Abstract

The impact of Torulaspora delbrueckii has been investigated for the first time in the production of Amarone wine, a high-alcohol dry red wine obtained from withered grapes. In two different vinifications, winery trials were inoculated by a selected strain of T. delbrueckii simultaneously and/or sequentially to Saccharomyces cerevisiae. Implantation analysis demonstrated T. delbrueckii was able to rapidly colonise the must remaining in wine up to 16.5 % v v−1 of ethanol. The effects of T. delbrueckii on the aroma of Amarone wine were linked to its persistence during the fermentation and a great number of compounds varied in wine obtained with mixed cultures. The most significant changes were observed among alcohols, fermentative esters, fatty acids and lactones, which are important in the Amarone wine flavour. This study confirms the role of T. delbrueckii on wine aroma and the potential of non-Saccharomyces use in winemaking.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural fermentation of grape juice is a complex biological process carried out by yeasts belonging to different species conventionally clustered in Saccharomyces and non-Saccharomyces based on the fundamental role that species of the genus Saccharomyces, in primis Saccharomyces cerevisiae, play on the alcoholic fermentation (AF) [1].

Recently, the role of non-Saccharomyces yeasts in the grape fermentation has been revealed due to their contribution to aroma complexity and improved wine quality [2–4]. Multistarter fermentations of several non-Saccharomyces species, such as Hanseniaspora uvarum, Torulaspora delbrueckii, Kluyveromyces thermotholerans, Pichia kluyveri, together with S. cerevisiae have been investigated under different winemaking conditions [5–7]. The positive impact with multistarter fermentation protocols stimulated the investigation and selection of new non-Saccharomyces starters able to carry out AF together with S. cerevisiae [3].

One of the positive reasons for the participation of non-Saccharomyces yeasts in AF is the enhanced production of important aroma molecules that makes the wine bouquet more complex [2, 6, 8, 9].

Torulaspora delbrueckii is one of the most investigated non-Saccharomyces yeasts as a potential co-starter in grape fermentation due to its positive effect on the chemical and sensory character of wine [7, 9–13]. This yeast has potential use in high-sugar fermentation, since its lower production of volatile acidity, and other undesirable volatile compounds, such as hydrogen sulphide and volatile phenols, than S. cerevisiae [10, 12]. Comitini et al. [3] confirmed that the association of both yeasts reduced the volatile acidity, in comparison with the control S. cerevisiae, enhancing also the 2-phenyl ethanol and polysaccharides content in wine. Since T. delbrueckii displayed these positive oenological traits, it was interesting to evaluate the effects of mixed culture of T. delbrueckii and S. cerevisiae in the vinification of Amarone wine. This renowned dry red wine is produced from withered grapes that are slowly dehydrated in lofts during 2–3 months. The specialised microflora, which is established on the grapes in these peculiar conditions, can have great influence on the Amarone wine production, in particular the osmophilic non-Saccharomyces strains (e.g. Candida spp., Zygosaccharomyces spp., Hanseniaspora spp., Metschnikowia spp.) associated with grape infection by mould and high-alcohol-tolerant Saccharomyces strains at the beginning and the end of AF, respectively.

The possibility to modulate the flavour and style of this peculiar raisin wine, by different fermentation strategies, might be appreciated by winemakers and consumers of Amarone wine, as well as by producers of other grape wines.

This study analysed two subsequent vinifications of Amarone wine carried out in two wineries, the simultaneous and sequential inoculation of a selected T. delbrueckii and S. cerevisiae to that of S. cerevisiae. It used a cell pre-adaptation protocol for the T. delbrueckii in order to evaluate the effects of cell adaptation on fermentative performance in harsh winemaking conditions, as previously demonstrated [14]. Implantation and colonisation of starter yeasts in the fermenting must were followed. Analytical profiles of the resulting wines were evaluated and differences in aroma compositions were discussed.

Materials and methods

Vinifications and starter cultures

Two vinifications (V1 and V2) of Amarone wine were carried out in two different wineries using withered Corvina, Rondinella and Corvinone grapes according to the regulation of Valpolicella wine production.

In V1, about 900 kg of grapes were used to prepare a total of 9 trials (100 kg each). After crushing the grapes, the solid fraction (grape pomace) was carefully separated from the juice (pH 3.31, reducing sugars 31.2° brix, total acidity 7.19 g tartaric acid L−1) mixed and subsequently divided in steel tanks of 150 L volume in the proper proportion in order to obtain homogenous trials. The same protocol was used in V2 but the amount of grapes (pH 3.35, reducing sugars 30.3° brix, total acidity 6.95 g tartaric acid L−1) was twice as much (200 kg for each trial in steel tank of 250 L volume). Before the yeast addiction, the grape juice was supplemented with 40 mg L−1 SO2 and 0.4 g L−1 of a nutrient composed of inactivated yeasts, ammonia salts and vitamins (Fermaid E®, Lallemand, Montreal, Canada).

For starter cultures, a Saccharomyces cerevisiae Lalvin EC1118® (Lallemand) and Torulaspora delbrueckii TD291 (Lallemand) in active dried yeast preparations were rehydrated according to manufacture’s instructions. In the simultaneous (SM) trials, the must was inoculated with a mixed culture of T. delbrueckii and S. cerevisiae. In the sequential (SQ) trials, T. delbrueckii inoculum was added to the must followed by S. cerevisiae addition when the ethanol content was about 2.0 % v v−1. In V2, in addition to the rehydration protocol as described above, a modified protocol of T. delbrueckii preparation consisting of cell adaptation in the same grape juice used for the vinification was applied. After rehydration in distilled water for 30 min at 30 °C (containing 30 g L−1 of the yeast protectant, Go-Ferm Protect®, Lallemand), the cell suspension was added to ten volumes of grape juice and held at 18–19 °C for 48 h before its addition into the vat. The final inoculum was about 1–3 × 106 cfu mL−1 for S. cerevisiae and 4–6 × 106 cfu mL−1 for T. delbrueckii in both vinifications. In V1, SM and SQ trials were used, in V2 only SQ trials. Trials inoculated only with S. cerevisiae were used as control in both vinifications. All trials (SM, SQ and controls) were carried out in triplicate.

AF was carried out in cellar rooms without controlled temperature that ranged between 17 and 24 °C. The devatting was carried out at the end of AF, and wines were allowed to settle for 2 days by natural sedimentation.

Yeast isolation and identification

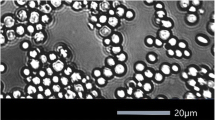

Must and wine samples were collected before and during AF to enumerate the yeasts by plate counting. WL agar (Fluka, Seelze, Germany) was used for Saccharomyces spp., and lysine agar medium (Oxoid Ltd., London, UK) for non-Saccharomyces. The plates were incubated for 3–5 days at 28 °C. The randomly selected colonies (about 160) were firstly classified for their morphology, observed with an optical microscope, and then species were identified by molecular analysis.

To identify yeast species, DNA extracted from the isolates was used for PCR amplification of the 5.8S-ITS region and subsequent restriction analysis according to Esteve-Zarzoso et al. [15]. PCR products and restriction fragments obtained with CfoI, HaeIII and HinfI (Thermo Fisher Scientific, Waltham, MA, USA) were separated on 2 % w v−1 agarose gels. Estimation of fragment lengths was obtained by using molecular markers (Low ladder molecular marker and 1 kb DNA ladder, Sigma, St. Louis, MO, USA).

Strain discrimination among S. cerevisiae isolates was carried out by microsatellite multiplex PCR as described by Vaudano and Garcia-Moruno [16].

Enzymatic assay

β-Glucosidase activity was measured in whole cells using 4-nitrophenol-β-D-glucopyranoside (Sigma) as substrate. Cells grown in YPD, collected in exponential phase, were washed in 0.9 % NaCl solution and, subsequently, in sodium acetate buffer 50 mM pH 5.0. The latter buffer containing 10 mM of substrate was used for the reaction. After 3 h of incubation at 30 °C, a 1:1 volume of saturated sodium bicarbonate solution was added to stop the reaction, then the optical density (OD) of the mix was read at 415 nm with a microplate reader (Model 680, Bio-Rad, Hercules, CA, USA). Standard curve was obtained using 4-nitrophenol (Sigma) dissolved in the appropriate reaction buffer at increasing concentration, and the activity was expressed as μmole of 4-nitrophenol liberated in 1 min per mL of must. The trial was done in triplicate.

Analysis of must and wine

Must-wine samples were analysed at crushing, during and at the end of AF. Ethanol was analysed by NIR spectroscopy using an Alcolyzer Wine apparatus (Anton Paar GmbH, Graz, Austria). Sugar content was determined by titration according to standard analysis methods. Organic acids were quantified using enzyme kits (La Roche, Basel, Switzerland).

Volatiles were analysed by gas chromatography—mass spectrometry (GC–MS) after solid-phase extraction (SPE) using ENV+ cartridge (1 g × 40–140 μm; Isolute, IST Ltd., Mid Glamorgan, UK), according to Boido et al. [17] and Fedrizzi et al. [18]. The process was performed with an Aspec XL SPE Sample Processor (Gilson Inc., Middleton, USA). The cartridges were sequentially conditioned with methanol (10 mL) and MilliQ water (10 mL). A total of 76 mL of wine sample diluted 1:4 v v−1, with distilled water and added with 1-heptanol as internal standard (500 μg L−1), was loaded onto the cartridge. The cartridge was then rinsed with 10 mL of distilled water. The residuals were washed with 10 mL of distilled water. The free aroma compounds were eluted with 9 mL of dichloromethane. The solution was dried with Na2SO4 and concentrated to 0.4 mL by a gentle nitrogen flow.

GC–MS analysis was performed with a 6,890 N Network GC System coupled with a 5978B inert XL EI/CI MS (Agilent Technologies, Milan, Italy), equipped with a HP-WAX Bonded PEG fused silica capillary column (60 m × 320 μm i.d. ×0.25 μm film thickness; Agilent Technologies). MS conditions were electron impact energy 70 eV and MS source temperature 230 °C. GC injector temperature was 250 °C, and helium was used as carrier (flow: 1.5 mL min−1). Column temperature programme was 50 °C (4 min), 4 °C min−1 to 240 °C, 240 °C (16 min).

All the analyses were recorded in full scan mode. Identification of the aroma compounds was achieved by injecting the pure reference compounds when available and using the NIST library as a confirmation. A response factor equal to 1 towards the internal standard was adopted, as commonly used in the analysis of aroma compounds.

Sensory wine analysis

A panel test conducted by eight judges (mainly Amarone wine producers) evaluated the experimental wines in two different sessions (one for V1 and the other for V2 wine). A preliminary analysis was carried out to discuss the more appropriate descriptors for the evaluation, considering that Amarone wine can be commercialised only after two ageing years, and only after this period, it could be possible a more reliable analysis on the real impact of T. delbrueckii on Amarone wine aroma. A total of 11 descriptors has been chosen (aroma intensity, floral, vegetal, jam, spicy, ripe red fruit, cinnamon, acidity, bitterness, astringency and sweetness) attributing a score using a 10-point scale to each one. The wines (one for each replicates) were randomly served at room temperature.

Statistical treatment of data

Student t-test were used for wine compounds and sensory scores to evaluate the differences in the samples. Principal component analysis (PCA) was performed on aroma compound data of all wines of V1 and V2 separately.

Results and discussion

Alcoholic fermentation kinetics

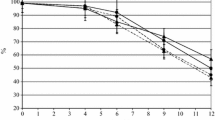

In V1, the type of inoculation influenced the AF kinetics. In fact, the rate of daily ethanol production in SQ trials was 6.7 g L−1 day−1, while in SM trials was 8.0 g L−1 day−1, similar to the control inoculated only with S. cerevisiae (8.1 g L−1 day−1) (Fig. 1).

In V2, the ethanol production rate of both trials with T. delbrueckii was similar regardless of the type of cell adaptation and resulted almost two-fold lower than the rate measured in the control (5.5 vs. 10.5 g L−1 day−1) (Fig. 1), confirming what was observed in V1 and in data reported by Cabrera et al. [19] on ethanol yield of Saccharomyces and T. delbrueckii strains, particularly in musts of high glucose content.

At the end of AF, the content of ethanol, residual sugars and organic acids wines ranged within standard values for Amarone wines in agreement with its production regulation (Table 1).

Indigenous yeasts and starter implantation analysis

Since the vinifications were carried out in a winery environment, it was important to evaluate the possible interference of the microbiota as well as to verify the starter implantation.

From grape must and fermenting wine samples, both non-Saccharomyces (Zygosaccharomyces bailii, Z. bisporus, Hanseniaspora uvarum, Rhodotorula spp. and other unidentified yeasts) and Saccharomyces yeasts (S. bayanus and wild strains of S. cerevisiae) (data not shown) were isolated. These indigenous yeasts (especially Saccharomyces spp.) participated partially to AF since their populations ranged at concentrations of 103–105 in both vinifications, even though starter yeasts were found at concentrations above 107 cell mL−1 at the peak of fermentation activity.

In SQ trials, T. delbrueckii was well adapted during fermentation remaining even up to 16.5 % v v−1 of ethanol (Figs. 2a and 3). In the SM inoculation, S. cerevisiae rapidly colonised the must, in spite of the inoculum size that was higher for T. delbrueckii, dominating progressively during the course of fermentation (Fig. 2b). Pre-adaptation condition of cells did not improve significantly their colonisation capability because T. delbrueckii persistence in must-wine was similar to the not pre-adapted cells (data not shown).

Aroma analysis

The T. delbrueckii, together with S. cerevisiae, during AF significantly influenced the aroma composition of Amarone wines as shown in Table 1. In V1, SQ wines displayed higher changes than SM wines (42 and 18 % of compounds varied significantly in the former and latter, respectively, vs. the control). The greatest change of aroma composition was obtained in V2 wines, and the cell pre-adaptation condition had little effect with respect to the not pre-adapted cells (58 and 56 % of compounds varied significantly in the former and the latter, respectively, vs. the control).

The effects, due to the presence of T. delbrueckii during the AF, on the content of aroma alcohols were evident, as demonstrated by the increase in benzyl alcohol observed in all wines produced by multistarter fermentations and also β-phenylethanol in SM and SQV1 (Table 1).

Considering that benzaldehyde, a potential precursor of benzyl alcohol, did not vary among the wines, an alternative precursor of this aromatic alcohol could be its glycoside [20, 21]. Enzymatic assay showed that T. delbrueckii yielded higher β-glucosidase activity than S. cerevisiae (0.90 ± 0.02 and 0.43 ± 0.01 mM/min/g dry weight, respectively, p < 0.001) and it may explain the different benzyl alcohol concentration among wines.

Similarly, the increase in β-phenylethyl alcohol (detected above its threshold of about 14 mg/L), observed in SM and SQV1 wines, could be generated by β-glucosidase activity, as proposed by Cabrera et al. [19] who found the yield of β-phenylethyl alcohol in wine produced by T. delbrueckii 4-fold higher than by S. cerevisiae. Nevertheless, in V2, where the β-phenylethyl alcohol content did not vary, other factors such as amino acid availability may have caused, together with the β-glucosidase activity, the accumulation of this alcohol in Amarone wines [22].

Contrary to previous studies [3, 9, 19], this study suggests that T. delbrueckii can influence the content of 1-hexanol in V2 approximately of 32 % lower with respect to the control. Further experiments are required to verify the metabolic role of non-Saccharomyces yeast involved in the accumulation of 1-hexanol as well as methionol and furfuryl alcohol, which varied significantly in V2 wines (Table 1).

The content of fermentative esters underwent significant variations, which may influence the sensory properties of wine. Isoamyl acetate (banana note) was found at lower concentration in SQ wines than control wines, especially in V2 (Table 1). According to Plata et al. [13], the higher hydrolysis activity of isoamyl acetate, via esterase, of T. delbrueckii over S. cerevisiae, could explain the different amount detected in Amarone wines. SQV1 wines were also characterised by lower content of ethyl hexanoate and ethyl octanoate. Even though below their respective thresholds, hexyl acetate and ethyl decanoate underwent significant reductions in all wines where T. delbrueckii dominated the beginning of AF. Only in the case of β-phenylethyl acetate, there was an opposite variation between V1 and V2, since only in the latter a decrease in this ester was marked. Most of these results, including the β-phenylethyl acetate, are in agreement to Comitini et al. [3] where the content of these and other esters, fatty acids and alcohols produced by T. delbrueckii and S. cerevisiae multistarter fermentations were compared with S. cerevisiae fermentations.

Among ethyl esters of hydroxyacids, it is interesting to note two opposite trends: ethyl 3-hydroxybutyrate and ethyl 2-hydroxyisoavalerate decreased, while ethyl 4-hydroxybutyrate and diethyl 2-hydroxyglutarate increased in wines produced with multistarter fermentations (Table 1). The content of ethyl 4-hydroxybutyrate was particularly high in V2 wines, and its variation could probably have an impact on sensory profile of Amarone wine.

Torulaspora delbrueckii seems to also favour the production of diethyl succinate and dimethyl malate since both esters increased in SQV1 and V2 wines. Moreover, in V2, it was observed a great increase in ethyl lactate. It has been previously demonstrated that the yeast activity could contribute to the different accumulation of these esters depending on species or strain [4, 12].

Torulaspora delbrueckii affected significantly the accumulation of fatty acids, except for isovaleric acid (Table 1). However, the variation of hexanoic and octanoic acid was different in the two vinifications since it decreased in V1 and increased in V2 with respect to their controls. The results of V1 are in agreement with previous investigations [3, 8, 9].

Despite the content variation of some benzenoids (detected below their thresholds) did not affect the aroma of Amarone wines, it is interesting to note the increase in homovanillic alcohol and vanillin, and the decrease in ethyl vanillate linked to T. delbrueckii (Table 1). On the other hand, Hernandez-Orte et al. [8] obtained synthetic wine that was high in ethyl vanillate fermented with T. delbrueckii when compared to other Saccharomyces and non-Saccharomyces strains. However, only the analysis during the Amarone ageing in wood barrels could help to understand the possible different role of the yeasts on the evolution of these compounds.

Amarone wine terpenes are generally detected at low concentrations since Corvina and Rondinella are non-floral grape varieties, so their contribution to its aroma can be often negligible [23]. The significant differences observed in several terpenes (Table 1) confirm the importance of the type of fermenting yeast on the flavour modulation of neutral aromatic grape varieties as previously reported [8, 17, 24]. Variation of the content of linalool, α-terpineol, nerol, geraniol, Ho-diendiol, endiol and 4-terpinenol, observed among wines of one and/or both vinifications, could be related to the different β-glucosidase activity (see above) and ability to convert these monoterpenes alcohols of the two yeasts according to King and Dickinson [25]. In particular, 4-terpineol, a molecule considered to be a marker of the B. cinerea infection, was found at concentrations much lower than those found in previous experiments [26], suggesting a very low and negligible involvement of this fungus on this grape material.

Also, among norisoprenoids, the variation of β-damascenone, actinidols and 3-oxo-α-ionol was found to be linked to the yeast species (Table 1). Hernandez-Orte et al. [8] revealed differences in these compounds between wines made with S. cerevisiae and T. delbrueckii. Then, this study highlighted that in Amarone wine, the role of the yeasts on the releasing terpenes and norisoprenoids could be more important than previously believed.

The effects of T. delbrueckii on Amarone wine were particularly evident by the analysis of lactones, an important compound category that has relevance to the aroma of this raisin wine [23, 25, 27]. V1SQ and V2 wines contained higher amount of lactones particularly due to the higher level of 4-carbethoxy-γ-butyrolactone and sherry lactones with respect to the controls (Table 1). In the V2 wines, the variation of 4-carbethoxy-γ-butyrolactone (sweet, coconut aroma) could have influence on the sensory properties of Amarone wine, since in those produced by mixed cultures, the content exceeded the threshold (400 μg L−1). The effect of T. delbrueckii was particularly evident analysing sherry lactones [28], where the amount produced differed up to almost 3-folds higher than the control, as the case of sherry lactone 2 in V1 wines (Table 1). Different metabolic yield between T. delbrueckii and S. cerevisiase on the production of these compounds could explain these data. In our previous investigations on botrytised Amarone wine [26, 27], the increase in sherry lactones was attributed to the flor yeasts, according to Muller et al. [28], associated with mould grape infection, but in the present study, their presence can be excluded. Further investigation is required to clarify the metabolism of T. delbrueckii involved in the sherry lactone production.

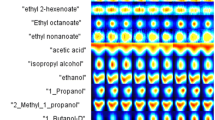

PCA analysis of aroma compounds

PC1 and PC2 explained most of the explained variance for each vinification (Fig. 4). In V1, a clear separation between SQ, SM and control wines is noticeable (Fig. 4a). PCA of V2 showed a clear separation between the mixed fermentations and the controls, whereas pre-adapted and non-pre-adapted experiments appeared quite close in the PCA score bi-plot (Fig. 4b). In particular, the pre-adapted biological replicates (e.g. 1, 2 and 3) appeared very close to each other, while not pre-adapted cell vinifications (e.g. 4, 5 and 6) were more spread in the PCA score bi-plot, suggesting better reproducibility of the wine quality in the former.

PCA of Amarone aroma compounds wines of two vinifications, V1 (A) and V2 (B). In V1, SQ wines (a, b and c), SM wines (d, e and f) and control (g, h and i). In V2 wines, pre-adapted T. delbrueckii cells (1, 2 and 3), not pre-adapted cells (4, 5 and 6) and control (7, 8, and 9). Compounds with PC1 loading value of <−0.8 or >0.8 in both vinifications: Av acetovanillone, Ba benzyl alcohol, Cb 4-carbethoxy-γ-butyrolactone, cH cis-3-hexenol, Dac decanoic acid, Des diethyl succinate, Dem diethyl malate, Dehg diethyl 2-hydroxyglutarate, Ed ethyl decanoate, Ehi ethyl 2-hydroxyisovalerate, Ehmp ethyl 2-hydroxy-4-methylpentanoate, E3hb ethyl 3-hydroxybutyrate, E4hb ethyl 4-hydroxybutyrate, Eg 4-ethylguaiacol, Eis ethyl and isoamyl succinate, Ehmp ethyl 2-hydroxy-4-methylpentanoate, 1H 1-hexanol, Oac octanoic acid, αT α-terpineol, Sl2 sherry lactone 2

Figure 4 shows also the compounds with PC1 loading scores higher or lower than 0.8 or −0.8, respectively, in both vinifications. Wines fermented sequentially by T. delbrueckii and S. cerevisiae were well described mainly by several esters together some terpenes, lactones and alcohols.

Sensory analysis

The sensory panel found differences between the profile aroma of the experimental wines produced by sequential multistarter fermentations and S. cerevisiae inoculation (control). In V1 session, SMV1 wines and controls were evaluated similarly, while SQV1 wines were characterised by significant higher intensity of some attributes such as aroma intensity, sweetness, astringency, ripe red fruit and lower intensity of vegetal (data not shown). In V2 session, the results of the analysis were similar to the previous session, and in particular, both wines produced by T. delbrueckii inoculation resulted clearly more sweet and fruity, where, in the latter, stronger smell of cherry was recognised by the tasters (data not shown). The highest levels of lactones of wines made with T. delbrueckii may help partially to explain the higher sweetness as previously described [8]. Moreover, high aroma intensity and fruitiness are effects that suggest a possible contribution of non-Saccharomyces to AF [2, 7], despite it remain difficult to find a correlation between sensory and analytical data, particularly in structured red wine such as Amarone wine [29].

Conclusions

This study demonstrated that T. delbrueckii can have an important role on the vinification of Amarone wine. This non-Saccharomyces participated actively to the fermentation of withered grapes for almost the entire duration of the process together with the S. cerevisiae. The ascertainment, by implantation analysis, that T. delbrueckii remaining viable up to 16.5 % v v−1 of ethanol demonstrated as this non-Saccharomyces yeast is suitable for the production of Amarone wine. The management of AF by using sequentially inoculated mixed cultures allows the winemaker to influence the wine flavour due to the significant influence of the non-Saccharomyces yeast on the formation of alcohols, esters, fatty acids and lactones. At sensory level, the use of T. delbrueckii confirmed to have a significant effects also in a structured red wine such as Amarone wine. Despite the pre-adaptation of T. delbrueckii cells ensured more reproducibility of aroma fingerprinting with respect to not pre-adapted cells, further studies are necessary to evaluate the importance of the cell pre-adaptation step to enhance the colonisation of stressful medium such as high-sugar musts from withered grapes. Finally, contribution of T. delbrueckii to the production of ethyl esters and lactones warrants further research, as well as its impact at sensory level after the ageing.

References

Ribéreau-Gayon P, Dubourdieu D, Donèche B, Lonvaud-Funel A (2006) Handbook of enology: the microbiology of wine and vinifications (Vol 1) 2nd edn. Wiley & Sons, Chichester

Ciani M, Comitini F, Mannazzu I, Domizio P (2010) Controlled mixed culture fermentation: a new perspective on the use of non-Saccharomyces yeasts in winemaking. FEMS Yeast Res 10:123–133

Comitini F, Gobbi M, Domizio P, Romani C, Lencioni L, Mannazzu I, Ciani M (2011) Selected non-Saccharomyces wine yeasts in controlled multistarter fermentations with S. cerevisiae. Food Microbiol 28:873–882

Viana F, Gil JV, Genovés S, Vallés S, Manzanares P (2008) Rational selection of non-Saccharomyces wine yeasts for mixed starters based on ester formation and enological traits. Food Microbiol 25:778–785

Andorrà I, Berradre M, Rozès N, Mas A, Guillamòn JM, Esteve-Zarzoso B (2010) Effect of pure and mixed cultures of the main wine yeast species on grape must fermentations. Eur Food Res Technol 231:215–224

Anfang N, Brajkovich M, Goddard MR (2009) Co-fermentation with Pichia kluyveri increases varietal thiol concentrations in Sauvignon Blanc. Aus J Grape Wine Res 15:1–8

Izquierdo Cañas PM, Palacios Garcia AT, Garcia Romero E (2011) Enhancement of flavour properties in wines using sequential inoculations of non-Saccharomyces (Hansenula and Torulaspora) and Saccharomyces yeast starter. Vitis 50:177–182

Hernandez-Orte P, Cersosimo M, Loscos N, Cacho J, Garcia-Moruno E, Ferriera V (2008) The development of varietal aroma from non-floral grapes by yeasts of different genera. Food Microbiol 107:1064–1077

Herraiz T, Reglero G, Herraiz M, Martin-Alvarez PJ, Cabezudo MD (1990) The influence of the yeast and type of culture on the volatile composition of wines fermented without sulfur dioxide. Am J Enol Vitic 41:313–318

Bely M, Stoeckle P, Masneuf-Pomarède I, Dubourdieu D (2008) Impact of mixed T. delbrueckii–S. cerevisiae culture on high-sugar fermentation. Int J Food Microbiol 122:312–320

Ciani M, Maccarelli F (1998) Oenological properties of non-Saccharomyces yeasts associated with wine-making. World J Microbiol Biotechnol 14:199–203

Renault P, Miot-Sertier C, Marullo P, Hernandez-Orte P, Lagarrigue L, Lonvaud-Funel A, Bely M (2009) Genetic characterization and phenotypic variability in T. delbrueckii species: potential applications in the wine industry. Int J Food Microbiol 134:201–210

Plata C, Millàn C, Mauricio JC, Ortega JM (2003) Formation of ethyl acetate and isoamyl acetate by various species of wine yeasts. Food Microbiol 20:217–224

Jménez-Marti E, Gomar-Alba M, Palacios A, Ortiz-Julien A, Del Olmo M (2011) Towards an understanding of the adaptation of wine yeasts to must: relevance of the osmotic stress response. Appl Microbiol Biotechnol 89:1551–1561

Esteve-Zarzoso B, Belloch C, Uruburu F, Querol A (1999) Identification of yeasts by RFLP analysis of the 5.8S rRNA gene and the two ribosomal internal transcribed spacers. Int J Syst Bacteriol 49:329–337

Vaudano E, Moruno-Garcia E (2008) Discrimination of S. cerevisiae wine strains using microsatellite multiplex PCR and band pattern analysis. Food Microbiol 25:56–64

Boido E, Lloret A, Medina K, Farina L, Carrau F, Versini G, Dellacassa E (2003) Aroma composition of Vitis vinifera Cv. Tannat: the typical red wine from Uruguay. J Agric Food Chem 51:5408–5413

Fedrizzi B, Zapparoli G, Finato F, Tosi E, Turri A, Azzolini M, Versini G (2011) Model aging and oxidation effects on varietal, fermentative, and sulfur compounds in a dry botrytized red wine. J Agric Food Chem 59:1804–1813

Cabrera MJ, Moreno J, Ortega JM, Medina M (1988) Formation of ethanol, higher alcohols, esters, and terpenes by five yeast strains in must from Pedro Ximénez grapes in various degrees of ripeness. Am J Enol Vitic 4:283–287

Daenen L, Sterckx F, Delvaux FR, Verachtert H, Derdelinckx G (2008) Evaluation of the glucoside hydrolase activity of a Brettanomyces strain on glucosides from sour cherry (Prunus cerasus L.) used in the production of special fruit beers. FEMS Yeast Res 8:1103–1114

Ugliano M, Bartowsky EJ, McCarthy J, Moio L, Henschke PA (2006) Hydrolysis and transformation of grape glycosidically bound volatile compounds during fermentation with three Saccharomyces yeast strains. J Agric Food Chem 54:6322–6331

Trinh TTT, Woon WY, Yu B, Curran P, Liu S-Q (2010) Effect of l-isoleucine and l-phenylalanine addition on aroma compound formation during Longan juice fermentation by a co-culture of S. cerevisiae and Williopsis saturnus. S Afr J Enol Vitic 31:116–124

Versini G, Schneider R, Carlin S, Depentori D, Nicolini G, Dalla Serra A (1999) Characterisation of some northern Italian Passiti-wines through aroma and stable isotope analysis. In: Lemperle E (ed), 12th international oenological symposium, Montréal, pp 544–571

Loscos N, Hernandez-Orte P, Cacho J, Ferreira V (2007) Release and formation of varietal aroma compounds during alcoholic fermentation from nonfloral grape odorless flavor precursors fractions. J Agric Food Chem 55:6674–6684

King A, Dickinson JR (2000) Biotransformation of monoterpene alcohols by S. cerevisiae, T. delbrueckii and Kluyveromyces lactis. Yeast 16:499–506

Fedrizzi B, Tosi E, Simonato B, Finato F, Cipriani M, Caramia G, Zapparoli G (2011) Changes in wine aroma composition according to botrytised berry percentage: a preliminary study on Amarone wine. Food Technol Biotechnol 49:529–535

Tosi E, Fedrizzi B, Azzolini M, Finato F, Simonato B, Zapparoli G (2012) Effects of noble rot on must composition and aroma profile of Amarone wine produced by the traditional grape withering protocol. Food Chem 130:370–375

Muller C, Maggiora L, Kepner RE, Webb AD (1969) Identification of two isomers of 4,5-dihydroxyhexanoic acid gamma lactone in Californian and Spanish flor Sherries. Am J Enol Vitic 17:1373–1376

Escudero A, Campo E, Fariña L, Cacho J, Ferreira V (2007) Analytical characterization of the aroma of five premium red wines. Insights into the role of odor families and the concept of fruitiness of wine. J Agric Food Chem 55:4501–4510

Author information

Authors and Affiliations

Corresponding author

Additional information

Michela Azzolini and Bruno Fedrizzi contributed equally to this work.

Rights and permissions

About this article

Cite this article

Azzolini, M., Fedrizzi, B., Tosi, E. et al. Effects of Torulaspora delbrueckii and Saccharomyces cerevisiae mixed cultures on fermentation and aroma of Amarone wine. Eur Food Res Technol 235, 303–313 (2012). https://doi.org/10.1007/s00217-012-1762-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-012-1762-3