Abstract

Recycling of cellulases is an effective way to reduce the cost of enzymatic hydrolysis for the production of cellulosic ethanol. In this study, we examined the adsorption and desorption behaviors of cellulase at different pH values and temperatures. Furthermore, we developed a promising way to recover both free and bound cellulases by pH-triggered adsorption-desorption. The results show that acidic pH (e.g., pH 4.8) was found to favor adsorption, whereas alkaline pH (e.g., pH 10) and low temperature (4–37 °C) favored desorption. The adsorption of cellulases reached an equilibrium within 60 min at pH 4.8 and 25 °C, leading to approximately 50 % of the added cellulases bound to the substrate. By controlling the pH of eluent (citrate buffer, 25 °C), we were able to increase the desorption efficiency of bound cellulases from 15 % at pH 4.8 to 85 % at pH 10. To recover cellulases after enzymatic hydrolysis, we employed adsorption by fresh substrate and desorption at pH 10 to recover the free cellulases in supernatant and the bound cellulases in residue, respectively. The recycling performance (based on the glucose yield) of this simple strategy could reach near 80 %. Our results provided a simple, low-cost, and effective approach for cellulase recycling during the enzymatic hydrolysis of lignocellulosic biomass.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The enormous energy demand and global environmental concerns had stimulated a lot of effort to produce renewable biofuels from lignocellulosic biomass. In this respect, lignocellulosic ethanol, as an alternative biofuel, has the potential to become a viable energy source in the near future. Nonetheless, the technology is not fully commercialized due to its low profit margins and uncertain returns on capital (Brethauer and Wyman 2010). More specifically, a major commercial barrier involves enzymatic conversion of lignocellulose into fermentable sugars, which includes the costly pretreatment and enzyme consumption (Eckard et al. 2013; Galbe and Zacchi 2012; Huang et al. 2010; Zhao et al. 2012). The cost of enzymes used for saccharification of lignocellulose is still the most expensive part of an overall bioconversion process. Lower enzyme cost has long been pursued for the industrialization of lignocellulosic bioethanol. Toward this end, one important strategy is to improve the enzyme performance by optimizing the enzyme complex (Berlin et al. 2007; Divya Nair et al. 2011; Lin et al. 2011; Zhang et al. 2010), adding non-catalytic additives (Eckard et al. 2013; Tu and Saddler 2010) or fed-batch enzymatic hydrolysis (Huang et al. 2011; Yang et al. 2011; Zhang et al. 2010). Another promising strategy is to reduce the enzyme loading by the recycling of enzymes (Huang et al. 2011; Qi et al. 2011; Tu et al. 2007a, b), improving pretreatment (Kumar and Wyman 2009b; Pan et al. 2006; Rollin et al. 2011), or using less-recalcitrant bioenergy plants (Chen and Dixon 2007). In addition, gene technology is also a potential alternative to reduce enzyme cost for bioethanol production (Hasunuma and Kondo 2012; Jang et al. 2012). However, it still needs more effort and time to obtain affordable cellulases with high activity and high stability. Among these approaches, the recycling of enzymes has been demonstrated as an effective way and thus received much attention in recent years.

After enzymatic hydrolysis of lignocellulose, some cellulases remain free in the liquid phases of the hydrolysate, while others remain bound to the lignin-rich solid residue. Different from the enzymes in homogeneous reactions, cellulases in heterogeneous hydrolysis cannot be effectively reused via common enzyme immobilization because of the steric hindrance, mass transfer resistance, and the difficulty (or high cost) of separating the immobilized enzyme from the solid residue. Generally, the cellulases are recovered by ultrafiltration or direct readsorption onto fresh substrates. Ultrafiltration has been proven to be capable of recovering cellulases and continuously remove sugars and other small compounds that may potentially inhibit enzyme activity (Li et al. 2012; Qi et al. 2011; Zhang et al. 2010). However, this method is limited by the fouling of the membrane, high cost, and/or low sugar concentration. Moreover, it is unable to recover the bound enzymes, which account for approximately 50 % the total enzymes due to the high lignin content in solid residue. In contrast, readsorption of cellulases onto fresh substrate gives a simple and low-cost way for recovering cellulases after hydrolysis (Qi et al. 2011; Tu et al. 2007b, 2009b). In this approach, fresh substrate is usually added into reaction slurry or filtrate after solid-liquid separation and readsorbs free cellulases. A previous study had demonstrated that ~80 % of the free cellulases in supernatant could be recovered using this method (Tu et al. 2007a). Nevertheless, direct readsorption often generates an increased buildup of lignin-rich residues or low recycling efficiency since the difficulty of recycling bound enzymes (Tu et al. 2009b; Weiss et al. 2013).

An effective recycling approach should require the recovery of both free and bound cellulases. To improve the recycling of bound cellulases, it is highly desirable to enhance desorption of cellulases from lignin-rich solid residue into liquid phase and then recover them via ultrafiltration or readsorption. One effective way is to add a desorbent, such as surfactant, which can facilitate desorption of bound cellulases and reach a new distribution equilibrium between two phases. For instance, Tu and Saddler (2010) demonstrated that the addition of Tween 80 significantly increased the free enzymes in the supernatant from 55 % of the initial cellulases to 96.4 %. The other chemical desorbents, like urea, guanidine-HCl, dimethylsulfoxide, and n-propanol, were also able to enhance desorption of cellulases (Reese 1982). However, the high cost and/or high dosage of desorbents needed made this approach impractical on a large scale. One much cheaper approach is to utilize pH change (without any chemical desorbent) to adjust the adsorption-desorption of cellulases. In this respect, fresh buffers with pH 4.8 or pH 7.0 had been employed to elute bound cellulases from solid residue (Qi et al. 2011; Tu et al. 2009b), but the recycling efficiency is still low, or much buffer is needed due to the high-affinity cellulases under acidic or neutral conditions. The effect of pH on adsorption-desorption of cellulases and their activity was also investigated in several studies (Du et al. 2012; Otter et al. 1988; Rodrigues et al. 2012; Zhu et al. 2009). For example, in our previous study, we examined the adsorption behaviors and stabilities of cellulases at different pH values ranging from 2 to 10. Only less than 20 % cellulases were bound onto lignocellulosic substrate at high pH (e.g., 10), suggesting the potential for cellulase recycling via pH adjustment (Du et al. 2012). However, to date, no report has discussed the pH-triggered adsorption-desorption of cellulases for the simultaneous recycling of both free and bound cellulases.

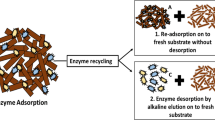

Herein, we report a simple and low-cost approach to simultaneously recover both free and bound cellulases via pH-triggered adsorption-desorption of cellulases. In this approach, aqueous ammonia-pretreated corncob and Spezyme CP (Genenchor International, Inc., Palo Alto, CA, USA) were chosen as targeted lignocellulosic biomass and cellulases, respectively. After a typical enzymatic hydrolysis of pretreated corncob, we utilized the high adsorption of cellulases at pH 4.8 to recover the free cellulases in liquid phase by adding fresh substrate. Meanwhile, we utilized the significant desorption of cellulases at pH 10 to recover the bound cellulases after enzymatic hydrolysis and solid-liquid separation. To obtain an optimal recycling efficiency, the adsorption-desorption behaviors of cellulases under different conditions (e.g., pH, temperature, and eluent dosage) were investigated in this work. Moreover, we present three different strategies to recover cellulases via their adsorption and/or desorption, including adsorption using fresh substrate (strategy A), integrated adsorption and desorption at pH 4.8 (strategy B), and integrated adsorption at pH 4.8 and desorption at pH 10 (strategy C). The hydrolysis efficiency of lignocellulose was further evaluated using the recycled cellulases based on these strategies.

Materials and methods

Materials

Air-dried corncob collected from a local farm (Tianjin, China) were pre-milled and screened to a nominal size of 20–80 meshes. The commercial cellulases (Spezyme CP, 36.8 mg protein/mL) were derived from Trichoderma reesei and purchased from Genencor International, Inc. (Palo Alto, CA, USA) in 2009. β-Glucosidase (Novozyme 188, 54.0 mg protein/mL) was obtained from Sigma-Aldrich (St. Louis, MO, USA). The average activities of Spezyme CP and Novozyme 188 were 71 filter paper unit (FPU)/mL and 926 cellobiase unit (CBU)/mL, respectively. Glucose (>99.5 %), cellobiose (>99 %), xylose (>99 %), galactose (>99 %), arabinose (>99 %), Brilliant Blue G, and bovine serum albumin (BSA, >98 %) were purchased from Sigma-Aldrich (St. Louis, MO, USA). All other reagents were of analytical grade and were obtained from Aladdin Industrial Co. (Shanghai, China).

Lignocellulose pretreatment by soaking in aqueous ammonia (SAA)

Air-dried corncob (100 g) was soaked in an aqueous ammonia (15 wt%) solution at a solid-to-liquid ratio (S/L) of 1:6. The pretreatment was then performed in a water bath at 60 °C without agitation for 12 h. After treatment, the corncob was separated by filtering and washed with distilled water to remove residual ammonia until the pH was neutral. The resulting solid was oven-dried at 60 °C for 3 days and collected for subsequent experiments.

Enzymatic hydrolysis of SAA-treated corncob

The pretreated corncob was added into a citrate buffer (50 mM, pH 4.8) solution at a solid loading of 5 % (w/v). All the enzymatic hydrolysis experiments were carried out in a rotary shaker at 50 °C and 150 rpm. Unless otherwise stated, enzyme loadings for hydrolysis were 30 FPU Spezyme CP and 60 CBU Novozyme 188 per gram of glucan. Aliquots of 1.5 mL were taken out at different time points and centrifuged to collect the supernatant. The sugars and protein content in the supernatant were determined by high-performance liquid chromatography (HPLC) and Bradford’s method, respectively. The residual solid was collected and oven-dried at 105 °C for compositional analysis.

Cellulase adsorption assay

Spezyme CP was added to a 5 % (w/v) SAA-treated corncob suspension (citrate buffer, 50 mM, pH 4.8) to a final concentration of 0.294 mg protein/mL (~30 FPU/g glucan). The cellulase adsorption assay was performed in a thermostat shaker bath at 25 (or 50 °C) and 150 rpm for an appropriate time. Aliquots of 1.0 mL were taken out at different time points and centrifuged at 5,000 g for 10 min. The protein contents in supernatant were then quantified by using Bradford’s method. The amount of adsorbed cellulases was calculated from the difference between the initial cellulases and the free cellulases in supernatant.

To determine the adsorption isotherm, the adsorption assay was carried out at 25 (or 50 °C) and 150 rpm with different cellulase concentrations ranging from 0.37 to 6.15 mg/mL. After 90-min incubation, 1.0-mL aliquots were taken out at different time points and centrifuged at 5,000 g for 10 min. The protein contents in supernatant were measured by using Bradford’s method.

The Langmuir theory of adsorption was applied to fit the experimental data. The concentration of adsorbed cellulases on the substrate (Г, mg/g substrate) was given by

where Гmax (mg/g substrate) is the maximum concentration of protein at full coverage, K (mL/mg protein) is the Langmuir constant, and C (mg/mL) is the protein concentration in bulk solution.

Cellulase desorption assay

The cellulases were added into SAA-treated corncob suspension to a final concentration of 0.294 mg protein/mL and incubated for adsorption according to the procedure described before. After 90-min adsorption, the solid containing adsorbed cellulases was collected by filtrating with glass microfiber membrane (Whatman GF/A, Kent, UK) and used for the desorption experiments. The resulting solid was suspended in citrate buffer solution for cellulase desorption. The pH, temperature, eluent volume, and rotate speed were varied according to the experimental design shown in Fig. 4. After 120-min desorption, the supernatant was collected by centrifuging and the pH adjusted to 4.8. In this case, the supernatant became turbid and needed to be centrifuged again. The protein content in the final supernatant was measured by Bradford’s method, while the precipitate generated in the pH adjustment process was dried at 105 °C for compositional analysis.

To monitor the desorption process, the solid containing bound cellulases was suspended in citrate buffer solution (50 mM, pH 10) at 25 °C without any agitation. Aliquots of 3 mL were taken out at 5, 15, 30, 60, 90, and 120 min and centrifuged to collect the supernatant, respectively. The other procedure is the same as described before. The desorption efficiency (E d) of cellulases was defined and calculated as follows:

where C (mg/mL) is the protein concentration in supernatant, V (mL) is the total volume of eluent, Г eq (mg/g substrate) is the concentration of bound cellulases when reaching an adsorption equilibrium at 90 min, m 0 (g) is the total mass of substrate.

Recycling of cellulases for enzymatic hydrolysis

After a 48-h standard enzymatic hydrolysis, as described before, the slurry was centrifuged at 4 °C and 5,000 g for 10 min, giving a separated residual solid and an aqueous solution containing free enzymes (cellulases and β-glucosidase) and sugar product.

The free cellulases in supernatant were recovered by adsorption using the same amount of fresh SAA-treated corncob that was used in the first cycle. The adsorption process was carried out in a water shaker bath at 25 °C and 150 rpm for 90 min. The fresh substrate containing bound cellulases was recovered by filtration using a glass microfiber membrane (Whatman GF/A, Kent, UK). Sugar product in the filtrate was collected for subsequent transformation. In strategy A, the fresh substrate was used to recover free cellulases via adsorption, as described before. The substrate containing the recovered free cellulases was then resuspended in citrate buffer for the next hydrolysis cycle with the supplement of fresh β-glucosidase (60 CBU per gram of glucan).

To recover bound cellulases, the residual solid was suspended in a 20-mL citrate buffer solution (50 mM, pH 4.8 for strategy B or pH 10 for strategy C) at 25 °C for 60 min without any agitation. The supernatant was collected by centrifuging at 4 °C and 5,000 g for 10 min. For strategy B, the collected supernatant was mixed with fresh substrate that contained recovered free cellulases (as mentioned before) for the next hydrolysis cycle with the supplement of fresh β-glucosidase (60 CBU per gram of glucan). For strategy C, the pH of the collected supernatant was turned to 4.8, and the resulting mixture was centrifuged again. The final supernatant was collected and mixed with fresh substrate that contained recovered free cellulases for the next hydrolysis cycle with the supplement of fresh β-glucosidase (60 CBU per gram of glucan).

Analytical methods

Compositional analysis of all lignocellulosic samples was performed by standard methods (NREL laboratory analytical procedure LAP-002, 2008). Soluble sugars, such as glucose and xylose, were quantified by an HPLC system (Agilent, USA) using an Aminex HPX-87H column (Bio-Rad, Hercules, CA, USA) at 65 °C. The mobile phase was 0.005 mol/L sulfuric acid, and the flow rate was 0.6 mL/min. All the samples were centrifuged and filtered through 0.45-μm membranes.

The activities of Spezyme CP and Novozyme 188 were determined using filter paper and cellobiose as substrates, respectively. Cellulase and β-glucosidase activities of the enzymes were determined according to the methods suggested by IUPAC (Wood and Bhat 1988). The protein content in enzyme solution was measured by the Bradford’s method with BSA as the standard using Coomassie Brilliant Blue reagent (Bradford 1976).

Results

Compositional changes, enzymatic digestibility, and cellulase distribution

Table 1 summarizes the change in composition after SAA pretreatment. The pretreatment conditions were solid-to-liquid ratio of 1:6, 15 wt% aqueous ammonia, 60 °C, and 12 h. The major change was the composition of lignin. Approximately 68.8 % of the lignin was removed after SAA treatment (Table 1). The glucan and xylan contents were well preserved showing no significant changes over the entire treatment period. The recovery ratios of glucan and xylan reach 97.1 and 80.0 %, respectively.

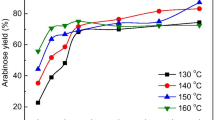

The sugar release from SAA-treated corncob and the cellulase content present in the reaction supernatant were monitored during the hydrolysis process. As shown in Fig. 1, the pretreated corncob were hydrolyzed by ~86 % at the 24th hour and by ~91 % at the 48th hour. As the hydrolysis proceeded, the cellulase content in supernatant decreased quickly from 100 to 64 % within the first 1 h and further to 44 % at 48th hour due to the enzyme adsorption onto solid substrate. Although the weight of solid substrate continuously decreased, the bound cellulases gradually increased from 0 to 55 % over the entire hydrolysis period. At 1 h, the specific adsorption of cellulases is 2.5 mg/mL, while this parameter increased to 11.5 mg/mL at 48th hour. The enhanced adsorption capacity of cellulases onto residual solid may be attributed to the higher lignin content, which was evidenced by the compositional analysis (49.1 vs 6.8 %, Fig. 2, Table 1).

The time course of enzymatic hydrolysis of SAA-treated corncob and cellulase distribution in the supernatant and solid residue during the hydrolysis process. The reaction conditions are the following: 1.0-g SAA-treated corncob, 20-mL citrate buffer (50 mM, pH 4.8), 30-FPU/g glucan cellulases, 60-CBU/g glucan β-glucosidase. Each error bar represents the standard deviation from three independent experiments

Cellulase adsorption onto SAA-treated corncob

In this work, we tried to use the fresh substrate to recover the free cellulases in the hydrolysate via readsorption. To achieve a good cellulase recovery, we investigated the adsorption behavior of cellulases onto SAA-treated corncob. Considering the influence of hydrolysis on adsorption, the concentration of adsorbed cellulases on the substrate (Г, mg/g substrate) was calculated by the mass balance equation:

where C 0 (mg/mL) and C t (mg/mL) are the protein concentration in reaction supernatant at time 0 and t, respectively, V (mL) is the volume of the aqueous phase in reaction system, m (g) is the mass of the solid substrate at time t.

Figure 3a shows the cellulase adsorption profiles for the SAA-treated corncob at pH 4.8. The adsorption amount of cellulases increased quickly in the first 30 min and reached equilibrium within 60 min. After adsorption equilibrium, approximately 50 % of the total cellulases were bound to the solid substrate. The adsorption rate has no significant change with the decreasing temperature from 50 to 25 °C, while a higher adsorption amount of cellulases (2.2 mg/mL) could be achieved at 25 °C. In this case, less than 5.7 % of the substrate was hydrolyzed during the adsorption process (120 min).

a The time course of cellulase adsorption onto SAA-treated corncob at pH 4.8 at a cellulase loading of 0.294 mg protein/mL (30 FPU/g glucan). b Cellulase adsorption isotherms onto SAA-treated corncob at pH 4.8 for 60 min. The data in Fig. 3b was fitted by Langmuir model. Other default conditions are the following: 1.0-g SAA-treated corncob, 20-mL citrate buffer (50 mM, pH 4.8). Each error bar represents the standard deviation from three independent experiments

The cellulase adsorption isotherm was further determined after the adsorption equilibrium at 60 min. In previous studies, the Langmuir adsorption isotherm had been utilized to study cellulase adsorption onto lignocellulosic substrates (Qi et al. 2011; Tu et al. 2007a, b, 2009a). The parameters of the Langmuir adsorption isotherm show the maximum amount of enzyme that can be adsorbed onto a substrate and the affinity of adsorption. Here, we also employ the Langmuir model to characterize the cellulase adsorption isotherms on SAA-treated corncob at pH 4.8. To establish the adsorption isotherm, various concentrations of cellulases were incubated in a substrate suspension (5 % solid loading, 50-mM citrate buffer) at 25 or 50 °C for 1 h to reach equilibrium. The adsorbed cellulases were calculated from the difference between the initial cellulase content and the free cellulase content in the supernatant. As shown in Fig. 3b and Table 2, experimental data well fit the Langmuir adsorption isotherm models (R 2 > 0.99). The adsorption capacity of cellulases onto SAA-treated corncob at 25 °C was 42.13-mg/g substrate, which is much higher than that at 50 °C (26.62-mg/g substrate). The equilibrium affinity constant of cellulases onto SAA-CC was 0.27 and 0.55 mL/mg at 25 and 50 °C, respectively. This result indicated that lower temperature is beneficial to the cellulase adsorption at the high protein concentration.

Optimization of cellulase desorption conditions and the desorption kinetics

Figure 4a shows the effect of operating pH values on the desorption efficiency. Interestingly, there was a significant increase of the cellulase desorption as the pH increased to 10.0. In this case, approximately 85 % of the bound cellulases were recovered. In our previous study, we investigated the effects of pH on cellulase stability. After incubating at pH 10.0 for 2 h and the pH was turned back to 4.8, the cellulases remained more than 97 % of activity (Du et al. 2012). Considering the high desorption efficiency and high stability of cellulases at pH 10.0, we employed the pH adjustment (pH 10.0) to recover the bound cellulases from the residual solid after hydrolysis process.

The effects of pH (a), temperature (b), eluent dosage (c), and rotate speed (d) on the desorption and recycling of cellulases that bound onto SAA-treated corncob. The default conditions unless otherwise noted are the following: a 25 °C, 20-mL buffer, 150 rpm, 120 min; b pH 10, 20-mL buffer, 150 rpm, 120 min; c pH 10, 25 °C, 150 rpm, 120 min; d pH 10, 25 °C, 20-mL buffer, 120 min. Other default conditions are the following: 1.0-g SAA-treated corncob. Each error bar represents the standard deviation from three independent experiments

We further investigated the effect of temperature on the cellulase desorption. As shown in Fig. 4b, there is a slight increase in desorption efficiency from 4 to 37 °C. However, when the temperature raised to 50 °C, the desorption efficiency of cellulases decreased rapidly. Additionally, we measured the cellulase desorption with different amounts of elution and rotate speed. As shown in Fig. 4c, d, the values for desorption efficiency under these different conditions had no significant difference.

To monitor the desorption process of the bound cellulases, we conducted a kinetic analysis at pH 10, 25 °C, and 20-mL elution without any agitation. The cellulase desorption at pH 4.8 was chosen as control experiment; the results are shown in Fig. 5a. The desorption of cellulases was very fast within the initial 20 min. After that, the desorption rate was found to decrease, leading to a desorption equilibrium at 60 min. The results also show that about 85 % of the bound cellulases was desorbed into the supernatant at pH 10.0, while less than 15 % of cellulases was released into the liquid phase at pH 4.8 even incubating for 120 min. This rapid desorption behavior at pH 10.0 is beneficial to recycling most of the bound cellulases, as well as to retaining the enzyme activity due to the short incubation under high pH value. Additionally, after cellulase adsorption and solid-liquid separation, the pH of the supernatant was turned back to 4.8 for remaining the activity of cellulases, leading to the precipitation of Klason lignin together with a few other components (Fig. 5b). No protein was found in the precipitate, indicating that all the cellulases were soluble in the supernatant during the pH adjustment process.

a The time course of cellulase desorption form SAA-treated corncob at 25 °C without any agitation (1.0-g SAA-treated corncob, pH 10, 25 °C, 20-mL buffer, 120 min). Each error bar represents the standard deviation from three independent experiments. b Amount of the precipitate after cellulase desorption (1.0-g SAA-treated corncob, pH 10, 25 °C, 20-mL buffer, 120 min) and pH adjustment from 10 to 4.8. KL and ASL represent Klason lignin and acid-soluble lignin, respectively

Recycling cellulases by pH-triggered adsorption-desorption

The following enzyme-recycling strategies were investigated, as shown in Fig. 6, including adsorption using fresh substrate (strategy A), integrated adsorption and desorption at pH 4.8 (strategy B), and integrated adsorption at pH 4.8 and desorption at pH 10 (strategy C). Specially, in strategy C, after enzymatic hydrolysis and solid-liquid separation, on the one hand, the same amount of fresh substrate was directly added to the supernatant (pH 4.8) to recover free cellulases. The fresh substrate containing recovered cellulases was then collected via filtration for subsequent enzymatic hydrolysis. On the other hand, the residual solid containing bound cellulases was suspended in citrate buffer solution (50 mM, pH 10) for cellulase desorption. The supernatant containing desorbed cellulases was then collected via centrifugation. After pH adjustment to 4.8, the recovered cellulases in supernatant, together with the recovered free cellulases in fresh substrate (as mentioned before) and the supplementary fresh β-glucosidase, were used to the next hydrolysis cycle.

To assess the feasibility of these cellulase recovery strategies, we investigated the hydrolysis efficiency using the original and recovered cellulases, respectively. As shown in Fig. 7a, the glucose yield is 42.1 % by using the recovered cellulases from strategy A. In this case, approximately 22 % (protein content) of the original cellulases were recovered, recycling 46.7 % glucose productivity (the ratio of glucose yield between two hydrolysis cycles). The glucose yield could increase to 56.2 % when using the recovered cellulases in strategy B, in which both the substrate readsorption and cellulase desorption were operated at pH 4.8. When the pH of desorption buffer was turned to 10, strategy C could achieve 70.3 % glucose yield, recycling 69 % of the total cellulases (50 % of the free cellulases in hydrolysate of first cycle and 83 % of the bound cellulases in residual solid) and 78.5 % glucose productivity. Additionally, with the enhancement in recycling cellulases, the xylose yield also increased from 47.9 (strategy A) to 58.2 % (strategy C, Fig. 7b). These results indicated that strategy C allows for efficient recycling and reuse of cellulases from both the hydrolysate and residual solid during the hydrolysis of lignocellulose.

Enzymatic hydrolysis of SAA-treated corncob into glucose (a) and xylose (b) by using the original and the recovered cellulases, respectively. Black column original cellulase, light gray column recovered cellulase. The default reaction conditions are the following: 1.0-g SAA-treated corncob, 20-mL buffer. Each error bar represents the standard deviation from three independent experiments

Discussion

Previous studies had demonstrated that lignin content had a significant effect on the distribution of cellulases between liquid and solid phases for its nonproductive adsorption for cellulases (Kumar and Wyman 2009a; Tu et al. 2009a). Alkaline pretreatment was proved to be effective to enhance lignin solubilization and simultaneously avoid the degradation of cellulose and hemicellulose (Chiaramonti et al. 2012; Modenbach and Nokes 2012; Saritha et al. 2012). In this work, we employed SAA as pretreatment approach to reduce lignin content from 16.3 to 6.8 %. During the enzymatic hydrolysis of SAA-treated corncob, cellulases were bound to solid substrate quickly in the initial stage due to the abundant binding sites in substrate (Fig. 1). As the reaction proceeded, the cellulose and hemicellulose were hydrolyzed continuously. This could result in a gradual decrease in cellulase-binding sites and thus desorption of the bound cellulases, reaching an adsorption-desorption equilibrium. In the later stage of reaction, a considerable amount of cellulases (56 % of initial cellulases protein) still remained bound to the residue due to the nonspecific adsorption of lignin. Similar results were reported in previous studies. For example, Tu et al. (2007a) investigated the adsorption-desorption of cellulases during hydrolysis of Avicel (no lignin) and organosolv acetic acid-pretreated Douglas fir (3 % lignin). After a 48-h hydrolysis, about 10 and 35 % of the initial cellulase proteins remained in residual substrate, respectively. Lu et al. (2002) also observed that 35 and 70 % of the initial cellulase proteins were presented in the residual solid after 48-h hydrolysis of hot alkali peroxide-treated Douglas fir (8.2 % lignin) and steam-exploded Douglas fir (46.1 % lignin). This specific distribution of cellulases during the hydrolysis of lignocellulosic biomass prompts us to recover both the free and bound cellulases.

We employed fresh substrate to adsorb the free cellulases present in supernatant after enzymatic hydrolysis and solid-liquid separation, achieving about 50 % of the free cellulases recovered. The recycling efficiency is highly dependent on the adsorption characteristics of cellulases to lignocellulosic substrate. There are many factors to influence the adsorption performance, including the substrate (e.g., cellulose and lignin content), pretreatment, enzyme, pH, temperature, and so on (Kumar and Wyman 2009a). In our case, the maximum adsorption amount (Гmax) and the equilibrium affinity constant (K) of cellulases at pH 4.8 and 25 °C are 42.13-mg/g substrate and 0.27 mL/mg (Table 2), respectively. The values are lower than those in the cases of pretreated corn stover (Kumar and Wyman 2009a) and Lodgepole pine (Tu et al. 2007b). For example, the ethanol-H2SO4-pretreated Lodgepole pine could achieve 60.35-mg/g maximum adsorption capacity and 3.17-mL/mg affinity constant. In consideration of this low adsorption ability of cellulases onto SAA-pretreated corncob, multiadsorption by fresh substrate or recycled adsorption may be an efficient strategy to enhance the recycling of free cellulases in future work.

There was a large amount of nonspecific bound cellulases on lignin, as mentioned before, in spite of almost complete hydrolysis of cellulose and hemicellulose, which limit the recycling of cellulases (Palonen et al. 2004; Rodrigues et al. 2012). These bound cellulases can be desorbed due to the structural change by adjusting pH to above 9.0, and their activity could be recovered when the pH is reset since the reversibility of this structural change (Du et al. 2012; Rodrigues et al. 2012). Based on our previous study (Du et al. 2012), in this work, we employed pH-triggered desorption of cellulases to recover the bound enzyme. Our results indicated that the pH and temperature were two significant factors affecting the cellulase desorption from substrate (Fig. 4). Alkaline condition (e.g., pH 9–10) and low temperature (e.g., 4–37 °C) were in favor of the desorption of bound cellulases, while further increase in pH or temperature would lead to the denaturation and precipitation of released protein (Pribowo et al. 2012; Rodrigues et al. 2012; Tu et al. 2009b; Wang et al. 2012). Under the optimal conditions (pH 10, 25 °C, 120 min), approximately 83 % of the bound cellulases in residual solid could be desorbed to liquid phase and thus be recovered via simple filtration or centrifugation. The desorption efficiency is higher than that in previous studies (e.g., 61 % for Avicel, 56 % for corn stover (Zhu et al. 2009), 41–45 % of Avicelase (Otter et al. 1984; Otter et al. 1988)). Further increase in pH value (e.g., 13) or addition of desorbents (e.g., Tween 80) could enhance the desorption of bound cellulases (Otter et al. 1988; Zhu et al. 2009).

Another important parameter is the activity of the recovered cellulases. In our previous study, we investigated the effect of pH on the activity of cellulases (Spezyme CP). The results showed that the cellulase activities could be recovered to 97 % when the enzyme was incubated at pH 10 (25 °C, 120 min) and then the pH was adjusted from 10 to 4.8. Therefore, we also used the same operating conditions (pH 10, 25 °C, 120 min) to desorb cellulases in this work. The overall activity of the recovered bound cellulases, together with the recovered free cellulases, was assessed via their catalytic hydrolysis of SAA-treated corncob. The difference in glucose yields from the original and recovered cellulases shows that approximately 80 % of the cellulase activity was recovered via simple pH-triggered adsorption-desorption process.

Previously, surfactants were used to increase the desorption of bound cellulases and thus to enhance the readsorption of cellulases onto fresh substrate (Tu et al. 2007b). For example, the surfactants Triton X-100, Tween 80, and Tween 20 enhanced the recycling of cellulases, based on the hydrolysis yield, from 60 to 85 %. Additionally, some surfactants could also improve the cellulase stability and the hydrolysis performance (Otter et al. 1988; Tu et al. 2007b). Therefore, the addition of surfactant, multi-readsorption, or recycled adsorption by fresh substrate as mentioned before, maybe can further enhance the recycling performance of the recovery strategy C (adsorption at 4.8 and desorption at 10). In conclusion, the results from this study show that pH-triggered adsorption-desorption is a simple, feasible, and efficient approach for the recycling of cellulases during the hydrolysis of SAA-treated lignocellulosic biomass.

References

Berlin A, Maximenko V, Gilkes N, Saddler J (2007) Optimization of enzyme complexes for lignocellulose hydrolysis. Biotechnol Bioeng 97:287–296

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Brethauer S, Wyman CE (2010) Review: continuous hydrolysis and fermentation for cellulosic ethanol production. Bioresour Technol 101:4862–4874

Chen F, Dixon RA (2007) Lignin modification improves fermentable sugar yields for biofuel production. Nat Biotechnol 25:759–761

Chiaramonti D, Prussi M, Ferrero S, Oriani L, Ottonello P, Torre P, Cherchi F (2012) Review of pretreatment processes for lignocellulosic ethanol production, and development of an innovative method. Biomass Bioenergy 46:25–35

Divya Nair MP, Padmaja G, Moorthy SN (2011) Biodegradation of cassava starch factory residue using a combination of cellulases, xylanases and hemicellulases. Biomass Bioenergy 35:1211–1218

Du R, Su R, Li X, Tantai X, Liu Z, Yang J, Qi W, He Z (2012) Controlled adsorption of cellulase onto pretreated corncob by pH adjustment. Cellulose 19:371–380

Eckard AD, Muthukumarappan K, Gibbons W (2013) Enzyme recycling in a simultaneous and separate saccharification and fermentation of corn stover: a comparison between the effect of polymeric micelles of surfactants and polypeptides. Bioresour Technol 132:202–209

Galbe M, Zacchi G (2012) Pretreatment: the key to efficient utilization of lignocellulosic materials. Biomass Bioenergy 46:70–78

Hasunuma T, Kondo A (2012) Development of yeast cell factories for consolidated bioprocessing of lignocellulose to bioethanol through cell surface engineering. Biotechnol Adv 30:1207–1218

Huang R, Su R, Qi W, He Z (2010) Understanding the key factors for enzymatic conversion of pretreated lignocellulose by partial least square analysis. Biotechnol Prog 26:384–392

Huang R, Su R, Qi W, He Z (2011) Bioconversion of lignocellulose into bioethanol: process intensification and mechanism research. BioEnergy Res 4:225–245

Jang YS, Park JM, Choi S, Choi YJ, Seung do Y, Cho JH, Lee SY (2012) Engineering of microorganisms for the production of biofuels and perspectives based on systems metabolic engineering approaches. Biotechnol Adv 30:989–1000

Kumar R, Wyman CE (2009a) Cellulase adsorption and relationship to features of corn stover solids produced by leading pretreatments. Biotechnol Bioeng 103:252–267

Kumar R, Wyman CE (2009b) Does change in accessibility with conversion depend on both the substrate and pretreatment technology? Bioresour Technol 100:4193–4202

Li Q, Gao Y, Wang H, Li B, Liu C, Yu G, Mu X (2012) Comparison of different alkali-based pretreatments of corn stover for improving enzymatic saccharification. Bioresour Technol 125:193–199

Lin ZX, Zhang HM, Ji XJ, Chen JW, Huang H (2011) Hydrolytic enzyme of cellulose for complex formulation applied research. Appl Biochem Biotechnol 164:23–33

Lu Y, Yang B, Gregg D, Saddler JN, Mansfield SD (2002) Cellulase adsorption and an evaluation of enzyme recycle during hydrolysis of steam-exploded softwood residues. Appl Biochem Biotechnol 98–100:641–654

Modenbach AA, Nokes SE (2012) The use of high-solids loadings in biomass pretreatment—a review. Biotechnol Bioeng 109:1430–1442

Otter DE, Munro PA, Scott GK, Geddes R (1984) Elution of Trichoderma reesei cellulase from cellulose by pH adjustment with sodium hydroxide. Biotechnol Lett 6:369–374

Otter DE, Munro PA, Scott GK, Geddes R (1988) Desorption of Trichoderma reesei cellulase from cellulose by a range of desorbents. Biotechnol Bioeng 34:291–298

Palonen H, Tjerneld F, Zacchi G, Tenkanen M (2004) Adsorption of Trichoderma reesei CBH I and EG II and their catalytic domains on steam pretreated softwood and isolated lignin. J Biotechnol 107:65–72

Pan X, Gilkes N, Kadla J, Pye K, Saka S, Gregg D, Ehara K, Xie D, Lam D, Saddler J (2006) Bioconversion of hybrid poplar to ethanol and co-products using an organosolv fractionation process: optimization of process yields. Biotechnol Bioeng 94:851–861

Pribowo A, Arantes V, Saddler JN (2012) The adsorption and enzyme activity profiles of specific Trichoderma reesei cellulase/xylanase components when hydrolyzing steam pretreated corn stover. Enzym Microb Technol 50:195–203

Qi B, Chen X, Su Y, Wan Y (2011) Enzyme adsorption and recycling during hydrolysis of wheat straw lignocellulose. Bioresour Technol 102:2881–2889

Reese ET (1982) Elution of cellulase from cellulose. Process Biochem 17:2–6

Rodrigues AC, Leitao AF, Moreira S, Felby C, Gama M (2012) Recycling of cellulases in lignocellulosic hydrolysates using alkaline elution. Bioresour Technol 110:526–533

Rollin JA, Zhu Z, Sathitsuksanoh N, Zhang YH (2011) Increasing cellulose accessibility is more important than removing lignin: a comparison of cellulose solvent-based lignocellulose fractionation and soaking in aqueous ammonia. Biotechnol Bioeng 108:22–30

Saritha M, Arora A, Lata (2012) Biological pretreatment of lignocellulosic substrates for enhanced delignification and enzymatic digestibility. Indian J Microbiol 52:122–130

Tu M, Saddler JN (2010) Potential enzyme cost reduction with the addition of surfactant during the hydrolysis of pretreated softwood. Appl Biochem Biotechnol 161:274–287

Tu M, Chandra RP, Saddler JN (2007a) Evaluating the distribution of cellulases and the recycling of free cellulases during the hydrolysis of lignocellulosic substrates. Biotechnol Prog 23:398–406

Tu M, Chandra RP, Saddler JN (2007b) Recycling cellulases during the hydrolysis of steam exploded and ethanol pretreated Lodgepole pine. Biotechnol Prog 23:1130–1137

Tu M, Pan X, Saddler JN (2009a) Adsorption of cellulase on cellulolytic enzyme lignin from lodgepole pine. J Agric Food Chem 57:7771–7778

Tu M, Zhang X, Paice M, MacFarlane P, Saddler JN (2009b) The potential of enzyme recycling during the hydrolysis of a mixed softwood feedstock. Bioresour Technol 100:6407–6415

Wang QQ, Zhu JY, Hunt CG, Zhan HY (2012) Kinetics of adsorption, desorption, and re-adsorption of a commercial endoglucanase in lignocellulosic suspensions. Biotechnol Bioeng 109:1965–1975

Weiss N, Borjesson J, Pedersen LS, Meyer AS (2013) Enzymatic lignocellulose hydrolysis: improved cellulase productivity by insoluble solids recycling. Biotechnol Biofuels 6:5

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Methods Enzymol 160:87–112

Yang J, Zhang X, Yong Q, Yu S (2011) Three-stage enzymatic hydrolysis of steam-exploded corn stover at high substrate concentration. Bioresour Technol 102:4905–4908

Zhang M, Su R, Li Q, Qi W, He Z (2010) Enzymatic saccharification of pretreated corn stover in a fed-batch membrane bioreactor. BioEnergy Res 4:134–140

Zhao X, Zhang L, Liu D (2012) Biomass recalcitrance. Part I: the chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels Bioprod Bioref 6:465–482

Zhu ZG, Sathitsuksanoh N, Zhang YHP (2009) Direct quantitative determination of adsorbed cellulase on lignocellulosic biomass with its application to study cellulase desorption for potential recycling. Analyst 134:2267–2272

Acknowledgments

The authors acknowledge the financial supports received from the National Natural Science Foundation of China (Nos. 21276192 and 20976125) and Tianjin (No. 11JCYBJC04400), Open Funding Project of the State Key Laboratory of Chemical Engineering (No. SKL-ChE-11B01), and the Ministry of Education (Nos. NCET-11-0372, 20110032130004, and B06006).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shang, Y., Su, R., Huang, R. et al. Recycling cellulases by pH-triggered adsorption-desorption during the enzymatic hydrolysis of lignocellulosic biomass. Appl Microbiol Biotechnol 98, 5765–5774 (2014). https://doi.org/10.1007/s00253-014-5761-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5761-0