Abstract

In this study, Streptococcus thermophilus and Lactobacillus bulgaricus were used to produce l(+)-lactic acid by simultaneous saccharification and fermentation (SSF). The use of hydrolyzed yeast as cheap nutrients and mixtures of cellulosic materials and starchy materials as carbon source for l(+)-LA production was evaluated. Heat treatment (121 °C) was proven to be an effective method to improve the performances of yeast as nutrients for the fermentations using different carbon sources. The addition of yeast hydrolyzate obviously lowered the surface tension of medium and improved enzyme hydrolysis of furfural residue (FR) as the concentration was beyond 10 g/L. Carbon–nitrogen ratio, substrates composition, substrates feeding rate and enzyme-feeding strategy will affect the productivity of l(+)-LA production from mixed substrates. SSF of FR and corn saccharification liquid tends to obtain good yields, when the total WIS content is in 10 % and carbon–nitrogen ratio is about 30. This study provides an encouraging means of producing l(+)-LA from lignocellulosic resource and starchy resource, which could optimize the use of raw materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lactic acid (LA) is applied in a wide array of industries because of its unique physicochemical properties, such as safety properties and optical activity [1]. There are two optical isomers of lactic acid, l(+)-lactic acid and d(−)-lactic acid. In recent years, attention has been focused on the great potential of l(+)-LA in manufacture of polylactic acid (PLA), a type of environment-friendly alternative to petrochemicals plastics [2].

Microbial fermentation based on renewable sources is the main way of LA production in industry because it allows pure isomers to be obtained [3]. l(+)-LA can be produced by species such as Lactobacillus rhamnosus and Lactococcus lactis, while d(−)-LA can be produced by species such as Lactobacillus delbrueckii. The starchy materials are the preferred carbon sources used in l(+)-LA production at present [4]. When using starchy materials to produce l(+)-LA, starch is usually pretreated by liquefaction followed by enzymatic saccharification and subsequent fermentation [5]. During those processes, non-starch polysaccharides cannot be used. Cellulase addition and chemical–thermal treatment could be used for conversion of non-starch polysaccharides into fermentable sugar [6, 7]. According to a previous study on economic evaluation of LA production from starchy materials, the costs of raw material, the sodium hydroxide in the fermentation step and the conversion of lactate to LA were found to contribute considerably to the total production cost [5]. The production cost could reach 0.833US $/kg product [5].

Further expansion of the LA industry will depend in part on the availability of low-cost lignocellulosic materials. The bioconversion of lignocellulosic biomass to LA occurs in two steps. The cellulose is first depolymerized by cellulase to produce glucose, which is subsequently fermented to produce LA. Simultaneous saccharification and fermentation (SSF) is preferred process option for LA production from lignocelluloses such as furfural residues (FRs) [8]. As a result of furfural production by hydrolyzing hemicelluloses of corncob, huge amounts of FR are generated annually in China. A potential use could be as raw materials for LA production because FR is rich in cellulose that can be easily hydrolyzed by cellulase [9].

The search for low-cost nutrient sources is some of the most important objectives to be achieved. Recently, spent cells, by-product of ethanol fermentation process, were used as a nutrient source in LA fermentation. Treatments, such as acid treatment, distillation and enzymatic hydrolysis, were used to improve the performance of yeast as nutrients [10–12]. Heat treatment, in the absence of added mineral acids, is desirable for facilitating the production and the recovery of fermentation products. Furthermore, the environmental and recovery side effects are avoided, and no by-products from mineral acid neutralization are produced. Heat treatment was, therefore, investigated in this study.

This paper deals with the fermentative production of l(+)-LA using mixtures of FR and corn saccharification liquid (CR) as main carbon source and yeast hydrolyzate (YH) as nutrients. The objectives were as follows: to optimize treatment conditions for the use of YH; to investigate the effect of YH addition on enzyme hydrolysis of cellulose; to investigate the feasibility of producing l(+)-LA from mixtures of cellulosic and starchy materials and select the best strategy.

Materials and methods

Raw material

FR was kindly provided by Chunlei Company (Xingtai, China) and had been water-rinsed before being used. The average contents of glucan, lignin and ash were 48.17, 43.29 and 6.42 %, respectively. Corn kernels with a starch content of 75.2 % and a protein content of 7.46 % were purchased from COFCO Ltd, in China. Yeast with a protein content of 48.09 % and a glucan content of 18.45 % was S. cerevisiae in the form of dry yeast and purchased from Angel Yeast Company Co., Ltd (Yichang, China).

Microorganisms and enzyme preparation

The microorganism used for l(+)-LA fermentation was freeze-dried lactic acid bacteria (LAB) (Meihua Company, Harbin, China), mainly comprising Streptococcus thermophilus and Lactobacillus bulgaricus. The recommended temperature of the commercial lactic bacteria used is 42–43 °C. In SSF and enzyme hydrolysis experiments, Cellulase (Celluclast 1.5 L, Novozymes) and β-glucosidase (Novozyme 188, Novozymes) were used. Celluclast 1.5 L had an activity of 75 filter paper units (FPU)/mL, measured using the IUPAC protocol [13], and 35 IU/mL β-glucosidase activity according to the method of Berghem and Petterson [14]. Novozyme 188 had a β-glucosidase activity of 174 IU/mL. α-amylase (150 U/g corn) and glucoamylase (20 U/g corn) (Aoboxing Universeen Bio-Tech Company Ltd, Beijing, China) were used for corn liquefaction and saccharification, respectively.

Preparation for corn saccharification liquid (CR) and yeast hydrolyzate (YH)

The saccharification of corn starch was realized by double enzymes method. Corn kernels were liquefied at 85 °C for 2 h using the commercial thermostable α-amylase with an enzyme activity of 4KU/g, followed by several hours of saccharification (pH 4.0, 60 °C) with amyloglucosidase. Before being used, the pH of CR was adjusted to 7.0 with 10 % NaOH.

Nine grams of yeast cells was added into a 180 mL sealed pressure bottle each containing 150 mL distilled water, and the slurry was hydrolyzed at 121 °C (or 100 °C) for a certain time. After cooled, YH was added into medium to achieve a certain concentration.

Enzyme hydrolysis

Enzyme hydrolysis were carried out by using 3 % FR, 30 g/L YH or mixtures of 3 % FR and YH (10, 20 or 30 g/L) as substrates. Enzyme hydrolysis was performed at 45 °C with a shaking speed of 150 rpm in 100 mL Erlenmeyer flasks containing 60 mL medium. The same amount of celluclast 1.5 L and Novozyme 188 was used in all experiments. In enzyme hydrolysis of 3 % FR, the amount of celluclast 1.5 L and Novozyme 188 added was 12.5 FPU and 13.5 IU per gram glucan of FR, respectively.

Fermentation experiments

The fermentation medium for utilization of sole starch materials contained 10 % CR, 10 g/L YH and 42 g/L CaCO3. The fermentation medium for utilization of sole lignocelluloses contained 5 % FR, 10 g/L YH and 30 g/L CaCO3. The fermentation medium for studying carbon–nitrogen ratio contained 9 % CR, 5 % FR, some YH (the concentrations ranged from 0 to 30 g/L) and 100 g/L CaCO3. The fermentation medium for studying substrate composition contained CR (the concentrations ranged from 2.5 to 7.5 %), FR (the concentrations ranged from 2.5 to 7.5 %), YH (0 or 10 g/L) and some CaCO3 (Calcium carbonate was added as 100 % (w/w) of glucose to the medium).

SSF with 5 g/L beef extract could obtain a 98.3 % of LA yield at 144 h, which is higher than that with 5 g/L yeast extract (94.5 %), so beef extract was chosen as control nitrogen source. Fermentation with full medium (KH2PO4, 0.5 g/L; MgSO4·7H2O, 0.5 g/L; NaCl, 0.1 g/L; beef extract, 5 g/L) and fermentation without any supplementations were carried out as control cases. FR and full medium were sterilized (121 °C, 15 min) before loading into the Erlenmeyer flask. The amounts of Celluclast 1.5 L and Novozyme 188 used in SSF were 15 FPU/g and 17 IU/g glucan of FR, respectively. The cellulase, CR and YH were added to the Erlenmeyer flask directly. Fermentations were carried out at 42 °C with a shaking speed of 150 rpm in 100 mL Erlenmeyer flasks containing 60 mL medium. The inoculation amount of all the fermentations was 0.21 % (W/V).

Analytical methods

Glucan and lignin of FR were analyzed according to the standard National Renewable Energy Laboratory (NREL) method [15]. One gram yeast was treated with 3 mL 72 % H2SO4 for 1 h at 30 °C, then diluted to 4 % H2SO4 and autoclaved for 1 h at 121 °C. Sugar contents were analyzed with high-performance liquid chromatography (Waters 2695e, USA) using an Aminex HPX-87P (300 × 7.8 mm: Bio-Rad, USA) at 85 °C and refractive index detection detector at 35 °C. The total starch was determined when the saccharification of corn starch was finished [16]. The total nitrogen content was determined by Kjeldahl nitrogen determination [17]. Protein content was obtained by multiplying the elemental N content by the universal factor of 6.25.

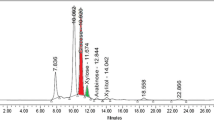

The liquid fraction of YH was diluted by different times before determining its surface tension. A JK99B automatic surface tensiometer (Shanghai, Zhongchen) was used to measure the surface tension to ±0.01 m Nm−1. Tensiometer equipped with a 5 cm Wilhelmy platinum at room temperature (30 ± 1 °C). Extreme care was taken with the platinum plate and experimental vessel. The solutions were equilibrated before running the experiments. The total amount of reducing sugars was measured by dinitrosalicylic acid method [18]. The liquid fraction of the supernatant after hydrolysis and fermentation were analyzed according to an NREL procedure [15]. l(+)-LA was analyzed by HPLC (Waters 2695e, USA) using an Aminex HPX-87H (300 × 7.8 mm: Bio-Rad, USA) at 65 °C and refractive index detection detector at 30 °C. Assays were performed in three repeated experiments, and the mean values are presented. SPSS Statistics 17.0 was used to analyze the data.

Polysaccharide utilization (%) was calculated as follows:

Results and discussion

Lactic acid production from CR with YH as nutrients

The moisture loss during treatment processes was detected to be less than 5 %. Solution containing yeast cells were treated at 121 °C for 10, 30 and 60 min, and YH obtained were labeled YH1, YH2 and YH3, respectively. CR was prepared by 22 h of saccharification. Fermentation using CR as carbon sources and YH as nutrients was carried out. Figure 1 shows the l(+)-LA and reducing sugars profiles. The low production rate and low glucose consumption in fermentation without any supplementations indicated a nutrient limitation in CR. YH addition had a great effect on LA fermentation, and YH2 had the best performance in all cases. Fermentation with YH3 obtained lower yield than that with YH2, which can be considered that longer treatment time lead to more nutrient destruction. Fermentation with YH had higher productivity than that with full medium, which indicated that heat treatment (121 °C) is an effective method.

Enzyme hydrolysis of YH

Enzymatic hydrolysis of YH was carried out, and the results were shown in Fig. 2a. Monomeric sugars were not detected at the beginning of hydrolysis, which indicated that polysaccharide of yeast could not be hydrolyzed during heat treatment. Figure 2a also shows that polysaccharide of yeast can be hydrolyzed to glucose by cellulases and heat treatment makes polysaccharide of yeast cell more accessible to enzymes. Gao et al. [11] proposed a diluted acid-hydrolysis to improve the performance of spent cells. After pH adjustment to 2 by the addition of 3 M H2SO4, the slurry was hydrolyzed at 121 °C for 20 min. Though attention was not focused on polysaccharide hydrolysis of yeast, it could be inferred that polysaccharide hydrolysis happens during the acid-hydrolysis in their study. When glucoses are used to produce LA, acid-hydrolysis is a promising method, which could optimize the use of yeast. However, when lignocelluloses are used in SSF, heat treatment is supposed to be better than acid-hydrolysis. Heat treatment needs less chemicals consumption, and enzyme addition could also realize polysaccharide hydrolysis of yeast.

The influence of the addition of yeast hydrolyzate (YH) on enzymatic hydrolysis of furfural residue (FR) and the surface tension of medium. a Total concentration of glucose during enzyme hydrolysis of FR and YH; b concentration of glucose produced from FR obtained by deducting glucose from YH; c the surface tension of yeast hydrolyzate (YH) with different concentrations

In the ethanol fermentation step of separate hydrolysis and fermentation (SHF) and SSF process, sugars are converted to ethanol, as well as to by-products and yeast [19]. When the solid residues from ethanol fermentation are used for LA production as nutrients, it would be very beneficial to simultaneously use polysaccharide from yeast. To improve the performances of spent cells from ethanol fermentation step as nutrients, distillation could have good performances [10]. However, to improve the access of polysaccharide from yeast to enzymes, more severe conditions are necessary according to this study.

Effect of YH on enzyme hydrolysis of FR

The results of enzymatic hydrolysis of YH were used to deduct glucose from yeast to investigate effect of YH on enzyme hydrolysis of FR, when enzyme hydrolysis was carried out by using mixtures of YH and FR as substrates. Figure 2b shows the probable value of glucose from FR. The addition of YH improved the cellulose hydrolysis of FR significantly, and YH3 had better performance than the other two (Fig. 2b). These interesting results might be attributed to that proteins in YH could prevent unproductive binding of cellulases. The correlation between the amount of YH2 and its effect on hydrolysis was also investigated. Increasing the amount of YH2 slightly decreased the cellulose hydrolysis of FR.

Surfactant addition can improve the enzymatic hydrolysis of various cellulosic materials [20]. Heat treatment destroyed the cell walls of yeast to stimulate the level of protein hydrolysis. Protein is also surface active [21]. To compare with YH obtained at 121 °C, YH obtained at 100 °C for 10, 30 and 60 min was labeled YH4, YH5 and YH6, respectively. As shown in Fig. 2c, the surface tension decreased more sharply with the concentration prior to YH concentration = 10 g/L. Beyond that the decreasing trend is slower. The results indicated that the active effect of YH addition on enzymatic hydrolysis would not be enhanced as its concentration is beyond 10 g/L. The results of enzyme hydrolysis (Fig. 2b) demonstrated this point. Treatment conditions have a significant effect on the surface tension. Higher temperature and longer residence time lead to lower surface tension.

YH is a cheaper addition with the same positive effects as surfactant. The surface tension of YH obtained at 100 °C (YH4, YH5 and YH6) is obviously higher than that obtained at 121 °C (YH1, YH2 and YH3), thus indicating that a temperature of 100 °C is too low to increase the surface activity of YH. The temperature for ethanol distillation is always lower than 100 °C, thus indicating that though distillation can improve the performances of spent cells as nutrients, it could not obviously improve the performances of spent cells as surfactant. An extra advantage of YH is its use as nutrients for further fermentation. Fermentation with YH (121 °C) had higher productivity than that with full medium, which also indicated that a temperature of 121 °C is better treatment temperature than 100 °C. When YH was treated at 121 °C, longer treatment time lead to lower surface tension but more nutrient destruction. A moderate treatment time is optimal.

Lactic acid production from FR

To evaluate the efficiency of the cellulosic fermentation process with YH2, the fermentations with full medium and YH2 were compared. Figure 3 shows the fact that little LA was produced in the medium that only consisted of 5 % FR. When YH2 was supplemented, higher productivity was obtained relative to full medium. This result was probably due to the improvement of YH2 on enzyme hydrolysis and the use of YH as nutrients.

Lactic acid production from mixtures of CR and FR

Cellulase addition could be used for conversion of non-starch polysaccharides in CR and YH into fermentable sugar. YH could improve enzyme hydrolysis of cellulose. It became, therefore, important whether FR, CR and YH could be used in the same system or not.

Effect of saccharification time on lactic acid production

It has been observed that the release of nutrients in starchy LA process is critical and may reduce LA fermentation rate [5]. The level of release of glucose is depended on saccharification time. Therefore, saccharification time is supposed to be an important factor, when starch materials are used as substrates. SSF with mixtures of 5 % FR and 10 % CR prepared by different hours of saccharification (1, 7 and 22 h) was carried out. The results indicated that LA production increased with the saccharification time. However, though completely starch hydrolysis was realized, relative low LA (54.77 g/L) was obtained at 120 h, thus indicating that completely starch hydrolysis could not eliminate the nutrient limitation of CR.

Effect of substrate composition on lactic acid production

YH2 (10 g/L) was used as nutrients in SSF with mixtures of FR and CR. Experiments were carried out to investigated the effect of substrate composition. Without YH2 addition, the final LA yield of SSF with 5 % FR decreased with increasing concentration of CR, which was probably due to high osmotic stress and end-product inhibition (Fig. 4). Without YH2 addition, the final LA yield of SSF with 5 % CR increased with the FR concentration (Fig. 4). YH2 improved the final yield of SSFs mainly due to its use as nutrients and its use as surfactant. YH2 addition increased the yield of SSF with 5 % CR and 2.5 % FR by 70.5 %, while YH2 addition increased that with 5 % CR and 7.5 % FR only by 3.1 % (Fig. 4). The interesting results may be due to that enzymes could also serve as nutrients. This inference could explain that, without YH2, the final LA yield of SSF with 5 % CR increased with increasing the concentration of FR. With YH2 addition, a LA concentration of 40.74 g/L at 120 h, which corresponded to a 87.1 % polysaccharide utilization, was obtained in SSF of 2.5 % CR and 5 % FR (Fig. 5), indicating that the process could optimize the use of raw materials.

Higher carbon–nitrogen ratio could not result higher final concentration of LA [22]. When 10 g/L YH2 was used, carbon–nitrogen ratio decreased with increasing the concentration of CR and FR. When SSF was carried out by using 10 % CR, 5 % FR and 10 g/L YH2, the carbon–nitrogen ratio was 63.25 (The carbon–nitrogen ratio was calculated by taking no account of nitrogen in CR). The high carbon–nitrogen was one of reasons for high residual sugar in SSF of 10 % CR and 5 % FR (Fig. 5). When carbon–nitrogen ratio was about 30, the reducing sugars reached the lowest level, 1.67 g/L (Fig. 5).

Effect of carbon–nitrogen ratio on lactic acid production

Increasing YH2 concentration could improve the carbon–nitrogen ratio. As shown in Fig. 6, LA production was improved by lowing carbon–nitrogen ratio. The limiting step in the overall kinetics of SSF was always LA formation. The carbon–nitrogen ratio decreased from 116.94 to 19.49 with increasing YH2 from 5 to 30 g/L. When 30 g/L YH2 was used, LA reached its highest concentration of 79.50 g/L. Figure 1 shows that LAB used will take more than 100 h to realize the completely sugar consumption in fermentation of 10 % CR. The residual glucose from CR inhibited enzymatic hydrolysis of cellulose. An initial high glucose concentration (from CR) in SSF influences the hydrolysis of cellulose efficiency negatively. Therefore, it is difficult to observe the active effect of YH on enzymatic hydrolysis during SSF.

The potential strategy for lactic acid production from mixtures of CR and FR

Use of novel and cheap nitrogen sources along with CR and FR could lead to design low-cost fermentation media for economic production of LA. YH is an alternative to nature materials. Considering the large amounts of ethanol production, it comes that YH is a kind of competitive nutrition sources. Heat treatment (121 °C) seems to be a novel method because treated YH could also improve enzyme hydrolysis, reduce enzyme loading and shorten residence time. For the purpose of utilization of yeast cells, a 121 °C temperature and 30 min appear to be the best scenario.

Batch mode is the classical form of SSF [23]. SSF of lignocelluloses is always difficult to obtain high final LA concentration because of lignin. Using CR in SSF could improve the final LA concentration and optimize the use of CR. However, a high CR concentration at the beginning of SSF should be avoided to prevent end-product inhibition and osmotic stress to LAB. An initial high FR concentration in SSF should also be avoided to improve mass transfer and reduce inhibition of the fermentation. Though the active effect of YH on enzyme hydrolysis would not be enhanced as the concentration of YH is beyond 10 g/L, an appropriate carbon–nitrogen ratio must be considered to obtain a high productivity of LA. In practice, SSF using batch mode is difficult to achieve good LA yields above WIS contents of 10 % (FR plus CR).

Pre-hydrolysis could decrease the initial viscosity at the start of fermentation based on lignocelluloses. A disadvantage of pre-hydrolysis may be a less efficient fermentation and enzyme hydrolysis due to the higher glucose concentration in the medium [23]. When SSF is carried out by using mixtures of CR and FR, pre-hydrolysis is obviously unnecessary. Therefore, fed-batch mode seems to be the best form of SSF using mixtures of starch materials and cellulosic materials. By not adding all CR at once, the levels of glucose can be kept lower, giving less osmotic stress to LAB. The gradual hydrolysis of added cellulosic materials can avoid mass and heat transfer problems. A suitable feed rate of YH could also reduce the amount of enzyme loading and shorten the residence time for SSF. In addition, the combination of enzyme and substrate feeding is necessary to maintain a high yield from fed-batch SSF [24].

Conclusion

The use of yeast hydrolyzed by heat treatment as cheap nutrients and mixtures of cellulosic materials and starchy materials as carbon source for l(+)-LA production was evaluated. Heat treatment (121 °C, sterilization temperature) was an effective method to improve the performances of yeast as nutrients in starchy LA. Longer treatment time results more serious nutrient destruction but lower surface tension. SSF of lignocellulosic materials was also improved by hydrolyzed yeast due to a combination of increased hydrolysis rate and improved LA fermentation. Carbon–nitrogen ratio, substrates composition, substrates feeding rate and enzyme-feeding strategy will affect the productivity of LA production from mixed substrates. The LAB used in this study are S. thermophilus and L. bulgaricus that are very common in yogurt production. But also there are other commercial lactic bacteria as Oenocous oenos that could be more adapted to media where almost the unique nutrients are dead cell yeast. Developing cheap nutrients source with the same effects as YH is still essential.

Abbreviations

- SSF:

-

Simultaneous saccharification and fermentation

- FR:

-

Water-rinsed furfural residue

- CR:

-

Corn saccharification liquid

- YH:

-

Yeast hydrolyzate

- LA:

-

Lactic acid

- LAB:

-

Lactic acid bacteria

References

John RP, Nampoothiri KM, Pandey A (2007) Appl Microbiol Biotechnol 74:524–534

Wee YJ, Kim JN, Ryu HW (2006) Food Technol Biotechnol 44:163–172

Wang LM, Zhao B, Liu B, Yu B, Ma CQ, Su F, Hua DL, Li QG, Ma YH, Xu P (2010) Bioresour Technol 101:7908–7915

Lu ZD, Lu MB, He F, Yu LJ (2009) Bioresour Technol 100:2026–2031

Akerberg C, Zacchi G (2000) Bioresour Technol 75:119–126

Kim TH, Nghiem NP, Taylor F, Hicks KB (2011) Appl Biochem Biotechnol 164:534–545

Linde M, Galbe M, Zacchi G (2008) Bioresour Technol 99:6505–6511

Marques S, Santos JAL, Girio FM, Roseiro JC (2008) Biochem Eng J 41:210–216

Tang Y, Zhao DQ, Zhu LW, Jiang JX (2011) Eur Food Res Technol 233:489–495

Bustos G, Moldes AB, Cruz JM, Dominguez JM (2004) J Agric Food Chem 52:5233–5239

Gao MT, Hirata M, Toorisaka E, Hano T (2006) Biochem Eng J 28:87–91

Chen KQ, Li JA, Ma JF, Jiang M, Wei P, Liu ZM, Ying HJ (2011) Bioresour Technol 102:1704–1708

Ghose TK (1987) Pure Appl Chem 2:257–268

Berghem LER, Petterson LG (1974) Eur J Biochem 2:295–305

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2004) National Renewable Energy Laboratory, Technical Report NREL/Tp-510-42618 and 42630, CO

McCleary BV, Solah V, Gibson TS (1994) J Cereal Sci 20:51–58

Kjeldahl J (1883) Z Anal Chem 22:366–382

Miller GL (1959) Anal Chem 31:426–428

Wingren A, Galbe M, Zacchi G (2003) Biotechnol Prog 19:1109–1117

Kristensen JB, Borjesson J, Bruun MH, Tjerneld F, Jorgensen H (2007) Enzyme Microb Tech 40:888–895

Sarnthein-Graf C, La Mesa C (2004) Thermochim Acta 418:79–84

Lu ZD, He F, Shi Y, Lu MB, Yu LJ (2010) Bioresour Technol 101:3642–3648

Olofsson K, Bertilsson M, Liden G (2008) Biotechnol Biofuels 1:7

Hoyer K, Galbe M, Zacchi G (2010) Biotechnol Biofuels 3:14

Acknowledgments

The authors are grateful for the financial support of this research from the Fundamental Research Funds for the Central Universities (BLYJ201212), National Science Foundation of China (31070510) and Major State Basic Research Projects of China (973-2010CB732204).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Y., Bu, L., He, J. et al. l(+)-Lactic acid production from furfural residues and corn kernels with treated yeast as nutrients. Eur Food Res Technol 236, 365–371 (2013). https://doi.org/10.1007/s00217-012-1865-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-012-1865-x