Abstract

Rapid growth of industrialization and depleting resources of fossil fuel coupled with air pollution caused by the emissions released by engines have been a threat for the future generations. In this work biodiesel extracted from the source Pongamia Pinnata (Karanja) and tested in diesel engine. Initially biooil is extracted from karanja plant and it is converted into biodiesel by transesterification process. The corresponding physical properties for biodiesel and its blends are tested and it is well matched with ASTM standards. Furthermore, experimental studies were performed in naturally aspirated, mono cylinder, water-cooled, DI diesel engine at various load conditions. Then the oxygen enrichment is done at the inlet with the percentage variation from 21 to 27%. Test results obtained reveals that BTE is increased by 8–9% for B20 blends with the increased oxygen concentration. BSFC reduces for B30 blends with the rise in inlet oxygen levels. Regarding emission parameters the gradual reduction in CO and smoke opacity is achieved at higher load conditions for biodiesel blends (B30). On the other hand, due to increased concentration in oxygen and high combustion chamber temperature, NOx emissions increases for pure biodiesel and its blends.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The rapid consumption of fossil fuels and its price hike in recent days makes us to explore alternate energy sources to satisfy our energy demands [1, 2]. Fossils like petrol and diesel on its combustion release very dangerous pollutants like UHBC, Nitrous oxide, Particulate matter and CO into ambient environment [3, 4]. In the recent decades even carbon dioxide which is considered as ideal product of combustion is considered as potential source for global warming scenario [5, 6]. On the other hand due to the stringent emission norms the adoption of post combustion devices like DPF and AdBlue technology to reduce NOx is made mandatory in current vehicles. These devices increase the overall cost of the vehicles and periodic replacement is required after several kilometers of operation [7]. In order to reduce emissions with lower cost the fuel modifications play a significant role in the past few decades. Biodiesel due to its easy availability considered as a potential alternate fuel source gained its importance among researchers for the last several decades [8].

Biooil can be derived from both non-consumable oil source and edible or consumable oil source. In the past few decades extracting biooil from consumable oil sources such as rapeseed oil, sunflower oil, soya bean, palm oil, and cotton oil etc. have been carried out [9,10,11]. On the other hand rapid consumption of edible sources leads to food scarcity issues in countries like India. In this regard various non edible oil extracted from the sources like Jatropha, Pongamia, Mahua and Tamuna oil has greater ability to replace fossil fuels [12,13,14]. In the present study biooil is derived from Karanja oil commonly known as and tested in diesel engine experimentally.

Pongamia pinnata majorly has its origins in tropical regions like Japan, India, China and Australia [15]. Karanja is, usually known as drought resistant tree usually grows with the height of about 20 m long [16]. Lohith et al. performed experiments by running CI engine with the biodiesel blends. Study reported that mechanical efficiency of nearly 66% is achieved for Karanja oil with 50% blend. BMEP is higher for biodiesel with 10% addition of Karanja oil into diesel while comparing with other blends [17]. Prajapati et al. experimentally tested the Karanja oil biodiesel blends in mono cylinder Direct injection diesel engine. In case of BSFC it declines for all blends while the applied load increases. Regarding emission parameters significant reduction in smoke and UHBC with the slight rise in CO emission is observed [18]. In another work they concluded that Karanja oil has ability to run in diesel engines successfully without preheating upto 50% blending ratio. Test results confirms that Karanja oil gives lower emissions with higher engine performance [19]. Bhatt et al. conducted experimental study and concluded that Karanja oil upto blends B40 can produce similar brake powers and BTE trends while comparing with diesel fuel [20]. Raheman et al. also confirmed that Karanja oil with 40% blended ratio has greater ability to replace biofuel with producing lesser emissions [21].

In recent years in order to increase the burning rate of fuel oxygen enrichment is adopted. This technique enhances combustion rate of biodiesel that also reduces smoke and NOx emissions simultaneously [22]. Baskar et al. performed study by running biodiesel blends in mono cylinder diesel engine by increasing oxygen content from 21 to 27%. They observed that SFC decreased by 5–12% and Brake Thermal efficiency increased by 4–8%. On the other hand hydrocarbons, Carbon Monoxide and smoke reduced by 40, 55 and 60% with the increased oxygen content [23]. Chin et al. indicated that the input energy required to burn fuel inside combustion chamber reduces greatly with the increase in oxygen content. This also reduces combustion noise since the delay period reduces with the increased ignition oxygen concentration [24].

In this present work study investigation of performance and emission parameters of Karanja with its blends and oxygen enrichment in four-stroke diesel engine are performed. In order to enhance the properties of pure jatropha oil transesterification process was performed. Once the oil is trans esterified it is made to blend with neat diesel and further emission and performance parameters are analyzed by running in diesel engines. After that oxygen enrichment is done with biodiesel blends (B30) and the obtained results are compared and studied.

2 Oil Preparation and Experimental Procedure

2.1 Transesterification Process of Karanja Oil

Raw oil extracted from the plant have higher viscosity and this makes them unsuitable to be used in diesel engine directly. Initially the Karanja oil is reacted with sulfuric acid and methanol and in the flask and it is stirred continuously at different temperature. This process prolongs until the acid value falls between 0.1 and 0.5. After the solution attains the prescribed acid value entire process is stopped and it is cooled further. Then the distillation process was carried out to get the unreacted methanol from the mixture. Remaining products further undergoes esterification process once again to obtain methyl ester. After this process the by-product Glycerol deposited at the bottom of the flask and the remaining Karanja oil is extracted for blending process. The extracted oil is mixed with diesel and the corresponding physical characterization study were carried out.

3 Experimental Setup and Its Procedure

Experimental investigation was performed on a mono cylinder water-cooled, naturally aspirated, DI four-stroke diesel engine. The complete configuration of engine test setup is given in Fig. 2. Engine testing was connected to a dynamometer for giving brake power at various operating conditions. Then the fuel consumption with the aid of mass air flow sensor connected at intake manifold. Rotational speed of the engine is acquired using tachometer which is mounted in the shaft of the engine. Various pollutants like Nitrous oxides Carbon Monoxide and HC were captured with the aid of emission gas analyzer. The exhaust gas measuring probe is connected in the tailpipe and the other end is connected to analyzer for measuring emissions. In the present work the Karanja oil was blended with diesel in the ratio 30:70. Many previous works made in biodiesel found that B20 blend shows optimum performance in all aspects while running in diesel engines [18, 19]. Then the engines were made to run with neat diesel and B30, the corresponding emission and performance parameters were noted down.

After this process oxygen enrichment is done with the aid of oxygen cylinder which is connected in intake manifold. The oxygen concentration is varied with the help of flow control value which is attached in oxygen cylinder supply hose pipe. Then the engine is tested with B30, and the oxygen is mixed with the concentration varying from 22 to 24%. After mixing oxygen with the inlet air, once again fuel consumption and emissions readings were recorded. In this experiment the oxygen enrichment ratio 22, 23 and 24% is labeled as B30(1%), B30(2%) and B30(3%) in the graphs (Fig. 2).

4 Results and Discussion

4.1 Specific Fuel Consumption

Figure 2 highlights the trend of BSFC at different load conditions for various brake power. The plot obtained clearly pointed out that blends of biodiesel gives marginally elevated BSFC while compared with neat diesel. It is also inferring that SFC decreases gradually as the brake power increases for diesel and blends of biodiesel. Present situation happens because as brake power rises, the fuel injected amount also rises which in turn increases peak pressure developed inside the combustion chamber. This scenario ends up in higher combustion chamber temperature with the reduced ignition delay and it results in enhanced burning rate of fuel [22]. However slight decrease in SFC is observed for biodiesel after enrichment since added oxygen enhances combustion rate. It was about nearly 4% to 15% reduction in BSFC is observed with the linear rise in oxygen concentration for B20 blend.

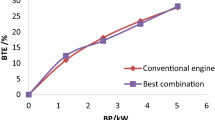

4.2 Brake Thermal Efficiency

Figure 3 shows the BTE obtained with respect to various load conditions at different oxygen concentrations. The plot obtained reveals that for both neat diesel and biodiesel blends BTE linearly increases along with applied load [25, 26]. BTE for B30 blends slightly declines at higher load conditions with the magnitude of 18.4%. Whereas in case of diesel BTE of around 23.2% is shown at similar conditions. When the addition of oxygen (22, 23, 24%) the BTE increases due to the complete combustion. The BTE for B30(2%) is higher 27.3%, while comparing with the diesel the BTE of B30(2%) is increased to 4% which results in efficient combustion and higher BTE. This scenario occurs since the oxygen enrichment results in increased burning rate of biodiesel blend with reduced ignition delay and it contributes to higher heat release rate [23].

4.3 Carbon Monoxide

Figure 4 gives the CO emissions with respective to different brake power for blends and neat diesel. CO is formed due to low availability of oxygen and insufficient temperature inside the combustion chamber. The plot obtained indicates CO reduces in align with the rise in inlet oxygen concentration. This happens since biodiesel have 10% concentration of oxygen in its composition and thus enhances combustion rate [27, 28]. Another reason for reduction is that due to oxygen enrichment at inlet makes the air fuel leaner and it increases oxidation reactions further. CO reduction percentage of around 57% is shown for B30(3%) at higher load conditions due to higher in cylinder temperature at this condition.

4.4 Smoke Opacity

Figure 5 gives the smoke pollutant trend with respect to various brake power. Particulate matter in the presence of sunlight react results formation of smoke. The plot obtained clearly pointed out that as brake power rises the smoke opacity also rises for both B20 and neat diesel. However, for biodiesel blends with rise in oxygen concentration the smoke opacity also declined linearly while compared with neat diesel. The particulate matter mainly formed due to insufficient oxygen concentration at elevated temperature. This enriched oxygen concentration inside the combustion chamber results in complete oxidation of soot particles. Maximum of around 45% reduction is achieved for B30(3%) oxygen enrichment for B30 blends at full load conditions (Fig. 5).

4.5 NO x Emissions

NOx is considered as potential treat to diesel engine and it is formed due to availability of oxygen and higher temperature inside the combustion chamber. Figure 6 indicates the NOx pollutant variation for different brake power conditions. The plot shows that NOx rises while the applied brake power increases for B30 and neat diesel. This may be due to enhanced oxidation reactions at higher applied load results higher in cylinder temperature and it results in higher NOx concentration [31, 32]. However NOx emission is reduced for biodiesel blends while compared with neat diesel [33, 34]. This occurs since biodiesel have higher viscosity and it results in improper fuel atomization which results in decline of peak cycle temperature of combustion chamber.

5 Conclusions

In this work biodiesel extracted from the Karanja oil and experiments were performed in mono cylinder diesel engine at various oxygen enrichment levels. The important conclusions obtained are as follows.

-

1

The Thermal Efficiency got raised with an average increment of 8–10% when oxygen gas was supplemented with biodiesel when compared to straight blends but the brake thermal efficiency of the B30(2%) remains higher with 27.3% efficiency at elevated load conditions.

-

2

The BSFC remained low for oxygen supplementing biodiesel an average decrement of 4–10% when compared to biodiesel blends but the curve remained low for diesel an average decrement of 6% when compared to biodiesel and high oxygen enriched.

-

3

The CO emission were reduced for biodiesel blend with the increase in oxygen enrichment percentages, an average decrement of 15% is observed.

-

4

The NOx emission is higher for the B20 blend with the increase in oxygen enrichment percentage of about 24% is observed at higher load operating conditions.

References

Subramaniam, M., Pachamuthu, S.: Two zone thermodynamic model for prediction of particulate matter emission from direct injection diesel engine. Therm. Sci. 20(suppl. 4), 1017–1028 (2016)

Subramaniam, M.K., Pachamuthu, S., Arulanandan, J., Muthiya, J.: Simultaneous reduction of HC, NOx and PM by using active regeneration technique. No. 2016-01-0912. SAE Technical Paper, (2016)

Mohankumar, S., Senthilkumar, P.: Particulate matter formation and its control methodologies for diesel engine: a Comprehensive review. J. Renew. Sust. Energy Rev. 80, 1227–1238 (2017)

Subramaniam, M., Jenoris Muthiya, S., Satish, S., Joshuva, A., Alexis, J.: Numerical investigation on various layouts of phase change materials based battery module used in electric vehicles. No. 2020-28-0499. SAE Technical Paper (2020)

Muthiya, S.J., Amarnath, V., Senthilkumar, P., Mohankumar, S.: Experimental investigation and controlling of CO2 emission from automobile exhaust by CCS technique. Int. J. Appl. Engg. Res. 10, 36–46 (2015)

Subramanian, M., Satish, S., Muthiya Solomon, J., Sathyamurthy, R.: Numerical and experimental investigation on capture of CO2 and other pollutants from an SI engine using the physical adsorption technique. Heat Transfer 49(2020), 2943–2960

Sathyamurthy, R., Balaji, D., Gorjian, S., Muthiya, S.J., Bharathwaaj, R., Vasanthaseelan, S., Essa, F.A.: Performance, combustion and emission characteristics of a DI–CI diesel engine fueled with corn oil methylester biodiesel blends. Sustain. Energy Technol. Assess. 43, 100981 (2021)

Subramaniam, M., Muthiya Solomon, J., Nadanakumar V., Anaimuthu S., Sathyamurthy, R.: Experimental investigation on performance, combustion and emission characteristics of DI diesel engine using algae as a biodiesel. Energy Rep. 6, 1382–1392 (2020)

Lipase M.M.: Lipase-catalyzed alcoholysis of sunflower oil. J. Am. Oil Chem. Soc. 67, 168170

Clark, S.J., Wagner, L., Schrock, M.D., et al.: Methyl and ethyl soybean esters as renewable fuels for diesel engines. J. Am. Oil Chem. Soc. 61, 1632–1638 (1984)

Ilgen, O., Dincer, I., Yildiz, M., et al.: Investigation of biodiesel production from canola oil using Mg-Al hydrotalcite catalysts. Turk. J. Chem. 31, 509–514

Ong, H.C., Mahlia, T.M.I., Masjuki, H.H., et al.: Comparison of palm oil, Jatropha curcas and Calophyllum Inophyllum for biodiesel: a review. Renew. Sust. Energ. Rev. 15, 3501–3515

Singh, S., Singh, D.: Biodiesel production through the use of different sources and characterization of oils andtheir esters as the substitute of diesel; a review. Renew. Sust. Energ. Rev. 14, 200–216

Dinesh, K., Tamilvanan, A., Vaishnavi, S., Gopinath, M., Raj Mohan, K.S.: Biodiesel production using Calophyllum inophyllum (Tamanu) seed oil and its compatibility test in a CI engine, Biofuels, 10(3), 347–353 (2019). https://doi.org/10.1080/17597269.2016.1187543

Panigrahi, N., et al.: Non-edible Karanja biodiesel-A sustainable fuel for CI engine. Int. J. Eng. Res. Appl. 2(6), 853–860 (2012)

Bobde, S.N., Khyade, V.B.: Detail study on properties of Pongamia pinnata (Karanja) for the production of biodiesel. Res. J. Chem. Sci. 2(7), 16–20 (2012)

Lohith, N., et al.: Experimental investigation of compressed ignition engine using Karanja oil methyl ester (KOME) as alternative fuel. Int. J. Eng. Res. Appl. 2(4), 1172–1180 (2012)

Prajapati, V.V., et al.: Performance and emission analysis of diesel engine fuelled with Karanja oil and Diesel. Int. J. Adv. Mech. Eng. 7(1), 15–29 (2017) ISSN 2250-3234

Agarwal, A.K., Das, L.M.: Bio-diesel development and characterization for use as a fuel in C.I. engines. J. Eng. Gas Turb. Power, ASME, vol. 123 (2001)

Bhatt, Y.C., Murthy, N.S., Datta, R.K.: Use of mahua oil (Madhuca indica) as a diesel fuel extender. J. Inst. Eng. (India): Agricul. Eng. Div. 85, 10–14 (2004)

Raheman, H., Phadatare, A.G.: Diesel engine emissions and per-formance from blends of Karanja Methyl ester and diesel. Biomass Bioenergy, 27(4), 393–397 (2004). https://doi.org/10.1016/j.biombioe

Senthilkumar, M., Arul K., Sasikumar, N.: Impact of oxygen enrichment on the engine’s performance, emission and combustion behavior of a biofuel based reactivity controlled compression ignition engine. J. Energy Inst. 92(1), 51–61

Baskar, P., Senthilkumar, A.: Effects of oxygen enriched combustion on pollution and performance characteristics of a diesel engine, Engineering Science and Technology. Int. J. 19(1), 438–443 (2016)

Banapurmath, N.R., Tewari, P.G., Hosmath, R.S.: Experimental investigations of a four-stroke single cylinder direct injection diesel engine operated on dual fuel mode with producer gas as inducted fuel and Honge oil and its methyl ester (HOME) as injected fuels. Renew. Energy 33(9), 2007–2018 (2008)

Solomon, J.M., Pachamuthu, S., Arulanandan, J.J., Thangavel, N., Sathyamurthy, R.: Electrochemical decomposition of NOx and oxidation of HC and CO emissions by developing electrochemical cells for diesel engine emission control. Environ. Sci. Pollut. Res. 27(26), 32229–32238 (2020)

Karuppan, D., Manokar, A.M., Vijayabalan, P., Sathyamurthy, R., Madhu, B., Mageshbabu, D., Bharathwaaj, R., Muthiya, S.J.: Experimental investigation on pressure and heat release HCCI engine operated with chicken fat oil/diesel-gasoline blends. Mater. Today: Proceed. 32, 437–444 (2020)

Ramakrishnan, B., Elumalai, S., Mayakrishnan, J., Saravanan, I., Jenoris Muthiya, S.: Investigation on tribological performance of NanoZnO and Mixed Oxide of Cu–Zn as additives in engine oil. No. 2020-01-1095. SAE Technical Paper (2020)

Sundar, S.P., Kumar, M.H., Muthiya, S.J.: Experimental investigation on performance combustion and emission characteristics of direct injection diesel engine using Calophyllum inophyllum methyl ester. Indian J. Environ. Prot. 39(7), 614–620 (2019)

Parthiban, K., Pazhanivel, K., Muthiya, S.J.: Emission control in multi-cylinder spark ignition engines using metal-oxide coated catalytic converter. Int. J. Veh. Struct. Syst. 9(2), 134 (2017)

Jayanth Joseph, S., Muthiya, J., Senthilkumar, P.: Reduction of NOx emissions in diesel engines by selective catalytic reduction using dual layer catalyst configurations. J. Chem. Pharm. Sci. 9(2), 789–793 (2016)

Jenoris Muthiya, S., Senthil Kumar, P., Mohan Kumar, S., Jayanth Joseph, A.: Investigation of effective storage capacity of lean NOx trap coated with NOx storage materials. J. Chem. Pharm. Sci. 9(2), 794–797 (2016)

Jenoris Muthiya, S., Mohankumar, S., Senthilkumar, P.: Effects of thermal barrier coating on single cylinder CI engine fuelled with diesel and biodiesel. J. Chem. Pharm. Sci. 9(2), 779–784 (2016)

Vinayagam, N.K., Hoang, A.T., Solomon, J.M., Subramaniam, M., Balasubramanian, D., EL-Seesy, A.I., Nguyen, X.P.: Smart control strategy for effective Hydrocarbon and Carbon monoxide emission reduction on a conventional diesel engine using the pooled impact of pre-and post-combustion techniques. J. Cleaner Prod. 127310 (2021)

Solomon, J.M., Pratap Singh, K., Sawant, L.D., Dhanraj, J.A., Subramaniam, M., Samson, R.M.: Experimental investigation on effect of LHR in diesel engine fuelled with waste cooking oil biodiesel. In: IOP Conference Series: Materials Science and Engineering, vol. 1130, no. 1, p. 012083. IOP Publishing (2021)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Subramaniam, M. et al. (2022). Experimental Study on Utilization of Karanja Bio Oil in Diesel Engines and Performance Enhancement by Oxygenated Additives. In: Chaurasiya, P.K., Singh, A., Verma, T.N., Rajak, U. (eds) Technology Innovation in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-7909-4_24

Download citation

DOI: https://doi.org/10.1007/978-981-16-7909-4_24

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7908-7

Online ISBN: 978-981-16-7909-4

eBook Packages: EngineeringEngineering (R0)