Abstract

The effects of two heat processes mild-temperature pasteurization (MTP: 75 °C, 23 s) and high-temperature pasteurization (HTP: 92 °C, 5 s) on undesirable brown color development and some quality attributes (pH, soluble solids content, and color parameters) of pasteurized tomato juice were evaluated and compared during 94 days of storage at 5 °C. Although both heat treatments combined with refrigeration prevented microbial growth for 64 days, the shelf life regarding acceptable microbial load of HTP-treated sample was higher than 94 days. Both processes produced lesser brown color formation in tomato juices than the commonly adopted thermal treatments although the MTP processing provides better color preservation than the HTP one. No effect of heat treatments on soluble solids content was observed while the HTP processing slightly increased the acidity of pasteurized tomato juice. The good relationship obtained between brown color and total color difference (TCD) suggests that TCD can be used to evaluate the visual color deterioration and browning in thermally processed tomato juice throughout refrigerated storage. Results presented in this study showed that the combination of a mild heat treatment plus refrigeration may help to ensure the microbiological safety and the nutritional value of pasteurized tomato juices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tomato (Solanum lycopersicum L.) is a primary source of bioactive micronutrients such us carotenoids, phenolic compounds, vitamin C, and folates [1–3] that are considered to be beneficial for human health providing protection against some types of cancer and coronary heart diseases [4, 5].

Although tomatoes are commonly consumed fresh in many forms, a large part of the world’s tomato crop is processed into tomato juice and other popular products. Thermal processing is the most common method to extend the shelf life of tomato juice by inactivating microorganisms and pectolytic enzymes. However, conventional heating processes often lead to flavor losses, browned color, and nutritional degradation [6]. Current industry practice frequently uses ultra high-temperature (UHT) short-time treatments to assure the destruction of natural microbiota and juice stability [7], although undesirable changes of organoleptic properties and in the levels of antioxidants and many other health-related compounds are potentially induced [8, 9].

Newer processing technologies like ohmic heating (OH) [10], sonication [11] and thermosonication (TS) [12], high hydrostatic pressure (HHP) [13], and high-intensity pulsed electric fields (HIPEF) [14, 15] may have the potential to change the method of heating and reduce or even eliminate heat treatment. This modern technology could be actually considered as a potential alternative to conventional heat treatments of tomato juice. Therefore, the exploration of techniques as homogenization [16] that is not frequently used by the processing industry and the optimization of time/temperature pasteurization process still are a great challenge.

The aim of the present work was to evaluate the effects of two high-temperature short-time (HTST) processes on inactivation of naturally occurring microorganisms and some quality attributes (pH, soluble solids content, brown pigment formation, and CIE Lab color parameters) of pasteurized tomato juice. In addition, the effect of storage at different temperatures on microbial growth and quality parameters was also investigated.

Materials and methods

Juice preparation

Red intense tomatoes (6 kg) from the commercial cluster-type cultivar ‘Pitenza’, harvested in Almería (Spain) in autumn 2008, were washed with water to remove residues and extraneous matter, adhering to the fruit. Tomatoes were cut in quarters and tomato juice was produced using an automatic sieve-juicer (Vitabar®, Robot Coupe USA, Inc., Jackson, Mississippi) with high-speed pulp extraction which could separate seeds and peel from the tomato pulp. The juice (~3.3 L) was then passed through a vibratory 40-mesh (0.42 mm) screen, dispensed in 15 mL volumes into sterile screw cap boiling tubes (100 × 20 mm), and immediately processed by heating.

Thermal treatments

Heat pasteurizations were applied at two temperatures 75 (23 s) and 92 °C (5 s). For each temperature, twelve screw cap boiling tubes containing 15 mL of raw tomato juice were preheated in an oil bath set to 110 °C to reach the designated temperature in less than 1 min with manual agitation and were then immediately transferred to an oil bath with immersion circulator HAAKE DC5 (Gebrüder HAAKE GmbH, Karlsruhe, Germany) preheated to the designated temperature, that is, 75 or 92 °C. Timing was started when the geometric center of the sample attained the desired temperature. Tubes were removed at predetermined time intervals (5 and 23 s) dependent on the temperature used. They were quickly cooled in an ice-water bath until the temperature of the sample was below 10 °C.

Microbiological analysis

To determine the number of microorganisms in raw tomato juice before heat treatment, samples were tested for total mesophilic aerobic plate counts (APCs) using the spread-plate technique. Samples (1 mL) were serially diluted in buffered peptone water (PW; Scharlau Chemie, S.A., Barcelona, Spain) to reduce the microbial population sufficiently to obtain separate colonies when plating. Then, 0.1 mL volumes of appropriate dilutions were spread-plated onto duplicate plates of plate count agar (PCA; Scharlau Chemie, S.A.), using a sterile bent glass rod. Plates were incubated at 30 °C for 24–96 h. Enumerations were made with a F37862-0000 Scienceware® colony counter (Bel-Art Products, Pequannock, New Jersey, USA).

Shelf-life study

Replicate samples of raw and heat-treated tomato juice contained in screw cap tubes were stored in a cooled incubator MIR-153 (Sanyo Electric Co., Ltd., Gunma, Japan) at 5, 12, and 25 °C and analyzed for number of microorganisms after 0, 2, 4, 7, 9, 11, 14, 16, 35, 64, and 94 days of storage. From agitated processed samples, 0.1 mL volumes were taken at each time period and total mesophilic APCs were performed as previously described for the microbiological analysis of fresh juice. For untreated samples, serial PW dilutions were made before spread-plating on PCA.

Soluble solids and pH

The total soluble solids expressed as °Brix and pH were measured with an Atago refractometer N-1E (Atago Co., Ltd., Tokyo, Japan) and a micropH 2001 pH meter (Crison Instruments S.A., Alella, Barcelona, Spain), respectively.

Color measurement

The Minolta Chroma meter CR-300 (Minolta Co., Ltd., Chuo-Ku, Osaka, Japan) tristimulus colorimeter was used for color measurements at room temperature using the CIE (Committee International d’Eclairage) L, a, and b color notation system. The instrument was calibrated with a white standard tile (L = 96.94, a = +0.18, b = +1.89). A glass Petri dish (52 mm diameter) containing raw or heat-treated juice was placed above a white tile, and the CIE L (lightness, brightness), a (redness), and b (yellowness) values were determined. The hue angle (h) and the color intensity (C, chroma) were calculated using Eqs. (1) and (2)

The color changes of juices were also expressed as a single numerical value that defines the magnitude of the total color difference (TCD) following Eq. (3)

where, a o, b o, and L o are the CIE Lab values of the untreated fresh or recently pasteurized sample.

Non-enzymatic browning determination

Formation of brown pigments (BPs) was determined by measuring the absorbance at 420 nm (A420) of a centrifuged and filtered juice sample using a Unicam Helios Delta 9423 UVD 1000E spectrophotometer (Cambridge, UK) following the method of Ting and Rouseff [17].

Statistical analysis

Treatments were performed in duplicate, and besides, all the parameters studied were technically determined in duplicate for each storage temperature and time period. Statgraphics® Plus for Windows 3.0 (Statistical Graphic Corp. and Graphic Software Systems Inc., Rockville, Maryland, USA) was used to perform all statistical analyses.

Results

Microbial inactivation

The effect of thermal processing on microbial inactivation is compared to raw tomato juice (Table 1). Overall, both heat treatments reduced naturally occurring microorganisms in tomato juice by at least 3 log cycles, but the high-temperature pasteurization (HTP) process was sufficient to decrease the total APC to a level below the detection limit, that is, no CFU was observed just after treatment.

Effects of thermal treatments on quality parameters

Some physical and physicochemical parameters of the heat-treated and raw tomato juice are shown in Table 2. Raw tomato juice had the lowest soluble solids content among the tomato juices assayed. The pH ranged from 4.27 to 4.22, but no statistically significant differences between raw and heat-treated tomato juices (P > 0.05) were monitored.

Fresh tomato juice was less bright than processed juices, but exhibited higher CIE a and b values than the heat-treated (Table 2). Consequently, fresh juice showed a higher average value of C and lower of h than the thermally treated. The kind of heat treatment applied led to differences on TCD values of tomato juices. Just after treatment, lower TCD was obtained in samples treated by HTP compared to the mild-temperature pasteurization (MTP). Changes in A420 between raw and heat-treated juices were not statistically significant (P > 0.05).

Main factors affecting quality parameters in the short-term storage

Results in Table 3 show the effects of processing and storage on the physical and physicochemical parameters of tomato juice. Heat-treated tomato juices maintained pH and CIE L and b values independently of storage temperature (ST) and time (St). Pasteurization temperature (PT) had a statistically significant effect (P = 0.0433) on CIE a value at the 95 % confidence level. MTP tomato juice showed significantly higher CIE a value (5.5575) compared to HTP-treated (5.3129) during 16 days of storage.

ST (P = 0.0232) and St (P = 0.0000) were the main factors affecting soluble solids content in the heat-treated tomato samples. The refrigerated storage of tomato juice led to significant differences on °Brix (4.6575) in comparison with those juices stored at 12 (4.7388) and 25 °C (4.7263). St provided significant differences on °Brix values of tomato juice throughout storage with that measured immediately after treatments (4.985 °Brix). Changes in tomato juice absorbance were also influenced by ST and St. Tomato samples stored at room temperature (25 °C) exhibited significantly higher absorbance (0.2519) compared to those maintained at 5 (0.1669) and 12 °C (0.1663). Average absorbance increased over the time in MTP- and HTP-treated tomato juices from 0.135 to 0.26, with significant differences between periods.

Microbiological shelf-life study

During storage at 5, 12, and 25 °C of untreated tomato juice samples, very high levels (≥7.45 log CFU/mL) of microbial growth were observed after 9, 4, and 2 days, respectively (Table 4). Stored juice at 25 °C was not sampled after 2 days due to the low consistency of tomato juice, showing separation into pulp and serum fractions (syneresis), gas formation by proliferating microorganisms, and fermentative odor. Weak serum separation was observed after 7 and 9 days of storage at 12 and 5 °C, respectively. Serum separation was further increased throughout the storage of untreated tomato juices.

Microbial count in MTP-treated tomato juice increased to a level higher than 3 log CFU/mL (Table 4) after 94, 16, and 7 days of storage at 5, 12, and 25 °C, respectively. In contrast, microbial growth in HTP-treated juice was almost nil or negligible up to 94 days of storage at 5 °C. In HTP-treated samples stored at 12 and 25 °C, microbial growth was negligible for at least 35 days of storage. If the incubators had worked properly, the shelf life of HTP-treated juice would probably be higher even at room temperature.

Soluble solids and pH in treated juices stored at 5 °C

Table 5 shows the evolution of soluble solids content and pH in the heat-treated tomato juices during refrigerated storage. According to the P values, TP (P = 0.1808) had not a statistically significant effect on ºBrix of tomato juices, while statistical significance of St (P = 0.0031) was indicated. The value determined immediately after heat treatments (4.975 °Brix) was significantly different from the others at the 95 % confidence level. TP (P = 0.0031) and St (P = 0.0157) had statistically significant effects on pH of tomato juices. MTP-treated samples showed significantly higher pH compared to HTP-treated ones (Table 5). Significant differences on pH measurements throughout storage were also found. After 35 days, the mean pH (4.27) of the samples significantly differed from that (4.24) determined at the early stages and end of storage.

Color changes and browning

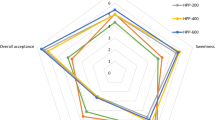

Figure 1 illustrates the overall color changes in thermally stabilized tomato juices throughout storage at 5 °C. Among color parameters, the increase in CIE L value and decrease in CIE a and b values were the characteristic changes in heat-treated samples during cold storage. St was the main factor affecting CIE Lab color parameters (P < 0.001), while PT affected only to the CIE b (P = 0.023). After 94 days cold storage, HTP-treated tomato juice showed a CIE L value increased in 5.8 units and CIE a and b values decreased in 4.6 and 10.1 units, respectively. In other words, the CIE L value increased by 17 % and the CIE a and b values decreased by 80.9 and 31.4 %, respectively. For the MTP-treated juice, the percentages of variation in CIE Lab parameters were 3.8, 26.1, and 14.3 %.

According to the above, St (P < 0.01) was also the main factor affecting the estimated parameters C and h. PT affected only parameter C (P = 0.0249). Lower C average value was obtained in HTP-treated tomato samples compared to the MTP-treated (Table 6). A decrease in C values was observed during the cool storage. Three homogenous groups corresponding to samples from 0 to 16 (32.265), 35 (29.21), and 64–94 (25.774) days of storage showed statistically significant differences for C means at the 95 % confidence level. Significant differences on increasing h values throughout storage were also determined (Table 6). The TCD values, moreover, rose dramatically during storage at 5 °C, reaching the highest values in HTP-treated juice after 64 and 94 days.

Changes in A420 for heat-treated tomato juices during 94 days of storage at 5 °C are exhibited in Fig. 2. The initial A420 value of heat-treated tomato juices increased about 4.5-fold during storage. Changes in tomato juice absorbance were influenced by PT (P = 0.0001) and St (P = 0.0000). HTP tomato juice showed significantly higher A420 value (0.3668) compared to MTP-treated (0.3222) during 94 days of storage. For the St factor, five homogenous groups corresponding to 0 (0.138), 16 (0.209), 35 (0.294), 64 (0.449), and 94 (0.633) days of storage showed statistically significant differences at the 95 % confidence level.

The relationships between the A420 parameter and each of the CIE Lab variables in HTP tomato juice were adequately fitted to a linear model (y = a + bx). A significant positive correlation was found between the A420 and CIE L parameters at the 99 % confidence level (correlation coefficient r = 0.9951; P = 0.0004 < 0.01). In contrast, A420 in HTP tomato juice was negatively correlated with CIE a (r = −0.9903; P = 0.0011) and b (r = −0.9845; P = 0.0023) values. Strong relationships between the A420 and CIE L (r = 0.9751; P = 0.0047), a (r = −0.8741; P = 0.0526), and b (r = −0.9748; P = 0.0048) variables were also found in MTP tomato samples. Similarly, C was negatively correlated with A420 (r > −0.9749; P < 0.005) in both types of thermally treated tomato juice. A close correlation was also noted between A420 and h in HTP tomato samples (r = 0.9986; P = 0.0001). TCD was found to be strongly correlated with A420 either in MTP (r = 0.9781; P = 0.0039) or HTP (r = 0.9897; P = 0.0013) tomato juices.

Discussion

Naturally occurring microorganisms in raw tomato juice are mostly yeasts and molds due to their survival and growth at low-pH environments and use of sugars and vitamins [18]. Krebbers et al. [19] and Nguyen and Mittal [15] reported initial microbial levels of 3.8 and 3.57 log CFU/mL, respectively. In this study, the number of endogenous microorganisms of raw tomato juice (4.5 log CFU/mL) was about 1 log unit higher than those indicated above.

Generally, tomato juice is thermally processed at temperatures from 60 to 100 °C to destroy vegetative microorganisms. Just after MTP and HTP processing, significant inactivation was found (Table 1), but only the HTP treatment resulted in a nil microbial count just after treatment. Although both thermal treatments prevented microbial growth in pasteurized tomato juice stored at 5 °C for 64 days, the shelf life regarding acceptable microbial load of HTP-treated sample was higher than 94 days (Table 4). The ST had a significant effect in controlling the growth of survivors (uninjured and sublethally injured cells) and extending the shelf life of MTP-treated tomato juice. The combination of MTP treatment and refrigeration temperature (5 °C) proved to be efficient inhibiting microbial growth for at least 64 days of storage. This inhibitory effect was maintained for >94 days when the juice was HTP-processed. Besides, the HTP-treated tomato juice was microbiologically stable for at least 35 days at both mild (12 °C) and severe (25 °C) abuse temperatures.

For conventional food preservation systems like mild heat treatment, refrigeration, pH manipulation, low water activity, or addition of inhibitory substances, optimal microbial control is achieved through the hurdle concept [20]. This paper provides an overall preservation strategy for tomato juice, where a thermal technology has been combined with low-temperature storage. One or more thermal and non-thermal processes have been also combined with refrigeration to improving control over foodborne microorganisms while minimizing the intensities of the treatments applied in orange juices [21, 22].

Fruit juice color is a primary factor considered by the consumer in assessing juice quality and sensory acceptance [23]. The color of tomato juice is mainly due to the presence of lycopene, lutein, and total carotenoids. Thus, CIE a and b values, or a combination of them as the red-yellow ratio a/b [14], should be considered as the physical parameters to describe the visual color deterioration. Nevertheless, it is known that any change in CIE a and b values is associated with a simultaneous change in CIE L value. In this study, CIE L values of tomato juice increased and CIE a and b values decreased after the two heat treatments applied (Table 2). Similar changes in the CIE Lab parameters have been reported by Aguiló-Aguayo et al. [24] in thermally treated tomato juice. An increase in CIE L values was also observed during the storage at 5 °C irrespective of the heat treatment conducted (Fig. 1). According to these results, Aguiló-Aguayo et al. [25] and Odriozola-Serrano et al. [26] reported an enhancement of brightness either in heat- or HIPEF-processed tomato juices after prolonged storage under refrigeration conditions. In these studies, furthermore, h values of treated juices increased with the increase of St, which is consistent with the results obtained herein (Table 6).

The TCD has been used to express the visual color changes of tomato juices. Aguiló-Aguayo et al. [24] reported a TCD value of 1.43 ± 0.001 for thermally treated tomato juice at 90 °C for 1 min. This value corresponds to small differences in perceivable color and is lower than those calculated in this work (Table 2) immediately after the HTP and MTP treatments. Although TCD values increased when St did, the application of MTP to tomato juice provided better color preservation than HTP (Table 6) after 94 days of refrigerated storage.

The high TCD values observed through the storage period may be due to the formation of BPs as a result of non-enzymatic reactions and, in particular, from the degradation of ascorbic acid, which provides reactive carbonyl groups as precursors [27]. Min and Zhang [14] reported values of brown color (A420) of 0.34 and 0.29 in thermally (92 °C, 90 s) and commercial-scale PEF-processed tomato juices at 0 days of storage, which are higher than the observed values herein (Table 2). The browning measurements also showed significant increase throughout storage of the pasteurized juice, reaching values ≥0.60 at 84 days. According to this result, at 94 days of storage, MTP- and HTP-treated tomato juices exhibited A420 values of 0.587 and 0.678, respectively (Fig. 2). Moreover, brown color was strongly correlated with TCD (0.9781 ≤ r ≤ 0.9897) as previously reported by Lee and Nagy [28] in stored grapefruit juice (r = 0.939). In the present study, the measure of non-enzymatic browning was performed in clarified tomato juice directly and, probably, carotenoids and BPs were measured together. This fact could explain the good relationship obtained between brown color and TCD. On the basis of this high correlation, TCD was found to be an important predictor of color change and could be used to evaluate the visual color deterioration and non-enzymatic browning in thermally processed tomato juice during refrigerated storage.

Heat processing and storage had little effect on physicochemical properties (ºBrix and pH) of tomato juice. Although statistical differences between fresh and pasteurized juices on soluble solids content were obtained just after treatment (Table 2), heat processing had no significant effect on this property (Table 5). No effect of thermal treatments on ºBrix was also reported by Odriozola-Serrano et al. [26], who determined ºBrix values (5.8–6.0) for fresh and heat-treated tomato juices higher than those found in this work. MTP- and HTP-treated tomato juices showed values of pH (Tables 2, 5) more acidic compared to the pasteurized tomato juices from Odriozola-Serrano et al. [26]. Significant differences between treatments in pH values were observed, suggesting that processing of juice at high temperatures slightly increases its acidity (Table 5). Differences in the pH values observed throughout the storage were not related to spoilage by microbial growth.

Finally, thermal processing affects the nutritional value of food products. Some studies have demonstrated that heat treatments affect the content of several health-related compounds naturally occurring in tomatoes such as lycopene, vitamin C, and folates [8, 16, 29]. In general, although the vitamin C level decreases, pasteurization improves the nutritional value of tomato juice, increasing the extractability of folates and lycopene content. This clear trend of bioactive compounds with moderate-to-intense thermal treatments should not change with more mild heat pasteurizations. Obviously, there will be losses in the content of bioactive compounds during storage irrespective of the temperature maintained.

Conclusions

The MTP treatment combined with refrigeration prevented microbial growth in tomato juice for at least 64 days. Overall results indicated that MTP process produces little BP formation in pasteurized tomato juice without greatly affecting its physicochemical attributes. Additionally, the good relationship obtained between brown color (A420) and TCD suggests that this last could be used to evaluate the visual color deterioration and browning in thermally processed tomato juice throughout refrigerated storage. Likewise, the use of a mild heat treatment combined with cool storage may be proposed as an alternative to the conventional commercial pasteurizations in order to stabilize tomato juices of high quality and high nutritional value.

References

Capanoglu E, Beekwilder J, Boyacioglu D, Hall R, De Vos R (2008) Changes in antioxidant and metabolite profiles during production of tomato paste. J Agric Food Chem 56:964–973

Pennington JAT (2002) Food composition databases for bioactive food components. J Food Comp Anal 15:419–434

Sánchez-Moreno C, Plaza L, de Ancos B, Cano MP (2006) Nutritional characterisation of commercial traditional pasteurised tomato juices: carotenoids, vitamin C and radical-scavenging capacity. Food Chem 98:749–756

Walfisch S, Walfisch Y, Kirilov E, Linde N, Mnitentag H, Agbaria R, Sharoni Y, Levy J (2007) Tomato lycopene extract supplementation decreases insulin-like growth factor-I levels in colon cancer patients. Eur J Cancer Prev 16:298–303

Willcox JK, Catignani GL, Lazarus S (2003) Tomatoes and cardiovascular health. Crit Rev Food Sci Nutr 43:1–18

Gould WA (1992) Tomato juice manufacture. In: Tomato production, processing and technology, 3rd edn. Woodhead Publishing Limited, Cambridge, pp 201–217

Dauthy ME (1995) Vegetable specific processing technologies. In: Fruit and vegetable processing, chap. 9. FAO agricultural services bulletin no. 119. Food and Agriculture Organization of the United Nations, Rome

Iniesta MD, Pérez-Conesa D, García-Alonso J, Ros G, Periago MJ (2009) Folate content in tomato (Lycopersicon esculentum). Influence of cultivar, ripeness, year of harvest, and pasteurization and storage temperatures. J Agric Food Chem 57:4739–4745

Shi J, Dai Y, Kakuda Y, Mittal G, Xue SJ (2008) Effect of heating and exposure to light on the stability of lycopene in tomato purée. Food Control 19:514–520

Onwnka UN, Akobundu ENT, Iwe MO (2008) Kinetics of inactivation of Listeria monocytogen, Clostridium perfringens, Escherichia coli and Salmonella spp. in ohmic heated tomato juices. J Pure Appl Microbiol 2:29–38

Valero M, Recrosio N, Saura D, Muñoz N, Martí N, Lizama V (2007) Effects of ultrasonic treatments in orange juice processing. J Food Eng 80:509–516

Wu J, Gamage TV, Vilkhu KS, Simons LK, Mawson R (2008) Effect of thermosonication on quality improvement of tomato juice. Innov Food Sci Emerg Technol 9:186–195

Mohácsi-Farkas C, Kiskó G, Mészáros L, Farkas J (2002) Pasteurisation of tomato juice by high hydrostatic pressure treatment or by its combination with essential oils. Acta Aliment 31:243–252

Min S, Zhang QH (2003) Effects of commercial-scale pulsed electric field processing on flavour and color of tomato juice. J Food Sci 68:1600–1606

Nguyen P, Mittal GS (2007) Inactivation of naturally occurring microorganisms in tomato juice using pulsed electric field (PEF) with and without antimicrobials. Chem Eng Process 46:360–365

Pérez-Conesa D, García-Alonso J, García-Valverde V, Iniesta MD, Jacob K, Sánchez-Siles LM, Ros G, Periago MJ (2009) Changes in bioactive compounds and antioxidant activity during homogenization and thermal processing of tomato puree. Innov Food Sci Emerg Technol 10:179–188

Ting SV, Rouseff RL (1986) Undesirable substances formed during processing and storage. In: Tannenbaum SR, Walstra P (eds) Citrus fruit and their products. Analysis and technology. Marcel Dekker, New York, pp 175–182

Deak T, Beuchat LR (1996) Yeasts in specific types of foods. In: Deak T, Beuchat LR (eds) Handbook of food spoilage yeasts. CRS Press, New York, pp 61–96

Krebbers B, Matser AM, Hoogerwerf SW, Moezelaar R, Tomassen MMM, van den Berg RW (2003) Combined high-pressure and thermal treatments for processing of tomato puree: evaluation of microbial inactivation and quality parameters. Innov Food Sci Emerg Technol 4:377–385

Leistner L (1999) Combined methods for food preservation. In: Shafiurr Rahman M (ed) Handbook of food preservation. Marcel Dekker Inc, New York, pp 457–485

Bull MK, Zerdin K, Howe E, Goicoechea D, Paramanandhan P, Stockman R, Sellahewa J, Szabo EA, Johnson RL, Stewart CM (2004) The effect of high pressure processing on the microbial, physical and chemical properties of Valencia and Navel orange juice. Innov Food Sci Emerg Technol 5:135–149

Leizerson S, Shimoni E (2005) Stability and sensory shelf life of orange juice pasteurized by continuous ohmic heating. J Agric Food Chem 53:4012–4018

Adekunte AO, Tiwari BK, Cullen PJ, Scannell AGM, O’Donnell CP (2010) Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem 122:500–507

Aguiló-Aguayo I, Soliva-Fortuny R, Martín-Belloso O (2009) Avoiding non-enzymatic browning by high-intensity pulsed electric fields in strawberry, tomato and watermelon juices. J Food Eng 92:37–43

Aguiló-Aguayo I, Soliva-Fortuny R, Martín-Belloso O (2008) Comparative study on color, viscosity and related enzymes of tomato juice treated by high-intensity pulsed electric fields or heat. Eur Food Res Technol 227:599–606

Odriozola-Serrano I, Soliva-Fortuny R, Hernández-Jover T, Martín-Belloso O (2009) Carotenoid and phenolic profile of tomato juices processed by high intensity pulsed electric fields compared with conventional thermal treatments. Food Chem 112:258–266

Kaanane A, Kane D, Labuza TP (1988) Time and temperature effect on stability of Moroccan processed orange juice during storage. J Food Sci 53:1470–1473

Lee HS, Nagy S (1988) Measurement of color changes due to browning in stored grapefruit juices. Proc Fla State Hort Soc 101:154–157

Odriozola-Serrano I, Soliva-Fortuny R, Martín-Belloso O (2008) Changes of health-related compounds throughout could storage of tomato juice stabilized by thermal or high intensity pulsed field treatments. Innov Food Sci Emerg Technol 9:272–279

Acknowledgments

Thanks to European Commission’s Lifelong Learning Programme Leonardo da Vinci, Technofruit Project, for the grant to Mrs. Õznur Hizarci, and Dirección General de Investigación, Spanish Ministry of Education and Science, Project AGL2004-06469/ALI, for the economical support of bench fees and pilot plant cost.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Giner, M.J., Hizarci, Õ., Martí, N. et al. Novel approaches to reduce brown pigment formation and color changes in thermal pasteurized tomato juice. Eur Food Res Technol 236, 507–515 (2013). https://doi.org/10.1007/s00217-012-1900-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-012-1900-y