Abstract

Enzymatic kinetic resolution is a widely used biotechnological tool for the production of enantiomerically pure/enriched compounds. This technique takes advantage of the enantioselectivity or enantiospecificity of an enzyme for one of the enantiomers of a racemic substrate to isolate the desired isomer. N-Carbamoyl-d- and l-amino acid amidohydrolases (d- and l-carbamoylases) are model enzymes for this procedure due to their strict enantiospecificity. Carbamoylase-based kinetic resolution of amino acids has been applied for the last three decades, allowing the production of optically pure d- or l-amino acids. Furthermore, this enzyme has become crucial in the industrially used multienzymatic system known as “Hydantoinase Process,” where the kinetic resolution produced by coupling an enantioselective hydantoinase and the enantiospecific carbamoylase is enhanced by the enzymatic/chemical dynamic kinetic resolution of the low-rate hydrolyzed substrate. This review outlines the properties of d- and l-carbamoylases, emphasizing their biochemical/structural characteristics and their biotechnological applications. It also pinpoints new applications for the exploitation of carbamoylases over the forthcoming years.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymes comprised in E.C. 3.5.1. act on carbon–nitrogen bonds in linear amides. Among these hydrolases, several enzymes present a common hydrolyzing function on carbamoyl derivatives of amines. d- and l-N-carbamoyl-amino acid amidohydrolases (d-carbamoylase, E.C. 3.5.1.77; l-carbamoylase, 3.5.1.87) hydrolyze enantiospecifically the amide bond of the carbamoyl group in d- or l-N-carbamoyl-amino acids, respectively, yielding the corresponding enantiomerically pure amino acid, ammonia, and CO2 (Fig. 1). Both enzymes attracted the attention of the scientific community because of their steorespecificity and substrate promiscuity, characteristics of considerable interest in the field of kinetic resolution, which allowed these enzymes to be widely used in industrial manufacturing processes (May et al. 2002; Clemente-Jiménez et al. 2008). Due to the interest in their biotechnological applications, little attention has been paid to other characteristics which might be interesting to understand the evolution of these enzymes and for new applications in the field of amino acid production.

This review aims to provide an overview of the research carried out on d- and l-carbamoylases over recent decades. Firstly, we will discuss the biochemical properties of both enzymes. The second section will be devoted to structural features of carbamoylases, using the sequence and structural information available, to enlighten their evolutionary relationship with other amidohydrolases. The third and final part highlights different ways in which carbamoylases are, or can be exploited for the biotechnological production of amino acids, thus providing a global idea of the versatility of these enzymes for industrial application.

Enzymatic properties

d-Carbamoylases

To the best of our knowledge, in 1979, Olivieri et al. made the first mention in the literature of an isolated d-carbamoylase, belonging to the genus Agrobacterium. In the same work, they already proposed its use together with a hydantoinase “to develop a one-step process for the preparation of D-amino acids.” Besides Agrobacterium enzymes (Hils et al. 2001; Louwrier and Knowles 1996; Nanba et al. 1998; Sareen et al. 2001), other organisms in which d-carbamoylases have been reported are Arthrobacter (Möller et al. 1988), Blastobacter (Ogawa et al. 1994), Comamonas (Ogawa et al. 1993), Pseudomonas (Yokozeki and Kubota 1987; Ikenaka et al. 1998c), Sinorhizobium (Wu et al. 2006), Flavobacterium, and Pasteurella (Nozaki et al. 2005). Moreover, a recent paper shows new organisms which are able to convert 5-monosubstituted hydantoins to the corresponding d-amino acids, highlighting that these genera might also contain a d-carbamoylase: Brevibacillus, Empedobacter, Microbacterium, and Staphylococcus (Mei et al. 2007). Particularly noteworthy is the work carried out by Dorrington’s group, in which they experimentally show the presence of two distinct enzymes with d-carbamoylase activity in the same organism for the first time (AtuC1 and AtuC2, Jiwaji et al. 2009). d-Carbamoylases optimum pH has been found in the range of 7.0 to 9.0, and they are generally known not to be thermostable (Table 1); in fact, the most thermostable enzyme found to date is the one from Pseudomonas sp. KNK003A, which retained 50% of residual activity after 20-min incubation at 73°C. Optimum reaction rates are found between 40°C (Comamonas sp., Ogawa et al. 1993) and 70°C (Agrobacterium sp., Louwrier and Knowles 1996). d-Carbamoylases are inhibited by metal ions and sulphydryl reagents; they are not affected by chelating agents, and they are reactivated by treating with reducing agents (Table 1). These characteristics suggested that cations were not necessary for enzymatic activity and that cysteine residues were involved in catalysis. The latter was firstly supported by oxidative susceptibility and mutagenesis studies of Agrobacterium d-carbamoylase (Grifantini et al. 1996). Subsequently, X-ray structures of the enzyme would completely confirm this hypothesis (see below).

d-Carbamoylases present broad substrate specificity, with affinity toward different N-carbamoyl-d-amino acids in the millimolar range (Tables 1 and 2). It is difficult to establish a classification based on the kind of N-carbamoyl-amino acids hydrolyzed, although there seems to be a tendency toward long aliphatic (N-c-Met and N-c-norleucine) and phenylalanine derivatives (N-c-phenylglycine (N-c-PG) and N-c-para-hydroxy-phenylglycine (N-c-pHPG), whereas charged/polar amino acids are not good substrates (N-c-Ser, N-c-Thr, N-c-Asp). Activity toward other N-substituted amino acids (N-acetyl or N-formyl derivatives, Table 1) was negative for Agrobacterium, Comamonas, or Blastobacter enzymes (Nanba et al. 1998; Ogawa et al. 1993, 1994; Olivieri et al. 1979; Sareen et al. 2001), contrary to what is observed for l-carbamoylases.

Inhibition of d-carbamoylases has been reported by (1) substrates, (2) substrate analogs, (3) reaction products, and (4) reaction product analogs. Louwrier and Knowles (1996) showed that Agrobacterium sp. d-carbamoylase was inhibited by the substrate N-c-d-pHPG at high concentrations (Ksi 50.3 mM) and by ammonium, one of the spontaneous decomposition products of the reaction. The latter is described as an inhibitor for d-carbamoylases from Agrobacterium (Nanba et al. 1998), Blastobacter (Ogawa et al. 1994), and Comamonas (Ogawa et al. 1993). The reaction product d-Phe slightly inhibited Comamonas d-carbamoylase (Ogawa et al. 1993), whereas l-Phe, l-Ala, N-acetyl-d-Phe, or N-acetyl-d,l-Met did not. Blastobacter d-carbamoylase was also inhibited by d-Phe, and in this case, an N-l-carbamoyl-amino acid derivative inhibited the reaction (N-c-l-Phe) (Ogawa et al. 1994). Agrobacterium enzyme was inhibited by N-c-l-PG (Olivieri et al. 1979), with a Ki value of 2.5 × 10−3 M, thus indicating strong inhibition compared to the substrate.

l-Carbamoylases and β-ureidopropionases with l-carbamoylase activity

Lieberman and Kornberg (1954) found that Zymobacterium (Clostridium) oroticum was able to hydrolyze l-ureidosuccinate (N-carbamoyl-l-aspartic acid) to l-aspartic acid. Although they named this enzyme ureidosuccinase, this is the only reported ureidosuccinase in the literature, and it might be the first l-carbamoylase described. However, it was not until in the late 1980s that other researchers focused their attention on these enzymes (Yamashiro et al. 1988b; Yokozeki and Kubota 1987; Yokozeki et al. 1987a), due to the ability of Bacillus, Pseudomonas, and Flavobacterium microorganisms to produce optically pure amino acids from their corresponding carbamoylated cyclic amides (hydantoins). Other genera in which l-carbamoylase activity has been detected are Alcaligenes (Ogawa et al. 1995), Arthrobacter (Wilms et al. 1999), Blastobacter (Yamanaka et al. 1997), Microbacterium (Suzuki et al. 2005), and Sinorhizobium (Martínez-Rodríguez et al. 2005). Furthermore, two β-ureidopropionases have been shown to be active toward N-carbamoyl-l-α-amino acids (Ogawa and Shimizu 1994; Martínez-Gómez et al. 2009). In their search for new organisms with hydantoinase and carbamoylase activity, Mei et al. (2007) have shown that Kurthia, Brevibacillus, and Aneurinibacillus genera present l-carbamoylase activity. Bacillus-related l-carbamoylases are the most studied of these enzymes (Batisse et al. 1997; Hu et al. 2003; Ishikawa et al. 1994; Yamashiro et al. 1988b).

The pH interval for optimal activity of l-carbamoylases with known activity ranges from 7.0 to 9.0, and the temperatures at which maximum conversion rates are observed range from 30°C to 70°C. The studied enzymes present low thermostability in general, although Bacillus kaustophilus l-carbamoylase retained its activity at 50°C for at least 15 days in the presence of Mn2+ and even up to 36 days at the same temperature with the addition of d- or l-carbamoyl substrates (Hu et al. 2003). l-Carbamoylases are metalloenzymes, as several divalent cations (particularly Mn2+ and Co2+, see Table 3) greatly enhance their activity, and chelating agents such as EDTA inhibit their catalysis. Sulphydryl reagents affect the activity of these enzymes, although no cysteine seems to be directly involved in catalytic activity (see discussion below), thus suggesting a putative structural role. Carbonyl groups have also been shown to be involved in catalysis/structure, as carbonyl-blocking reagents also diminished the activity of the enzyme (Ogawa et al. 1995; Ogawa and Shimizu 1994).

The substrate spectrum seems to be even broader than that of d-carbamoylases, although at the same affinity levels (millimolar range, Tables 3 and 4). On the other hand, substrate promiscuity is even greater for l-carbamoylases: they often hydrolyze not only the N-carbamoyl moiety of amino acids, but also the N-formylated and N-acetylated species (Table 4). Authors have tried to classify the enzymes as (1) aliphatic, (2) aromatic, or (3) with no clear preference for aliphatic/aromatic substrates (Table 4). However, the more enzymes are studied, the more difficult it becomes to determine a clear tendency.

The inhibition of l-carbamoylases by substrate, products, substrate/product analogs, or by compounds other than those discussed above, has not been studied as much as the inhibition of d-carbamoylases. The most studied enzymes in this field are the homolog β-ureidopropionases from Pseudomonas putida and Agrobacterium tumefaciens (Ogawa and Shimizu 1994; Andújar-Sánchez et al. 2009). The former was inhibited by nonhydrolyzed N-carbamoyl-amino acids (N-c-l-Leu, N-c-l-Phe, and N-c-d-Ala) and reaction products (β-Ala and l-Ala). Sinorhizobium meliloti enzyme binds several N-carbamoyl-d-amino acids (N-c-d-Trp, N-c-d-Met, N-c-d-pHPG; Martínez-Rodríguez et al. 2006), but inhibition by these compounds has not been studied; on the other hand, Alcaligenes enzyme is not inhibited by N-c-d-Ala or N-c-d-Val (Ogawa et al. 1995). Glycine buffer decreased the activity of B. kaustophilus enzyme (Hu et al. 2003), and this was also observed for A. tumefaciens β-ureidopropionase (Martínez-Gómez et al. 2009). Together with the inhibition caused by l-alanine in the β-ureidopropionase from P. putida (see above), this might indicate product inhibition for these enzymes, though more studies must be carried out to confirm this. Reaction product analogs such as propionate and other organic acids are inhibitors of β-ureidopropionases with l-carbamoylase activity (Ogawa and Shimizu 1994; Andújar-Sánchez et al. 2009), but as far as we know, only propionate has been tested and proved as an inhibitor with a “strict” l-carbamoylase from Alcaligenes (Ogawa et al. 1995). The latter was also inhibited when treated by serine–protease inhibitors (phenylmethylsulfonyl fluoride, diisopropyl fluorophosphate), whereas Pseudomonas sp. NS671 l-carbamoylase, was inhibited by ATP (Ishikawa et al. 1996).

Structural features of d- and l-carbamoylases

d-Carbamoylases

A primary sequence comparison between d-carbamoylases with proven activity (Fig. 2) shows sequence homology of over 90% for those from Agrobacterium and Sinorhizobium (except the second paralog belonging to the same genus, AtuC2); those from Flavobacterium and Pasteurella show similarities of 80%, while those from Pseudomonas, Arthrobacter, and AtuC2 are less similar. Experimental relative molecular masses of d-carbamoylase monomers range between 32 and 40 kDa, whereas the native enzymes vary from 67 to 150 kDa; dimeric, trimeric, and tetrameric quaternary structures have been suggested in the literature as the native form presented by these enzymes (Table 1). The involvement of thiol groups in d-carbamoylase activity was soon discovered (Olivieri et al. 1979) and was further supported by oxidative susceptibility of these enzymes, sequence analysis, and mutagenesis experiments (Grifantini et al. 1996). Crystal structures of two Agrobacterium d-carbamoylases confirmed it and pinpointed the existence of a catalytic C–E–K (Cys–Glu–Lys) involved in catalytic activity (Nakai et al. 2000; Wang et al. 2001). A DALI search (Holm et al. 2008) with one of these structures (Protein Data Bank (PDB) 1FO6) reveals that d-carbamoylase shares 10–30% sequence similarity with several putative and active-proven C–N hydrolases, among them, β-ureidopropionase from Drosophila melanogaster (PDB 2VHH, Lundgren et al. 2008), aliphatic amidases from Pseudomonas aeuroginosa (PDB 2UXY, Andrade et al. 2007) and Geobacillus pallidus (PDB 2PLQ, Agarkar et al. 2006), and formamidase from Helicobacter pyroli (PDB 2DYU, Hung et al. 2007). They belong to one of the branches of the nitrilase superfamily, sharing a common structural framework constituted by (1) an α-β-β-α fold and (2) an α-β-β-α:α-β-β-α dimerization arrangement, though d-carbamoylase is not necessarily a dimer in its native form (Table 1). This core contains a completely conserved catalytic C–E–K triad, highlighting a putative divergent evolution from a common ancestor.

Amino acid sequence alignment of d-carbamoylases with proven activity generated with the Espript software (Gouet et al. 1999), using the CLUSTALW alignment as input, together with PDB 1FO6. d-Carbamoylases belonging to Agrotu Agrobacterium tumefaciens GenBank ID Q44185, AspKNK Agrobacterium sp. (strain KNK712) GenBank ID P60327, AspIP Agrobacterium sp. IP I-671 GenBank ID Q8VT65, AtuC1 Agrobacterium tumefaciens HyuC1 GenBank ID ABS11193, AtuC2 Agrobacterium tumefaciens HyuC2 GenBank ID ABS11194, Sinomo Ensifer adhaerens (Sinorhizobium morelens) GenBank ID AAV53595, Pseusp Pseudomonas sp. KNK003A GenBank ID BAD00008, Flavsp Flavobacterium sp. AJ11199 translated from GenBank ID AR890757, Pastpn Pasteurella sp. AJ11221 translated from GenBank ID AR930237, Arthcr Arthrobacter crystallopoietes GenBank ID AAO24770. CEK triad (asterisks), substrate binding residues according to PDB 1UF5, Hashimoto et al., unpublished results (crosses), residues which have been mutated to study thermostability and/or oxidative susceptibility (dollar signs)

The reaction mechanism of the conserved C–E–K triad (Fig. 2) seems to take place via an acylation–deacylation process (Wang et al. 2001), and this has been further confirmed by experimental X-ray structures of d-carbamoylase mutants cocrystallized with several substrates (unpublished results, PDB 1UF4, 1UF7, and 1UF8; Fig. 3). Cys acts as a nucleophile; Lys stabilizes the transition state intermediate, whereas Glu has a two-task proton shuffle role. To explain this in greater detail, acylation occurs when the carbonyl carbon of the carbamoyl moiety is attacked by the preactivated thiol group (formed after abstraction of the S–H proton, by the carboxy group of the catalytic glutamate). Reaction takes place mediated by a tetrahedral intermediate where the conserved Lys would stabilize the formed oxyanion adduct of the reaction, after which a molecule of NH3 is liberated (expected to be accompanied by protonation of the amine group by the conserved Glu); the deacylation process then occurs, by the nucleophilic attack of a water molecule (which might be activated by deprotonation, once again by the conserved Glu). The reaction finishes by spontaneous decomposition of the N-carboxy-α-amino acid to the corresponding amino acid and CO2.

C171A/V236A d-carbamoylase mutant structure from Agrobacterium sp., complexed with the substrate N-carbamoyl-d-methionine (PDB 1UF5, Hashimoto et al., unpublished results). Surface representation of the dimeric structure where the catalytic cleft can be observed (left). Catalytic center of the enzyme (right ), where the substrate binding residues and their corresponding interactions can be visualized, together with the C–E–K triad (in this structure, Cys171 is mutated to Ala171; the catalytic triad is formed by Cys171–Glu46–Lys126). NcDMet N-carbamoyl-d-methionine (CPK code). Manual modeling and image creation was performed using PyMOL (DeLano 2002)

l-Carbamoylases

Despite their similar activities, d- and l-carbamoylases are structurally unrelated, with sequence identities lower than 15%. Amino acid sequence analysis of l-carbamoylases with proven activity shows sequence similarities over 90% for enzymes belonging to Bacillus genus, decreasing in the rest of the cases to 25–45% (Fig. 4). When compared to β-ureidopropionases from Saccharomyces and Agrobacterium genera, values range between 27% and 39%, except for that of Sinorhizobium, which has the highest similarity to Agrobacterium β-ureidopropionase (80%). l-Carbamoylases are described as homodimers, except for the one belonging to Pseudomonas sp. ON-4, which presents a homotetrameric species (Ohmachi et al. 2004; Table 3). Their monomeric relative molecular mass is around 45 kDa in all cases except for Alcaligenes, which was determined as 65 kDa (Ogawa et al. 1995). Ogawa et al. and Ishikawa et al. demonstrated the cation requirement of l-carbamoylases in 1995 and 1996, respectively. Whether the metal was structurally or catalytically related was not known until 2006, when a bimetallic center was found conserved between a large set of carbamoyl-amidohydrolases (Martínez-Rodríguez et al. 2006; Fig. 5). Based on the comparison of their amino acid sequences and the preliminary crystallographic data of l-carbamoylase from Bacillus stearothermophilus CECT43 (Martínez-Rodríguez et al. 2008), l-carbamoylases belong to the peptidase family M20/M25/M40. They share a common scaffold with allantoate-amidohydrolase (PDB 1Z2L, Agarwal et al. 2007), β-alanine synthase (PDB 1R3N, Lundgren et al. 2003), carboxypeptidase G2 (PDB 1CG2, Rowsell et al. 1997), peptidase T (PDB 1FNO, Håkansson and Miller 2002), and peptidase V (PDB 1LFW, Jozic et al. 2002). This common architecture is formed by two domains which are known as (1) “catalytic” and (2) “lid” or “dimerization” domains. The catalytic domain is larger and contains the metal binding and hydrolysis-responsible residues (Martínez-Rodríguez et al. 2006). This catalytic domain must accomplish large-scale rearrangements toward the dimerization domain for substrate hydrolysis, in order to allow the carbamoyl moiety of the substrate to enter the catalytic center.

Amino acid sequence alignment of l-carbamoylases and β-ureidopropionases with proven activity toward l-α-carbamoyl-amino acids, generated with the Espript software (Gouet et al. 1999), using the CLUSTALW alignment as input together with PDB 1R3N. SklBup Saccharomyces kluyveri β-ureidopropionase GenBank ID Q96W94, AtuBup Agrobacterium tumefaciens β-ureidopropionase GenBank ID A4ZZ71, BacKau Bacillus kaustophilus CCRC1123 GenBank ID Q8GQG5, BacstNS Bacillus stearothermophilus NS1122A GenBank ID Q53389, BacstNCIB Bacillus stearothermophilus NCIB8224 GenBank ID P37113, ArtAur Arthrobacter aurescens DSM 3747 GenBank ID Q9F464, PsespNS, Pseudomonas sp. NS761 GenBank ID Q01264, PsespON Pseudomonas sp. ON-4a GenBank ID Q9FB05, Sinmel Sinorhizobium meliloti CECT 4114 GenBank ID Q92MZ4. Residues forming the conserved bimetallic center (asterisks), substrate binding and hydrolysis residues (crosses)

Bimetallic center present in l-carbamoylases and other members of the peptidase M20/M25/M40 family. Superposition of the bimetallic centre of l-N-carbamoylase model (up) from Sinorhizobium meliloti CECT4114 (Sinmel, orange), β-ureidopropionase from Saccharomyces kluyveri (SklBup, gray, PDB 1R3N), carboxypeptidase G2 from Pseudomonas sp. (CPG2, cyan, PDB 1CG2), peptidase V from Lactobacillus delbrueckii (PePV, pink, PDB 1LFW), peptidase T from Salmonella typhimurium (PepTSt, green, PDB 1FNO), and allantoate amidohydrolase from Escherichia coli (EcAam, blue, PDB ID 1Z2L). The original numbering of metal atoms from the X-ray structures has been changed in order to compare similar residues. Manual model building of the structures and image creation was performed with PyMOL (DeLano 2002). Corresponding residues in each enzyme (down), also showing the conservation of the general base (Glu) used to activate the hydroxyl group which hydrolyzes the substrate

The involvement of several residues in substrate recognition (Fig. 4) and more concretely a key role for a conserved Arg in the dimerization domain both in l-carbamoylases and β-ureidopropionases were highlighted recently (Martínez-Rodríguez et al. 2006; Andersen et al. 2008). This conserved Arg binds the carboxyl group of N-carbamoyl-amino acids in a previous step of the substrate hydrolysis (Fig. 6a, b). After binding, large-scale movements of the enzyme were hypothesized to occur, allowing the ureido group of the substrate to reach the bimetallic center site (Martínez-Rodríguez et al. 2006). This was further confirmed by the crystalline structure of Saccharomyces kluyveri β-ureidopropionase homolog bound to the substrate and reaction product (Andersen et al. 2008). Activation of a water molecule by a proton shuffle glutamic residue (Fig. 6b), (also conserved in the homologous enzymes, Figs. 4 and 5) then occurs, forming a hydroxyl group which produces a nucleophilic attack on the carbonyl carbon in the carbamoyl group. This produces the hydrolysis of the carbon–nitrogen bond, and the subsequent release of the reaction product, ammonia, and carbon dioxide (produced by spontaneous decomposition of the carbamoyl group) allows the cycle to start again (Fig. 6b, c).

Natural function of d- and l-carbamoylases: are we biased by their industrial application?

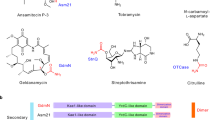

There is a degree of uncertainty as to the natural function of both enzymes. As carbamoylases are principally studied due to their ability to produce optically pure amino acids from cheap precursors in industrial applications, most of the research focuses on N-carbamoyl-α-amino acids as substrates. Furthermore, their functions have been frequently associated to hydantoinases/dihydropyrimidinases, as these enzymes provide the linear N-carbamoyl-α-amino acid starting from the cyclic amide known as hydantoin, and the genes encoding for hydantoinases/dihydropyrimidinases and carbamoylases normally appear in a cluster at the genetic level (Fig. 7). This, together with the work carried out by Taillades et al. (1998), who proved that formation of hydantoins and N-carbamoyl-α-amino acids in the primitive hydrosphere was more favored than the formation of free amino acids, led Syldatk et al. (1999) to speculate that “primitive microorganisms on earth may have been able to use hydantoins and N-carbamoyl-α-amino acids as C and/or N sources, by evolving a hydantoinase and a carbamoylase.” In this sense, these enzymes would constitute two alternative routes to produce d- or l-amino acids for the cell starting from monosubstituted hydantoins.

Different genetic organizations found for d- and l-carbamoylases (and β-ureidopropionases) with respect to a hydantoinase/dihydropyrimidinase in different microorganisms. a Arthrobacter aurescens, Microbacterium liquefaciens, and Delftia sp. b Brevibacillus agri. c Ochrobactrum sp. and Sinorhizobium meliloti. d Agrobacterium sp. KNK712 and IP I-671 and Agrobacterium tumefaciens. e Pseudomonas putida RU-KM3S. f Arthrobacter crystallopoietes (Dürr et al. 2008 and Clemente-Jiménez et al. 2008, and references therein for further details)

So far, everything fits, and it is perfectly understandable that carbamoylases could constitute part of an alternative ancestral route to produce α-amino acids for the cells. However, such a conclusion might convert this topic into a more difficult question if we try to account for all the information known about: (1) the natural function of hydantoinases/dihydropyrimidinases and their relationship with carbamoylases, (2) the genetic organization of carbamoylases, (3) amino acid sequences and structural topology of d- and l-carbamoylases, and (4) the substrate specificity of carbamoylases. As this is not the first case in which enzymes have been industrially applied before their natural function has been demonstrated, we will try to summarize all this information, although it is difficult to establish a firm conclusion from it.

Genetic organizations of hydantoinases/dihydropyrimidinases and d- and l-carbamoylases occur commonly in a cluster, as also occurs with dihydropyrimidinase and β-ureidopropionase (Fig. 7; Clemente-Jiménez et al. 2008; Dürr et al. 2008, and references therein); whether hydantoinases and dihydropyrimidinases are the same enzyme has been extensively discussed, but it seems clear nowadays that almost all the so-called hydantoinases in the literature are dihydropyrimidinasesFootnote 1, as they hydrolyze the natural substrates of this enzyme, 5,6-dihydrouracil or 5,6-dihydrothymine (EC 3.5.2.2). Dihydropyrimidinase is involved in the reductive pathway of pyrimidine degradation, catalyzing the hydrolysis of dihydrouracil and dihydrothymine to the corresponding N-carbamoyl-β-amino acids, which are further degraded to the β-amino acid by N-carbamoyl-β-alanine amidohydrolase (β-alanine synthase, β-ureidopropionase, EC 3.5.1.6). The relationship among β-ureidopropionases and carbamoylases has been shown previously (Gojkovic et al. 2001; Hu et al. 2003). Amino acid sequences and structural topologies of carbamoylases relate them to two different classes of β-ureidopropionases: D-carbamoylases would be related to a first general class, constituted by eukaryotic enzymes, whereas l-carbamoylases would be homolog to a phylogenetically different class, constituted by fungal enzymes (Hu et al. 2003; Lundgren et al. 2008). At this stage, it would be easy to think that carbamoylases and ureidopropionases might be the same enzyme, or that they are intimately related in evolution. This would be supported by the results of Matcher et al. (2004) showing that the hydantoin hydrolysis pathway in P. putida RU-KM3S is due to the appearance of dihydropyrimidinase and ureidopropionase. However, when analyzing the biochemical data available for these enzymes, it has been shown that some d- and l-carbamoylases present activity toward natural substrates of β-ureidopropionases (Louwrier and Knowles 1996; Möller et al. 1988; Yokozeki and Kubota 1987; Yokozeki et al. 1987a), but others do not (Hu et al. 2003; Ishikawa et al. 1996; Martínez-Rodríguez et al. 2005; Nanba et al. 1998; Ogawa et al. 1995; Ogawa and Shimizu 1997; Sareen et al. 2001; Wilms et al. 1999). Furthermore, some β-ureidopropionases have shown activity toward N-carbamoyl-α-amino acids (Martínez-Gómez et al. 2009; Ogawa and Shimizu 1994; Tamaki et al. 1987). Thus, a controversy arises from the biochemical data which precludes assimilating both carbamoylases and β-ureidopropionases as the same enzyme. Nevertheless, we could argue that d- and l-carbamoylases are enzymes one evolutionary step back from the two classes of β-ureidopropionases; d- and l-carbamoylases would have already evolved in some prokaryotes, becoming an alternative route for β-alanine production.

Apart from the hypothetical tasks described above, l-carbamoylases have been proposed to be detoxifying enzymes for the N-carbamoyl-l-amino acids formed between active carbamoyl groups, such as carbamoyl phosphate and amino acids present in the cell (Gojkovic et al. 2001). In this sense, the literature shows that formation of N-carbamoyl-amino acids at physiological pHs is possible, at least in humans (Kraus et al. 1998; Stark 1965). These compounds can be formed by reaction of cyanate (formed from the natural decomposition of urea) and the free amino acid. Thus, if carbamoylation can also occur in microorganism cells, l-carbamoylase enzymes could fulfill a “detoxification” task. Pseudomonas sp. strains BS and ON-4a l-carbamoylases have been described as being involved in the synthesis of l-cysteine in association with a hydrolase (l-ATCase) different to dihydropyrimidinase (Ohmachi et al. 2004). As no clear conclusions arise from the information available, further research needs to be carried out to evaluate whether the industrial application of carbamoylases in the production of optically pure amino acids has biased the determination of the natural function of these enzymes.

Protein engineering

As the “hydantoinase process” has been more widely used for the production of d-amino acids, d-carbamoylases have been studied more than l-carbamoylases. In this sense, d-carbamoylases have been engineered to increase parameters such as thermostability and oxidative resistance. Further proving the importance of Cys172 in D-carbamoylase activity, Grifantini et al. (1996) already highlighted that Cys243 and Cys279 from Agrobacterium radiobacter enzyme might be responsible for the formation of intermolecular disulfide bridges under oxidizing conditions, thus inactivating the enzyme by aggregation, although they did not carry out any stability experiments to support their hypothesis. Ikenaka et al. (1998a, b) carried out random and site-directed random mutagenesis on the d-carbamoylase from A. tumefaciens KNK712, obtaining several mutants with almost the same activity as the wild type, but improving thermostability by about 5–10°C. This increase was mainly due to the mutation of three amino acids (His57, Pro203, and Val236 according to the original nomenclature, where initial Met is not taken into account, see Fig. 2). The same mutant showed increased stability at lower and higher pH and improved resistance to oxidative inactivation. Chiang et al. (2008) evolved d-carbamoylase from A. radiobacter by DNA shuffling, obtaining several mutants with higher in vitro thermal and oxidative stability than the wild-type enzyme, mainly due to mutations of Val40, Gly75, and Val237 (Fig. 2). Other work by Roger Chien et al. (2002) showed the effect of mutating the nine methionines of the A. radiobacter enzyme (Fig. 2) by other nonoxidizable residues such as Leu and their effect on oxidative inactivation. Although only two of these mutants presented similar activities to that of the native enzyme, the other seven presenting reduced activities; they were able to prove how a single substitution of some solvent-exposed methionines resulted in proteins with higher resistance to oxidation, but with less activity (around 50% of the original). In short, a lot of information on evolving d-carbamoylases is already available to allow the scientific community to increase important properties for their industrial application.

Applications of carbamoylases: “hydantoinase process” and new trends

Optically pure amino acids are used as additives in animal and human foodstuffs, in the pharmaceutical and cosmetics industries, and as chiral synthons in organic synthesis (Clemente-Jiménez et al. 2008). Extensive knowledge of the synthesis of racemic mixtures of amino acids is available (the Strecker reaction represents one of the simplest and most economical methods for the preparation of α-amino acids), and as a general method, N-carbamoyl-amino acids can be easily produced by carbamoylation of the former using potassium cyanate (Ware 1950). Thus, both d- and l-carbamoylases per se allow kinetic resolution of racemic mixtures of N-carbamoyl-amino acids. To date, and as one of the drawbacks of kinetic resolution, “only” 50% of the racemic mixture of the carbamoyl-amino acid will be transformed in the desired compound. However, coupling of this enzyme with an enantioselective hydantoinase/dihydropyrimidinase increases the versatility of the process by (1) decreasing synthesis costs and (2) total consumption of the precursor used. This multienzymatic method is known as the “hydantoinase process,” an enzymatic cascade of reactions in use for over 30 years, but in ever-increasing demand because of the importance and new uses of the products obtained (see Altenbuchner et al. 2001; Clemente-Jiménez et al. 2008; Syldatk et al. 1999; and references therein for further insights). The “hydantoinase process” is a cheap and environment-friendly method for the potential production of any optically pure amino acid from a wide spectrum of d,l-5-monosubstituted hydantoins (Fig. 8a). It has been extensively reported in the literature and is most commonly used for the production of optically pure d-amino acids, as most hydantoinases/dihydropyrimidinases present clear d-enantioselectivityFootnote 2. This method was initially used in the manufacture of d-para-hydroxy-phenylglycine and d-phenylglycine, amino acids whose hydantoin precursors racemize rapidly under the reaction conditions, allowing total conversion to the amino acid (chemical racemization rates of several 5-monosubstituted hydantoins can be seen in Pietzsch and Syldatk 2002 or Clemente-Jiménez et al. 2008). However, the inclusion of a third enzyme (hydantoin racemase) converts this method into a dynamic kinetic resolution process, allowing the use of the nonhydrolyzed isomer of the substrate into the opposite one, achieving the total conversion of the initial racemic mixture in those cases where chemical racemization is not favored (Martínez-Rodríguez et al. 2002; Las Heras-Vázquez et al. 2003). In this sense, several natural microorganisms and recombinant systems have been developed in the last decades for the production of optically pure d-amino acids using different d-carbamoylases (Chao et al. 1999; Martínez-Gómez et al. 2007; Martínez-Rodríguez et al. 2002; Nozaki et al. 2005; Yokozeki et al. 1987b). On the other hand, although the “L-system” of the “Hydantoinase Process” is known, hydantoinases with better l-enantioselectivity are less available than d-hydantoinases (May et al. 1998; 2002, and references therein). Researchers have still tried to force the production of l-amino acids by taking advantage of the “residual” l-activity of hydantoinases together with an l-specific carbamoylase (Ishikawa et al. 1994; Kao et al. 2008; Wilms et al. 2001; Yamashiro et al. 1988a; Yokozeki et al. 1987c). As hydantoinases are able to catalyze the reverse reaction over the N-carbamoyl-d-amino acid produced, the presence of an l-carbamoylase will produce the total conversion of the precursor, although at slower rates than those for the d-system (Fig. 8a).

Different applications of d- and l-carbamoylases. a “Hydantoinase process” (d-system, dashed line; l-system, full line) b “Acylase process” (R 1 acetyl) and “Carbamoylase process” (R 1 carbamoyl; l-system, dashed line; d-system, full line) c “Modified hydantoinase process” (l-system). Hyd 5-monosubstitued hydantoin, c-aa N-carbamoyl-amino acid, ac-aa N-acetyl-amino acid, aa amino acid

However, as the above method might not be considered “ideal,” researchers have paid increasing attention in recent years to alternative methods to improve the use of l-carbamoylases, due to their versatility. Two approaches are currently being used, both of which take advantage of the enzymatic substrate promiscuity of l-carbamoylase and N-succinyl-amino acid racemase (NSAAR). Although this enzyme is more widely known as N-acetyl-amino acid racemase because of its industrial application in the “Acylase Process” (Hsu et al. 2006; May et al. 2002; Tokuyama 2001; Fig. 8b), its natural function has recently been discovered (Sakai et al. 2006). NSAAR shows large substrate promiscuity, and it is able to racemize not only N-succinyl-amino acids, but also other N-substituted-amino acids, e.g., N-acetyl- and N-carbamoyl-amino acids (Tokuyama 2001; Pozo-Dengra et al. (2009)).

The first approach derives from the “Acylase Process,” where an NSAAR is used together with an l-acylase to produce the total conversion of the N-acetyl-amino acid derivative to the corresponding optically pure amino acid (Hsu et al. 2006; May et al. 2002; Tokuyama 2001). As NSAAR presents activity toward N-carbamoyl-amino acids, its substrate promiscuity means that together with an l-carbamoylase, it can produce several optically pure amino acids: two alternative biosynthesis methods arise by combining the activities of NSAAR and l-carbamoylase (Fig. 8b), starting from N-acetyl or N-carbamoyl-amino acids. In this sense, a new field of study has arisen, as both NSAAR and l-carbamoylase substrate promiscuity require further research. Hsu et al. (2007) were the first group to present results in the literature exploiting this idea to produce l-homophenylalanine. On the basis of the substrate specificity of the NSAARs and l-carbamoylases studied in our lab, we can predict that several optically pure l-amino acids can be produced with this system.

The second method consists of a modification of the hydantoinase process, based on the same idea as described above: the dynamic kinetic resolution is produced not over the hydantoin, but over the N-carbamoyl-amino acid (Fig. 8c). This can be achieved by again using the nonnatural function of NSAAR. This method is, at least in theory, further developed than the one described above, as hydantoinases and carbamoylases have already been studied in greater detail than NSAAR; thus, only the activity of NSAAR on N-carbamoyl-amino acids has to be investigated further. The first work where this approach is considered belongs to Lo et al. (2009), who adopt an interesting approach to produce l-homophenylalanine: an evolved mutated hydantoinase (with improved l-activity), together with an NSAAR and an l-carbamoylase are used for this purpose. We are currently investigating the N-carbamoyl-amino acid racemase activity of several recombinant NSAARs available in our lab, and again, we can confidently predict that this “modified hydantoinase process” will represent a clear trend for future research.

Conclusions

d- and l-carbamoylases represent one of the most studied examples of enzymatic kinetic resolution. They cleave enantiospecifically the amide bond of d- or l-N-carbamoyl-amino acids and also constitute a good example of enzymatic substrate promiscuity. Furthermore, they conform (together with hydantoinase) one of the most widely used multienzymatic systems to date, the “Hydantoinase Process.” The increasing demand for nonnatural amino acids makes this enzyme even more interesting, especially since the use of racemases allows the dynamic kinetic resolution of cheap substrates, which will be of great industrial interest. The substrate promiscuity of both l-carbamoylase and NSAAR enzymes is opening up a new field in carbamoylase-based technology for the production of optically pure amino acids, which is sure to be exploited in the coming years. Thus, the isolation of new carbamoylases with different substrate specificities, improved activity, or higher stability continues to be of great biotechnological application.

Notes

As Dürr and colleagues have recently highlighted in their work about hydantoinases/dihydropyrimidinases (2008), “only a few real hydantoinases are known and except for biochemical data no further differentiation is known.”

When referring to d- and l-hydantoinases, it does not mean that they only hydrolyze one of the isomers, as happens with d- and l- carbamoylases: hydantoinases are “stereoselective,” so they will recognize both isomers, although they preferentially cleave one of them. l-hydantoinase is so called, as it produces an enantiomeric excess of the l-isomer compared to that known as d-hydantoinase (May et al. 1998).

References

Agarkar VB, Kimani SW, Cowan DA, Sayed MF, Sewell BT (2006) The quaternary structure of the amidase from Geobacillus pallidus RAPc8 is revealed by its crystal packing. Acta Crystallogr Sect F Struct Biol Cryst Commun 62:1174–1178

Agarwal R, Burley SK, Swaminathan S (2007) Structural analysis of a ternary complex of allantoate amidohydrolase from Escherichia coli reveals its mechanics. J Mol Biol 368:450–463

Altenbuchner J, Siemann-Herzberg M, Syldatk C (2001) Hydantoinases and related enzymes as biocatalysts for the synthesis of unnatural chiral amino acids. Curr Opin Biotechnol 12:559–563

Andersen B, Lundgren S, Dobritzsch D, Piskur J (2008) A recruited protease is involved in catabolism of pyrimidines. J Mol Biol 379:243–250

Andrade J, Karmali A, Carrondo MA, Frazão C (2007) Structure of amidase from Pseudomonas aeruginosa showing a trapped acyl transfer reaction intermediate state. J Biol Chem 282:19598–19605

Andújar-Sánchez M, Martínez-Gómez AI, Martínez-Rodríguez S, Clemente-Jiménez JM, Las Heras-Vázquez FJ, Rodríguez-Vico F, Jara-Pérez V (2009) Inhibitory effect of different product analogues on β-alanine synthase: a thermodynamic and fluorescence analysis. J Chem Thermodyn 41:212–220

Batisse N, Weigel P, Lecocq M, Sakanyan V (1997) Two amino acid amidohydrolase genes encoding L-stereospecific carbamoylase and aminoacylase are organized in a common operon in Bacillus stearothermophilus. Appl Environ Microbiol 63:763–766

Chao YP, Fu H, Lo TE, Chen PT, Wang JJ (1999) One-step production of D-p-hydroxyphenylglycine by recombinant Escherichia coli strains. Biotechnol Prog 15:1039–1045

Chiang CJ, Chern JT, Wang JY, Chao YP (2008) Facile immobilization of evolved Agrobacterium radiobacter carbamoylase with high thermal and oxidative stability. J Agric Food Chem 13:6348–6354

Clemente-Jiménez JM, Martínez-Rodríguez S, Rodríguez-Vico F, Las Heras-Vázquez FJ (2008) Optically pure α-amino acids production by the "Hydantoinase Process". Recent Patents on Biotechnology 2:35–46

DeLano WL (2002) The PyMOL Molecular Graphics System on World Wide Web. Available via: http://www.pymol.org

Dürr R, Neumann A, Vielhauer O, Altenbuchner J, Burton SG, Cowan DA, Syldatk C (2008) Genes responsible for hydantoin degradation of a halophilic Ochrobactrum sp. G21 and Delftia sp. I24—new insight into relation of D-hydantoinases and dihydropyrimidinases. J Mol Catal B 52–53:2–12

Gojkovic Z, Sandrini MPB, Piškur J (2001) Eukaryotic beta-alanine synthases are functionally related but have a high degree of structural diversity. Genetics 158:999–1011

Gouet P, Courcelle E, Stuart DI, Metoz F (1999) ESPript: multiple sequence alignments in PostScript. Bioinformatics 15:305–8

Grifantini R, Pratesi C, Galli G, Grandi G (1996) Topological mapping of the cysteine residues of N-carbamyl-D-amino-acid amidohydrolase and their role in enzymatic activity. J Biol Chem 271:9326–9331

Håkansson K, Miller CG (2002) Structure of peptidase T from Salmonella typhimurium. Eur J Biochem 269:443–450

Hils M, Munch P, Altenbuchner J, Syldatk C, Mattes R (2001) Cloning and characterization of genes from Agrobacterium sp. IP I-671 involved in hydantoin degradation. Appl Microbiol Biotechnol 57:680–688

Holm L, Kaariainen S, Rosenstrom P, Schenkel A (2008) Searching protein structure databases with DaliLite v.3. Bioinformatics 24:2780–2781

Hsu S-K, Lo H-H, Kao C-H, Lee D-S, Hsu W-H (2006) Enantioselective synthesis of L-homophenylalanine by whole cells of recombinant Escherichia coli expressing L-aminoacylase and N-acylamino acid racemase genes from Deinococcus radiodurans BCRC12827. Biotechnol Prog 22:1578–1584

Hsu S-K, Lo H-H, Lin W-D, Chen I-C, Kao C-H, Hsu W-H (2007) Stereoselective synthesis of L-homophenylalanine using the carbamoylase method with in situ racemization via N-acylamino acid racemase. Process Biochem 42:856–862

Hu HY, Hsu WH, Chien HR (2003) Characterization and phylogenetic analysis of a thermostable N-carbamoyl-L-amino acid amidohydrolase from Bacillus kaustophilus CCRC11223. Arch Microbiol 179:250–257

Hung CL, Liu JH, Chiu WC, Huang SW, Hwang JK, Wang WC (2007) Crystal structure of Helicobacter pylori formamidase AmiF reveals a cysteine-glutamate-lysine catalytic triad. J Biol Chem 282:12220–12229

Ikenaka Y, Nanba H, Yajima K, Yamada Y, Takano M, Takahashi S (1998a) Increase in thermostability of N-carbamyl-D-amino acid amidohydrolase on amino acid substitutions. Biosci Biotechnol Biochem 62:1668–1671

Ikenaka Y, Nanba H, Yajima K, Yamada Y, Takano M, Takahashi S (1998b) Relationship between an increase in thermostability and amino acid substitutions in N-carbamyl-D-amino acid amidohydrolase. Biosci Biotechnol Biochem 62:1672–1675

Ikenaka Y, Nanba H, Yamada Y, Yamija K, Takano M, Takahasi S (1998c) Screening, characterization and cloning of the gene for N-carbamoyl-D-amino acid amidohydrolase from thermotolerant soil bacteria. Biosci Biotechnol Biochem 62:882–886

Ishikawa T, Mukohara Y, Watabe K, Kobayashi S, Nakamura H (1994) Microbial conversion of D, L-substituted hydantoins to the corresponding L-aminoacids by Bacillus stearothermophilus NS1122A. Biosci Biotechnol Biochem 58:265–270

Ishikawa T, Watabe K, Mukohara Y, Nakamura H (1996) N-carbamyl-L-amino acid amidohydrolase of Pseudomonas sp. strain NS671: purification and some properties of the enzyme expressed in Escherichia coli. Biosci Biotechnol Biochem 60:612–615

Jiwaji M, Hartley CJ, Clark S-A, Burton SB, Dorrington RA (2009) Enhanced hydantoin-hydrolyzing enzyme activity in an Agrobacterium tumefaciens strain with two distinct N-carbamoylases. Enzym Microb Tech 44:203–209

Jozic D, Bourenkow G, Bartunik H, Scholze H, Dive V, Henrich B, Huber R, Bode W, Maskos K (2002) Crystal structure of the dinuclear zinc aminopeptidase PepV from Lactobacillus delbrueckii unravels its preference for dipeptides. Structure 10:1097–1106

Kao C-H, Lo H-H, Hsu S-K, Hsu W-H (2008) A novel hydantoinase process using recombinant Escherichia coli cells with dihydropyrimidinase and L-N-carbamoylase activities as biocatalyst for the production of L-homophenylalanine. J Biotechnol 134:231–239

Kraus LM, Jones MR, Kraus AP Jr (1998) Essential carbamoyl-amino acids formed in vivo in patients with end-stage renal disease managed by continuous ambulatory peritoneal dialysis: isolation, identification, and quantitation. J Lab Clin Med 131:425–431

Las Heras-Vázquez FJ, Martínez-Rodríguez S, Mingorance-Cazorla L, Clemente-Jiménez JM, Rodríguez-Vico F (2003) Overexpression and characterization of hydantoin racemase from Agrobacterium tumefaciens C58. Biochem Biophys Res Commun 303:541–547

Lieberman I, Kornberg A (1954) Enzymatic synthesis and breakdown of a pyrimidine, orotic acid. II. Dihydroorotic acid, ureidosuccinic acid, and 5-carboxymethylhydantoin. J Biol Chem 207:911–924

Lo C-K, Kao C-H, Wang W-C, Wu H-M, Hsu W-H, Lin L-L, Hu H-Y (2009) Engineering of the critical residues at the stereochemistry-gate loops of Brevibacillus agri dihydropyrimidinase for the production of L-homophenylalanine. Process Biochem 44:309–315

Louwrier A, Knowles CJ (1996) The purification and characterization of a novel D(-)-specific carbamoylase enzyme from an Agrobacterium sp. Enzyme Microb Technol 19:562–571

Lundgren S, Gojkovic Z, Piškur J, Dobritzsch D (2003) Yeast β-alanine synthase shares a structural scaffold and origin with dizinc-dependent exopeptidases. J Biol Chem 278:51851–51862

Lundgren S, Lohkamp B, Andersen B, Piškur J, Dobritzsch D (2008) The crystal structure of β-alanine synthase from Drosophila melanogaster reveals a homooctameric helical turn-like assembly. J Mol Biol 377:1544–1559

Martínez-Gómez AI, Martínez-Rodríguez S, Clemente-Jiménez JM, Pozo-Dengra J, Rodríguez-Vico F, Las Heras-Vázquez FJ (2007) Recombinant polycistronic structure of hydantoinase process genes in Escherichia coli for the production of optically pure D-amino acids. Appl Environ Microbiol 73:1525–1531

Martínez-Gómez AI, Martínez-Rodríguez S, Pozo-Dengra J, Tessaro D, Servi S, Clemente-Jiménez JM, Rodríguez-Vico F, Las Heras-Vázquez FJ (2009) Potential application of N-carbamoyl-β-alanine amidohydrolase from Agrobacterium tumefaciens C58 for β-Amino acid production. Appl Environ Microbiol 75:514–520

Martínez-Rodríguez S, Las Heras-Vázquez FJ, Clemente-Jiménez JM, Mingorance-Cazorla L, Rodríguez-Vico F (2002) Complete conversion of D, L-5-monosubstituted hydantoins with a low velocity of chemical racemization into D-amino acids using whole cells of recombinant Escherichia coli. Biotechnol Prog 18:1201–1206

Martínez-Rodríguez S, Clemente-Jiménez JM, Rodríguez-Vico F, Las Heras-Vázquez FJ (2005) Molecular cloning and biochemical characterization of L-N-carbamoylase from Sinorhizobium meliloti CECT4114. J Mol Microbiol Biotechnol 9:16–25

Martínez-Rodríguez S, Andújar-Sánchez M, Clemente Jiménez JM, Jara-Pérez V, Rodríguez-Vico F, Las Heras-Vázquez FJ (2006) Thermodynamic and mutational studies of L-N-carbamoylase from Sinorhizobium meliloti CECT 4114 catalytic centre. Biochimie 88:837–847

Martínez-Rodríguez S, García-Pino A, Las Heras-Vázquez FJ, Clemente-Jiménez JM, Rodríguez-Vico F, Loris R, García-Ruiz JM, Gavira JA (2008) Crystallization and preliminary crystallographic studies of the recombinant L-N-carbamoylase from Geobacillus stearothermophilus CECT43. Acta Crystallogr Sect F Struct Biol Cryst Commun 64:1135–1138

Matcher GF, Burton SG, Dorrington RA (2004) Mutational analysis of the hydantoin hydrolysis pathway in Pseudomonas putida RU-KM3S. Appl Microbiol Biotechnol 65:391–400

May O, Siemann M, Pietzsch M, Kiess M, Mattes R, Syldatk C (1998) Substrate-dependent enantioselectivity of a novel hydantoinase from Arthrobacter aurescens DSM 3745: purification and characterization as new member of cyclic amidases. J Biotechnol 61:1–13

May O, Verseck S, Bommarius A, Drauz K (2002) Development of dynamic kinetic resolution processes for biocatalytic production of natural and nonnatural L-amino acids. Org Process Res Dev 6:452–457

Mei Y, He B, Liu N, Ouyang P (2007) Screening and distributing features of bacteria with hydantoinase and carbamoylase. Microbiol Res D. doi:10.1016/j.micres.2006.12.006

Möller A, Syldatk C, Shulze M, Wagner F (1988) Stereo- and substrate specificity of a D-hydantoinase and a D-N-carbamoylamino acid amidohydrolase of Arthrobacter crystalopoietes AM 2. Enzyme Microb Technol 10:618–625

Nakai T, Hasegawa T, Yamashita E, Yamamoto M, Kumasaka T, Ueki T, Nanba H, Ikenaka Y, Takahashi S, Sato M, Tsukihara T (2000) Crystal structure of N-carbamyl-D-amino acid amidohydrolase with a novel catalytic framework common to amidohydrolases. Structure Fold Des 8:729–737

Nanba H, Ikenaka Y, Yamada Y, Yajima K, Takano M, Takahashi S (1998) Isolation of Agrobacterium sp. strain KNK712 that produces N-carbamyl-D-amino acid amidohydrolase, cloning of the gene for this enzyme, and properties of the enzyme. Biosci Biotechnol Biochem 62:875–881

Nozaki H, Kira I, Watanabe K, Yokozeki K (2005) Purification and properties of D-hydantoin hydrolase and N-carbamoyl-D-amino acid amidohydrolase from Flavobacterium sp. AJ11199 and Pasteurella sp. AJ11221. J Mol Catal B 32:205–211

Ogawa J, Shimizu S (1994) Beta-ureidopropionase with N-carbamoyl-alpha-L-amino acid amidohydrolase activity from an aerobic bacterium, Pseudomonas putida IFO 12996. Eur J Biochem 223:625–630

Ogawa J, Shimizu S (1997) Diversity and versatility of microbial hydantoin-transforming enzymes. J Mol Catal B 2:163–176

Ogawa J, Shimizu S, Yamada H (1993) N-carbamoyl-D-amino acid amidohydrolase from Comamonas sp. E222c purification and characterization. Eur J Biochem 212:685–691

Ogawa J, Chung MC, Hida S, Yamada H, Shimizu S (1994) Thermostable N-carbamoyl-D-amino acid amidohydrolase: screening, purification and characterization. J Biotechnol 38:11–19

Ogawa J, Miyake H, Shimizu S (1995) Purification and characterization of N-carbamoyl-L-amino acid amidohydrolase with broad substrate specificity from Alcaligenes xylosoxidans. Appl Microbiol Biotechnol 43:1039–1043

Ohmachi T, Narita M, Kawata M, Bizen A, Tamura Y, Asada Y (2004) A novel N-carbamoyl-L-amino acid amidohydrolase of Pseudomonas sp. strain ON-4a: purification and characterization of N-carbamoyl-L-cysteine amidohydrolase expressed in Escherichia coli. Appl Microbiol Biotechnol 65:686–693

Olivieri R, Fascetti E, Angelini L, Degen L (1979) Enzymatic conversion of N-carbamoyl-D-amino acids to D-amino acids. Enzym Microb Tech 1:201–204

Pietzsch M, Syldatk C (2002). In: Drauz D, Walmann H (ed) Enzyme catalysis in organic synthesis. Weinheim, Wiley-VCH, pp. 761–799

Pozo-Dengra J, Martínez-Gómez AI, Martínez-Rodríguez S, Clemente-Jiménez JM, Rodríguez-Vico F, Las Heras-Vázquez FJ (2009) Racemization study on different N-acetylamino acids by a recombinant N-succinylamino acid racemase from Geobacillus kaustophilus CECT4264. Process Biochem 44:835–841

Roger Chien HC, Hsu CL, Hu HY, Wang WC, Hsu WH (2002) Enhancing oxidative resistance of Agrobacterium radiobacter N-carbamoyl D-amino acid amidohydrolase by engineering solvent-accessible methionine residues. Biochem Biophys Res Commun 297:282–287

Rowsell S, Pauptit RA, Tucker AD, Melton RG, Blow DM, Brick P (1997) Crystal structure of carboxypeptidase G2, a bacterial enzyme with applications in cancer therapy. Structure 5:337–347

Sakai A, Xiang DF, Xu C, Song L, Yew WS, Raushel FM, Gerlt JA (2006) Evolution of enzymatic activities in the enolase superfamily: N-succinylamino acid racemase and a new pathway for the irreversible conversion of D- to L-amino acids. Biochemistry 45:4455–4462

Sareen D, Sharma R, Nandanwar HS, Vohra RM (2001) Two-step purification of D(-)-specific carbamoylase from Agrobacterium tumefaciens AM10. Protein Expr Purif 21:170–175

Stark GR (1965) Reactions of cyanate with functional groups of proteins. III. Reactions with amino and carboxyl groups. Biochemistry 4:1030–1036

Suzuki S, Takenaka Y, Onishi N, Yokozeki K (2005) Molecular cloning and expression of the hyu genes from Microbacterium liquefaciens AJ 3912, responsible for the conversion of 5-substituted hydantoins to α-amino acids, in Escherichia coli. Biosci Biotechnol Biochem 69:1473–1482

Syldatk C, May O, Altenbuchner J, Mattes R, Siemann M (1999) Microbial hydantoinases-industrial enzymes from the origin of life? Appl Microbiol Biotechnol 51:293–309

Taillades J, Beuzelin I, Garrel L, Tabacik V, Bied C, Commeyras A (1998) N-carbamoyl-α-amino acids rather than free α-acids formation in the primitive hydrosphere: a novel proposal for the emergence of prebiotic peptides. Orig Life Evol Biosph 28:61–77

Tamaki N, Mizutani N, Kikugawa M, Fujimoto S, Mizota C (1987) Purification and properties of beta-ureidopropionase from the rat liver. Eur J Biochem 169:21–26

Tokuyama S (2001) Discovery and application of a new enzyme N-acylamino acid racemase. J Mol Catal B 12:3–14

Wang WC, Hsu WH, Chien FT, Chen CY (2001) Crystal structure and site-directed mutagenesis studies of N-carbamoyl-D-amino-acid amidohydrolase from Agrobacterium radiobacter reveals a homotetramer and insight into a catalytic cleft. J Mol Biol 306:251–261

Ware E (1950) The chemistry of the hydantoins. Chem Rev 46:403–470

Wilms B, Wiese A, Syldatk C, Mattes R, Altenbuchner J, Pietzsch M (1999) Cloning, nucleotide sequence and expression of a new L-N-carbamoylase gene from Arthrobacter aurescens DSM 3747 in E. coli. J Biotechnol 68:101–113

Wilms B, Wiese A, Syldatk C, Mattes R, Altenbuchner J (2001) Development of an Escherichia coli whole cell biocatalyst for the production of L-amino acids. J Biotechnol 86:19–30

Wu S, Liu Y, Zhao G, Wang J, Sun W (2006) Thermostable D-carbamoylase from Sinorhizobium morelens S-5: purification, characterization and gene expression in Escherichia coli. Biochimie 88:237–244

Yamanaka H, Kawamoto T, Tanaka A (1997) Efficient preparation of optically active p-trimethylsilylphenylalanine by using cell-free extract of Blastobacter sp. A17p–4. J Ferment Bioeng 84:181–184

Yamashiro A, Kubota K, Yokozeki K (1988a) Mechanism of stereospecific production of L-amino acids from the corresponding 5-substituted hydantoins by Bacillus brevis. Agric Biol Chem 52:2857–2863

Yamashiro A, Yokozeki K, Kamo H, Kubota K (1988b) Enzymatic production of L-amino acids from the corresponding 5-substituted hydantoins by a newly isolated bacterium, Bacillus brevis AJ-12299. Agric Biol Chem 52:2851–2856

Yokozeki K, Kubota K (1987) Mechanism of asymmetric production of D-amino acids from the corresponding hydantoins by Pseudomonas sp. Agric Biol Chem 51:721–728

Yokozeki K, Sano K, Eguchi C, Iwagami H, Mitsugi K (1987a) Optimal conditions for the enzymatic production of L-amino acids from the corresponding 5-substituted hydantoins. Agric Biol Chem 51:729–736

Yokozeki K, Nakamori S, Yamanaka S, Eguchi C, Mitsugi K, Yoshinaga F (1987b) Optimal conditions for the enzymatic production of D-amino acids from the corresponding 5-substituted hydantoins. Agric Biol Chem 51:715–719

Yokozeki K, Hirose Y, Kubota L (1987c) Mechanism of asymmetric production of L-aromatic amino acids from the corresponding hydantoins by Flavobacterium sp. Agric Biol Chem 51:737–746

Acknowledgments

This work was supported by the Spanish Ministry of Education and Science BIO2007-67009 and Andalusian Regional Council of Innovation, Science and Technology P07-CVI-2651 projects. SMR was supported by the Andalusian Regional Government, Spain. The authors thank Andy Taylor for critical discussion of the manuscript.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Martínez-Rodríguez, S., Martínez-Gómez, A.I., Rodríguez-Vico, F. et al. Carbamoylases: characteristics and applications in biotechnological processes. Appl Microbiol Biotechnol 85, 441–458 (2010). https://doi.org/10.1007/s00253-009-2250-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2250-y