Abstract

In this study, biological degradation of 2,4,6-trinitrotoluene (TNT) which is very highly toxic environmentally and an explosive in nitroaromatic character was researched in minimal medium by Bacillus cereus isolated from North Atlantic Treaty Organization (NATO) TNT-contaminated soils. In contrast to most previous studies, the capability of this bacteria to transform in liquid medium containing TNT was investigated. During degradation, treatment of TNT was followed by high-performance liquid chromatography (HPLC) and achievement of degradation was calculated as percentage. At an initial concentration of 50 and 75 mg L−1, TNT was degraded respectively 68 % and 77 % in 96 h. It transformed into 2,4-dinitrotoluene and 4-aminodinitrotoluene derivates, which could be detected as intermediate metabolites by using thin-layer chromatography and gas chromatography–mass spectrometry analyses. Release of nitrite and nitrate ions were searched by spectrophotometric analyses. Depending upon Meisenheimer complex, while nitrite production was observed, nitrate was detected in none of the cultures. Results of our study propose which environmental pollutant can be removed by using microorganisms that are indigenous to the contaminated site.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Xenobiotic compounds, such as nitroamines (royal demolition explosive, hexogen, octogen), nitroaromatics (TNT, picric acid, 2,4,6-trinitrophenylmethylnitramine and hexanitrodiphenylamine), aliphatics (pentaerythritol tetranitrate, nitroguanidine), nitrobenzenes produced by many military activities, are widely used in the synthesis of pesticides, plastics, polymers pharmaceuticals, dyes and explosives [5, 9, 13, 18]. These chemicals constitute an important group of environmental pollutans due to their recalcitrant structures [21, 26]. The highly energetic chemical TNT that produced the primary explosive during World War II is a nitroaromatic explosive [33]. TNT and its derivates found not only at producing and processing facilities but also at many disposal sites where they could leak out into soil and groundwater in different ways [36]. TNT is well known to be cytotoxic and mutagenic to many living organisms including humans [7, 47]. TNT that is a C-class carcinogen chemical has been reported to cause various disorders ranging from aplastic anemia, toxic hepatitis, dermatitis, cyanosis, sneezing, cough, peripheral neuritis, cataract, muscular pain to kidney damage [6, 24, 42]. Mutagenic effect of TNT has been shown by Ames test made on Salmonella sp [39].

Therefore, enhancing the attractive technology for removal of TNT-polluted sites as quickly as possible will be required. Microbial processes could be widely used for the remediation TNT because of their high performance in biotransformations of chemical compounds [12]. Both aerobic and anaerobic TNT degradation by many different bacteria have been reported [22, 25]. In aerobic conditions, removal of TNT is divided to two reductive pathways, including reduction of one or two nitro groups to a hydroxylamino group followed by the formation of various amino-substitued metabolites such as amino-dinitrotoluenes and diamino-nitrotoluenes and the transformation of TNT into dinitrotoluene with the release of nitrite through the hydride–Meisenheimer complex of TNT by hydride attack on the aromatic ring [10, 41]. TNT is degraded to triaminotoluene (TAT) in anaerobic conditions [31].

In this article, the metabolic pathway of a TNT-degrading bacterium, Bacillus cereus, was examined; the fate of TNT and its reduction products in the bacterial culture was also investigated by chromatographic and spectrophotometric analysis.

Methods

Colourimetric Analysis of TNT in Soil Sample

Twenty grams of dried soil was homogenised with 100 mL acetone (96 %) for 10 min. The suspension was kept at room temprature and thus provided sedimentation of soil. Twenty-five millilitres of supernatant was added to 0.2 g KOH and 0.2 g Na2S. And then the mixture was treated for 1–5 min with a sonicator [48].

Quantitative analysis of TNT in soil sample

One gram of dried soil was extracted with 9 mL acetonitrile, and then the suspension was strongly stirred. The whole mixture was filled into 50 mL Teflon-coated brownglass vial and treated for 18 h with a sonicator. After sonication, mixture was maintained at room temprature for 30 min. Ten millilitres of supernatant taken from vial was mixed with 10 mL of CaCl2 (5 g L−1), and then the mixture was centrifuged at 10,000×g for 10 min. Following centrifugation, the supernatant was filled into a 1.5-mL brownglass vial and stored at +4 °C until high-performance liquid chromatography (HPLC) analysis [3, 11].

Isolation and identification of nitroaromatic explosive-degrading bacteria

A soil sample collected from NATO military industry region, İzmir, Turkey, was used as the source of microorganism-degraded nitroaromatic explosives. The minimal salt medium, pH 7.2, comprised of (grams per litre): NaH2PO4.H20, 0.6; K2HPO4, 1.8; (NH4)2SO4, 1.5 and yeast extract (0.5 mg mL−1). An aliquot (10 mL L−1) of a stock trace element solution containing (milligrams per 100 mL): MgC12, 2000; CaC12, 400; MnCI2.4H20, 80; FeCI3.6H20, 50; Na2MoO4.2H20, 150 was added to the minimal salts medium. Adding picric acid (0.44 mM, 100 mg L−1) as nitroaromatic explosive from a 1,000 mg L−1standard solution which was adjusted to pH 7.5 with 1 N NaOH prior to filter sterilisation, the medium was enhanced [40]. One gram of soil sample per 100 mL of medium was added to minimal medium, and cells grown aerobically with shaking (180 rpm) at 30 °C. Serial transfers (5 % inoculum) into fresh medium were made every 72 h. After three serial transfers, decolourised culture was transferred onto fresh agar plates containing minimal salts medium; strains that used picric acid were isolated [2]. Strains were defined using VITEK bacterial identification system.

Tolerance of Strains to TNT

Growth of isolated strains were tested in liquid medium contained different concentrations of TNT (5, 10, 15, 30, 50, 75 and 100 mg L−1). The isolated strains were analysed for its tolerance to TNT by growing in degrading medium. This medium consisting of (in grams per litre) K2HPO4, 6.18; KH2PO4, 1.93; yeast extract, 1, at pH 7.2 was prepared to add from the stock solution of TNT prepared in acetone (1,000 mg L−1), was filtered through (0.22 μm), and sterilised. Degradation medium stated by previous researchers was modified by adding yeast extract [46].

TNT Biodegaradation and Growth Condition of Strain

Cells of isolate were grown into 2 L Erlenmeyer flask contaning 500 mL of pre-production medium, pH 7.2, consisting of (per litre) meat extract, 10; meat peptone, 10; NaCl, 5; K2HPO4, 2; KH2PO4, 1; MgSO4.7H2O, 0.2 [46] at 180 rpm and 30 °C for 24 h. After incubation, the bacterial culture was centrifuged to harvest at 9,000×g for 10 min. All of centrifugation works were continued at +4 °C, and then separated cells were washed twice with 50 mM potasium phosphate buffer (pH 7.3). The optical density of the bacterial biomass in same buffer was adjusted to 4.8 at 600 nm. Fifty millilitres of this suspension was dispensed into 2 L Erlenmeyer flask containing 450 mL of degradation medium added at final concentaration 50 and 75 mg L−1 TNT. The flasks were incubated at 180 rpm, 30 °C in the dark for 96 h. TNT biodegradation was tested using HPLC, gas chromatography (GC-MS) and thin-layer chromatography (TLC) analysis. Bacterial growth of liquid culture was determined by following optical density at 600 nm and counting viable colonies on plate count agar plates.

Isolation of Reduction Products

To isolate and identify the transformational metabolites of TNT, during 6, 12, 24, 48, 72 and 96 h of incubation, 50 mL of buffer removed from the controls and degrading mediums were centrifuged at 9000×g for 1 h at 4 °C. 20 mL of supernatant was acidified with 1 N HCl 160 μL for per 1 mL and extracted twice with equal volume of ethyl acetate. Collected organic phase was separated and dried with anhydrous Na2SO4 and then evaporated on a vacuum rotavapor at 35 °C. The residue was redissolved in 1 mL of acetonitrile [43]. Elutions were stored at +4 °C in 1.5 mL Teflon-coated brownglass vial for analytical works.

Analytical Analyses

The persistence of TNT amount was detected by HPLC (Schimadzu, Japan). For HPLC analyses, 20 μL of elutions were injected into a C18 reverse-phase column at 30 °C and separated using an isocratic mobile phase of 21 % (vol/vol) acetonitrile, 35 % methanol and 44 % deionised water at a flow rate of 0.7 mL min−1. The retention time of TNT was determined by UV detector at 254 nm and quantified by comprasion with reference standarts. HPLC method by reported previously Boopathy et al. was used with modification [4].

Reduction products were determined GC-MS. GC analysis was continued using TR5-MS column (60 m × 0.25 mm, 0.25 μm film thickness) and ionisation detector under the following conditions: injection temperature 240 °C; amount of injection 1 μL; helium was carrier gas at 1 mL min−1; initial oven temperature 80 °C for 1 min, then ramped to 300 °C at 10 °C min−1 and held at same temperature for 12 min. Samples were identifed by compared with standarts. GC-MS method by notified previously Oh and Kim was used by modifying [37].

TLC analyses were prolonged on pre-coated plates of silica gel F254 purchased from Merck. Compounds separated using a mobile system of ethyl acetate/hexan (40:60 v/v) [32]. Reduction products were visualised by plates exposed to UV light. Rf values of the spots were matched those of the standards.

Nitrite and Nitrate Estimation

During growth microorganism, demineralisation of TNT in the form of release nitrite and nitrate was tested. Nitrite analysis was continued colourimetrically [33]. Ten millilitres of the culture withdrawn from 0, 6, 12, 24, 48, 72 and 96 h of incubation was centrifuged at 9000×g for 1 h. Two hundred microlitres of supernatant was appended with 50 μL (prepared by dissolving 5 g sulphanilamide in a solution containing 26 mL HCl and total volume of solution adjusted to 500 mL in distilled water) sulphanilamide solution, andthe mixture was incubated at room temperature for 5 min. Fifty microlitres N-(1-naphthly) ethylenediamine dihydrochloride solution (prepared by dissolving 0.5 g N-(1-naphthyl) ethylenediamine dihydrochloride dihydrochloride in 500 mL deoinised water) was added, and then the mixture was incubated at room temperature for 20 min. Total volume of reaction mixture was adjusted at 1 mL by adding 700 μL deoinised water. Concentration of nitrite release was measured at 540 nm using sodium nitrite as the standard.

To determine the oxidation of nitrite to nitrate in cultures, 5 mL of supernatant was involved with 1 mL 1 N HCl, and then concentration of nitrate in samples was examined at 220 nm using sodium nitrate as the referance [1].

Results

Qualitative and Quantitative Analyses of TNT in Soil

Colourimetric analysis of TNT-contaminated soil is based on these components reacting with alcali hydroxides and forming the Meinsenheimer anion that can change the colour of extraction from violet to red after reaction. In this analyses, sodium sülfite was used to accelerate the reaction, and soil sample was extracted with acetone to ensure the stability of the colour change. However, presence of TNT in NATO soil sample was determined with the expected colour change in extraction. TNT and its derivates in soil were separated using HPLC. In result of HPLC, TNT concentration in NATO soil sample was found to be 61.35 mg L−1 but its derivates were not encountered.

Selection of Strains that Are Capability-Transformed

During growth on minimal salt medium contaning picric acid, a change in colour from yellow to orange–brown was observed in the culture. After diluted samples of these decolourised culture was transferred onto agar plates including same medium, orange–brown colonies surrounded by transparent zone were selected. The formation of this colour demonstrated that bacteria mineralised picric acid from the medium. Microscopic examinations of the picric acid-degrading isolates proved that all were Gram-positive and rod-shaped cells. Degradation process was continued with B. cereus defined by VITEK identification system.

The capability of B. cereus to tolerate TNT was evaluated by its growth in degradation medium. While the maximum TNT concentration did not tolerate bacteria, it showed growth at the other concentrations. The two highest concentrations observed bacterial growth were selected for use in degradation studies.

Growth of B. cereus and TNT Transfromation

B. cereus isolated from NATO soil was examined to determine its capability in removal of TNT. In experiments performed in flasks at an initial concentration of 50 and 75 mg L−1 TNT, it was determined by HPLC that B. cereus achived 68 % and 77 % of the TNT degradation in 96 h (Fig. 1). In the uninoculated controls contaning TNT, initial concentrations changed with time. Chemical hydrolysis of TNT in these abiotic cultures was detected as 16 % and 13 %. Microbial degradation of TNT was calculated with explusion amounts of TNT which was determined with HPLC analyses of abiotic cultures.

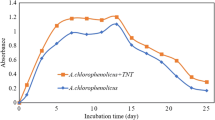

Bacterial growth and nitrite release were associated with the transformation of TNT. Time-dependent change in turbidity and colony-forming units (CFU) was shown in Fig. 2. The initial inoculi for microorganism was about 62.5 × 105 CFU mL−1. Microbial growth in the culture medium arose after the sixth incubation and reached maximum at 24 h (139 × 105 CFU mL−1) and 12 h (162 × 105 CFU mL−1) of incubation in cultures including respectively 50 and 75 mg L−1 TNT (Fig. 2b ). Rates of TNT removal at these hours when recorded at higher cell densities were determined as 55 % and 59 % (Fig. 2a ).

And then while toxicity of TNT and accumulation of its intermediate lead to gradual decrease of bacterial growth its transformation proceeded with viable cells at resting (Fig. 2). After 72 h, bacterial densities in both concentrations remained nearly constant.

Nitrite and Nitrate Release from TNT

Nitrite analyses were carried out to prove TNT demineralisation by B. cereus, during incubation time. Data of nitrite assays were showed graphically in Fig. 3. The findings of nitrite release corresponded to removal of TNT from liquid cultures. Nitrite concentrations in bacterial cultures including 50 mg L−1 TNT increased after incubating for 6 h and the increase, which continued up to 48 h, arrived a maximum of 0.41 mg L−1, and thereafter, it remained stable. In high concentration of TNT, the nitrite groups removed from TNT arose through the first 2 days of incubation. At the end of 48 h, the amount of maximum nitrite was determined as 0.55 mg L−1.

In uninoculated cultures which were treated with only TNT, amounts of nitrite released during the first 24 h were ignored. But after this time, amounts of nitrite released from TNT were averagely recorded 0.15 mg L−1 at 96 h when maximum transformation of TNT was determined, for both of abiotic cultures. Because amounts of nitrate were negligible as determined in cultures, it was concluded that the oxidation of nitrite to nitrate was not performed by B. cereus. The results of nitrate assays were shown in Fig. 4.

Change of pH During Degradation

pH values measured from supernatant after adding TNT and B. cereus were regarded as initial values. According to initial pH values of TNT degradation medium in the biotic and abiotic cultures for both concentrations was accepted as pH 7.4 ± 0.2. It was detected that pH changed between 7.4 and 7.55 whenever changes of pH in abiotic cultures which followed chemical degradation of TNT were compared with bacterial cultures until the degradation ends.

Products of TNT Transfromation

The change in colour of biotic mediums was observed during cultivation. Colour of medium was whitish in the beginning and started turning yellowish, and then was reddish brown, darkening at 96 h. TNT derivates isolated from this reddish–brown-coloured supernatant were identified by GC-MS and TLC analyses performed at the end of 96 h. The GC-MS data were shown in Fig. 5. Peaks of standards based on mass/charge by MS for 2,4-dinitrotoluenes (2,4-DNTs), TNT and 4-ADNT were respectively detected as peak A at 15.65 min, peak B at 17.54 min and peak C at 20.14 min (Fig. 5a ).

When GC-MS results of samples were compared with authentic standards, it was accepted that peaks at 20, 14 and 20.69 min were 4-ADNT (Fig. 5b, c ), TNT, 2,4-DNT and 4-ADNT standards migrated with Rf values 0.83, 0.67 and 0.5 on silica gel TLC plates (Fig. 6a ). Spots at Rf values 0.8 and 0.63 were presented as 2,4-DNT and TNT by compared with spots of standarts in samples (Fig. 6b, c ). Residual TNT in biotic cultures that was not designated by GC-MS methods could be showed on TLC plates. No intermediate products of TNT were detected in abiotic cultures by GC-MS and TLC methods.

TLC observing of TNT degradation products in B. cereus culture samples. a Presentation of standard metabolites on TLC plates, respectively, T: TNT, D: 2,4-DNT, A: 4-ADNT, M: mixture of their, by exposing to UV. b Monitoring residual of TNT and its derivates that accumulated abiotic cultures (1 and 6 respectively contaning 50 and 75 mg L−1 TNT) and c is showing cultures (2 and 7 including 50 and 75 mg L−1 TNT) incubated with B. cereus at the end of degradation

Discussion

This study was focused on reduction mechanisms of the bacterium belonging to the genus Bacillus that reduced TNT during growth. Under aerobic conditions, it was determined that B. cereus isolated from TNT-contaminated soil transformed TNT to its derivates using TNT as substrate for bacterial growth. In the ligth of above HPLC findings, it was detected that TNT concentrations 50 and 75 mg L−1 were degraded at respectively 68 % and 77 % within 96 h. Previous researches indicated biodegrading ability and tolerance to higher TNT concentration of Bacillus sp. [20, 34, 35]. The isolate accumulated NO−2 in degradation cultures contaning both concentrations. Other searchers denoted supportively our findings on nitrite liberation by reduction during microbial degradation of TNT [8, 23, 28, 29, 36, 38]. The rates of TNT transfromation and nitrite release showed an increase with the rise in TNT concentrations. Transformation of TNT and nitrite release were observed abiotically as well as biotically. In previous studies, chemical degradation of TNT under abiotic condition was reported [7, 36]. When nitrate concentrations in bacterial cultures were compared with abiotic medium, a significant formation of nitrate in cultures including both TNT concentrations was not observed during degradation process. For this reason, it can be concluded that oxidation of nitrite to nitrate by bacterial and chemical reactions was not realised. In contast to our results about nitrate accumulation, some searchers revealed the findings of nitrate in the cultures of Clavibacterium, Sphingomonas and their mixture contaning TNT during degradation [39].

In cultures, a rise in time-dependent bacterial growth is a positive evidence of TNT removal. When microbial growth reached maximum, nitrite accumulation and rate of degradation in the medium increased. The performed researches on TNT-biodegrading ability of Bacillus sp. acquired similar results where cell density and degradation rate of TNT correspondingly raised [37, 47]. But a number of previous studies are in contrast to our findings; it was found that bacterial growth decreased with increasing concentration of TNT [27]. The determined decrease in turbidity and CFU in biotic cultures was associated to toxicity to some of transformation products. Because of nutrient depletion and reduction in the microbial population, a clear decrease in rate of TNT degradation at the end of 96 h was declared.

Previous researchers reported chemical hydrolysis of TNT at a pH of approximately 8 [30]. Based upon results of pH, our studies detected chemical hydrolysis dependent on pH changes.

A pinksih red to brown color which gradually darkened towards the end of incubation was appeared in medium during process of TNT degradation, and the formation of the colour showed removal of TNT via the elimination of nitro groups. But any colour change disappeared in abiotic cultures. The hydride–Meisenheimer complex of TNT formed by aerobic bacteria seemed red–brown-coloured as referred to in previous studies [35, 38]. Nitrite and dinitrotoluenes (DNTs) are intermediate products released from the dihydride–Meisenheimer complex.

Reduction products were identified for the investigation of the metabolic pathway of TNT biotransformation. In our experiments, the reaction products that were isolated from red-coloured supernatant which is similar to previous investigations were detected by comprasion to the standard compounds using TLC and GC-MS analyses [28, 34]. 2,4-DNT and 4-ADNT as transformation products of TNT were presented.

Despite the fact of nitrite accumulation and chemical degradation in abiotic culture, none of transformation products were encountered during TNT metabolism. The formation of DNT and ADNT derivates showed that B. cereus degraded to TNT by two different pathways mentioned below.

Symmetrical arrangement which provided stability of aromatic ring and the electron-withdrawing properties of nitro groups covering its aromatic ring created steric hindrance [25]. Electron deficient in π-orbitals and high redox potentials are characteristic properties of TNT in which nitro groups result from the electron-withdrawing nature. Increasing number of nitro groups depends on aromatic ring; TNT develops resistance to aerobic degradation by inhibiting electrophilic attack that leads to ring fission [14]. So microbial attack on TNT is limited from reduction of nitro groups to formation of nitroso and hydroxylamino products [45]. Microbial activites on TNT are a conventional pathway covering elimination of nitro groups from the aromatic ring and metabolism of the remaining carbon skeleton [44]. This pathway is examined in three categories: (1) ring oxygenation which causes to form nitrite, (2) nucleophilic attack by a hidride anion to the hydride–Meisenheimer complex that form adding di-nitro derivates to hidride anions [26], and (3) reduction to produce of a hydroxylamine [45].

The accumulation of both 2,4-DNT and 4-ADNT, releasing nitrite and appearance of red-colour in our studies supported the finding that elimination of a nitro group at either the ortho position or the para position from aromatic ring, the formation of Meissheimer complex by nucleophilic attack and reduction of the nitro groups to amino groups occured by addition of two electrons.

Several researchers have reported microbial transformation of TNT by aerobic including Bacillus sp., anaerobic or combined pathways [7, 17, 25, 47, 49]. Biodegradation of TNT via reductive pathways, producing dinitrotoluene, hydroxylamino or amino-derivates, is a co-metabolic process that requires exogen nutrient source as nitrogen or carbon to provide reducing equivalent [5, 22, 41]. Aerobic process catalysed by various bacteria begins with an oxidative microbial attack on aromatic ring and continues with reduction of nitro groups to amino groups, leading to a variety of monoamino-dinitrotoluenes and diamino-mononitrotoluenes without mineralisation [10, 41]. In the anaerobic process, nitro groups of TNT completely were reduced and produced TAT as the last derivates [12, 16].

Recent studies have shown that bacterial enzymes possess remarkable biodegradative properties [15, 41]. Nitroreductase enzyme which is responsible for aerobic and anerobic degradation of TNT catalyses the conversion of nitro groups on aromatic ring into nitro, nitroso and amino groups [19]. During enzymatic process, why different metabolites apart from reductive metabolites described as DNTs, ADNTs, HADNTs and TAT in common are produced by bacteria is completely clarified.

Conclusions

Because of its mutagenic and carcinogenic effects on ecosystem, TNT is an environmental pollutant, which requires it to be cleared from contaminated sites. Even though removal of this pollutant uses many different processes, such as physical and chemical methods, increased attention to bioremediation that is an efficient, eco-friendly and cost-effective process recently. So in our study, the degradation of TNT by aerobic bioremediation is easy to continue rather than anerobic culture conditions was researched. B. cereus isolated from NATO soil transformed TNT into 4-ADNT and 2,4-DNT in liquid medium including TNT. It was observed that B. cereus not only removed nitro groups from TNT but also converted the nitro groups to amino derivates. In addition to degradation with bacteria, it will be able to remove TNT from large parts of the contaminated soil using nitroreductase enzyme purified from this bacteria, in further works.

References

Al-Absi A (2008) Nitrate contamination of ground water and methemoglobinemia in gaza strip. J Al-Aqsa Unv 12:1–14

Behrend C, Heesche-Wagner K (1999) Formation of hydride-meisenheimer complexes of picric acid (2,4,6-trinitrophenol) and 2,4-dinitrophenol during mineralization of picric acid by Nocardioides sp. strain CB 22–2. Appl Environ Microbiol 65:1372–1377

Boopathy R (2000) Bioremediation of explosives contaminated soil. Int Biodeterior Biodegrad 46:29–36. doi:10.1016/S0964-8305(00)00051-2

Boopathy R, Wilson M, Montemagno CD, Manning Jnr JF, Kulpa CF (1994) Biological transformation of 2,4,6-trinitrotoluene (TNT) by soil bacteria isolated from TNT-contaminated soil. Bioresour Technol 47:19–24. doi:10.1016/0960-8524(94)90023-X

Caballero A, Esteve-Núñez A, Zylstra GJ, Ramos JL (2005) Assimilation of nitrogen from nitrite and trinitrotoluene in Pseudomonas putida JLR11. J Bacteriol 187:396–399. doi:10.1128/JB.187.1.396-399.2005

Čėnas N, Nemeikaitė-Čėnienė A, Marozienė A, Šarlauskas J, Vilutienė V, Baublys J (2001) Explosives as toxic environmental pollutants: the level of contamination, toxicity and its mechanisms. EUExcert (Certifying Expertise in European Explosives Sector) 1–8

Claus H, Bausinger T, Lehmler I, Perret N, Fels G, Dehner U, Preuss J, König H (2007) Transformation of 2,4,6-trinitrotoluene (TNT) by Raoultella terrigena. Biodegradation 18:27–35. doi:10.1007/s10532-005-9033-7

Duque E, Haidour A, Godoy F, Ramos JL (1993) Construction of a Pseudomonas hybrid strain that mineralizes 2,4,6-trinitrotoluene. J Bacteriol 175:2278–2283

Diwani GE, Rafie SE, Hawash S (2009) Degradation of 2,4,6-trinitrotoluene in aqueous solution by ozonation and multi-stage ozonation biological treatment. Int J Environ Sci Technol 6:619–628

Esteve-Núñez A, Caballero A, Ramos JL (2001) Biological degradation of 2,4,6-trinitrotoluene. Microbiol Mol Biol Rev 65:335–352. doi:10.1128/MMBR.65.3.335-352.2001

Fallahi S, Habibi-Rezaei M, Khayami M, Heydari R (2007) Soil decontamination of 2,4,6-trinitrotoluene by alfalfa (Medicago sativa). Pak J Biol Sci 10:4406–4412. doi:10.3923/pjbs.2007.4406.4412

Fleischmann TJ, Walker KC, Spain JC, Hughes JB, Craig AM (2004) Anaerobic transformation of 2,4,6-TNT by bovine ruminal microbes. Biochem Biophys Res Commun 314:957–963. doi:10.1016/j.bbrc.2003.12.193

Gorontzy T, Drzyzga O, Kahl MW, Bruns-Nagel D, Breitung J, von Loew E, Blotevogel KH (1994) Microbial degradation of explosives and related compounds. Crit Rev Microbiol 20:265–284. doi:10.3109/10408419409113559

Han S (2008) In situ bioremediation and natural attenuation of dinitrotoluenes and trinitrotoluene. Ph.D, Dissertation, Georgia Institute of Technology

Hannink N, Rosser SJ, French CE, Basran A, Murray JAH, Nicklin S, Bruce NC (2001) Phytodetoxification of TNT by transgenic plants expressing a bacterial nitroreductase. Nat Biotechnol 19:1168–1172. doi:10.1038/nbt1201-1168

Hawari J, Beaudet S, Halasz A, Thiboutot S, Ampleman G (2000) Microbial degradation of explosives: biotransformation versus mineralization. Appl Microbiol Biotechnol 54:605–618. doi:10.1007/s002530000445

Heiss G, Knackmus HJ (2002) Bioelimination of nitroaromatic compounds: immobilization versus mineralization. Curr Opin Microbiol 5:282–287. doi:10.1016/S1369-5274(02)00316-8

Jain RK, Kapur M, Labana S, Lal B, Sarma PM, Bhattacharya D, Thakur IS (2005) Microbial diversity: application of microorganisms for the biodegradation of xenobiotics. Curr Sci 89:101–112

Kahng H-Y, Lee B-U, Cho Y-S, Oh K-H (2007) Purification and characterization of the NAD(P)H-nitroreductase for the catabolism of 2,4,6-trinitrotoluene (TNT) in Pseudomonas sp. HK-6. Biotechnol Bioprocess Eng 12:433–440. doi:10.1007/BF02931067

Kalafut T, Wales ME, Rastogi VK, Naumova RP, Zaripova SK, Wild JR (1998) Biotransformation patterns of 2,4,6-trinitrotoluene by aerobic bacteria. Curr Microbiol 36:45–54. doi:10.1007/s002849900278

Kalderis D, Juhasz AL, Boopathy R, Comfort S (2011) Soils contaminated with explosives: environmental fate and evaluation of state-of-the-art remediation processes. (IUPAC Technıcal Report). Pure Appl Chem 83:1407–1484

Khachatryan GE, Mkrtchyan NI, Simonyan NV, Khachatryan TV, Tatikyan SS (2000) Two unidentified aerobic bacterial strains that transform 2,4,6-trinitrotoluene. World J Microbiol Biotechnol 16:393–395. doi:10.1023/A:1008980425334

Kim H-Y, Bennett G, Song H-G (2002) Degradation of 2,4,6-trinitrotoluene by Klebsiella sp. isolated from activated sludge. Biotechnol Lett 24:2023–2028. doi:10.1023/A:1021127201608

Kim H-Y, Song H-G (2000) Transformation of 2,4,6-trinitrotoluene by white rot fungus Irpex lacteus. Biotechnol Lett 22:969–975. doi:10.1023/A:1005636914121

Kubota A, Maeda T, Nagafuchi N, Kadokami K, Ogawa HI (2008) TNT biodegradation and production of dihydroxylamino-nitrotoluene by aerobic TNT degrader Pseudomonas sp. strain TM15 in an anoxic environment. Biodegradation 19:795–805. doi:10.1007/s10532-008-9182-6

Kulkarni M, Chaudhari A (2007) Microbial remediation of nitro-aromatic compounds: an overview. J Environ Manage 85:496–512. doi:10.1016/j.jenvman.2007.06.009

Kurinenko BM, Yakovleva GY, Denivarova NA, Abreimova YV (2003) Specific toxic effects of 2,4,6-trinitrotoluene on Bacillus subtilis SK1. Appl Biochem Microbiol 39:275–278. doi:10.1023/A:1023527611310

Litake GM, Joshi SG, Ghole VS (2005) TNT biotransformation potential of the clinical isolate of Salmonella typhimurium—potential ecological implications. Indian J Occup Env Med 9:29–34. doi:10.4103/0019-5278.16039

Maeda T, Kadokami K, Ogava HI (2006) Characterization of 2,4,6-trinitrotoluene (TNT)-metabolizing bacteria isolated from TNT-polluted soils in the Yamada Green Zone, Kitakyushu, Japan. J Environ Biotechnol 6:33–39

Maleki N (1994) Treatment and biodegradation of high explosives: a literature review. Dissertation, University of California, Ph.D

Maloney SW, Adrian NR, Hickey RF, Heine RL (2002) Anaerobic treatment of pinkwater in a fluidized bed reactor containing GAC. J Hazard Mater 92:77–88. doi:10.1016/S0304-3894(01)00375-2

Nam SI (1997) On-site analysis of explosives in soil evaluation of thin-layer chromotography for confirmation analyte identity. Cold Reg Res Eng Lab Spec Rep 97–21

Nyanhongo GS, Erlacher A, Schroeder M, Guebitz GM (2006) Enzymatic immobilization of 2,4,6-trinitrotoluene (TNT) biodegradation products onto model humic substances. Enzym Microb Technol 39:1197–1204. doi:10.1016/j.enzmictec.2006.03.004

Nyanhongo GS, Aichernig N, Ortner M, Steiner W, Guebitz GM (2008) A novel environmentally friendly 2,4,6-trinitrotoluene (TNT) based explosive. Maced J Chem Chem Eng 27:107–116

Nyanhongo GS, Aichernig N, Ortner M, Steiner W, Guebitz GM (2009) İncorporation of 2,4,6-trinitrotoluen (TNT) transforming bacteria into explosive formulations. J Hazard Mater 165:285–290. doi:10.1016/j.jhazmat.2008.09.107

Oh B, Shea PJ, Drijber RA, Vasilyeva GK, Sarath G (2003) TNT biotransformation and detoxification by a Pseudomonas aeruginosa strain. Biodegradation 14:309–319. doi:10.1023/A:102565325834

Oh K-H, Kim Y-J (1998) Degradation of explosive 2,4,6-trinitrotoluene by s-triazine degrading bacterium isolated from contaminated soil. Bull Environ Contam Toxicol 61:702–708. doi:10.1007/s001289900818

Pak JW, Knoke KL, Noguera DR, Fox BG, Chambliss GH (2000) Transformation of 2,4,6-trinitrotoluene by purified xenobiotic reductase B from Pseudomonas fluorescens I-C. Appl Environ Microbiol 66:4742–4750. doi:10.1128/AEM.66.11.4742-4750.2000

Rahal AG, Moussa LA (2011) Degradation of 2,4,6-trinitrotoluene (TNT) by soil bacteria isolated from TNT contaminated soil. Aust J Basic Appl Sci 5:8–17

Rajan J, Valli K, Perkins RE, Sariaslani FS, Barns SM, Reysenbach AL, Rehm S, Ehringer M, Pace NR (1996) Mineralization of 2,4,6-trinitrophenol (picric acid): characterization and phylogenetic identification of microbial strains. J Ind Microbiol Biotechnol 16:319–324. doi:10.1007/BF01570041

Roldán MD, Pérez-Reinado E, Castillo F, Moreno-Vivián C (2008) Reduction of polynitroaromatic compounds: the bacterial nitroreductases. FEMS Microbiol Rev 32:474–500. doi:10.1111/j.1574-6976.2008.00107.x

Seth-Smith HMB (2002) Microbial degradation of RDX. Dissertation, University of Cambridge, Ph.D

Schackmann A, Müller R (1991) Reduction of nitroaromatic compounds by different Pseudomonas species under aerobic conditions. Appl Microbiol Biotechnol 34:809–813. doi:10.1007/BF00169355

Sheikh KS (2006) Kinetics of 2,4,6-trinitrotolene reduction by Pseudomonas putida. University of Ohio, Msc. Dissertation

Spain JC (1995) Biodegradation of nitroaromatic compounds. Annu Rev Microbiol 49:523–555. doi:10.1146/annurev.micro.49.1.523

Tope AM, Jamil K, Baggi TR (1999) Transformation of 2,4,6-trinitrotoluene (TNT) by immobilized and resting cells of Arthrobacter sp. J Hazard Subst Res 2:3–9

Ullah H, Shah AA, Hasan F, Hameed A (2010) Biodegradation of trinitrotoluene by immobilized Bacillus SP. YRE1. Pak J Bot 42:3357–3367

Uzer A (2004) Basic and derivative spectrophotometric determination of some nitrophenols. University of Istanbul, Msc Dissertation

Zhang C, Bennett GN (2005) Biodegradation of xenobiotics by anaerobic bacteria. App Microbiol Biotechnol 67:600–618. doi:10.1007/s00253-004-1864-3

Acknowledgements

This study was funded by Cukurova University, Institute of Science, Scientific Research Project Unit. We thank Mechanical and Chemical Industry Corporation, Rocket & Explosive Factor for help on obtaining TNT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mercimek, H.A., Dincer, S., Guzeldag, G. et al. Aerobic Biodegradation of 2,4,6-Trinitrotoluene (TNT) by Bacillus cereus İsolated from Contaminated Soil. Microb Ecol 66, 512–521 (2013). https://doi.org/10.1007/s00248-013-0248-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00248-013-0248-6