Abstract

This work investigates the experimental study to examine the operation characteristics of an orange peel oil biodiesel (BD100) along with water as an oxygenated additive in various volume fractions. Hard water is mixed into 100% of BD100 at 4 and 8% volume. Span 80 was employed as a nonionic surfactant, which emulsifies water into biodiesel. The experimental investigation on diesel engine reveals that the addition of water to BD100 resulted in enhancement of brake thermal efficiency (BTE) with a reduction in brake specific fuel consumption (BSFC). The tested emission parameters such as CO, HC, NOx and smoke were decreased by 11.4, 9.89, 3.36 and 5.14% for BD94W4S2 (94% volume of biodiesel) + (4% volume of water) + (2% volume of surfactant) and 12.22, 10.11, 4.85 and 6.18% for BD90W8S2 (90% volume of biodiesel) + (8% volume) + (2% volume) respectively when compared to BD100. Further, the cylinder pressure and heat release rate and were enhanced by adding water to base fuel (BD100). Overall, improvement in ignition characteristics of the engine was finer by adding, 4 and 8% volume of water to BD100 on account of its chemical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Diesel engines are governing the transportation, agricultural and power sectors down to their enhanced fuel economy, higher durability, and longer reliability than petrol engine. The great challenge of employing diesel fuel is the pollution caused by their use in the engines. Clean and sustainable fuels for diesel engines are extremely vital. In this context, biodiesel (BD) as a supplementary diesel engine fuel seems suitable to minimize the drawback of diesel fuel [1,2,3]. Nontoxic nature, biodegradability are the major benefits of biodiesel [3, 4]. Currently, many countries are utilizing the biodiesel mixing its blend with pure diesel in their engines. Many authors have agreed to the reductions in pollutant emissions and comparable performance when diesel engines run by BD or its blends with raise in NOx [5,6,7,8]. Many investigations have employed using orange peel oil biodiesel as a prospective candidate as a possible option fuel to diesel. Deep [9] investigated the engine output parameters of a diesel engine using orange peel oil biodiesel and they found that 100% of palm biodiesel can be fed as fuel. Purushothaman [10] investigated the engine output parameters using various blends of orange peel oil biodiesel and their results have shown a significant improvement in thermal efficiency with lower fuel consumption. Further CO, HC, and NOx are reduced by blending orange peel oil biodiesel with diesel. From the comprehensive literature reports, it is observed that no significant study has been experimentally carried out on the water - orange peel oil biodiesel blends at different proportions to analyze of its combustion, emission and performance characteristics.

Many investigations have also proved that by adding oxygenated additives such as alcohol, water to biodiesel facilitates as a catalyst in boosting the engine combustion and performance and improve its fuel properties [11,12,13,14,15,16,17,18]. Oxygenated additives alter the chemical composition of biodiesel and enhance the oxidation characteristics. The oxygenated additive also aids the engine combustion and performance characteristics of fuel [17]. Vellaiyan [11] formulated the water-emulsified diesel and conducted the experiments in a research engine. The results show that an increase in water concentration with diesel directly reduces the NOx emissions due to latent heat absorption of water particles during the combustion process. In another study, Vellaiyan [12] tried the water emulsification method with diesel. Senthilkumar and Jaikumar [13], Sadhik Basha and Anand [14] attempted the water emulsification process with waste cooking oil and jatropha methyl ester oil blends respectively and found a significant reduction in NOX emissions. Koc and Abdullah [15] conducted a research work on the water to diesel-biodiesel blends in a CI engine. Results showed a fuel shows a significant drop in NOX, HC, CO and smoke emission by adding water to diesel-biodiesel blends. Lthnin [16] conducted a research work on adding water to diesel. Significant reduction of HC, CO, NO, smoke emissions were obtained by adding water to diesel. Selim and Ghannam [17] investigated the effect of oxygenated-additives (water) in diesel and found a considerable reduction in all the emissions. An in detail review of the previous work has shown a space in accomplishing the addition of BD100 with water in CI engine application. Hence, the present study aims to analyze the emission, performance and combustion characteristics of BD100, water emulsified BD100 (BD94W4S2, and BD90W8S2) and compared with diesel.

2 Materials and methods

2.1 Base fuel preparations

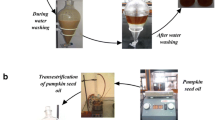

The steam distillation plant was used for the extraction of orange peel oil. The plant consists of a steam preparation chamber and orange peel heating distillation chamber. Figure 1 shows the photographic view of distillation Set-up. The steam distillation process was employed to extract the orange peel oil from the orange peels by using steam. 1.2 kg of orange peels are placed in the steam chamber and heated to 110 °C. The fumes consisting of orange essence and steam vapor are routed to a condensing chamber for cooling purpose. The mixture of liquid water and orange peel oil was collected in a collection tank. Orange peel oil was separated from the mixture due to its density difference. 1.2 kg of orange peel yielded 700 ml of orange peel oil. A 500 g sample of orange peel oil in the reactor was heated to the temperature of 65 °C. The molar ratio of 5:1 (methanol to orange peel oil) and catalysts of 0.3% (wt/wt) to orange peel oil was used in transesterification process. The mixture was allowed to cool in the vessel yielding two distinct layers of ester and glycerol. Orange oil biodiesel was separated and washed with water. The emulsion preparation was carried out by varying the concentration of orange oil biodiesel, surfactants (Span 80), and water. In the emulsion preparation process, an electromagnetic stirrer along with ultrasonicator was used to mix the water with oil in presence of surfactants [19].

2.2 Properties of test fuels

The physicochemical properties of BD90W8S2, BD94W4S2, BD100, and diesel are listed in Table 1. The density of BD100 is 5.7% higher than diesel due to its molecular structure and weight. An inclusion of water in BD100 marginally increases its density. The viscosity of BD100 is 31% higher than diesel that may affect the fuel atomization process in the diesel engines [20]. However, upon adding the water to biodiesel (BD90W8S2, BD94W4S2) exhibits 13.2% reduction in viscosity. Lower viscous fuel, as in the case of BD90W8S2, BD94W4S2 will result in proper mixing with air and end up with better combustion than BD100 [20]. The calorific value of BD100 is 9.5% lower than diesel, which indicates that for the, BD100 fuelled diesel engine requires more fuel for same engine power output. An inclusion of water further (BD90W8S2, BD94W4S2) reduces the heating value of fuel due to latent heat absorption of water. However, the supplementary oxygen present in BD90W8S2, BD94W4S2 can reimburse the fuel consumption [21]. The cetane index of diesel is higher than biofuels due to its shorter chain length. The fuel with higher cetane index (BD100, BD90W8S2, and BD94W4S2) will promote smoother and complete combustion [21]. The flash point of BD100, BD90W8S2, and BD94W4S2 is higher than diesel. Higher flash points are desirable for safer handling of fuel for transportation and storage.

2.3 Experimental setup

The experimental investigation was carried out on a naturally aspirated, 2-cylinder, four-stroke, and DI (Direct injection) diesel engine with a rated power of 9 kW at 2400 rpm. The engine technical specifications of the experimental setup are tabulated in Table 2. The experimental setup consisted of an engine, a dynamometer, fuel supply system, data acquisition unit, emission analyzer and a smoke opacimeter. AVL emission analyzer was employed to measure HC, NOx, and CO emissions. AVL 437C model opacimeter was employed to measure smoke opacity. The engine is made to warm up for 15 min after feeding each fuel blend so as to attain the static operating conditions. Uncertainty of all measured values was evaluated by square root method and shown in Table 3.

3 Results and discussion

3.1 Carbon monoxide emissions (BSCO)

Variation of BSCO with Brake Power (BP) for Diesel, BD100, BD94W4S2, and BD90W8S2 is presented in Fig. 2. At lower BP, the formation of CO emissions from tested fuels is in lower range, which is due to the lower fuel intake and lean mixture. By increasing the BP on the engine, the quantity of fuel intake is increased causing incomplete combustion and higher CO emission [22, 23]. CO emission from BD100 is lesser than diesel at all conditions. This is down to inherent oxygen in BD100 [24, 25]. Adding water reduces the CO emission from BD100. Addition of water reduces the temperature of fuel during combustion owing to its higher heat absorption, which reduces BSCO emissions [11, 13]. The BSCO emissions of BD100 is further reduced by increasing the water from 4 to 8% vol. Higher volume of water augments the rate of combustion and also provides excess oxygen and reduces BSCO emissions [14]. These result matches to the many literatures [11, 13] that reported lower BSCO emissions of diesel engine powered by biodiesel, diesel and water mixture. CO emissions at peak conditions for Diesel, BD100, BD94W4S2, and BD90W8S2 are 3.7, 3.1, 2.3 and 2.1 g/kW-hr respectively.

3.2 Unburned hydrocarbon emissions (BSHC)

Variation of BSHC emission with BP for Diesel, BD100, BD94W4S2, and BD90W8S2 is presented in Fig. 3. The observation is similar to BSCO emissions. At lower brake power, the formation of BSHC emissions from tested fuels is in lower range, which is due to the lean mixture [26]. By increasing the BP on the engine, the magnitude of fuel is amplified which results in rich mixture causing incomplete combustion and higher BSHC emissions [22, 27]. BSHC emission from BD100 is lesser than diesel. The inherent oxygen content of BD100 promotes combustion process and reduces BSHC emissions. Adding water reduces the BSHC emission from BD100. Addition of water reduces the temperature of fuel during combustion owing to its higher heat absorption, which reduces BSHC emissions [11]. The BSHC emissions of BD100 is further reduced by increasing the water from 4 to 8% vol. Water particles present in the mixture provides the additional oxygen for oxidation reaction of BSHC emissions. The other possible reason is due increase in concentration of hydroxyl with addition of water particles in BD100 [13]. The presence of water particles in the BD100 accelerates the heat sink effect which in turn lower the BSHC emission. These result matches to the many literatures [11, 13, 15] that reported lower BSHC emissions of diesel engine powered by biodiesel, diesel and water particle mixture. BSHC emissions at peak conditions for Diesel, BD100, BD94W4S2, and BD90W8S2 are 0.42, 0.33, 0.25 and 0.23 g/kW-hr respectively.

3.3 Oxides of nitrogen emissions (BSNOX)

Variation of BSNOX emission with BP for Diesel, BD100, BD94W4S2, and BD90W8S2 is presented in Fig. 4. BSNOx emission increases with BP for all tested fuels. This is owing to the increasing cylinder temperature during combustion [28]. BD100 has shown higher NOx emission compared to diesel. The inherent oxygen content of BD100 is the chief motive for higher NOx generation at all engine loads [29, 30]. However, BSNOx emission is significantly lower for BD100 with addition of water at all BP. Water present in BD100 initiates the combustion by reducing the combustion temperature and delay period [14,15,16]. NOx emissions are further reduced with increase in water content from from 4 to 8% vol to POBD. The shorter ignition delay period with addition of water particles to POBD reduces the combustion duration and NOx emission [17]. In addition, drop in local combustion temperature due high latent heat absorption of inner phase water particles during the combustion results in low level of BSNOX emission [18]. BSNOX emissions at peak conditions for Diesel, BD100, BD94W4S2, and BD90W8S2 are 10.9, 12.1, 10.1 and 10.7 g/kW-hr respectively.

3.4 Smoke opacity

Smoke opacity of Diesel, BD100, BD94W4S2, and BD90W8S2 is presented in Fig. 5. At lower BP, the formation of smoke emissions from tested fuels is in lower range, which is due to the lean mixture. With rise in BP, the quantity of fuel supplied is increased, which results in rich mixture causing incomplete combustion and higher smoke emissions. Smoke emission from BD100 is lesser than diesel. The inherent oxygen content of BD100 promotes combustion process and reduces smoke emissions [19, 22, 30]. Adding water reduces the smoke emission from BD100. Addition of water reduces the temperature of fuel during combustion owing to its higher heat absorption, which reduces smoke emissions. The endothermic reaction of water associated with BD94W4S2, and BD90W8S2 shows low magnitude of smoke emission at all BP when compared with BD100 and diesel. These result matches to the many literatures [31,32,33,34] that reported lower smoke emissions of diesel engine powered by biodiesel, diesel and water mixture. Smoke emissions at peak conditions for Diesel, BD100, BD94W4S2, and BD90W8S2 are 1.5, 1.3, 1.1 and 0.8% respectively.

3.5 Brake thermal efficiency

BTE of Diesel, BD100, BD94W4S2, and BD90W8S2 are presented in Fig. 6. BTE of all tested fuels is improved with an increase in BP of the engine. The BTE for BD100, BD94W4S2, and BD90W8S2 is lower than diesel at all engine loads.This is due to the higher density, lower calorific value, and higher viscosity of the biofuels [12, 20, 21]. Adding water increases the BTE of BD100. This may be due to the latent heat absorption of water particles present in emulsion fuel and pro-longed ignition period [4, 5]. The other possible reason could be due to vigorous micro-explosion of water in BD100, which in turn increases the air and fuel mixing and results in higher BTE [4, 5]. These result matches to the many literatures [31,32,33,34] that reported lower BTE of diesel engine powered by diesel, biodiesel and water mixture. BTE at peak conditions for Diesel, BD100, BD94W4S2, and BD90W8S2 are 29.8, 24.3, 25.1 and 26.3% respectively.

3.6 Brake specific energy consumption

BSFC of Diesel, BD100, BD94W4S2, and BD90W8S2 are presented in Fig. 7. With the increase in BP, the total quantity of BSFC increases but the brake power increases more effectively after overcoming some inevitable engine operating losses, for which the BSFC decreases [35, 36]. The BSFC for BD100, BD94W4S2, and BD90W8S2 is higher than diesel at all conditions. Lower heating value of the BD100, BD94W4S2, and BD90W8S2 increases the fuel consumption rate in all circumstances [11, 17]. In addition, this is also due to the higher density, lower calorific value, and higher viscosity of the biofuels [12, 20, 21]. Adding water lowers the BSFC of BD100. Water present in BD94W4S2 and BD90W8S2 accelerates the combustion process owing to improved micro-explosion behaviour [37]. The other possible reason for this behaviour is the water content in the BD94W4S2 and BD90W8S2 which converts into superheated steam and produce more power which in turn reduce the fuel consumption rate at all engine load [7, 8]. This result matches to the many kinds of literature [31,32,33,34] that reported lower BSFC of diesel engine powered by biodiesel, diesel and water mixture. BSFC at peak conditions for Diesel, BD100, BD94W4S2, and BD90W8S2 are 0.21, 0.43, 0.29 and 0.24 kg/kW-hr respectively.

3.7 In-cylinder pressure variation

The in-cylinder pressure variations for the BD100, BD94W4S2, and BD90W8S2 and diesel are depicted in Fig. 8. The diesel engine produces similar in-cylinder pressure pattern for all test fuels. The peak pressure for BD100, BD94W4S2, and BD90W8S2 and Diesel is 66.2, 63.2, 61.8 and 57.11 bar. Since the viscosity of diesel is lower than BD100, BD94W4S2, and BD90W8S2, the ignition delay of diesel is shortened and results in uniform combustion and lower peak pressure [22, 24]. The other reason for lower peak pressure for diesel is due to its higher calorific value [38]. Fuel with higher calorific value requires a lesser quantity of fuel during combustion [22, 25]. It is observed that adding water to BD100 observe a considerable increase in peak pressure. Water present in BD94W4S2 and BD90W8S2 accelerates the combustion process owing to improved micro-explosion behaviour [20, 21]. Hence the combustion is initiated early causing higher peak pressure. Further, the combustion starts early for BD100 with an increase in the content of water particles [26, 39]. This is due be due to vigorous micro-explosion of water in BD100, which in turn increases the air and fuel mixing and results in higher peak pressure [26]. This result matches to the many kinds of literature [22,23,24,25,26] that reported similar pressure variation of diesel engine powered by biodiesel, diesel and water mixture.

3.8 Heat release rate

The variation in heat release rate for the tested fuels is shown in Fig. 3. The possible reason for higher heat release rate for diesel is due to its higher calorific value. Fuel with higher calorific value produces more quantity of heat during combustion [22]. By adding 4 and 8 vol% of water particles to BD100 observe a considerable increase in heat release rate. This is due to the higher surface area to volume ratio of water particles which results in improved combustion, reduced delay period and higher heat release rate [23, 24]. Further, the HRR raises for BD100 with an increase in the content of water particles. This is due to vigorous micro-explosion of water in BD100, which in turn increases the air and fuel mixing, accelerates the combustion, and releases the maximum HRR [24, 25]. This result matches to the many kinds of literature [22,23,24,25,26] that reported similar HRR variation of diesel engine powered by biodiesel, diesel, and water mixture Fig. 9.

4 Conclusion

The ignition characteristics of orange peel oil biodiesel (BD100) and various concentration of water (4 and 8% vol) added in orange peel oil biodiesel are detailed in the present study and the results are compared with diesel. The study conclusions are as follows:

-

The dosage of ppm of 4 and 8% vol of water improves the combustion attributes such as heat release rate and cylinder pressure owing to the improved thermal conductivity of orange peel oil biodiesel.

-

Brake Thermal Efficiency for orange peel oil biodiesel is lesser than Diesel at all conditions. However, the water inclusion with BD100 effectively enhanced the efficiency. In addition, the BSFC values of BD100 reduced with the inclusion of water particles across the entire engine operating conditions

-

The BD100 releases more amount of NOx emission compared to diesel. However, the water inclusion with BD100 significantly reduces the NOx emission of BD100 fuelled diesel engine.

-

The BD100 releases considerably less amount of HC, Smoke and CO emission than diesel. Additionally, the water inclusion with BD100 further reduces the HC, Smoke and CO emission of BD100 fuelled diesel engine.

References

Anderson A, Devarajan Y, Nagappan B (2017) Effect of injection parameters on the reduction of NOx emission in bio-diesel fuelled diesel engine. Energy Sources, Part A: Recover, Util, Environ. Eff 40(2):186–192

Joy N, Devarajan Y, Nagappan B, Anderson A (2017) Exhaust emission study on biodiesel and alcohol blends fueled diesel engine. Energy Sources, Part A: Recover, Util, Environ Eff 40(1):115–119

Karthikeyan A, Venkatesh D, Ramkumar T (2015) Experimental investigation on spark ignition engine using blends of bio-ethanol produced from citrus peel wastes. International Journal of Ambient Energy 38(2):112–115

Anbarasu A, Karthikeyan A (2016) Performance and emission characteristics of a diesel engine using cerium oxide nanoparticle blended biodiesel emulsion fuel. Journal of Energy Engineering 142(1):04015009. https://doi.org/10.1061/(asce)ey.1943-7897.0000270

Melo-Espinosa EA, Piloto-Rodríguez R, Goyos-Pérez L, Sierens R, Verhelst S (2015) Emulsification of animal fats and vegetable oils for their use as a diesel engine fuel: an overview. Renew Sust Energ Rev 47:623–633

Annamalai M, Dhinesh B, Nanthagopal K, SivaramaKrishnan P, Lalvani JIJ, Parthasarathy M, Annamalai K (2016) An assessment on performance, combustion and emission behavior of a diesel engine powered by ceria nanoparticle blended emulsified biofuel. Energy Convers Manag 123:372–380

Pandian AK, Munuswamy DB, Radhakrishanan S, Devarajan Y, Ramakrishnan RBB, Nagappan B (2018) Emission and performance analysis of a diesel engine burning cashew nut shell oil bio diesel mixed with hexanol. Pet Sci. https://doi.org/10.1007/s12182-017-0208-8

Arul Gnana Dhas A, Devarajan Y, Nagappan B (2018) Analysis of emission reduction in ethyne–biodiesel-aspirated diesel engine. International Journal of Green Energy 15(7):436–440

Deep A, Singh A, Vibhanshu V, Khandelwal A, Kumar N (2013) Experimental investigation of orange peel oil methyl ester on single cylinder diesel engine. SAE Technical Paper Series. https://doi.org/10.4271/2013-24-0171

Purushothaman K, Nagarajan G (2009) Experimental investigation on a C.I. engine using orange oil and orange oil with DEE. Fuel 88(9):1732–1740. https://doi.org/10.1016/j.fuel.2009.03.032

Vellaiyan S, Amirthagadeswaran KS (2017) Emission characteristics of water-emulsified diesel fuel at optimized engine operation condition. Pet Sci Technol 35(13):1355–1363

Vellaiyan S, Amirthagadeswaran KS, Vijayakumar S (2017b) Combustion of stable water-in-diesel emulsion fuel and performance assessment. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 39(5):505–513

Senthil Kumar M, Jaikumar MA (2014) Comprehensive study on performance, emission and combustion behavior of a compression ignition engine fuelled with WCO (waste cooking oil) emulsion as fuel. J Energy Inst 87:263–271

Basha JS, Anand RB (2011) An experimental study in a CI engine using nanoadditive blended water-diesel emulsion. International Journal of Green Energy 8(3):332–348

Koc AB, Abdullah M (2013) Performance and NOX emissions of a diesel engine fueled with biodiesel-diesel-water nanoemulsions. Fuel Process Technol 109:70–77

Lthnin AM, Ahmad MA, Bakar MAA (2015) Combustion performance and emission analyzing of diesel engine fuelled with water-in-diesel emulsion fuels made from lowgrade diesel fuel. Energy Convers Manag 90:375–382

Selim MYE, Ghannam M (2010) Combustion study of stabilized water-in-diesel fuel emulsion. Energy Sources, Part A: Recover, Util, Environ. Eff. 32:256–274

Nguyen KB, Dan T, Asano I (2015) Effect of double injection on combustion, performance and emissions of Jatropha water emulsion fueled direct-injection diesel engine. Energy 80:746–755. https://doi.org/10.1016/j.energy.2014.12.033

Pandian AK, Ramakrishnan RBB, Devarajan Y (2017) Emission analysis on the effect of nanoparticles on neat biodiesel in unmodified diesel engine. Environ Sci Pollut Res 2429:23273–23278

Venkata Ramanan M, Yuvarajan D (2015) Performance study of preheated mustard oil methyl Ester on naturally aspirated CI engine. Appl Mech Mater 787:761–765. https://doi.org/10.4028/www.scientific.net/amm.787.761

Devarajan Y, Munuswamy DB, Mahalingam A, Nagappan B (2017) Performance, combustion, and emission analysis of palm oil biodiesel and higher alcohol blends in a diesel engine. Energy Fuel 31(12):13796–13801

Debnath BK, Sahoo N, Saha UK (2013) Adjusting the operating characteristics to improve the performance of an emulsified palm oil methyl ester run diesel engine. Energy Convers Manag 69:191–198

Yuvarajan D, Surendran R, Vinoth Kumar V, Devanathan R (2016) Role of additives on emission characteristics of methyl Ester in constant speed diesel engine. Appl Mech Mater 852:729–733. https://doi.org/10.4028/www.scientific.net/amm.852.729

Venkata Ramanan M, Yuvarajan D (2015) Emissions analysis of preheated methyl Ester on CI engine. Appl Mech Mater 812:21–25. https://doi.org/10.4028/www.scientific.net/amm.812.21

Devarajan Y, Munuswamy DB, Nagappan B, Pandian AK (2018) Performance, combustion and emission analysis of mustard oil biodiesel and octanol blends in diesel engine. Heat Mass Transf. https://doi.org/10.1007/s00231-018-2274-x

Radhakrishnan S (2017) Emissions analysis on diesel engine fueled with palm oil biodiesel and pentanol blends. Journal of Oil Palm Research 29:380–386. https://doi.org/10.21894/jopr.2017.2903.11

Boretti A (2017) Numerical study of the substitutional diesel fuel energy in a dual fuel diesel-LPG engine with two direct injectors per cylinder. Fuel Process Technol 161:41–51. https://doi.org/10.1016/j.fuproc.2017.03.001

Mahalingam A, Munuswamy DB, Devarajan Y, Radhakrishnan S (2018) Emission and performance analysis on the effect of exhaust gas recirculation in alcohol-biodiesel aspirated research diesel engine. Environ Sci Pollut Res 25(13):12641–12647. https://doi.org/10.1007/s11356-018-1522-4

Kishore Pandian A, Munuswamy DB, Radhakrishana S, Bathey Ramakrishnan RB, Nagappan B, Devarajan Y (2017) Influence of an oxygenated additive on emission of an engine fueled with neat biodiesel. Pet Sci 14(4):791–797. https://doi.org/10.1007/s12182-017-0186-x

Devarajan Y, Munuswamy DB, Radhakrishnan S, Mahalingam A, Nagappan B (2018c) Experimental testing and evaluation of neat biodiesel and Heptanol blends in diesel engine. J Test Eval 47(2):20170307. https://doi.org/10.1520/jte20170307

Yogish H, Chandarshekara K, Pramod Kumar MR (2013) A study of performance and emission characteristics of computerized CI engine with composite biodiesel blends as fuel at various injection pressures. Heat Mass Transf 49(9):1345–1355. https://doi.org/10.1007/s00231-013-1181-4

Devarajan Y, Madhavan VR (2017) Emission analysis on the influence of ferrofluid on rice bran biodiesel. J Chil Chem Soc 62(4):3703–3707. https://doi.org/10.4067/s0717-97072017000403703

Senthil R, Silambarasan R, Pranesh G (2016) Exhaust emissions reduction from diesel engine using combined Annona–Eucalyptus oil blends and antioxidant additive. Heat Mass Transf 53(3):1105–1112. https://doi.org/10.1007/s00231-016-1882-6

Senthil R, Silambarasan R, Pranesh G (2016) Antioxidant (A-tocopherol acetate) effect on oxidation stability and NOx emission reduction in methyl ester of Annona oil operated diesel engine. Heat Mass Transf 53(5):1797–1804. https://doi.org/10.1007/s00231-016-1939-6

Bragadeshwaran A, Kasianantham N, Balusamy S, Muniappan S, Reddy DMS, Subhash RV, Subbarao R (2018) Mitigation of NOx and smoke emissions in a diesel engine using novel emulsifiedlemon peel oil biofuel. Environ Sci Pollut Res 25(25):25098–25114. https://doi.org/10.1007/s11356-018-2574-1

Senthilkumar G, Sajin JB, Arunkumar T (2018) Evaluation of emission, performance and combustion characteristics of dual fuelled research diesel engine. Environ Technol 1–8. https://doi.org/10.1080/09593330.2018.1509888

Rathinam S, Justin Abraham Baby S, Devarajan Y (2018) Influence of water on exhaust emissions on unmodified diesel engine propelled with biodiesel. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 40(21):2511–2517. https://doi.org/10.1080/15567036.2018.1503756

Devarajan Y, Munuswamy DB, Mahalingam A (2018) Influence of nano-additive on performance and emission characteristics of a diesel engine running on neat neem oil biodiesel. Environ Sci Pollut Res 25(26), 26167–26172. https://doi.org/10.1007/s11356-018-2618-6

Devarajan Y, Mahalingam A, Munuswamy DB, Nagappan B (2018) Emission and combustion profile study of unmodified research engine propelled with neat biofuels. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-018-2137-5

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Radhakrishnan, S., Munuswamy, D.B., Devarajan, Y. et al. Performance, emission and combustion study on neat biodiesel and water blends fuelled research diesel engine. Heat Mass Transfer 55, 1229–1237 (2019). https://doi.org/10.1007/s00231-018-2509-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2509-x