Abstract

Phaffia rhodozyma (now Xanthophyllomyces dendrorhous) and Haematococcus pluvialis are known as the major prominent microorganisms able to synthesize astaxanthin natural pigment. Important research efforts have been made to determine optimal conditions for astaxanthin synthesis. When the focus is on astaxanthin production, the maximal reported value of 9.2 mg/g cell is obtained within H. pluvialis grown on BAR medium, under continuous illumination (345 μmol photon m−2 s−1) and without aeration. Whereas fermentation by mutated R1 yeast grown on coconut milk produced 1,850 μg/g yeast. However, when looking at astaxanthin productivity, the picture is slightly different. The figures obtained with P. rhodozyma are rather similar to those of H. pluvialis. Maximal reported values are 170 μg/g yeast per day with a wild yeast strain and 370 μg/g yeast per day with mutated R1 yeast. In the case of H. pluvialis, maximal values ranged from 290 to 428 μg/g cell per day depending on the media (BG-11 or BAR), light intensity (177 μmol photon m−2 s−1), aeration, etc. The main aim of this work was to examine how astaxanthin synthesis, by P. rhodozyma and H. pluvialis, could be compared. The study is based on previous works by the authors where pigment productions have been reported.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

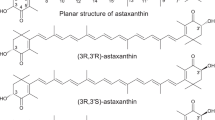

Astaxanthin is an abundant carotenoid pigment responsible for the color of the flesh of many marine species by the ingestion of microorganisms that synthesize the pigment (Gu et al. 1997; Johnson and Schroeder 1995; Olaizola 2003). Its antioxidant properties have increased the industrial interest on the uses of astaxanthin in the aquaculture, chemical, pharmaceutical, and alimentary industries (Fang and Chiou 1996; Yamane et al. 1997; Ramírez et al. 2001; Fang and Wang 2002; Del Río et al. 2005; Orosa et al. 2005). Synthetic versions of the pigment were very popular in the1980s, but it was demonstrated that some of them may induce human cancer (Newsome 1986), and astaxanthin is rather expensive ($2,500–3,000 per kilogram). Only few microorganisms can synthesize astaxanthin (Brevibaterium, Mycobacterium lacticola, Neils and Leenheer 1991; Agrobacterium auratim Yokayama and Miki 1995; Haematococus pluvialis, Lotan and Hirschberg 1995) and the yeast P. rhodozyma (Andrews et al. 1976). Microalgal astaxanthin purified from H. pluvialis is indeed a powerful antioxidant agent in vitro under both hydrophobic and hydrophilic conditions (Kobayashi and Sakamoto 1999). Developments for commercial pigment production were carried out in 25,000 l outdoor photobioreactors (Olaizola 2000, 2003).

Previous studies on H. pluvialis have shown the complex relationships between nutrients, growth, cell yield, cell type, and astaxanthin formation (Droop 1954, 1955; Pringsheim 1966; Cordero et al. 1996). Changes in primary metabolism due to high astaxanthin accumulation in H. pluvialis have been analyzed (Kobayashi et al. 1992a,b; Kang et al. 2007). It was stated that astaxanthin production by H. pluvialis is enhanced by oxidative stress and then speculated that could remove free radicals (Kobayashi et al. 1993). On the other hand, Kakizono et al. (1992) reported that the production of astaxanthin by H. pluvialis was enhanced by a high C/N ratio.

Phaffia rhodozyma is able to ferment glucose and other sugars and produce carotenoids such as astaxanthin, (Johnson and An 1991). The yeast was grown on cane molasses (Haard 1988), sugar cane juice (Fontana et al. 1996), corn wet-milling by-products (Hayman et al. 1995), alfalfa residual juice (Okagbue and Lewis 1984), grape juice (Meyer and du Preez 1994a), hydrolyzed peat (Acheampong and Martin 1995; Martin et al. 1993), maize residues (Leathers 2003), and coconut milk (Domínguez-Bocanegra and Torres-Muñoz 2004). In addition, Johnson and Schroeder (1995) have reported that carotenoid biosynthesis was regulated by singlet oxygen and peroxide radicals in P. rhodozyma.

The aim of this work was to compare the synthesis of astaxanthin by H. pluvialis and P. rhodozyma on the basis of productivity and not on production of the pigment. The analysis is based on the maximal reported values for both microorganisms (Domínguez-Bocanegra et al. 2004; Domínguez-Bocanegra and Torres-Muñoz 2004).

Materials and methods

A brief description of materials and methods for both P. rhodozyma and H. pluvialis is presented. Their complete description can be found in Domínguez-Bocanegra et al. (2004), Domínguez-Bocanegra and Torres-Muñoz (2004); the first article dealing with H. pluvialis and the second with P. rhodozyma.

Microorganisms

P. rhodozyma

Strain NRRL-10921 (sexual state Xanthophyllomyces dendrorhous) was obtained from the ARS culture collection (USDA, Peoria, III). The process for obtaining the mutated R1 strain is reported in Jiménez (1999) and recalled in Domínguez-Bocanegra and Torres-Muñoz (2004).

H. pluvialis

NIES-144 was obtained from the National Institute for Environmental Studies (NIES), University of Tokyo, Japan. Stock culture and inoculum were grown on bold basal medium (BBM) as was reported in Domínguez-Bocanegra et al. (2004).

Inoculum preparation

P. rhodozyma

Cell inoculum was grown in 50 ml of YM medium in a 250-ml Erlenmeyer flask under constant temperature of 22°C, stirrer speed of 150 rpm, for 48 h. Fresh medium was inoculated with the seed culture at 10% volume. The yeast was grown under the same culture conditions.

H. pluvialis

Cell inoculum was grown in 700 ml of BBM medium in a 1,000-ml Erlenmeyer flask under continuous white fluorescent illumination (177 μmol photon m−2 s−1) and constant temperature (28°C). Fresh medium was then inoculated with the seed culture at 10% volume.

Growth kinetics

P. rhodozyma

Cultures were grown aseptically in 250-ml Erlenmeyer flasks containing 50 ml of culture media (YM, YPG or coconut milk) under constant temperature 22°C, gyrate shaking at 150 rpm during 5 days. The cultures were inoculated with 5 ml YM medium in the exponential phase.

H. pluvialis

Cultures were grown in 1,000-ml Erlenmeyer flasks containing 700 ml of medium BAR or BG-11 at 28°C, with daily manual agitation, without aeration 1.5% C02, and under continuous illumination (177 μmol photon m−2s−1) during 8 days. Cultures were also grown under the same conditions, but with 20% of inoculum and under continuous illumination (345 μmol photon m−2 s−1) without aeration during 14 days.

Analytical methods

Dry weight determination

P. rhodozyma

Culture samples (2 ml) were centrifuged at 3,500 × g × 1,000, for 5 min at room temperature. The cell pellet was washed twice with 2 ml of distilled water and filtered through a 0.45-μm Millipore pre-weight filter. Then, filters were dried at 60°C for 24 h.

Growth determination

H. pluvialis

Microalgal cell growth was assessed daily through cell microscopic counting using 5-ml samples taken from three different cultures. Cell samples were centrifuged at 3,000 × g × 1,000 for 5 min and heated in 90:10 (v/v) methanol: water for 3 min at 80°C in the dark and centrifuged as before. Absorbance was taken as in Domínguez-Bocanegra et al. (2004).

Pigment extraction

P. rhodozyma

Firstly, cells were washed and mixed with 1 ml acetone, 1 ml petroleum ether, and 1 ml NaCl at 20% w/v. To extract the pigment, samples were centrifuged for 5 min at 3,500 × g. Carotenoids were monitored by spectrophotometry, and astaxanthin was further quantified using a commercial standard (Hoffmann, La Roche, Switzerland) with the high performance liquid chromatography (HPLC) method of Jian-Ping et al. (1997).

H. pluvialis

Pigment concentration was determined using a modified Britton (1985) procedure. Triplicates of three different 5-ml samples were centrifuged at 900 × g × 1,000 for 5 min. Cell pellet was washed twice (5 ml distilled water) then added 5 ml of glass pearls and 5 ml of hexane/acetone/ethyl alcohol (100:70:70). Colorant was extracted and quantified at 474 nm, 1% = 2,100 extinction coefficient for total carotenoids and 1% = 1,600 for astaxanthin (Sedmak et al. 1990). Astaxanthin was quantified by the HPLC method of Jian-Ping et al. (1997).

Sugar content evaluation

P. rhodozyma

The direct numerical simulation (DNS) method of Miller (1959) was used to evaluate the content of residual reducing sugars. A 1-ml sample was centrifuged (3,500 × g/5 min), and 1 ml of DNS reagent was added to the supernatant. Samples were heated to boiling for 5 min and placed in an ice-bath; then, 8 ml distillated water was added, and the tubes were shaken (vortex mod. G-560 Sc., NY) for 5 min. Optical density of glucose concentration was determined by spectrometry at 575 nm.

Chlorophyll content determination

H. pluvialis

Chlorophyll content was determined in 5-ml samples using the APHA procedure (APHA and WCPF 1992).

Statistical analyses

All experiments were performed in triplicate. A tri-factorial analysis of variance was applied to cell density values and astaxanthin content of P. rhodozyma and H. pluvialis. Post hoc comparisons were carried out through the Newman–Keuls test (P = 0.05; Sokal and Rohlf 1981).

Results

P. rhodozyma

Regarding astaxanthin production, three different culture media (YM, YPG, and coconut milk) and two different yeast strains, namely wild strain (NRRL-10921) and a hyper-productive mutated yeast R1, were used.

When coconut milk was used as the culture medium, maximal yeast growth rates were 9.2 g/l (wild yeast) and 6.2 g/l (R1 strain). In other media, lower maximal growth rates were recorded: in YM, 5.6 g/l (wild strain) and 4.7 g/l (R1 strain), and in YPG, 4.9 g/l (wild strain) and 3.9 g/l (R1 strain). All the figures were recorded at day 5 (see Fig. 1).

Regarding carotenoid synthesis, maximal values were as follows: (1) wild strain, 378 μg/g yeast in YPG, 450 μg/g yeast in YM, and 850 μg/g yeast in coconut milk; (2) R1 strain, 884 μg/g yeast in YPG, 1,060 μg/g yeast in YM, and 1,850 μg/g yeast in coconut milk; all figures were recorded at day 5 (Fig. 2). Coconut milk improved astaxanthin production in at least 75% of all cultures.

Covariance analyses were carried out using of the Newman–Kuels test. The interaction between coconut milk as substrate and the strain was not significantly different, either in the case of yeast growth with P = 0.61 or for astaxanthin production with P = 0.43.

Pigment productivities of the wild yeast, computed as the maximal astaxanthin production divided by the number of days, were 75.6, 90, and 170 μg/g yeast per day in YPG, YM, and coconut milk media, respectively. In the case of R1 yeast, the recorded figures were 176.8, 212, and 370 μg/g yeast per day in YPG, YM, and coconut milk media, respectively (see Fig. 5).

Growth kinetics at 120 h in coconut milk was such that sugar consumption was of 92% with strain NRRL-10921 and 84% with mutated R1 yeast. The results are not reported here, but details may be found in Domínguez-Bocanegra and Torres-Muñoz (2004).

H. pluvialis

The effects of light intensity (continuous or photoperiod), aeration, and nutritional conditions were evaluated with respect to carotenoid accumulation. Initially, light intensity was fixed at 177 μmol photon m−2s−1 (continuous illumination). In non-aerated cultures, the maximal green cell growth rates were 9.3 × 104 cell per milliliter in BG-11 medium and 6 × 104 cell per milliliter in BAR medium in both cases with manual agitation. Under the same conditions, aerated cultures exhibited a higher growth rate reaching 27.3 × 104 cell per milliliter and 7.3 × 104 cell per milliliter in BG-11 and BAR media, respectively. When operating under a 12-h light/12-h dark cycle, the growth rate was lower in all experiments (see Table 1).

Concerning pigment accumulation, non-aerated cultures accumulated more astaxanthin than aerated cultures. Maximal values increased from 1.3 to 2.0 mg/g cell in BG-11 medium and from 2.2 to 3.3 mg/g cell in BAR medium from aerated to non-aerated cultures respectively. Under a photoperiod (12 h/12 h), maximal values decreased in comparison with continuous lighting, but followed a similar path going from 1.2 to 1.4 mg/g cell in BG-11 medium and from 1.7 to 3.0 mg/g cell in BAR medium in aerated or non-aerated cultures, respectively (see Table 2). The recorded values were quantified at day 7.

Regarding astaxanthin productivity, maximal values were recorded in non-aerated cultures: (a) under photoperiod 12 h/12 h, maximal productivity was 200 μg/g cell per day with BG-11 medium and 428 μg/g cell per day with BAR medium; (b) under continuous illumination, the figures were 290 μg/g cell per day with BG-11 and 471 μg/g cell per day with BAR media, respectively (see Fig. 6).

Then, light intensity was set at 345 μmol photon m−2 s−1, and BAR medium was chosen for subsequent experiments because of the highest pigment accumulation. Cell growth rate was higher in cultures with air supply, 0.7 g/l under continuous illumination and 0.6 g/l under photoperiod recorded at day 12. In non-aerated cultures, growth rates were 0.2 g/l under continuous illumination and 0.45 g/l under photoperiod at day 12. Recorded values were the maximal ones, except in the case of non-aerated culture under continuous illumination (0.26 g/l at day 9; see Fig. 3).

With regard to astaxanthin production, non-aerated cultures gave rise to the highest figures: 9.2 mg/g cell (under continuous illumination) and 6.4 mg/g cell (under 12-h/12-h photoperiod). By contrast, significantly lower pigment concentrations were recorded in aerated cultures: 2.5 mg/g cell and 2.0 mg/g cell under continuous illumination and a 12-h/12-h photoperiod, respectively. Figures were recorded every 24 h until day 12 (see Fig. 4). As a consequence, astaxanthin productivity on non-aerated cultures reached the maximal figures: a maximum 767 μg/g cell per day under continuous illumination and 535 μg/g cell per day under 12-h/12-h photoperiod. In turn, aerated cultures exhibited significantly lower pigment productivities: 211 μg/g cell per day under continuous illumination and 168 μg/g cell per day under 12-h/12-h photoperiod.

Discussion

P. rhodozyma

Working with two different yeast strains and the results obtained support the hypothesis that vitamins, amino-acids, but mainly the inherent carbon source present in coconut milk (CM), are nutritional stress factors that influence the cellular metabolism so that pigment synthesis occurs even when biomass growth stopped and sugars were exhausted (Johnson and An 1991; Domínguez-Bocanegra and Torres-Muñoz 2004).

Sugar consumption (not reported here) reached 92% when the yeast was growing on coconut milk, 88% on YM, and 85% on YPG at 120 h. Cellular growth was directly correlated with the availability of sugar in CM or YM (Meyer and du Preez 1994b), but not in YPG where inhibition by excess of sugar appeared; the maximum growth was recorded in CM and was about twice the maximum in YPG or YM. Astaxanthin synthesis still occurred after growth stopped, thanks to intermediary extracellular carbon source produced during the growth process, this inducing late carotenogenesis (Johnson and An 1991). Maximal pigment production was registered in CM and was at least 70 and 150% higher than peak figures in YM and YPG, respectively (see Fig. 2).

Pigment production figures obtained in CM and compared with other natural carbon sources like cane molasses, grape juice, etc. are substantially higher than those reported in Okagbue and Lewis (1984), Haard (1988), Acheampong and Martin (1995), Martin et al. (1993), Meyer and du Preez (1994a), Hayman et al. (1995), and Fontana et al. (1996).

Pigment production by wild or mutated yeast grown on CM is about twice that recorded by Fleno et al. (1988) and An et al. (1989) who used specific wild and mutated yeast (Meyer et al. 1993).

When culturing the mutated yeast strain R1, a 100% increase in astaxanthin production was obtained compared with wild yeast grown in CM, and a more than 300% increase compared with yeast grown on YM and YPG media (see Fig. 2). However, the kinetic parameters (i.e., the growth coefficient) were lower for R1 yeast compared with wild yeast; this characteristic is typical of mutated yeast (Johnson and An 1991; Meyer and du Preez 1994a; Fang and Chiou 1996).

The type of yeast and culture media influenced pigment productivity independently. Indeed, the wild yeast productivity in CM was 125% higher than that in YPG. With YM media, productivity of the R1 yeast was 135% higher than that obtained with wild yeast. But, it turned out that productivity of R1 in CM was 389% higher than that obtained with wild yeast in YPG (see Fig. 5).

The influence of CM on astaxanthin productivity may be highlighted even in the case of the wild yeast strain NRRL-10921. A productivity of 170 μg/g yeast per day well compares with productivity recorded with H. pluvialis (170 or 238 μg/g yeast per day), which depends on the nutrient (BAR or BG-11 medium) and environmental conditions (photoperiod 12 h/12 h and aerated cultures; see Fig. 5).

These results suggest that the best option is to choose a suitable hyper-synthesizer yeast (like R1 yeast) and grow it on an inexpensive rich carbon source such as coconut milk. The maximal recorded productivity of 370 μg/g yeast per day is comparable with the highest productivities obtained with H. pluvialis (see Figs. 5 and 6). Although the wild yeast in YM exhibited a productivity of 170 μg/g yeast per day, that is comparable with certain figures obtained with H. pluvialis (170 or 238 μg/g yeast per day), depending on the nutrient (BAR or BG-11 medium) and environmental conditions (photoperiod 12 h/12 h and aerated cultures; see Figs. 5 and 6).

H. pluvialis

Nutritional and environmental factors may act on the morphological transformation of green cells into red aplanospores rich in astaxanthin (see Boussiba et al. 1999 and the references therein). The content of sodium acetate in the BAR culture medium, together with a high light intensity, limited the growth and photosynthesis, thus stimulating cyst formation, which, in the presence of a high C/N ratio, inducted the synthesis of astaxanthin (Kobayashi et al. 1992a,b; Kakizono et al. 1992).

The influence of non-aeration can be discussed in the following way: Firstly, it resulted in the lowest cell growth in all cultures exhibiting significant differences with respect to the aerated ones; secondly, it inducted the highest astaxanthin production with significant differences with respect to aerated cultures (see Figs. 3 and 4). Once the stationary phase was reached at 120 h, a relatively low content of nitrate present in BG-11 and BAR culture media was indispensable to reach reasonable concentration of carotenoids (Boussiba et al. 1992).

In general, the increase in light intensity results in an increase in synthesis astaxanthin (Kobayashi et al. 1997). Moreover, limiting the nitrate content together with a high irradiation level increases carotenoid synthesis (Lee and Soh 1991; García-Malea et al. 2005, 2006). We have shown that in addition to nitrate deficiency and high irradiation, the absence of aeration highly enhanced both the production and productivity of astaxanthin (Fábregas et al. 2001; Domínguez-Bocanegra et al. 2004).

Optimal conditions for growing green cells were continuous illumination (177 μmol photon m−2 s−1) and aeration of cultures grown on BG-11 medium. Optimal conditions for astaxanthin accumulation were of higher light intensity (345 μmol photon m−2 s−1), non-aerated cultures and sodium acetate as inorganic carbon source in the BAR culture medium (see Tables 1 and 2).

The productivity of astaxanthin followed a similar path as the production of the pigment; the largest value of 767 μg/g cell per day was obtained under high light intensity (345 μmol photon m−2 s−1) with non-aerated cultures and BAR as a culture medium.

P. rhodozyma vs H. pluvialis

With respect to astaxanthin production, maximal values obtained with H. pluvialis [3.3 mg/g cell at day 7 (or 9.2 mg/g cell at day 12) on BAR medium, in non-aerated cultures, continuous light 177 μmol photon m−2 s−1 (or 345 μmol photon m−2 s−1)] are far behind the best figures obtained with P. rhodozyma (850 μg/g yeast for the wild yeast and 1,850 μg/g yeast for the mutated R1, both grown on coconut milk at day 5; see Figs. 2 and 4).

The differences on astaxanthin production are basically linked with the metabolic characteristics of both microorganisms. It is worth noticing that the figures reported here are congruent with those reported in well-known references; see for instance Meyer and du Preez (1994a), Leathers (2003) for P. rhodozyma and Kakizono et al. (1992), Kang et al. (2007) for H. pluvialis.

However, when pigment productivity is scrutinized, the maximal values obtained were 290 μg/g cell per day with BG-11 culture medium and 471 μg/g cell per day with BAR culture medium, in the case of H. pluvialis and 170 μg/g yeast per day for the wild-type yeast, 370 μg/g yeast per day for the R1 yeast both grown on CM medium in the case of P. rhodozyma (see Figs. 5 and 6).

Increasing the light intensity to 345 μmol photon m−2 s−1 was a key factor for reaching maximal pigment productivity, namely 767 μg/g cell per day with continuous illumination and 535 μg/g cell per day under a photoperiod at day 12 (Fig. 4). Indeed, the induction of astaxanthin accumulation increases as a function of the average irradiance, which is a typical characteristic of secondary metabolites that are partially linked to growth (Boussiba and Vonshak 1991; Lee and Soh 1991; García-Malea et al. 2005, 2006). Let us mention that several studies consider 177 μmol photon m−2 s−1 as high illumination intensity (You-Chul et al. 2006).

Among others, some key factors that process engineers should assess is the possible use of coconut milk, an industrial residual that is an inexpensive source of energy which enhances both biomass growth and astaxanthin production. The possible instability of the mutated R1 yeast should also be taken into account, while we have obtained significant productivity rates with wild yeast.

Astaxanthin production by H. pluvialis is more demanding, as it requires different culture conditions to reach high pigment concentration. The composition of a suitable media (like BBM) may increase the cost of the process.

References

Acheampong E, Martin A (1995) Kinetic studies on the yeast Phaffia rhodozyma. J Basic Microbiol 35:147–155

Andrews AG, Phaff HJ, Starr MP (1976) Carotenoids of Phaffia rhodozyma red pigmented fermenting yeast. Phytochemistry 15:10003–10007

An GH, Schuman DB, Johnson EA (1989) Isolation of Phaffia rhodozyma mutants with increased astaxanthin content. Appl Environ Microbiol 55:116–124

APHA, WCPF (1992) Standard methods for the examination of waters and wastewaters, 17th edn. Washington, DC

Boussiba S, Vonshak A (1991) Astaxanthin accumulation in the green alga Haematococcus pluvialis. Plant Cell Physiol 7:1077–1082

Boussiba S, Fan L, Vonshak A (1992) Enhancement and determination of astaxanthin accumulation in the green alga Haematococcus pluvialis. Methods Enzymol 213:386–391

Boussiba S, Bing-Bing W, Yuan JP, Zarka A, Chen F (1999) Changes in pigments profile in the green alga Haematococcus pluvialis exposed to environmental stresses. Biotechnol Lett 21:601–604

Britton G (1985) General carotenoids. Methods Enzymol 111:115–149

Cordero B, Otero A, Patiño M, Arredondo BO, Fábregas J (1996) Astaxanthin production from the green alga Haematococcus pluvialis with different stress conditions. Biotechnol Lett 18:213–218

Del Río E, Acién FG, García-Malea MC, Rivas J, Molina E, Guerrero MG (2005) Efficient one-step production of astaxanthin by the microalga Haematococcus pluvialis in continuous culture. Biotechnol Bioeng 91(7):808–815

Domínguez-Bocanegra AR, Torres-Muñoz JA (2004) Astaxanthin hyperproduction by Phaffia rhodozyma (now Xanthophyllomyces dendrorhous) with raw coconut milk as sole source of energy. Appl Microbiol Biotechnol 66:249–252

Domínguez-Bocanegra AR, Guerrero-Legarreta I, Martínez-Jerónimo F, Tomassini-Campocosio A (2004) Influence of environmental and nutritional factors in the production of astaxanthin from Haematococcus pluvialis. Bioresour Technol 92:209–214

Droop MR (1954) Conditions governing haematochrome formation and loss in the alga Haematococcus pluvialis. Arch Microbiol 20:391–397

Droop MR (1955) Carotenogenesis in Haematococcus. Nature 175:42

Fábregas J, Otero A, Maseda A, Domínguez A (2001) Two-stage cultures for the production astaxanthin from Haematococcus pluvialis. J Biotechnol 89:65–71

Fang TJ, Chiou TY (1996) Batch cultivation and astaxanthin production by to mutant of the net yeast Phaffia rhodozyma NCHU-FS501. J Ind Microbiol 16:175–181

Fang TJ, Wang JM (2002) Extractability of astaxanthin in a mixed culture of a carotenoid over-producing mutant of Xanthophyllomyces dendrorhous and Bacillus circulans in two-stage batch fermentation. Process Biochem 37:1235–1245

Fleno B, Christensen Y, Larser R (1988) Astaxanthin producing yeast cells, methods for their preparation and their use. WO 88/08025

Fontana JD, Guimaraes MF, Martins NT, Fontana CA, Baron M (1996) Culture of the astaxanthin ogenic yeast Phaffia rhodozyma in low-cost media. Appl Biochem Biotechnol 57–58:413–422

García-Malea MC, Brindley C, Del Río-Sánchez E, Acién FG, Fernández JM, Molina E (2005) Modeling of growth and accumulation of carotenoids in Haematococcus pluvialis as a function of irradiance and nutrients supply. Biochem Eng J 25:187–194

García-Malea MC, Del Río-Sánchez E, Casas-López JL, Acién-Fernández FG, Fernández-Sevilla JM, Guerrero MG, Molina-Grima E (2006) Comparative analysis of the outdoor culture of Haematococcus pluvialis in tubular and bubble column photobioreactors. J Biotechnol 123:329–342

Gu WL, An GH, Johnson EA (1997) Ethanol increases carotenoid production in Phaffia rhodozyma. J Ind Microbiol Biotechnol 19:114–117

Haard N (1988) Astaxanthin formation by the yeast Phaffia rhodozyma on molasses. Biotechnol Lett 10:609–614

Hayman TG, Mannarelli BN, Leathers TD (1995) Production of carotenoids by Phaffia rhodozyma grown on media composed of corn wet-milling co-products. J Ind Microbiol 115:173–183

Jian-Ping Y, Xian-Di G, Feng C (1997) Separation and analysis of carotenoids and chlorophylls in Haematococcus lacustris by high-performance liquid chromatography photodiode array detection. J Agric Food Chem 45:1952–1956

Jiménez R (1999) Obtención de una mutante de Phaffia rhodozyma hiperproductora de astaxanthin. Master in Sc thesis, Departamento de Biotecnología y Bioingeniería, CINVESTAV-IPN, México (in Spanish)

Johnson EA, An GH (1991) Astaxanthin from microbial sources. Crit Rev Biotechnol 11:297–326

Johnson EA, Schroeder WA (1995) Microbial carotenoids. In: Fiechter A (ed) Advances biochemical engineering and biotechnology. Springer, Berlin 53:119–178

Kakizono T, Kobayashi M, Nagai S (1992) Effect of carbon/nitrogen ratio on the encystment accompanied with astaxanthin formation in to green alga, Haematococcus pluvialis. J Ferment Bioeng 74:403–405

Kang CD, Lee JS, Park TH, Sim SJ (2007) Complementary limiting factors of astaxanthin synthesis during photoautotrophic induction of Haematococcus pluvialis: C/N ratio and light intensity. Appl Microbiol Biotechnol (in press) DOI https://doi.org/10.1007/s00253-006-0759-x

Kobayashi M, Sakamoto Y (1999) Singlet oxygen quenching ability of astaxanthin esters from the green alga Haematococcus pluvialis. Biotechnol Lett 21:265–269

Kobayashi M, Kakizono T, Yamaguchi K, Nishio N, Nagai S (1992a) Growth and astaxanthin formation of Haematococcus pluvialis in heterotrophic and mixotrophic conditions. J Ferment Bioeng 74:17–20

Kobayashi M, Kakizono T, Nagai S (1992b) Effects of light intensity, light quality and illumination cycle on astaxanthin formation in a green alga. J Ferment Bioeng 74:61–63

Kobayashi M, Kakizono T, Nagai S (1993) Enhanced carotenoid biosynthesis by oxidative stress in acetate induced cyst cells of to green alga Haematococcus pluvialis. Appl Environ Microbiol 59:867–873

Kobayashi M, Kakizono T, Nishio N, Nagai S, Kurimura Y, Tsuji Y (1997) Antioxidant role of astaxanthin in the green alga Haematococcus pluvialis. Appl Microbiol Biotechnol 48:351–356

Leathers DT (2003) Bioconversions of maize residues to value-added coproducts using yeast-like fungi. FEMS Yeast Research 3:133–140

Lee YK, Soh CW (1991) Accumulation of astaxanthin in Haematococcus lacustris (Chlorophyta). J Phycol 27:575–577

Lotan T, Hirschberg J (1995) Cloning and expression in Escherichia coli of the gene encoding β-C-4-oxygenase, that converts β-carotene to the ketocarotenoid canthaxanthin in Haematococcus pluvialis. FEBS Lett 364:125–128

Martin AM, Acheampong E, Patel TR (1993) Production of astaxanthin by Phaffia rhodozyma using peat hydrolysates as substrate. J Chem Technol Biotechnol 58:223–230

Meyer PS, du Preez JC (1994a) Astaxanthin production by Phaffia rhodozyma mutant on grape juice. World J Microbiol Biotechnol 10:178–183

Meyer PS, du Preez JC (1994b) Effect of culture conditions on astaxanthin production by mutant of Phaffia rhodozyma in batch and chemostat culture. Appl Microbiol Biotechnol 40:361–356

Meyer PS, du Preez JC, Kilian SG (1993) Selection and evaluation of astaxanthin-overproducing mutants of Phaffia rhodozyma. World J Microbiol Biotechnol 9:514–520

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Neils HJ, Leenheer AP (1991) Microbial sources of carotenoid pigments uses in foods and feeds. J Appl Bacteriol 70:181–191

Newsome RL (1986) Food colors. Food Technol 49–56

Okagbue RN, Lewis MW (1984) Autolysis of the red yeast Phaffia rhodozyma: a potential tool to facilitate extraction of astaxanthin. Biotechnol Lett 6:247

Olaizola M (2000) Commercial production of astaxanthin from Haematococcus pluvialis using 25,000-liter outdoor photobioreactors. J Appl Phycol 12:499–506

Olaizola M (2003) Commercial development of microalgal biotechnology: from the test tube to the marketplace. Biomol Eng 20:459–466

Orosa M, Franqueira D, Cid A, Abalde J (2005) Analysis and enhancement of astaxanthin accumulation in Haematococcus pluvialis. Bioresour Technol 95(3):373–378

Pringsheim EG (1966) Nutritional requirements of Haematococus pluvialis and related species. J Phycol 2:1–7

Ramírez J, Gutierrez H, Gschaedler A (2001) Optimization of astaxanthin production by Phaffia rhodozyma through factorial design and response surface methodology. J Biotechnol 88:259–268

Sedmak JJ, Weerasinghe DK, Jolly SO (1990) Extraction and quantization of astaxanthin by Phaffia rhodozyma. Biotechnol Tech 4:107–112

Sokal RR, Rohlf FJ (1981) Biometry. The principles and practice of statistics in biological research, 2nd edn. Freeman, San Francisco, USA

Yamane Y, Higashida K, Nishio N (1997) Influence of oxygen and glucose on primary metabolism and astaxanthin production by Phaffia rhodozyma in fed-batch cultures: kinetic and stoichiometric analysis. Appl Environ Microbiol 63:4471–4478

Yokayama T, Miki W (1995) Composition and presumed biosynthetic pathway of carotenoids in the astaxanthin-producing bacterium Agrobacterium aurantiacum. FEMS Microbiol Lett 28:139–144

You-Chul J, Chul-Woong Ch, Yeoung-Sang Y (2006) Combined effects of light intensity and acetate concentration on the growth of unicellular microalga Haematococcus pluvialis. Enzyme Microb Technol 39:490–495

Acknowledgments

The authors would like to express their full gratitude to Professor Albert Sasson for his encouraging comments along the preparation of the manuscript. They would, as well, like to express their thanks to anonymous reviewers for their constructive criticism.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Domínguez-Bocanegra, A.R., Ponce-Noyola, T. & Torres-Muñoz, J.A. Astaxanthin production by Phaffia rhodozyma and Haematococcus pluvialis: a comparative study. Appl Microbiol Biotechnol 75, 783–791 (2007). https://doi.org/10.1007/s00253-007-0889-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-007-0889-9