Abstract

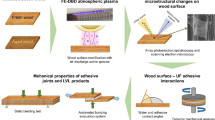

This study tests the hypothesis that thermal modification of wood influences the effectivity of air plasma treatment. Micro-veneers of European beech, Scots pine and Norway spruce were thermally modified at two different temperatures and subsequently plasma-treated for 1 and 3 s. The veneer surfaces were characterized in terms of morphology, wetting behaviour and surface chemistry. No severe changes in the veneer surfaces due to plasma treatment were observed by scanning electron microscopy. Plasma treatment increased surface free energy and wettability by water and urea–formaldehyde adhesive; it was more effective on thermally modified wood than on unmodified wood. X-ray photoelectron spectroscopy revealed a similar distribution of oxygen-containing functional groups on the wood surface after plasma treatment of thermally modified and unmodified beech wood. It is suggested that enhanced wettability through plasma treatment is due to the generation of carboxyl groups within the lignin network, which contribute to the polar part of the surface free energy. The high effectiveness of plasma treatment on thermally modified wood might thus be explained by its high relative proportion of lignin.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Air plasma treatment changes the surface characteristics of wood and wood products. It has previously been used to enhance the wettability (Wolkenhauer et al. 2007, 2008; Avramidis et al. 2009; Aydin and Demirkir 2010), liquid uptake (Avramidis et al. 2012; Wascher et al. 2014b) or adhesion properties (Asandulesa et al. 2010; Avramidis et al. 2010; Busnel et al. 2010; Scholz et al. 2010; Huang et al. 2011; Acda et al. 2012) of wood. Spectroscopic analyses based on Fourier transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS) showed that the plasma treatment leads to an increase in polar functional groups on wood surfaces (Odraskova et al. 2008; Avramidis et al. 2009; Wascher et al. 2014a). In addition, there is evidence that air plasma causes oxidation of lignin, whereas cellulose loses oxygen (Klarhöfer et al. 2010). Treatment at high plasma intensities and exposure times revealed that the wood cell walls can be etched and that lignin might be more resistant to etching compared to cellulose (Jamali and Evans 2011). Plasma treatment is only a surface treatment which affects less than 1 µm of the wood surface (Král et al. 2015), thus limiting the effect to the outermost cells. There is, however, evidence that air plasma can reach into deeper layers of beech wood because it might penetrate through the vessels and then ignite therein (Wascher et al. 2014a).

Thermal modification of wood in the temperature range of 160–230 °C is acknowledged as an environmental friendly technique to enhance dimensional stability and biological durability of wood, with various industrial scale implementations in Europe (Hill 2006; Militz and Altgen 2014). The improvement in properties can be assigned to chemical changes in the cell wall polymers at elevated temperatures. While hemicelluloses are preferentially degraded, the percentage of lignin increases due to its higher thermal stability (Bourgois et al. 1989; Zaman et al. 2000). Chemical changes in lignin, however, such as demethoxylation and cleavage of ether linkages on the one hand, as well as cross-linking and condensation reactions on the other hand, are evident during heat treatment of wood (Sivonen et al. 2002; Wikberg and Maunu 2004; Nuopponen et al. 2005). The more hydrophobic character of wood after thermal modification is regarded as beneficial due to reduced water vapour sorption (Kollmann and Schneider 1963; Popper et al. 2005) and liquid water uptake (Metsa-Kortelainen et al. 2006) as well as enhanced dimensional stability (Yildiz 2002; Popper et al. 2005). These alterations improve the performance in many exterior applications. However, the reduced wettability of thermally modified wood might adversely affect coating or gluing (Gérardin et al. 2007).

Plasma treatment at atmospheric pressure increases surface free energy of thermally modified beech wood (Wolkenhauer et al. 2008) and thus improves wetting and absorption of water and water-based melamine resin (Avramidis et al. 2012). Thermally modified wood might be very susceptible to plasma treatment because of its higher proportion of condensed, more hydrophobic lignin. In order to test this hypothesis, this study evaluates the effect of air plasma treatment at atmospheric pressure on several wood species which were thermally modified at different temperatures.

Materials and methods

Micro-veneers preparation and heat treatment

Wood blocks of European beech (Fagus sylvatica L.), Norway spruce (Picea abies (L.) H. Karst), as well as sap- and heartwood of Scots pine (Pinus sylvestris L.) with dimensions of 1.5 × 5 × 4 cm3 (radial × axial × tangential), were vacuum-impregnated (30 min vacuum, <13 kPa pressure) in 10 % aqueous ethanol (v/v) to avoid contamination with microorganisms and kept in the solution for 1 week. Micro-veneers (100 µm thick) were cut from the radial surface of the blocks using a sliding microtome and conditioned at 20 °C and 65 % RH to a moisture content of approximately 12 %.

The heat treatment of the conditioned veneers was performed in a conventional oven by increasing the temperature stepwise by 30 °C per 30 min up to 200 or 220 °C in a steam atmosphere. The peak temperature was held for 120 min before decreasing the temperature stepwise by 40 °C per 30 min to 80 °C. During the process, the veneers were pressed between thin glass plates to avoid curling. The veneers were conditioned at 20 °C and 65 % RH prior to testing.

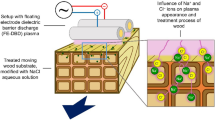

Plasma treatment

The veneers were attached to microscopy slides and transported through the plasma discharge on a band conveyer with a continuous speed of 3 m min−1. The general set-up of the plasma equipment was based on a direct dielectric barrier discharge using compressed air as process gas. A plasma discharge was generated between the ground and high voltage by means of an alternating pulsed voltage with an amplitude of 23 kV, a pulse duration of 1 µs and a pulse repetition frequency of 15 kHz (at 225 W in the discharge injected electrical power). The used DBD set-up was operated in filamentary mode. Homogenous treatment effect over the entire sample surface can be assumed, because the numerous micro-discharges are uniformly distributed over the whole discharge area. The veneers were treated two and six times, yielding a treatment time of 1 and 3 s. For the observation of possible morphological changes on the veneer surface, two additional plasma treatments with a treatment time of 10 and 30 s were performed.

X-ray photoelectron spectroscopy (XPS)

X-ray photoelectron spectroscopy analysis was performed using a PHI 5000 Versa Probe II spectrometer (Physical Electronics, Ismaning, Germany) equipped with a 180° spherical energy analyser and a multichannel detection system. Spectra were acquired at a base pressure of 5 × 10−7 Pa using a monochromatic Al–Kα source (1486.6 eV) with a spot diameter of 200 μm. Survey spectra were recorded with a pass energy of 188 eV and a step size of 0.8 eV (spot size of 200 μm). For the high-resolution spectra of the O1s and C1s peaks, energy ranges of 524–539 and 275–295 eV were scanned with a spot size of 200 μm, a pass energy of 23.5 eV and a step size of 0.1 eV. Data were analysed using the program MultiPak (version 9.6.0.15, 2015-02-19). C1s photoelectron peaks were decomposed using a Gauss–Lorentz peak shape. Atomic concentrations were calculated for C1s and O1s peaks using a Shirley background (Shirley 1972), whereas the corresponding cross sections were automatically included in the calculation by MultiPak and were in accordance with cross sections provided by Yeh and Lindau (1985).

Microscopic evaluation

Urea–formaldehyde (UF) adhesive (Kaurit 350, BASF SE, Ludwigshafen, Germany) was applied on the veneers using a spraying nozzle. The spraying nozzle was automatically moved along the veneers, ensuring the same amount of adhesive application on each veneer. After drying, the veneers were stained with 0.1 % Brilliant Sulfoflavine solution (CAS 2391-30-2, Chemos, Regenstauf, Germany). An epi-fluorescent microscope (Nikon Eclipse600, Nikon Instruments Inc., Melville, NY), equipped with a B-2E filter block and a 2 × objective, was used to record five images per treatment variant. The adhesive drops on the veneers were analysed with Fiji software (ImageJ 1.46d, Maryland, USA). The green channel of RGB images and the filter IsoData were used to detect adhesive drops larger than 20 µm2. The amount of analysed drops varied between 3000 and 10,000 depending on the treatment of the veneers. The circularity was calculated as described by Altgen et al. (2015b) using Eq. 1 which provides values from 0 to 1 with 1 being a perfect circle.

Morphological changes due to plasma treatment were studied with an environmental scanning electron microscope (SEM) (EVO LS 15, Zeiss, Jena, Germany) after carbon coating of the samples.

Contact angle and surface free energy

The contact angle was assessed by the sessile drop technique using the drop shape analyser Krüss GS 10 (Krüss GmbH, Hamburg, Germany) and the corresponding software Krüss DSA 1. Six droplets per treatment variant were studied to calculate the contact angles. Videos of the droplets were taken for 10 s after drop application, and the contact angle was determined when the wetting rate became constant (dθ/dt = constant) (Nussbaum 1999). The surface free energy was calculated according to the formulations of Owen et al. (1969), Kaelble (1970) and Rabel (1971). In this approach, the total surface energy (σ s) can be divided into a polar (σ P) and a dispersive part (σ D). The interfacial tension (γ sl) between a solid and a liquid phase is evaluated by the geometric mean equation (Eq. 2)

with the dispersive (σ Ds ) and polar (σ Ps ) parts of the solid and the dispersive (σ Dl ) and polar (σ Pl ) parts of the liquid. The combination of Young’s equation (Eq. 3) for surface energy

and the equation for interfacial tension (Eq. 2) leads to a linear equation according to y = mx + b (Eq. 4).

If the contact angles θ are measured using at least two liquids with known values for σ Dl and σ Pl , the data can be used to determine an equalizing straight line which can be used to directly determine the dispersive (y axis intercept = \(\sqrt {\sigma_{\text{s}}^{\text{D}} }\)) and polar (slope = \(\sqrt {\sigma_{\text{s}}^{\text{P}} }\)) parts of the solid.

Three liquids were used for the calculation of the surface free energy: distilled water (σ D = 18.7 mN m−1, σ P = 53.6 mN m−1 (Rabel 1971), 16 µl), glycerol (σ D = 28.3 mN m−1, σ P = 36.9 mN m−1 (Rabel 1971), 21 µl) and diiodomethane (σ D = 48.5 mN m−1, σ P = 2.3 mN m−1 (Fowkes 1964), 6 µl).

The UF adhesive (25 µl) was also used for contact angle measurements in order to directly assess the effect of the plasma treatment on the behaviour of the adhesive.

Results and discussion

Morphological changes

Scanning electron microscope images were recorded in order to verify whether plasma treatment changes the morphology of thermally modified and unmodified veneers (Fig. 1). Thermally modified variants revealed no distinct morphological changes due to plasma treatment up to 3 s. Unmodified beech and pine veneers, however, occasionally exhibited damaged pit membranes; these damages only occurred in pit chambers with both borders (Fig. 1a, b). Bordered pits, which exposed the pit membrane because one border had been removed during preparation, did not show damages. Sporadic holes in the cell wall of unmodified spruce were observed with increasing treatment durations up to 30 s (Fig. 1c, d). The holes were located in the region of pits, but were considerably larger than the normal pit chambers. Therefore, pits appeared to be more sensitive to plasma treatment than the cell wall itself. This is similar to an observation by Jamali and Evans (2011) who used air plasma to etch the wood cell wall. They found that pit membranes and borders of pits in coniferous wood were etched more easily than surrounding wall layers and suggested that the structure of bordered pits might allow for a plasma treatment from both sides of the cell wall. Compared with the etching of the cell wall, this study observed holes in pit areas but no further damages in surrounding cell wall layers. Still, slightly damaged pits by plasma treatment occurred only rarely if the treatment time did not exceed 3 s. It is thus concluded that the differences in wettability due to plasma treatment applied in this study were not caused by a changed surface morphology in µm range.

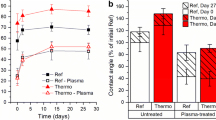

Wetting behaviour

The contact angles of water and the waterborne urea–formaldehyde (UF) adhesive are shown in Fig. 2. By using micro-veneers, which originate from the same wood block and display the same year ring distribution, effects due to variations in the raw material of one wood species are minimized. Changes in contact angle can thus directly be assigned to the effect of thermal modification and/or plasma treatment. The water contact angles of thermally modified wood species were higher than those of the unmodified controls (Fig. 2a) indicating a more hydrophobic surface. After plasma treatment, all variants showed lower contact angles, with only minor differences between the plasma treatment times. The contact angles of UF adhesive (Fig. 2b) are comparable to the water contact angles, although the impact of plasma treatment was less prominent.

The general increase in the water contact angles on thermally modified wood is well known and explained by the loss of hydroxyl groups which is associated with the degradation of amorphous hemicelluloses (Gérardin et al. 2007), and by a plasticization and reorganization of the lignin during the thermal modification (Hakkou et al. 2005). The latter explanation is based on the observation that the contact angle of water already increased at a relatively low temperature range close to the glass transition point of lignin, where mass loss does not yet occur. Changes in the chemical composition due to thermal modification also reduce the equilibrium moisture content of wood (Kollmann and Schneider 1963; Popper et al. 2005) which might have an additional effect on the contact angle. Scheikl and Dunky (1998), however, did not find a clear correlation between the wood moisture content and the contact angle of water on wood surfaces.

Based on the contact angles of water, the thermally modified variants exhibited generally more hydrophobic characteristics before plasma treatment compared with the unmodified variants, but the contact angles of the thermally modified variants became more hydrophilic after plasma treatment compared with the unmodified variants. Therefore, the changes in contact angles due to the plasma treatment are more pronounced on thermally modified wood. The contact angles of UF adhesive followed the same trend as the contact angles of water, but with smaller differences. The results of the contact angle measurement indicate a higher effectivity of plasma treatment on thermally modified wood.

The wetting properties of the UF adhesive on a micro-scale are presented in the histogram of circularity (Fig. 3). In case of enhanced wetting, the drops flatten on the surface, run along the fibres and merge with other drops. This leads to a decreased circularity of the drops, causing a shift in the circularity histogram to the left side. While thermal modification shifts the histogram towards higher circularities, the opposite effect is achieved by plasma treatment. However, changes in the circularity caused by plasma treatment are more pronounced on thermally modified variants, leading to similar or even more left-shifted histograms than for unmodified variants after plasma treatment. This further verifies a higher effectivity of plasma treatment on thermally modified wood.

As previously shown (Gérardin et al. 2007; Kutnar et al. 2013), thermal modification decreased the polar part of the surface free energy while it somewhat increased the dispersive part (Fig. 4). This has been explained by the relative increase in crystalline cellulose and in lignin (Sivonen et al. 2002). Isolated lignin displays slightly lower polar values of surface energy than isolated cellulose (Eriksson et al. 2007; Notley and Norgren 2010), which coincides with decreasing polar values on the lignin-rich surfaces of thermally modified samples. The decrease in the polar part after thermal treatment could be further explained by the migration of native nonpolar wood extractives to the wood surface during the modification process (Nuopponen et al. 2003). The thermal modification of micro-veneers between glass plates might have hindered the evaporation of these extractives, which thus accumulate on the veneer surface.

Plasma treatment increased the surface energy for all variants compared with the reference as reported previously for different wood species (Odraskova et al. 2008; Avramidis et al. 2009; Custódio et al. 2009; Wolkenhauer et al. 2009). The polar part of the surface free energy of all variants increased, whereas the dispersive part decreased due to plasma treatment. After plasma treatment, the dispersive part reached similar values irrespective of the applied thermal modification, the wood species or the plasma treatment time. Therefore, differences in surface energy between variants after plasma treatment are attributed to increased polar parts. While thermally modified samples showed lower polar parts than the respective unmodified samples before plasma treatment, the polar parts of thermally modified samples were higher than those of the unmodified samples after plasma treatment. This is in accordance with the higher effectivity of plasma treatment on thermally modified wood surfaces indicated by circularity measurements.

X-ray photoelectron spectroscopy (XPS)

Beech veneers exhibited decreasing O/C ratios with increasing thermal modification intensities. This is explained by the degradation of amorphous hemicelluloses, which are rich in hydroxyl groups, while the carbon-rich lignin remains in the wood. Decomposing the C1s spectra into four peaks allows defining the chemical bond of oxygen and carbon based on their binding energy (Fig. 5). The C1 peak is assigned to C–C and C–H bonds, which are mainly found in lignin and extractives; the C2 peak corresponds to C–O, single bonds of oxygen and carbon, which are found in hydroxyl or ether groups of lignin and polysaccharides; the C3 peak represents the double bonding of carbon and oxygen as found in O–C–O or C=O, which are present in cellulose, hemicelluloses and lignin; and the C4 peak is assigned to carboxyl groups (O=C–O), which are, to a low extent, present in hemicelluloses (Briggs and Beamson 2000). The thermal modification of beech veneers increased the C1 peak and decreased the C2 peak (Table 1), which is again in accordance with increasing percentages of lignin and decreasing percentages of hemicelluloses as shown previously (Inari et al. 2006). After plasma treatment, the O/C ratios of all samples are highly increased, because oxygen-rich groups are formed on the wood surface. Plasma treatment decreased the C1 peak of the unmodified sample and increased the C2, C3 and C4 peaks due to oxidation of the surface. Thermally modified variants reached similar values for C2, C3 and C4 after plasma treatment, although they showed slightly lower values for C2, C3 and C4 than the unmodified variants before plasma treatment. The differences before and after plasma treatment are therefore more distinct on thermally modified wood.

The results of wetting behaviour and the decomposition of the chemical bond of oxygen and carbon revealed a higher effectiveness of plasma treatment on thermally modified wood. An explanation for this result might be the relatively high amount of lignin in thermally modified wood. It has previously been shown by using isolated lignin and cellulose or lignin- and cellulose-rich substrates, that lignin is oxidized during oxygen plasma treatment, whereas cellulose is reduced (Strom and Carlsson 1992; Klarhöfer et al. 2010; Zhou et al. 2012). This effect might be explained by the formation of ozone among hydroxyl radicals, atomic oxygen and nitrogen–oxygen radicals within the air plasma (Eliasson and Kogelschatz 1991). Ozone preferably reacts with lignin rather than with cellulose, and hydroxyl radicals are generated during ozone treatment (Kang et al. 1995). These hydroxyl radicals have the potential to further degrade cellulose (Halliwell 1965). The decrease of carbonyl and carboxyl groups due to the thermal modification is attributed to the preferential degradation of hemicelluloses (Fengel 1966; Zaman et al. 2000; Alen et al. 2002). After plasma treatment, both thermally modified and unmodified variants gained similar values for C3 and C4, but the differences were higher for thermally modified wood. This suggests a more facile formation of new groups at thermally modified variants. Due to the relatively high amount of lignin in thermally modified wood, it is assumed that carbonyl and carboxyl groups found after plasma treatment are formed within the lignin network.

Gellerstedt and Gatenholm (1999) modified wood fibres with succinic anhydride to increase the amount of carboxyl groups on the fibre surface. Lignin-rich wood fibres showed enhanced wettability with increasing amount of carboxyl groups, whereas the wettability on delignified wood fibres decreased. The enhanced wettability was caused by increasing polar parts of the surface free energy. This is in line with this study, as the higher effectiveness of the thermally modified samples was attributed to higher polar parts.

Additional effects might be caused by soluble extractives in thermally modified wood, composed of native wood extracts and degradation products, as some native wood extracts are very sensitive to oxidation during the plasma treatment (Strom and Carlsson 1992). Thermal modification leads to the generation of polyaromatic compounds (Kamdem et al. 2000) after cleavage of β-O-aryl ether linkages within the lignin network (Nuopponen et al. 2005) and to increased extraction yields due to degradation products (Ahajji et al. 2009). Sakata et al. (1993) showed that contact angles of water-based UF adhesive on different wood species decreased with increasing intensity of plasma treatment. Wood species with a high amount of extractives gained a higher reduction in contact angles compared to wood species with low extractives due to the plasma treatment. The authors attributed this effect to the oxidation of highly hydrophobic substances among the extractives.

Plasma treatment was shown to be a good method to compensate for the hydrophobic surface characteristics caused by the thermal modification. It could be a useful technique to enhance the performance of water-based adhesives or varnishes on thermally modified wood.

A plasma treatment of wood particles led to enhanced mechanical properties of particleboards (Altgen et al. 2015a). This effect was recently attributed to a better resin efficiency within particleboards (Altgen et al. 2015b) indicated by a decreased UF adhesive circularity on thermally modified beech particles. The results in this study indicate a particular good performance of plasma-treated thermally modified wood particles for wood-based panel production.

Conclusion

Thermal modification of wood veneers generated hydrophobic surfaces, while plasma treatment caused hydrophilization of the surfaces without causing changes in the morphology. Thermal modification and a subsequent plasma treatment, however, produced more hydrophilic surfaces than the sole plasma treatment. This is attributed to increased polar properties of the wood surface. It is assumed that the enhancement in polar properties of the surface free energy by plasma treatment is mostly based on the generation of carboxyl groups within the lignin network. This is in accordance with the high effectiveness of plasma treatment on lignin-rich, thermally modified wood.

References

Acda MN, Devera EE, Cabangon RJ, Ramos HJ (2012) Effects of plasma modification on adhesion properties of wood. Int J Adhes Adhes 32:70–75

Ahajji A, Diouf PN, Aloui F, Elbakali I, Perrin D, Merlin A, George B (2009) Influence of heat treatment on antioxidant properties and colour stability of beech and spruce wood and their extractives. Wood Sci Technol 43(1–2):69–83

Alen R, Kotilainen R, Zaman A (2002) Thermochemical behavior of Norway spruce (Picea abies) at 180–225 °C. Wood Sci Technol 36(2):163–171

Altgen D, Bellmann M, Wascher R, Viöl W, Mai C (2015a) Enhancing mechanical properties of particleboards using plasma treated wood particles. Eur J Wood Wood Prod 73(2):219–223

Altgen D, Bellmann M, Wascher R, Mai C (2015b) Enhanced urea-formaldehyde adhesive spreading on plasma treated wood particles. Eur J Wood Wood Prod 74(4):617–620

Asandulesa M, Topala I, Dumitrascu N (2010) Effect of helium DBD plasma treatment on the surface of wood samples. Holzforschung 64(2):223–227

Avramidis G, Hauswald E, Lyapin A, Militz H, Viöl W, Wolkenhauer A (2009) Plasma treatment of wood and wood-based materials to generate hydrophilic or hydrophobic surface characteristics wood. Mater Sci Eng 1–2:52–60

Avramidis G, Scholz G, Nothnick E, Militz H, Viöl W, Wolkenhauer A (2010) Improved bondability of wax-treated wood following plasma treatment. Wood Sci Technol 45(2):359–368

Avramidis G, Militz H, Avar I, Viöl W, Wolkenhauer A (2012) Improved absorption characteristics of thermally modified beech veneer produced by plasma treatment. Eur J Wood Wood Prod 70(5):545–549

Aydin I, Demirkir C (2010) Activation of spruce wood surfaces by plasma treatment after long terms of natural surface inactivation. Plasma Chem Plasma Process 30(5):697–706

Bourgois J, Bartholin MC, Guyonnet R (1989) Thermal-treatment of wood—analysis of the obtained product. Wood Sci Technol 23(4):303–310

Briggs D, Beamson G (2000) XPS database of polymers in high resolution. Surface Spectra Ltd., Manchester

Busnel F, Blanchard V, Pregent J, Stafford L, Riedl B, Blanchet P, Sarkissian A (2010) Modification of sugar maple (Acer saccharum) and black spruce (Picea mariana) wood surfaces in a dielectric barrier discharge (DBD) at atmospheric pressure. J Adhes Sci Technol 24(8–10):1401–1413

Custódio J, Broughton J, Cruz H, Winfield P (2009) Activation of timber surfaces by flame and corona treatments to improve adhesion. Int J Adhes Adhes 29(2):167–172

Eliasson B, Kogelschatz U (1991) Modeling and applications of silent discharge plasmas. IEEE Trans Plasma Sci 19(2):309–323

Eriksson M, Notley SM, Wågberg L (2007) Cellulose thin films: degree of cellulose ordering and its influence on adhesion. Biomacromolecules 8(3):912–919

Fengel D (1966) On changes of wood and its components in temperature range up to 200 °C. Part II. The hemicelluloses in untreated and thermally treated sprucewood. Holz Roh-Werkst 24(3):98–109

Fowkes FM (1964) Attractive forces at interfaces. Ind Eng Chem 56(12):40–52

Gellerstedt F, Gatenholm P (1999) Surface properties of lignocellulosic fibers bearing carboxylic groups. Cellulose 6(2):103–121

Gérardin P, Petrič M, Petrissans M, Lambert J, Ehrhrardt JJ (2007) Evolution of wood surface free energy after heat treatment. Polym Degrad Stabil 92(4):653–657

Hakkou M, Pétrissans M, Zoulalian A, Gérardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stabil 89(1):1–5

Halliwell G (1965) Catalytic decomposition of cellulose under biological conditions. Biochem J 95:35–40

Hill CAS (2006) Wood modification: chemical, thermal and other processes. Wiley, Chichester

Huang H, Wang BJ, Dong L, Zhao M (2011) Wettability of hybrid poplar veneers with cold plasma treatments in relation to drying conditions. Dry Technol 29(3):323–330

Inari GN, Petrissans M, Lambert J, Ehrhardt JJ, Gérardin P (2006) XPS characterization of wood chemical composition after heat-treatment. Surf Interf Anal 38(10):1336–1342

Jamali A, Evans P (2011) Etching of wood surfaces by glow discharge plasma. Wood Sci Technol 45(1):169–182

Kaelble DH (1970) Dispersion-polar surface tension properties of organic solids. J Adhes 2(2):66–81

Kamdem DP, Pizzi A, Triboulot MC (2000) Heat-treated timber: potentially toxic byproducts presence and extent of wood cell wall degradation. Holz Roh-Werkst 58(4):253–257

Kang GJ, Zhang YJ, Ni YG, Vanheiningen ARP (1995) Influence of lignins on the degradation of cellulose during ozone treatment. J Wood Chem Technol 15(4):413–430

Klarhöfer L, Viöl W, Maus-Friedrichs W (2010) Electron spectroscopy on plasma treated lignin and cellulose. Holzforschung 64(3):331–336

Kollmann F, Schneider A (1963) On the sorption-behaviour of heat stabilized wood. Holz Roh-Werkst 21(3):77–85

Král P, Ráhel’ J, Stupavská M, Šrajer J, Klímek P, Mishra P, Wimmer R (2015) XPS depth profile of plasma-activated surface of beech wood (Fagus sylvatica) and its impact on polyvinyl acetate tensile shear bond strength. Wood Sci Technol 49(2):319–330

Kutnar A, Kricej B, Pavlic M, Petric M (2013) Influence of treatment temperature on wettability of Norway spruce thermally modified in vacuum. J Adhes Sci Technol 27(9):963–972

Metsa-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170 °C, 190 °C, 210 °C and 230 °C. Holz Roh-Werkst 64(3):192–197

Notley SM, Norgren M (2010) Surface energy and wettability of spin-coated thin films of lignin isolated from wood. Langmuir 26(8):5484–5490

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2003) The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci Technol 37(2):109–115

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2005) Thermal modifications in softwood studied by FT-IR and UV resonance Raman spectroscopies. J Wood Chem Technol 24(1):13–26

Nussbaum RM (1999) Natural surface inactivation of Scots pine and Norway spruce evaluated by contact angle measurements. Holz Roh-Werkst 57(6):419–424

Odraskova M, Rahel J, Zahoranova A, Tino R, Cernak M (2008) Plasma activation of wood surface by diffuse coplanar surface barrier discharge. Plasma Chem Plasma Process 28(2):203–211

Owens DK, Wendt R (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13(8):1741–1747

Popper R, Niemz P, Eberle G (2005) Investigations on the sorption and swelling properties of thermally treated wood. Holz Roh-Werkst 63(2):135–148

Rabel W (1971) Einige Aspekte der Benetzungstheorie und ihre Anwendung auf die Untersuchung und Veränderung der Oberflächeneigenschaften von Polymeren (Some aspects of wetting theory and its application to the study and change of surface properties of polymers) (In German). Farbe und Lack 77(10):997–1005

Sakata I, Morita M, Tsuruta N, Morita K (1993) Activation of wood surface by corona treatment to improve adhesive bonding. J Appl Polym Sci 49(7):1251–1258

Scheikl M, Dunky M (1998) Measurement of dynamic and static contact angles on wood for the determination of its surface tension and the penetration of liquids into the wood surface. Holzforschung 52(1):89–94

Scholz G, Nothnick E, Avramidis G, Krause A, Militz H, Viöl W, Wolkenhauer A (2010) Adhesion of wax impregnated solid beech wood with different glues and by plasma treatment. Eur J Wood Wood Prod 68(3):315–321

Shirley DA (1972) High-resolution X-ray photoemission spectrum of the valence bands of gold. Phys Rev B 5(12):4709–4714

Sivonen H, Maunu SL, Sundholm F, Jamsa S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56(6):648–654

Strom G, Carlsson G (1992) Wettability of kraft pulps—effect of surface-composition and oxygen plasma treatment. J Adhes Sci Technol 6:745–761

Wascher R, Avramidis G, Vetter U, Damm R, Peters F, Militz H, Viöl W (2014a) Plasma induced effects within the bulk material of wood veneers. Surf Coat Technol 259:62–67

Wascher R, Schulze N, Avramidis G, Militz H, Viöl W (2014b) Increasing the water uptake of wood veneers through plasma treatment at atmospheric pressure. Eur J Wood Wood Prod 72(5):685–687

Wikberg H, Maunu S (2004) Characterisation of thermally modified hard- and softwoods by 13C CPMAS NMR. Carbohydr Polym 58(4):461–466

Wolkenhauer A, Avramidis G, Cai Y, Militz H, Viöl W (2007) Investigation of wood and timber surface modification by dielectric barrier discharge at atmospheric pressure. Plasma Process Polym 4:470–474

Wolkenhauer A, Avramidis G, Militz H, Viöl W (2008) Plasma treatment of heat treated beech wood—investigation on surface free energy. Holzforschung 62(4):472–474

Wolkenhauer A, Avramidis G, Hauswald E, Militz H, Viöl W (2009) Sanding vs. plasma treatment of aged wood: a comparison with respect to surface energy. Int J Adhes Adhes 29(1):18–22

Militz H, Altgen M (2014) Processes and properties of thermally modified wood manufactured in Europe. In: Deterioration and protection of sustainable biomaterials, ACS symposium series, vol 1158

Yeh JJ, Lindau I (1985) Atomic subshell photoionization cross sections and asymmetry parameters: 1 ≤ Z ≤ 103. Atom Data Nucl Data 32(1):1–155

Yildiz S (2002) Effects of heat treatment on water repellence and anti swelling efficiency of beech wood. The International Research Group On Wood Preservation, Document No: IRG/WP 02-40223

Zaman A, Alén R, Kotilainen R (2000) Thermal behavior of Scots pine (Pinus sylvestris) and Silver birch (Betula pendula) at 200–230 C. Wood Fiber Sci 32(2):138–143

Zhou XY et al (2012) Glass transition of oxygen plasma treated enzymatic hydrolysis lignin. Bioresources 7(4):4776–4785

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Altgen, D., Avramidis, G., Viöl, W. et al. The effect of air plasma treatment at atmospheric pressure on thermally modified wood surfaces. Wood Sci Technol 50, 1227–1241 (2016). https://doi.org/10.1007/s00226-016-0856-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-016-0856-7