Abstract

Cyclodextrin glycosyltransferases (CGTases) are important enzymes in biotechnology because of their ability to produce cyclodextrin (CD) mixtures from starch whose relative composition depends on enzyme source. A multiple alignment of 46 CGTases and Shannon entropy analysis allowed us to find differences and similarities that could be related to product specificity. Interestingly, position 179 has Gly in all the CGTases except in that from Bacillus circulans DF 9R which possesses Gln. The absence of a side chain at that position has been considered as a strong requirement for substrate binding and cyclization process. Therefore, we constructed two mutants of this enzyme, Q179L and Q179G. The activity and kinetic parameters of Q179G remained unchanged while the Q179L mutant showed a different CDs ratio, a lower catalytic efficiency, and a decreased ability to convert starch into CDs. We show that position 179 is involved in CGTase product specificity and must be occupied by Gly—without a side chain—or by amino acid residues able to interact with the substrate through hydrogen bonds in a way that the cyclization process occurs efficiently. These findings are also explained on the basis of a structural model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cyclodextrins (CDs) are cyclic α-1,4-glycosidic-linked oligosaccharides that consist of six, seven, or eight glycosyl units, known as α-, β-, and γ-CD, respectively. Due to their hydrophobic inner cavity and hydrophilic outer surface, they can interact with a wide range of compounds leading to the inclusion complex obtention that modifies chemical, physical, and biological properties of such compounds. Moreover, they have multiple applications in industries related to food, pharmaceuticals, cosmetics, chemicals, and agriculture (Astray et al. 2009; Loftsson and Duchêne 2007; Martin del Valle 2004). Cyclodextrin glycosyltransferase (CGTase; EC 2.4.1.19) catalyzes CD production from starch usually rendering a mixture of CDs. The relative composition of such mixture depends mainly on the origin of the enzyme employed, classified as α-, β-, or γ-CGTase according to their product specificity. Additionally, several α/β- and β/γ-CGTases have been described (Leemhuis et al. 2010). The genus Bacillus is the main source of CGTases, Bacillus circulans strains being mainly β-producers (Blackwood and Bucke 2000; Parsiegla et al. 1998; Schmid 1989). However, we have previously described a CGTase from B. circulans strain DF 9R which is the only one with an unusual product specificity since it is capable of producing similar amounts of α- and β-CD (Ferrarotti et al. 1996). CGTases, as all members of the GH13 family (http://www.cazy.org/CAZY, Cantarel et al. 2009), have a (β/α)8 barrel-type structure. The nine sugar-binding subsites are numbered from −1 to −7 (donor subsites) and +1 and +2 (acceptor subsites). The glycosidic bond cleavage occurs between subsites +1 and −1 (Uitdehaag et al. 1999a). Up to now, it is known that the donor subsites −3, −6, and −7 contribute to CD formation. Many chemical and genetic modifications have been made to understand the CGTase structural characteristics that determine product specificity (Kelly et al. 2009) and to alter the type of CD obtained (Leemhuis et al. 2010). Nevertheless, the mechanism determining the size of the synthesized CD remains unknown. The diversity of CDs obtained could be the consequence of specific amino acid substitutions, insertions, or deletions in the −3 and −7 subsites (Goh et al. 2009; Kelly et al. 2009; Li et al. 2009a, b; Parsiegla et al. 1998; Takada et al. 2003; van der Veen et al. 2000a, b). The −6 subsite (Y167, G179, G180, N193, and D196) is highly conserved in all CGTases whose primary structure is already known except that from B. circulans DF 9R (Costa et al. 2009). Moreover, the absence of side chains at positions 179 and 180 has been proposed as a strong requirement for substrate binding and cyclization reaction (Leemhuis et al. 2002). However, we reported the presence of Gln instead of Gly at position 179 of the B. circulans DF 9R α/β-CGTase; this enzyme is the first CGTase displaying a natural mutant at this otherwise conserved position (Costa et al. 2009).

With the aim of better understanding the cyclization reaction, we compared the primary structure of 46 CGTases to find differences and similarities which could be related to product specificity. We constructed two recombinant CGTases with a single amino acid mutation each (Q179G and Q179L) and studied the influence of these modifications on enzyme activity and product specificity. Besides, results were analyzed on a molecular model of B. circulans DF 9R CGTase built using the structure of the B. circulans 251 CGTase as the template.

Materials and methods

B. circulans DF 9R is deposited in Colección de Cultivos Microbianos, FFyB, UBA, catalog number CCM-A-29: 1290 from WFCC. Soluble potato starch and α-, β-, and γ-CD were obtained from Sigma Chemical Co. (MO, USA). The QIAEX II Gel Extraction Kit was from Qiagen (Valencia, CA, USA), the expression vector from Novagen (Darmstadt, Germany), and the Pfu ultra-high-fidelity (HF) polymerase from Stratagene (La Jolla, CA, USA). All other reagents for DNA manipulation, cloning, and sequencing—molecular biology grade—were from Invitrogen (San Diego, CA, USA). Cassava starch for food use was from a local supplier. All other chemicals were AR-grade.

CGTase gene amplification

DNA was extracted and purified from B. circulans DF 9R (Costa et al. 2009) and used as the template (5 ng for each polymerase chain reaction (PCR) reaction). The fragment encoding the CGTase without its signal peptide was amplified using 0.3 mM Nt-NcoI and Ct-XhoI primers (Table 1), 0.2 mM dNTPs, and 2.5 U platinum Pfx DNA polymerase in a 50-μl final volume. The amplification protocol included one cycle at 94 °C for 5 min, 35 cycles at 94 °C for 1 min, one cycle at 58 °C for 0.5 min, and one cycle at 68 °C for 2.5 min. The amplified products were purified using a QIAEX II gel extraction kit, cloned into the TOPO TA cloning vector and sequenced using an ABI 3730 XL automated sequencer (Applied Biosystems). The plasmid obtained was named pCR2.1/CGTase. Escherichia coli DH5α transformants were selected on lysogeny broth (LB) agar plates with kanamycin and X-Gal as described previously (Costa et al. 2009).

Site-directed mutagenesis

The purified pCR2.1/CGTase plasmid was used as a template (5 to 50 ng) for site-directed mutagenesis into the 179 codon by PCR with 2.5 U Pfu ultra-HF, 0.2 mM dNTPs, and 125 ng of mutagenic primers in a 50-μl final volume, following the manufacturer’s instructions. To obtain both mutants, the site-directed mutagenesis Stratagene QuikChange® Primer Design Program was used to replace Gln 179 by Gly (Q179G) or Leu (Q179L). Complementary oligonucleotides containing the appropriate base changes were synthesized according to the corresponding coding sequence (Table 1). The amplification protocol included one cycle at 95 °C for 1 min, 16 cycles at 95 °C for 1 min, 55 °C for 1 min, and 72 °C for 6 min. After 2 min in an ice bath, the reaction mixture was incubated with 10 U of DpnI for 2 h at 37 °C. Then, an aliquot of the digested amplification product was used to transform 50 μl of competent E. coli DH5α. Recombinant cells were selected on LB with ampicillin (100 μg/ml), and at least eight recombinant clones were analyzed by automatic sequencing to confirm the mutations. Finally, the inserts were subcloned into restriction sites NcoI and XhoI of the pET22b (+) expression vector.

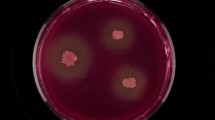

Purification of native and heterologous CGTases

Native CGTase (n-CGTase) was obtained and purified according to Ferrarotti et al. 1996. Heterologous proteins were expressed from the pET22b derivatives construct in E. coli BL21 (DE3) cells by using the procedure described by Sambrook and Russell (2001) and purified from the periplasm as described by Li et al. (2010). Briefly, 200-ml cultures of E. coli BL21 (DE3) transformed with the corresponding expression plasmids were grown for 18 h with isopropyl-β-d-thio-galactoside (IPTG) 0.4 mM. Cells were harvested by centrifugation for 20 min at 20,000 × g and 4 °C, and the pellets were resuspended in cold 30 mM Tris–HCl pH 7.0 with 25% sucrose and 1 mM EDTA. The mixture was then stirred for 2 h at 200 rpm and 4 °C and centrifuged for 20 min at 20,000 × g and 4 °C. Finally, the supernatant was subjected to affinity chromatography (Ferrarotti et al. 1996).

CGTase characterization

Protein concentration was determined according to Bradford (1976) with bovine serum albumin as the standard. Sodium dodecyl sulphate-polyacrylamide gel electrophoresis (SDS-PAGE) was performed according to Laemmli (1970) and the corresponding zymography developed according to Park et al. (1999). The N-terminal sequencing was carried out at the Facility for Peptide and Protein Sequencing (Universidad de Buenos Aires) with a Procise 492 Applied Biosystems sequencer. Samples were applied to a polybrene-coated filter. Phenylthiohydantoin amino acids were identified by using an online reverse-phase high-performance liquid chromatography (HPLC) system.

Circular dichroism measurements were performed in the 190–250 and the 250–350 nm ranges at 25 °C in a Jasco J-810-1505 spectropolarimeter with a cell provided with a circular window, 1 mm path length, calibrated with camphorsulfonic acid. Protein concentration was 0.35 to 0.50 mg/ml, and a 100 mM phosphate buffer, pH 7.4, was used. Spectra are the average of three determinations.

The β-cyclizing activity was measured according to Goel and Nene (1995).

CDs production from starch

To study the reaction products, the experimental conditions reported by Szerman et al. (2007) were utilized. The reaction mixture was then centrifuged for 15 min at 20,000 × g, and the supernatant was ultrafiltered through a membrane with a 10-kDa cut-off. The products were analyzed by HPLC using an LKB 2248 apparatus, with a column for carbohydrate analysis (Wat 84038) at 25 °C. Samples (30 μl, 10–20 mg of carbohydrate/ml) were injected, and oligosaccharides were eluted with acetonitrile/water (70:30), at a flow rate of 0.5 ml/min. Sugars were detected with a Shimadzu RID-10A differential refractometer.

Kinetic parameter determination

Aliquots of 1 ml of gelatinized soluble potato starch solutions (0.1 to 15.0 mg/ml) in a 25 mM phosphate buffer pH 6.4 were incubated with 10 μl of each purified CGTase (n-CGTase; recombinant without any mutation: r-CGTase; recombinants with a mutation: Q179G and Q179L), 5 U/g of starch, at 56 °C. The β-CD production initial rate was determined by using the phenolphthalein method (Goel and Nene 1995). One unit of CGTase is defined as the amount of enzyme catalyzing the production of 1 μmol of β-CD per minute under the reaction conditions. Experiments were performed in triplicate. Results were analyzed with the GraphPadPrism version 5.00 software (San Diego, CA, USA), and K m, V max, and k cat values were obtained.

Multiple sequence alignment

Multiple sequence alignment of 46 CGTases was performed with the ClustalX program (Thompson et al. 1997) and manually adjusted. The amino acid frequencies at each position of the multiple alignments were shown using the graphical Logo representation (Crooks et al. 2004). To obtain quantitative information of amino acid conservation the “Shannon entropy” method (Strait and Dewey 1996) was applied.

Homology modelling

B. circulans DF 9R CGTase model was built by using as template the crystal structure of B. circulans 251 strain, sharing 69.3% identity (PDB 1CXL, 1.81 Å resolution; Uitdehaag et al. (1999b)) and the program suite MODELLER 9v2 (Eswar et al. 2006). Structural alignment was done according to the combinatorial extension method by using the server http://cl.sdsc.edu/ (Shindyalov and Bourne 1998). The stereochemical quality of the model was examined with PROCHECK (Laskowski et al. 1993), Verify3D (Bowie et al. 1991), and ProQ (Wallner and Elofsson 2003). All graphical molecular representations were generated using CHIMERA (http://www.cgl.ucsf.edu/chimera/; Pettersen et al. 2004). The root mean square deviation (RMSD) between the template and model alpha carbon backbones was calculated with the combinatorial extension method (Shindyalov and Bourne 1998). A maltononaose substrate was transferred from the active site of PDB 1CXK (Uitdehaag et al. 1999b) CGTase to the active site of the model. Finally, an energy minimization of the enzyme–substrate interaction was carried out with the Amber-based energy minimization method provided by CHIMERA with default parameters.

Gene accession number

The CGTase gene from B. circulans DF 9R was deposited in the GenBank database under the accession number EU644086.

Results

Sequence and structure analysis

The primary structure of CGTase from B. circulans DF 9R was previously determined by Edman degradation, cloning, and sequencing (Costa et al. 2009). The CGTase gene possesses 2,319 nucleotides encompassing a 2,160-bp open reading frame. The deduced amino acid sequence is 719 amino acids long, 685 corresponding to the mature protein and 34 to the signal peptide. Multiple alignment with other 45 CGTase sequences (Electronic supplementary material) showed that the B. circulans DF 9R enzyme contains the five described CGTase domains and the seven regions conserved in the glycoside hydrolase Family 13 (Janeček 2002) as well as the catalytic triad and those residues required for carbohydrate (Machovič and Janeček 2006) and calcium binding sites (Ishii et al. 2000). On the other hand, the CGTase under study presents 43 positions with a residue not present in any other of the CGTase family members; Shannon entropy analysis (Fig. 1) indicates that only 13 have an entropy value higher than 65%. Among them, positions 179, 247, 537, and 609 show non-conservative substitutions making a deeper study of the changes relevant including their influence on enzyme biological properties in order to find possible product specificity determinants. From the last four positions above-mentioned, 179 is the most conserved and the only belonging to a binding subsite, the highly conserved −6 subsite. The other positions are located more than 10 Å from the catalytic triad. However, six positions (559, 669, 616, 630, 658, and 668) contact within 10 Å with amino acid residues belonging to maltose binding sites. On the other hand, a role in cyclodextrin size specificity has been described for the −3 and −7 subsites. The −3 subsite consists of positions 47, 89, 94, and 371. The CGTase under study shows K47 such as other α/β-CGTases and S94 unlike the other CGTases isolated from different strains of B. circulans. All CGTases show D371 and variability at position 89. The −7 subsite consists of the stretch 145SET147 in CGTase from B. circulans DF 9R such as other α/β-CGTases (Costa et al. 2009). Moreover, the loops including the subsites −3 and −7 are identical in CGTases from strains DF 9R and 251.

Therefore, we decided to analyze its putative role in product specificity through the construction of mutants in which the Gln from the native protein was replaced by Gly (Q179G) or Leu (Q179L).

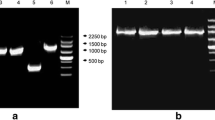

Expression, purification, and characterization of heterologous CGTases

The mutants Q179G and Q179L were successfully constructed by site-directed mutagenesis from pCR2/CGTase by PCR and verified by DNA sequencing. The recombinant CGTase and its two mutants were expressed in E. coli BL21 (DE3) with 0.4 mM IPTG as inductor and employing the pET22b(+) system, which carries an N-terminal pelB signal sequence able to direct the proteins to periplasm. To verify if the heterologous CGTases were not degraded, SDS-PAGE and zymography were carried out. Figure 2 shows the r-CGTase expression pattern at pre-defined times with or without induction and purified n-CGTase as control. Furthermore, heterologous proteins were purified and characterized as previously described. N-terminal sequencing confirmed the absence of the pelB signal peptide. Regarding protein conformation, when circular dichroism spectra of the native and heterologous enzymes were analyzed, no differences were found in either the far or in the near UV. These results indicate that recombinant technology including the mutations at position 179 had not introduced any important associated conformational changes.

Kinetic parameters and CDs production

As indicated in Table 2, r-CGTase and Q179G mutant showed almost identical kinetic parameters to those of the native protein as regards β-cyclizing formation. On the contrary, the mutation Q179L had a significant effect on β-CD production which led to a decrease in V max and k cat values as well as in catalytic efficiency; nevertheless, the K m value remained unchanged.

We analyzed the percentage of pregelatinized cassava starch transformed in CDs by n-, r-, and mutant-CGTases. Table 3 shows the results obtained which indicate that only Q179L presented a significant decrease (p < 0.05). Production of each CD was determined by HPLC. While the yield for enzymes with Gly or Gln at position 179 remained unchanged when compared with that obtained with the native enzyme, production of α- and β-CD decreased 40% and 20%, respectively (p < 0.0001 and p < 0.05), when Q179L was used. γ-CD production reached the same level, whichever enzyme was used. Table 3 also shows a change in the Q179L α-/β-/γ-CD ratio, a value related to product specificity.

Homology modelling

A homology model of B. circulans DF 9R CGTase was built using the crystallographic structure of B. circulans strain 251 CGTase as the template (PDB 1CXL). Both CGTases share 69.3% identity, and sequence alignment shows only one gap at position 341. The overall structure of both proteins was very similar (RMSD of 0.1 Å for 685 superimposed Cα). The model stereochemical quality was assessed by PROCHECK, having 91.8% of the residues in the most favored and 0.2% in disallowed regions, respectively. The residues R340 and D537, localized in disallowed regions, are not involved in either substrate binding or catalytic site. The compatibility of the atomic model (3D) with its own amino acid sequence (1D) was confirmed by Verify analysis which showed that the model has no residues with values less than zero. The correctness of the model was also assessed by ProQ, the values for LG and MaxSub obtained allowed to consider the model as very good.

Overall results indicate that the modelled structure of B. circulans DF 9R CGTase can be considered appropriate for subsequent analyses.

Discussion

It is well known that some subsites belonging to the substrate binding site are related to CGTase product specificity (Kelly et al. 2009; Leemhuis et al. 2010). CGTases from different strains of B. circulans are mainly producers of β-CD; however, the enzyme from the DF 9R strain catalyzes the bioconversion of starch into similar amounts of α- and β-CDs. Herein, we studied some structural and biological aspects of this enzyme as a contribution to the understanding of the molecular reasons underlying this process.

An alignment of 46 CGTase sequences plus Shannon entropy analysis allowed us to identify some positions in the sequence of the B. circulans DF 9R CGTase which could be involved in product specificity. Among them, position 179 deserves special consideration as it belongs to the −6 subsite and is highly conserved in all CGTases previously studied. The B. circulans DF 9R CGTase has Gln in that position instead of Gly, present in all other CGTases whose primary structure is already known. Consequently, we constructed two mutants, Q179G and Q179L, and studied their biological properties. The n- and r-CGTases and the Q179G mutant showed no differences neither in the kinetic constants nor in CDs production while Q179L showed a lower catalytic efficiency (40%) and a decreased capacity (30%) of CD production as well as a different α-/β-/γ-CD ratio. α-CD production is particularly affected not only because of suboptimal contact at the −6 subsite but also because of the shorter length of its chain that may prevent its interaction with the −7 subsite, which gives additional assistance to the circularization process (Leemhuis et al. 2002). Accordingly, the β-CD production was less affected, and the γ-CD formation remained unchanged.

As expected, a molecular homology model showed that structures of B. circulans 251 and B. circulans DF 9R CGTases were very similar, and, on this basis, it is reasonable to assume the same location for the substrate and therefore transfer the substrate of the template into the active site of the modelled enzyme. Special emphasis was put on the analysis around position 179. We postulate that, despite having a relative accessible surface area 2.3 times larger than that of Gly (Ahmad et al. 2003), Gln can interact efficiently with the substrate, being capable of establishing a hydrogen bond with the C6 hydroxyl group of the sixth glucose ring of starch through a water molecule (Fig. 3). Bond lengths (2.7 and 2.9 Å) as well as the angle between them (96.44°) fulfil the geometric criteria proposed by Torshin et al. (2002). On the other hand, Leu has a relative accessible surface area similar to that of Gln (183.1 and 178.6 Å2, respectively) but its hydrophobicity is higher (+3.8 compared with −3.5 for Gln in the Kyte and Doolite scale). These characteristics prevent the Q179L mutant from interacting with the substrate, mainly altering the circularization process and, consequently, leading to a decrease in catalytic activity. In conclusion, results of experimental work as well as the molecular model of the B. circulans DF 9R CGTase led to our proposal that position 179 must be occupied by Gly—without a side chain—or those amino acid residues capable of interacting with the substrate through hydrogen bonds thus allowing the completion of the cyclization process efficiently. Moreover, the nature of the residue at position 179 plays a role in CGTase specificity giving rise to the rational design of new mutants with particular properties and biotechnological relevance.

CGTase from B. circulans DF 9R model: interaction between residue at position 179 and the substrate. Dashed lines indicate the hydrogen bond, mediated by a water molecule, between Gln and a substrate glucose residue. L179 is on the left and the van der Waals volume of substrate and Gln side chain is shown. The crystal structure of B. circulans 251 strain (PDB 1CXL) was used as the template

References

Ahmad S, Gromiha MM, Sarai A (2003) Real value prediction of solvent accessibility from amino acid sequence. Proteins 50:629–635

Astray G, González-Barreiro C, Mejuto JC, Rial-Otero R, Simal-Gándara J (2009) A review on the use of cyclodextrins in foods. Foods Hydrocolloids 23:1631–1640

Blackwood AD, Bucke C (2000) Addition of polar organic solvent can improve the product selectivity of cyclodextrin glycosyltransferase: solvent effects on CGTase. Enzyme Microb Technol 27:704–708

Bowie JU, Lüthy R, Eisenberg D (1991) A method to identify protein sequences that fold into a known three-dimensional structure. Science 253:164–170

Bradford M (1976) Quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Cantarel BL, Coutinho PM, Rancurel C, Bernard T, Lombard V, Henrissat B (2009) The carbohydrate-active enzymes database (CAZy): an expert resource for glycogenomics. Nucleic Acids Res 37:233–238

Costa H, del Canto S, Ferrarotti S, de Jiménez B, Bonino M (2009) Structure–function relationship in cyclodextrin glycosyltransferase from Bacillus circulans DF 9R. Carbohydr Res 344:47–79

Crooks GE, Hon G, Chandonia JM, Brenner SE (2004) WebLogo: a sequence logo generator. Genome Res 14:1188–1190

Eswar N, Marti-Renom MA, Webb B, Madhusudhan MS, Eramian D, Shen M, Pieper U, Sali A (2006) Comparative protein structure modeling with MODELLER. Current Protocols in Bioinformatics. Wiley & Sons, Inc., New Jersey; Supplement 15, 5.6.1-5.6.30.

Ferrarotti SA, Rosso AM, Marèchal MA, Krymkiewicz N, Marèchal L (1996) Isolation of two strains (S-R type) of Bacillus circulans and purification of a cyclomaltodextrin-glucanotransferase. Cell Mol Biol 42:653–657

Goel A, Nene S (1995) Modifications in the phenolphtalein method for spectrophotometric estimation of Beta-cyclodextrin. Starch 47:399–400

Goh KM, Mahadi NM, Hassan O, Rhaman RNZRA, Illias RM (2009) A predominant β-CGTase G1 engineered to elucidate the relationship between protein structure and product specificity. J Mol Catal B: Enzym 57:270–277

Ishii N, Haga K, Yamane K, Harata K (2000) Crystal structure of asparagine 233-replaced cyclodextrin glucanotransferase from alkalophilic Bacillus sp. 1011 determined at 1.9 Å resolution. J Mol Recognit 13:35–43

Janeček S (2002) How many conserved sequence regions are there in the α-amylase family? Biologia Bratisl 57:29–41

Kelly RM, Dijkhuizen L, Leemhuis H (2009) The evolution of cyclodextrin glucanotransferase product specificity. Appl Microbiol Biotechnol 84:119–133

Laemmli UK (1970) Cleavage of structural protein during the assembly of the head of bacteriophage T4. Nature 227:680–685

Laskowski RA, MacArthur MW, Moss DS, Thornton JM (1993) PROCHECK: a program to check the stereochemical quality of protein structures. J Appl Cryst 26:283–291

Leemhuis H, Uitdehaag JCM, Rozeboom HJ, Dijkstra BW, Dijkhuizen L (2002) The remote substrate binding subsite −6 in cyclodextrin-glycosyltransferase controls the transferase activity of the enzyme via an induced-fit mechanism. J Biol Chem 277:1113–1119

Leemhuis H, Kelly RM, Dijkhuizen L (2010) Engineering of cyclodextrin glucanotransferases and the impact for biotechnological applications. Appl Microbiol Biotechnol 85:823–835

Li ZF, Zhang JY, Sun Q, Wang M, Gu ZB, Du GC, Wu J, Chen J (2009a) Mutations of lysine 47 in cyclodextrin glycosyltransferase from Paenibacillus macerans enhance beta-cyclodextrin specificity. J Agric Food Chem 57:8386–8391

Li ZF, Zhang JY, Wang M, Gu ZB, Du GC, Li J, Wu J, Chen J (2009b) Mutations at subsite −3 in cyclodextrin glycosyltransferase from Paenibacillus macerans enhancing α-cyclodextrin specificity. Appl Microbiol Biotechnol 83:483–490

Li ZF, Gu ZB, Wang M, Du GC, Wu J, Chen J (2010) Delayed supplementation of glycine enhances extracellular secretion of the recombinant alpha-cyclodextrin glycosyltransferase in Escherichia coli. Appl Microbiol Biotechnol 85:553–561

Loftsson T, Duchêne D (2007) Cyclodextrins and their pharmaceutical applications. Int J Pharm 329:1–11

Machovič M, Janeček S (2006) Starch-binding domains in the post-genome era. Cell Mol Life Sci 63:2710–2724

Martin del Valle EM (2004) Cyclodextrins and their uses: a review. Process Biochem 39:1033–1046

Park TH, Shin HD, Lee YH (1999) Characterization of the β-cyclodextrin glucanotransferase gene of Bacillus firmus var. alkalophilus and its expression in E. coli. J Microbiol Biotechnol 9:811–819

Parsiegla G, Schmidt AK, Schulz GE (1998) Substrate binding to a cyclodextrin glucanotransferase and mutations increasing the γ-cyclodextrin production. Eur J Biochem 255:710–717

Pettersen EF, Goddard TD, Huang CC, Couch GS, Grrenblatt DM, Meng EC, Ferrin TE (2004) UCSF Chimera—a visualization system for exploratory research and analysis. J Comput Chem 25:1605–1612

Sambrook J, Russell DW (2001) Molecular cloning, a laboratory manual, 3rd edn. Cold Spring Harbor Laboratory, Cold Spring Harbor, NY

Schmid G (1989) Cyclodextrin glycosyltransferase production: yield enhancement by overexpression of cloned genes. Trends Biotechnol 7:244–248

Shindyalov IN, Bourne PE (1998) Protein structure alignment by incremental combinatorial extension (CE) of the optimal path. Protein Eng 11:739–747

Strait BJ, Dewey TG (1996) The Shannon information entropy of protein sequences. Biophys J 71:148–155

Szerman N, Schroh I, Rossi AL, Rosso AM, Krymkiewicz N, Ferrarotti SA (2007) Cyclodextrin production by cyclodextrin glycosyltransferase from Bacillus circulans DF 9R. Bioresour Technol 98:2886–2891

Takada M, Nakagawa Y, Yamamoto M (2003) Biochemical and genetic analyses of a novel gamma-cyclodextrin glucanotransferase from an alkalophilic Bacillus clarkii 7364. J Biochem (Tokyo) 133:317–324

Thompson JD, Gibson TJ, Plewniak F, Jeanmougin F, Higgins DG (1997) The ClustalX windows interface: flexible strategies for multiple sequence alignment aided by quality analysis tools. Nucleic Acids Res 24:4876–4882

Torshin IY, Weber IT, Harrison RW (2002) Geometric criteria of hydrogen bonds in proteins and identification of ‘bifurcated’ hydrogen bonds. Protein Eng 15:359–363

Uitdehaag JCM, Halk KH, van der Veen BA, Dijkhuizen L, Dijkstra BW (1999a) The cyclization mechanism of cyclodextrin glycosyltransferase (CGTase) as revealed by a γ-cyclodextrin-CGTase complex at 1.8-Å resolution. J Biol Chem 274:34868–34876

Uitdehaag JC, Mosi R, Kalk KH, van der Veen BA, Dijkhuizen L, Withers SG, Dijkstra BW (1999b) X-ray structures along the reaction pathway of cyclodextrin glycosyltransferase elucidate catalysis in the alpha-amylase family. Nat Struct Biol 6:432–436

van der Veen B, Uitdehaag JCM, Dijkstra BW, Dijkhuizen L (2000a) Engineering of cyclodextrin glycosyltransferase reaction and product specificity. Biochim Biophys Acta 1543:336–360

van der Veen BA, Uitdehaag JCM, Dijkstra BW, Dijkhuizen L (2000b) The role of arginine 47 in the cyclization and coupling reactions of cyclodextrin glycosyltransferase from Bacillus circulans strain 251. Implications for product inhibition and product specificity. Eur J Biochem 267:3432–3441

Wallner B, Elofsson A (2003) Can correct protein models be identified? Protein Sci 12:1073–1086

Acknowledgments

We thank Drs. J. Delfino, L. Curto, and G. Gómez for performing circular dichroism experiments; Drs. O. Taboga and M.I. Gismondi for their supervision on cloning and sequencing; Lic. S. Linskens and Farm. C. Paván for their technical assistance on mass spectrometry, and Prof. Karen Todel for language supervision. This work was supported by grants from the Universidad Nacional de Luján, Universidad de Buenos Aires, and the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET). AJD, CMB, and MBJB are career members of CONICET.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 132 kb)

Rights and permissions

About this article

Cite this article

Costa, H., Distéfano, A.J., Marino-Buslje, C. et al. The residue 179 is involved in product specificity of the Bacillus circulans DF 9R cyclodextrin glycosyltransferase. Appl Microbiol Biotechnol 94, 123–130 (2012). https://doi.org/10.1007/s00253-011-3623-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3623-6