Abstract

Poly(ε-l-lysine) (ε-PL) producer strain Streptomyces albulus PD-1 secreted a novel polymeric substance into its culture broth along with ε-PL. The polymeric substance was purified to homogeneity and identified. Matrix-assisted laser desorption ionization-time of flight mass spectrometry and nuclear magnetic resonance spectroscopy as well as other analytical techniques revealed that the substance was poly(l-diaminopropionic acid) (PDAP). PDAP is an l-α,β-diaminopropionic acid oligomer linking between amino and carboxylic acid functional groups. The molecular weight of PDAP ranged from 500 to 1500 Da, and no co-polymers composed of l-diaminopropionic acid and l-lysine were present in the culture broth. Compared with ε-PL, PDAP exhibited stronger inhibitory activities against yeasts but weaker activities against bacteria. ε-PL and PDAP co-production was also investigated. Both ε-PL and PDAP were synthesized during the stationary phase of growth, and the final ε-PL and PDAP concentration reached 21.7 and 4.8 g L-1, respectively, in fed-batch fermentation. Citric acid feeding resulted in a maximum ε-PL concentration of 26.1 g L-1 and a decrease in the final concentration of PDAP to 3.8 g L-1. No studies on ε-PL and PDAP co-production in Streptomyces albulus have been reported previously, and inhibition of by-products such as PDAP is potentially useful in ε-PL production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, poly(amino acid)s secreted from living organisms have drawn considerable attention because of their functional and biocompatible characteristics (Kunioka 1997). A poly(amino acid) is composed of one type of amino acid solely in the backbone. By this definition, only three poly(amino acid)s, including the non-proteinic amino acid homopolymer, are known to occur naturally: poly(γ-glutamic acid), poly(ε-l-lysine) (ε-PL), and poly(γ-l-diaminobutanoic acid) (γ-PAB) (Ivánovics and Erlös 1937; Shima and Sakai 1977; Takehara et al. 2008). Polymers consisting of more than one type of amino acid are called co-poly(amino acid)s. These polymers include poly(arginyl-histidine) purified from the secretions of an ergot fungus, multi-l-arginyl-poly-l-aspartic acid (cyanophycin) located only inside cyanobacteria cells, and poly(γ-glutamyl-csyteinyl)glycine (phytochelatin) found in plants (Nishikawa and Ogawa 2004; Borzi 1887; Rauser 1995). Poly(amino acid)s have exhibited various and remarkable biological and chemical functions that are primarily attributed to their polycationic or polyanionic nature. With the aforementioned functions and other established or potential technical applications, the potential uses of poly(amino acid)s in medicine, food, agriculture, electronics, and chemical materials have attracted considerable research interest (Chiang and Yeh 2003; Yoshida and Nagasawa 2003).

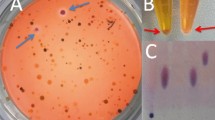

ε-PL is an extracellularly biosynthesized l-lysine linear homopolymer that exhibits a unique structure linking ε-amino and α-carboxylic acid groups. This homopolymer is cationic because of its amino acids with positively charged side chains. Consequently, it is considered that ε-PL acts electrostatically on the acidic surfaces of target microbial cells and inhibits the proliferation of microorganisms (Shima et al. 1982, 1984). ε-PL has been introduced as a food preservative in Japan, South Korea, USA, and other countries because of its antimicrobial activity against a wide spectrum of microorganisms (Yoshida and Nagasawa 2003). ε-PL was first discovered from the culture broth of Streptomyces albulus No. 346 (Shima and Sakai 1977). More ε-PL-producing strains were discovered years later using a simple and sensitive screening acidic polymeric dye called Poly R-478 (Nishikawa and Ogawa 2002). Studies on ε-PL synthetase and ε-PL-degrading enzymes indicated that the chain length diversity of ε-PL is controlled by an unusual non-ribosomal peptide synthetase rather than ε-PL-degrading enzymes (Yamanaka et al. 2008, 2010; Hamano et al. 2006 ).

Among the ε-PL-producing strains, Streptomyces celluloflavus and Streptomyces roseoverticillatus were found to secrete two kinds of novel poly(amino acid)s into culture broths: γ-PAB and lariat-shaped γ-poly(l-glutamic acid) (ls-gPGA), respectively (Takehara et al. 2008; Nishikawa and Kobayashi 2009). γ-PAB was identified as an l-α,γ-diaminobutanoic acid linear oligomer, with its number average molecular weight (Mn) ranging from 2,100 to 2,200 Da. Compared with ε-PL, γ-PAB exhibited stronger inhibitory activities against yeasts but weaker actions against bacteria. Ls-gPGA consisted of 10 to 13 l-glutamic acid residues, and the glutamic acid oligomers exhibited an incomplete circular structure of a lariat-shaped structure with an intact γ-carboxyl group. However, the Streptomyces celluloflavus and Streptomyces roseoverticillatus strains produced ε-PL in low quantities and as such could only be used in fundamental research rather than industrial production.

In the previous study, we performed a screening study targeting the actinomycetes as producers of ε-PL (Ouyang et al. 2006). ε-PL-producing strains such as Kitasatospora sp. and Streptomyces albulus were isolated from soil. We investigated the fermentation conditions of Kitasatospora sp. PL6-3 and the immobilization of its mutant strain Kitasatospora sp. MY 5–63 on loofah sponge (Ouyang et al. 2006; Zhang et al. 2010). In the present study, we purified a novel non-proteinic amino acid oligomer known as poly(l-diaminopropionic acid) (PDAP) from the culture broth of the ε-PL producer strain Streptomyces albulus PD-1. PDAP antimicrobial activity as well as ε-PL and PDAP co-production was investigated. ε-PL has been manufactured commercially, however, no studies on the by-products of ε-PL fermentation by Streptomyces albulus have been reported. Thus, the inhibition of by-products such as PDAP is potentially useful in ε-PL production.

Materials and methods

Chemicals and strains

Standard ε-PL samples were purchased from Nanjing Shineking Biotechnology Co., Ltd. (Nanjing, China). Analytical-grade l-α,β-diaminopropionic acid (L-DAP) • HCl and DL-α,β-diaminopropionic acid (DL-DAP) • HCl were purchased from Shanghai Aladdin (Shanghai, China). All the other chemicals used were of analytical grade and obtained from commercial sources. The ε-PL-producing strain Streptomyces albulus PD-1 was isolated from the soil and deposited in the China Center for Type Culture Collection with accession number of M2011043. Other microbial strains were obtained from China General Microbiological Culture Collection Center (CGMCC) (Beijing).

Production and purification of ε-PL and PDAP

A two-stage culture method consisting of (1) cell growth and (2) production cultures in shake flasks and fed-batch fermentations in a 5-L jar fermentor was performed for ε-PL and PDAP co-production. In the two-stage culture method, experiments were conducted as previously described (Hirohara et al. 2006), with slight modifications in the production medium (220 mM glycerol, 20 mM citric acid, and 76 mM (NH4)2SO4). The production culture broths were analyzed for factors affecting polymer production.

In the fed-batch fermentations, medium composition for slant culture was (grams per liter): glucose, 10; yeast extract, 1; beef meat extract, 1; polypepton, 2; and agar, 20; the medium pH was adjusted to 7.5 with 2 M NaOH solution. M3G medium, which contained (grams per liter) glucose, 50; yeast extract, 5; (NH4)2SO4, 10; KH2PO4, 1.36; K2HPO4, 0.8; MgSO4·7H2O, 0.5; ZnSO4·7H2O, 0.04; and FeSO4·7H2O, 0.03, was used for both seed culture and production culture. The initial pH of the M3G medium was adjusted to 6.8 with an NH4OH solution (25–28 %, w/v). The media were sterilized in an autoclave for 20 min at 121 °C, in each case, glucose was autoclaved separately.

Fed-batch fermentations with a two-stage pH control strategy were conducted as described in a previous study (Kahar et al. 2001). For seed culture, a loopful of Streptomyces albulus PD-1 was inoculated into a 500-mL Erlenmeyer flask containing 100 mL M3G medium and cultured at 30 °C and 200 rpm for 24 h on a rotary shaker. Fermentation was performed in a 5-L jar fermentor (KoBio Tech Co. Ltd., Korea) with a working volume of 3 L at 30 °C, and a 300-mL pre-cultured seed was inoculated into 2.7-L sterilized M3G medium. During the first 48 h (phase I), the pH was maintained at 6.0 to increase the cell growth; during the remaining time (phase II), pH was maintained at 4.0 to increase ε-PL and PDAP co-production. To maintain the pH level, 10 % (v/v) NH4OH was added to the culture broth. Varying agitation rates from 300 to 600 rpm were applied to control the dissolved oxygen (DO) at approximately 30 %. Aeration was provided using a ring sparger ranging from 0.5 to 2.0 vvm. When glucose concentration in the culture broth decreased to lower than 10 g L-1, the feeding solution composed of glucose (500 g L-1) and (NH4)2SO4 (50 g L-1) was pumped into the bioreactor to control the residual glucose concentration at approximately 10 g L-1. An anti-foam agent KM-70 was used as needed.

Citric acid was supplemented in addition to glucose-(NH4)2SO4 feeding to enhance ε-PL production. The feeding solution consisted of glucose (500 g L-1), (NH4)2SO4 (50 g L-1), and citric acid (50 g L-1; pH was adjusted to 4.0 with an NH4OH solution). The components of the feeding solution were individually prepared and separately autoclaved. Glucose and (NH4)2SO4 were mixed after cooling, whereas citric acid was fed separately. Citric acid was added to the culture broth during the stationary phase (approximately 75 h) of fermentation. The feeding solution was added continuously to maintain the concentration of glucose and citric acid at 10 and 2 g L-1, respectively.

When fermentation ended, the culture filtrate was adjusted to a pH of 2.5 with an HCl solution and then saturated with a methanol/acetone (3:1) mixture to a level from 0 to 40 %. The resulting precipitate was dissolved in deionized water and purified by ion-exchange chromatography on a DEAE-Sepharose column (GE Healthcare, USA) equilibrated with 50 mM potassium phosphate buffer (pH 7.5). Elution was performed with a linear gradient of NaCl in the buffer. The fraction of PDAP was collected and applied to ultrafiltration. The ultrafiltration retentate was further purified by reversed-phase chromatography on a SinoChrom ODS-BP column (Dalian Elite Analytical Instruments, Co. Ltd., Dalian, China) eluted with 0.1 % trifluoroacetic acid/methanol (95:5). The collected effluent was applied with active carbon and dialysis. Thoroughly purified PDAP was finally obtained as a white powder by freeze-drying. ε-PL was obtained from the ε-PL•HCl solution precipitated with 40 to 67 % saturated methanol/acetone (3:1), as described previously (Hirohara et al. 2006).

Identification of PDAP

Fourier transform infrared spectroscopy (FT-IR) was performed on a Nicolet 380 spectrometer (Thermo, USA). The spectroscopic properties of the purified oligomer were evaluated using a KBr pellet at a concentration of 2.5 % (w/w). Matrix-assisted laser desorption ionization-time of flight mass spectrometry (MALDI-TOF/MS) was conducted using a spectrometer (Autoflex 2, Bruker Daltonics Inc., USA), 2,5-dihydroxybenzoic acid was used as a matrix.

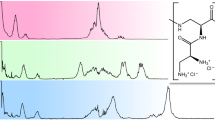

The proton and 13C nuclear magnetic resonance (NMR) spectra were recorded using a Bruker AVANCE AV-500 NMR spectrometer at 500 and 125 MHz, as described previously (Hirohara et al. 2007). The purified oligomer samples were prepared as ca. 4 % solution in D2O containing a small amount of deuterated TMSP [3-(trimethylsilyl) propionic acid sodium salt]. Chemical shifts were measured at 25 °C using 5-mm tubes.

The amino acid composition of the purified oligomer and the L/D isomer ratio of the oligomer residue were determined using high-performance liquid chromatography (HPLC) as described previously for ε-PL (Hirohara et al. 2006) with several modifications. The former was analyzed after hydrolysis (6 M HCl, 110 °C, for 24 h) by precolumn derivatization with ortho-phthalaldehyde according to the manufacturer’s instructions (Agilent Technologies, USA), and the derivatized sample was injected into a Hypersil AA-ODS column(2.1 × 200 mm, Agilent Technologies, USA). The L/D isomer ratio of the oligomer residue was determined using a Crownpak CR (+) column (Daical, Tokyo) in a perchloric acid solution with a pH of 1.4 at 10 °C. The molecular weight distribution of the oligomer was measured by gel permeation chromatography (GPC) on a TSKgel G3000PWXL column (7.8 × 300 mm, Tosoh, Japan). The column was eluted by 0.3 M Na2SO4 (pH was adjusted to 4.0 with acetic acid) at a flow rate of 0.5 mL min-1. The effluent was monitored at 215 nm. The Mn of the oligomer was estimated from the elution profile of GPC column by using polyethylene glycol (weight average molecular weight: 960, 1,460, 4,290, and 7,130) as a molecular weight standard.

Determination of antimicrobial activity

The antimicrobial activity of PDAP and ε-polylysine was evaluated using a 50 % growth-inhibitory concentration (IC50), as described previously for γ-PAB (Takehara et al. 2008). Briefly, each of the test microorganisms listed in Table 1 was inoculated into a liquid medium containing the given concentration of PDAP or ε-polylysine, at the start of the culture, the ODs of each culture broth were adjusted to 0.10 ± 0.01 at 660 nm, and after 24 h of incubation, the turbidities at 660 nm of the culture media were used as a measure of microbial growth. The antimicrobial activity was expressed as a 50 % growth-inhibitory concentration (IC50), the PDAP or ε-polylysine concentration that inhibited the growth of the microorganism to 50 % of that in the absence of each oligomer.

Analytical method

The concentration of ε-PL and PDAP was determined using the HPLC method by Kahar (Kahar et al. 2001) with several modifications. A TSKgel ODS-120T column (4.6 × 250 mm, Tosoh, Tokyo) was used and equilibrated with 0.05 % trifluoroacetic acid/acetonitrile (95:5). The elution was divided into two stages. In the first stage, PDAP was eluted by the equilibrating solution, while ε-PL remained in the column, the first stage of elution lasted for 10 min. In the second stage of elution, the ratio of acetonitrile to 0.05 % trifluoroacetic acid was adjusted in a linear gradient from 5 to 15 % over 5 min, and the ε-PL was eluted. The flow rate was 0.4 mL min -1, and the absorbance of the effluent was recorded at 215 nm at 30 °C.

Fermentation samples were withdrawn from the fermentor for analysis at regular intervals. The broth was centrifuged, and the resulting precipitate was collected, washed twice with distilled water, and dried at 105 °C to a constant weight for dry cell weight (DCW) measurement. The concentration of citric acid was determined using an HPLC system (Agilent, 1200 series, USA) with an ion exchange column Aminex HPX-87H (300 × 7.8 mm, Bio-Rad, USA). A 5 mM H2SO4 solution was used as the mobile phase with a flow rate of 0.6 mL min-1. The effluent was recorded at 215 nm at 60 °C (Sanchez et al. 2008). The glucose concentration was measured using a biosensor (SBA-40C, Shangdong Science Academy, China), and the enzymatic reaction was determined with glucose oxidase.

Results

Purification and identification of a novel non-proteinic amino acid oligomer

The ε-PL producer strain Streptomyces albulus PD-1 secreted an unknown substance identified as product II into its culture broth, along with ε-PL. Gel permeation chromatography indicated that the Mn of product II was 1.26 kDa (Fig. 1), suggesting that product II would be a polymeric substance. We attempted to purify product II for further study considering that the by-products of ε-PL fermentation by Streptomyces albulus have not been reported previously and that product II showed potential as an oligomer. The purification procedures for product II were conducted similarly with that of ε-PL, with several modifications. Purified product II in a white powder was obtained.

The purified samples were characterized first by FT-IR and MALDI-TOF/MS to determine the primary structure. The absorption band in the FT-IR spectrum (Fig. S1) at 1,668 cm-1 (C = O), 1,537 cm-1 (N–H), 1,113 cm-1 (C–N), and 620 cm-1 (N–H) indicated the presence of a secondary amide bond in product II. Thus, product II could be considered a polypeptide, an amino acid oligomer with a linkage between the carboxyl group and the amino group.

The MALDI-TOF/MS spectrum verified the aforementioned speculation (Fig. 2). The arrayed peaks at equal intervals of 86.05 exhibited a repeating structure composed of units with a molecular mass of 86.05, suggesting that product II is an oligomer. We assumed that the oligomer was a linear molecule produced by dehydration of water, the molecular weight of the monomer would then be 104.07 (86.05 + 18.02), and the molecular weight of the oligomer would be calculated based on the formula 104.07 × n − 18.02 × (n − 1), where n is the number of residues. Product II had a series of (M + H)+ values that fit the formula. For example, the signal at 879.50 was consistent with the value obtained by substituting 10 for n in the formula. The amino acid with a molecular mass of 104.07 was supposed to be diaminopropionic acid (DAP). We speculated that product II was poly(diaminopropionic acid) with a molecular mass distribution ranging from 500 to 1,500 Da.

Amino acid and NMR analyses were performed to verify the aforementioned speculation. The amino acid analysis revealed that product II was composed of only one amino acid, which was identified as DAP through HPLC experiments on the hydrolysate of product II and authentic DAP • HCl (Fig. S2). NMR analysis also confirmed this finding. The chemical structures of product II, proton, and 13C NMR spectra are shown in Fig. 3. Chiral HPLC analysis suggested that product II is composed of l-isomer only. The hydrolysate of product II by 6 M HCl at 110 °C for 24 h was identified as L-DAP through HPLC experiments on authentic L-DAP • HCl and DL-DAP • HCl (Fig. S3). Taken together, the oligomer co-produced with ε-PL by Streptomyces albulus PD-1 was identified as poly(l-diaminopropionic acid) consisting of 6–17 L-DAP residues. No co-polymers composed of L-DAP and l-lysine were found in the culture broth.

Antimicrobial activity of PDAP

PDAP is polycationic and secretory. Such characteristics are commonly observed in numerous antimicrobial peptides such as ε-PL and γ-PAB. To verify whether PDAP also exhibits antimicrobial activity, an antimicrobial assay against various microorganisms was performed, and IC50 was employed as a measure of antimicrobial activity. Table 1 summarizes the antimicrobial activity of PDAP against various bacteria and yeasts.

Compared with ε-PL, PDAP exhibited weaker antimicrobial activity against all of the bacteria examined. However, PDAP exhibited stronger inhibitory activity against yeasts than did ε-PL. The aforementioned antimicrobial activity of PDAP was quite similar to that of γ-PAB (Takehara et al. 2008). These findings might suggest that the cationic charge density of the polymer was not the major factor affecting the antibacterial activity, which is generally considered to be caused by the polycationic nature of the antimicrobial peptides. Combining PDAP and ε-PL rather than using them separately might be more advantageous in antimicrobial application.

ε-PL and PDAP co-production

Firstly, we examined ε-PL and PDAP co-production by Streptomyces albulus PD-1 in shake flasks. The production culture medium had an initial pH value of 4.0 for optimal PDAP production and an initial pH value of 4.5 for optimum ε-PL production. However, the medium pH spontaneously decreased to approximately 3.2 at the latter stage of the culture, and the maximum accumulated concentrations of ε-PL and PDAP were simultaneously achieved.

Regarding medium composition of the production culture, organic acids in the citric acid cycle greatly affected the regulation of ε-PL and PDAP co-production (Fig. 4). Among these acids, citric acid facilitated ε-PL production but inhibited PDAP production, whereas α-ketoglutarate and malate exerted the opposite effects. However, succinate completely inhibited the production of both polymers. These phenomena are consistent with previous findings regarding the effects of organic acids on ε-PL synthesis in Streptomyces lydicus USE-11 and Streptomyces sp. USE-51 strains (Hirohara et al. 2006).

Effect of organic acids on ε-PL and PDAP co-production in shake flasks. The production culture medium consisted of 220 mM glycerol, 76 mM (NH4)2SO4, and 20 mM of each organic acids. Samples that were cultured in the medium without any organic acid served as controls. Legend: dark bars ε-PL, gray bars PDAP. Error bars indicate standard deviations obtained from three independent experiments

Further studies were conducted using a 5-L jar fermentor to obtain more information on ε-PL and PDAP co-production. Conventional fed-batch fermentation with a two-stage pH control strategy was applied, considering that PDAP accumulated when the initial pH value of the culture medium was 4.0. The time profile of ε-PL and PDAP co-production is shown in Fig. 5a. The production levels of ε-PL and PDAP were much higher in the fed-batch fermentation, probably because of sufficient aeration and feeding solution in the jar fermentor. Both ε-PL and PDAP were synthesized during the stationary phase of fermentation when pH decreased to below 5.0. The ε-PL concentration reached 21.7 gL-1 at the end of fermentation. By contrast, a final PDAP concentration of 4.8 g L-1 was achieved in approximately 125 h, a markedly shorter time compared with that for ε-PL.

Time profile of ε-PL and PDAP co-production by the strain Streptomyces albulus PD-1 in a 5-L jar fermentor. Fed-batch fermentations with a two-stage pH control strategy were performed. In the first 48 h, the pH was maintained at 6.0. For the remaining fermentation period, the pH was maintained at approximately 4.0. The feeding solution consisted of glucose–(NH4)2SO4 (a) and glucose–(NH4)2SO4–citric acid (b), respectively. Symbols: ε-PL (filled circle), PDAP (filled square), DCW (empty triangle), glucose (empty diamond), and citric acid (empty square)

On the basis of the findings that citric acid facilitated ε-PL production but inhibited PDAP production, citric acid supplementation was expected to enhance ε-PL production on a larger scale. Thus, a citric acid-feeding strategy was employed in ε-PL production by fed-batch fermentation in a 5-L jar fermentor. Considering that both ε-PL and PDAP were synthesized during the stationary phase of fermentation, citric acid was added to the culture broth during this phase (about 75 h). As shown in Fig. 5b, feeding citric acid enhanced both cell growth and ε-PL production, the final DCW increased from 28.2 to 32.3 g L-1, and ε-PL yield increased by 20.3 % from 21.7 to 26.1 g L-1. By contrast, the final concentration of PDAP decreased from 4.8 to 3.8 g L-1, and the production of PDAP was inhibited to a certain degree.

Discussion

To the best of our knowledge, PDAP is another novel poly(amino acid) co-produced with ε-PL in addition to γ-PAB and ls-gPGA, which has not been reported previously. During the purification, PDAP was precipitated at a saturation concentration (0 to 40 %) of methanol/acetone (3:1) mixture that was lower than that of ε-PL (40 to 67 %), suggesting that PDAP was of a higher charge density compared with ε-PL. HPLC quantitative determination (Fig. S4) found that PDAP was eluted by an acetonitrile concentration lower than that of ε-PL. Therefore, PDAP was more hydrophilic than ε-PL.

In addition to γ-PAB and ls-gPGA, PDAD is known as a poly(amino acid) co-produced with ε-PL, suggesting that poly(amino acid) production commonly occurs in some Streptomyces species. Both PDAD and ε-PL have the same antimicrobial spectra but varying specific activities against particular microbes. It is worthy to mention that the short-chain polycations such as PDAP and γ-PAB, as well as ε-PL of 5–20 residues (Takehara et al. 2010), exhibit strong inhibitory activities against various yeasts, whereas long-chain ε-PL (20–35 residues) exhibits no such inhibitory activities (Shima et al. 1984). This finding suggests that the antimicrobial activity of polycations depends not only on electrostatic adsorption onto the cell surface but also on another factor, depending on the composition of microbe cell membranes. Yeast cell membrane usually contains higher ratio of lipids than bacteria, which might lead to more PDAP absorbed electrostatically onto the cell membrane of yeast than that of bacteria, and the antimicrobial activity of PDAP is more effective against yeast than bacteria.

The results in Figs. 4 and 5 may lead to the following discussion. In bacteria, lysine is formed from aspartate produced by combining oxaloacetate in the citric acid cycle with an ammonium ion of a nitrogen source, and ε-PL is non-ribosomally synthesized from lysine monomer. By contrast, L-DAP is present in a number of plants. Several species of Mimosa (Gmelin et al. 1959) and Vicia baicalensis (Bell and Tirimanna. 1965) contain this free amino acid. Besides, L-DAP is a precursor of some peptide antibiotics such as viomycin and capreomycin (Carter et al. 1974; Wang and Gould. 1993). However, the metabolic pathway of L-DAP has not been elucidated thoroughly. By precursor labeling studies in Streptomyces species, the backbone of L-DAP was determined to be synthesized from l-serine (Carter et al. 1974; Wang and Gould. 1993), and l-ornithine was expected to convert to l-proline with the release of ammonia to form L-DAP (Thomas et al. 2003). Thus, we assumed that Streptomyces albulus PD-1 synthesized L-DAP as previously reported and polymerized L-DAP monomer into PDAP.

With the above putative metabolic pathway considered, the effect of organic acids on the ε-PL and PDAP co-production is reasonable. Aspartate transaminase (AAT, EC 2.6.1.1) and glutamate dehydrogenase (GDH, EC 1.4.1.2) influence the regulation of ε-PL and PDAP co-production. Citric acid was reported to inhibit GDH activity to a certain degree (Stone et al. 1979; Kawakami et al. 2007). Consistent with this finding, the metabolic flux of AAT increased, and the production of ε-PL increased when citric acid was added to the medium. α-Ketoglutarate and malate were proven to inhibit AAT activity (Lowe and Rowe 1985; Owen and Hochachka 1974). Thus, the conversion of oxaloacetate to aspartate was inhibited by the addition of α-ketoglutarate and malate. Meanwhile, ε-PL production decreased as PDAP production increased. Succinate inhibits reactions from fumarate to malate (Wigler and Alberty 1960), which terminates the citric acid cycle. Hence, no production of ε-PL and PDAP by the addition of succinate is understandable. Incorporating the results above with those previous studies on the L-DAP metabolic pathway, we proposed a putative metabolic pathway for ε-PL and PDAP co-production in Streptomyces albulus PD-1, as shown in Fig 6.

Recent studies on ε-PL have provided sufficient knowledge on the occurrence and production of this polymer. Novel screening methods have revealed that ε-PLs frequently occur in Streptomyces strains (Nishikawa and Ogawa 2002). More poly(amino acid)s could be discovered in future studies other than the three purified poly(amino acid)s co-produced with ε-PL and some other co-poly(amino acid)s. The discovery of these poly(amino acid)s has contributed to the existing literature on the polymer structure, including various aspects of their production behavior. Such knowledge can be used in both fundamental research and technical applications.

In conclusion, PDAP, a novel non-proteinic amino acid oligomer, was purified from the culture broth of ε-PL-producing strain Streptomyce albulus PD-1. This oligomer exhibited stronger inhibitory activities against yeasts but weaker actions against bacteria than ε-PL. ε-PL production was enhanced, whereas PDAP production was inhibited by citric acid feeding. A putative metabolic pathway in Streptomyces albulus PD-1 was proposed based on previous studies on the L-DAP metabolic pathway and the results of ε-PL and PDAP co-production in the present study. ε-PL is currently industrially produced by fermentation using Streptomyces albulus, to enhance ε-PL production, purposeful inhibition of by-products such as those of PDAP is an effective direction, and further studies are currently in progress in our laboratory.

Reference

Bell EA, Tirimanna AS (1965) Associations of amino acids and related compounds in the seeds of forty-seven species of Vicia: their taxonomic and nutritional significance. Biochem J 97:104–111

Borzi A (1887) Le comunicazioni intracellulari delle Nostochinee. Malpighia 1:74–203

Carter JH II, Du Bus RH, Dyer JR, Floyd JC, Rice KC, Shaw PD (1974) Biosynthesis of viomycin. I. Origin of alpha, beta-diaminopropionic acid and serine. Biochemistry 13:1221–1227

Chiang CH, Yeh MK (2003) Contribution of poly(amino acids) to advances in pharmaceutical biotechnology. Current Pharm Biotechnol 4:323–330

Gmelin R, Strauss G, Hasenmaier G (1959) New amino acids from Mimosaceae. Hoppe-Seyler's Z physiol Chem 314:28–32

Hamano Y, Yoshida T, Kito M, Nakamori S, Nagasawa T, Takagi H (2006) Biological function of the pld gene product that degrades ε-poly-l-lysine in Streptomyces albulus. Appl Microbiol Biotechnol 72:173–181

Hirohara H, Saimura M, Takehara M, Miyamoto M, Ikezaki A (2007) Substantially monodispersed poly(ε-l-lysine)s frequently occurred in newly isolated strains of Streptomyces sp. Appl Microbiol Biotechnol 76:1009–1016

Hirohara H, Takehara M, Saimura M, Ikezaki A, Miyamoto M (2006) Biosynthesis of poly(ε-l-lysine)s in two newly isolated strains of Streptomyces sp. Appl Microbiol Biotechnol 73:321–331

Ivánovics G, Erlös L (1937) Ein Beitrag zum Wesen der Kapselsubstanz des Milzbrandbazillus. Z Immunitätsforsch Exp Ther 90:5–19

Kahar P, Iwata T, Hiraki J, Park EY, Okabe M (2001) Enhancement of ε-polylysine production by Streptomyces albulus strain 410 using pH control. J Biosci Bioeng 91:190–194

Kawakami R, Sakuraba H, Ohshima T (2007) Gene cloning and characterization of the very large NAD-dependent l-glutamate dehydrogenase from the psychrophile Janthinobacterium lividum, isolated from cold soil. J Bacteriol 189:5626–5633

Kunioka M (1997) Biosynthesis and chemical reactions of poly(amino acid)s from microorganisms. Appl Microbiol Biotechnol 47:469–475

Lowe PN, Rowe AF (1985) Aspartate:2-oxoglutarate aminotransferase from Trichomonas vaginalis. Identity of aspartate aminotransferase and aromatic amino acid aminotransferase. Biochem J 232:689–695

Nishikawa M, Kobayashi K (2009) Streptomyces roseoverticillatus produces two different poly(amino acid)s: lariat-shaped γ-poly(l-glutamic acid) and ε-poly(l-lysine). Microbiology 155:2988–2993

Nishikawa M, Ogawa K (2002) Distribution of microbes producing antimicrobial ε-poly-l-lysine polymers in soil microflora determined by a novel method. Appl Environ Microbiol 68:3575–3581

Nishikawa M, Ogawa K (2004) Antimicrobial activity of a chelatable poly(arginyl-histidine) produced by the ergot fungus Verticillium kibiense. Antimicrob Agents Chemother 48:229–235

Ouyang J, Xu H, Li S, Zhu HY, Chen WW, Zhou J, Wu Q, Xu L, Ouyang PK (2006) Production of ε-poly-l-lysine by newly isolated Kitasatospora sp. PL6-3. Biotechnol J 1:1459–1463

Owen TG, Hochachka PW (1974) Purification and properties of dolphin muscle aspartate and alanine transaminases and their possible roles in the energy metabolism of diving mammals. Biochem J 143:541–553

Rauser WE (1995) Phytochelatins and related peptides. Structure, biosynthesis, and function. Plant Physiol 109:1141–1149

Sanchez C, Neves AR, Cavalheiro J, dos Santos MM, Garcia-Quintans N, Lopez P, Santos H (2008) Contribution of citrate metabolism to the growth of Lactococcus lactis CRL 264 at low pH. Appl Environ Microbiol 74:1136–1144

Shima S, Fukuhara Y, Sakai H (1982) Inactivation of bacteriophages by ε-poly-l-lysine produced by Streptomyces. Agric Biol Chem 46:1917–1919

Shima S, Matsuoka H, Iwamoto T, Sakai H (1984) Antimicrobial action of ε-poly-l-lysine. J Antibiot 37:1449–1455

Shima S, Sakai H (1977) Polylysine produced by Streptomyces. Agric Biol Chem 41:1807–1809

Stone SR, Copeland L, Kennedy IR (1979) Glutamate-dehydrogenase of lupin nodules: purification and properties. Phytochemistry 18:1273–1278

Takehara M, Hibino A, Saimura M, Hirohara H (2010) High-yield production of short chain length poly(ε-l-lysine) consisting of 5–20 residues by Streptomyces aureofaciens, and its antimicrobial activity. Biotechnol Lett 32:1299–1303

Takehara M, Saimura M, Inaba H, Hirohara H (2008) Poly(γ-l-diaminobutanoic acid), a novel poly(amino acid), coproduced with poly(ε-l-lysine) by two strains of Streptomyces celluloflavus. FEMS Microbiol Lett 286:110–117

Thomas MG, Chan YA, Ozanick SG (2003) Deciphering tuberactinomycin biosynthesis: isolation, sequencing, and annotation of the viomycin biosynthetic gene cluster. Antimicrob Agents Chemother 47:2823–2830

Wang M, Gould SJ (1993) Biosynthesis of capreomycin. 2. Incorporation of l-serine, l-alanine, and l-2,3-diaminopropionic acid. J Org Chem 58:5176–5180

Wigler PW, Alberty RA (1960) The pH dependence of the competitive inhibition of fumarase. J Am Chem Soc 82:5482–5488

Yamanaka K, Kito N, Imokawa Y, Maruyama C, Utagawa T, Hamano Y (2010) Mechanism of ε-poly-l-lysine production and accumulation revealed by identification and analysis of an ε-poly-l-lysine-degrading enzyme. Appl Environ Microbiol 76:5669–5675

Yamanaka K, Maruyama C, Takagi H, Hamano Y (2008) ε-Poly-l-lysine dispersity is controlled by a highly unusual nonribosomal peptide synthetase. Nat Chem Biol 4:766–772

Yoshida T, Nagasawa T (2003) ε-Poly-l-lysine: microbial production, biodegradation and application potential. Appl Microbiol Biotechnol 62:21–26

Zhang Y, Feng XH, Xu H, Yao Z, Ouyang PK (2010) ε-Poly-l-lysine production by immobilized cells of Kitasatospora sp. MY 5–36 in repeated fed-batch cultures. Bioresour Technol 101:5523–5527

Acknowledgments

This work was supported by the National Nature Science Foundation of China (No. 21176123 and No. 21006050), the National Basic Research Program of China (973) (No. 2013CB733600), Specialized Research Fund for the Doctoral Program of Higher Education (No. 20113221130001), Changjiang Scholars and Innovative Research Team in University (No. IRT1066) and Graduate Student Innovation Project of Jiangsu Province (No.CXZZ13_0464).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 678 kb)

Rights and permissions

About this article

Cite this article

Xia, J., Xu, H., Feng, X. et al. Poly(l-diaminopropionic acid), a novel non-proteinic amino acid oligomer co-produced with poly(ε-l-lysine) by Streptomyces albulus PD-1. Appl Microbiol Biotechnol 97, 7597–7605 (2013). https://doi.org/10.1007/s00253-013-4936-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-4936-4