Abstract

The addition of sprouted grains and seeds to cereal products has been identified as one of the upcoming trends in recent market reports. In this study, seven types of sprouts (amaranth, brown millet, corn, lentil, lupin, pea, quinoa) were milled and characterised with respect to their compositional (starch, protein, fat, ash, fibre, moisture) and functional properties (water hydration properties). These sprouted flours were included in a gluten-free bread formulation at a level of 5% and the impact on dough (temperature-dependent rising behaviour, pasting and rheological properties) and bread quality parameters (volume, crumb structure and texture) was evaluated. Factors such as the method of germination and the botanical origin influenced the chemical composition of the applied raw material. The functional properties of the different malts and sprouts are affected by the chemical composition of the individual grains. The differences in functional properties were, in turn, found to affect the dough properties and the quality parameters of the baked gluten-free breads. However, statistical analysis showed no correlation between the various factors. Based on this, effects on dough and bread properties were hypothesised to be caused by a combination of multiple factors. All bread formulations containing sprouted flour had significantly improved bread quality parameters in comparison to the control (without sprouted flour). The addition of amaranth sprouted flour, however, resulted in the highest loaf volume and the softest breadcrumb, suggesting its potential for further investigations in further studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The inclusion of sprouted grain into cereal products, for their claimed health benefits, has been named as one of the major trends by recent market reports [1]. Until recently the process of germination has been mainly used to produce fermentable extracts for brewing and distilling purposes. Today, however, it is also considered as a tool for the production of ingredients with an enhanced nutritional profile and health-promoting compounds [2]. Thus, sprouted grains and seeds have been promoted in recent literature for the improvement of the nutritional aspects of gluten-free bakery products, in particular breads [3, 4].

Gluten-free bread is one of the most consumed gluten-free goods by people who suffer from coeliac disease (CD), one of the most common food intolerances. The prevalence of CD is increasing and affects approximately 1% of the world population. The disease is triggered, in susceptible individuals, by the ingestion of gluten [5]. However, CD is not the only disease which is caused by gluten. Under the umbrella term “gluten-related disorders” many more diseases are found, which increases the number of people who must follow a gluten-free diet as part of a treatment [6]. Despite increasing research interest and the consequent improvement of gluten-free bread quality over the past number of decades, consumers remain unsatisfied with the quality. Gluten-free breads are still lacking in techno-functional properties and nutritional value [6].

Literature in the application and effects of sprouts on gluten-free bread quality is scarce. Nevertheless, published research has shown positive effects of malted oat and quinoa [7], malted sorghum [8] and germinated brown rice [9, 10] on gluten-free bread properties. The application of malted oats was reported to improve the volume, crumb structure and texture of gluten-free bread; however, quinoa malt was found to only add to the flavour and nutritional properties [7]. Sorghum malt was shown to reduce crumb hardness when used as a replacement for ungerminated sorghum flour (50:50; 100:50) in a gluten-free bread and to potentially improve the chemical composition [9]. Improved breadcrumb texture of gluten-free breads was reported to be influenced by the addition of germinated brown rice flour, however, the germination time of the rice also had an effect. Flours produced with a prolonged germination time were shown to have a negative effect on the baked breads [9]. Germinated brown rice flour was further found to improve the nutritional quality of gluten-free bread [10]. The addition of germinated amaranth in a gluten-free cookie was also reported, which improved the nutritional value, based on an increased content of protein and total dietary fibre and level of antioxidant activity in comparison to raw amaranth flour [11].

Based on the aforementioned evidence of positive effects of germinated grains, the aim of this study was to investigate the gluten-free bread/making potential of sprouts including, amaranth, brown millet, quinoa, lupin, lentil, pea and corn. The suitability of these sprouts for application in a gluten-free system was evaluated and their effects on the composition and properties of dough and the final bread products were investigated. The results gained from this study are expected to contribute knowledge for improving gluten-free bread quality.

Experimental

Materials and methods

Potato starch was supplied by Emsland, Germany; pea protein isolate (min. 83% protein) by Roquette, France; pectin by Cp Kelco, Germany; sugar by Siucra Nordzucker, Ireland and salt by Glacia British Salt Limited, UK. Instant active dry Baker’s yeast was obtained from Puratos, Belgium. Sprouts were purchased form Ziegler, Germany (amaranth sprouts, brown millet sprouts, quinoa sprouts) and Keimkraft, Austria (lupin sprouts, lentil sprouts, pea sprouts, corn sprouts). All chemicals were supplied by Sigma-Aldrich, Arklow, Ireland.

Milling of germinated seeds and grains

Commercially purchased sprouted grains and seeds were milled using a Bühler Universl disc mill (Uzwil, Switzerland) with settings for a particle size of 250 µm. After milling samples were passed through a sieve with a pore size of 250 µm. Separated husks and larger particles were discarded.

Compositional analysis

The total nitrogen content of the potato protein was analysed using the Kjeldahl method (MEBAK 1.5.2.1). A nitrogen-to-protein conversion factor of 6.25 was used. Moisture content was determined according to AACC method 44 − 15 A. The total available carbohydrate level of the milled samples was determined spectrophotometrically using an enzyme kit (K-TSTA) supplied by Megazyme, Ireland. The ash content was determined according to AACC method 08 − 01.01. The lipid content was determined according to the Soxhlet method (AACC methods 30 − 25.01) after acid hydrolysis. Total dietary fibre contents were determined according to the AOAC method 991.43 by Concept Life Sciences, UK.

Enzyme activity

The amylase activity of alpha- (AACC Method 22 − 02.01 (K-CERA)) and beta-amylase (K-BETA3) was determined using commercially available enzyme kits, supplied by Megazyme, Ireland. Protease activity was determined according to Brijs et al. [12], with slight modifications. Protease activity was extracted from 0.3 g of milled sample in 0.05 M acetate buffer containing 2 mM cysteine (pH 5.0) under shaking for 30 min at 5 °C. The sample extract was assayed after centrifugation (10,000g x 15 min at 4 °C) against 1.0% haemoglobulin in 0.2 M sodium acetate buffer. Therefore, 0.25 ml of haemoglobulin solution and 0.4 ml of sample extract were mixed and incubated for 2.5 h at 40 °C. The reaction was stopped by adding 0.4 ml of cold TCA (10% w/v). Subsequently, the tubes were centrifuged at 10,000g for 10 min to remove precipitated proteins. A reaction blank was assayed for each flour by adding the stopping reagent prior to the incubation. The supernatants were analysed for free α-amino nitrogen, using trinitrobenzene sulfonic acid (TNBS) reagent (0.3%, w/v, in 0.2 M sodium phosphate buffer, pH 8.0). Absorption of samples and reaction blanks was measured at 340 nm against distilled water.

Sugars

Sugar levels (glucose and fructose) of dough and bread crumb were analysed with an Agilent 1260 high-performance liquid chromatography system (HPLC) with a Sugar-Pak column (Waters, Cork, Ireland) coupled to a refractive index detector (RID) at 40 °C. The sugars were extracted with distilled water for 20 min shaking and then centrifugated at 3000g for 10 min. HPLC analysis was performed at 80 °C column temperature with 0.0001 M CaEDTA (HPLC grade) at a flow rate of 0.5 mL/min.

Flour hydration properties

Flour hydration properties were analysed according to Cornejo and Rosell [9]. The water holding capacity (WHC) was determined by mixing 1.000 g +/− 0.001 g of milled sample with distilled water (10 ml) and holding at room temperature for 24 h. Supernatant was discarded carefully by the use a 100-ml pipette, not touching the pellet of sediment. WHC was expressed as grammes of water retained per grammes of sample. For the determination of the swelling power (SP) 1.000 g ± 0.001 g of sample were placed in a graduated cylinder and mixed with distilled water (10 ml). The sample was kept at room temperature for 24 h and swelling power was calculated by dividing the total volume of swollen sample by the original weight of flour. The water-binding capacity (WBC) was measured similar to the WHC with the addition of a centrifugal step (2000g for 10 min).

Dough analysis

Pasting properties

The pasting behaviour of dough formulations with different sprouts (dry mix, excluding yeast) was measured using a Rapid Visco Analyzer (RVA Super 3 Rapid Visco Analyser Newport Scientific, Warriewood, Australia). Each blend (3.0 g) was mixed with 25 ml of distilled water in a container, heated at a rate of 0.2°C/s from 50 °C to 95 °C, maintained at 95 °C for 162 s, cooled at the rate of 0.2°C/s to 50 °C, and held for 120 s at 50 °C before the test ended.

Dough frequency test

Rheological measurements of dough samples (prepared as in Sect. 2.8, excluding yeast) containing the different sprouts were carried out by using a Rheometer Physica MCR 301 (Anton Paar GmbH, Germany) equipped with serrated parallel plate geometry (diameter 50 mm, gap 1 mm). Dough samples were placed between the plates of the rheometer. Samples were left to rest for 5 min after loading prior to the performance of a frequency sweep test at 25 °C from 100 Hz to 0.1 Hz within a linear viscoelastic range. Data obtained were complex viscosity (G*) and damping factor (tan δ).

Time- and temperature-dependent rising behaviour of dough

The measurements were conducted according to Horstmann et al. [13] using an Anton Paar MCR rheometer with the TruStrain™ option. 3 g of dough sample (including yeast) were loaded into a stainless steel cylinder with the height of 33 mm and the inner diameter of 25 mm. To mimic the proofing properties the temperature was set at 30 °C for 45 min with a constant normal force of FN = 0.0 to ensure permanent contact between sample and upper plate. For determination of the oven spring and the determination of yeast activity during the baking process, the temperature was increased to 90 °C with a heat rate of 4 °C/min. Recorded and calculated parameters were the max height (mm), which is the maximum height the dough reached during the measurement. Further the slope (mm/min) during the fermentation process (Slope FP) and then during the baking process (Slope BP) for determination of yeast activity and dough performance was determined. Also, the max height temperature (TMH) (°C) was recorded.

Bread-making procedure

Bread samples were produced based on a simple recipe (80% water, 5% sprouted flour, 2% pea protein, 2% pectin, 2% salt, 4% sugar, 2% yeast, based on potato starch weight). For the pre-fermentation, yeast was suspended in warm water (25 °C) and regenerated for a period of 10 min. Mixing was carried out with a k-beater (Kenwood, Havant, UK) at low disk speed (level 1 of 6) for 1 min in a Kenwood Major Titanium kmm 020 Mixer (Kenwood, Havant, UK). After that, the dough was scraped down from the bowl walls and a further mixing of 2 min at higher disk speed (level 2 of 6) was carried out. The batter was scaled to 300 g in 9 baking tins of 16,5 cm x 11 cm x 7 cm and placed in a proofer for 45 min at 30 °C and 85% relatively humidity (RH). The dough samples were then baked for 45 min at 220 °C top and 220 °C bottom heat in a deck oven, previously steamed with 0.7 L of water. The breads were cooled for 2 h prior to analysis.

Bread analysis

The specific volume of the bread was determined by use of a Vol-scan apparatus (Stable Micro System, UK). The specific volume is calculated on the basis of loaf volume and weight. An image analysis system (Calibre Control International Ltd., UK) was used to analyse the breadcrumb structure chosen parameters were the cell diameter and the number of cells per slice area. Crumb firmness was analysed using a Texture Profile Analyser (TA-XT2i, Stable Micro Systems, Godalming, England) with a 25-kg load cell, which compresses the breadcrumb with a 20-mm aluminium cylindrical probe. Bread samples were cut in 20-mm slices and analysed with a test speed of 5 mm/s and a trigger force of 20 g, compressing the middle of the breadcrumb to 10 mm. The measurement with the various parameters was conducted on the baking day and 24 h after baking to monitor the staling process. The colour values of breadcrumb samples were measured using the CIE L* a* b* colour system, where L* is an indicator for lightness, a* is redness, and b* is yellowness. The analysis was performed using a Colorimeter CR-400 (Konica Minolta, Osaka, Japan). The colorimetric parameters L*, a* and b* were referred to CIE standard illuminant D65.

Statistical analysis

All measurements were performed at least in triplicate. The significance of the results was analysed using one-way ANOVA (R version 3.0.1). The level of significance was determined at p < 0.05.

Results and discussion

Chemical composition

The germination process of seeds and grains has considerable influence on the final chemical composition of the raw material. Parameters such as time and temperature of the germination are crucial factors during this process [14]. In addition, the milling and sieving of the sprouted material can further alter this composition. Husks of seeds which are mainly fibres are more difficult to process than the kernel itself and are often sifted out. This concentrates the amounts of other components such as starch, protein and fat in the milled flour in comparison to the whole seed or grain. Commercially purchased sprouts of amaranth, brown millet, quinoa, lupin, lentil, pea and corn were milled and sifted through a sieve with a 250-µm pore size for the use as flour in gluten-free baking. The different flours milled from the various sprouts will be referred to as SF (sprout flour). Their chemical composition is listed in Table 1. Based on the differences in botanical origin, modified germination regimes and the milling processes, significant differences between the sprouts were found.

Total starch contents showed significant differences between the various sprouts. Corn SF contained the highest amount of total starch (76.47 g/100 g), which was about 40% higher than found in the other sprouts. The significantly lowest value was found in lupin SF with a content of 22.02 g/100 g. Analysed sugars showed the significantly highest amount of disaccharides in lupin SF. The significantly lowest amount was found in brown millet SF. This flour also contained the lowest concentration of fructose, while lupin SF contained the highest amount. Differences were observed in the glucose contents, with quinoa SF having the highest content. Pea SF contained the lowest amount of glucose. Overall only small quantities of the free sugars were found. However, significantly different amounts can influence the fermentation process of the dough. The more sugars are available the more the yeast can metabolise, and the more CO2 is produced [15]. A higher production of CO2 in conjunction with the supporting dough viscosity can increase the specific volume of a gluten-free model bread [13]. Protein analysis showed that lupin SF had the highest protein content (43.08 g/100 g), which was 25% higher than the second highest protein content determined in lentil SF. A high protein content in lupin SF was expected, since lupin seeds contain already high amounts (> 30 g/100 g) of protein [16]. The lowest amount of protein was found in corn SF. Similar low values for ungerminated corn flour have been recently reported in another gluten-free study [17]. The highest fibre content was found in lupin SF while the significant lowest fibre content was found in lentil SF. The addition of fibre-rich ingredients can help to improve the nutritional profile of gluten-free breads. However, fibres can absorb up to 10 times their own weight of water [18]. Thus, the application of high-fibre containing ingredients can affect the baking performance of the fragile gluten-free system. Significant differences in the composition of the various sprouts were also found in the fat content. The fat content ranged from 1.25 g/100 g to 8.01 g/100 g, with pea SF having the lowest and lupin SF the highest content. Lipids can affect the gelatinisation properties of starch through complex formation with amylose during heating [19]. A limiting effect of starch swelling by lipids was reported to result in a softer breadcrumb or weakened crumb, depending on the amount added [20]. Such an effect was discussed in a previous study performed on the application of different starches in a gluten-free model system [21]. The addition of minerals (ash), in the natural amounts in which they occur in raw materials, to the authors’ knowledge, does not influence the bread-making process or the structure of the final bread. However, ingredients rich in mineral contents offer the potential to improve the nutritional profile of products which are lacking minerals, such as gluten-free breads [2]. The highest content of ash was found in amaranth SF (3.77 g/100 g) followed by brown miller SF (3.19 g /100 g). No significant differences between quinoa SF, lupin SF., lentil SF and pea SF were found (approx. 2.60 g/100 g). The significantly lowest content was found in corn SF which was lower than 1%. The moisture content of the various SF showed significant differences. The highest content was determined in lentil SF, while the lowest amount was found in quinoa SF. Differences in the moisture content are often influenced by the drying procedure after germination [14].

The germination of seeds or grains activates enzymes by metabolic processes [22]. Enzyme activities of raw material have significant effects on dough and final bread properties [23]. In wheat breads barley malt flour is added in small amounts (0.1–0.8%) to improve baking properties and improve loaf volume and structure [18]. However, high amounts of barley malt flour can cause liquefaction of the dough, leading to a detrimental result. In gluten-free systems, a controlled level of enzymatic activity can either positively or negatively affect the baking properties [8]. Based on the previously observed positive and negative effects of enzymes in the aforementioned studies, their activities in the different SFs was determined. Protease activity showed significant differences, amaranth SF the highest (8.65 U/g) and pea SF the lowest activity (0.82 U/g). No activity was recorded in lentil SF and corn SF. This can be used to promote gluten relaxation in wheat-based systems. However, excessive protease activity has been reported to destroy the gluten network producing a viscous system or even a liquid batter [18, 24, 25].

The cleaving of complex sugars to simple sugars by amylases is a crucial process which can affect the baking process drastically. Generated glucose and fructose can be metabolised by yeast into CO2 and ethanol and expand gas cells [13]. Amylases can further retard the retrogradation process of starch in bread and hence delay staling [26]. Alpha-amylase activity was only found in corn SF, with a high activity (12.55 U/g). The analysis of beta-amylase activity showed only low but significantly different levels between the SF. The significantly highest activity was found in lupin SF (0.61 U/g) and the lowest activity in SF produced from brown millet (0.04 U/g). No activity was recorded for quinoa SF. No lipase activity was detected in any of the SFs (data not shown). This lower enzymatic activity of the selected sprouts enables their use in higher concentrations than, for example, barley malt, while not causing a deleterious liquefication effect. Use of higher amounts of SF used in gluten-free formulation could, therefore, improve the nutritional profile.

Flour hydration properties

Based on differences in chemical composition in SF, such as in fibre and its potential to absorb and affect baking properties, the hydration properties of the SFs were determined. Parameters analysed for the hydration properties were the water-holding capacity (WHC), swelling power (SP) and the water-binding capacity (WBC) as described by Cornejo and Rosell [9]. The WHC determines the amount of water was retained by the sample without being subjected to any stress. The highest amount of water retained by lupin SF, which was nearly twice as high as the other SFs (Table 1). Brown millet SF retained the least amount of water. Similar trends were found for the SP, which is defined as the volume gained after hydration of the sample. Also, here lupin SF was found to have the highest SP, while brown millet SF showed the lowest SP. The WBC of a sample is defined similar to the WHC, with the exception that it is determined after low-speed centrifugation [10]. Lupin SF was found to retain the highest amount of water after centrifugal stress in comparison to the remaining SFs. No significant differences between other SFs were found. The assumption that the total fibre content is the main contributor to the WHC was ruled out, since lupin SF and brown millet SF have the highest fibre contents but low WHC. This was explained by the different types of fibres which were found. Lupin SF contains 16.8% insoluble fibre, while brown millet SF contains 3.3%. The remaining 10.8% are soluble and hypothesised to be discarded with the supernatant and hence less water could be retained. This hypothesis is strengthened by the finding that corn SF, being the second lowest water-retaining SF, also contained only a low amount of insoluble fibre content. Similar results were also found by Wang, Rosell [27], who analysed the effect of fibres on wheat dough, the authors found that carob fibre which was rich in insoluble fibre increased the water absorption more than inulin, which was rich in soluble fibre. Also, factors like hydroxyl groups, ionic charge, chain length and molecular weight can influence the water hydration properties and are mainly linked to the source of origin [27,28,29]. However, not only the soluble and insoluble parts of fibre affect the water hydration properties of a SF. The protein content also plays a significant role in the hydration properties of a raw material [30].

Pasting properties of dough formulations

The analysis of pasting properties using a rapid visco analyser was conducted on the dough formulation, excluding yeast. Results of the viscosity profiles during applied shear and a range of temperature are shown in Table 2. Dough formulations containing SF showed a reduced viscosity profile in comparison to the control. Viscosity reducing effects were also reported in literature [7,8,9]. Apart from the viscosity reducing effect of SF addition, significant differences between the applied SF on the viscosity profiles were found.

Analysis of the reached peak viscosities showed significant differences. The highest peak viscosities after the control formulation were found in the doughs containing quinoa SF. The significantly lowest value was found in samples containing brown millet SF. The peak viscosity is usually described as the maximum swelling of the starch granules before bursting [31]. In a dough formulation, it can refer to the entire system and factors such as protein denaturation, hydrocolloid and fibre swelling, and the enzymatic activity must be considered. These factors can also further affect pasting parameters such as the breakdown viscosity. The breakdown viscosity has been described as an indicator for the breaking of granules upon heating after the maximum swelling at the peak viscosity [32]. Hence in a dough formulation, it can be used as an indicator for the stability of the system, and ability to withstand heat and mechanical shear conditions. The highest breakdown viscosity was found for the control and the formulations containing brown millet SF and pea SF. The most stable dough system with the significantly lowest breakdown viscosity was that containing corn SF addition.

The final viscosity is the viscosity reached after cooling. It is described as the reassociation of starch granules during cooling and is considered as an indicator for bread staling [33]. The highest final viscosity was reached by quinoa SF formulations, showing no significant differences from the control formulation. The lowest viscosity was found in doughs formulated with brown millet SF.

The low-viscosity results determined for brown millet SF in comparison to the remaining SFs is hypothesised to be attributed to its chemical composition, which was earlier discussed and linked to its low hydration properties. The overall decreasing viscosity results for most of the SFs cannot be limited to only one, but many factors. All the applied sprouts contain lipids, which were earlier described to build complexes with amylose, limiting starch swelling [20, 21]. Furthermore, the denaturation and source of protein were recently discussed as influencing the pasting properties of dough formulations [30]. In addition, the effect of enzymes must be taken into consideration, since a broad range of temperature during the measurement is applied, activating different enzymes [34]. These were found to decrease viscosity profiles by changing the molecular structure of starch through the breakdown of polymer chains [7, 9]. This breakdown reduced the ability to bind water and increased the viscosity. This has been demonstrated by previous studies using germinated flour [8], increasing the concentration of germinated flour [7] or by increasing the time of germination [9]. All of these approaches led to a higher enzyme activity in the analysed sample, decreasing its viscosity profile.

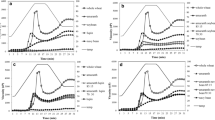

Oscillatory viscosity

Viscoelastic properties are an important characteristic of dough in order to facilitate gas/air cell expansion [35]. The effect of the different SFs on the visco-elastic properties was measured and is shown in Fig. 1. The complex viscosity and the damping factor of the dough (excluding yeast) were analysed. A decrease in complex viscosity over angular frequency was observed for all the dough samples. Similar findings were reported in a previous study applying different hydrocolloids to the gluten-free formulation [28]. However, doughs formulated with lentil SF, pea SF, lupin SF and corn SF showed higher viscosity values than the control. The analysis of the damping factor is an indicator of the viscoelastic behaviour. The dough samples prepared with the different SFs showed a higher viscous behaviour at lower rather than higher angular frequency. Different results for the control were reported in a previous study [28]. In this study the damping factor of the control (excluding sprouts) decreased (0.75–0.35) during increasing frequency (0.1–10), but recovered to a small extent during the angular frequency from 10 to 100. In the previously reported study, the damping factor increased with increasing angular frequency from 0.5 to 0.88. The differences were explained by the change the amount of water added to the formulation and the addition of a protein source (pea protein). The added protein was reported in a further study to decrease the damping factor of a gluten-free model system [30]. Furthermore, aside from the protein addition, in this study different sprouts were added to the formulation. These were found to have significantly different chemical compositions and water interacting properties. Despite their different properties, however, the addition of SF showed only significant differences at low angular frequency (angular frequency < 1). This is hypothesised by low molecular interactions between the different chemical components and water interacting properties of the various SFs. At this stage of the measurement only the addition of amaranth SF showed a higher damping factor than the control, referring to a more viscous behaviour. The addition of the remaining SFs showed either no significant difference compared to the control (corn SF, brown millet SF, lentil SF) or a significantly lower damping factor (lupin SF, quinoa SF). Overall, these results are similar to the ones found in literature, showing the damping factor 0.1 < tan delta < 1 [28, 36,37,38].

Time- and temperature-dependent rising behaviour of dough

The method of the rising behaviour of dough being dependent on time and temperature was described in a recent study [13]. This measurement was found to be a suitable alternative method for the analysis of gluten-free doughs. However, even though the CO2 content is not recorded, the dough rise itself successfully correlated with the final bread properties of a gluten-free model system [13]. The method was described as a good indicator of yeast activity. Based on the different chemical compositions and enzyme activities of the various SFs their potential effect on yeast activity and related dough rise was analysed.

Rising behaviour of the doughs formulated with the different sprouts showed significant differences (Fig. 2/Table 3). The slope of dough rise during fermentation (Slope FP) is an indicator of how fast the dough rises. Doughs formulated with quinoa SF showed the fastest dough rise (0.192 mm/min). The slowest rise was determined in the control dough, which did not contain SF (0.126 mm/min). The lower performance of the control is likely due to a limitation of available sugars for yeast metabolism. In comparison to the control dough, doughs containing SF, however, have more available sugars based on their chemical composition (Table 1).

An increase in the speed of dough rise was observed when the temperature increased and the slope of the “baking process” (Slope BP) was measured. An increase in temperature on a dough system has various effects: (1) starch gelatinisation, (2) protein denaturation, (3) hydrocolloid gelling, (4) increased enzymatic and yeast activity and (5) interactions and crosslinks between the aforementioned effects [39, 40]. Thus, changes in dough rise during the baking process are mainly influenced by the chemical composition. The highest increase and the fastest dough rise were observed in doughs containing brown millet SF. The increase is hypothesised to be due to temperature-induced changes of the chemical components of the dough and their interactions, since no correlation to any one component was found. As observed in the rheological investigations, doughs containing brown millet SF showed a higher damping factor (viscous behaviour) in comparison to other doughs. A more viscous behaviour facilitates cell growth better than low damping factors (elastic behaviour) [30]. The lowest and even decreased dough rise rate was found in doughs formulated with lupin SF. The slope during baking was reduced by more than 50% in comparison to the slope during the fermentation process. This detrimental effect is assumed to be caused by the significantly higher protein and insoluble fibre content in lupin SF, in comparison to the other SFs. The higher amount of protein is understood to denature, build a strong dough network and increase dough viscosity. The increase of viscosity caused by an increase in protein content, resulting in an elastic rather than viscous behaviour, has been recently reported in a previous study by [30]. The remaining chemical components are further factors which are described to affect the dough rising behaviour and contributing to a rather high viscosity. The authors in this study assume that the chemical components compete with the starch for free water. Starch gelatinisation is described as a result of granule swelling during heating, increasing viscosity [41]. When the starch granules reach their maximum swelling capacity, they burst which results in a drop in viscosity [31]. The increase of viscosity caused by an increase in protein content, resulting in an elastic rather than viscous behaviour, has been recently reported in a previous study by [30]. The remaining chemical components are further factors which are described to affect the dough rising behaviour and contributing to a rather high viscosity. The authors in this study assume that the chemical components compete with the starch for free water. Starch gelatinisation is described as a result of granule swelling during heating, increasing viscosity [41]. When the starch granules reach their maximum swelling capacity, they burst which results in a drop in viscosity [31]. This granular bursting and related viscosity drop is hypothesised to be restrained by the competition with other chemical components such as fibre, protein. Also, the amount of lipids has to be considered, as lipids can coat the starch granules and interact with amylose restraining starch swelling [21]. Prevention of granular bursting would maintain the high viscosity in the dough system and could further restrain gas cell expansion.

The differences in dough rise rates over the various stages of fermentation and baking leads to further significant differences in the maximum height (maxH). Doughs containing brown millet SF, quinoa SF, amaranth SF, corn SF and lentil SF reached a higher maxH than the control. However, the highest maxH was reached by doughs containing quinoa SF and brown millet SF. The addition of pea SF and lupin SF had a decreasing effect on the maxH, where lupin SF showed the significantly lowest maxH. The low maxH for lupin SF is linked to the slow dough rise during the baking stage. The dough rise is affected by available nutrients for the yeast to metabolise, but also by the viscosity of the dough system [13]. The compositional analysis of the SFs showed significant differences in their compositions. This suggests that there are many influencing factors as discussed for the differences observed in dough rise rates. Based on the complexity of the gluten-free formulation, many influencing factors were found which makes it difficult to draw significant correlations between the chemical constituents of the SFs and the dough rising properties.

Baked bread properties

Baked breads formulated with the various SFs showed different results. Figure 3 gives an overview of the cross section and whole loaf of the baked breads. Except for brown millet SF all breads showed an even crumb texture without any large holes. The hole in brown millet SF is assumed to be caused by the low hydration properties which allow more water to evaporate during the early stages of baking and weakens the dough. The combination of the two is assumed to cause a coalition of crumb cells under the crust, which is formed very early in the baking process and thus not allowing the evaporated water to escape. Furthermore, differences in colour, volume and crumb structure were observed. The quantitative differences of the various parameters are shown in Table 4. The addition of amaranth SF to the gluten-free formulation increased the specific volume giving the highest value of 3.01 ml/g. Lupin SF was found to decrease the specific volume and showed the lowest value of 2.29 ml/g. Overall it was observed that the addition of SFs increased the specific volume in comparison to the control. Only lupin SF decreased the specific volume. Lentil SF-containing breads showed no significant difference to the control bread. Mixed results for the addition of germinated flours are also reported in literature. A positive effect on specific volume was reported for the addition of germinated brown rice flour in a gluten-free bread [9]. No influence was reported for the addition of germinated quinoa flour [7]. However, germinated oat flour applied in the same study was found to increase the specific volume. The authors correlated this result with the higher alpha-amylase activity in oat malt, causing a drop in viscosity of the dough, which allowed greater gas cell expansion. Similar findings were observed for the addition of germinated rice flour in comparison to ungerminated rice flour [9]. In this study, however, except in corn SF, no alpha-amylase activity was detected (Table 1). Furthermore, corn SF-formulated bread did not show the highest specific volume. This suggests that other factors play a key role in the baking process. It was not possible to establish correlations between dough properties and final bread results. The authors hypothesise that this is caused by complex and multiple interactions related to the chemical composition. The interactions are assumed to be the result of temperature changes during baking, which cannot be completely mimicked in the dough analyses performed. Nevertheless, the authors consider fibre and protein content to be major key factors. These were found to be significantly high in lupin SF, leading to high water hydration properties. These were further understood to cause a lower damping factor and a higher viscosity, indicating a more elastic dough in comparison to the remaining sprouts. The elastic dough is assumed to restrain gas cell expansion during fermentation, leading to smaller bread volume. This was demonstrated in the dough rise measurement of the various dough formulations (Fig. 2; Table 3). Similar findings were observed in previous studies [13, 28, 30]. Restrained gas cell expansion was confirmed by the results generated during breadcrumb analysis. The greatest cell diameter was measured in breads formulated with amaranth SF, while the smallest diameter was found in breads containing lupin SF and lentil SF. The diameter of cells, however, is not only influenced by the restrained gas cell expansion, but also the amount of CO2 produced during fermentation. The different chemical composition of the SF provides the yeast with different amounts of nutrients for fermentation. In general, higher amounts of simple sugars lead to a greater production of CO2, which ultimately leads to a greater cell diameter [13]. However, in this study, no link between available sugars and cell diameter could be established. The authors assume that the diverse enzyme activities provide further amounts of sugars for the yeast to metabolise. The additional sugars are fermented and increase the amount of CO2 produced, which in turn increases gas cell expansion. In addition to the cell diameter, the number of cells must be considered when links to the specific volume are established. However, the number of cells did not show significant variation amongst the baked breads. Thus, it is not surprising that amaranth SF-containing breads showed the least cells per area and lupin SF and lentil SF. The application of amaranth SF, brown millet SF, quinoa SF and pea SF showed an increase in cell size compared to the control, while the remaining SFs produced either decreased the cell diameter or showed no significant difference. An increasing and decreasing effect on cell diameter was also recently reported by the addition of germinated oat and quinoa flour, respectively [7]. A greater specific volume provides more surface area and hence facilitates water evaporation, leading to an increase in bake loss [13, 30]. In this study, however, no significant differences between the bake loss of the baked breads were found. This is assumed to be caused by the variation in water hydration properties, being able to bind dissimilar amounts of water to the dough system. A higher amount of water in the dough system can lead to a softening of the breadcrumb [42]. Bread texture is an important quality parameter for consumer acceptance [43]. The hardness of bread after baking is influenced by the retrogradation process of amylose and amylopectin [42]. Furthermore, it was recently found that the number of cells per area and cell diameter also influence the breadcrumb hardness [13]. The authors hypothesised, that a higher cell diameter decreases the number of cell walls compressed by a measuring probe, leading to a softer breadcrumb. The hardness values of the baked breads showed significantly different results. Breads baked with amaranth SF, quinoa SF and pea SF showed a lower hardness in comparison to the control. The remaining SFs increased the hardness. An increase in hardness over time is defined as the staling process. During this process, water migrates from crumb to crust and recrystallisation of starch proceeds, which alters the bread texture [42]. The crumb hardness of all the baked breads increased after 24 h. However, after 24 h the crumb hardness of the various breads differed and did not correlate with that which was measured on the baking day, indicating differences in staling rates. Breads formulated with brown millet SF, pea SF and the control bread showed the significantly highest hardness values. The softest breadcrumb however, was found for breads formulated with amaranth SF. These results are within the range of hardness values previously reported for this model bread system [28, 30]. A decreasing effect on hardness, by the addition of germinated sorghum flour, was recently reported by Phattanakulkaewmorie et al. [8]. The authors analysed the effect of different amounts of germinated sorghum flour on gluten-free bread properties. Another study also found a decreasing effect on bread hardness by the addition of germinated brown rice flour [9]. The authors found that a longer germination time leads to degradation of starch by alpha-amylase resulting thinner cell walls of the gluten-free breads. The effect of other enzyme activities and their effect on bread staling have been recently discussed. Lipase activity was described to alter the polarity of lipids which results in cell wall strengthen allowing greater gas cell explanation [44, 45]. However, in this study, no lipase activity was found in the analysed sprouts (data not shown). Proteolytic activities of germinated flours were reported to reduce crumb hardness in gluten-free bread [24]. However, the study also stated that the impact strongly depends on the applied matrix. Hence it is assumed, that the differences in chemical composition of the applied sprouts in this study created such aforementioned matrices. This assumption is based on the generated results showing no correlation between protease activity and crumb hardness. The hardness and staling process can be further affected by other factors. Such factors could be the aforementioned formation of lipid–amylose complexes, protein–starch and or starch–hydrocolloid interactions [28].

The addition of the various SF further affected the colour values of the bread crumbs (Fig. 3). For the evaluation of the changes in colour of the breadcrumb, the CIE-L*a*b* system was applied. The addition of amaranth, brown millet and quinoa sprouts reduced the L* value, which indicates a darker crumb. Lupin, lentil and pea sprouts, however, increased the L* value. The addition of corn sprouts showed no effect on the L* value compared to the control breadcrumb. Similar values have been reported by the addition of germinated brown rice flour [9]. They were further stated to be similar to those values reported for commercial gluten-free bread [46]. Detected a* and b* values of the bread crumbs baked with the different sprouts indicated an increase in yellow colour in comparison to the control. While the study by Matos and Rosell [48] showed colour intensity changes due to germination time, in this study the main factor affecting colour change is attributed to the raw material applied.

Conclusion

In this study, the effect of sprouted flour from different plants (amaranth, brown millet, corn, lentil, lupin, pea and quinoa) on a gluten-free dough and bread formulation was compared. The flours of the commercially purchased sprouts showed significant differences in their chemical composition. The low enzyme activity of the sprouted flours allowed their application in the gluten-free formulation at a concentration of 5% w/w. The differences in composition were further found to influence the flour hydration properties, which in turn affected dough properties. Sprouted flour of lupin showed the highest flour hydration properties which were assumed to be caused by the specific chemical composition, high in fibre and protein. The high water-binding capacity was further postulated to be related to the higher viscosity and a more elastic behaviour in comparison to the remaining sprouted flours. Doughs with more elastic behaviour were found to have a reduced dough rise, due to restrained gas cell expansion. The decreased gas cell expansion leads to smaller breads with a denser texture. However, the hardest breadcrumb was found in breads formulated with brown millet sprouted flour, which showed the lowest hydration properties. Hence, statistical analysis revealed no correlation between the chemical composition and the dough and bread properties. Thus, as discussed, this suggests the influence of more than one single factor, such as starch gelatinisation, protein denaturation, hydrocolloid/fibre gelling, enzymatic activity and their chemical interactions. Despite the various influencing factors, all the baked formulations containing the sprouted flours resulted in bread-like products and improved quality parameters in comparison to the control (no sprouted flour). The addition of amaranth sprouted flour increased the specific volume of baked breads significantly. It further reduced the crumb hardness. The chemical composition of amaranth was also suggested, based on its protein and ash/mineral content to improve the nutritional value of gluten-free bread. This study demonstrated the successful application of gluten-free sprouted flours in a gluten-free bread system with the potential to increase the nutritional value of gluten-free breads.

References

Online-Source:, The Washington Post: plant proteins, healthy fats and more 2017 Food Trends. Date Accessed 21 May 2018

Hübner F, Arendt EK (2013) Germination of cereal grains as a way to improve the nutritional value: a review. Crit Rev Food Sci Nutr. 53(8):853–861

Omary MB et al (2012) Effects of germination on the nutritional profile of gluten-free cereals and pseudocereals: a review. Cereal Chem. 89(1):1–14

Deora NS, Deswal A, Mishra HN (2014) Alternative approaches towards gluten-free dough development: recent trends. Food Eng Rev. 6(3):89–104

Lionetti E et al (2015) Celiac disease from a global perspective. Best Pract Res Clin Gastroenterol. 29(3):365–379

Foschia M et al (2016) Nutritional therapy–facing the gap between coeliac disease and gluten-free food. Int J Food Microbiol. 239:113–124

Mäkinen OE, Zannini E, Arendt EK (2013) Germination of oat and quinoa and evaluation of the malts as gluten free baking ingredients. Plant Foods Human Nutr. 68(1):90–95

Phattanakulkaewmorie N, Paseephol T, Moongngarm A, (2011) Chemical compositions and physico-chemical properties of malted sorghum flour and characteristics of gluten free bread. World Acad Sci Eng Technol. 5(7): p. 532–538

Cornejo F, Rosell CM (2015) Influence of germination time of brown rice in relation to flour and gluten free bread quality. J Food Sci Technol. 52(10):6591–6598

Cornejo F et al (2015) Effects of germination on the nutritive value and bioactive compounds of brown rice breads. Food Chem. 173:298–304

Chauhan A, Saxena D, Singh S (2015) Total dietary fibre and antioxidant activity of gluten free cookies made from raw and germinated amaranth (Amaranthus spp.) flour. LWT Food Sci Technol. 63(2):939–945

Brijs K et al (2002) Proteolytic enzymes in germinating rye grains. Cereal Chem. 79(3):423–428

Horstmann SW, Atzler JJ, Heitmann M, Zannini E, Arendt EK (2018) Fundamental study on the impact of different S. cerevisiae yeast strains on gluten-free dough and bread quality parameters. Eur Food Res Technol 1–11

Kunze W (1999) Malt production. Technology brewing and malting. VLB, Berlin, pp 88–170

Randez-Gil F, Sanz P, Prieto JA (1999) Engineering baker’s yeast: room for improvement. Trends Biotechnol. 17(6):237–244

Sujak A, Kotlarz A, Strobel W (2006) Compositional and nutritional evaluation of several lupin seeds. Food Chem. 98(4):711–719

Hager A-S et al (2012) Nutritional properties and ultra-structure of commercial gluten free flours from different botanical sources compared to wheat flours. J Cereal Sci. 56(2):239–247

Sluimer P (2005) Principles of breadmaking: functionality of raw materials and process steps. American Association of Cereal Chemists, St. Paul, MN

Copeland L et al (2009) Form and functionality of starch. Food hydrocoll. 23(6):1527–1534

Gallagher E (2009) Gluten-free food science and technology. John Wiley & Sons, Hoboken, New Jersey

Horstmann SW et al (2016) Fundamental study on the impact of gluten-free starches on the quality of gluten-free model breads. Foods. 5(2):30

Mäkinen OE, Arendt EK (2015) Nonbrewing applications of malted cereals, pseudocereals, and legumes: a review. J Am Soc Brew Chem. 73:223–227

Rosell CM, Enzymatic manipulation of gluten-free breads. Gluten Free Food Sci Technol. 2009: p. 83–98

Renzetti S, Arendt E (2009) Effect of protease treatment on the baking quality of brown rice bread: From textural and rheological properties to biochemistry and microstructure. J Cereal Sci. 50(1):22–28

Haros M, Rosell CM, Benedito C (2002) Effect of different carbohydrases on fresh bread texture and bread staling. Eur Food Res Technol. 215(5):425–430

Giannone V et al (2016) A novel α-amylase-lipase formulation as anti-staling agent in durum wheat bread. LWT Food Sci Technol. 65:381–389

Wang J, Rosell CM, de Barber CB (2002) Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 79(2):221–226

Horstmann SW, Axel C, Arendt EK (2018) Water absorption as a prediction tool for the application of hydrocolloids in potato starch-based bread. Food Hydrocoll. 81:129–138

Rosell C, Rojas J, De Barber CB (2001) Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 15(1):75–81

Horstmann S, Foschia M, Arendt E (2017) Correlation analysis of protein quality characteristics with gluten-free bread properties. Food Funct. 8(7):2465–2474

Schirmer M, Jekle M, Becker T (2015) Starch gelatinization and its complexity for analysis. Starch-Stärke. 67(1–2):30–41

Rojas J, Rosell C, De Barber CB (1999) Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 13(1):27–33

Chanapamokkhot H, Thongngam M (2007) The chemical and physico-chemical properties of sorghum starch and flour. Kasetsart J Nat Sci. 41:343–349

Poutanen K, Enzymes (1997) An important tool in the improvement of the quality of cereal foods. Trends Food Sci Technol. 8(9):300–306

Capriles VD, Arêas JAG (2014) Novel Approaches in Gluten-Free Breadmaking: Interface between Food Science, Nutrition, and Health. Compr Rev Food Sci Food Saf. 13(5):871–890

Ziobro R et al (2013) Supplementation of gluten-free bread with non-gluten proteins. Effect on dough rheological properties and bread characteristic. Food Hydrocoll. 32(2):213–220

Witczak M et al (2012) Influence of modified starches on properties of gluten-free dough and bread. Part I: Rheological and thermal properties of gluten-free dough. Food Hydrocoll. 28(2):353–360

Pruska-Kędzior A et al (2008) Comparison of rheological, fermentative and baking properties of gluten-free dough formulations. Eur Food Res Technol. 227(5):1523

Morris GA et al. (2008) Global hydrodynamic analysis of the molecular flexibility of galactomannans. Carbohyd Polym. 72(2): 356–360

BeMiller JN, Whistler RL (2009) Starch: chemistry and technology. Academic Press, Cambridge, Massachusetts

BeMiller JN, Pasting, paste, and gel properties of starch–hydrocolloid combinations. Carbohyd Polym. 2011. 86(2): 386–423

Fadda C et al. (2014) Bread staling: updating the view. Compr Rev Food Sci Food Saf. 13(4): 473–492

Cauvain SP, Young LS (2016) Technology of breadmaking. Springer, Berlin

Primo-Martín C, Hamer RJ, de Jongh HH, Surface layer properties of dough liquor components: are they key parameters in gas retention in bread dough? Food Biophys. 2006. 1(2): 83–93

Nunes MHB et al. Impact of emulsifiers on the quality and rheological properties of gluten-free breads and batters. Eur Food Res Technol. 2009. 228(4): 633–642

Matos ME, Rosell CM (2012) Relationship between instrumental parameters and sensory characteristics in gluten-free breads. Eur Food Res Technol. 235(1): 107–117

Acknowledgements

The authors want to thank Tom Hannon for his technical support. The work for this study was part of the PROTEIN2FOOD project. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 635727.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interest.

Ethical approval

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Horstmann, S.W., Atzler, J.J., Heitmann, M. et al. A comparative study of gluten-free sprouts in the gluten-free bread-making process. Eur Food Res Technol 245, 617–629 (2019). https://doi.org/10.1007/s00217-018-3185-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-018-3185-2