Abstract

Rheological properties of chocolate play a relevant role either in process design or texture definition. Nevertheless, only flow properties of molten product or mechanical properties of samples cooled at fixed temperature (usually 20 °C) are measured, whilst testing conditions close to the industrial applications (temperature close to 30 °C) are less common to be used. In this work, chocolate samples (cooled at 1 and 5 °C min−1) were characterised at 30 °C by using small-amplitude oscillations and low-stress creep tests, aiming at establishing how material properties are related to the chocolate microstructure. The effects of either 3 anhydrous milk fats (AMF), having different melting points, or sugar particle size were evaluated. It was found that addition of AMFs, owing to their solid content, can yield an increase in consistency; however, this effect is less relevant when coarse sugar is used, because of the broader particle size distribution, and it depends on the thermal history because of the different fat crystallisation time. Finally, creep tests resulted to be very sensitive in detecting changes in chocolate rheological properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Like many other food products, chocolate is a complex multi-phase system containing cocoa butter and milk fat as solid continuous phase, sugar and other solid (fat-insoluble) ingredients as disperse phase [1]. In addition, active surface components, like emulsifiers, are often added to the formulations aiming to modify the interactions among the other ingredients [1, 2].

Some important applications, like coating or filling, require the use of chocolate in the molten state; therefore, rheological properties should be carefully considered either in process design [3] or in texture control procedures. Many studies are present in literature on this topic [2, 4–6], even though mainly flow characteristics, such as viscosity, were extensively studied and controlled in order to obtain good quality products and weight control during enrobing, shell making and moulding processes.

Chocolate rheological properties are affected by both formulation (i.e. fat content, particles size distribution, moisture content, emulsifiers) and processing conditions (mainly process time and temperature) [2, 3, 8–10]. The most important ingredient of chocolate is cocoa butter, a mixture of different triglycerides (TAGs), essentially solid at temperatures below 25 °C, but entirely liquid at body temperature [11]. The fat crystals in cocoa butter pack together in six different forms [2, 12] having increasing melting points; for practical applications, the best texture is achieved when cocoa butter is present in the form V (β2) [11]. Operating conditions, mainly cooling rate and thermal history (i.e., crystallisation temperature and tempering process), have significant effects on the kinetics and physical properties of the crystallised systems. Therefore, a controlled cooling step, often followed by a partial re-heating under shear, is necessary to have the proper crystalline forms [4, 13, 14]. Many authors showed that suitable cooling rates and annealing temperatures allow the formation of a single rapidly nucleating TAG crystal form which produces a spherulitic network with a small fractal dimension and the final product exhibits a high elastic modulus. On the other hand, low cooling rates and annealing temperatures will allow coexistence of various TAG polymorphs, producing a more disordered network with large fractal dimension and a final product with a small elastic modulus as a consequence [15].

Recently, several authors have shown that the macroscopic properties of the product can be related to the dimension of the particles in the network formed by cooling [7, 8, 14, 16], including not only the fat crystals formed during chocolate solidification but also other dispersed particles [10, 17]. The solid content can vary in concentration (between 65 and 73 g/100 g formulation, depending on the recipe), particle size distribution (PSD), shape and surface properties [3]. PSD is a key factor affecting rheological properties in chocolate and sensory perception [2] even though this relationship generally comes from experience-based knowledge [8]. Both particle size and distribution play a relevant role; for example, a bimodal PSD promotes viscosity reduction and better mixing, yielding improvements in final product stability [2], whilst the increase in particle sizes reduces yield stress, apparent viscosity, firmness, index of viscosity, hardness and melting index of products [8]. One of the main solid components is sucrose that constitutes more than 40% of solids dispersed in fat [17]; it appears to act as a heterogeneous nucleation agent, preferentially promoting the formation of lower melting polymorphs [13].

Emulsifiers are used mainly to promote the interaction between sugar particles (lipophobic) and the fat phase, reducing the amount of fats necessary to guarantee the desired flow properties [2]. The most common emulsifiers used in chocolate manufacturing are lecithin and polyglycerol polyricinoleate (PGPR). Because of their molecular structure, these surface-active ingredients lower the interfacial tension between the dispersed and the continuous phase, affecting processability (e.g. during tempering) as well as some physical properties, such as the sensitivity to moisture and temperature [18].

Cocoa butter is, often, partially replaced by different fats, such as anhydrous milk fats (AMF), useful in improving flavour, smoothing texture of milk chocolate and preventing fat bloom [19]. According to the melting point, milk fat fractions can be roughly classified as very high–melting fractions (melting above 45 °C), high-melting fractions (between 35 and 45 °C), middle-melting fractions (between 25 and 35 °C), low-melting fractions (between 10 and 25 °C) and very low–melting fractions (melting below 10 °C). Typically, high-melting fractions are recommended because they reduce fat bloom without significant negative effects on rheological properties [20].

Because of the augmented viscosity, chocolate containing high-melting fractions of anhydrous milk fat requires slightly higher crystallisation temperature, whereas middle and low fraction of anhydrous milk fat can be successfully tempered by modifying crystallisation time and temperature [19].

As described previously, chocolate rheology can be controlled by modifying fat content and type, adding emulsifiers or, more recently, by acting on particle size distribution. However, according to the International Confectionery Association (ICA, previously IOCCC-International Office of Cocoa, Chocolate and Sugar Confectionery) guidelines [3, 16], literature mainly reports only on flow properties (i.e. viscosity) at 40 °C or on mechanical properties (measured by tensile machine or Dynamic Mechanical Analyzer, DMA) at room temperature (typically 20 °C) [9, 20, 21]. Both situations refer to extreme behaviours (molten state or solid chocolate) and no information is available about material structure at intermediate conditions, adopted in industrial productions (for example, in enrobing or moulding processes).

In this case, when material properties are required, flow properties are not useful to analyse the chocolate structure and to understand as formulation and operating conditions can affect it. Therefore, it should be necessary to adopt techniques able to measure parameters related to material structure and independent on deformation history. This is the case of the so-called “asymptotic kinematics” carried out in conditions of linear material behaviour where measured material functions are independent on the amplitude of applied load and are only the function of microstructure [5, 22].

By using these techniques, this work aims to investigate the effects of some ingredients and cooling rate on linear rheological properties of chocolate at 30 °C. In order to obtain information on material structure [22], rheological parameters in linear viscoelastic conditions were measured for chocolate samples prepared by varying either the anhydrous milk fat content or the sugar particle size distribution.

Materials and methods

Materials

Samples were prepared by using cocoa liquor (I.C.A.M. S.p.a., Italy), cocoa butter (Dulcistar s.n.c., Italy), anhydrous milk fats, sugar and a commercial soya lecithin (Carrefour, France). Three anhydrous milk fats, AMF 15, 32 and 41, melting, respectively, at 15, 32 and 41 °C, were kindly supplied by Corman SA (Belgium); two different sugar types were adopted to study the effects of particle size: Zefiro (Z), (Eridania Italy) and Silandecor (S) (Silanpepe S.r.l., Italy). Zefiro sugar was sieved (Bicasa, Italy) at 125 μm before use to reduce particle size.

Total fat content of cocoa liquor was determined by Soxhlet method [23] and it is 50.9 g/100 g total mass.

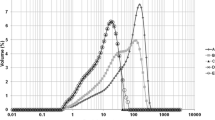

The sugar particle size was determined employing a MasterSizer 2000 (Malvern Instruments, UK), and the experimental data were analysed using the Malvern software. The obtained particle size distributions (PSD) were described mainly by two parameters, the Sauter diameter, d 32, and the span, an indicator for the width of the PSD, defined as:

where d 90, d 50, d 10 are volume-based diameters below which 90, 50 and 10% of particles are undersize, respectively [16]. The values of Sauter diameter and span are reported in Table 1 together with other data obtained from experimental particle distribution. Experimental data evidence a clear difference between the two materials: mean diameter of sugar S is close to the typical industrial values even though in the presence of a bimodal distribution, whilst sugar Z is coarser than sugar S and shows a narrower distribution.

It was worth noticing that the presence of coarse particles (like in sugar Z) can lead to undesired organoleptic effects (such as “sandy” perception during consumption). However, this is a minor issue when chocolate is adopted as coater or filler or in the presence of other “crispy” ingredients (piece of nuts, chunks of candy, etc.) [16]; therefore, in the present work, this issue was not considered.

Samples preparation

A typical formulation for dark chocolate [24] containing sugar (237.5 g), cocoa liquor (175 g), cocoa butter (86 g) and soya lecithin (1.5 g) was used as base recipe with a total fat content of about 35 g per 100 g. Modified samples were prepared by replacing 15 g of cocoa butter with anhydrous milk fats, keeping constant the total fat content and using either the S or the Z sugar. The samples were identified according to sugar type (CS or CZ) and the melting point of AMF (15, 32, 41); for example, CS32 was prepared by using S sugar and AMF melting at 32 °C, whilst sample CS was prepared by using S sugar without AMF.

Chocolate was prepared by mixing the cocoa liquor, pre-melted at 60 °C, with the molten cocoa butter (containing the anhydrous fats when used), sugar and lecithin. In order to guarantee proper homogenisation, the mixture was continuously mixed (RW20, Ika Werke, Germany) and held at 50 °C in a thermostatic bath (ED, Julabo, USA) for 20 h.

Rheological measurements

The rheological characterisation was carried out by using a stress control rheometer (DSR500, Rheometric Scientific, USA), equipped with a Peltier system, acting only under the lower plate, and serrated steel plates (ϕ = 40 mm), holding a constant gap of 1.1 ± 0.1 mm. Samples were poured on the plate at 50 °C, then cooled down to 27 °C and finally heated up to 30 °C to obtain mainly V form crystals [2]; both testing plates were pre-heated to 50 °C, before loading the sample, to avoid undesired and uncontrolled cooling effects on the solid surfaces.

For all samples, two different cooling ramps were used: 5 and 1 °C min−1. After a 5-min rest period at 30°, samples were characterised under small-amplitude oscillations. During these tests, knows as “dynamic tests”, samples are subjected to oscillatory motions by applying small deformations (or stresses) to maintain linear viscoelastic conditions [5, 25]. The linear viscoelastic region was previously determined by stress sweep tests at 1 Hz, and then frequency sweep tests were performed within the linear region by increasing the oscillation frequency in the range 0.1–3 Hz [5, 25].

No chocolate contraction was observed for all samples, in the considered temperature range, as confirmed by visual inspection before starting each test.

Even though dynamic tests are very useful in determining material properties [25], when weakly structured materials are considered and dynamic moduli are close each to the other, they could be not enough sensitive to detect small differences between samples. On the other hand, a different transient test, such as creep in linear condition, [5] could be useful because of its capability to separate “solid like” behaviour (at short times and high Deborah numberFootnote 1) from the “liquid-like” one (at long times and low Deborah number). In a creep test, an instantaneous stress is applied to the sample and the change in strain is measured over time; when low stress values are adopted, the obtained material function (the creep compliance J(t), i.e. the ratio of measured strain to applied stress) does not depend on the magnitude of the load and it is related to the microstructure [5].

Therefore, some samples (CS, CZ, CS32) were also characterised by creep tests (300 s) carried out in linear viscoelastic conditions (3–7 Pa for samples CS and CZ, 1–4 Pa for sample CS32) to avoid structural changes.

For all the characterisation, the preparation of all samples was triplicated and presented results are average values; differences of measurement are shown by standard deviations (typically lower than 10%).

Data analysis

Chocolate, from a structural point of view, can be considered as a fractal network based on the interactions among fat crystals forming roughly spherical domains, flocs, entrapping the liquid phase [9, 12, 15]. Depending on the strength of network interactions, compared to the flocs-internal ones, it is possible to have a strong-link or a weak-link behaviour; when a high solid content is present (such as for chocolate), a weak-link behaviour is typically observed [21]. According to this description of the microstructure, the chocolate can be considered as a weakly structured 3-D network where rheological units (the crystal flocs) are bound by weak physical interactions. Many foods can be described as weakly structured systems having a three-dimensional network with rheological “units” connected by weak bonds like London or van der Waals forces. Therefore, they seem to behave as “critical gels” [26, 27], showing a solid-like behaviour under small deformations. This mechanical behaviour can be described, in a limited frequency range, by a power law relationship between the dynamic complex modulus G * and the oscillation frequency, ω (Weak Gel model [26]):

In Eq. 2, G′ and G″ are, respectively, storage and loss modulus, z is the network extension, related to the number of rheological units interacting within the network, and A is a measure of the strength of these interactions. High A value indicates an increase in the interaction forces within the network and high z value indicates a broad network extension. It is worth reminding that the rheological behaviour of foods, as weakly structured materials, is described by this power law model in a limited frequency window, usually ranging between 0.1 and 100 Hz, whilst for lower frequencies, different relaxation mechanisms should be considered [26].

According to this model, dynamic data obtained for tested chocolate samples were fitted by Eq. 2 and obtained parameters (A and z) were used throughout the paper to describe the material structure.

Data from creep were analysed according to the Bohlin theory of cooperative flow [28], describing the material structure as a lattice of interacting rheological units (the crystal flocs in this case) having a “coordination number” z′. The macroscopic flow of materials is then assumed to be the consequence of a cooperative rearrangement of a number of flow units [28]. According to the theory, the dimensionless strain in a creep test, from time zero up to steady state, can be described as:

where t is time, λ is an average relaxation time, γ is the measured strain, and z′ is the coordination number. Even though from a different perspective, the theory of cooperative flow describes the material structure as a network that, under flow, is characterised by a typical extension, z′, and an average relaxation time, λ, that can be considered as a measure of the ratio between the solid-like and the liquid-like behaviour.

Experimental data were fitted by using a commercial software (Table Curve, Jandel Scientific, USA), and all parameters are reported as mean value and standard error.

Results and discussion

Dynamic tests

Stress sweep tests were performed in order to identify the linear viscoelastic region after the two cooling steps at 5 °C min−1 or at 1 °C min−1. Experimental results showed a narrow linear region, approximately ranging from 1 to 8 Pa for both the cooling rates, depending on specific chocolate formulation.

Typical frequency sweeps, obtained for samples CS and CS41 conditioned at 1 °C min−1, are reported in Fig. 1; it can be seen that both dynamic moduli show the typical behaviour of weakly structured systems, and the loss modulus is greater than the storage one in the considered frequency range, evidencing a prevalent liquid-like behaviour. Moreover, it can be noticed that AMF 41 modifies rheological properties, increasing both moduli, with a different effect on loss and storage modulus, yielding a less liquid-like behaviour. This result is more evident when dynamic data are shown in terms of complex modulus (Fig. 2a) and loss tangent (Fig. 2b) (defined as the ratio between loss and storage modulus [25]). It can be seen that AMF 15 leads to a slight reduction in complex modulus, whilst either AMF 32 or AMF 41 cause a significant increase in G *. As far as loss tangent is concerned, a continuous decrease, related to a more solid-like behaviour, is observed, particularly when AMF 41 is used. This rheological behaviour is due to the AMF solid content at the testing temperature, i.e. 30 °C, depending on the fat melting point (see Table 2). At 30 °C, the fat AMF 15 does not contain any crystal, and therefore, its addition slightly reduces chocolate consistency, according to the literature evidence [20]. On the contrary, when CS32 and CS41 are tested, the presence of a greater amount of solid fat particles affects the chocolate crystal network, increasing either consistency (described by the complex modulus) or the solid-like behaviour (related to the loss tangent).

A similar, but less marked, trend for dynamic moduli is found when increasing the cooling rate at 5 °C min−1 (Fig. 3a, b). In fact, the increased thermal ramp (as it will be described in the following discussion) enhances differences for both G * and tg(δ) in sample CS41, whilst other formulations exhibit a quite similar behaviour.

Complex modulus data were fitted with Eq. 2 to calculate the weak gel model parameters; it can be seen, from Figs. 2a, 3a, that the model adequately describes the experimental data, except at the lowest frequencies where a slight deviation from the power law behaviour can be noticed, mainly for CS sample. Similar results were obtained for all tested samples, and the weak gel model parameters for all the samples are reported in Fig. 4a, b.

When systems prepared by using fine sugar are considered, it can be seen that samples CS32 and CS41 slowly cooled (1 °C min−1) exhibit values of A greater than those of the standard chocolate CS, whilst CS15 is characterised by a lower value; on the other hand, all samples containing AMF exhibit similar z values greater than that computed for CS. According to the previous discussion on dynamic data, this behaviour is due to the different AMF solid content at the testing temperature; for AMF 32 and AMF 41, the larger amount of solid fat particles increases the crystal network strength and, less evidently, interactions. On the contrary, for AMF 15, a slight reduction in A parameter is observed because of the lower fat particles content at 30 °C.

When the effects of the thermal history are considered, it can be seen that no relevant difference is found for samples CS and CS15, whilst, due to fast cooling conditions, samples CS32 and CS41 exhibit lower values of both weak gel parameters (see Fig. 4a, b). It is worth reminding that thermal ramp affects only fat crystal formation, whilst it does not affect physical and chemical properties of other chocolate components.

Experimental results seem in contrast with literature data [15] showing that fast cooling rates produces high elastic modulus. Nevertheless, it should be considered that, in the mentioned paper, a long and constant annealing period is used to complete the crystallisation process at each thermal ramp. On the contrary, in the present work, samples were subjected to different crystallisation times, owing to the different cooling period followed by a constant short annealing time. Therefore, differences can be attributed to the effect of milk fats that may significantly delay the crystallisation phenomena [20], causing an apparent decrease in network strength at higher cooling rates because of the shorter crystallisation time. In fact, Wiking et al. [32] studied microstructure and rheology of milk fats at two different thermal ramps, 0.1 and 10 °C min−1, and measuring the complex modulus as function of time, they found that in the first crystallisation period (approximately up to 50 min), the sample cooled at slow rate was characterised by higher values of the complex modulus because of the lower solid content; on the contrary, at long time (longer than 50 min), the opposite trend was found owing to the different nature of the formed microstructural elements (i.e. size and morphology of fat crystals) caused by the two thermal histories.

Even though chocolate samples studied in the present work, owing to the high sugar content, are characterised by a solid fraction higher than samples studied by Wiking and co-workers [32], a similar effect of thermal history on fat is expected; therefore it can be deduced that samples containing AMF and slowly cooled (1 °C min−1) have a low solid fat content and they are characterised by a less structured network as evidenced by the weak gel model parameters.

When the effects of different sugars are considered, it can be seen that standard formulations (i.e. sample CZ and sample CS) do not exhibit relevant differences in interaction strength. The effect of PSD is evident when AMFs are added to standard formulation as clearly shown in Fig. 4a where modified samples containing S sugar are characterised by A values higher than those computed for samples containing Z sugar. These results are due to the different solid fat content at testing temperature and they are in agreement with literature data evidencing that coarse particles, being characterised by a lower specific surface, require a lower amount of fat for their external coating and, therefore, leave a larger fraction of fats available to decrease the suspension viscosity [16]. This effect becomes more evident when increasing AMF melting point owing to the lower available amount of molten fats.

It is worthy to notice, also for samples containing Z sugar, the effects of AMF on the weak gel model parameters. Samples containing AMF are characterised by values of A lower than those obtained for standard formulations at both cooling rate and the interaction strength increases with fat melting point (and therefore with solid content); this behaviour, different from that discussed for samples containing S sugar, is due to the fat crystal dimensions that are usually small compared to Z sugar particle (see for example [32]). Therefore, owing to the crystallisation phenomena, both an increased solid content and a broader particle size distribution were obtained, and as a compromise between these opposite phenomena, a macroscopic reduction in chocolate consistency is observed. On the contrary, the different thermal history does not yield relevant differences probably owing to the broader particle size distribution as discussed previously.

Creep tests

Low stress creep tests were used to study the standard samples (CS and CZ) cooled by using the two thermal ramps and a sample (CS32) cooled at 5 °C min−1, more interesting for industrial applications.

The obtained results for tested sample at both cooling rates are shown in Fig. 5 in terms of creep compliance J(t) as time function; it can be seen that the slow ramp yields higher value of compliance, and therefore, higher deformability, probably due to the presence of larger but less structured crystal domains.

It is worth noticing that samples CS and CS32 cooled down at 5 °C min−1 seems to approach a constant compliance value, evidencing a constant deformation and, therefore, a potential yield stress [33]. On the contrary, apparent flow conditions seem to be obtained in the other tests; however, the investigated time range is too narrow to withdraw reliable information about steady-state behaviour [33].

Experimental data were fitted by using the Bohlin theory of cooperative flow (Eq. 3) in the early stage of the test (0–200 s) for all samples, and a good agreement was obtained, as shown in Fig. 6, for CS sample at both thermal ramps. It was found that for standard formulations (Table 3), the coordination number z’ decreases when decreasing the cooling rate. This is probably due to the formation of a lower amount of larger crystals, leading to a less extended network. On the contrary, the relaxation time λ increases with the decrease in thermal ramp, evidencing a more solid-like behaviour for slowly cooled samples.

The addition of AMF to chocolate (CS32) leads to high values of λ (Table 3) when compared with the standard sample (CS), whilst no relevant difference is found for z′ and, as already discussed for dynamic tests, this result can be explained because of the higher amount of solid particles.

Conclusions

The rheological analysis based on dynamic and transient tests seems able to evaluate the influence of cooling rate on rheological properties of chocolate samples prepared with different fat content, particle size and emulsifiers. Creep test was revealed to be a reliable alternative to dynamic tests; in fact, it is able to evidence differences in materials having different formulations and thermal histories.

Small-amplitude oscillation tests have shown that large sugar particles strongly affect final rheological properties reducing the relevance of the fat crystals morphology. This is evidenced by the results obtained for samples containing coarse sugar, having dynamic moduli fairly independent either on the adopted thermal ramp or on the fat content.

On the contrary, when decreasing the sugar particles size, a clear effect of the cooling rate is detected with a significant increase in both network extension and strength when decreasing the ramp. This effect is due to the increase in crystal amount because of the different crystallisation time and it is dependent on the melting point of the adopted anhydrous fat that is responsible for the different solid content.

Particle size distribution has confirmed to be an important factor able to affect both network strength and extension with fine particle yielding higher elasticity.

References

Götz J, Balzer H, Hinrichs R (2005) Characterisation of the structure and flow behaviour of model chocolate systems by means of NMR and Rheology. Appl Rheol 15:98–111

Afoakwa EO, Paterson A, Fowler M (2007) Factors influencing rheological and textural qualities in chocolate—a review. Trends Food Sci Technol 18:290–298

Tscheuschner HD (1994) Rheological and processing properties of fluid chocolate. Appl Rheol 94:83–88

Sherman P (1970) Industrial rheology, 1st edn. Academic Press, London

Steffe JF (1996) Rheological methods in food process engineering, 2nd edn. Freeman Press, East Lansing

Wichchukit S, McCarthy MJ, McCarthy KL (2005) Flow behavior of milk chocolate melt and the application to coating flow. J Food Sci 70:E165–E171

Afoakwa EO, Paterson A, Fowler M (2008) Effects of particle size distribution and composition on rheological properties of dark chocolate. Eur Food Res Technol 226:1259–1268

Afoakwa EO, Paterson A, Fowler M, Vieira J (2008) Relationships between rheological, textural and melting properties of dark chocolates as influenced by particle size distribution and composition. Eur Food Res Technol 227:1215–1223

Afoakwa EO, Paterson A, Fowler M, Vieira J (2008) Effects of tempering and fat crystallisation behaviour on microstructure, mechanical properties and appearance in dark chocolate systems. J Food Eng 89:128–136

Servais C, Jones R, Roberts I (2002) The influence of particle size distribution on the processing of food. J Food Eng 51:201–208

Beckett ST (2008) The science of chocolate, 1st edn. The Royal Society of Chemistry Publishing, Cambridge

Narine SS, Marangoni AG (1999) Relating structure of fat crystal networks to mechanical properties: a review. Food Res Intern 32:227–248

Dhonsi D, Stapley AGF (2006) The effect of shear rate, temperature, sugar and emulsifier on tempering of cocoa butter. J Food Eng 77:936–942

Pèrez-Martinez D, Alvarez-Salas C, Charò-Alonso M, Dibildox-Alvarado E, Toro-Vazquez JF (2002) The cooling rate effect on the microstructure and rheological properties of blends of cocoa butter with vegetable oils. Food Res Intern 40:47–62

Fessas D, Signorelli M, Schiraldi A (2005) Polymorphous transitions in cocoa butter. A quantitative DSC study. J Therm Anal Calorim 82:691–702

Do T-AL, Hargreaves JM, Wolf B, Hort J, Mitchell JR (2007) Impact of particle size distribution on rheological and textural properties of chocolate models with reduced fat content. J Food Sci 72:E541–E552

Sokmen A, Gunes G (2006) Influence of some bulk sweeteners on rheological properties of chocolate. LWT Food Sci Technol 39:1053–1058

Schantz B, Rohm H (2005) Influence of lecithin-PGPR blends on rheological properties of chocolate. LWT Food Sci Technol 38:41–45

Reddy SY, Full N, Dimick PS, Ziegler GR (1996) Tempering method for chocolate containing milk- fat fractions. J Am Oil Chem Soc 73:723–727

Pajin B, Jovanovic O (2005) Influence of high-melting milk fat fraction on quality and fat bloom stability of chocolate. Eur Food Res Technol 220:389–394

Herrera ML, Hartel RW (2000) Effect of processing conditions on the physical properties of milk fat model system: rheology. J Am Oil Chem Soc 77:1177–1187

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology, 1st edn. Elsevier Science Publishers, Amsterdam

ICA (1990) ICA, determination of fat content of cocoa and chocolate products. Analytical method, vol 37. CAOBISCO, Brussels

Zoumas BL, Azzara CD, Bouzas J (2004) Chocolate and Cocoa. In: Kirk-Othmer RE (ed) Kirk-Othmer encyclopedia of chemical technology, vol 6. Wiley-Blackwell, Chichester, pp 350–372

Rao MA (1999) Measurement of flow and viscoelastic properties. In: Rao MA (ed) Rheology of fluid and semisolid foods, principles and applications, 1st edn. Aspen Publishers, Gaithersburg, pp 59–152

Gabriele D, D’Antona P, de Cindio B (2001) A weak gel model for foods. Rheol Acta 40:120–127

Ng TSK, McKinley GH (2008) Power law gels at finite strains: the nonlinear rheology of gluten gels. J Rheol 52:417–449

Bohlin L (1979) A theory of flow as a cooperative phenomenon. J Colloid Interface 74:423–434

Corman SA (2006a) Technical bulletin, Anhydrous Milk Fat—AMF 15

Corman SA (2006b) Technical bulletin, Anhydrous Milk Fat—STANDARD AMF

Corman SA (2006c) Technical bulletin, Anhydrous Milk Fat—AMF 41

Wiking L, De Graef V, Rasmussen M, Dewettinck K (2009) Relations between crystallisation mechanisms and microstructure of milk fat. Int Dairy J 19:424–430

Sun A, Gunasekaran S (2009) Yield stress in foods: measurements and applications. Int J Food Prop 12:70–101

Acknowledgments

Acknowledgments are due to the Laboratory of Rheology and Food Engineering at University of Calabria, where the experimental tests were performed. The authors are, also, grateful to Prof. Brunello Formisani and Dr. Vincenzino Vivacqua, for the analysis concerning particle size distribution, and to Dr. Deborah Facciolo, for the rheological measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baldino, N., Gabriele, D. & Migliori, M. The influence of formulation and cooling rate on the rheological properties of chocolate. Eur Food Res Technol 231, 821–828 (2010). https://doi.org/10.1007/s00217-010-1334-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1334-3