Abstract

A previously uncharacterized glycation compound was isolated from a reaction mixture of N-α-Boc-lysine and 3-deoxypentosone by semi-preparative ion-exchange chromatography and was identified by nuclear magnetic resonance (NMR) spectroscopy as 6-(2-formyl-1-pyrrolyl)-l-norleucine (formyline). 3-Deoxypentosone and pentoses like ribose, arabinose, or xylose were identified as the predominant precursors of the new glycation compound, but formyline can also be formed from lysine and degradation products of disaccharides and glucuronic acid. The Amadori products lactuloselysine and ribuloselysine, which were synthesized by improved methods and characterized by NMR spectroscopy, were shown not to form formyline when heated in dry state without lysine added, indicating that reactions between the lysine side chain and dicarbonyl compounds are the main pathways for formyline formation rather than transformation of lysine containing Amadori products. Finally, it was shown by HPLC analysis after enzymatic digestion that peptide-bound formyline can be formed during incubation of casein and 3-deoxypentosone under conditions comparable to food processing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Proteins can severely be modified in the course of the Maillard reaction (“glycation”), which takes place in food systems when sugars and their degradation products react non-enzymatically with lysine and arginine side chains or the N-termini of proteins or peptides, respectively [1, 2]. Amadori products, the relatively stable addition products of sugars and amino groups formed in the initial stage of the reaction cascade, are prone to degrade in the advanced stage, thereby giving rise to highly reactive 1,2-dicarbonyl compounds like 3-deoxyglucosone and fission products like glyoxal and methylglyoxal [3, 4]. Sugars can also degrade to 1,2-dicarbonyl compounds during caramelization reactions, i.e., in the absence of amines. Thermal degradation of disaccharides, especially of lactose, can lead to the C5-dicarbonyl compounds 3-deoxypentosone [5] and 3,4-dideoxypentosone [6]. It is mainly the 1,2-dicarbonyl compounds that react with nucleophilic protein side chains in the final stage of the Maillard reaction to form “advanced glycation end products” (AGEs), an entity of structurally strongly differing compounds [1, 2]. Several Maillard reaction products (MRPs) formed in foods have successfully been analyzed in physiological fluids as well [7]. MRPs can accumulate in tissues with poor protein turnover like eye crystallins or collagen and are discussed in the context of the course of degenerative diseases like diabetes mellitus and morbus Alzheimer and the general aging process [8]. But also the 1,2-dicarbonyl compounds and their degradation products might have adverse effects, e.g., in solutions for peritoneal dialysis [9].

While the Maillard reaction of hexoses has been well studied in the past, rather little is known about specific products resulting from the reaction of pentoses and the respective dicarbonyl compounds, although first reports were published over 50 years ago [10]. Pentoses and especially their phosphorylated derivatives are supposed to be strong glycating agents in vivo [11]. Mixtures of lysine and ribose heated in dry state display cytotoxic and mutagenic activities [12, 13], which could only partly be explained by the content of furfural and have otherwise not been assigned to a special compound.

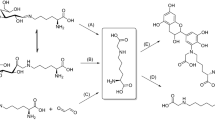

Some structures of pentose-derived AGEs are shown in Fig. 1. Ribuloselysine 1 is an Amadori product formed when ribose and lysine react non-enzymatically [14]. 4-(2,3-Dihydroxypropyl)-2-N-methylamino-2-imidazolin-5-one 2 [15] and N-δ-[5-(3-hydroxypropyl)-4-oxoimidazolon-2-yl]-l-ornithine (PIO) 3 [16], two guanidine-derived AGEs, have been described in model systems. Pentosidine 4, an AGE crosslinking the side chains of an arginine and a lysine residue in a pentose-derived heterocyclic system [17], has been widely analyzed in plasma and tissues [7] but also in foods [18]. The formylpyrrolyl derivatives 5a–c, furfural 5d and the 3-oxopyridinium compound 6a were isolated from reaction mixtures of amino compounds and pentoses and pentose derivatives, respectively [11, 19–21]. 2-Ammonio-6-(3-oxopyridinium-1-yl)hexanoate (OP-lysine) 6b as the corresponding protein-bound lysine derivative was isolated from cataractous lenses [22]. The hydroxymethylpyrrole derivative 7 was identified as an intermediate in the Maillard reaction of 2-deoxyribose with amines [23].

Pentose-derived Maillard reaction products. 1 ribuloselysine, 2 4-(2,3-dihydroxypropyl)-2-N-methylamino-2-imidazolin-5-one [15], 3 N-δ-[5-(3-hydroxypropyl)-4-oxoimidazolon-2-yl]-l-ornithine (PIO) [16], 4 pentosidine [17], 5a–c N-substituted formylpyrrole derivatives [11, 19, 20], 5d furfural [12], 6a 1-methyl-3-oxopyridiniumbetain [21], 6b 2-Ammonio-6-(3-oxopyridinium-1-yl)hexanoate (OP-lysine) [22], 7 N-methyl-2-(hydroxymethyl)pyrrole [23]

Lysine derivatives with a pyrrole moiety like pyrraline 8 and N-ε-pyrrolylnorleucine 9 (Fig. 2) are either formed during the reaction of 3-deoxyosones and amino compounds [24] or in lipid peroxidation reactions of 4,5-epoxy-2-alkenals as degradation products of ω-3 and ω-6 fatty acids [25]. Both compounds have been identified covalently bound to proteins in food [25, 26].

A pentose-derived lysine modification corresponding to the structure of pyrraline 8 has not yet been characterized in the literature. Therefore, it was the aim of this study to examine the reactivity of 3-deoxypentosone toward lysine in model systems. We describe in the following sections the isolation by semi-preparative ion-exchange chromatography and structural elucidation by mass spectroscopy and different nuclear magnetic resonance experiments of the hitherto unknown compound 6-(2-formyl-1-pyrrolyl)-l-norleucine (formyline) 10. Its formation in a food model system and its relevance for glycation reactions will be discussed.

Materials and methods

Chemicals

N-α-t-Butoxycarbonyl-l-lysine (Boc-Lys) and benzaldehyde were obtained from Fluka (Steinheim, Germany). HPLC gradient grade acetonitrile, acetic acid and ethylacetate were from VWR Prolabo (Leuven, Belgium). Benzoylhydrazine and heptafluorobutyric acid were purchased from Alfa Aesar (Karlsruhe, Germany). Microcrystalline cellulose (particle size 20–160 μm), hydrochloric acid, xylose, arabinose, maltose, gluconic acid, pepsin (10 FIP-U/mg protein), and pronase E (4,000 PU/mg protein) from Merck (Darmstadt, Germany) were used. Ribose, lactulose, maltulose, deuterium oxide, prolidase (106 U/mg protein), and dialysis tubings (cellulose, MWCO ca. 12 kDa) were obtained from Sigma–Aldrich (Steinheim, Germany). DOWEX 50W-X8 ion-exchange resin (200–400 mesh) was from Acros (Geel, Belgium). Pyridine and p-toluidine were purchased from Riedel-de-Haën (Seelze, Germany). Pyridine was redistilled before use. Lactose was from Roth (Karlsruhe, Germany) and Lewatit cation-exchange resin from Bayer (Leverkusen, Germany). Butanone from Applichem (Darmstadt, Germany) and aminopeptidase M (11 U/mg protein) from Roche Diagnostics (Mannheim, Germany) were used. Mixed-bed ion exchanger Serdolit MB-2 (20–50 mesh) and glucuronic acid were purchased from Serva (Heidelberg, Germany). The water used for the preparation of buffers and solutions was obtained using a Purelab plus purification system (USFilter, Ransbach-Baumbach, Germany). Preparation of 3-deoxyglucosone (3-DG) [24], pyrraline 8 [27], and sodium caseinate from raw cow’s milk [28] were performed according to the literature stated.

High-pressure liquid chromatography

All analytical HPLC analyses were performed using a high-pressure gradient system from Amersham Pharmacia Biotech (Uppsala, Sweden), consisting of a pump P-900 with an online degasser (Knauer, Berlin, Germany), a column oven, and a UV detector UV-900 operating at 280, 293, and 297 nm, simultaneously.

For the analysis of model mixtures, a stainless steel column (150 mm × 4.6 mm) filled with Eurospher-100 RP-18 material of 5-μm particle size with an integrated guard column (5 mm × 4 mm) of the same material was used (Knauer, Berlin, Germany). Fifty microliters of the samples described below was injected, and the separation was performed at a column temperature of 30 °C and a flow rate of 1 mL/min. The mobile phases were 5 mM heptafluorobutyric acid (HFBA) in water (solvent A) and 5 mM HFBA in 80% methanol (solvent B). A linear gradient from 13 to 55% B in 20 min was applied.

Analytical separation in samples from enzymatically hydrolyzed proteins was achieved using a stainless steel column (250 mm × 4.6 mm) filled with Prontosil 60 phenyl material of 5-μm particle size with an integrated guard column (5 × 4 mm) of the same material (Knauer, Berlin, Germany). The injection volume was 50 μL, and the column temperature was set to 37 °C. The mobile phases were 5 mM HFBA in water (solvent A) and 5 mM HFBA in 60% acetonitrile (solvent B). A linear gradient from 3 to 45% B in 23 min was applied at a flow rate of 1 mL/min. External calibration was performed with the standards synthesized as described in the following sections or in the literature [27].

Lyophilization

An Alpha 1–2 device from Martin Christ (Osterode/Hz, Germany) was used.

Mass spectroscopy

For mass-spectroscopic analyses, a PerSeptive Biosystems Mariner time-of-flight mass spectrometry instrument equipped with an electrospray ionization source (ESI-TOF-MS, Applied Biosystems, Stafford, USA) working in the positive mode was used. Calibration of the mass scale was established using a mixture of bradykinin, angiotensin I, and neurotensin. After appropriate dilution with 1% formic acid in 50% acetonitrile, the sample was injected into the ESI source by a syringe pump at a flow rate of 5 μL/min. Spray Tip Potential, Nozzle Potential, Quadrupol RF Voltage, and Detector Voltage were adjusted to 4,812.3, 80, 1,000, and 2,400 V, respectively.

Ultraviolet (UV) spectroscopy

Absorption spectra were recorded on a Specord S100 diode array spectrophotometer (Carl Zeiss, Jena, Germany) with a wavelength accuracy of ±1 nm. Compounds were dissolved in 100 mM phosphate buffers of different pH values (3.0, 7.0, 11.0) and a mixture of methanol and water (2/8, v/v) at a concentration of 100 μM. The maxima and molar coefficients of extinction were calculated based on triplicate measurements starting from three different synthesis products using quartz cuvettes 115-QS (Hellma, Müllheim, Germany) of 10.00 mm path length.

Nuclear magnetic resonance (NMR) spectroscopy

1H and 13C NMR spectra were recorded on a Bruker DRX 500 instrument (Rheinstetten, Germany) at 500 and 125 MHz, respectively. Typically, 3–5 mg of the substances was dissolved in 750 μL of deuterium oxide for analysis. All chemical shifts are given in parts per million (ppm), those of protons relative to the internal HOD signal (4.70 ppm), those of carbon atoms relative to external standard tetramethylsilane. Assignments of 1H and 13C signals are based on 1H–1H COSY (correlation spectroscopy), HSQC (heteronuclear single quantum coherence); HMBC (heteronuclear multiple bond correlation), and DEPT (distortionless enhancement by polarization transfer) experiments. The spectra of ribuloselysine were recorded on a Bruker Avance III instrument at 600 MHz (1H) and 150 MHz (13C), respectively. In 750 μL of deuterium oxide (pH = 5.0), 36.4 mg of ribuloselysine was dissolved. The solution was stored overnight at room temperature to allow mutarotation. A NOESY (nuclear Overhauser enhancement spectroscopy) experiment was performed in addition to the above-mentioned 2D experiments.

Elemental analysis

Elemental analysis data were obtained on a Euro EA 3000 elemental analyzer (Eurovector, Milano, Italy). Elemental analysis was used to calculate the true product content of the preparations. These were free of N-containing substances, e.g., residual pyridine, as analyzed by NMR. The product content was then calculated as the percentage of nitrogen in the preparation divided by the theoretical percentage of nitrogen of the target substance and expressed in percent by weight.

Synthesis of 3-deoxypentosone 11

In 450 mL of 96% ethanol and 22 mL of glacial acetic acid, 16.7 g (0.11 mol) of d-ribose and 11.0 g (0.10 mmol) of p-toluidine were suspended, and the mixture was heated under reflux for 30 min. To this, 33.0 g (0.24 mmol) of benzoylhydrazine was added and the heating was continued for 7 h. The mixture was slowly cooled and the bisbenzoyl hydrazone of 3-deoxypentosone collected in two portions by suction after overnight crystallization. Each isolate was washed three times each with 30 mL of cold ethanol and afterward with 30 mL of cold diethyl ether. The product was air-dried before further use. Finally, 13.94 g of white crystals was obtained.

For transhydrazonation, 9.2 g of the isolate was suspended in 300 mL of ethanol and 500 mL of water containing 22 mL of glacial acetic acid and 16 mL of benzaldehyde and heated under reflux for 2 h at a bath temperature not exceeding 90 °C. Benzaldehyde benzoylhydrazone, which crystallized readily on cooling, was filtered off and the ethanol removed using a rotary evaporator. The aqueous solution was left on standing overnight and then filtered again. To this solution, 60 g of mixed-bed ion exchanger Serdolit MB-2 was added. After stirring for 15 min, the solution was filtered, and the filtrate was concentrated in vacuo to about 100 mL. The solution was extracted six times with 80 mL of diethyl ether and then evaporated to an oily syrup of approximately 5 mL, which was taken up in 5 mL of water and 50 mL of 96% ethanol. Ten grams of Serdolit MB-2 was added, and the solution was stirred for 10 min and filtered through filter paper. The filtrate was evaporated to dryness, taken up in water and freeze-dried to yield 2.28 g (ca. 15 mmol) of 3-DPs as a highly hygroscopic brownish syrup. The purity of the isolate was determined as described previously [6]. Briefly, a 0.1 μg/mL aqueous solution of 3-DPs was prepared and incubated overnight with o-phenylenediamine. The resulting quinoxaline was measured by RP-HPLC with UV detection; no other quinoxalines were detectable.

Synthesis and isolation of 6-(2-formyl-1-pyrrolyl)-l-norleucine (Formyline) 10

The synthesis method recently published for pyrraline 8 [27] was adapted. In 4.1 mL of 0.1 N sodium acetate buffer, pH 5.0, 335 mg (1.4 mmol) of Boc-Lys and 710 mg (ca. 4.7 mmol) of 3-DPs 11 were dissolved and the pH was adjusted to 5.0 with acetic acid. The solution was mixed with 3.66 g of cellulose powder and incubated for 4 h at 70 °C in a drying oven after lyophilization. The brown powder was then extracted in three portions with a total of 300 mL of water. The pH of the pooled extracts was adjusted to 1.0 with 4 N hydrochloric acid. Crude Boc-formyline was then extracted five times each with 100 mL of ethyl acetate. The combined organic phases were evaporated to dryness and dissolved in 1,000 mL of 10% acetic acid. The solution was heated under reflux at 70 °C for 4 h in order to hydrolyze the Boc protecting group. Acetic acid was then removed by rotary evaporation. The brown residue was dissolved in 30 mL of 0.1 M pyridinium formate buffer, pH 3.00 and the pH adjusted to 3.00 with formic acid. Formyline 10 was separated from by-products by semi-preparative ion-exchange chromatography using a column (1.5 cm × 48 cm) of DOWEX 50 WX-8 (200–400 mesh) previously equilibrated with 250 mL 6 N of hydrochloric acid, 250 mL of water, 250 mL of 2 N aqueous pyridine, 250 mL of water, and 250 mL of 0.1 M pyridinium formate buffer pH 3.00. Formyline 10 was eluted by gravity with 0.3 M pyridinium formate buffer, pH 3.75 at a flow rate of 0.30 mL/min. Fractions of 10 mL were collected using a fraction collector (RediFrac, Pharmacia Biotech, Uppsala, Sweden), and the presence of the product was first monitored by spotting 1 μL of the fractions on TLC plates and spraying with 0.1% ninhydrin in ethanol. Selected fractions were then diluted and analyzed by HPLC using the gradient system described earlier. Formyline 10 was found to elute between 250 and 400 mL. The fractions were combined, repeatedly evaporated in vacuo and taken up in water until the smell of pyridine had become imperceptible. Finally, the residue was dissolved in 1.5 mL of methanol. The solution was slowly dropped into cold butanone, the precipitate was filtered off after 16 h and washed with butanone. The residue was placed in an evacuated desiccator for 2 days. Formyline 10 was then collected and stored at −20 °C.

Formyline 10: ESI-MS, positive mode, [M + H]+ m/z 225.1; UV spectroscopy: λmax (methanol/water, 2/8, v/v) 292 nm (log ε = 4.07) and 261 nm (shoulder, log ε = 3.57); Elemental analysis: C11H16N2O3 (MW = 224.26), calculated, C 58.91%, H 7.19%, N 12.49%; found, C 58.22%, H 6.93%, N 11.95%; content = 95.7%, based on nitrogen. Yield = 121 mg (molar yield = 36.9%).

Synthesis and isolation of N-ε-(1-deoxy-d-ribulosyl)lysine (ribuloselysine) 1

Ribuloselysine 1 was prepared largely according to the method published by Krause et al. [29] for fructoselysine synthesis with some modifications. In 6 mL of water, 505.5 mg (2.06 mmol) of Boc-Lys and 1.21 g (8.09 mmol) of ribose were dissolved. The solution was mixed with 4.0 g of cellulose and lyophilized. The resulting powder was stored for 35 days in a desiccator at room temperature and a relative humidity of 35%, which was maintained by a saturated solution of calcium chloride [29]. Then, the brown powder was extracted with 150 mL of water, filtered, and the resulting solution acidified by addition of 5 mL of glacial acetic acid. Removal of the Boc protecting group and the excess of sugar was achieved by ion-exchange chromatography on a 2.5 cm × 20 cm column filled with the cation exchanger Lewatit S100, previously equilibrated with 250 mL of 6 N hydrochloric acid and 250 mL of water. The column was first washed with 300 mL of water to remove the sugar and then with 300 mL of 2 N pyridinium acetate buffer, pH 6.0 after overnight incubation. The eluate was evaporated to dryness in vacuo at a maximum bath temperature of 35 °C and taken up in 30 mL of 0.1 N pyridinium formate buffer, pH 3.0. The pH was adjusted to 3.0 using formic acid and the solution applied to the column used for formyline fractionation prepared as described earlier. Ribuloselysine 1 was eluted by gravity with 400 mL of 0.4 N pyridinium acetate buffer, pH 4.25 at a flow rate of 0.2 mL/min and the eluate collected in fractions of 10 mL. The presence of the product in the collected fractions was first examined by spotting with ninhydrin as described earlier. The spots were also visualized using 1% triphenyl tetrazolium chloride (TTC) in 1 N NaOH [29]. Ninhydrin-positive substances able to reduce TTC were eluted between 190 and 280 mL of the elution buffer. The fractions were combined, repeatedly evaporated in vacuo and finally taken up in 3 mL of methanol. The solution was dropped into cold butanone and the solid filtered off after 16 h and washed with butanone. The residue was placed in an evacuated desiccator for 2 days. Ribuloselysine 1 was then collected and stored at −20 °C.

Ribuloselysine 1: ESI-MS, positive mode, [M + H]+ m/z 279.1; Elemental analysis: C11H22N2O6 (MW = 278.30), calculated, C 47.47%, H 7.97%, N 10.07%; found, C 47.04%, H 8.36%, N 8.45%; content = 83.9%, based on nitrogen (traces of acetate and butanone were visible in the NMR spectra). Yield = 243 mg (molar yield = 35.6%).

Synthesis and isolation of N-ε-(1-deoxy-d-lactulosyl)lysine (lactuloselysine) 12

In a mixture of 30 mL of N,N-dimethylformamide (DMF) and 70 mL of methanol, 745.7 mg (3.03 mmol) of Boc-Lys and 6.20 g (18.1 mmol) of anhydrous d-lactose were suspended and heated under reflux for 3 h [29, 30]. Methanol was then evaporated in vacuo and DMF by repeated coevaporation with water. The residue was dissolved in 200 mL of water and treated as described for ribuloselysine. After removal of the Boc protecting group, separation of lactuloselysine 12 from by-products was achieved by means of ion-exchange chromatography with the same column as for ribuloselysine 1. Lactuloselysine 12 eluted between 50–90 mL of the elution buffer 0.4 N pyridinium acetate, pH 4.35. Fractions containing lactuloselysine 12 were pooled and repeatedly evaporated under reduced pressure. Finally, the residue was taken up in 3 mL of methanol and precipitated in ice-cold butanone as described earlier. After filtration of the precipitate and overnight standing in an evacuated desiccator, lactuloselysine 12 was obtained as an off-white powder.

Lactuloselysine 12: ESI-MS, positive mode, [M + H]+ m/z 471.2; 1H-NMR (500 MHz, D2O)—δ [ppm]: 1.37 (m, 2H, Lys-H4); 1.66 (m, 2H, Lys-H5); 1.79 (m, 2H, Lys-H3); 3.02 (dt, 2H, Lys-H6); 3.21 (s, 2H, H1’); 3.48 (dd, 1H, H2’’); 3.53–3.73 (m, 6H, Lys-H2, H6A’, H6’’, H5’’, H3’’); 3.75 (d, 1H, H3’); 3.81 (m, 1H, H4’’); 3.90 (d, 1H, H6B’); 3.99 (m, 1H, H4’); 4.10 (m, 1H, H5’); 4.44 (d, 1H, H1’’); elemental analysis: C18H34N2O12 (MW = 470.47), calculated, C 45.95%, H 7.28%, N 5.95%; found, C 42.92%, H 8.52%, N 5.08%; content = 85.4%, based on nitrogen (traces of formate and butanone were visible in the NMR spectrum). Yield = 589 mg (molar yield = 35.3%).

Boc-lysine/sugar incubations

We prepared 100 mM carbohydrate solutions (lactose, lactulose, maltose, maltulose, ribose, arabinose, xylose, 3-deoxypentosone (3-DPs 11), gluconic acid, glucuronic acid, ribuloselysine 1, lactuloselysine 12). Fifty microliters of each carbohydrate solution was mixed with 50 μL of a 25 mM Boc-Lys solution in 0.2 N sodium acetate buffer, pH 5.5 containing 2% (w/v) of suspended cellulose in a sealable glass tube (molar ratio Boc-Lys:carbohydrate 1:4). For the incubation of Amadori products without lysine added, 21 mM solutions were prepared in 0.1 N sodium acetate buffer, pH 5.5 containing 2% (w/v) of suspended cellulose. Portions of 100 μL of these solutions were transferred to sealable glass tubes. The mixtures were freeze-dried overnight, and then the water activity of each sample was adjusted to a W = 0.86 by placing the sample in a desiccator for 48 h which had been equilibrated for 3 days with a saturated solution of potassium chloride. The tubes were then sealed and incubated in a pre-warmed sand bath at different temperatures for different times (4 h, 70 °C; 1 h, 100 °C; 130 °C, 30 min). Directly afterward, 1.5 mL of 10% acetic acid was added, and the mixtures were heated at 70 °C in a water bath for 4 h in order to hydrolyze the Boc protecting group [24]. Aliquots of the samples were then centrifuged at 10,000 rpm for 15 min and measured by HPLC. Samples were prepared in triplicate. In order to investigate the formation of formyline during freeze-drying and humidity adjustment, three samples of Boc-Lys and sugars (3-DPs 11, ribose, lactose) were also worked up without heating.

Casein/sugar incubations

Samples each consisting of 2.5 mL of a 0.4% casein solution in 0.1 N sodium acetate buffer, pH 5.5 and 50 μL of a 0.42 mM solution of 3-DG or 3-DPs, respectively, were prepared in duplicate in 30-mL test tubes (molar ratio Boc-Lys:sugar 1:4). After lyophilization, the samples were incubated at 70 °C in a pre-warmed sand bath. Samples were withdrawn after 15, 30, 60 min, 2, 4, and 8 h, suspended in a small volume of water and dialyzed for 3 days against distilled water, which was changed every 12 h. The dialyzed samples were lyophilized and then hydrolyzed enzymatically [31]. First, 2–4 mg of casein was incubated for 24 h at 37 °C in the presence of 1 FIP-U of pepsin in 1.05 mL of 0.02 N hydrochloric acid. Thereafter, 300 μL of 2 N TRIS buffer, pH 8.2 and 400 PU of pronase E were added and the solution incubated for further 24 h at 37 °C. Finally, 0.4 U of aminopeptidase M and 1 U of prolidase were added. After further incubation for 24 h at 37 °C, the solutions were lyophilized, reconstituted in 1 mL of solvent A and centrifuged at 10,000 rpm for 15 min before HPLC analysis.

Results and discussion

Isolation and characterization of 6-(2-formylpyrrol-1-yl)-l-norleucine (formyline) 10

The Maillard reaction of pentoses has been studied since 1953 [10] when browning of fish flesh was traced back to the presence of ribose. Cytotoxic and mutagenic activities [12, 13] of lysine/ribose mixtures as well as the radical scavenging activity of pentose-modified proteins [32] have been studied, but the properties have rarely been attributed to distinct structures. Considering the formation mechanism and structure of pyrraline 8, we supposed that the reaction of 3-deoxypentosone—a compound likely to be formed from ribose by enolization and dehydratation [4]—and the ε-amino group of lysine should give rise to a pyrrol compound lacking the hydroxymethyl group of pyrraline (Fig. 2).

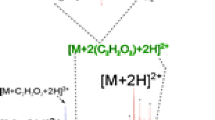

Therefore, a synthesis trial was performed based on our recently published protocol for the isolation of pyrraline 8 derivatives [27]: Boc-Lys was incubated with 3-deoxypentosone in dry state at 70 °C for 4 h. The resulting brown powder was worked up by liquid/liquid extraction and the extract obtained at pH 1.0 heated in diluted acetic acid in order to hydrolyze the Boc protecting group. One main product was isolated from this extract by semi-preparative ion-exchange chromatography in a molar yield of 36.9%. The isolated compound was first characterized by mass spectroscopy after direct injection into the ESI source. The molecular mass M r of 224.1 is equivalent to the addition of one molecule of 3-deoxypentosone to one molecule of lysine and the loss of three molecules of water. The compound was shown to have its absorption maximum at 292 nm at pH 7.0, thereby excluding 2-Ammonio-6-(3-oxopyridinium-1-yl)hexanoate (OP-lysine) 6b (Fig. 1) [22], which has two absorption maxima around 250 and 320 nm in neutral solutions. Moreover, the spectroscopic properties did not change when the pH value was varied between 3.0 and 11.0, indicating that no ionizable group is part of the chromophore as would be the case for the 3-hydroxypyridinium compounds 6a and 6b [21, 22]. The spectrum of the isolated compound, showing a shoulder at 261 nm, is similar to that of pyrraline 8 with the maxima hypsochromically shifted.

Unequivocal confirmation of the supposed structure as 6-(2-formyl-1-pyrrolyl)-l-norleucine (formyline) 10 was performed via one- and two-dimensional NMR measurements, the results of which are presented in Table 1 and Fig. 3. The 1H NMR signals of H-3 and H-4 of the pyrrolyl ring virtually have the same chemical shift and coupling constant as the corresponding signals of pyrraline [24, 27], with the H-3 signals further shifted downfield than the H-4 signals due to the adjacent formyl group. Since in formyline, the hydroxymethyl group of pyrraline is replaced by a hydrogen atom, H-3 and H-4 signals are further split into doublets of doublets due to coupling with H-5. As the long-range coupling constants are quite small, the H-5 signal is broadened and the individual peaks are not fully resolved. The NMR signals of the formylpyrrolyl ring are in agreement with published data for the derivatives 5a [20] and 5b [11]. Evidence for the ring to enclose the ε-nitrogen of lysine was drawn from the HMBC spectrum, where the H-6 of the lysyl residue showed cross peaks to C-2 and C-5 of the formylpyrrolyl ring. Some of the long-range connectivities from the HMBC spectrum are shown in Fig. 3. It can also be seen that the formyl group must be attached to C-2 of the pyrrolyl ring, because the CHO proton only couples with two instead of three carbon atoms (C2 and C3) in the HMBC spectrum.

In summary, the isolated compound has been identified as a lysine derivative with the ε-amino group being part of a 2-formylpyrrolyl ring. The structure deduced from the NMR spectra is in agreement with the mass and UV spectroscopy results.

Identification of formyline precursors

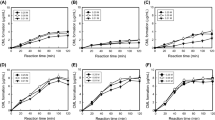

The generation of formyline 10 was first assessed in a model system consisting of Boc-Lys and the sugars in fourfold molar excess using cellulose as a support. The reaction mixtures were buffered at pH 5.5, lyophilized and incubated after 2 days of equilibration over a saturated solution of potassium chloride at a relative humidity of 86% [33]. These parameters were chosen with respect to bakery products, e.g., white bread made of yeast dough. The formation of formyline 10 was investigated at three different heating conditions. 3-DPs 11 (Fig. 4) as the direct formyline precursor can be formed primarily from pentoses but also from disaccharides in specific degradation reactions [5, 6]. Therefore, three pentoses (ribose 13, arabinose 14, and xylose 15) and four disaccharides (lactose, lactulose, maltose, maltulose) were chosen for the study along with 3-DPs 11. Gluconic and glucuronic acids 16, for which we expected decarboxylation reactions during incubation, were also included. Hydrolysis in 10% acetic acid, necessary to remove the Boc protection group, did not show an impact on formyline 10 formation, since it was not detected in mixtures of Boc-Lys and 3-DPs 11 under these conditions. Nor did cellulose degrade to any product interfering with the measurements. Samples were analyzed by RP-HPLC using heptafluorobutyric acid as an ion pairing reagent. A molar conversion of lysine to formyline 10 of as low as 0.02% could be measured with this method.

In a first experiment, the influence of lyophilization and humidity adjustment on formyline formation was assessed. Samples of Boc-Lys and sugars (3-DPs 11, ribose 13, and lactose) were therefore subjected to the deprotection step without prior heat treatment. The mere lyophilization of Boc-Lys/3DPs mixtures already led to a molar conversion of lysine to formyline of 10.6% which only increased to 11.9% when the humidity adjustment was included. Lyophilization and humidity adjustment in a Boc-Lys/ribose mixture resulted in considerably less conversion (0.07%), and no formyline was detectable in a Boc-Lys/lactose mixture without heating.

The results representing the molar degradation of lysine to formyline 10 in the heated mixtures are presented in Fig. 5. Irrespective of the thermal impact applied, 3-DPs 11 was by far the most potent precursor always leading to a conversion of about 12% (data not shown). The fact that only scarcely more compound 10 is quantified after heating the lyophilized mixtures indicates that the presence of the precursor is sufficient for the reaction to proceed even at room temperature as long as the reactants are homogeneously distributed. Moreover, formyline 10 is easily formed from pentoses already under moderate heating conditions. In the case of pentoses, however, heat treatment is necessary to generate 3-DPs 11 as the precursor which then reacts with the ε-amino group of Boc-Lys. Interestingly, ribose 13 produced significantly less compound 10 than did arabinose 14 and xylose 15. More intramolecular hydrogen bonds can be formed in the ribopyranose 13 molecule than in other pentoses thereby leading to improved stability. Though this was shown to not play an important role in aqueous media [34], it could explain the differences in pentose stability seen in this study, as water was strongly limited.

Formation of formyline in lyophilized mixtures of Boc-Lysine and carbohydrates (molar ratio Boc-Lys to carbohydrate 1:4) during incubation at a relative humidity of 86% on a cellulose support. The incubations were performed at 70 °C for 4 h (white bars), at 100 °C for 1 h (gray bars), and at 130 °C for 30 min (black bars). Formyline was measured by RP-HPLC after removal of the Boc protecting group. Lac, lactose; Lul, lactulose; Mal, maltose; Mul, maltulose; Rib, ribose 13; Ara, arabinose 14; Xyl, xylose 15; GlcA, gluconic acid; GlcU, glucuronic acid 16; RibLys, ribuloselysine 1; LacLys, lactuloselysine 12; n.d., not detectable; LOQ, limit of quantification. Data are mean values ± SD, n = 3

Caramelization of disaccharides is not favoured below 100 °C, and therefore, only minor amount of compound 10 was measured in the mixtures heated at 70 °C. At 100 °C and above, formyline 10 formation from lactose and maltose is equal but slightly lower than from lactulose and maltulose. This is in accordance with the degradation pathway of lactose and maltose [5, 6], where lactulose and maltulose are formed initially by the van Ekenstein rearrangement; generation of 3-DPs 11 then proceeds via 4-deoxy-d-glycero-2,3-hexodiulose 17 as the common intermediate in the caramelization of oligosaccharides with a (1 → 4)-glycosidic linkage. It can be expected that formyline 10 is formed from pentoses in real food systems, however, as their occurrence in food is limited to their presence in nucleic acids and hemicelluloses, disaccharides like lactose and maltose should be the predominant precursors when food is processed under conditions that allow caramelization. Markedly, more formyline 10 was detected when heat treatment was intensified from 70 °C (4 h) to 100 °C (1 h) but no more on further heating. In contrast, incubation at 130 °C for 30 min in most cases led to intensely browned mixtures which were only incompletely dissolved during incubation in 10% acetic acid. Polycondensation of pyrrole compounds like 5c and 7 has been described by Tressl et al. [23]. It has to be expected that formyline 10 is thermodynamically not stable and participates in the formation of melanoidin-like polymers.

Glucuronic acid 16 forms formyline 10 much faster than gluconic acid. Glucuronic acid 16 can decarboxylate easier than gluconic acid, because the carboxyl group does not participate in ring formation as is the case for lactones of gluconic acid. The resulting xylose 15 molecule bears an aldehyde group and further degrades to 3-DPs 11 as the direct precursor (Fig. 4). Decarboxylation of glucuronic acid 16 in the presence of peptides has already been assessed by Horvat et al. [35]. The authors describe the formation of N-terminal 3-oxopyridinium peptides structurally related to compound 6 (Fig. 1) in relatively high amounts from the N-terminal Amadori adduct of glucuronic acid 16. On the contrary, gluconic acid can only yield arabitol on decarboxylation, which, most probably, will not lead to the formation of compound 10.

It might also be possible that formyline 10 is generated during degradation of Amadori products [4], which, in our experiment, could have been formed during lyophilization or the 2 days equilibration period. Ribuloselysine 1 and lactuloselysine 12 were therefore chosen as model Amadori products to study possible degradation reactions and synthesized because they are not commercially available. Due to the instability of ribose 13, any heating above 40 °C was avoided during ribuloselysine 1 synthesis. At a relative humidity of 35%, Boc-Lys and ribose 13 in a twofold molar excess reacted in sufficient yields already at room temperature during 3–4 weeks. The compound was isolated in a molar yield of 35.6% and characterized by two-dimensional NMR experiments (see Table 2). In aqueous solution (D2O), ribuloselysine 1 appears mainly in its furanose forms (35% α-furanose, 42% β-furanose) and to a quite high proportion in the open-chain form (23%) as was deduced from the integration of well-resolved 1H signals. Beyond that, the interconversion of the α-furanose to the β-furanose form through the open-chain form as an interstage was verified by evaluating characteristic exchange signals in the NOESY spectrum. The high percentage of open-chain form should make ribuloselysine 1 a very labile structure. The formyline 10 content of the preparation was determined to 0.09%. To the best of our knowledge, this is the first detailed description of the synthesis and characterization of ribuloselysine 1 after the protocol published by Fortpied et al. [14]. The synthesis of lactuloselysine 12 was performed largely according to literature methods [29, 30] with some minor modifications and provided the Amadori product in high yield and purity due to the implementation of ion-exchange chromatography. The 1H NMR data were in accordance with published data [29, 30]. The preparation was free of formyline 10. Once having synthesized the compounds, they were first incubated and analyzed analogously to the Boc-Lys/sugar mixtures, but without the addition of Boc-Lys. The low formyline 10 content of ribuloselysine 1 decreased with increasing temperature indicating that compound 10 cannot be formed by conversion of the bound sugar residue in a monomolecular reaction. Lactuloselysine 12 was degraded to formyline 10 to a very small proportion (0.04%) only at 100 °C. The results were different when a fourfold molar excess of the Amadori products was incubated with Boc-Lys (Fig. 5). The amount of compound 10 found in the Boc-Lys/Ribuloselysine mixtures cannot completely be explained by the original amount of formyline 10 in ribuloselysine 1. The Amadori product must also have degraded to 3-DPs to a very small extent by 1,2-enolization and subsequent elimination of lysine [4]. Stronger thermal impact significantly lowers the formyline 10 content, which supports the aforementioned polymerization hypothesis. Even though compound 1 is present in its open-chain form to a high amount, it has a lower tendency to form 3-DPs 11 than the pentoses 13–15. The amount of compound 10 generated from lactuloselysine 12 is still low in the presence of Boc-Lys and also lower than the amounts formed from disaccharides. On the contrary, much pyrraline 8 was detected in the Boc-Lys/lactuloselysine mixtures (data not shown). It can be expected that ribuloselysine also degrades to compounds other than formyline 10, possibly OP-lysine 6b (Fig. 1) [22].

We conclude that in dry state, formyline 10 can only be produced from the sugar 3-DPs 12 by reaction with lysine but not from the direct (monomolecular) conversion of Amadori products like ribuloselysine 1 and lactuloselysine 12. The different formyline 10 formation properties of the sugars and Amadori products reflect their intrinsic potential to form 3-DPs 11. Once generated, 3-DPs 12 is further dehydrated to 3,4-dideoxypentosone-3-ene 18 [19] which then reacts with lysine to the formylpyrrole derivative formyline 10 as depicted in Fig. 4.

Formation of formyline on proteins

In order to investigate whether formyline can also be formed on proteins under conditions relevant for food processing, casein was incubated with 3-DPs 11 (molar ratio 3-DPs to protein-bound lysine was 4:1) in dry state according to the conditions used for formyline 10 synthesis. For a comparison to pyrraline 8, the same incubations were performed with 3-DG instead of 3-DPs 12. Samples were immediately incubated for 4 h at 70 °C after lyophilization. The incubated samples were dialyzed prior to further analysis in order to remove the 1,2-dicarbonyl compounds and their possible degradation products before enzymatic hydrolysis, which had to be adopted due to the instability of formyline 10 and pyrraline 8 during acidic hydrolysis. Changes in the gradient of the aforementioned HPLC system could not impede coelution of formyline 10 and tryptophan. Therefore, a phenyl-modified column with improved selectivity especially for aromatic compounds was used for protein analyses. The method allowed the quantification of formyline 10 and pyrraline 8 at as low as 0.1 μmol/g protein, which in the case of casein corresponds to a lysine modification of 0.02%. Chromatograms of standards and hydrolyzed casein samples are shown in Fig. 6. The results demonstrate that 3-DPs 11 is a more potent glycating agent than 3-DG. The content of formyline 10 in the casein/3-DPs 12 mixtures is more than three times higher than the pyrraline 8 content after lyophilization and 15 min of heat treatment at 70 °C (Fig. 7). Generation of formyline is faster and remains more pronounced even on further heating, which can be explained by the structures of 3-DPs 12, which are reported to be less complex than those of 3-DG, and there are no bicyclic forms [36]. 3-DPs 12 can thus convert more easily to the reactive open-chain form. Even though the same molar excess of dicarbonyl compound to lysine was used in both the precursor and the protein modification experiments, the yield of compound 10 is higher by a factor of almost four, when lysine is protein-bound. The presence of other reactive amino acids in a protein should therefore have an impact on formyline 10 formation as has already been discussed for the cysteine-catalyzed formation of N-ε-carboxymethyllysine (CML) [37].

Further studies will have to elucidate the mechanisms by which formyline 10 is formed on proteins and if its presence might be responsible for the high radical scavenging activity of proteins modified with ribose or arabinose [32] or the cytotoxic and mutagenic activities of ribose/lysine mixtures [12, 13]. Regarding the results of our precursor experiments, we suppose that it could have been formed easily during the experiments stated in the literature [12, 13, 32]. Since formyline 10, as being structurally related to pyrraline, is a target molecule for intestinal absorption [27], studies are currently underway in our laboratory concerning the occurrence of formyline in food products and its physiological properties.

References

Ledl F, Schleicher E (1990) Angew Chem 102:597–626

Henle T (2005) Amino Acids 29:313–322

Hodge JE (1953) J Agric Food Chem 1:928–943

Yaylayan VA, Huyghues-Despointes A (1994) Crit Rev Food Sci 34:321–369

Hollnagel A, Kroh LW (2002) J Agric Food Chem 50:1659–1664

Mavric E, Henle T (2006) Eur Food Res Technol 223:803–810

Thornalley PJ, Battah S, Ahmed N, Karachalias N, Agalou S, Babaei-Jadidi R, Dawnay A (2003) Biochem J 375:581–592

Henle T, Miyata T (2003) Adv Ren Replace Ther 10:321–331

Linden T, Cohen A, Deppisch R, Kjellstrand P, Wieslander A (2002) Kidney Int 62:697–703

Tarr HLA (1953) Nature 171:344–345

Munanairi A, O’Banion SK, Gamble R, Breuer E, Harris AW, Sandwick RK (2007) Carbohydr Res 342:2575–2592

Cuzzoni MT, Stoppini G, Gazzani G, Mazza P (1988) Food Chem Toxic 26:815–822

Vagnarelli P, De Sario A, Cuzzoni MT, Mazza P, De Carli L (1991) J Agric Food Chem 39:2237–2239

Fortpied J, Gemayel R, Stroobant V, van Schaftingen E (2005) Biochem J 388:795–802

Sopio R, Lederer MO (1995) Z Lebensm Unters Forsch 201:381–386

Mavric E, Kumpf Y, Schuster K, Kappenstein O, Scheller D, Henle T (2004) Eur Food Res Technol 218:213–218

Sell DR, Monnier VM (1989) J Biol Chem 264:21597–21602

Henle T, Schwarzenbolz U, Klostermeyer H (1997) Z Lebensm Unters Forsch 204:95–98

Kato H (1967) Agric Biol Chem 31:1086–1090

Tressl R, Kersten E, Rewicki D (1993) J Agric Food Chem 41:2125–2130

Pachmayr O, Ledl F, Severin T (1986) Z Lebensm Unters Forsch 182:294–297

Argirov OK, Lin B, Ortwerth BJ (2004) J Biol Chem 279:6487–6495

Tressl R, Wondrak GT, Krüger RP, Rewicki D (1998) J Agric Food Chem 46:104–110

Henle T, Bachmann A (1996) Z Lebensm Unters Forsch 202:72–74

Zamora R, Alaiz M, Hidalgo FJ (1999) J Agric Food Chem 47:1942–1947

Henle T, Walter AW, Klostermeyer H (1994) In: Labuza TP (ed) Maillard reactions in food, chemistry, and health. The Royal Society of Chemistry, Cambridge, pp 195–200

Hellwig M, Geißler S, Peto A, Knütter I, Brandsch M, Henle T (2009) J Agric Food Chem 57:6474–6480

Siegl T (2003) PhD Thesis, TU Dresden

Krause R, Knoll K, Henle T (2003) Eur Food Res Technol 216:277–283

Vinale F, Monti SM, Panunzi B, Fogliano V (1999) J Agric Food Chem 47:4700–4706

Henle T, Walter H, Klostermeyer H (1991) Z Lebensm Unters Forsch 113:119–122

Chobert JM, Gaudin JC, Dalgalarrondo M, Haertlé T (2006) Biotechnol Adv 24:629–632

Rockland LB (1960) Anal Chem 32:1375–1376

Wei C, Pohorille A (2009) J Am Chem Soc 131:10237–10245

Horvat Š, Roščič M, Lemieux C, Nguyen TMD, Schiller PW (2007) Chem Biol Drug Des 70:30–39

Weenen H, van der Veen JGM, van der Linde LM, van Duynhoven J, Groenewegen A (1998) In: O’Brien J (ed) The Maillard reaction in foods and medicine. The Royal Society of Chemistry, Cambridge, pp 57–64

Schwarzenbolz U, Mende S, Henle T (2008) Ann N Y Acad Sci 1126:248–252

Acknowledgments

We thank Dr. Uwe Schwarzenbolz, Institute of Food Chemistry, for the acquisition of the mass spectra. We are grateful to the members of the Institute of Organic Chemistry, namely Dr. Margit Gruner and Anett Rudolph, for recording the NMR spectra and Anke Peritz for performing the elemental analyses. This work was supported by a research grant of the Deutsche Forschungsgemeinschaft (HE 2306/9-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hellwig, M., Henle, T. Formyline, a new glycation compound from the reaction of lysine and 3-deoxypentosone. Eur Food Res Technol 230, 903–914 (2010). https://doi.org/10.1007/s00217-010-1237-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1237-3