Abstract

This work considered gelatinized wheat flour fraction with properties similar to hydrocolloid to enhance the strength of dough network by improving water retention and rheological characteristics. The gelatinized (90 °C) fraction of the wheat flour was incorporated in the dough formulation at different levels (5, 10, and 20% w/w). The effects of the gelatinized flour (GF) fraction on the dough rheology and thermal properties were studied. The incorporation of GF induced a moderate increase of dough viscoelasticity and reduced the freezing and melting enthalpies. On the other hand, the changes in bread textural properties brought by incorporation of GF were insignificant, indicating that the gelatinized fraction acted as a binder that enhanced water trapping in the structure. SEM images showed a more heterogeneous crumb microstructure (e.g., gas cells, porous, etc.) bread prepared using GF. Drying kinetics obtained from TGA indicated that the water diffusivity decreased with the incorporation of GF, which suggested that the bread had a compact microstructure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The effects of the incorporation of pregelatinized starch (PS) fractions for dough and bread making have been explored in the recent decade. Commonly, PS is obtained by heating starch dispersions at about 60–80 °C by 15–20 min and then spray-drying. The powder is used as a flour substitute to induce desired rheological and textural properties of dough and bread (Miyazaki et al. 2006). The specialized literature dealing with the effects of PS addition is relatively scarce. Satin (1988) proposed PS as a mean to provide gas occlusion and bread stability. Seyhun et al. (2005) found experimental evidence indicating that PS decreased moisture loss during baking and storage, concluding that PS is an effective form staling delay. Miller et al. (2008) showed that the addition of PS improved the bread output as water adsorption capacity is increased. Onyango et al. (2011) studied the rheological and baking characteristics of gluten-free batter and bread prepared from pregelatinized cassava starch and sorghum flour, showing that PS emulated to certain degree the elastic properties attributed to gluten. Lee and Lim (2013) investigated the effects of pregelatinized rice flour on the textural properties of rice cookies, showing that hardness of dough and cookies increased upon the addition of PS. Hesso et al. (2014) considered wheat and corn PS as flour substitutes to study texture and staling of pound cakes, showing that the denser structure these cakes increased the softness of the material and attenuated the adverse effects of staling. Pongjaruvat et al. (2014) showed that substitution of pregelatinized tapioca starch for the rice flour enhanced dough viscoelasticity and improved bread quality, although lower crumb hardness and chewiness were obtained. Fu et al. (2016) studied the effect of partially gelatinized corn starch on the rheological properties of wheat dough, finding that the rheological properties were affected by the substitution extent more than by the degree of gelatinization. In the recent years, Purhagen et al. (2008, 2011, 2012) have studied the effects of adding modified flour and starch fraction in the staling of bread variations. It was shown that the water absorption properties can be improved by adding normal or heat-treated barley flour in small amounts (2 and 4%) to a white wheat bread recipe (Purhagen et al. 2008). Also, it was shown that bread variations were less firm than their normal counterpart after seven days of storage when adding barley flour and waxy barley starch. It was found that the addition of relatively small amounts (3% flour basis) of pre-gelatinized oat and barley flours in combination with emulsifiers retarded the staling of gluten-free bread variations (Purhagen et al. 2008).

In the aforementioned studies, the PS was obtained by spray drying process and incorporated in the dough formulation by mixing directly with the base flour. Spray drying is an energy demanding process that might increase the cost of bread fabrication. Since water is routinely used in dough formulations, an alternative for cost saving is to incorporate directly the gelatinized flour (GF) dispersion without appealing to spray drying steps. In this case, the GF dispersion would play the role of a hydrocolloid aimed to improve dough texture and viscoelasticity and to reduce the adverse effects of staling. Studies in this direction are lacking in the scientific literature.

The aim of the present work was to study the impact of GF fractions on the rheology and thermal characteristics of wheat-based dough and bread without further additives. The results provide valuable insights in the use of GF fractions playing the role of hydrocolloids in the preparation of dough and bread.

Materials and methods

Materials

Canada Western Soft White Spring (CWSWS) wheat flour (protein 11.1%, fat 1.2%, dietetic fiber 0.64%, sodium 0.03%) was provided by Bunge S.A. de C.V. (Toluca, Mexico). This flour is commonly used for flat breads, steamed breads, chapattis, cookies, cakes and pastries. Whole milk powder with soya lecithin as emulsifier and fat content not less than 28% w/w was used (Nestlé, Switzerland). Sugar, butter, baker’s dry yeast (Nevada Brand, Mexico) and salt were obtained at a local super market (Walmart, Mexico). Distilled water was used in all formulations.

Dough preparation

The components of the basic recipe for dough were wheat flour (29.4% w/w), milk powder (3.4% w/w), sugar (2.5% w/w), butter (3.0% w/w), baker’s dry yeast (1.7% w/w), and water (60% w/w). The ingredients were mixed in a Laboratory Spiral Mixer (SP-800-J Alpha Simet Group S.A. de C.V., Mexico) for 10 min at low speed and for 5 min at high speed. Water was added in the mixer at the beginning of the low speed period, and 0.5% salt was added at the beginning of the high-speed period.

The formulations containing GF were made as follows. GF wheat flour (5, 10 or 20% w/w) was mixed with the whole amount of water to be used in the recipe described above. The dispersion was heated at 90 °C for 20 min to achieve complete gelatinization of the starch. Subsequently, the gelatinized dispersion was allowed to cool down to room temperature (about 20 °C). Then, the gelatinized dispersion was incorporated in the mixer at the beginning of the mixing. The dough was rest for 10 min and then divided in pieces of 300 g and put into silicone containers. The bread dough was then leavened in a fermenting chamber for 1 h at 28 °C and 85% relative humidity. The dough formulations were coded as D0 for the basic recipe (i.e., not GF was added), and D5, D10 and D20 for dough containing 5, 10 and 20% (w/w) of GF, respectively. It should be clarified that higher percentage of gelatinized wheat flour were not viable because a sticky dough was obtained, making the handling of the dough quite different.

Rheological properties of bread doughs

To assess the effects of the GF, all rheological measurements were carried out before the leavening phase, just after the dough was prepared. Flow and oscillatory measurements were carried out using a Physica MCR 300 rheometer (Physica Meβtechnik GmbH, Germany), with cone-plate geometry, rotating cone 50 mm in diameter, and cone angle of 2° with a gap of 0.05 mm. A dough sample (~5.0 g) was placed in the measuring system, and left to rest for 5 min at 25 °C. The edges of samples were covered with oil to reduce water evaporation. Temperature maintenance was achieved with Physica TEK 150P temperature control. Flow curves were obtained by varying the shear rate from 0.00001 to 1000 s−1. Amplitude sweeps were carried out in the range of 0.01–1000% at 1.0 rad s−1. This frequency value was chosen because it typically represented the deformation dynamics during the dough formation in the mixer, which worked at about 60 rpm. In this way, the considered frequency reflected the viscoelastic properties during the mixing of ingredients and dough formation. The storage modulus (\( G' \)) and the loss modulus (\( G'' \)) were measured.

Determination of the freezing and melting properties of doughs

Freezing and melting properties were studied using a differential scanning calorimeter DSC 1000 (TA Instruments, New Castle, USA) previously calibrated with indium (melting point = 156.61 °C; ΔHfus = 28.54 J g−1) and water (melting point = 0 °C and ΔHm = 333.5 J g−1). To avoid water condensation, nitrogen gas was continuously flushed through the calorimeter head at a rate of 50 mL min−1. About 10.0 mg was placed in a hermetic aluminum pan (20 μL), which was placed inside the calorimeter and frozen to a temperature of −90 °C. The samples were then heated to 25 °C at a heating rate of 5 °C min−1. An identical empty pan was used as reference. The freezing and melting properties, including the freezing temperature (Tf), freezing enthalpy (ΔHf), onset melting temperature (Tm,o), peak melting temperature (Tm,p), endset melting temperature (Tm,e), melting enthalpy (ΔHm) and glass transition temperature (Tg), were determined on fresh dough samples and calculated using associated software (Universal Analysis 2000, New Castle, USA). As done for rheological measurements, all DSC measurements were carried out before the leavening phase, just after the dough was prepared.

Bread making

The dough was put into a pre-heated (210 °C, 20% relative humidity, 25 min) automatically controlled static convection oven (Rational AG, Landsberg, Germany). The containers with the bread were withdrawn from the oven, and let to cool down to warm temperature. At this point, the breads were removed from the containers and allowed to cool down to room temperature, after which they were put into waterproof plastic bags. For reference, the breads were coded as B0 for the basic recipe (i.e., not GF was added), and B5, B10 and B20 for dough containing 5, 10 and 20% (w/w) of GF, respectively.

Scanning electron microscopy (SEM) of bread variations

The morphology of bread was evaluated using a scanning electron microscope (JEOL JMS 7600F, Akishima, Japan). Samples were directly mounted on circular aluminum stubs with double-sided adhesive carbon tape, followed by the gold coated for 100 s, then examined at an accelerated voltage of 15 kV at room temperature with LM mode. Micrographs at 100× magnification were presented.

Thermal characterization of bread variations

The equipment described in Subsection 2.4 was used for thermal analysis of bread variations. To this end, samples (10.0 ± 1 mg) of each bread variations were hermetically closed in aluminum pans and heated in a calorimeter from 25 to 100 °C at constant rate 10.0 °C/min. Empty aluminum pan was used as reference. Temperatures (To–onset, Tp–peak, Te–endset) and enthalpy of thermal transitions (ΔH) were determined with the use of instrument’s software Universal Analysis 2000 (New Castle, DE, USA). Enthalpy values were expressed as J g−1.

Weight, width, volume, color and moisture content

Weight of bread loaves was determined with an electronic weighing balance and width of bread loaves was measured using a tape measure. The volume of bread (cm3) was determined using the rapeseed displacement method (AACC 2000).

Color of the crust of each bread loaves was analyzed using Hunter Lab Colorimeter Model 45/0L (Hunter Associates Lab., Indiana, USA). The color parameters L*, a* and b* are measures of lightness, redness/greenness and yellowness/blueness, respectively. To this end, the instrument was calibrated against a standard white tile (L* = 97.63, a* = 0.78 and b* = 0.25).

Moisture content of the crust was measured using the AACC method (AACC 2000). 3 g of sample was dried in an oven at 130 °C for 1 h. After cooling in a desiccator, the dried sample was weighed.

Texture profile analysis (TPA) of bread variations

Texture profile analysis (TPA) of bread crumb was performed using a Brookfield CT3-4500 texturometer (Massachusetts, USA) at the compression rate 1.0 mm s−1 (loaves used for analysis in the following 3 and 72 h were stored in plastic bags at 25 ± 2 °C, humidity 60%). Sample of bread crumb, taken from the center of the loaf with a height 2.0 cm was pressed to reach 40% deformation by a TA25/1000 aluminum cylinder probe (diameter = 50.8 mm, length = 20 mm), in two cycles with a 2 s delay. The resulting hardness, adhesiveness, resilience, cohesiveness, springiness, and chewiness of the crumb were used as indicators of textural changes during storage. The calculations were performed using the attached software TexturePro CT (Brookfield, Massachusetts, USA). The analysis was performed after 3, 24 and 72 h after baking.

Thermogravimetric analysis (TGA)

Staling is a complex phenomenon occurring in bread during aging. It involves both chemical and physical changes in crumb and crust. Amylopectin retrogradation and amylose–lipid complex formation have been recognized as two main mechanisms involved in bread staling (Gray and Bemiller 2003). In this regard, the strength and extension of water binding play an important role in the rate of bread staling. TGA has been used for characterizing the staling behaviour of bread, finding that water diffusion between binding sites determines to a large extent the staling rate (Schiraldi et al. 1996). The loss of binding water due to diffusion mechanisms leads to important rearrangement of the bread microstructure as amylopectin retrogradation due to water depletion is present. Given that water loss is an important factor in bread staling, this work used drying kinetics from TGA at constant temperature conditions as a mean for characterizing staling kinetics of the different bread variations. Commonly, bread is stored by consumers at room temperature (about 15–18 °C), under which bread staling takes about 24–72 h. Here, staling was accelerated by using a higher temperature to speed-up the diffusion of the water from the bread microstructure to the environment. The experimental runs were carried out as follows. Cubic samples of about 0.5 cm of length were extracted from the center of the crumb region of the different bread variations. Drying experiments were performed at 30 °C using a thermogravimetric analyzer (TGA, 2950, TA Instruments, New Castle, USA). The TGA was equipped with an infrared furnace to provided precise temperature control. The flow rate of carrier gas (nitrogen) was kept at 100 mL/min. A computer connected to the thermogravimetric analyzer automatically recorded the changes in weight, and then processed the data. All experiments were replicated three times for each bread formulation and averages of weight loss were used. The moisture ratio \( MR \) was calculated using the following equation:

where \( MR \) is the moisture content at any time, \( W_{0} \) is the initial weight and \( W_{e} \) is the equilibrium weight. The \( W_{e} \) values were obtained from the drying curves and were estimated when the sample weight became constant during the drying time.

Determination of water effective diffusivity

The Fick’s second law of diffusion is commonly used to describe the drying process of biological materials. To this end, it is assumed that internal mass transfer controls the drying dynamics. The differential equation describing the drying dynamics is given by

The mathematical solution of this equation is given in terms of an infinite series as follows:

where \( L \) is a characteristic length of the sample. When sample shrinkage is negligible and initial moisture content is uniform is assumed, Eq. (2) is suitable for determining the effective diffusivity. However, the numerical fitting (via the solution of a least-squares problem) is not an easy task. A simple approach consists in taking only the first term of the series in Eq. (3), so that one obtains the following approximation (Vega-Gálvez et al. 2010):

Based on this expression, a plot of \( \ln \left( {MR} \right) \) versus time leads to a straight line with slope \( k_{eff} = \frac{{\pi^{2} D_{eff} }}{{4L^{2} }} \). Hence, the estimate of the effective diffusivity is given by \( D_{eff} = \frac{{4L^{2} k_{eff} }}{{\pi^{2} }} \). However, this approach might led to poor fitting results, so that it is better to use Eq. (3) with a finite number of exponential factors to estimate the effective diffusivity.

Statistical analysis

Data were analyzed using a one way analysis of variance (ANOVA) and a Tukey’s test for a statistical significance P ≤ 0.05, using the SPSS Statistics 19.0.

Results and discussion

Dough viscosity

Figure 1a presents the dependence of the apparent viscosity of the dough formulations on shear rate. The apparent viscosity increased with GF content, which was consistent with previous results obtained for dough containing pregelatinized starch fractions (Onyango et al. 2010a; Hesso et al. 2014). Three behaviors can be distinguished: (a) a shear-thickening region for small shear-rate values, up to about 2.3 × 10−4 s−1. The apparent viscosity showed a slight increase induced by the jamming of particles and microstructure compaction (Hoffman 1998). (b) A newtonian-like region in the range from 2.3 × 10−4 to about 0.01 s−1. Here, the apparent viscosity was nearly constant, which reflected a stabilization of the dough microstructure as the shear stress was applied. This viscosity plateau was far right for D0 and moved left as the GF fraction was increased. This suggested that the GF (mainly amylose chains) acted as a lubricant between the particles and aggregates dispersed in the dough bulk. (c) A shear-thinning region for high shear-rate values (Singh et al. 2007). Although the apparent viscosity was increased with the GF fraction, not significant differences were found for shear-rate values higher than 1.0 s−1 (Fu et al. 2016). This indicated that the GF fraction had only a marginal effect in the flow pattern for high shear rate conditions, which may be due to the dominance of the elastic microstructures linked to the gluten fraction of the wheat flour. The pregelatinized starch added to the wheat flour acted as a hydrocolloid dispersed in the dough bulk. It has been reported that hydrocolloids (e.g., sodium alginate, xanthan gum and hydroxypropylmethylcellulose) improved dough stability by strengthening the microstructure. Viscosity was increased due to the hydroxyl groups in the hydrocolloid structure, which allowed more water interactions through hydrogen bonding (Rosell et al. 2001). In this way, hydrocolloids added to dough have the ability of dispersing and absorbing more water as compared to native starch (Ortolan et al. 2015). According to Li and Nie (2016), the viscosity of the pregelatinized starch contained in colloidal suspensions was increased by the thickening of the liquid phase attributed to liquid absorption and resultant swelling of the dispersed colloid.

Dough viscoelasticity

Figure 1b, c show the storage (G′) and loss modules (G″) as function of strain for 1.0 rad s−1 oscillation. These results provided valuable insights of the microstructure changes as the dough deformed. In this regard, three regions can be observed: (a) For small deformations, up to 1% strain, the modules were nearly constant, suggesting that the microstructure was unaltered by the action of the oscillatory shear stress. This region corresponded to the linear viscoelastic behavior where the modulus G′ and G″ did not depend on the magnitude of the strain (Mariotti and Alamprese 2012). The reduction of the storage modulus G′ started to occur above 1% strain, indicating the breakdown of the dough structure. (b) A gradual decay can be observed for higher deformations. The reduction of the shear stress for high deformations can be attributed to the alignment of the dough microstructure along the deformation direction. (c) The fast modules decay for strain values higher than 500% can be due to the breakage of particle aggregate dispersed in the dough bulk. In turn, this led to a fragmentation of the dough microstructure. The above effects were magnified by the addition of GF with storage and loss modules increased with the GF fraction. It was apparent that, similar to particle-filled hydrogel composites (Yanagioka and Frank 2008), the GF acted as a hydrocolloid entrapping the particles dispersed in the dough bulk. GF fraction formed a 3D network where the different dough fractions were dispersed, resulting in highly consolidated dough microstructure with improved elastic properties (Zhang et al. 2015). (d) Fig. 1d exhibits the loss factor tan (δ) = G″/G′. A solid-like behavior (tan (δ) < 1) was observed for strain values as higher as 200%, which was a typical behavior of wheat flour (Tao et al. 2016). The transition (tan (δ) = 1) to a liquid-like behavior was not affected by the GF fraction, although the loss factor value was smaller as the GF fraction increased. This suggested that the GF fraction improved the elasticity of the dough microstructure. This was consistent with previous reports showing an increasing contribution of the elastic component in dough with higher amount of hydrocolloids (Rosell et al. 2001).

Freezing and melting properties of doughs

At commercial scales, dough are prepared and stored at freezing temperatures to enhance the shelf life (Räsänen et al. 1998). An interesting issue was the modification of the freezing and melting properties as affected by the GF addition. Water molecules were trapped into the dough microstructure, achieving freezing at temperature below 0 °C. The sharp rise of the exothermic heat flow indicated that a fraction of the water molecules was freezable. On the other hand, the subsequent smooth decrease of the heat flow is linked to ice formation within the network formed by the dough components. Contrarily, the dough melting did not exhibit a sharp change, but instead a gradual transformation from ice to free water at temperatures above 0 °C. In the freezing process, phase separation occurs upon formation of ice crystals from free water. Upon melting, syneresis occurred because free water can be easily released from the dense network (Karim et al. 2000). The freezing-melting process is not reversible since water rearrangement can occur during the freezing phase. Table 1 presents the freezing and melting parameters for the different dough variations. The following comments are in order: (a) The freezing temperature (Tf) showed a slight decrease with the GF addition. In fact, the decrease was to the extent of 0.37 °C from D0 to D20. This suggested that the correlative properties of freezable water were not affected by the presence of GF components, mainly amylose. (b) In contrast, the freezing enthalpy ΔHf exhibited a huge decrease from 39.48 to 12.89 J g−1. The freezing temperature was related to the proportion of freezable water in the dough matrix. This way, GF addition reduced the free water proportion by improving the compactness of the dough network. It has been postulated that amylose in starch granules has a tight helical conformation which was maintained by intramolecular hydrogen bonding. Upon gelatinization, intramolecular hydrogen bonds were replaced with intermolecular hydrogen bonds, resulting in stronger elastic gels (McGrane et al. 2004). A fraction of the added water was trapped into these intermolecular hydrogen bonds, which was reflected as an effective reduction of free water by the effect of the GF addition. (c) The onset melting temperature Tm,o suffered only a slight negative displacement of about 1.75 °C from D0 to D20. However, the peak temperature Tm,p was reduced from −1.63 to −6.83 °C. Also, the endset melting temperature decreased from 9.46 to 5.40 °C. In turn, the melting temperature range (Tm,e–Tm,o) varied from 34.46 °C for D0 to 32.25 °C for D20, suggesting a more homogeneous ice crystal formation with the incorporation of GF. (d) Paralleling the freezing enthalpy, the corresponding melting enthalpy also decreased with the GF addition, supporting the idea that the gelatinized fraction reduced the proportion of freezable water in the dough network. The changes in glass transition temperature (Tg) of frozen foods were strongly dependent on interactions with freezable water (Reid et al. 1994). The freezable water content and glass transition temperature were decreased from −16.58 to −25.74 °C with the GF addition (Table 1). In the food industry, water is recognized as the most important dispersing medium contributing to sensory, processing and storage properties. Generally, the presence of water in food matrix is defined according to its response to freezing. During freezing, only freezable water crystallizes into ice, whereas unfreezable water undergoes no changes (Ding et al. 2015).

Bread morphology

Figure 2a–d present images of the bread variations, from B0 to B20, respectively. The basic bread B0 exhibited a typical shape, with a height-to-width ratio of about 0.9. The addition of GF reduced this ratio, with about 0.71 for B20. This effect can be attributed to the formation of a stronger dough network that limits the mobility of gases and dough components. Similar effects were observed for other bread variations, including sorghum-based bread with pregelatinized cassava starch (Onyango et al. 2011), and in degassed pound cakes supplemented with pregelatinized wheat starch (Hesso et al. 2014). It seems that the shape and size of the bread was negatively affected by the addition of hydrocolloid components into the dough formulation. In fact, the relative height of the breads relative to the control bread B0 were 96.4 ± 0.3%, 89.4 ± 0.4% and 76.8 ± 0.7% for B5, B10 and B20, respectively. The gelatinized fraction may have been critical for the formation of a cohesive network to prevent the escape of carbon dioxide and collapse of the gas cells. In turn, this led to the formation of a finer crumb structure with a more heterogeneous distribution of porous size. For a better assessing of this feature, Fig. 2e–h present the respective SEM images of the bread crumb. Bread B0 in Fig. 2e exhibited large gas cells distributed within a homogeneous matrix. As the GF fraction was increased (Fig. 2f–h), the crust exhibited a more heterogeneous distribution of gas cells, with an unevenly porous distribution. In the presence of GF, the pores appeared to be slightly smaller as compared to B0. It has been pointed out that high amounts of pregelatinized starch in sorghum-based breads had negative effect on the crumb structure of bread (Hugo et al. 2000). The uneven distribution of gas cells were probably caused by stiffness of the dough as caused by a strong network induced by the GF addition (Schober et al. 2005).

Thermal properties of bread variations

Table 1 presents the thermal properties of the bread variations. The endothermic heat flow pattern (not shown) exhibited with a wide band. This band moved right as the GF proportion was increased, as indicated by the onset, peak and end temperatures in Table 1. The bread crumb was more compact as the GF fraction was increased (Fig. 2e–h). In turn, this suggests that the GF fraction enhanced the ordering of the dough components in the bread making phase. In this way, higher peak temperatures are related to more ordered microstructure. On the other hand, the enthalpy decreased with the GF fraction since this component was already deconstructed during the gelatinization process. In turn, smaller enthalpy value indicates that the baking process involves lower thermal requirements.

Weight, width, volume, color and moisture content

The weight, width, volume, color and moisture content of control and modified breads were evaluated (Table 2). The control bread B0 showed the lowest weight and the highest volume. In contrast, the weight increased and the volume decreased with incorporation of GF. This effect was also displayed by breads incorporated with fiber and was possibly resulted from a weakening effect caused by added GF on dough structure and subsequently a reduction of CO2 gas retention (Sangnark and Noomhorm 2004).

Breads containing GF showed higher moisture content. This increase suggested that a large amount of water was bound when GF was added into the bread. In fact, strong water binding can be associated with interactions between water and hydroxyl and carbonyl groups of the gelatinized starch, as well as to amine groups of flour proteins.

Slight differences in color were observed between the control bread Bo and the breads containing GF. The lightness (L* value) of breads decreased with the addition of GF. The detected a* values indicated that breads with GF exhibited different intensity of redness (positive a* values). A change in positive b* value is related to variations of yellowness. Table 2 showed that yellowness decreased with the GF content. Yellowness changes might be induced by the gelatinized fraction, which exhibited a gray-like appearance during preparation. It should be mentioned that other coloration mechanisms can be also linked to Maillard and caramelization reactions (Purlis and Salvadori 2009).

Texture profile analysis (TPA) of bread variations

Table 3 presents the textural analysis of the fresh and staled (after 24 and 72 h) breads. Hardness increased with GF fraction, indicating that gelatinized fractions induced a more robust bread structure. The addition of GF resulted in increase in chewiness. This suggests that the structural properties observed for the dough variations were retained in terms of texture properties after the baking phase. The positive effect of the GF addition was observed for the bread after 72 h of staling. In fact, hardness increased about 800% for D0, and about 390% for D20. Chewiness is related to the energy required to masticate food and is a product of hardness, cohesiveness and springiness. Chewiness increased about 530% for D0, and about 330% for D20 after 72 h. Cohesiveness is an indicator of the cohesion of the material, breads with low cohesiveness are more susceptible to crumble and fracture (Onyango et al. 2010b). From a practical viewpoint, breads with relatively high cohesiveness desirable. The GF fraction had not effect on the cohesiveness of the bread. However, the bread cohesiveness decrease from 0.67 to 0.47 after 72 h of staling. In contrast, breads containing GF retarded the cohesiveness degradation. In fact, the cohesiveness of the bread (B20) was unaltered after the staling. A reduction of springiness reflected the loss of elasticity. The results in Table 3 showed that springiness of B0 was reduced after 24 and 72 h, while this increased for bread containing GF.

TGA and water effective diffusivities

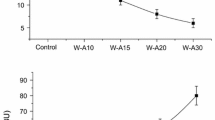

Figure 3a presents the drying curves obtained from TGA of the breads containing different levels of GF. The drying kinetics exhibits an apparent monotonous decreasing behavior with the control bread B0 displayed the highest weight loss. In contrast, the weight loss decreased with the incorporation of GF. Table 2 shows that all bread have similar weight. This feature in conjunction with the drying pattern in Fig. 3a suggests that the gelatinized gel enhanced the water binding within the bread microstructure. Equation (3) was used to estimate the effective diffusivity of water during the drying dynamics of the different bread variations. To this end, twenty (i.e., n = 20) terms were used in Eq. (3) and the results are exhibited in Fig. 3b. The effective diffusivity decreased with the content of GF. This indicates that GF induced a stronger binding of water in the bread microstructure, which might be attributed to the retention of water within the gelatinized amylose network expanding along the dough body.

a Drying kinetics as obtained from TGA. b Effective diffusivity of water estimated with Eq. (3) with twenty exponential factors

Conclusion

This work proposed to use gelatinized flour as a hydrocolloid to modify the dough rheology and to improve the bread textural characteristics. The gelatinized flour fraction was incorporated in the dough formulation as an alternate to spray dried pregelatinized starch. The dough viscoelasticity increased with the gelatinized flour incorporation, while the freezing and melting dough characteristics were enhanced. The results indicated that the gelatinized flour fraction acted as a binder that improved the dough capacity to retain water. Besides, texture analysis indicated that the gelatinized flour fraction retarded the bread staling as reflected by slower increase of hardness and decrease of cohesiveness relative to the basic bread.

References

American Association of Cereal Chemists, AACC (2000) Approved methods of the AACC. AACC, Minnesota

Ding X, Zhang H, Wang L, Qian H, Qi X, Xiao J (2015) Effect of barley antifreeze protein on thermal properties and water state of dough during freezing and freeze-thaw cycles. Food Hydrocolloid 47:32–40

Fu ZQ, Che LM, Li D, Wang LJ, Adhikari B (2016) Effect of partially gelatinized corn starch on the rheological properties of wheat dough. LWT-Food Sci Technol 66:324–331

Gray JA, Bemiller JN (2003) Bread staling: molecular basis and control. Compr Rev Food Sci F 2(1):1–21

Hesso N, Loisel C, Chevallier S, Le-Bail A (2014) Impact of pregelatinized starches on the texture and staling of conventional and degassed pound cake. Food Bioprocess Technol 7(10):2923–2930

Hoffman RL (1998) Explanations for the cause of shear thickening in concentrated colloidal suspensions. J Rheol 42(1):111–123

Hugo LF, Rooney LW, Taylor JRN (2000) Malted sorghum as a functional ingredient in composite bread. Cereal Chem 77(4):428–432

Karim AA, Norziah MH, Seow CC (2000) Methods for the study of starch retrogradation. Food Chem 71(1):9–36

Lee JK, Lim JK (2013) Effects of pregelatinized rice flour on the textural properties of gluten-free rice cookies. J Korean Soc Food Sci Nutr 42(8):1277–1282

Li JM, Nie SP (2016) The functional and nutritional aspects of hydrocolloids in foods. Food Hydrocolloid 53:46–61

Mariotti M, Alamprese C (2012) About the use of different sweeteners in baked goods. Influence on the mechanical and rheological properties of the doughs. LWT-Food Sci Technol 48(1):9–15

McGrane SJ, Mainwaring DE, Cornell HJ, Rix CJ (2004) The role of hydrogen bonding in amylose gelation. Starch-Stärke 56(3–4):122–131

Miller RA, Maningat CC, Hoseney RC (2008) Modified wheat starches increase bread yield. Cereal Chem 85(6):713–715

Miyazaki M, Van Hung P, Maeda T, Morita N (2006) Recent advances in application of modified starches for breadmaking. Trends Food Sci Tech 17(11):591–599

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2010a) Batter rheology and bread texture of sorghum-based gluten-free formulations modified with native or pregelatinised cassava starch and α-amylase. Int J Food Sci Tech 45(6):1228–1235

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2010b) Rheological and baking characteristics of batter and bread prepared from pregelatinised cassava starch and sorghum and modified using microbial transglutaminase. J Food Eng 97(4):465–470

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011) Rheological and textural properties of sorghum-based formulations modified with variable amounts of native or pregelatinised cassava starch. LWT-Food Sci Technol 44(3):687–693

Ortolan F, Brites LTG, Montenegro FM, Schmiele M, Steel CJ, Clerici MTPS, Almeida EL, Chang YK (2015) Effect of extruded wheat flour and pre-gelatinized cassava starch on process and quality parameters of French-type bread elaborated from frozen dough. Food Res Int 76:402–409

Pongjaruvat W, Methacanon P, Seetapan N, Fuongfuchat A, Gamonpilas C (2014) Influence of pregelatinised tapioca starch and transglutaminase on dough rheology and quality of gluten-free jasmine rice breads. Food Hydrocolloid 36:143–150

Purhagen JK, Sjöö ME, Eliasson AC (2008) Staling effects when adding low amounts of normal and heat-treated barley flour to a wheat bread. Cereal Chem 85(2):109–114

Purhagen JK, Sjöö ME, Eliasson AC (2011) The use of normal and heat-treated barley flour and waxy barley starch as anti-staling agents in laboratory and industrial baking processes. J Food Eng 104(3):414–421

Purhagen JK, Sjöö ME, Eliasson AC (2012) The anti-staling effect of pre-gelatinized flour and emulsifier in gluten-free bread. Eur Food Res Technol 235(2):265–276

Purlis E, Salvadori VO (2009) Modelling the browning of bread during baking. Food Res Int 42(7):865–870

Räsänen J, Blanshard JMV, Mitchell JR, Derbyshire W, Autio K (1998) Properties of frozen wheat doughs at subzero temperatures. J Cereal Sci 28(1):1–14

Reid DS, Kerr W, Hsu J (1994) The glass transition in the freezing process. J Food Eng 22(1–4):483–494

Rosell CM, Rojas JA, De Barber CB (2001) Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloid 15(1):75–81

Sangnark A, Noomhorm A (2004) Chemical, physical and baking properties of dietary fiber prepared from rice straw. Food Res Int 37(1):66–74

Satin M (1988) Bread without wheat. New Sci 28:56–59

Schiraldi A, Piazza L, Riva M (1996) Bread staling: a calorimetric approach. Cereal Chem 73(1):32–39

Schober TJ, Messerschmidt M, Bean SR, Park SH, Arendt EK (2005) Gluten-free bread from sorghum: quality differences among hybrids. Cereal Chem 82(4):394–404

Seyhun N, Sumnu G, Sahin S (2005) Effects of different starch types on retardation of staling of microwave-baked cakes. Food Bioprod Process 83(1):1–5

Singh J, Kaur L, McCarthy OJ (2007) Factors influencing the physico-chemical, morphological, thermal and rheological properties of some chemically modified starches for food applications—A review. Food Hydrocolloid 21(1):1–22

Tao H, Wang P, Ali B, Wu F, Jin Z, Xu X (2016) Fractionation and reconstitution experiments provide insight into the role of wheat starch in frozen dough. Food Chem 190:588–593

Vega-Gálvez A, Miranda M, Díaz LP, Lopez L, Rodriguez K, Di Scala K (2010) Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresource Technol 101(19):7265–7270

Yanagioka M, Frank CW (2008) Effect of particle distribution on morphological and mechanical properties of filled hydrogel composites. Macromol 41(14):5441–5450

Zhang Z, Zhang R, Decker EA, McClements DJ (2015) Development of food-grade filled hydrogels for oral delivery of lipophilic active ingredients: pH-triggered release. Food Hydrocolloid 44:345–352

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Carrillo-Navas, H., Guadarrama-Lezama, A.Y., Vernon-Carter, E.J. et al. Effect of gelatinized flour fraction on thermal and rheological properties of wheat-based dough and bread. J Food Sci Technol 53, 3996–4006 (2016). https://doi.org/10.1007/s13197-016-2399-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2399-1