Abstract

The typical quality attributes of chocolate, such as its glossy appearance, hard and brittle texture, sharp melting, and fat bloom resistance, are determined by the process conditions under which solidification occurs. It is therefore reasonable to test the success of this process from their solid form through thermal, textural, and/or optical analysis. However, the solidification process of chocolate consists of a dynamic pre-crystallization step and a subsequent static crystallization step that relies on the crystallization of cocoa butter in its matrix. Each of these crystallization steps has a different mechanism and target. Additionally, the flow parameters such as apparent viscosity and yield stress during each crystallization step change and may affect the subsequent process steps. This work evaluates the possibility of performing rheological tests to follow changes in the flow behavior of dark chocolate during and immediately following pre-crystallization, as well as during solidification. Different tempering protocols, consisting of distinct time and temperature profiles, were performed by manually stirring and scraping the molten chocolate from a glass beaker in temperature-controlled water baths. Selected protocols were mimicked in the rheometer equipped with sandblasted parallel plates by performing a rotational test with temperature ramps to monitor changes in flow behavior. Key experimental settings including gap size, shear rate, pre-conditioning temperature, and residential time are discussed in this paper. Thermal and shear effects attributed to the evolution of apparent viscosity can be monitored within different phases of pre-crystallization. The flow curves of tempered chocolates from corresponding manual and rheometer tempering protocols, as well as the melting profiles upon their solidification, were comparable, reproducible, and indicating well-tempered chocolate characteristics. Furthermore, it was possible to follow up static crystallization in the rheometer after tempering. Thus, rheometrical techniques are proven to be a useful tool to monitor flow behavior changes in different phases of the solidification step in chocolate manufacturing and may provide important rheological data of molten, pre-crystallized, and solid chocolate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cocoa butter (CB) crystallization is an important step of the chocolate manufacturing process and essential to the respected final macroscopic quality of chocolate concerning appearance, texture, mouthfeel, and long-term physical stability. Despite the abundance of symmetrical mono-unsaturated triacylglycerols (TAGs), several polymorphic forms of CB are recognized: unstable γ and α polymorphs, metastable β’ form, and stable βV and βVI polymorphs (Bresson et al. 2011; Van Malssen et al. 1999). This polymorphism serves as an important aspect in respect of chocolate solidification as stable polymorphs can only be attained via solid-state transition from the metastable polymorph under static conditions. Meanwhile, among the stable polymorphs, the βV polymorph is responsible for the desired macroscopic quality of chocolate.

Pre-crystallization, a processing step involving shear at an appropriate time and temperature combinations, is therefore a necessary step for confectionery products containing CB. Conventionally, this process starts from the completely melted chocolate, cooling to the crystallization point to induce nucleation to produce unstable, metastable, and stable seed crystals before finally reheating to retain only the stable seed crystals, all under dynamic conditions to homogenously distribute stable seed crystals in the matrix. This step, commonly known as the tempering, is vital to generate more than 90% of βV polymorph during the subsequent solidification process upon cooling (Zeng and Windhab 1999). Tempering aims to avoid crystal growth of unstable or metastable polymorphs responsible for disordered fat crystal network development, undesirable dull appearance, inconsistent heat stability, and occurrence of fat bloom. Shearing and scraping are likewise essential during tempering to control mixing, heat exchange rate, and crystal size distribution (Mishra et al. 2023; Windhab 2017). While the degree of shearing, time, and temperature play critical roles in the final product quality, there is no unique set of conditions to achieve proper tempering (Afoakwa et al. 2008b).

The generation of stable seed crystals during pre-crystallization consequently modifies the flow behavior of the chocolate. Hence, although well-tempered chocolate can be achieved from different combinations of tempering process parameters (shear rate, time and temperature), type, and scale of tempering machines, the flow behavior of the final product might be different. Tempered chocolate must be able to be transferred into subsequent application steps, such as molding, enrobing, coating or even three-dimensional printing, in which the flow properties are essential (Mantihal et al. 2017; Windhab 2017). Therefore, generally, the aim is to acquire the smallest increase of viscosity in the pre-crystallized mass (Bolliger et al. 1998; Windhab et al. 1991). Flow properties of chocolate after pre-crystallization might evolve due to both the number and size of crystal seeds. More crystal seeds with smaller sizes are preferred promoting desirable flow properties (Seguine 1991).

Rheological properties of chocolate are typically examined in their untempered, molten state using a viscometer or rheometer. A flow curve test methodology is employed, consisting of a multistep constant shear test performed at defined series of shear rates or shear stress. General guidelines comprising the test protocol, measuring geometries, and mathematical model have been set (ICA 2000) and widely used to characterize molten chocolate. However, in our previous paper, we discussed the implementation of an accurate use of measurement protocol, geometry, and model fitting since inaccurate rheological methodology and interpretation before the solidification step of molten chocolate often remains an issue (Hendrik et al. 2023). Moreover, the flow properties of molten untempered chocolate are often assumed to be directly linked to the application and final macroscopic quality of solid chocolate without considering that tempering may consequently change the flow behavior of the molten chocolate.

The degree of pre-crystallization is often determined based on the solidification mechanism or the macroscopic properties of the solid chocolate. A temper meter, an instrument to record the temperature change of chocolate during cooling, has been widely employed to determine the tempering degree (Afoakwa et al. 2008a; Bolliger et al. 1998; Le Révérend et al. 2009; Loisel et al. 1997; Svanberg et al. 2013). The slope beyond the inflection point in the temperature curve monitored by this instrument is then correlated with a tempering index (TI), classifying under-tempered, well-tempered, or over-tempered chocolate. While such a tempering degree classification works well as a general guidance for quality control purposes, the development of new chocolate products cannot rely solely on TI, since results are heavily dependent on the composition of chocolate, selected pre-crystallization method, and shear and thermal history (Bolliger et al. 1998; Seguine 1991; Svanberg et al. 2013). Thermal analysis such as melting profile from differential scanning calorimetry (DSC) or spectroscopic analysis such as X-ray diffraction (XRD) techniques are often utilized to deduct tempering degree by qualifying and quantifying the CB polymorph from a solid pre-crystallized chocolate (Afoakwa et al. 2009; Bolliger et al. 1998; Bolliger et al. 1999; Dhonsi and Stapley 2006; Le Révérend et al. 2009; Le Révérend et al. 2010; Loisel et al. 1997; Svanberg et al. 2013). Determination of the macroscopic quality of solid chocolate could be performed by observing the contraction before demolding (Windhab et al. 2009), hardness using a texture analyzer (Afoakwa et al. 2008a), or fat bloom development (Afoakwa et al. 2008a; Bolliger et al. 1998; Kinta and Hartel 2010; Svanberg et al. 2013; Svenstrup et al. 2005). These techniques are useful to monitor exclusively certain aspect among the extensive crystallization phases in chocolate that includes primary crystallization, polymorphism, microstructural, or macroscopic development. Furthermore, they are generally performed on solid chocolates while neglecting effects such as heat transfer during solidification itself. Eventually, no flow behavior information could be obtained using any of these techniques, indicating the importance of rheometrical method on pre-crystallized chocolate.

Flow behavior of pre-crystallized matrices has been mostly studied by investigating rheological parameters during crystallization on CB or chocolate model systems (Bolliger et al. 1999; Dhonsi and Stapley 2006; Maleky and Marangoni 2008; Mazzanti et al. 2003; Mishra et al. 2023; Toro-Vazquez et al. 2005); however, there have been some attempts to monitor rheological data of chocolate during or after pre-crystallization. A laboratory scraped-surface heat exchanger has been exploited to simulate the pre-crystallization of chocolate (Loisel et al. 1997; Loisel et al. 1998). Nevertheless, an equivalent viscosity based on torque was estimated following calibration of a Newtonian liquid, which contrasts with chocolate as non-Newtonian fluid. Though obtaining the evolution of apparent viscosity during pre-crystallization using a viscometer not feasible, Stapley et al. (1999) crafted a tempering apparatus mimicking a concentric cylinder viscometer and found a good correlation between variation of shear rate during tempering and melting profile data using DSC. A similar attempt to characterize different pre-crystallization methods or protocols has been done by correlating the flow behavior of pre-crystallized chocolate using a viscometer with results from other analyses such as from temper curve, melting profile, fat bloom development (Bolliger et al. 1998), or in-line near-infrared spectroscopy (Bolliger et al. 1999). Aside from the limitation of the viscometer to measure one flow condition at a time over a narrower range of shear rate, simulating solidification in a viscometer is inaccurate (Dhonsi and Stapley 2006) as it fails to measure viscoelastic behavior, unlike rheometers. Briggs and Wang (2004) pioneered the first attempt to simulate pre-crystallization using a rheometer followed by a steady shear flow analysis to investigate the effect of shear rate and tempering time; however, no validation of tempering degree based on the identification of polymorphic form was provided. Meanwhile, Bergemann et al. (2018) utilized a temper meter to attain well-tempered milk chocolate from a table-top tempering machine and characterized the flow curve to be used in a proposed constitutive model to obtain yield behavior. The flow behavior of untempered molten chocolate is often correlated with handling properties and final macroscopic quality, overlooking the significant changes in flow behavior that occur due to the tempering process. Therefore, a study that simulates and characterizes rheological evolution during tempering followed by solidification of chocolate, with validation based on the polymorphic form identification, can be of great utility.

This work discusses the rheological tests and setup to follow changes in the flow behavior of dark chocolate during and following pre-crystallization, as well as during solidification taking into consideration validation of the temper quality. To achieve this, firstly a manual batch tempering protocol was set and compared with the untempered counterpart. Calorimetrical and rheometrical analyses were employed to validate the tempering degree. Next, manual tempering protocols were selected for chocolate pre-crystallization in the rheometer using different rheometrical settings and equally validated with the same calorimetrical and rheometrical analysis as manual tempering. Finally, the rheometer tempering protocol was further tested for experimental simulation of solidification under small deformation in a rheometer whereby the evolution of rheological parameters during solidification was monitored. Therefore, this research investigates the potential of a rheometer to simulate the chocolate tempering process and subsequently characterizes the resulting product and further characterizes chocolate’s behavior during solidification.

Materials and Methods

Chocolate

Dark chocolate callets comprising 34.8% cocoa butter, 20.2% cocoa solids, and 44.5% sucrose, suitable for molding, were purchased from Belcolade (Erembodegem, Belgium). Further composition of the chocolate, such as fat content, was studied in another research, referred as medium-viscosity chocolate (Hendrik et al. 2023). Preceding any treatment, samples were kept in a sealed plastic container for a minimum of 2 h placed in a thermostatic chamber Terma 2S (LED techno, Heusden-Zolder, Belgium) at 52 °C ± 0.2 °C to ensure liquid sampling. Non-tempered chocolate (NT) samples were prepared as a standard of comparison with tempered samples.

Manual Tempering

A method to produce manually tempered chocolate (MT) was adapted from the method described by Smith et al. (2007). Two circulating water baths F12-MA (Julabo, Seelbach, Germany) with temperature stability of 0.02 °C were used. A total of 150 g of liquid chocolate was transferred into a 300-ml glass beaker and directly cooled in a water bath at a specific crystallization temperature whilst stirring manually with a spatula. Stirring was done by constantly scraping the walls and bottom surface of the glass beaker to ensure sample homogeneity. When the sample became too thick to stir, the sample was partially remelted in another water bath at an elevated temperature and stirring was continued until the sample was pourable. The temperature for crystallization (TC) and remelting (TM) of each sample are provided in Table 1. A waterproof immersion thermoelectric couple TC type K (Testo NV/SA, Ternat, Belgium) with temperature reading accuracy of ± 0.75% was connected to a thermologger Testo 735 (Testo NV/SA, Ternat, Belgium). The thermoelectric couple and the thermologger were calibrated with silicone oil at – 20 °C, 0 °C, and 60 °C with a standardized electronic thermometer and mercury thermometer giving similar results with ± 0.05 °C. The thermoelectric couple was positioned laterally in the center of the beaker and 10 ± 1 mm above the bottom surface of the beaker. The temperature of MT was recorded every second. This experiment was done in triplicate and average temperatures are reported.

Rheometrical Methods

All rheological measurements were performed using a stress-controlled rheometer MCR 302 (Anton Paar GmbH, Graz, Austria) temperature-controlled with a Peltier system connected to a Paar VT2 circulator (Julabo, Seelbach, Germany) and equipped with 25-mm sandblasted parallel plates. Unless otherwise stated, the measuring gap was set to 0.5 mm to limit the thermal gradient without having particle interference compromising rheological data. Preliminary PSD analysis was performed with Malvern Mastersizer S Long Bench (Malvern Instruments Ltd., Worcestershire, UK) and shows that the size of the biggest particle (42.95 ± 3.01 μm). This indicate that 0.5-mm gap height is still within the recommended gap setting for dispersion, which is at least 10 times larger than the largest dimension of particles (Mezger 2014). All rheological measurements were done in triplicate and averages are reported.

Rheometer Tempering

The manual tempering protocol Tc20Tm33 and Tc22Tm33 were set as those to be simulated by performing a temperature ramp during rotational measurements in the rheometer to produce rheometer-tempered chocolate (RT). Variation and combination of experimental setups, ranging from gap size (0.5 and 0.4 mm), shear rate (50, 75 and 100 s-1), pre-conditioning geometry temperature (33.5 and 40.0 °C), sampling location (gap center and surface of geometry), and temperature profile (Table 2), were tested. Prior to measurement, the temperature of the measuring geometry was pre-conditioned at the selected temperature for 30 min. Two temperature profiles were approached. The first approach (RTa) mimicked the evolution of actual chocolate temperature during manual tempering, consisting of a combination of cooling, holding, and remelting step. The second approach (RTs) was to enforce the same water bath temperature as in the manual tempering, adding 400-s holding time between the cooling and remelting phase and adding a residential time of an hour.

Flow Curve

Flow curve measurements were adapted from the newly proposed protocol described by Hendrik et al. (2023), performing pre-shearing at 5 s−1 for 300 s, followed by shear rate ramp-up within 1–90 s−1 with 10 measurement points each for 16 s. Temperature, including pre-conditioning temperature for the measuring geometry, was set at 40 °C for NT and corresponding remelting temperatures (30 °C, 32 °C, or 33.5 °C) for tempered chocolate. A modified Herschel-Bulkley model (de Souza Mendes 2011) was employed as follows:

where τ0, k, n, η∞, and \(\dot{\gamma}\) are the yield stress (Pa), the consistency index, the power law index, the viscosity at infinite shear rate (Pa s), and the shear rate, respectively. Non-linear curve fitting of the experimental data with the mathematical model was performed using OriginPro Version 2023 (OriginLab Corporation, Northampton, USA).

Rheometer Solidification

An oscillatory time sweep test was performed with a constant frequency (f) of 1 Hz and shear strain (γ) of 0.01% strain following the temperature ramp protocol of Tc20Tm33 and Tc22Tm33. The temperature was set at 20 °C and kept for 60 min to induce crystallization. Three rheograms were obtained by plotting the mean values of complex modulus (G∗), storage modulus (G′), and loss modulus (G′′), and phase shift angle (δ), as a function of crystallization time.

Melting Profile

Crystallization and melting of chocolate were monitored using Q1000 DSC (TA Instruments, New Castle, USA) equipped with a refrigerated cooling system purged with nitrogen and calibrated with indium (TA Instruments, New Castle, USA), azobenzene (Sigma-Aldrich, Bornem, Belgium) and undecane (Acros Organics, Geel, Belgium). A sample mass of 8–12 mg of untempered or freshly tempered chocolate was loaded in the pans and sealed in hermetic aluminum pans, whilst an empty pan served as reference. Pans were stored in a 20 °C thermal cabinet for 6 h prior to thermal analysis. Measurements were done in triplicate. Melting profiles were recorded by heating at 5 °C/min to 60 °C. The melting parameters consisting of melting enthalpy (∆H), onset temperature (Tonset), offset temperature (Toffset), and peak temperature (Tpeak) were obtained by data processing using universal analysis (TA Instruments, New Castle, USA). The difference between Toffset and Tonset was noted as temperature range (∆T).

Statistical Analysis

Statistical analysis was performed with SPSS statistics 28 (SPSS Inc., Illinois, USA). Flow curve parameters and melting parameters were subjected to one-way analysis of variance (ANOVA) with a 5% significance level. Assumptions of normality and equality of variance were tested before analyzing using the Shapiro-Wilk test and modified Levene’s test, respectively. When assumptions were fulfilled, a post hoc Tukey’s test was used to investigate different levels of predictors.

Results and Discussion

Methodologies to validate and monitor rheological parameters in different chocolate solidification steps are discussed in this section. First, MT with different tempering protocols were prepared, followed by investigating the process and the product with various techniques. Information gained from the validation techniques comprise (i) chocolate and water bath temperature evolution during tempering, (ii) the flow curve of freshly tempered samples, and (iii) the melting profile of tempered samples after 6 h of solidification. Next, selected tempering protocols were simulated in the rheometer to produce RT using different experimental settings. The same techniques to investigate the temper quality of MT were then applied to validate RT. Finally, selected rheometer tempering protocol was further tested for experimental simulation of solidification in a rheometer whereby the evolution of rheological parameters during solidification was discussed.

Validation of Manual Tempering

The selected temperature ranges in Table 1 aim to explore the effects of different cooling rates and possible crystal polymorphic distributions, allowing different tempering techniques to be validated against the commonly used calorimetric method. Although manual tempering was performed using 6 different protocols, Tc20Tm30 and Tc22Tm30 are deemed unsuitable to be performed in laboratory-scale experiments. Manual shearing was insufficient to create a homogenous and reproducible sample considering lump formation observed in the tempered chocolate after 60 min of shearing at final TM of 30 °C. Windhab (2017) reported that local maximum shear rates acting tempering machines can vary from 500 to 12000 s−1, a range that will never be achieved by hand tempering. The shear stress acting on the crystal aggregate might be insufficient to induce fragmentation into individual crystals or smaller aggregates (Mishra et al. 2021a; Mishra et al. 2023) that were already formed in the primary crystallization during manual tempering before remelting at 30 °C, aside from distributing heat transfer to melt the product homogenously.

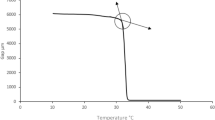

The evolution of chocolate temperature during different manual tempering protocols is displayed in Fig. 1. A thermoelectric couple was placed in the middle of the chocolate mass while shearing is involved amid tempering. Except for Tc22Tm32, all tempering profile seems to indicate good reproducibility by the end of the remelting phase. Debaste et al. (2008) identified a thermal gradient between different positions of thermoelectric couple during static crystallization directly after an alternative artisanal tempering method, where solid pieces of chocolate is used as seed material.. Although the thermologger only measured 1 point in the middle of chocolate mass in our research, the manual shearing ensures heat and mass transfer distribution, resulting in reproducible data and can be used to validate tempering protocols based on its temperature evolution.

Thermodynamic phenomena can be further detected from the chocolate temperature evolution during manual tempering method (Fig. 1). A sudden increase followed by a slight decrease in chocolate temperature appeared succeeding the peak crystallization temperature of samples with TC at 20 °C and slightly in TC at 22 °C, indicating latent heat release due to CB crystallization (Windhab 2017). Tempering with TC at 20 °C required a shorter crystallization time (tC) than TC at 22 °C (Table 3); however, the effect towards TM at both 32 °C and 33.5 °C was different. All MT tempering protocols retained comparable remelting time (tM), however, chocolate temperature of samples with TC at 20 °C never reached 33.5 °C in the end, while the chocolate temperature of both TC at 20 °C and 22 °C reached a final temperature identical with water bath TMat 32°C. Though a lower product temperature in comparison to the heating medium during conventional tempering is expected (Svenstrup et al. 2005), the variation might also be influenced by the initial polymorph that was created during crystallization. Windhab (2017) indicated that unstable α polymorphs form at TC below 22 °C, whereas a mix of metastable β and a small amount of stable β polymorphs form at TCbetween 22 and 27 °C in a conventional tempering setup. The existence of the mix of metastable and stable polymorphs in MT Tc22Tm33 might explain why the chocolate temperature never reached 33.5 °C as higher temperature is required to melt the metastable polymorphs.

Significantly distinct flow behavior between NT measured at 40, 33.5, or 32 °C in Fig. 2 demonstrates the temperature dependence of molten chocolate as expected from a non-Newtonian suspension. Intermolecular interactions and structure of TAG fractions in CB vary at different temperature (Campos and Marangoni 2014) which consequently alters the flow behavior of molten chocolate as a whole. Lower measuring temperature allow stronger molecular forces in TAG fractions and therefore increases the measured apparent viscosity (η) or shear stress (τ) values, regardless of its measuring \(\dot{\gamma}\). For this reason, corresponding TMfor every tempering protocol should be used as the measurement temperature instead of 40 °C as suggested by ICA (2000) protocol, including when compared with NT samples.

Measuring the steady-shear flow of tempered chocolate can give important flow information missing from measuring the steady-shear flow of molten untempered chocolate. While the contrast in the flow behavior between MT Tc20Tm33 and MT Tc22Tm33 in Fig. 2a is insignificant, both tempered chocolates have a slightly higher η at \(\dot{\gamma}\) = 1 s−1 of 17.59 ± 0.29 and 17.57 ± 0.01 when compared with NT33 with η of 15.99 ± 0.03 (Fig. 2a). Meanwhile, a substantial increase in both η of Tc20Tm32 and Tc22Tm32 is obvious when compared with NT32 (Fig. 2b). An increase of η indicates the successful creation of CB seed crystals (Bolliger et al. 1999; Briggs and Wang 2004). A significant increase in τ0 (Table 4) between respective NT and MT also confirms the increase of CB seed crystals and the difference in their quantity between different MT tempering protocols. Thus, measuring the flow curve of tempered chocolate at their correspondent remelting temperature might support the determination of tempering quality along characterization of the flow behavior of tempered chocolate.

Accurate methodology and interpretation are nevertheless essential while performing steady-shear flow on tempered chocolate. Briggs and Wang (2004) found a plateau at \(\dot{\gamma}\) > 70 s−1 when attempting to analyze flow curve of tempered chocolate from different tempering protocols. Similar plateau exist in the shear stress curve of MT Tc20Tm32 and MT Tc22Tm32 on Fig. 2b at \(\dot{\gamma}\) > 70 s−1, although lacking in MT on Fig. 2a. In fact, spillage from the parallel plate was qualitatively observed following flow measurement of MT Tc20Tm32 and MT Tc22Tm32. Such phenomenon happens in matrices with higher volume fraction and caused by a flow artifact namely edge fracture, which might be caused by the result of centrifugal force that is higher than the surface tension from the two parallel plate (Hendrik et al. 2023). Nucleation of seed crystals during crystallization phase increases the volume fraction of CB as continuous phase in chocolate, where higher increase was observed in a more stable polymorph (Sonwai and Mackley 2006). The higher volume fraction of MT with TM at 32 °C (Fig. 2b) prompted higher η over MT with TM at 33.5 °C (Fig. 2a). Such increase in η is undesirable for the handling, application, or further solidification processing step (Bolliger et al. 1998; Seguine 1991). Moreover, reproducibility seems to be an issue for MT with TM at 32 °C in Fig. 2b which is in accordance with the reproducibility of chocolate temperature evolution during tempering in Fig. 1b.

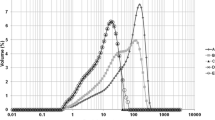

A comparison of the melting profile performed between NT and MT of different protocols is illustrated in Fig. 3. A melting rate of 5 °C/min was performed next to 6 h of solidification at 20 °C using the DSC to ensure reproducibility. Direct measurement after sampling appears to be problematic as difficulty arises when determining a linear baseline to obtain integral area for melting enthalpy (Ioannidi et al. 2021) and variation due to secondary crystallization of CB might occur regardless of the pre-crystallization status (Fessas et al. 2005). Analyzing melting profile using DSC is a popular method to examine crystallization in fat-based suspensions including chocolate matrix, where mostly the enthalpy needed to melt is correlated with a certain polymorphic form of CB or even to specific TAGs (Bresson et al. 2011; Van Malssen et al. 1999). Even though CB polymorphs affect the overall melting profile of the chocolate matrix, the presence of non-fat ingredients such as bulk sugar and emulsifiers should be considered, as such ingredients act as a nucleation site for heterogeneous crystallization (Svanberg et al. 2011). This explains the delay of the melting of CB in a chocolate matrix when compared with the melting of pure CB (Fessas et al. 2005). Meanwhile, relying only on DSC profiles from literature to interpret the crystallization behavior of chocolate is misrepresentative due to a variation in composition, measurement protocol or even environmental influences (Ioannidi et al. 2021). For this reason, the comparison between melting profiles in Fig. 3 only acts as an approach to determine tempering quality between one batch of chocolate produced by the same process condition prior to analysis. Meanwhile, approach to describe polymorphic distribution of CB between tempering protocols are to be accompanied with the thermologger and flow curve result, making up the purpose of toolbox for validation.

Unlike the single melting peak in the melting profile of all MT tempering protocols, two melting peaks can be observed in NT in Fig. 3. This marks the absence of a stable CB polymorphs in NT and can be identified as two ongoing crystallization events following 6 hours of solidification at 20 °C: (i) nucleation of unstable α polymorphic form from melt and (ii) solid-state transition of some readily α polymorphs into metastable β polymorphs. Two simultaneous crystallization events have been previously observed during static crystallization of isolated crystalline fractions of CB (Campos and Marangoni 2014). Meanwhile, Shi and Maleky (2015) found a melting peak and a noticeable shoulder in the DSC curve of a chocolate model system consisting of CB, sucrose, and lecithin after 13 h of static crystallization and confirmed the existence of two different polymorphic forms from a representative XRD pattern. Existence two melting peaks was also observed in a DSC curve of tempered CB crystal melt suspension with the lower temperature peak indicating the presence of an unstable crystal polymorph (Mishra et al. 2021b). The presence of two melting peaks in the DSC after static crystallization at 20 °C can therefore act as a control for whether or not a sample has been pre-crystallized.

The reproducibility between repetitions appears as another visible variation between NT and MT from different tempering protocols in Fig. 3. A lower reproducibility is expected in a conventional tempering method due to the complexity of dynamic over static crystallization such as in the case of NT, even when the tempering method utilizes an automated system covering a certain degree of shear, time and temperature (Svanberg et al. 2013). While the reproducibility of the melting parameters of MT from different protocols (Table 4) seems to be acceptable, deviation in MT of Tc22Tm32 appears to be the highest, consistent with the tempering profile and flow curve result.

A wider melting range of MT with TM at 32 °C in comparison to MT with TM at 33.5 °C can be noticed in Fig. 3. Although a melting range depicts the melting of different fat fractions in CB, it is further correlated with the distribution of different CB polymorphic forms, especially in the case of a pre-crystallized sample. Therefore, well-tempered molten chocolate may consist of mixed polymorphic form of CB (Loisel et al. 1998). Both Tonset and Toffset of MT with various protocols, unlike NT, ranges from metastable to stable polymorphic form when referred to the melting temperatures of CB (Bresson et al. 2011; Van Malssen et al. 1999). However, Afoakwa et al. (2009) suggested that a wider temperature range can be attributed to over-tempered chocolate, such as in the case of MT with TM at 32 °C with significantly wider ∆T reported in Table 4.

The Tpeak of MT from varying protocols after 6 h of solidification at 20 °C reported in Table 4 fell in the range of stable CB polymorphic form (Bresson et al. 2011; Van Malssen et al. 1999). Despite a certain delay in the melting profile reading of a chocolate matrix over a pure CB, a substantial difference was prominent when comparing the Tpeak of MT with the second Tpeak of NT. For this reason, all of the manual tempering profiles can be considered to be successfully tempered. The varying melting parameters, while still indicating well-tempered chocolate, are heavily influenced by the different tempering protocols. The selection of TC and tC during MT affect the final CB polymorphic distribution after tempering (Stapley et al. 1999; Windhab 2017).

A combination of synchronous chocolate temperature recording during tempering followed by a flow curve test directly following tempering and melting profile after 6 h of solidification time at 20 °C are able to characterize the tempering quality of a conventional tempering protocol. This collection of techniques can be utilized to test tempering protocol reproducibility, where higher variability can be observed in MT with TC at 22 °C. An obvious distinctiveness can be observed between NT and MT samples from the flow curve and melting profile, and additionally, each of the MT from different protocols can be further characterized. In the case of MT with TC at 22 °C, undesirable higher η in Fig. 2 and the significantly wider ΔT in Table 4 can be noticed. Moreover, Tpeak of MT at Tc22Tm32 is significantly higher than the other MT at 33.41 ± 0.94 °C. For this reason, only MT with TC at 20 °C will be considered for further experiments.

Experimental Setup of Rheometer Tempering

Figure 4a shows the melting profile of RTa Tc20Tm33 performed at 50 s−1 sampled from the middle of the gap between plates measured at different gap sizes. A gap size of 0.5 mm was chosen to reduce the possibility of contraction, and sandblasted profile was chosen to mimic the gap size between rotating blades on a scraped-surface heat exchanger system that is used in industrial tempering (Loisel et al. 1997; Mishra et al. 2021a). Briggs and Wang (2004) notice contraction of radial direction up to a length of 0.5 mm using a smooth parallel plate with 1-mm gap size when simulating tempered chocolate. Despite the similar melting profiles, the measurement at 0.4-mm gap size demonstrates a higher deviation. For this reason, 0.5-mm gap size was used for further measurements. Meanwhile, gap height is recommended to be at least 10 times larger than maximum particle size in suspensions as bigger particles would take the interparticle free space when in motion, influencing deformation and flow behavior. The gap size of 0.4 mm already surpasses the gap height recommendation as the biggest particle size in the mass recorded was at 42.95 ± 3.01 μm, which might explain the higher deviation in the melting profile.

Figure 4b reveals the melting profile of Tc20Tm33 performed at 50 s−1 sample measured at 0.5-mm gap size and the sampling for DSC measurement was taken from the middle of the gap and the surface of the measuring geometry. As secondary crystallization might occur from the surface and the heating material is only available from the bottom plate, heterogeneous crystal artifacts are expected. Sample from the surface gave a slightly higher melting profile, nonetheless compromising the reproducibility of the result. Bolliger et al. (1998) noticed that selected gap size and shear flow are necessary to improve secondary nucleation from the surface and therefore create a homogenous crystal polymorph distribution. While it might be possible to modify the selected gap and shear rate in our system to improve secondary crystallization on the surface of the geometry, flow artifacts such as edge fractures might also appear due to the adjustment. For this reason, samples were obtained only from the middle of the gap for further experimental setup.

The melting profile of Tc20Tm33 measured at 0.5-mm gap size sampled from the middle of the gap and performed at different shear rates are demonstrated in Fig. 4c. The \(\dot{\gamma}\) at 50–100 s−1 was selected as they represent the possible \(\dot{\gamma}\) during manual tempering (Mezger 2014). Applied \(\dot{\gamma}\), combined with crystallization temperature, however, influences crystallization rate (Padar et al. 2009). A higher \(\dot{\gamma}\) enhance the crystallization of higher melting polymorph at a hold temperature between 20 and 23 °C (Dhonsi and Stapley 2006). The result in Fig. 4c follows such theory, where samples measured at a \(\dot{\gamma}\) of 75 s−1 and 100 s−1 show a higher melting profile and consequently increase the deviation between the samples. For this reason, a \(\dot{\gamma}\) of 50 s−1 will be used for further experimental setup.

Although selecting the appropriate rheometrical setups such as gap size, shear rate, and sampling location (Fig. 4) improves the reproducibility of the melting profile, a characteristic well-tempered chocolate melting profile was absent from such setup. Geometry temperature and imposed tempering time were concluded to be directly contributing to the success of producing well-tempered chocolate as illustrated in Fig. 5. Setting rheometer geometry pre-conditioning temperature to 33.5 °C with a longer holding time at TC and an additional 1 h of shearing at TM, was found to produce well-tempered chocolate, producing a single Tpeak at 32.74 ± 0.43 °C. When the tempering profile was measured with rheometer geometry temperature at 40 °C, a higher melting profile was produced compared to the chocolate tempering profile, but still produce a two-step crystallization, indicating an under-tempered sample. Characteristic tempering time is then important when tempering is performed in a rheometer. This coincides with the work of Stapley et al. (1999) where a given induction time is required to start the crystallization. A residence time of holding temperature under shear subsequent to tempering is important ahead of further crystallization, possibly to ensure a homogenous polymorphic distribution after tempering.

Validation of Rheometer Tempering

Figure 6 displays imposed temperature profile during temperature ramp measurement and the effect on viscosity evolution during tempering. For both tempering profiles, the temperature dropped to the selected cooling temperature in the first 100 s marked by an increase in viscosity for both tempering profiles followed by a sudden decrease in η during isothermal holding time at respective TC. Briggs and Wang (2004) discovered a resembling phenomenon when investigating using a smooth parallel plate of 35-mm diameter with 1-mm gap height, presuming that the immediate decrease in η occurs due to the possibility of apparent wall slip or contraction. However, such wall slip or contraction based on normal force reading was absent in our experiment as 25-mm diameter serrated parallel plates with 0.5-mm gap height were utilized to prevent such issues. During holding time at the corresponding TC, η slowly decreased; however, it can be noted that viscosity starts to increase by the end of the crystallization period for Tc22Tm33. This might indicate an induction time occurring in Tc22Tm33. Temperature-dependent effects clarify the huge viscosity difference between the two tempering profiles during crystallization. Meanwhile, the η of both tempering profiles drops to an identical value during remelting and remains relatively stable, with η of Tc22Tm33 slightly above that of Tc20Tm33. This confirms that a matching flow characteristic of pre-crystallized chocolate can be achieved from different tempering methods. Thus, this final constant η of both tempering profiles at 33.5 °C holding temperature and \(\dot{\gamma}\) of 50 s−1 acts as an important rheological indicator needed preceding subsequent processing steps such as solidification.

The tempering quality of RTs from different protocols can be compared with MT from the corresponding protocol by performing the validation toolbox consisting of a steady shear flow test and melting profile following 6-h solidification at 20 °C as shown in Fig. 7. Based on the flow curve test in Fig. 7a, it is evident that tempering in the rheometer can produce comparable quality and quantity of crystal seeds to manual tempering protocol required for further crystallization, marked by higher η value at the \(\dot{\gamma}\) of 1-10 s−1 in comparison to NT. Despite no statistical difference between respective TC between each tempering method, τ0 of RTs of Tc20Tm33 is significantly lower than that of MT (Table 5). This could be due to the distinct historical shear applied prior to the flow curve measurement as the flow curve of chocolates tempered in the rheometer was performed subsequently and temperature is kept constant at the final remelting temperature. Meanwhile, the time required for applying a manual tempering sample on the measuring geometry might compromise the flow curve measurement, regardless of whether the pre-shearing has been applied. At \(\dot{\gamma}\) > 10 s−1, all tempered samples behave proportionate to NT, regardless of the instrument and protocol, establishing a desirable characteristic of pre-crystallized chocolate preceding to further chocolate processing (Bolliger et al. 1998; Windhab et al. 1991).

Comparable to the product of manual tempering, tempering in the rheometer was successful with two different crystallization temperatures resulting in a single melting peak as an indication of a single crystallization event contrary as opposed to the two crystallization event that occurs in NT (Fig. 7b). Moreover, Tpeak between MT and RTs were comparable (Table 5), indicating a similar higher distribution of the same polymorphic form, specifically the βV polymorph when referred to melting profiles of CB (Bresson et al. 2011; Van Malssen et al. 1999). This confirms that not only tempering in the rheometer can produce stable crystal seeds, but it can also simulate conventional tempering. However, it can be noticed in Table 5 that RTs retain a narrower melting profile as indicated in ΔT, confirmed with the higher Tonset and the lower Toffset in comparison to MT. This could be explained by the automatic shearing and longer residence time on RTs that ensure more uniform development of different CB polymorphs in the matrix. Distinct polymorphic distribution might explain different flow behavior as can be seen from a proportionate correlation between ΔT and τ0 in Table 5. Correlation between thermal behavior, uniform particle size and yielding behavior have been previously reported in molten chocolate (Afoakwa et al. 2008c). However, it can be noted that samples tempered in a rheometer require less enthalpy needed to completely melt the sample in comparison to manual tempering. Meanwhile, the difference in ΔH between MT and RTs seems to indicate different microstructural development which could additionally be influenced by diverse CB polymorphic distribution.

Similar flow behavior and Tpeak of different TC, whether in MT or RT, is primarily influenced by the different tC of each protocol. The shorter tC in samples tempered with TC at 20 °C in comparison to the ones at 22 °C were determined qualitatively and observed during MT (Table 3) and, in turn, simulated in RTs in Fig. 6. Stapley et al. (1999) found significantly different crystallization and melting curves of dark chocolate measured with DSC after different holding time prior to crystallization at 22 °C. Induction time for nucleation in CB happens later and becomes more shear-dependent at higher crystallization temperatures (Dhonsi and Stapley 2006). Distinct nucleation time could be influenced by the different types of polymorph formed at different temperatures as unstable α polymorph formed at TC below 22 °C in comparison to a mix of unstable β’ polymorph and a small fraction of βV polymorph at TC of 22–27 °C (Windhab 2017). This might explain the resemblance in flow and thermal behavior in Tc20Tm33 and Tc22Tm33, as each of the tempering protocols has different tC and especially RTs possessed different isothermal holding times subsequent to crystallization. Meanwhile the identical TM at 33.5 °C can predominantly eliminate unstable seed crystals of all tempering protocols.

Aside from Tpeak, other melting parameters along with flow parameters can be employed to elucidate possible microstructural development variation between tempering protocols. Comparable to the difference between MT and RT, the wider ΔT in RTs with Tc22Tm33 over RTs with Tc20Tm33 can be spotted in Table 5. The wider polymorphic distribution of RTs with Tc22Tm33 might be responsible for the higher η by the end of rheometer tempering (Fig. 6) and in turn responsible for higher τ0 from the modified Herschel-Bulkley model fitting of the flow curve test reported in Table 5.

Flow behavior characterization subsequent to rheometer tempering provides an efficient means to simulate and characterize the tempering process. Both manual and rheometer tempering protocol has been validated against conventional DSC results (Fig. 7b), demonstrating their effectiveness. Furthermore, rheometer tempering offers enhanced control over both thermal and shear history as supported by the flow curve data (Fig. 7a) where thermal history holds greater significance than shear history in the tempering process as reflected in different tempering protocols. Notably, Bhattacharyya and Joshi (2022) findings highlight a similar mechanism where the evolution of rheological properties resulting from thermal rejuvenation differs from mechanical rejuvenation, with the former exhibiting a more abrupt evolution. Further research is needed to compare the rheometer protocol with industrial-scale conditions, considering different shear flow conditions, to enhance accuracy.

Rheometer Solidification

An isothermal crystallization was imposed on RTs of two protocols to investigate the capability of the rheometer to observe rheological changes during the setting of pre-crystallized chocolate. Small-amplitude oscillatory shear (SAOS) time sweep has been done on palm oil (De Graef et al. 2006) and CB (Sonwai and Mackley 2006; Toro-Vazquez et al. 2005) to investigate the rheological behavior of crystallizing fats. Nevertheless, SAOS has never been done on chocolate, let alone a pre-crystallized one. We found that the solidification can be performed subsequently to the tempering in the rheometer without changing any settings as no flow artifacts were found during the previous rheometer tempering and the chocolate sample is still intact between the sandblasted parallel plates. The complex viscosity, storage modulus, loss modulus, and phase shift angle were recorded over the course of 1 h at 20 °C.

The evolution of G∗of both RTs with Tc20Tm33 and Tc22Tm33 are indicated in Fig. 8a. For both tempering protocol, G∗ decreases in the first 50 s of isothermal condition, possibly due to shear history from rotational shear during rheometer tempering with \(\dot{\gamma}\) at 50 s−1, transitioning to SAOS with f at 1 Hz. Trend of G∗ continues equivalently for both samples with an exponential increase followed by a steady increase. G∗ of RTs with Tc22Tm33 continues to increase to a value around 107 Pa until becoming constant since the 1500s of isothermal time. Yet, another pattern can be seen for RTs with Tc20Tm33 where G∗ undergo steady decrease until becoming constant after the 2100s with a value almost half of the G∗ of RTs with Tc22Tm33. Although the distinct crossover time of G′and G′′ between RTs with Tc20Tm33 and Tc22Tm33 can be remarked in Fig. 8b, a comparable trend of G∗ in Fig. 8a is likely due to similar crystallization of CB melt in both tempering protocols. Meanwhile, variation in microstructural development mechanism might explain the different development of G∗ between the protocols toward the end of isothermal crystallization. Such growth in the microstructure could be related to the different polymorphic distribution that was discovered via the tempering validation techniques on pre-crystallized RTs. Sonwai and Mackley (2006) found a matching tendency while performing a SAOS time sweep where rheological evolution marked the onset of the primary phase of crystallization occurring within up to 150 s of isothermal time at 20 °C followed by a different trend of rheological evolution that was correlated with the secondary phase of crystallization. Moreover, the different shear rate steps were applied to simulate pre-crystallization, which influences the variation of the secondary trend of the rheological evolution before leading to linear development.

Progress of viscoelastic behavior of different tempering protocols of RTs can be further investigated in Fig. 8b. A different crystallization onset can already be observed between the two protocols in the inset of Fig. 8b, where the ratio G′and G′′ below 100 s of isothermal time start to slope up with time prior to the crossover point between the two moduli. The crossover point, occurring at a different time point between the two tempering protocols, can be considered a characteristic point that marks the transition in the chocolate from a viscoelastic liquid into a viscoelastic solid material. Interestingly, the ratio did reach a proportional trend up until 1000 s of isothermal time. This could further strengthen the premise of the border between primary crystallization and microstructural development occurring in both protocols. Moreover, the different ratio of G′and G′′ between RTs with Tc20Tm33 and Tc22Tm33 by the end of isothermal time could indicate different microstructures of chocolate that might be reflected in their final macroscopic structural quality. The difference in the G′, G′′, and the characteristic crossover point was previously detected in various pre-crystallization methods of dark chocolate by differing the addition of CB crystal suspension, although observed during non-isothermal crystallization (Grob et al. 2021).

In Fig. 8c, the phase shift angle δ is plotted as a function of isothermal time during setting and solidification at 20°C of pre-crystallized MV from two tempering protocols of Tc20Tm33 and Tc22Tm33. The evolution of δ starts with some discrepancy at the beginning of isothermal crystallization below 90°. δ indicates energy stored or dissipated in the material, with δ = 90° indicating a perfectly viscous material and δ = 0° indicating a perfectly elastic material (Mezger 2014). Since the pre-crystallized chocolate consists of both solid crystallized CB seeds and non-fat solids such as sucrose and cocoa solids, it was anticipated that the start of the δ during isothermal crystallization appears lower than 90°. However, δ immediately decreases steeply until reaching a plateau at 20°, indicating a decrease in the viscous character of the material. Both samples from the two protocols exhibit a similar trend and the δ stays constant in the following 600 s, indicating no changes between the viscous and solid characteristics of the material. At the 1100 s, a second decrease occurs and the behavior of the sample from the two protocols changes following the decline, with δ of Tc22Tm33 staying at 10° until 60 min of isothermal time whereas δ of Tc20Tm33 increased at 1300s until reaching a stable plateau at 20°.

While most of the trend of δ for both tempering protocols follows their G∗, some notable differences could further elucidate microstructure development in each of the tempering protocols by observing the δ. The first declination of δ into 20° of samples from both protocols could be related to the primary crystallization of the CB from melt to α crystal polymorphs followed by a solid-state transition into β’ crystals when δ stays constant for 600 s. However, in Fig. 8a, it can be observed that G∗ continues to increase steadily during this constant δ period. De Graef et al. (2006) found the same disparity between δ and G∗ in the resembling time-scale during isothermal crystallization of palm oil at 18 °C, indicating correlation of the evolution of δ and non-solid-state polymorphic transitions, whilst relating the evolution of G∗ to a more complete crystallization phase, including any polymorphic transition and microstructural development. Therefore, it could be postulated that the increase of G∗ during the constant period of δ between 600 and 1100 s is due to pure aggregation of available crystals in the matrix. Moreover, this could explain the previous exponential increase of G∗ from 150 to 600 s where both aggregation and polymorphic transition from melt to α crystal polymorphs simultaneously occur.

The second declination of δ after 1100s of isothermal crystallization time (Fig. 8c) could then be indicating a direct polymorphic transition from melt to β’ crystals. Van Malssen et al. (1999) discovered the different transition times between melt to α polymorph and melt to β’ polymorph in an isothermal condition at different temperatures from an extensive DSC work. Such patterns were also found in the previous observation of δ during static crystallization of CB and palm oil (De Graef et al. 2006; Toro-Vazquez et al. 2005). Interestingly, the two different tempering protocols influence the length of this transition from melt to β’ crystals and the crystallization thereafter. The difference between the tempering protocol could be related to the release of crystallization heat. This could be related to the initial CB polymorph that was produced during TC of each tempering protocol at different tC (Fig. 6). Presuming α polymorphs are produced at TC of 20 °C during tempering in the rheometer, the increase of δ subsequent to the 1200 s of isothermal crystallization at 20 °C (Fig. 8c) is expected as recrystallization of α polymorph that was melted due to latent heat release occurs. Meanwhile, as an abundant amount of β’ polymorph with a small amount of β polymorph arises at TC of 22 °C, effects from this release of crystallization heat are small that it was unrecorded in the change of δ in Fig. 8c. In addition, the abundance of metastable and stable polymorph in RTs with Tc22Tm33 by the end of isothermal crystallization coincides with the wider polymorphic distribution toward a higher melting profile from DSC result following 6 hours of solidification at the same isothermal temperature. This proves the importance of rheological data to follow and characterize (pre-)crystallization of molten chocolate to investigate their primary crystallization, microstructural development and macroscopic properties.

Conclusions

Rheometrical methods exhibit a robust capability in monitoring the microstructural changes occurring during (pre-)crystallization of chocolate, while simultaneously tracking the evolution of rheological properties under controlled thermal and shear conditions. The influence of selected pre-crystallization time and temperature can be mimicked with a rotational temperature ramp test, resulting in a higher reproducibility in comparison to the manual tempering protocol, given an accurate rheometrical experimental setup. A flow curve test for pre-crystallized chocolate was performed without compromising the state of the available stable seed crystals following the simulation of tempering in the rheometer. An oscillatory time sweep test can be performed subsequently to the rheometer tempering to follow the crystallization behavior simulating the solidification process step for chocolate. Moreover, these successive combinations of rheometrical methods only require a small amount of sample in comparison to the required minimum capacity of the manual tempering method and undoubtedly a conventional tempering machine.

Rheometrical techniques allow for differentiation between different tempering degrees and further clarify distinctions within a tempering degree, including variations observed in the primary crystallization, microstructure development, and overall macroscopical quality among different well-tempered chocolate. Supplementing these rheometrical analyses with calorimetric analysis using DSC can enhance the interpretation and comparison of the final macroscopical quality of chocolates. These combined techniques enable the potential to engineer the flow behavior and crystallization mechanisms for specific chocolate applications without fundamentally altering the molten chocolate matrix.

Data Availability

The authors declare that the data supporting the findings of this study are available within the article.

Abbreviations

- CB:

-

Cocoa butter

- TAGs:

-

Triacylglycerols

- NT:

-

Non-tempered chocolate

- MT:

-

Manually tempered chocolate

- RT:

-

Rheometer-tempered chocolate

- DSC:

-

Differential scanning calorimetry

References

Afoakwa EO, Paterson A, Fowler M, Vieira J (2008a) Effects of tempering and fat crystallisation behaviour on microstructure, mechanical properties and appearance in dark chocolate systems. J Food Eng 89(2):128–136. https://doi.org/10.1016/j.jfoodeng.2008.04.021

Afoakwa EO, Paterson A, Fowler M, Vieira J (2008b) Modelling tempering behaviour of dark chocolates from varying particle size distribution and fat content using response surface methodology. Innovative Food Sci Emerg Technol 9(4):527–533. https://doi.org/10.1016/j.ifset.2008.02.002

Afoakwa EO, Paterson A, Fowler M, Vieira J (2008c) Relationship between rheological, textural and melting properties of dark chocolate as influenced by particle size distribution and composition. Eur Food Res Technol 227(4):1215–1223. https://doi.org/10.1007/s00217-008-0839-5

Afoakwa EO, Paterson A, Fowler M, Vieira J (2009) Influence of tempering and fat crystallization behaviours on microstructural and melting properties in dark chocolate systems. Food Res Int 42(1):200–209. https://doi.org/10.1016/j.foodres.2008.10.007

Bergemann N, Heil M, Smith B, Juel A (2018) From elastic deformation to flow in tempered chocolate. J Rheol 62(5):1187–1195. https://doi.org/10.1122/1.5038253

Bhattacharyya T, Joshi YM (2022) Effect of thermal and mechanical rejuvenation on the rheological behavior of chocolate. Phys Fluids 34(3). https://doi.org/10.1063/5.0083335

Bolliger S, Breitschuh B, Stranzinger M, Wagner T, Windhab EJ (1998) Comparison of precrystallization of chocolate. J Food Eng 35(3):281–297. https://doi.org/10.1016/S0260-8774(98)00046-6

Bolliger S, Zeng Y, Windhab EJ (1999) In-line measurement of tempered cocoa butter and chocolate by means of near-infrared spectroscopy. JAOCS, J Am Oil Chemistsʼ Soc 76(6):659–667. https://doi.org/10.1007/s11746-999-0157-5

Bresson S, Rousseau D, Ghosh S, El Marssi M, Faivre V (2011) Raman spectroscopy of the polymorphic forms and liquid state of cocoa butter. Eur J Lipid Sci Technol 113(8):992–1004. https://doi.org/10.1002/ejlt.201100088

Briggs JL, Wang T (2004) Influence of shearing and time on the rheological properties of milk chocolate during tempering. J Am Oil Chem Soc 81(2):117. https://doi.org/10.1007/s11746-004-0868-9

Campos R, Marangoni AG (2014) Crystallization dynamics of shear worked cocoa butter. Cryst Growth Des 14(3):1199–1210. https://doi.org/10.1021/cg4017273

De Graef V, Dewettinck K, Verbeken D, Foubert I (2006) Rheological behavior of crystallizing palm oil. Eur J Lipid Sci Technol 108(10):864–870. https://doi.org/10.1002/ejlt.200600102

de Souza Mendes PR (2011) Thixotropic elasto-viscoplastic model for structured fluids. Soft Matter 7(6):2471–2483. https://doi.org/10.1039/c0sm01021a

Debaste F, Kegelaers Y, Liégeois S, Amor HB, Halloin V (2008) Contribution to the modelling of chocolate tempering process. J Food Eng 88(4):568–575. https://doi.org/10.1016/j.jfoodeng.2008.03.019

Dhonsi D, Stapley AGF (2006) The effect of shear rate, temperature, sugar and emulsifier on the tempering of cocoa butter. J Food Eng 77(4):936–942. https://doi.org/10.1016/j.jfoodeng.2005.08.022

Fessas D, Signorelli M, Schiraldi A (2005) Polymorphous transitions in cocoa butter: a quantitative DSC study. J Therm Anal Calorim 82(3):691–702. https://doi.org/10.1007/s10973-005-0952-7

Grob L, Papadea K, Braun P, Windhab EJ (2021) In-line detection method for crystallization, contraction and mold detachment during cooling of confectionery products. J Food Eng 292. https://doi.org/10.1016/j.jfoodeng.2020.110322

Hendrik NJ, Marchesini FH, Van de Walle D, Dewettinck K (2023) Accurate evaluation of the flow properties of molten chocolate: circumventing artefacts. Food Anal Methods 16(1):109–205. https://doi.org/10.1007/s12161-022-02406-z

ICA, 2000. Viscosity of cocoa and chocolate products., Analytical method 46. CAOBISCO, Bruxelles, Belgium

Ioannidi E, Risbo J, Aarøe E, van den Berg FWJ (2021) Thermal analysis of dark chocolate with differential scanning calorimetry—limitations in the quantitative evaluation of the crystalline state. Food Anal Methods 14(12):2556–2568. https://doi.org/10.1007/s12161-021-02073-6

Kinta Y, Hartel RW (2010) Bloom formation on poorly-tempered chocolate and effects of seed addition. JAOCS, J Am Oil Chemists' Soc 87(1):19–27. https://doi.org/10.1007/s11746-009-1473-5

Le Révérend BJD, Fryer PJ, Bakalis S (2009) Modelling crystallization and melting kinetics of cocoa butter in chocolate and application to confectionery manufacturing. Soft Matter 5(4):891–902. https://doi.org/10.1039/b809446b

Le Révérend BJD, Fryer PJ, Coles S, Bakalis S (2010) A method to qualify and quantify the crystalline state of cocoa butter in industrial chocolate. J Am Oil Chem Soc 87(3):239–246. https://doi.org/10.1007/s11746-009-1498-9

Loisel C, Keller G, Lecq G, Launay B, Ollivon M (1997) Tempering of chocolate in a scraped surface heat exchanger. J Food Sci 62(4):773–780. https://doi.org/10.1111/j.1365-2621.1997.tb15454.x

Loisel C, Lecq G, Keller G, Ollivon M (1998) Dynamic crystallization of dark chocolate as affected by temperature and lipid additives. J Food Sci 63(1):73–79. https://doi.org/10.1111/j.1365-2621.1998.tb15679.x

Maleky F, Marangoni AG (2008) Process development for continuous crystallization of fat under laminar shear. J Food Sci 89(4):399–407. https://doi.org/10.1016/j.jfoodeng.2008.05.019

Mantihal S, Prakash S, Godoi FC, Bhandari B (2017) Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innovative Food Sci Emerg Technol 44:21–29. https://doi.org/10.1016/j.ifset.2017.09.012

Mazzanti G, Guthrie SE, Sirota EB, Marangoni AG, Idziak SHJ (2003) Orientation and phase transitions of fat crystals under shear. Cryst Growth Des 3(5):721–725. https://doi.org/10.1021/cg034048a

Mezger TG (2014) The rheology handbook, 4th edn. Vincentz Network, Hanover, Germany. https://doi.org/10.1515/9783748600367

Mishra K, Grob L, Kohler L, Zimmermann S, Gstöhl S, Fischer P, Windhab EJ (2021a) Entrance flow of unfoamed and foamed Herschel–Bulkley fluids. J Rheol 65(6):1155–1168. https://doi.org/10.1122/8.0000286

Mishra K, Kohler L, Kummer N, Zimmermann S, Ehrengruber S, Kämpf F, Dufour D, Nyström G, Fischer P, & Windhab EJ (2021b) Rheology of cocoa butter. J Food Eng 305. https://doi.org/10.1016/j.jfoodeng.2021.110598

Mishra K, Kummer N, Bergfreund J, Kampf F, Bertsch P, Pauer R, Nystrom G, Fischer P, Windhab EJ (2023) Controlling lipid crystallization across multiple length scales by directed shear flow. J Colloid Interface Sci 630:731–741. https://doi.org/10.1016/j.jcis.2022.10.005

Padar S, Mehrle YE, Windhab EJ (2009) Shear-induced crystal formation and transformation in cocoa butter. Cryst Growth Des 9(9):4023–4031. https://doi.org/10.1021/cg900194t

Seguine ES (1991) Tempering: The inside story. Manuf Confectioner 5:117–125

Shi X, Maleky F (2015) Effects of external shear forces on crystallisation kinetics of model fat blends. Int J Food Sci Technol 50(10):2255–2263. https://doi.org/10.1111/ijfs.12878

Smith KW, Cain FW, Talbot G (2007) Effect of nut oil migration on polymorphic transformation in a model system. Food Chem 102(3):656–663. https://doi.org/10.1016/j.foodchem.2006.05.045

Sonwai S, Mackley MR (2006) The effect of shear on the crystallization of cocoa butter. JAOCS, J Am Oil Chem Soc 83(7):583–596. https://doi.org/10.1007/s11746-006-1243-6

Stapley AGF, Tewkesbury H, Fryer PJ (1999) Effects of shear and temperature history on the crystallization of chocolate. JAOCS, J Am Oil Chem Soc 76(6):677–685. https://doi.org/10.1007/s11746-999-0159-3

Svanberg L, Ahrné L, Lorén N, Windhab E (2011) Effect of sugar, cocoa particles and lecithin on cocoa butter crystallisation in seeded and non-seeded chocolate model systems. J Food Eng 104(1):70–80. https://doi.org/10.1016/j.jfoodeng.2010.09.023

Svanberg L, Ahrné L, Lorén N, Windhab E (2013) Impact of pre-crystallization process on structure and product properties in dark chocolate. J Food Eng 114(1):90–98. https://doi.org/10.1016/j.jfoodeng.2012.06.016

Svenstrup G, Heimdal H, Nørgaard L (2005) Rapid instrumental methods and chemometrics for the determination of pre-crystallization in chocolate. Int J Food Sci Technol 40(9):953–962. https://doi.org/10.1111/j.1365-2621.2005.01029.x

Toro-Vazquez JF, Rangel-Vargas E, Dibildox-Alvarado E, Charó-Alonso MA (2005) Crystallization of cocoa butter with and without polar lipids evaluated by rheometry, calorimetry and polarized light microscopy. Eur J Lipid Sci Technol 107(9):641–655. https://doi.org/10.1002/ejlt.200501163

Van Malssen K, Van Langevelde A, Peschar R, Schenk H (1999) Phase behavior and extended phase scheme of static cocoa butter investigated with real-time X-ray powder diffraction. JAOCS, J Am Oil Chem Soc 76(6):669–676. https://doi.org/10.1007/s11746-999-0158-4

Windhab E, Mehrle Y, Pfister B (2009) Method for the in-line measurement of the setting, contraction and wall release behaviour of confectionery/chocolate products which have been poured into moulds during production, and apparatus for carrying out this method. US Patent US8522616B2

Windhab E, Rolfes L, Rohenkohl H (1991) Shear-induced effects on crystallization from molten fats. Chem Ing Tech 63(4):385–385. https://doi.org/10.1002/cite.330630423

Windhab EJ (2017) Tempering. In: Beckett ST, Fowler M, Ziegleder GR (eds) Beckettʼs industrial chocolate manufacture and use, 5th edn. John Wiley & Sons Ltd, Chichester, West Sussex, UK, pp 314–355. https://doi.org/10.1002/9781444301588.ch10

Zeng Y, Windhab EJ (1999) 101. Kontinuierliche Vorkristallisation von Schokoladen durch Animpfen mit hochstabilen ßVI-Kakaobutterkristallen. Chem Ing Tech 71(9):1008–1009. https://doi.org/10.1002/cite.3307109105

Funding

This research was funded by the Special Research Fund of Ghent University under the call of Concerted Research Actions with project number BOF.GOA.2018.0002.03.

Author information

Authors and Affiliations

Contributions

Nathaniel J. Hendrik: conceptualization, methodology, data collection, data analysis and interpretation, writing—original manuscript preparation and finalization. Flávio H. Marchesini: conceptualization, methodology, data interpretation, writing—reviewing and editing. Davy Van de Walle: conceptualization, methodology, data interpretation, writing—reviewing and editing. Koen Dewettinck: conceptualization, methodology, and writing—reviewing.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

Nathaniel J. Hendrik declares that he has no conflict of interest. Flávio H. Marchesini declares that he has no conflict of interest. Davy Van de Walle declares that he has no conflict of interest. Koen Dewettinck declares that he has no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

J. Hendrik, N., H. Marchesini, F., Van de Walle, D. et al. Chocolate Tempering in a Rheometer: Monitoring Rheological Properties During and After Crystallization of Cocoa Butter. Food Anal. Methods 16, 1555–1570 (2023). https://doi.org/10.1007/s12161-023-02522-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-023-02522-4