrid-Romero for technical assistance. We also thank Carmen Hernández-Cervantes for assistance with the polarimetry measurements.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 162 kb)

Rights and permissions

About this article

Cite this article

Soriano-Maldonado, P., Las Heras-Vazquez, F.J., Clemente-Jimenez, J.M. et al. Enzymatic dynamic kinetic resolution of racemic N-formyl- and N-carbamoyl-amino acids using immobilized l-N-carbamoylase and N-succinyl-amino acid racemase. Appl Microbiol Biotechnol 99, 283–291 (2015). https://doi.org/10.1007/s00253-014-5880-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5880-7