Abstract

The antibacterial polymer ɛ-poly-l-lysine (ε-PL) has been widely used as a safe food preservative. As the synthesis of ε-PL requires a rich supply of nitrogen, the efficiency of nitrogen translocation and utilization is extremely important. The objective of this study was to improve the production of ε-PL by overexpressing the ammonium transporter gene amtB in Streptomyces albulus PD-1. Using the recombinant bacteria, the optimum carbon-to-nitrogen ratio in the synthesis stage of fermentation increased from 3 to 4.71, compared with that obtained using the wild-type strain, and the utilization efficiency of ammonium was improved too. Ultimately, the production of ε-PL increased from 22.7 to 35.7 g/L upon fed-batch cultivation in a 5 L bioreactor. Determination of the expression of the genes and enzymes associated with ammonium metabolism and ε-PL synthesis revealed that the overexpression of amtB in S. albulus PD-1 enhanced ε-PL biosynthesis by increasing the activity of the corresponding metabolic pathways. To the best of our knowledge, this is the first report on enhancing ε-PL production by overexpression of the amtB gene in an ε-PL-producing strain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

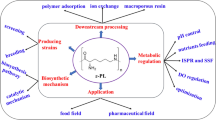

The biopolymer ε-poly-l-lysine (ε-PL) is composed of 25–35 l-lysine residues with linkages between the ɑ-carboxyl and ε-amino groups [1]. It is mainly produced by the members of the family Streptomycetaceae [2, 3]. ε-PL is regarded as safe for human consumption owing to its broad-spectrum antimicrobial properties, water solubility, thermal stability, and non-toxicity [4]. As such, ε-PL has been approved as a food preservative in Japan, Korea, the United States and China [5, 6]. Furthermore, because it is biocompatible and biodegradable, ε-PL and its derivatives have been widely used as emulsifiers, biodegradable fibers, high-strength hydrogels, drug carriers, and biochips [7,8,9]. For example, recent studies demonstrate that the ε-PL-based hydrogels can be easily integrated into biological tissues, thus serving as wound dressings [10].

Nitrogen is a constituent element of cellular components such as proteins, nucleic acids and several cofactors [11]. It also regulates primary and secondary metabolism in different bacteria, including Streptomyces [12,13,14]. ε-PL is synthesized from l-lysine monomers by a non-ribosomal peptide synthetase, and the polymerization process requires a large amount of l-lysine, which acts as the direct precursor. The supply of a sufficient amount of nitrogen is essential for ε-PL fermentation, because each l-lysine molecule contains two nitrogen atoms, although most of the other amino acids have only one. Among the many nitrogen sources, inorganic (NH4)2SO4 was found to have a strong positive effect on ε-PL production [4, 15]. Furthermore, some organic nitrogen sources, such as yeast extract and beef extract, were found to contribute to the production of ε-PL by promoting cell growth [16, 17]. However, the excessively high nitrogen concentrations affect both the synthesis of enzymes involved in primary and secondary metabolism, as well as the utilization of different nitrogen sources from the fermentation medium [18]. To alleviate its negative effects, the residual nitrogen concentration is often maintained at a suitable level using fed-batch fermentation strategies [19]. With the development of molecular biotechnology, it has become possible to increase the utilization efficiency of nitrogen sources through genetic manipulation [20].

Ammonium transport proceeds in two ways, via free diffusion in the form of NH3 gas and active transport in the form of the NH4+ cation. When NH3 diffusion across the membrane is limited during metabolism, the ammonium transporter amtB is expressed to facilitate the transport of NH4+ from the extracellular environment into the cells [12, 21]. Because ε-PL is synthesized under acidic conditions of pH 4.0 in the fermentation process [22], ammonia primarily exists in the form of NH4+ ions in the fermentation broth. Therefore, NH4+ ions enter the cell primarily through the ammonium transporter, providing a nitrogen source for cell growth and ε-PL synthesis. Several studies have demonstrated that increasing the expression of genes related to nitrogen transport can significantly enhance the production of many valuable compounds. For example, Sindelar et al. improved l-lysine production by overexpressing the amtA-ocd-soxA operon in Corynebacterium glutamicum [23]. Similarly, Meng et al. enhanced the synthesis of antibiotics via heterologous expression of nitrate/nitrite transporter genes in actinomycetes [24]. Judging by the findings of these studies, the question whether the overexpression of amtB in S. albulus PD-1 can be used to produce more ε-PL remains of great significance.

In this study, the amtB gene was overexpressed using different promoters in S. albulus PD-1 to investigate its effect on ε-PL production. The fermentation results showed a significant increase in the production of ε-PL. Furthermore, to elucidate the effects of amtB in S. albulus PD-1, we analyzed the transcriptional level and enzyme activity of ε-PL synthetase and proteins related to nitrogen absorption and assimilation. The findings of this study, thus, broaden our understanding of nitrogen metabolism in S. albulus PD-1, and provide an efficient fermentation strategy to improve the industrial fermentation of ε-PL.

Materials and methods

Strains and plasmids

The ε-PL producer S. albulus PD-1 has been deposited in the China Center for Type Culture Collection (Accession No. M2011043). Escherichia coli DH5α (Tiangen Biotech CO., Beijing, China) was used as the host strain for maintenance and propagation of plasmids. Escherichia coli ET12567 (pUZ8002) [25] was used as the non-methylating plasmid donor strain for intergeneric conjugation with S. albulus PD-1. The chromosomally integrated shuttle vector (E. coli/Streptomyces), pSET152, which can integrate specifically into the attB sites on the Streptomyces chromosome via integrase-attp-directed site-specific recombination, was used for overexpression of amtB.

Culture media

The Luria–Bertani (LB) medium for E. coli strains comprised 10 g/L tryptone, 5 g/L yeast extract, and 10 g/L NaCl; solid medium was produced by adding 20 g/L agar. Mannitol-soy flour (MS) agar medium comprising 20 g/L mannitol, 20 g/L soy flour, 40 mM MgCl2 and 20 g/L agar was used for intergeneric conjugation. Medium 3G (M3G) that was used for fermentation consisted of 50 g/L glucose, 10 g/L (NH4)2SO4, 5 g/L yeast extract, 0.5 g/L MgSO4·7H2O, 0.8 g/L K2HPO4, 1.36 g/L KH2PO4 0.03 g/L FeSO4·7H2O, 0.04 g/L and ZnSO4·7H2O. When required, antibiotics were used at the following concentrations: 30 µg/mL apramycin, 25 µg/mL kanamycin, 25 µg/mL chloramphenicol and 25 µg/mL nalidixic acid.

Molecular manipulations

For the construction of amtB overexpression plasmids, the strong promoter PermE* and the original promoter (PamtB) of amtB were compared (Fig. 1). The nucleotide sequences of amtB gene and amtB gene with PamtB were amplified from genomic DNA of S. albulus PD-1 using the primers amtB-F/amtB-R and amtB-F’/amtB-R, respectively. The promoter ermE* was amplified from plasmid pIB139 using the primers PermE*-F/PermE*-R. The resulting PCR products were inserted into the vector backbone pSET152 which had been digested with the corresponding enzymes to create plasmids pSET152-PermE*-amtB and pSET152-PamtB-amtB by seamless cloning [26]. The resulting recombinant vectors were introduced into E. coli ET12567 and then transferred into S. albulus PD-1 by intergeneric conjugation. All the constructed plasmids were verified by restriction enzyme digestion and DNA sequencing. The manipulations were conducted as described before with some modifications [27]. Furthermore, to investigate the effect of pSET152 on ε-PL biosynthesis, the empty plasmid pSET152 was also integrated into the S. albulus PD-1 genome, generating S. albulus PD-1-pSET152. The corresponding primers are listed in Table 1.

Shake flask two-stage culture

Firstly, cells were cultured 24 h in M3G medium at 30 °C and 200 rpm. The resulting seed cultures were used to inoculate the second stage medium at 10% (v/v), after which fermentation was conducted at 30 °C and 200 rpm for 7 days. In the second stage, the glucose concentration was kept constant at 10 g/L, and the nitrogen content in (NH4)2SO4 were controlled at 0.2, 0.3, 0.4, 0.5, 1 g/L, 1.5 and 2, respectively. The carbon nitrogen ratio (C/N) (mol/mol) was varied from 23, 16.5, 11.5, 9.17, 4.71, 3 and 2.36 by calculation of the carbon nitrogen ratio formula, respectively. The concentration of NH4+–N was determined according to Zhou et al. [28]. The standard solution of ammonium was diluted with water to different concentrations and their absorbance determined separately after indophenol blue reaction for 35 min to generate a standard curve of NH4+–N concentrations. The content of carbon and nitrogen in the fermentation broth was based on the initial concentration of glucose and ammonium nitrogen (CGlu and CNH4+–N). The carbon-to-nitrogen ratio (mol/mol) was calculated according to the following formula

Fed-batch fermentation and analysis of key parameters

Fed-batch fermentation was performed in a 5-L jar-fermenter (Baoxing Corp., Shanghai, China) using a published two-stage pH control method [29]. The pH was initially maintained at 6.0 by adding ammonia for 24 h to promote cell growth, after which it was reduced to 4.0 to stimulate ε-PL production. The residual sugar in the fermentation broth was measure using an SBA-40C biological analyzer (Shandong Academy of Sciences, China). The broth was centrifuged, and the resulting precipitate was collected, washed twice with distilled water, and dried at 105 °C to a constant weight to determine the dry cell weight (DCW). The concentration of ε-PL was determined via high-performance liquid chromatography (HPLC) using TSKgel ODS-120T column (4.6 × 250 mm, Tosoh, Tokyo), according to a previously reported method [30].The detection wavelength was recorded at 215 nm at 30 °C.

RNA sample preparation and qRT-PCR analysis

As the fed-batch fermentation reached 110 h, the maximum specific ε-PL production rate was reached. At this timepoint, the transcriptional levels of amtB, glutamate dehydrogenase (GDH) gene (gdhA), GS (glnA), GOGAT (gltB), aspartate kinase (ask) and ε-PL synthetase (pls) were determined by quantitative real-time PCR (qRT-PCR) using a previously described method [31]. RNA extraction was performed using an RNeasy MiniKit (TaKaRa Biotechnology Company, Dalian, China), and reverse transcription reactions were performed using a PrimeScript RT Reagent Kit (TaKaRa Biotechnology Company, Dalian, China). qRT-PCR was carried out in 25µL reaction mixtures comprising SYBR Premix ExTaq (12.5 µL), forward primer (1 µL; 5 pmol), reverse primer (1 µL; 5 pmol), and cDNA (2 µL; 25 ng/µL) in ddH2O. The PCR reaction conditions were as follows: 30 s at 95 °C, followed by 40 cycles comprising 5 s at 95 °C and 30 s at 60 °C each, and a final cycle comprising 15 s at 95 °C, 1 min at 60 °C, and 15 s at 95 °C. All reactions were repeated three times and the qRT-PCR results were subjected to the 2−∆∆Ct method [32] for relative quantification with the hrdB gene as endogenous control [33, 34]. Primers were designed according to the S. albulus PD-1 genome sequence and are listed in Table 1.

Enzyme activity assays

When the fed-batch fermentation reached 110 h, the mycelia from 10 mL of culture broth were harvested by centrifugation, washed twice with 0.85% (w/v) saline, and suspended in 1 mL buffer containing 40% glycerol, 10 mM dithiothreitol and 100 mM Tris–HCl buffer (pH8.0). The suspended mycelia were disrupted by sonication. Cell debris was removed by centrifugation at 16,000×g for 20 min, and the supernatant was collected as crude extract for enzymatic activity assays. The GDH and GOGAT activities were measured spectrophotometrically by monitoring the rate of NADPH oxidation at 340 nm [35]. The GDH activity was measured by adding a crude enzyme solution to a solution containing 50 mM Tris-HC1 buffer (pH 7.6), 150 mM NH4Cl, 7 mM α-ketoglutarate and 0.12 mM NADPH. The GOGAT activity was measured by adding a crude enzyme solution to a solution containing 50 mM Tris-HC1 buffer (pH 7.6), 15 mM glutamine, 3 mM α-ketoglutarate, 0.05 Mm NADPH. One unit of enzyme activity is defined as the amount of enzyme which catalyzes the oxidation of 1 µmol of NADPH per min. The GS activity [35] was measured by adding a crude enzyme solution to a solution containing 50 mM imidazole–HCl buffer (pH 7.0), 15 mM MgCl2, 55 mM glutamate (sodium salt-pH was adjusted to 7.0 with 1 N NaOH), 2.5 mM ATP, 25 mM NH4Cl. One unit of GS activity is defined as the amount of enzyme which catalyzes the formation of 1 µmol γ-glutamyl hydroxamate per min in the transferase; Aspartate kinase (Ask) was measured according to Xu et al. [31], the reaction mixture with a total volume of 100 mM Tris–HCl (pH 7.0), 600 mM (NH4)2SO4, 600 mM hydroxylamine–NaOH (pH7.0), 10 mM MgSO4, 10 mM ATP and 10 mM aspartate–NaOH (pH7.0) and crude extract. One unit of Ask activity catalyzed the formation of 1 µmol of aspartyl-β-hydroxamate per minute in the assay at 30 °C. ε-PL synthetase (Pls) were measured according to Chen et al. [36]. Briefly, the Pls activity was determined by monitoring the reduction of l-lysine using HPLC in a 1 mL reaction mixture with the following composition: 100 mM Tris–HCl (pH 8.0), 100 mM l-lysine, 50 mM ATP, 50 mM MgCl2, 50 mM dithiothreitol, and 20µL membrane fraction solutions. One unit of enzyme activity is defined as the amount of enzyme catalyzing the consumption of 1 pmol l-lysine per second at 30 °C.

Results and discussion

Construction of recombinant plasmids and strains

As depicted in Fig. 1, two plasmids, pSET152-PermE*-amtB and pSET152-PamtB-amtB, were constructed and verified via single- and double restriction enzyme digestions. The results suggested that the two recombinant plasmids were successfully constructed. Subsequently, intergeneric conjugation was used to individually transfer these two recombinant plasmids and the empty vector control pSET152 into S. albulus PD-1, resulting in the three strains S. albulus PD-1-pSET152, S. albulus PD-1-pSET152-PermE*-amtB and S. albulus PD-1-pSET152-PamtB-amtB.

Effects of amtB overexpression on ε-PL synthesis

The modified S. albulus strains PD-1-pSET152, PD-1-pSET152-PermE*-amtB and PD-1-pSET152-PamtB–amtB, as well as the wild-type S. albulus PD-1 were cultured in shake flasks to investigate the effects of amtB overexpression on DCW, ε-PL synthesis and ammonium utilization. As shown in Table 2, the empty vector control pSET152 that was integrated into the chromosome of S. albulus PD-1 had no effect on ε-PL production, as expected. By contrast, the two recombinant strains overexpressing the target gene showed a great production improvement over the wild type. The results revealed that the plasmids pSET152-PamtB-amtB and pSET152-PermE*-amtB led to increases of ε-PL production by 11.5 and 22.1% over the parental strain, respectively (Table 2). Similarly, Sindelar et al. reported that overexpression of amtA-ocd-soxA enhanced l-lysine production, and they speculated that this was caused by increased ammonium uptake due to higher AmtA levels [23]. In this study, the residual NH4+–N of the amtB-overexpressing strains was lower than that of the wild type (Table 2). This result indicated that the overexpression of the ammonium transporter improved the efficiency of nitrogen source utilization. Moreover, the effect was stronger with PermE* than with the native promoter of amtB. As a strong promoter, PermE* showed a good performance in the genetic manipulation of many ε-PL-overproducing strains [37, 38]. Other studies have shown that the strong constitutive ermE* promoter could overwhelm the complex regulatory cascade in the metabolic process and increase the production of target chemicals [39]. Furthermore, the biomass of these two recombinant strains showed a slight improvement over the wild type. These results showed that the overexpression of amtB enhanced the transport of ammonium ions and promoted the synthesis of ε-PL. The S. albulus strain PD-1-pSET152-PermE*-amtB was selected for further experiments and renamed as S. albulus PD-1-amtB for sake of brevity.

Optimum carbon-to-nitrogen ratio during the synthesis stage

The ratio of carbon and nitrogen is an important parameter in microbial fermentations, and a suitable ratio can greatly increase the synthesis of target products [40]. Previous studies focused on optimizing the initial C/N ratio of fermentation materials, and ignored the direct influence of the C/N ratio during the phase of active ε-PL synthesis. In view of this problem, S. albulus PD-1-amtB and S. albulus PD-1 were subjected to two stages of flask fermentation [4] at different carbon-to-nitrogen ratios at a constant carbon concentration.

As shown in Fig. 2, with the decrease of C/N concentration in the medium, the synthetic ability of S. albulus PD-1 and S. albulus PD-1-amtB presented a trend that changed from increase to decrease. Thus, it was found that too low or too high concentrations of nitrogen sources had inhibitory effects on cell growth and product synthesis, and similar results were also observed in other studies [41,42,43]. Moreover, under the same C/N ratio, the ε-PL yield of S. albulus PD-1-amtB was higher than that of S. albulus PD-1. Furthermore, the optimal C/N ratio of S. albulus PD-1-amtB was 4.71, higher than that of S. albulus PD-1, and their ε-PL titers were 1.475 and 1.236 g/L, respectively. This implied that the ammonium utilization efficiency of strain S. albulus PD-1-amtB was increased after overexpressing amtB. Thus, the optimal C/N ratio for S. albulus PD-1-amtB during the ε-PL synthesis period was found to be 4.71, which provided guidance for the following fed-batch fermentations.

Influence of different C/N ratios at a constant C concentration on the ε-PL yield in two-stage shake flask fermentations for 7 days. The initial carbon source in the production culture medium was 10 g/L glucose, and the nitrogen content in (NH4)2SO4 were controlled at 0.2, 0.3, 0.4, 0.5, 1 g/L, 1.5 and 2, respectively. *p < 0.05; Duncan’s multiple range test

Fed-batch fermentation performance of the recombinant strains

Based on the optimization in two-stage shake-flask fermentations, 5 L fed-batch fermentations were performed with C/N ratios for S. albulus PD-1 and S. albulus PD-1-amtB of 3 and 4.71, respectively. The residual sugar concentration was maintained at approximately 10 g/L during the fed-batch fermentation, as described in a previous study [44].

As shown in Fig. 3a, b, S. albulus-PD-1-amtB showed a 15.8% increase of the final DCW (32.3 g/L) and 55.2% increase of ε-PL production (35.7 g/L) compared to the wild-type strain. To analyze the dynamic changes of pH, cell growth and ε-PL production, the specific cell growth rate and specific ε-PL production rate of the two strains were fitted based on the data shown in Fig. 3. The specific cell growth rate is shown in Fig. 4a. Notably, S. albulus PD-1-amtB maintained a certain growth advantage over the wild-type strain throughout the fermentation process. This was attributed not only to the increase of ammonium transport efficiency, but also to the low nitrogen supplement concentration in the culture supernatant of S. albulus PD-1-amtB, which may alleviate the repression that occurs at higher NH4+ concentrations to some extent [18].

Comparison of the wild type and amtB-overexpressing strain in fermentations in a 5-L jar bioreactor using a two-stage pH control strategy. The residual sugar concentration was maintained at approximately 10 g/L during the fed-batch fermentation; the C/N ratios for S. albulus PD-1 and S. albulus PD-1-amtB were maintained at 3 and 4.71 during the fed-batch fermentation, respectively. a S. albulus PD-1, b S. albulus PD-1-amtB

The specific ε-PL production rate is shown in Fig. 4b. During the first 48 h, there was almost no difference in the synthetic ability of the two strains, because the early stage mainly encompasses the growth of the bacteria. After the pH was reduced to 4.0, the ε-PL began to enter the high-speed synthesis period. During this time, the specific ε-PL production rate of S. albulus PD-1-amtB was significantly higher than that of the wild-type strain, indicating that the ε-PL synthesis ability of the cells was strengthened after overexpressing amtB. Thus, this work offers great promise for the industrial production of ε-PL.

Enhancement of relevant metabolic pathways

Ammonium is utilized as the main nitrogen source via two stages of uptake and assimilation [45]. After ammonium is transported into the cells, assimilation proceeds via glutamate dehydrogenase (GDH) or glutamine synthetase/glutamate synthase (GS/GOGAT), depending on the ammonium availability in the medium. At high concentrations (> 1 mM), it is primarily assimilated by GDH, while at low concentrations it is solely assimilated by GS/GOGAT to yield l-glutamate [46, 47]. However, to meet the demand for the synthesis of glutamine, the GS pathway is still active at high nitrogen concentrations [48]. Since the concentration of ammonium in our study was maintained at a high level during the synthesis phase of ε-PL, the GDH pathway was utilized for the synthesis of glutamate. Thus, to investigate the mechanism by which the overexpression of the ammonium transport protein increased ε-PL production, the transcription profiles of genes related to nitrogen metabolism and ε-PL synthesis were measured.

The transcription level of amtB was increased 2.1-fold (Fig. 5a), which indicated that amtB was successfully overexpressed under the control of the strong PermE* promoter. Thus, it is conceivable that ammonium uptake was increased due to higher amtB levels [23]. As shown in Fig. 5a, b, the transcription level and enzyme activity of the GDH gene (gdhA) were increased 1.5 and 1.3 times compared to the control group, respectively. The higher amtB transcription level could in turn have stimulated ammonium assimilation. Consequently, the high expression of GDH, could enhance the accumulation of glutamate [49]. Furthermore, the glutamate could provide nitrogen for the synthesis of the precursor l-lysine through transamination, while the formation of α-ketoglutaric acid could promote the TCA cycle at the same time, providing carbon for l-lysine synthesis [50]. Ultimately, these metabolic changes led to an increase of ε-PL production.

In addition, another assimilation system was investigated by measuring the transcription level of the GS gene (glnA). It was found to be increased 1.2 times (Fig. 5a) and its enzyme activity accordingly increased from 1.45 to 1.92 U/mg protein (Fig. 5b). Glutamine functions as a nitrogen donor in the synthesis of carbamoyl phosphate, histidine, purines, and glucosamine-6-phosphate, a precursor of peptidoglycan [51]. Therefore, the stronger GS activity promoted the synthesis of more glutamine, which could have improved the growth of the bacteria. By contrast, the transcriptional level of the GOGAT gene (gltB) and its enzyme activity were almost unchanged (Fig. 5a, b), which also proved that the GOGAT system does not play an important role at high nitrogen concentrations [12].

Further investigations of the key enzymes in the ε-PL synthesis pathway were also conducted. The transcription level of the aspartate kinase gene (ask) was found to be increased 1.4 times (Fig. 5a) and its enzyme activity accordingly increased from 37.45 to 52 U/mg protein (Fig. 5b). As the key enzyme of the diaminopimelic acid pathway (DAP), the increase of ask activity indicated that more l-lysine was used for the synthesis of ε-PL [19]. Furthermore, the transcription level of the ε-PL synthetase gene (pls) was found to be increased 1.6 times (Fig. 5a) and the enzyme activity increased from 59.87 to 73.5 U/mg protein (Fig. 5b). These results suggested that amtB overexpression has a profound effect not only on ammonium assimilation but also on ε-PL biosynthesis. In conclusion, the overexpression of amtB strengthened the transport of ammonium, thereby promoting its assimilation, which in turn resulted in intracellular accumulation of l-lysine and increased the yield of ε-PL. Nevertheless, the specific relationship between nitrogen metabolism and the ε-PL synthesis pathway is still unclear and further studies are needed.

Conclusions

In this study, the amtB gene was successfully overexpressed by increasing its transcriptional level in the ε-PL-producing strain S. albulus PD-1 for the first time. Consequently, the production of ε-PL increased from 22.7 to 35.7 g/L in fed-batch culture in a 5 L bioreactor. The analysis of transcriptional and enzyme activity levels showed that the strain’s ammonium absorption and assimilation abilities were enhanced, which promoted the ε-PL synthesis pathway. Therefore, this study deepens our understanding of nitrogen utilization in the ε-PL-producing strain S. albulus PD-1, and will provide the basis for improving the production of biochemicals in other actinomycetes by rational engineering.

References

Xu Z, Xu Z, Feng X, Xu D, Liang J, Xu H (2016) Recent advances in the biotechnological production of microbial poly(ɛ-l-lysine) and understanding of its biosynthetic mechanism. Appl Microbiol Biotechnol 100:6619–6630

Hiraki J, Ichikawa T, Ninomiya S, Seki H, Uohama K, Seki H, Kimura S, Yanagimoto YBJ Jr (2003) Use of adme studies to confirm the safety of epsilon-polylysine as a preservative in food. Regul Toxicol Pharmacol 37:328–340

Pandey AK, Kumar A (2014) Improved microbial biosynthesis strategies and multifarious applications of the natural biopolymer epsilon-poly-L-lysine. Process Biochem 49:496–505

Hirohara H, Takehara M, Saimura M, Ikezaki A, Masayuki A, Miyamoto M (2006) Biosynthesis of poly(epsilon-l-lysine)s in two newly isolated strains of streptomyces sp. Appl Microbiol Biotechnol 73:321–331

Yoshida T, Nagasawa T (2003) Epsilon-poly-l-lysine: microbial production, biodegradation and application potential. Appl Microbiol Biotechnol 62:21–26

Xu D, Yao H, Xu Z, Wang R, Xu Z, Li S, Feng X, Liu Y, Xu H (2017) Production of ɛ-poly-lysine by Streptomyces albulus PD-1 via solid-state fermentation. Bioresour Technol 223:149–156

Cai L, Tabata H, Kawai T (2001) Probing electrical properties of oriented DNA by conducting atomic force microscopy. Nanotechnology 12:211–216

Laurinavicius V, Kurtinaitiene B, Liauksminas V, Ramanavicius A, Meskys R, Rudomanskis R, Skotheim T, Boguslavsky L (1999) Oxygen insensitive glucose biosensor based on PQQ-dependent glucose dehydrogenase. Anal Lett 32:299–316

Shih IL, Shen MH, Van YT (2006) Microbial synthesis of poly(ε-lysine) and its various applications. Bioresour Technol 97:1148–1159

Wang R, Li J, Chen W, Xu T, Yun S, Xu Z, Xu Z, Sato T, Chi B, Xu H (2017) A biomimetic mussel-inspired ε-poly-l-lysine hydrogel with robust tissue-anchor and anti-infection capacity. Adv Funct Mater 27:1604894

Evans HJ, Bottomley PJ, Newton WE (1985) Nitrogen fixation research progress. Springer, Netherlands

Merrick MJ, Edwards RA (1996) Nitrogen control in bacteria. Microbiol Rev 59:604–622

Hodgson DA (2000) Primary metabolism and its control in streptomycetes: a most unusual group of bacteria. Adv Microb Physiol 42:47–238

Mart Xed JF (2004) Phosphate control of the biosynthesis of antibiotics and other secondary metabolites is mediated by the PhoR-PhoP system: an unfinished story. J Bacteriol 186:5197–201

Shih IL, Shen MH (2006) Application of response surface methodology to optimize production of poly-ɛ-lysine by Streptomyces albulus IFO 14147. Enzym Microb Technol 39:15–21

Chen X, Tang L, Li S, Liao L, Zhang J, Mao Z (2011) Optimization of medium for enhancement of ε-poly-l-lysine production by Streptomyces sp. M-Z18 with glycerol as carbon source. Bioresour Technol 102:1727–1732

Liu SR, Wu QP, Zhang JM, Mo SP (2015) Efficient production of ε-poly-l-lysine by Streptomyces ahygroscopicus using one-stage pH control fed-batch fermentation coupled with nutrient feeding. J Microbiol Biotechnol 25:358–365

Sanchez S, Demain AL (2002) Metabolic regulation of fermentation processes. Enzyme Microb Technol 31:895–906

Ren XD, Chen XS, Tang L, Zeng X, Wang L, Mao ZG (2015) Physiological mechanism of the overproduction of ε-poly-l-lysine by acidic pH shock in fed-batch fermentation. Bioprocess Biosyst Eng 38:2085–2094

Reuther J, Wohlleben W (2007) Nitrogen metabolism in streptomyces coelicolor: transcriptional and post-translational regulation. J Mol Microbiol Biotechnol 12:139–146

Detsch C, Stülke J (2003) Ammonium utilization in bacillus subtilis: transport and regulatory functions of nrgA and nrgB. Microbiology 149:3289–3297

Ren XD, Chen XS, Zeng X, Wang L, Tang L, Mao ZG (2015) Acidic pH shock induced overproduction of ε-poly-l-lysine in fed-batch fermentation by Streptomyces sp.M-Z18 from agro-industrial by-products. Bioprocess Biosyst Eng 38:1113–1125

Sindelar G, Wendisch VF (2007) Improving lysine production by corynebacterium glutamicum through dna microarray-based identification of novel target genes. Appl Microbiol Biotechnol 76:677–689

Meng S, Wu H, Wang L, Zhang B, Bai L (2017) Enhancement of antibiotic productions by engineered nitrate utilization in actinomycetes. Appl Microbiol Biotechnol 101:1–12

Kieser T, Bibb MJ, Buttner MJ, Chater KF, Hopwood DA (2000) Practical Streptomyces genetics. The John Innes Foundation, Norwich

Lu Q (2005) Seamless cloning and gene fusion. Trends Biotechnol 23:199–207

Xu Z, Cao C, Sun Z, Li S, Xu Z, Feng X, Xu H (2015) Construction of a genetic system for Streptomyces albulus PD-1 and improving poly(ε-l-lysine) production through expression of Vitreoscilla hemoglobin. J Microbiol Biotechnol 25:1819–1826

Zhou YP, Ren XD, Wang L, Chen XS, Mao ZG, Tang L (2015) Enhancement of ε-poly-lysine production in ε-poly-lysine-tolerant Streptomyces sp. by genome shuffling. Bioprocess Biosyst Eng 38:1705–1713

Kahar P, Iwata T, Hiraki J, Park EY, Okabe M (2001) Enhancement of ε-polylysine production by streptomyces albulus strain 410 using pH control. J Biosci Bioeng 91:190–194

Xia J, Xu Z, Xu H, Feng X, Bo F (2014) The regulatory effect of citric acid on the co-production of poly(ε-lysine) and poly(l-diaminopropionic acid) in streptomyces albulus PD-1. Bioprocess Biosyst Eng 37:2095–2103

Xu Z, Bo F, Xia J, Sun Z, Li S, Feng X, Xu H (2015) Effects of oxygen-vectors on the synthesis of epsilon-poly-lysine and the metabolic characterization of Streptomyces albulus PD-1. Biochem Eng J 94:58–64

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2−∆∆Ct method. Methods 25(4):402–408

Wang G, Hosaka T, Ochi K (2008) Dramatic activation of antibiotic production in streptomyces coelicolor by cumulative drug resistance mutations. Appl Microbiol Biotechnol 74:2834–2840

Zhou TC, Kim BG, Zhong JJ (2014) Enhanced production of validamycin a in streptomyces hygroscopicus 5008 by engineering validamycin biosynthetic gene cluster. Appl Microbiol Biotechnol 98:7911–7922

Ertan H (1992) Some properties of glutamate dehydrogenase, glutamine synthetase and glutamate synthase from corynebacterium callunae. Arch Microbiol 158:35–41

Chen XS, Mao ZG (2013) Comparison of glucose and glycerol as carbon sources for ε-poly-L-lysine production by streptomyces sp. M-Z18. Appl Biochem Biotechnol 170:185–197

Gu Y, Wang X, Yang C, Geng W, Feng J, Wang Y, Wang S, Song C (2016) Effects of chromosomal integration of the vitreoscilla hemoglobin gene (vgb) and s-adenosylmethionine synthetase gene (metk) on ε-poly-L-lysine synthesis in streptomyces albulus NK660. Appl Biochem Biotechnol 178:1445–1457

Hamano Y, Nicchu I, Shimizu T, Onji Y, Hiraki J, Takagi H (2007) ɛ-poly-l-lysine producer, streptomyces albulus, has feedback-inhibition resistant aspartate kinase. Appl Microbiol Biotechnol 76:873–882

Wu H, Liu W, Dong D, Li J, Zhang D, Lu C (2014) Slnm gene overexpression with different promoters on natamycin production in streptomyces lydicus A02. J Ind Microbiol Biotechnol 41:163–172

Zheng ZY, Jiang Y, Zhan XB, Ma LW, Wu JR, Zhang LM, Lin CC (2014) An increase of curdlan productivity by integration of carbon/nitrogen sources control and sequencing dual fed-batch fermentors operation. Prikladnaia Biokhimiia I Mikrobiologiia 50:35–42

Xu N, Zhang X, Xiao F, Han L, Zeng C (2001) Effects of nitrogen source and concentration on growth rate and fatty acid composition of Ellipsoidion sp. (eustigmatophyta). J Appl Phycol 13:463–469

Yang J, Zhou X, Zhang Y (2004) Improvement of recombinant hirudin production by controlling NH4 +, concentration in pichia pastoris, fermentation. Biotechnol Lett 26:1013–1017

Cheng P, Wang Y, OseiWusu D, Wang Y, Liu T (2018) Development of nitrogen supply strategy for scenedesmus rubescens attached cultivation toward growth and lipid accumulation. Bioprocess Biosyst Eng 41:435–442

Xia J, Xu Z, Xu H, Liang J, Li S, Feng X (2014) Economical production of poly (ε-l-lysine) and poly (l-diaminopropionic acid) using cane molasses and hydrolysate of streptomyces cells by Streptomyces albulus PD-1. Bioresour Technol 164:241–247

Glibert PM, Wilkerson FP, Dugdale RC, Raven JA, Dupont CL, Leavitt PR, Parker AE, Burkholder JM, Kana TM (2016) Pluses and minuses of ammonium and nitrate uptake and assimilation by phytoplankton and implications for productivity and community composition, with emphasis on nitrogen-enriched conditions. Limnol Oceanogr 61:284–300

Tiffert Y, Supra P, Wurm R, Wohlleben W, Wagner R, Reuther J (2008) The streptomyces coelicolor glnr regulon: identification of new glnr targets and evidence for a central role of glnr in nitrogen metabolism in actinomycetes. Mol Microbiol 67:861–880

Amon J, Titgemeyer F, Burkovski A (2010) Common patterns-unique features: nitrogen metabolism and regulation in gram-positive bacteria. Fems Microbiol Rev 34:588–605

Tesch M, Graaf AAD, Sahm H (1999) In vivo fluxes in the ammonium-assimilatory pathways in Corynebacterium glutamicum studied by 15N nuclear magnetic resonance. Appl Environ Microbiol 65:1099–1109

Huang B, Qin P, Xu Z, Zhu R, Meng Y (2011) Effects of cacl2, on viscosity of culture broth, and on activities of enzymes around the 2-oxoglutarate branch, in bacillus subtilis, CGMCC 2108 producing poly-(γ-glutamic acid). Bioresour Technol 102:3595–3598

Takehara M, Hibino A, Saimura M, Hirohara H (2010) High-yield production of short chain length poly(ε-L-lysine) consisting of 5–20 residues by streptomyces aureofaciens, and its antimicrobial activity. Biotechnol Lett 32:1299–1303

Gottschalk G (1986) Bacterial metabolism, 2nd edn. Springer, New York

Acknowledgements

This work was supported by the National Key R&D Program of China (No. 2017YFD0400400), the National Nature Science Foundation of China (Nos. 21476112 and 51703095), the China Postdoctoral Science Foundation (No. 51229018), the State Key Laboratory of Materials-Oriented Chemical Engineering (No. KL15-09 to J. Zhou), and the Key Projects in the National Science & Technology Pillar Program during the Twelfth Five-year Plan Period (No. 2015BAD15B04), the Jiangsu Synergetic Innovation Center for Advanced Bio-Manufacture (No. XTB1804).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xu, D., Yao, H., Cao, C. et al. Enhancement of ε-poly-l-lysine production by overexpressing the ammonium transporter gene in Streptomyces albulus PD-1. Bioprocess Biosyst Eng 41, 1337–1345 (2018). https://doi.org/10.1007/s00449-018-1961-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-1961-9