Abstract

The rheological properties and microstructure of imitation cheeses containing 3%, w/w, pre-gelatinised maize, waxy-maize, wheat, potato or rice starches were compared to a control (0%, w/w, starch). Dispersions of pre-gelatinised rice or waxy-maize starches with casein had the highest viscosities following heating at 80 °C compared to casein heated alone or in mixtures with the other starches. Imitation cheese products containing pre-gelatinised starches had larger fat globule size distributions (especially rice or waxy-maize starch) and less homogeneous background protein matrices than the control as evidenced by scanning electron microscopy, which indicated poorer fat emulsification. The resultant imitation cheeses were softer, less cohesive and had reduced melting properties compared to the control. During processing, the pre-gelatinised starch competed with the rennet casein for water and impaired the caseins hydration as evidenced visually by delayed emulsification of free oil. Differences in levels of amylose retrogradation may have been responsible for variances in functionality between starches of different origins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Imitation (analogue) cheese products may be classified as cheese substitutes or imitations, which partly or wholly substitute or imitate cheese and in which milk fat, milk protein or both are partially or wholly replaced by non-milk-based components, principally of vegetable origin [1]. Imitation cheese is widely used in the food industry as an ingredient for prepared foods such as pizza, lasagne, cordon bleu products where its rheological properties, that dictate whether it melts or maintains its structure, are critical [2]. Ingredients such as rennet casein, vegetable oils or fats, salts, acids and flavourings are generally used in the manufacture of imitation cheese [3]. Rennet casein is an insoluble calcium paracasein that is converted to a soluble sodium-phosphate paracaseinate by calcium-sequestering salts such as disodium phosphate or trisodium citrate and heat [4]. Due to its high cost, considerable effort has been vested in the partial replacement of casein with cheaper ingredients, of which, starch has been the most effective low-cost casein substitute [1].

Recent work has shown that the interaction between the added starch and casein influences the rheological properties of the imitation cheese [2, 3, 5]. The addition of different native starches in partial casein replacement results in marked variations in the textural, melt and temperature dependent dynamic rheological properties of imitation cheese [2]. The individual effects of native starches are influenced by their properties such as granule size, gelatinisation temperature and amylose content. However, it is also evident that the starch is present as discrete entities in the protein matrix. This may be due to starch insolubility arising from the poor availability of water and/or the processing temperature–time combination being insufficient to fully gelatinise and solubilise the starch. Imitation cheese hardness and storage modulus (G′) are increased by partially replacing fat with resistant maize starch-derived products [5]. The greatest increases are with retrograded resistant starch (Novelose240) compared to maltodextrin (Novelose330) [5].

Starch granule swelling during gelatinisation has a ‘‘packing effect’’ on surimi gels resulting in increased gel rigidity [6, 7] whereas pre-gelatinised starch reduces the rigidity of the fish gels. It is also suggested that granular starch is more efficient than pre-gelatinised (pre-cooked) starch in imitation cheese manufacture in providing better thickening properties [8, 9]. In contrast, it is suggested that pre-gelatinisation is a pre-requisite for starches prior to further modifications in order to give the desired texture in imitation cheese [10]. Pre-gelatinised starch, which is dispersible in cold water, is more likely to interact with the protein network and behave less like a filler as seems to be the case with native starch. The objective of this study is to investigate the effects of pre-gelatinised starches on the rheology, meltability and microstructure of imitation cheese.

Materials and methods

Manufacture of imitation cheeses

A control imitation cheese was manufactured with the following formulation: 48.8% water, 24.5% rennet casein (82% protein)(Kerry Ingredients, Listowel, Ireland), 26% vegetable fat (Trilby Trading Ltd, Liverpool, England), 2.18% emulsifying salts, [1.08% trisodium citrate, 0.62% citric acid (Jungbunzlauer, Pernhofen, Austria), 0.48% disodium phosphate (Ellis and Everard, Ireland)], 1.67% sodium chloride (Salt Union, Cheshire, England) and 0.1% sorbic acid (Hoechst Ireland Ltd, Dublin, Ireland). All ingredients (except citric acid) were blended in a twin-screw cooker (model CC-010, Blentech Corporation, CA) at 35 °C and heated to 78 °C using direct steam. Citric acid was added. After 5 min of mixing at 100 rpm the product was packaged, cooled to 4 °C and vacuum packed (model C 10 H, Webomatic®, Bochum, Germany) 24 h later. During cooking the solid screw agitators of the cooker turned in opposite directions causing the product to be folded into the centre and moved around the cooker in a counter clockwise direction resulting in a well-emulsified homogeneous cheese mass. Using a similar manufacturing process, a series of imitation cheeses were prepared by replacing 15% of the rennet casein (3%, w/w, of the total product) in the control formulation with pre-gelatinised; maize, waxy-maize, wheat, potato or rice starch (added dry) and reducing the concentration of emulsifying salts (trisodium citrate, citric acid and disodium phosphate) used to solubilise the casein by 15%. The maize and waxy-maize starch were supplied by National Starch and Chemical, CA, England; wheat starch was supplied by Roquette, Lille Cedex, France; potato starch was supplied by AVEBE, Veendam, The Netherlands and rice starch was supplied by REMY Industries, Leuven, Belgium. Three 4 kg batches of each cheese were manufactured.

Compositional analysis of imitation cheeses

Samples of imitation cheese were analysed 1 day after manufacture for moisture (IDF, 1958, 11), fat (National Standards Authority of Ireland 1955, 12), protein (IDF 1993, 13) content and pH (model 9,450 pH meter, Unicam Ltd, CA, England). An amylose/amylopectin assay kit (Megazyme International Ireland Ltd, Bray, Ireland) was used to determine the amylose content of the starches.

Micro-structural analysis using cryo-scanning electron microscopy

Cryo-scanning electron microscopy (SEM; JEOL JSM-5410LV Scanning Microscope, JEOL Instruments, Tokyo, Japan) was used to examine the microstructure of the imitation cheeses (3–4 days after manufacture) as previously described [2]. Prisms approximately 1 × 3 × 8 mm were cut from blocks of imitation cheese using a scalpel, mounted on a specimen holder and cryofixed in nitrogen slush (−210 °C). Specimens were transferred (under vacuum at −180 °C) to the cryo chamber and the interior of the sample was exposed using a scalpel. The fracture face was etched at −88 °C by heating on the microscope stage in the microscope chamber. When sufficient water was sublimed (after approximately 5 min) the specimen was cooled to −180 °C. The specimen was then sputtered with gold (3 mA, 2 min) in the cryo chamber prior to analysis in the microscope chamber using an accelerating voltage of 10 kV.

Melt test of imitation cheeses

A modification of the Olson and Price [14] method was used as described by Mounsey and O’Riordan [3] to assess imitation cheeses meltability 2 days after manufacture. Cylinders (25 mm diameter, 40 mm height) were cut from blocks of imitation cheese and placed into one end of a Pyrex glass tube (250 mm long, 30 mm diameter). The tubes were placed horizontally in a conventional oven at 180 °C for 15 min. The tubes were removed from the oven and the distance flowed from a reference line was measured in mm and used as an indication of meltability.

Textural hardness determination of imitation cheeses

Textural hardness (N) of the imitation cheeses was determined 2 days after manufacture using an Instron Universal Testing Machine (Instron Model 4301, Instron Corp., Canton, MA) as described by Mounsey and O’Riordan [2]. Cylinders of cheese 20 mm high and 18 mm in diameter were compressed by 80% of their initial height at a crosshead speed of 50 mm/min. The uniaxial compression test was performed in two successive cycles, and the textural parameters; hardness and cohesiveness were calculated as described by Szczesniak [15].

Dynamic rheology evaluation of imitation cheeses

Rheological characterisation of the imitation cheeses was undertaken 3–4 days after manufacture as previously described [3] using a controlled stress rheometer (model SR 2000, Rheometrics Inc., Piscataway, NJ) fitted with a 25 mm parallel plate with a 2.4 mm gap. Disc-shaped samples of cheese (24 mm diameter, 2.4 mm thick) were prepared using a slicer and borer. The samples were placed on the lower plate and compressed 0.2 mm to prevent slippage. An oscillatory stress was applied to give a target strain of 0.3% at a frequency of 1 Hz. The temperature of the samples was increased from 22 to 100 °C, at 6 °C/min using a Peltier heating element. Parameters included the storage modulus (G′), loss modulus (G″) and loss angle [tan δ (G″/G′)].

Determination of viscosity effects of pre-gelatinised starches on casein

To model the conditions in imitation cheese, a 3.86%, w/w protein, rennet casein dispersion was dispersed in an aqueous solution of emulsifying salts (0.21%, w/w, trisodium citrate and 0.09%, w/w, disodium phosphate). Rennet casein/starch dispersions were prepared by replacing 15% of the rennet casein with pre-gelatinised (maize, waxy-maize, wheat, potato or rice) starches and reducing the emulsifying salt content by 15%. Dispersions were stirred for 20 min before heating to 80 °C on a magnetic stirrer hotplate (Model HB 502, Bixby Sterlin Ltd, Stone Staffordshire, England) and holding at this temperature for 20 min before cooling back to 22 °C in an iced bath. The temperature of samples was monitored using a digital thermometer (Hanna Model H193510, Sigma-Aldrich Ireland Ltd, Dublin, Ireland).

Viscosity determinations on heat-treated dispersions were undertaken using a controlled stress rheometer (SR 2000, Rheometrics Inc. Piscataway, NJ). A 25 mm parallel plate geometry with a gap of 1 mm was used. A shear stress sweep from 1 to 20 Pa was applied over 4 min and the apparent viscosity (mPa s) of the sample was taken at a shear stress of 2 Pa.

Statistical analysis

The imitation cheeses were manufactured in triplicate batches and analysis was performed in quadruplicate for each batch within 2–4 days of manufacture. PROC GLM of SAS (SAS Institute, Cary, NC, USA) was used to determine differences between treatment means. Treatment means were considered significantly different at P ≤ 0.05.

Results and discussion

Compositional analysis of imitation cheeses

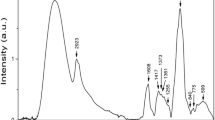

The compositional analyses of the imitation cheeses manufactured with pre-gelatinised starch were compared. No significant (P ≤ 0.05) differences were obtained between imitation cheese products for fat (mean of 25.8 ± 0.2%, w/w), moisture (mean of 48.9 ± 0.21%, w/w), and pH values (mean of 5.84 ± 0.06). The starch-containing products had lower protein values (17 ± 0.2%, w/w) than the control sample (20.3 ± 0.29%, w/w) due to the replacement of the casein with starches. The amylose contents of maize, waxy-maize, wheat, potato or rice starch were 24.6, 3.2, 28.1, 25.5 or 14.2%, w/w, respectively, which is in line with suppliers specifications and published values [16].

Microstructure of imitation cheeses

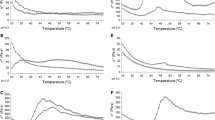

The imitation cheeses were examined using SEM to relate the microstructure of the imitation cheeses to their processing behaviour as well as meltability and rheology (Fig. 1). The microstructure (SEM) of the control imitation cheese (no starch) (Fig. 1a), showed a uniform distribution of well-emulsified spherical fat globules (F) up to ∼20 μm in diameter, dispersed in a smooth protein matrix as previously reported [2, 5, 17, 18]. Imitation cheese products containing potato (Fig. 1b), wheat (Fig. 1c) or maize (Fig. 1d) starch appeared to have fat globules evenly distributed within the protein matrix but some globules were larger in diameter than those of the control (up to 30 μm in diameter). Waxy-maize (Fig. 1e) or rice (Fig. 1f) starch-containing products had even larger fat globules (ranging in size from 2 up to 65 μm) that were unevenly distributed within the protein matrix. In the imitation cheese manufacture, all the dry ingredients (except citric acid) were mixed in the oil and water at 35 °C prior to heating to 78 °C. During manufacture, the complete emulsification of oil as assessed visually by the disappearance of free oil, took 2.5–3 min after reaching 78 °C in pre-gelatinised starch containing products, compared to 1.5–2 min for the control. The cold water dispersible pre-gelatinised starches probably hydrated more rapidly than the casein which would have first required the action of the calcium chelating salts (disodium phosphate and trisodium citrate) to disrupt the calcium-mediated protein–protein cross-bridges to facilitate its solubilisation. Consequently the reduced availability of water in this system would have reduced the conversion of rennet casein to more soluble sodium paracaseinate compared to the control.

Electron micrographs (×500) of imitation cheese containing (a) 0%, w/w, starch (control) or 3%, w/w, pre-gelatinised; (b) potato starch, (c) wheat starch, (d) maize starch, (e) waxy-maize starch, (f) rice starch. g Shows imitation cheese containing 3%, w/w, pre-gelatinised maize starch at higher magnification (×3,500), S starch particle

In an attempt to model the viscosity effects of pre-gelatinised starches during imitation cheese manufacture, a dispersion of emulsifying salts and rennet casein with/without various pre-gelatinised starches was heated to 80 °C before cooling to 22 °C. All samples showed Newtonian viscosity behaviour. The control (0%, w/w, starch) had an apparent viscosity of 19.5 ± 0.3 mPa s at a shear stress of 2 Pa. The replacement of 15% of the protein in the dispersions with pre-gelatinised starches resulted in increases in apparent viscosity in the order rice starch (26.3 ± 1.2 mPa s) > waxy-maize (24.6 ± 0.4 mPa s) > wheat (22.2 ± 0.5 mPa s) > potato (21.6 ± 0.6 mPa s) > maize (20.0 ± 0.5 mPa s) starch. It is likely that during processing, the pre-gelatinised starch competed with the rennet casein for water, impairing the caseins hydration and conversion to the more soluble sodium-phosphate paracaseinate. This may have impaired the ability of the protein to emulsify the fat droplets, resulting in larger, less well-emulsified fat droplets and a less hydrated protein matrix with impaired thermo-reversibility. The results of the present work indicates that pre-gelatinised starches have the opposite effect to native starches shown previously [2, 19], namely in increasing viscosity of the system during processing but resulting in a less well emulsified imitation cheese on cooling.

In addition, the pre-gelatinised starches would have brought about an immediate viscosity increase in the early stages of imitation cheese manufacture, which would have further decreased the protein’s ability to diffuse to the fat interface resulting in poorer fat emulsification. Both these effects possibly contributed to the long processing times for pre-gelatinised starch containing products. The lower amylose products, rice and especially waxy-maize starches have lesser tendencies to retrograde [16, 20], so would have been expected to contribute a smaller viscosity increase than the high amylose starches, and so had less of a barrier to fat coalescence.

These results contrasted with previous findings [2] where during imitation cheese manufacture the fat in native starch containing products was more rapidly emulsified than that of the control. These insoluble native starches possibly functioned as inert fillers increasing the availability of water to solubilise the reduced quantity of casein and improve its fat emulsifying properties resulting in smaller fat globule sizes. In the previous work [2], residual starch granular structures were more clearly evident in micrographs compared to in the present work where soluble pre-gelatinised starch was used. In all imitation cheese samples containing pre-gelatinised starch, irregular shaped particles were observed (at higher magnification) disrupting the protein matrix. An example of such a starch particle (S) is shown in Fig. 1g at higher magnification (×3,500) for imitation cheese containing pre-gelatinised maize starch (note the scale bar has a length of 5 μm). In Fig. 1g there is a noticeable phase boundary separating the starch particle and the protein matrix, as shown by Montesinos et al. [5] for native resistant starch and maltodextrin.

The SEM images of imitation cheeses containing added pre-gelatinised starch in the present work or starches added in the native granular form in previous work [2] indicate that interactions between the protein matrix and the starch components, amylose and amylopectin were probably unfavourable. It could be hypothesised that there was mutual exclusion of each component from the polymer domains of the other. Other workers [21, 22] have suggested that this exclusion effect increases the effective concentrations of each component and can lead to separation of the system producing a multi-textured gel.

Textural hardness and cohesiveness properties of imitation cheeses

The effects of the different pre-gelatinised starches on textural hardness and cohesiveness of imitation cheeses are presented in Table 1. The pre-gelatinised starches significantly (P ≤ 0.05) decreased the imitation cheese hardness relative to the control in the order, waxy-maize = rice > wheat > maize > potato starch. In agreement with previous findings [2], the lower amylose starches (waxy-maize or rice) gave the softest products, suggesting that hydrogen-bonding association of leached amylose during cooling of the imitation cheeses probably contributed more to the product structure than association of amylopectin. In the case of surimi gels, it has been reported that their penetration force increased with an increase in the amylose content of the starch used in their preparation [23]. It has been shown that amylose gels were stiffened by the association of the linear amylose molecule in more than one crystallite, while amylopectin gels were softer and more brittle due to fewer intermolecular interactions owing to the clustering of the outer molecular chains of amylopectin [24]. Potato starch containing products were significantly (P ≤ 0.05) harder than maize or wheat starch containing products although all three starches had relatively high amylose contents (24–28%). This is consistent with the findings of Conde-Petit and Escher [25] who found that potato starch gels formed harder gels than wheat or maize starch gels because of the absence of amylose–lipid complexes in potato starch although it should be noted that the findings of these authors were for native granular starches and not pre-gelatinised starches. Compared to their equivalent imitation cheeses containing native starches [2], the hardness values of imitation cheese products containing pre-gelatinised starches were lower by amounts ranging from 11.8%, w/w for potato starch to 36.8%, w/w for wheat starch. Wu et al. [6] found that the addition of pre-gelatinised starch reduced the rigidity of the fish gels formed with heat. In contrast, the addition of native starch granules resulted in granule swelling during gelatinisation, which had a ‘‘packing effect’’ on surimi gels resulting in increased gel rigidity.

All products containing starch had significantly (P ≤ 0.05) lower cohesiveness than the control except the product containing rice (not significantly lower). Maize starch resulted in a product with least cohesion. Because the imitation cheese containing rice starch had low hardness, less stress was developed and the product resisted fracture possibly resulting in its relatively high cohesiveness. Similar results were obtained by Mounsey et al. [2] where native maize and rice starches caused the greatest and least effects, respectively, on imitation cheese cohesiveness. Increasing either or both the salt and citric acid levels reduced the cohesiveness of cheese analogues [26]. In the present study with the partial replacement of casein with starch, the NaCl: casein ratio was higher than the control, which may also have had some influence on cohesiveness. It has been suggested that the number of re-formable protein bonds in imitation cheese products containing added native starch was reduced because of the lower protein contents and this as well as a poorly hydrated protein matrix possibly contributed to low cohesion [2]. While the inter- and intra-molecular bonds in the protein network in imitation cheese break and reform during repeated straining, starch particles would not be expected to contribute to the cohesion of the imitation cheese [2], particularly given the separation between the starch particle and the protein matrix as evidenced in Fig. 1g.

Melting properties of imitation cheeses

All pre-gelatinised starches significantly (P ≤ 0.05) decreased meltability of the imitation cheese products relative to the control with maize starch causing the greatest reduction (Table 1). The meltability of waxy-maize, wheat, potato or rice starch containing products did not differ significantly from each other, with the exception of the product containing wheat starch, which had significantly (P ≤ 0.05) higher meltability than the product containing waxy-maize starch. Pre-gelatinised starches generally caused a greater reduction in imitation cheese meltability compared to the equivalent native starches in previous work [2] but the source of starch had less influence on meltability in the case of pre-gelatinised starches relative to the native starches. Previous authors have shown the importance of the hydration status of the protein matrix in the melting of model imitation gels [1, 18]. During imitation cheese preparation, rapid immobilization of water by pre-gelatinised starches probably impaired protein hydration leading to an aggregated protein matrix. Thus the increase in thermal energy required to disrupt the aggregates and dissociate the proteins possibly reduced the products potential to melt and flow at high temperatures. In the case of the native starches used in previous work [2], the hydrophobic outer granular layer and hydrogen bonding between adjacent starch molecules probably prevented starch granule swelling and hydration at temperatures below ∼55 °C and consequently minimised protein dehydration. The lack of thermoplasticity of retrograded amylose molecules may have additionally affected meltability in products containing high amylose starches [2]. Guinee et al. [27] found poor flow properties in heated imitation cheeses containing pre-gelatinised starch compared to natural cheese and suggested post-manufacture retrogradation and gelation of starch during storage impeded the flow of the imitation cheese on heating. However, the increase in viscosity brought about by the partial replacement of casein with pre-gelatinised starch in the model system of the present study indicates starch-induced viscosity increases during imitation cheese processing were responsible for the reduced melt in imitation cheese containing added pre-gelatinised starch.

Dynamic rheological properties of imitation cheeses as a function of temperature

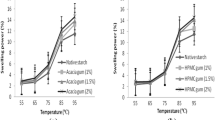

Effects of starches on the rheological parameters G′ and tan δ (G″/G′) of imitation cheese measured as a function of temperature are shown in Figs. 2 and 3, respectively. The storage modulus (G′) at 22 °C of products containing maize or potato starch (62 ± 3.4 and 56.1 ± 4.1 kPa, respectively) was significantly (P ≤ 0.05) higher than the rice starch-containing product (40.3 ± 1.8 kPa) and the control (49.4 ± 2.3 kPa). It is possible that hydrogen-bonding association of amylose in imitation cheeses containing potato or maize starch was responsible for the higher G′ values, under small/non-destructive deformation, compared to the control. This contrasted with the reduced hardness values, under large/destructive deformation, of these starch-containing products compared to the control. It has been suggested that stress localisation at the starch-protein matrix interface causes structural failure in imitation cheese under large deformation [5], which might account for the reduced hardness values in the starch-containing products.

Effect of heating temperature on the storage modulus (G′) of imitation cheese containing 0%, w/w, starch (control) (filled diamond), or 3%, w/w, pre-gelatinised waxy-maize (open square), rice (open triangle), wheat (multi symbol), maize (plus symbol) or potato (open circle) starch. Each curve represents the mean of triplicate trials

Effect of heating temperature on the tan δ(of imitation cheese containing 0%, w/w, starch (control) (filled diamond), or 3%, w/w, pre-gelatinised waxy-maize (open square), rice (open triangle), wheat (multi symbol), maize (plus symbol) or potato (open circle) starch. Each curve represents the mean of triplicate trials

The G’ of all products decreased significantly (P ≤ 0.05) with increasing measuring temperature from 22 to 85 °C, due to melting of the vegetable fat and softening of the protein matrix [2, 3, 28]. The decreases in G′ with increasing temperature of the products containing maize or wheat starch were comparable to those of the control up to ∼70 °C. Imitation cheese containing potato starch had the highest G′ values in the temperature ranges 55–85 °C, which was possibly due to extensive starch retrogradation impeding the flow of casein. Because of the absence of amylose retrogradation in imitation cheese containing waxy-maize starch, the greater decrease in G′ values of this product with increasing temperature compared to the higher amylose starches (maize, potato and wheat starch) is expected. It is, however, surprising that the imitation cheese containing rice starch with its intermediate amylose content had the largest decrease in G′ on heating. However, imitation cheese containing waxy-maize or rice starch added in the native (granular) form also had significant decreases in G′ relative to the control on heating [2].

All products containing starch had significantly (P ≤ 0.05) lower tan δ values at 22 °C (ranging from 0.36 ± 0.02 for waxy-maize to 0.42 ± 0.013 for rice starch-containing imitation cheese) compared to the control imitation cheese (0.44 ± 0.012) and native starches of the same origin in the work of Mounsey et al. [2], indicating more elastic (less viscoelastic) structural behaviour compared to the control. The decreases in imitation cheese tan δ values by the pre-gelatinised starches in the current study could be due to factors such as dehydration of the protein matrix and starch retrogradation. As the temperature increased from 22 to 85 °C the tan δ values for the control imitation cheese product increased (Fig. 3), reaching a peak of 1.73 ± 0.15 at 85 °C. Heating to 40 °C results in melting of the vegetable fats and the imitation cheese begins to lose its predominantly solid elastic nature. Concomitantly, the protein matrix absorbs energy which affects the balance between entropic and enthalpic interactions, with the former becoming stronger while the latter weaken with heating to 80°C. This disruption of enthalpically controlled protein interactions aided by the lubricating effect of the fluid oil phase allows the product to deform and flow [29]. This temperature-dependent behaviour is critical when imitation cheese is designed for pizza-like applications. For products containing starch the tan δ values increased in a broadly similar fashion to the control with heating to ∼55 °C but with further heating, levelling-off occurred. Similar findings were obtained by Montesinos-Herrero et al. [5], where fat was partially replaced with maltodextrin. They found that maltodextrin caused a levelling-off in the tan δ values of imitation cheese above ∼60 °C.

Tan δ values of the product containing waxy-maize starch most closely resembled the control up to 75 °C with a peak of 1.35 ± 0.08 but then levelled off. Peak tan δ values of products containing pre-gelatinised starches decreased significantly (P ≤ 0.05) compared to the control in the order, potato = wheat > maize > rice > waxy-maize. Similar trends were obtained in the previous work [2], where amylose contents of the native starches used were inversely related to the peak tan δ values. However, imitation cheeses containing native starches of similar origins had comparatively higher peak tan δ values than products containing pre-gelatinised starches. With pre-gelatinised starches, while the fat was not well emulsified, moisture bound by starch was probably unavailable to contribute to the mobility of the protein molecules at temperatures above 60 °C. Additionally the associated amylose molecules which require temperatures as high as 140–160 °C [30] for melting probably hindered the softening of the protein matrix, and ultimately the melt and flow properties of the imitation cheese. The tan δ profile of the imitation cheese containing waxy-maize starch most closely matched that of the control, possibly due to minimal amylose retrogradation. Because of its thermo-reversibility, any retrograded amylopectin present should have dissociated at lower temperatures (40–60 °C) [31, 32].

Conclusions

Pre-gelatinised starches with reduced amylose levels (rice and waxy-maize starch) resulted in the greatest increases in the viscosity of model dispersions of starch and casein following heating at 80 °C compared to casein. During imitation cheese manufacture, the pre-gelatinised starches competed with the casein for water, thus limiting casein’s hydration and ability to emulsify fat and resulting in longer processing time. The resultant imitation cheeses were softer, less cohesive and had reduced melting properties compared to the control. Differences in the levels of amylose retrogradation may have been responsible for differences in functionality between starches of different origins. The use of pre-gelatinised starches with reduced amylose levels (rice and waxy-maize starch) resulted in the softest imitation cheeses.

References

Guinee TP, Caric M, Kalab M (2004) In cheese: chemistry, physics and microbiology, 3rd edn, vol 2. Major Cheese Groups. Elsevier, Amsterdam, pp 349–394

Mounsey JS, O’Riordan ED (2001) J Food Sci 66:586–591

Mounsey JS, O’Riordan ED (1999) J Food Sci 64:701–703

Ennis MP, Mulvihill DM (1999) Food Hydrocoll 13:325–337

Montesinos-Herrero C, Cottell DC, O’Riordan ED, O’Sullivan M (2006) Int Dairy J 16:910–919

Wu MC, Lanier TC, Hamann DD (1985) J Food Sci 50:20–25

Kong CS, Ogawa H, Iso N (1999) J Food Sci 64:283–286

Pellegrino L, Resmini P, De Noni I, Masotti F (1996) J Dairy Sci 79:725–734

IDF (1989) Bull IDF 239:1–20

Zwiercan GA, Lacrourse NL, Lenchin JM (1987) US Patent 4,695,475

IDF (1958) International Dairy Federation, Brussels (Standard FIL-IDF 4)

NSAI (1955) National Standards Authority of Ireland, Dublin (IS 69)

IDF (1993) International Dairy Federation, Brussels (Standard FIL-IDF 20B)

Olson NF, Price WV (1958) J Dairy Sci 41:999–1000

Szczesniak AS (1963) J Food Sci 28:385–389

Swinkels JJM (1985) Starch/Stärke 37:1–5

Hennelly PJ, Dunne PG, O’Sullivan M, O’Riordan ED (2005a) Eur Food Res Technol 220:415–420

Hennelly PJ, Dunne PG, O’Sullivan M, O’Riordan ED (2005b) J Food Eng 75:388–395

Carpenter RN, Finnie KJ, Olsen RL (1998) US Patent 5,807,601

Davies L (1995) Food Technology Europe June/July, pp 44–52

Morris ER (1991) In: Harris P (ed) Food gels. Elsevier Applied Science, London, UK, pp 291–359

Tolstoguzov VB (1991) Food Hydrocoll 4:429–468

Kim JM (1986) PhD Thesis, Department of Food Science and Nutrition, University of Rhode Island, Kingston, RI

Zobel HF (1988) Starch/Stärke 40:44–50

Conde-Petit B, Escher F (1994) Starch/Stärke 46:172–177

Stampanoni CR, Noble AC (1991) J Texture Stud 22:381–392

Guinee TP, Auty MAE, Mullins C (1999) Aust J Dairy Technol 54:84–89

Zhou N, Mulvaney SJ (1998) J Dairy Sci 81:2561–2571

Paulson BM, McMahon DJ, Oberg CJ (1998) J Dairy Sci 81:2053–2064

Biliaderis CG, Page CM, Slade L, Sirett RR (1985) Carbohydr Polym 5:367–389

Ring SC, Colonna P, I’Anson J, Kalichvesky MT, Miles MJ, Morris VJ, Orford PD (1987) Carbohydr Res 162:277–293

Eliasson AC, Gudmunson M (1996) In: Eliasson AC (ed) Carbohydrates in food. 1, Marcel Dekker, Inc., New York, pp 431–503

Acknowledgments

This research has been funded by the Irish Department of Agriculture and Food under the Food Institutional Research Measure (National Development Plan).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mounsey, J.S., O’Riordan, E.D. Modification of imitation cheese structure and rheology using pre-gelatinised starches. Eur Food Res Technol 226, 1039–1046 (2008). https://doi.org/10.1007/s00217-007-0629-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-007-0629-5