Abstract

A newly isolated Geobacillus sp. IIPTN (MTCC 5319) from the hot spring of Uttarakhand's Himalayan region produced a hyperthermostable α-amylase. The microorganism was characterized by biochemical tests and 16S rRNA gene sequencing. The optimal temperature and pH were 60°C and 6.5, respectively, for growth and enzyme production. Although it was able to grow in temperature ranges from 50 to 80°C and pH 5.5–8.5. Maximum enzyme production was in exponential phase with activity 135 U ml−1 at 60°C. Assayed with cassava as substrate, the enzyme displayed optimal activity 192 U ml−1 at pH 5.0 and 80°C. The enzyme was purified to homogeneity with purification fold 82 and specific activity 1,200 U mg−1 protein. The molecular mass of the purified enzyme was 97 KDa. The values of K m and V max were 36 mg ml−1 and 222 µmol mg−1 protein min−1, respectively. The amylase was stable over a broad range of temperature from 40°C to 120°C and pH ranges from 5 to 10. The enzyme was stimulated with Mn2+, whereas it was inhibited by Hg2+, Cu2+, Zn2+, Mg2+, and EDTA, suggesting that it is a metalloenzyme. Besides hyperthermostability, the novelty of this enzyme is resistance against protease.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Among various starch containing biomass, cassava (Manihot esculenta) now-a-days is attracting the modified starch industries because of low production cost, cultivation in poor soil, and excellent starch quality. At present, the modified starch industries besides native starch, which is used in the production of glucose and maltose syrups and syrups with different level of dextrose equivalent, also needed cassava for the food, paper, and textile industries, for production of monosodium glutamate, sorbitol, vitamin C, various sweeteners, and alcohol for biofuel, drinking, and industrial purposes (Srinivas 2007). The starch industry is the biggest consumer of enzymes for the hydrolysis of starch (Haki and Rakshit 2003; Sivaramakrishnan et al. 2006).

α-Amylase (EC3.2.1.1, 1,4-α-d-glucan glucanohydrolase and endoamylase) hydrolyze the starch by randomly cleaving internal α-1,4-glucosidic linkages and produce reducing sugar. Amylases from different sources like plant and microbial (bacterial and fungal) source have been used for centuries as food additives and in brewing industry. Among bacterial source, Bacillus sp. like B. subtilis, B. stearothermophilus, B. licheniformis, and B. amyloliquefaciens were potentially exploited for thermostable α-amylase production to fulfill industrial requirements (Sivaramakrishnan et al. 2006). Thermophilic microorganisms and thermostable enzymes have been of great scientific interest for several decades, principally in regard to their potential industrial applications (Kumar et al. 2009a). Thermostability, acidic pH and long-term stability at normal condition is a desired characteristic for the amylases to fit potentially in starch-processing industry. There are very few commercially available α-amylase that work between 80–120°C and pH 5.0–5.5, e.g., B. licheniformis (100°C, pH 6.0–6.5) (Viara et al. 1993), B. stearothermophilus (70–80°C; pH 5.0–6.0) (Vihinen and Mantsala 1990).

Therefore, screening of microorganisms that can produce novel amylases with higher stability at extreme condition is necessary (Gupta et al. 2003). In the present paper, we report the purification and characterization of novel hyperthermostable amylase produced by thermophilic strain Geobacillus sp. IIPTN (MTCC 5319), which efficiently hydrolyze the cassava and other starch biomass as well as showing resistant to protease degradation.

Material and methods

Isolation, identification, and culture conditions of microorganism

The bacterial strains were isolated from hot spring water of Uttarakhand's Himalayan region (India). The water samples were inoculated into nutrient broth containing (g l−1): peptone, 5.0; yeast extract, 3.0; NaCl, 5.0; glucose, 10.0 (pH 7.0), and incubated at 60°C. Subsequent dilutions of the 24-h old culture were spreaded on nutrient gelrite starch plates (g l−1: peptone, 5.0; yeast extract, 3.0; NaCl, 5.0; soluble starch, 10.0; gelrite, 10.0; pH 7.0) for further screening of amylase producing strain and incubated at 60°C. After 16-h growth, the plates were flooded with iodine soultion to check the zone of clearance against gelrite starch plate as control. The one isolate, identified as Geobacillus sp. IIPTN (deposited in ‘Microbial Type Culture Collection, Institute of Microbial Technology, Chandigarh (India)’ with accession no. MTCC 5319), that showed the clear zone of more than 1.0 cm diameter with iodine test, was selected and maintained routinely on rich medium slants (1% (w/v) yeast extract, 1% (w/v) peptone, 0.5% (w/v) NaCl, 1% (w/v) gelrite, and 0.5% (w/v) soluble starch, at pH 6.8–7.0). The master culture was preserved in 40% (v/v) glycerol at −80°C.

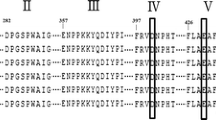

The newly isolated strain Geobacillus sp. IIPTN (MTCC 5319) was characterized by partial 16S rRNA gene sequencing. The primers selected for PCR amplification experiments were, forward primer 5′ CAGGCCTAACACATGCAAGTC and reverse primer 5′ GGGCGGWGTGTACAAGGC. The partial 862-bp 16S rRNA gene sequence was aligned with submitted sequences available in the NCBI database using clustalX software, and the phylogenetic tree was depicted using the TREEVIEW program. The partial 16S rRNA gene sequence has been deposited to the GenBank under the accession no. DQ323407.

Production of α-amylase

Geobacillus sp. IIPTN was grown in basal salt medium containing (g l−1): NaH2PO4 × 2H2O, 1.56; NH4NO3, 5.0; KCl, 0.745; Na2SO4 × 10H2O, 0.644; citric acid, 0.42; MgCl2 × 6H2O, 0.25; soybean meal, 5.0; yeast extract, 2.5; soluble starch, 5.0; trace elements (CaCl2, 2.2×10−3; ZnO, 2.5×10−3; FeCl3 × 6H2O, 2.7×10−2; MnCl2 × 4H2O, 1.0×10−2; CuCl2 × 2H2O, 8.5×10−4; CoCl2 × H2O, 2.4×10−3; NiCl3 × 6H2O, 2.5×10−4; H3BO3, 3.0×10-4; Na2MoO4, 1.0×10−3), 20 ml; pH was adjusted to 6.8–7.0 with 1 M NaOH before sterilization (Santos and Martins 2003). The medium was inoculated with 12-h old culture and incubated at 60°C in orbital shaker at 130 rpm.

The effect of temperature and pH on enzyme production was studied. The bacterial strain was also grown on the different carbon and nitrogen sources. The various carbon sources with concentration 1–5 g l−1 used were: maltose, glucose, amylose, amylopectin, and raw starchy substrates like cassava, tapioca root, corn starch, sweet sorghum. To study the effect of nitrogen on enzyme production, different organic source (yeast extract, beef extract, tryptone, casein hydrolysate, peptone, and soybean meal) and inorganic source (ammonium sulfate, ammonium chloride, ammonium nitrate, ammonium acetate, and urea) were used. The concentration of nitrogen source used was 1–5 g l−1. The studies were carried out in Erlenmeyer shake flask.

Enzyme assay

α-Amylase activity was determined by estimating the reducing sugar from 1% (w/v) cassava starch as substrate at 80°C and pH 5.0. The amount of released reducing sugars was determined by the dinitrosalicylic acid method (Miller 1959). The d-glucose was used as standard. One unit of α-amylase activity was defined as the amount of enzyme that released 1 µmol of reducing sugars per minute at 80°C.

Purification of α-amylase

Ultrafiltration of the enzyme

The culture broth was centrifuged at 34,000×g for 10 min at 4°C in refrigerated centrifuge SORVALL Evolution®. The cell-free supernatant was collected and filtered through Amicon Ultrafiltration unit using 10,000 NMWL regenerated cellulose membrane from Millipore (USA).

Chromatography

Four milliliters of concentrated enzyme (concentration 8 mg ml−1) was applied to a Macro Prep High S support (strong cationic exchanger purchased from BIORAD, USA) column (1.5 × 30 cm), pre-equilibrated with 20 mM phosphate buffer pH 6.5. The unbound proteins were eluted by using same buffer at flow rate of 0.5 ml min−1, while the bound proteins were eluted by using linear salt gradient with 1 M NaCl in the same buffer at flow rate of 0.5 ml min−1. The active fractions no 5–15 out of 40 collected fractions (1 ml each) was concentrated in Millipore Amicon Ultra, centrifugal filter device Ultracel-30 K that has 30,000 MNCO regenerated cellulose membrane (Millipore, USA).

The concentrated enzyme (500 µl) was applied to the pre-equilibrated CHT Type I Ceramic Hydroxyapatite binding column (1×10 cm) from BIORAD, USA. The unbound proteins were eluted with 10 mM phosphate buffer pH 6.8 and 0.3 mM CaCl2 at a flow rate of 1 ml min−1 (1 ml per fraction) and bound proteins were eluted by using 400 mM phosphate buffer pH 6.8. Among the collected 40 fractions, fractions no. 9–11 (1 ml each) showed the activities which were concentrated and used for sodium dodecyl sulfate-polyacrlyamide gel electrophoresis (SDS-PAGE).

Electrophoresis and molecular mass determination

SDS-PAGE was carried out according to Laemmli (1970) with 7.5% polyacrylamide. Electrophoresis was performed in a PROTEAN II xi cell (BIO-RAD). The molecular weight markers (29 to 205 KD) purchased from SIGMA run along with samples. The protein bands were visualized by staining with coomassie brilliant blue G 250.

Zymogram preparation

The purified enzyme was evaluated in PAGE according to Laemmli (1970). After electrophoresis, the gel was washed with deionized water and immersed in 20-mM acetate buffer of pH 5.0. Then the gel was imbibed in 0.5% (w/v) soluble starch at 4°C for an hour to assure starch penetration into the gel. Gel was then incubated for 2 h at 60°C, after which it was stained with iodine solution. After staining, amylase band was detected as clear yellow zone against dark blue background of non-hydrolyzed stained starch. The gel was immediately photographed using Gel Doc™ XR (BIORAD, USA) (Martínez et al. 2000).

Protein estimation

Protein content was measured by Folin–Lowry method (Lowry et al. 1951) using bovine serum albumin as a standard.

Blue value determination

The residual starch was determined by blue value method. One milliliter of reaction mixture was removed at various time intervals. The reaction was stopped by adding 1 ml of 0.1 N HCl and then 1 ml iodine solution was added to develop the color. The reduction in optical density was monitored at 660 nm. The reduction in value was determined with the standard graph (Najafi et al. 2005).

Characterization of the enzyme

Influence of temperature and pH on enzyme activity

The temperature profile to achieve maximum activity was determined by incubating the enzyme for 30 min in the temperature range of 20–120°C. After incubation the enzyme was kept at 4°C. The activity was measured by assaying the reducing sugar using 1% (w/v) cassava starch at different temperature. Similarly, the effect of pH on amylase activity was determined at 80°C in the pH ranges of 3.0 to 10.0 with glycine-HCl buffer (3.0–4.0), acetate buffer (5.0–6.0), phosphate buffer (6.0–8.0), and glycine-NaOH buffer (9.0–10.0). The enzyme was incubated with these buffers at 80°C for 10 min without substrate and then activity was determined on 1% (w/v) cassava starch by measuring the reducing sugars produced.

Effects of metal ions and denaturing chemicals

Effect of metal ions on activity was measured by incubating the enzyme with 5 mM metal solutions of MnSO4, CaCl2, NaCl, CoCl2, MgCl2, FeCl3, HgCl2, KCl, ZnSO4, CuSO4, BaCl2 and 5 mM denaturing agents like EDTA, SDS, urea for 30 min without substrate. Relative enzyme activity was measured on 1% (w/v) cassava at 80°C and pH 5.0. The control was used without any metal ion or denaturing reagents and reported as 100% activity.

Kinetic determinations

The initial rate of reaction for starch hydrolysis was calculated by estimating the reducing sugar by dinitrosalicylic acid method at different starch concentrations of 1 to 10 g l−1. The Michaelis constant (K m ) and the rate of reaction (V max ) were determined according to Lineweaver–Burk plot (Lineweaver and Burk 1934).

Substrate specificity

Different starch such as potato soluble starch (SIGMA, USA), corn starch (Hi-Media, India), amylopectin (Hi-Media, India), cassava, tapioca, maize flour, and sweet sorghum were used to determine the substrate specificity of the enzyme. All the substrates were used in gelatinized as well as in native form. The hydrolysis was carried out at 80°C with 1% (w/v) substrate concentration in 20-mM acetate buffer of pH 5.0.

Mode of action

The partially purified enzyme was incubated with 1% (w/v) cassava at 80°C and pH 5.0. The samples were removed at fixed time intervals. The residual starch and reducing sugar determined accordingly. The end products were analyzed by high-performance liquid chromatography (HPLC) using high-performance carbohydrate column (Waters) at 30°C with acetonitrile and water mixture (75:25) as mobile carrier at a flow rate 1.4 ml min−1 and detected by a Waters 2414 refractive index detector (Kumar et al. 2009b).

Stability of enzyme against protease

The partially purified amylase was kept at 4°C without adding PMSF. After 6 months, the enzyme tested for its stability. The reaction was carried out at 80°C and pH 5.0 with 1% (w/v) cassava. The enzyme stability was also checked against Proteinase K (SIGMA, USA). The partially purified amylase was incubated with 10 U of proteinase K at room temperature for 30 min. Amylase activity was checked by assaying reducing sugar with 1% (w/v) cassava at 80°C and pH 5.0

Results

Isolation, characterization, and taxonomic classification of geobacillus sp. IIPTN

Geobacillus sp. IIPTN was found potent amylase producer which showed the zone of clearence on starch plate when flooded with iodine solution (Fig. 1). The morphological and physiological characteristics of the isolate was observed as rod shape, Gram positive, catalase positive, indole test negative, positive to fermentation test for glucose and xylose, and thermophilic in nature since it was unable to grow below 50°C.

The phylogenetic tree clearly depicts that the strain was maximum homologous with Geobacillus sp. and thus submitted to genebank as Geobacillus sp. IIPTN (accession no. DQ323407) (Fig. 2).

Production of enzyme

Geobacillus sp. IIPTN was able to grow and produce amylase in the temperature ranges from 50°C to 80°C and pH 5.5–8.5 (data not shown) showed maximum production of amylase at its optimum growth temperature 60°C and pH 6.5. Amylase production was found to be growth associated. Enzyme production started at early log phase and reached maximum in exponential phase (Fig. 3). The α-amylase, produced by Geobacillus sp. IIPTN, was named as IIPTN α-amylase.

Growth of Geobacillus sp. IIPTN and α-amylase production during growth on basal salt medium at 60°C. Dry cell weight and amylase production was monitored at different interval of time: (filled square) DCW (g l−1); (filled circle) amylase production (U ml−1) was determined by measuring protein (Folin–Lowry) and activity of enzyme by assaying reducing sugar

Among the various carbon sources such as maltose, glucose, amylase, amylopectin, cassava, tapioca root, corn starch, and sweet sorghum, the maximum production of enzyme was observed on the medium containing 0.5% (w/v) cassava. In case of nitrogen sources, 0.5% (w/v) tryptone, yeast extract, soymeal, ammonium chloride, and ammonium nitrate enhanced the amylase production. No growth was observed with ammonium acetate.

Purification of α-amylase

The crude enzyme sample obtained after ultrafiltration was purified on a cation-exchange chromatography Macro Prep High S support column. The elution pattern showed a major and broad peak of amylase activity (Fig. 4a). The amylase activity was found in unbound protein fractions collected from ion exchanger. Before applying to the hydroxyapatite column, SDS-PAGE was run for the active fractions. SDS-PAGE results showed the multiple bands (Fig. 5, Lane 3). The concentrated active fractions were then applied to the hydroxyapatite binding column. A single peak of amylase activity was obtained (Fig. 4b). The SDS-PAGE analysis showed the single protein band (Fig. 5, Lane 4). A summary of the purification is given in Table 1. These procedures yielded a pure amylase with specific activity of 1,200 U mg−1 of protein with purification fold 82 and a reasonable yield of 31%. The molecular mass of the purified amylase was found 97 KD on 7.5% SDS-PAGE.

Effects of temperature and pH on enzyme activity

Influence of temperature on enzyme activity was observed by incubating the enzyme at different temperatures. The results showed that the activity increased sharply with gradual increase in temperature up to 80°C (specific activity 83.5 U mg−1), and it declined gradually with further rise in temperature (Fig. 6a). The enzyme was 75 % active at 120°C. The effect of pH on IIPTN amylase activity was a bell shaped curve with an optimal activity at pH 5.0 (Fig. 6b). It was active at 4.5 and 9.5 with 19% and 36% of maximum activity, respectively.

Effects of metal ions and denaturing chemicals

Effect of metal ions on IIPTN amylase activity was determined at pH 5.0 and 80°C (Table 2). Enhancement in the activity of amylase on different metals at a final concentration of 5 mM was in following order: Mn2+>Ca2+>Ba2+>Co2+>Na+>Fe3+>K+. However, inactivation effect of Mg2+ and Zn2+ was found to be 33% and 50% of original activity, respectively. Mn2+ enhanced the amylase activity 91% more than the original activity. The sulfhydryl oxidant metals like Cu2+ and Hg2+ totally inhibited the enzyme activity. The enzyme was completely deactivated in presence of chelating agent EDTA, suggesting that it is a metallozyme. The effect of SDS and urea on the amylase activity was examined and found that both the chemicals enhanced the activity 42% and 47% more than the original activity, respectively, at the concentration of 5 mM.

Kinetic constants

Apparent K m and V max values were determined from Lineweaver–Burk plot (Fig. 7) as 36 mg ml−1 and 222 µmol mg−1 protein min−1, respectively, with cassava starch as substrate.

Substrate specificity

IIPTN α-amylase was examined for its ability to hydrolyze different gelatinized and raw starch by taking the hydrolysis rate of soluble starch as 100%. It efficiently hydrolyzed the gelatinized cassava starch, corn starch, soluble starch, tapioca root, amylopectin, sweet sorghum, and corn flour with relative hydrolysis rate 129%, 107%, 100%, 88%, 86%, 62%, and 58%, respectively. IIPTN α-amylase also hydrolyzed the raw starch substrates with relative hydrolysis rate for cassava, 106%; corn starch, 68%; soluble starch, 67%; amylopectin, 56%; and tapioca root, 50% (Table 3).

The end product of starch hydrolysis was analyzed by HPLC (data not shown). The major end products were maltose, maltotriose, and glucose. The rapid reduction in blue value and production of reducing sugars suggested the endo mode of action (Fig. 8).

Geobacillus sp. IIPTN amylase enzyme was stable more than 6 months at 4°C without adding PMSF. There was no loss detected in original activity (192 U ml−1), and the enzyme was found fully active after proteinase K treatment.

Discussion

The strain Geobacillus sp. IIPTN is a hyperthermophilic Gram-positive rod. The partial 16S rRNA gene sequence of strain Geobacillus sp. IIPTN falls within the radiation of the genus Geobacillus. The α-amylase production during growth of Geobacillus sp. IIPTN in mineral salt medium supplemented with 0.5% (w/v) cassava substrate was studied. Maximum amylase production was observed at 12 h with enzyme activity 135 U ml−1, and it was found to have declined gradually after the 20th hour (90 U ml−1) (Fig. 3). It was observed that the maximum amylase was produced by Geobacillus sp IIPTN when cell population reached at the exponential phase. The production of enzyme was growth associated (Santos and Martins 2003). The amylase production has been reported parallel with growth in B. subtilis (Stephenson et al. 1998), B. licheniformis TCRDC-B13 (Bajpai and Bajpai 1989), and Bacillus subtilis JS-2004 (Asgher et al. 2007). The amylase was produced by Geobacillus sp. IIPTN at its optimum growth temperature 60°C. The microorganism could grow the temperature ranges from 50°C to 80°C but the maximum amylase production was observed at 60°C. A wide range of temperature has been reported for optimum growth and α-amylase production using bacteria (Burhan et al. 2003; Konsula and Liakopoulou-Kyriakides 2004; Malhotra et al. 2000). Even the hyperthermophiles like P. furiosus and P. woesei have been reported to produce α-amylase at their optimum growth temperature of 100°C (Koch et al. 1990; James and Simpson 1996). The strain could not grow in the culture medium having pH below 5.0 and above 8.0. The enzyme production was increased with an increase in pH from 5 to 7 and higher enzyme synthesis was at pH 6.5, which was a result of enhanced bacterial growth. Most of the Bacillus strains are used for the commercial production of α-amylases that have an optimum pH between 6.0 and 9.0 for growth and enzyme production (Burhan et al. 2003; Jin et al. 1999). In this study, Geobacillus sp. IIPTN strain showed optimum growth and maximum α-amylase yield at pH 6.5. Amylase production from Geobacillus sp. IIPTN was inductive since the enzyme synthesis was high in the presence of cassava (135 U ml−1) and soluble starch (126 U ml−1). Geobacillus sp. IIPTN showed comparatively low enzyme production (50 U ml−1) when glucose was used as carbon source. This might due to glucose effect that repressed the enzyme production. It has been reported that the synthesis of carbohydrate-degrading enzymes in most species of the genus Bacillus is subject to catabolic repression by readily metabolizable substrates such as glucose (Santos and Martins 2003). Similar results were also reported to the hyperthermophilic archaeon Sulfolobus solfataricus in which glucose repressed production of α-amylase, demonstrating that a classical glucose effect was operative in this organism (Haseltine et al. 1996). Amongst various nitrogen sources, the isolate showed the highest amylase synthesis in the presence of soyabean meal and ammonium nitrate. Soya bean meal was found as the best nitrogen source for α-amylase production by Bacillus sp. I-3 (Sodhi et al. 2005). The combination of ammonium chloride and tryptone also showed the good amylase synthesis. Ramachandran et al. (2004) reported that peptone (1% w/v) and ammonium nitrate (1% w/v) enhanced the enzyme yield in SSF using coconut oil cake as substrate when supplemented individually. Malhotra et al. (2000) reported that tryptone was found good nitrogen source for amylase production.

The enzyme was purified by cation exchange and hydroxyapatite binding chromatography. The molecular mass of purified amylase was 97 KD. High molecular mass amylase was reported in Bacillus spp. (97 KD) (Kim et al. 1995), amylase from B. brevis had molecular mass of 205 KD (Ray et al. 2008). Temperature and pH are the critical parameters for starch hydrolysis. IIPTN α-amylase was optimally active at 80°C. Extracellular and cell-bound hyperthermophilic enzymes are optimally active at temperatures above or far above the host organism's optimum growth temperature and found highly stable (Vieille and Zeikus 2001). The enzyme was active in the broad range of temperature (40–120°C) (Fig. 6a). Few Bacillus sp. has been reported which work optimally at 70–100°C, e.g., amylases from B. licheniformis (100°C), B. stearothermophilus (70–80°C), B. amyloliquefaciens (70°C), and B. stearothermophilus (70°C) (Haki and Rakshit 2003). The optimum pH of IIPTN α-amylase was 5.0, and it was stable over a wide range of pH, 5.0 to 9.0 (Fig. 6b). At pH below 4.5, there was complete deactivation of enzyme; this could be due to the structure of functional groups in the active site which seems to be basic and resulted into acid hydrolysis of peptide bonds. Acid hydrolysis of peptide bonds at low pH was reported by Vieille and Zeikus (2001), which explained that it occurred most often at C-terminal side of Asp residues, with the Asp-Pro bond being the most susceptible. This may be due to the facts that the nitrogen of proline is more basic than that of other residues, and Asp has an increased propensity for α-β isomerization when linked on the N side of a proline. The natural pH of the starch slurry is approximately 4.5. In present starch-processing methods, the pH of the starch slurry adjusted to 5.8 or above for starch liquefaction. The higher pH values cause by-products and color formation which is not desirable in starch industries. Very few hyperthermostable amylases are reported that works up to 100°C and pH 5.0 like Thermococcus profundus with optimal activity at 80°C, pH 4.0–5.0, Pyrodictium abyssi with optimal activity at 100°C, pH 5.0, Staphylothermus marinus optimal activity at 100°C, pH 5.0 (Vieille and Zeikus 2001). Geobacillus sp. IIPTN novel α-amylase worked up to temperature of 120°C and pH 5.0.

Most of the amylases used in industry are reported to be metal ions dependent like, Ca2+, Mg2+, Mn2+, Zn2+, Fe3+ (Sivaramakrishnan et al. 2006). Geobacillus sp. IIPTN α-amylase was also found a metallozyme since the highest relative activity (191%) was observed in the presence of Mn2+ ion (Table 2). It has been reported that α-amylases specifically bind to Ca2+. The α-amylase catalytic site is located in a cleft between two domains (an [α/β]8 barrel and a large loop). Coordinated by ligands belonging to these two domains, Ca2+ is essential for the enzyme's catalytic activity and thermostability (Vieille and Zeikus 2001). But in case of Geobacillus sp. IIPTN α-amylase, we can assume that Mn2+ in place of Ca2+ played the role in catalytic activity. EDTA inhibited the amylase activity which confirmed that it is metallozyme. The relative activity was also enhanced by Ca2+ (180%), Ba2+ (163%), Co2+ (162%), Na+ (142%), Fe3+ (133%), K+ (131%). The effect of Cu2+ and Hg2+ was found completely inhibitory which suggested that a cysteine residue could be involved in the enzyme activity (Goyal et al. 2005).

Apparent values of K m and V max , determined from Lineweaver–Burk plot, were 36 mg ml−1 and 222 µmol mg−1 protein min−1, respectively, with cassava starch as substrate. Geobacillus sp. IIPTN showed substrate affinity towards cassava and corn starch with hydrolysis rate 129% and 107%, respectively, taking soluble starch hydrolysis rate as 100% (Table 3). It has been reported that natural starch such as raw sago starch, corn starch, and wheat starch increased α-amylase activities. It could hydrolyzed the wide variety of starch in the order cassava>corn starch>soluble starch>tapioca root>amylopectin>sweet sorghum>corn flour. Similar findings on digestibility of various starch by α-amylase of A. niger from rotting cassava bagasse reported were of the order maize starch>cassava starch>sorghum starch>soluble potato starch (Sivaramakrishnan et al. 2006). This enzyme could hydrolyzed the raw starch with hydrolysis rate in the order: cassava (106%)>corn starch (68%)>soluble starch (67%)>amylopectin (56%)>tapioca root (50%). Enzyme showed the affinity for raw cassava starch that is made up of tapioca root but in case of tapioca root the rate of hydrolysis was 50%. The possibility might be, some cultivars have high content of cyanogens and such type of cultivars can be used after cooking (Balagopalan 2002). The cyanogens might have affected the enzyme; therefore, the cooked tapioca root showed 88% hydrolysis rate than uncooked which was 50%. Raw starch hydrolysis also depends upon the C-terminal domain within the enzyme, which has been reported to be necessary for degradation of granular starch by mould glucoamylases. However, in case of bacterial amylases, binding to starch granules is not necessary requirement for the hydrolysis of the raw starch (Goyal et al. 2005). Another factor that counts is the ratio of amylose and amylopectin. The higher facility for water entrance in cassava starch is due to high content of amylopectin and the low molecular density. This property made the enzyme to access the substrate, therefore, raw cassava in this study showed 106% hydrolysis rate (Moore and Amante 2005).

Mostly industrial starch processes involve starch hydrolysis into glucose, maltose, or oligosaccharides. These sugars are then used in fermentation to produce a variety of chemicals e.g., ethanol, lysine, and citric acid. Starch bioprocessing generally involves two steps, liquefaction and saccharification, which run at high temperatures. During liquefaction, starch granules are gelatinized in a jet cooker at 105°C to 110°C for 5 min in aqueous solution (pH 5.8 to 6.5) and then partially hydrolyzed at α-1,4 linkages with a thermostable α-amylase at 95°C for 2 to 3 h. The α-amylases typically used from B. licheniformis and B. stearothermophilus are inactivated at temperature beyond 105°C. There is need of α-amylases which can operate above 100°C at acidic pH values for improved starch processing. The isolated novel IIPTN α-amylase can efficiently work up to 120°C at pH 5.0. The high-temperature stability, acidic pH, and raw starch degradability of IIPTN α-amylase revealed that this enzyme has the potential to fit into industrial requirements.

References

Asgher M, Asad MJ, Rahman SU, Legge RL (2007) A thermostable α-amylase from a moderately thermophilic Bacillus subtilis strain for starch processing. J Food Eng 79:950–955. doi:10.1016/j.jfoodeng.2005.12.053

Bajpai P, Bajpai P (1989) High-temperature alkaline α-amylase from Bacillus licheniformis TCRDC-B13. Biotechnol Bioeng 33:72–78

Balagopalan C (2002) Cassava utilization in food, feed and industry. In: Hillocks RJ, Thresh JM, Bellotti AC (eds) Cassava: Biology. Production and Utilization, CAB International, UK, pp 301–318

Burhan A, Nisa U, Gokhan C, Omer C, Ashabil A, Osman G (2003) Enzymatic properties of a novel thermophilic, alkaline and chelator resistant amylase from an alkalophilic Bacillus sp. isolate ANT-6. Proc. Biochem 38:1397–1403. doi:10.1016/S0032-9592(03)00037-2

Goyal N, Gupta JK, Soni SK (2005) A novel raw starch digesting thermostable α-amylase from Bacillus sp. I-3 and its use in the direct hydrolysis of raw potato starch. Enzyme Microb Technol 37:723–734. doi:10.1016/j.enzmictec.2005.04.017

Gupta R, Gigras P, Mohapatra H, Goswami VK, Chauhan B (2003) Microbial α-amylase: a biotechnological perspective. Proc Biochem 38:1599–1616. doi:10.1016/S0032-9592(03)00053-0

Haki GD, Rakshit SK (2003) Developments in industrially important thermostable enzymes: a review. Bioresour Technol 89:17–34. doi:10.1016/S0960-8524(03)00033-6

Haseltine C, Rolfsmeier M, Blum P (1996) The glucose effect and regulation of α-amylase synthesis in the hyperthermophilic archaeon Sulfolobus solfataricus. J Bacteriol 178:945–950

James J, Simpson BK (1996) Application of enzymes in food processing. Crit Rev Food Sci Nutri 36:437–463

Jin B, Van-Leeuwen JH, Patel B (1999) Mycelial morphology and fungal protein production from starch processing wastewater in submerged cultures of Aspergillus oryzae. Proc Biochem 34:335–340. doi:10.1016/S0032-9592(98)00098-3

Kim TU, Gu BG, Jeong JY, Byun SM, Shin YC (1995) Purification and characterization of a maltotetraose-forming alkaline α-amylase from an alkalophilic Bacillus strain GM8901. Appl Environ Microbiol 61:3105–3112

Koch R, Zablowski P, Spreinat A, Antranikian G (1990) Extremely thermostable amylolytic enzyme from the archaebacterium Pyrococcus furiosus. FEMS Microbiol Lett 71:21–26

Konsula Z, Liakopoulou-Kyriakides M (2004) Hydrolysis of starches by the action of an α-amylase from Bacillus subtilis. Proc Biochem 39:1745–1749. doi:10.1016/j.procbio.2003.07.003

Kumar S, Singh SP, Mishra IM, Adhikari DK (2009a) Recent advances in production of bioethanol from lignocellulosic biomass. Chem Eng Technol 32:517–526. doi:10.1002/ceat.200800442

Kumar S, Singh SP, Mishra IM, Adhikari DK (2009b) Ethanol and xylitol production from glucose and xylose at high temperature by Kluyveromyces sp. IIPE453. J Ind Microbiol Biotechnol 36:1483–1489. doi:10.1007/s10295-009-0636-6

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Lineweaver H, Burk D (1934) The determination of enzyme dissociation constants. J Am Chem Soc 56:658–666

Lowry OH, Rosebrough AJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–273

Malhotra R, Noorwez SM, Satyanarayan T (2000) Production and partial characterization of thermostable and calcium-independent α-amylase of an extreme thermophile Bacillus thermooleovorans NP54. Lett Appl Microbiol 31:378–384. doi:10.1046/j.1472-765x.2000.00830.x

Martínez TF, Alarcón FJ, Díaz-López M, Moyano FJ (2000) Improved detection of amylase activity by sodium dodecyl sulfate-polyacrylamide gel electrophoresis with copolymerized starch. Electrophoresis 21:2940–2943

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Moore GRP, Amante LRCER (2005) Cassava and corn starch in maltodextrin production. Quim Nova 28:596–600

Najafi MF, Deobagkar D, Deobagkar D (2005) Purification and characterization of an extracellular α-amylase from Bacillus subtilis AX20. Protein Expression Purif 41:349–354. doi:10.1016/j.pep. 2005.02.015

Ramachandran S, Patel AK, Nampoothiri KM, Francis F, Nagy V, Szakacs G, Pandey A (2004) Coconut oil cake-A potential raw material for the production of α-amylase. Bioresour Technol 93:169–174. doi:10.1016/j.biortech.2003.10.021

Ray RC, Kar S, Nayak S, Swain MR (2008) Extracellular α-amylase production by Bacillus brevis MTCC 7521. Food Biotechnol 22:234–246. doi:10.1080/08905430802262558

Santos EO, Martins MLL (2003) Effect of the medium composition on formation of amylase by Bacillus sp. Braz Arch Biol Technol 46:129–134

Sivaramakrishnan S, Gangadharan D, Nampoothiri MK, Soccol CR, Pandey A (2006) α-Amylases from microbial sources—an overview on recent developments. Food Technol Biotechnol 44:173–184

Sodhi HK, Sharma K, Gupta JK, Soni SK (2005) Production of a thermostable α-amylase from Bacillus sp. PS-7 by solid-state fermentation and its synergistic use in the hydrolysis of malt starch for alcohol production. Proc Biochem 40:525–534. doi:10.1016/j.procbio.2003.10.008

Srinivas T (2007) Industrial demand for cassava starch in India. Starch 59:477–481. doi:10.1002/star.200700657

Stephenson K, Carter NM, Harwood CR, Petit-Glatron MF, Chambert R (1998) The influence of protein folding on late stages of the secretion of α-amylase from Bacillus subtilis. FEBS Lett 430:385–389. doi:10.1016/S0014-5793(98)00698-X

Viara N, Elena P, Elka I (1993) Purification and characterization of a thermostable alpha-amylase from Bacillus licheniformis. J Biotechnol 28:277–289

Vieille K, Zeikus GJ (2001) Hyperthermophilic enzymes: sources, uses, and molecular mechanisms of thermostability. Microbiol Mol Biol Rev 65:1–43. doi:10.1128/MMBR.65.1.1-43.2001

Vihinen M, Mantsala P (1990) Characterization of a thermostable Bacillus stearothermophilus alpha-amylase. Appl Biochem Biotechnol 12:427–435

Acknowledgements

We thank Dr. M.O. Garg, Director IIP, Dehradun for his valuable suggestion and encouragement to carry out this research work. The authors (Pratibha Dheeran and Sachin Kumar) gratefully acknowledge Senior Research Fellowship awarded by Council of Scientific and Industrial Research (CSIR), India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dheeran, P., Kumar, S., Jaiswal, Y.K. et al. Characterization of hyperthermostable α-amylase from Geobacillus sp. IIPTN. Appl Microbiol Biotechnol 86, 1857–1866 (2010). https://doi.org/10.1007/s00253-009-2430-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2430-9