Abstract

Increasing moisture content may be a practical and cost-effective means to control the functional properties of imitation cheese. Imitation cheeses with moisture contents of 46, 50, 52 and 54 g/100 g were manufactured. An increase in the moisture content of the imitation cheese resulted in significantly increased meltability, tanδ values and decreased hardness (all P<0.05). The relationship between moisture content (x) and meltability (y) was described by the model \( y = 2.2272x^{2} - 215.31x + 5262.9 \) (r2=0.99). A linear relationship emerged between moisture content (x) and hardness (y), where \( y = 2141x - 36.82 \) (r2=0.95) but cohesiveness was unaffected by moisture content. Increasing the moisture content to 52 or 54 g/100 g led to pockets of “free” water within the cheese and larger but fewer fat globules. The maximum level of moisture that the cheese matrix can retain appears to be 54 g/100 g.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The functional properties of cheese are controlled by the chemical composition, including the moisture content [1]. Hence, alteration of the formulation of imitation cheese has implications for its functional behaviour in practical applications such as in pizza toppings and lasagne. For such applications, predictability of hardness is critically important for shredding, dicing and slicing the cheese and controlled meltability is essential. Moisture acts as a plasticiser in the cheese network and so has important impacts on the textural properties [2]. It has been reported [3] that high-moisture processed cheese has a weak body and grainy texture, with a tendency for fat separation, whereas at low moisture levels the cheese is firm, dry and brittle. With increasing moisture, Mozzarella cheese becomes softer and less shreddable [4] and the meltability increases [5]. An incidental advantage of increasing the moisture content of imitation cheese is a concomitant reduction in fat content without impairing the lubricity or “creamy” mouthfeel and texture otherwise provided by the fat [6].

Despite the positive economic gain to the manufacturer from increasing the moisture content of imitation cheese, little information is available on the effects of increased water on the functionality of this product. Substantial research has been conducted on the importance of casein hydration in imitation cheese but has tended to focus more on model systems than on actual cheese [7–9]. Thus, rennet casein “hydration” studies in an actual imitation cheese system might provide some useful information regarding moisture levels attainable under practical conditions. Using this rationale, the objective of the present study was to determine the effect of increasing the formulated moisture content on the texture, rheological properties and microstructure of imitation cheese manufactured with rennet casein.

Materials and methods

Laboratory chemicals and imitation cheese ingredients

Rennet casein was supplied by Kerry Ingredients, Listowel, Co. Kerry, Ireland. Hydrogenated palm oil (HPO) and rapeseed oil were supplied by Trilby Ireland, Drogheda, Co. Louth, Ireland and Caterers Kitchen, I.F.S., Dublin, Ireland, respectively. All other ingredients, including sodium chloride (Pure Dried Vacuum Salt, Cheshire, UK), trisodium citrate and citric acid (Jungbunzlauer, Perhofen, Austria), disodium phosphate [Ellis and Everard (Eurochem), Lucan, Co. Dublin, Ireland] and sorbic acid (Hoechst Ireland, Dublin, Ireland) were of food grade. All the laboratory chemicals used were of general purpose reagent grade or better and were supplied by British Drug Houses Laboratory Supplies, Poole, Dorset, UK or Thompson and Capper, Runcorn, Cheshire, UK.

Formulation

The formulation used for the manufacture of the cheeses was 49.85% rennet casein, 29.20% HPO, 14.38% rapeseed oil, 1.77% trisodium citrate, 0.82% disodium phosphate, 2.80% sodium chloride, 1.02% citric acid and 0.16% sorbic acid, expressed on a dry weight basis. The quantity of water added to the dry ingredients was calculated to yield 4 kg batches of cheese with nominal moisture contents of 46, 50, 52 or 54 g/100 g (46MC, 50MC, 52MC and 54MC, respectively), with the 50MC cheese considered “typical” of commercial products. As the quantity of water increased, the relative proportions of the dry matter ingredients were kept constant.

Manufacture of imitation cheese

A Blentech twin-screw cooker (model CC–0010, Blentech Corp., Rhonert Park, CA, USA), prewarmed to 50 °C using a steam jacket, was used in the production of imitation cheese. Melted HPO was added directly to the cooker, followed by rapeseed oil and water. The temperature of the mix was increased to 50 °C using the steam jacket and the ingredients were mixed at 100 rpm for 1 min. Trisodium citrate, disodium phosphate, sodium chloride and sorbic acid were added and mixed for a further 1 min then rennet casein was added gradually with continued mixing at 100 rpm. The time taken to disperse the rennet casein was recorded and mixing was continued for 1 min following its dispersion. The direct steam valve (DSV) was opened for approximately 2 min and the mixture was allowed to reach 80 °C. The DSV was closed and this temperature (80 °C) was maintained for 5 min using the steam jacket. Citric acid was added and mixing continued for a further 1 min, or until a homogeneous cheese mass had formed. The cheese mass (4 kg) was discharged into plastic-lined cardboard boxes which were placed in a freezer at −18 °C until the cheese reached 20 °C (after approximately 3 h). The cheeses were transferred to a refrigerator at 4 °C. After 24 h, the cheese block was divided into three sections, vacuum-packed and stored at 4 °C until required.

Compositional analysis

The moisture content of imitation cheese was analysed using an oven-drying method [10] and protein content was determined using the Kjeldhal method [11]. Fat was determined by the Gerber method [12]. The pH was measured by inserting a calibrated Unicam glass/Ag/AgCl combination pH electrode attached to a pH meter (model 9450, Unicam, Cambridge, UK) directly into the cheese at four randomly chosen locations after equilibration of imitation cheese to room temperature for at least 1 h. The ash content was determined by heating 5 g of grated cheese at 550 °C in a furnace for 4 h or until all of the sample was ashed [13]. All analyses were performed in triplicate.

Meltability

The meltability was determined using a modification of the method of Mounsey and O’Riordan [14] whereby cylindrical samples (24-mm diameter, 20-mm height) were bored from the block of imitation cheese and after 6 min at 180 °C the distance flowed by the melted cheese was recorded. Melt tests were performed in triplicate.

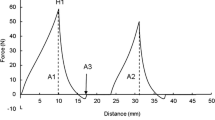

Texture profile analysis

Texture profile analysis (TPA) was performed on the cheese samples using an Instron Universal testing machine model 5540 (Instron Corp., Canton, MA, USA), fitted with a 1-kN load cell and 35-mm diameter plates. The samples were compressed by 80% and textural parameters were calculated according to the method of Mounsey and O’Riordan [15] using the Instron Merlin Series 9 software. Six samples from each cheese block were analysed.

Dynamic rheology

Dynamic oscillatory measurements were performed according to the method of Mounsey and O’Riordan [14]. The storage modulus (G’), loss modulus (G”) and loss angle tanδ (G”/G’) were measured as functions of increasing temperature from 22 to 95 °C. The crossover temperature was also calculated.

Cryo-scanning electron microscopy

Cryo-scanning electron microscopy (SEM) (Jeol JSM-5410LV Scanning Microscope, Jeol Instruments, Tokyo, Japan) was used to examine the microstructure of imitation cheese, according to the method of Mounsey and O’Riordan [15].

Statistical analysis

Three batches of cheese were manufactured at each moisture content and analysis was performed in triplicate for each batch. Proc GLM of SAS V.6 (SAS Institute, Cary, NC, USA) was used to statistically determine differences between treatment means, which were considered significantly different at P≤0.05, unless stated differently.

Results

As the moisture content increased the protein, fat and ash contents decreased (P<0.05) but there was no significant difference in pH (Table 1). Increasing the moisture content of imitation cheese increased (P<0.05) the meltability (Table 2). Within the range of moisture contents in the present study the relationship between meltability (y, millimetres) and moisture content (x, grams per 100 g) was best described by a quadratic model, \( y = 2.2272x^{2} - 215.31x + 5262.9 \) (r2=0.99). Increasing the moisture content decreased (P<0.05) the hardness of imitation cheese but had no significant effect on cohesiveness (Table 2). It may be possible to predict hardness values (y, newtons) for various moisture content (x, grams per 100 g) cheeses within the moisture range of the present study using the linear model \( y = 2141x - 36.82 \) (r2=0.95). The crossover temperature, where tanδ equals unity and is often taken as the melting temperature, decreased (P<0.001) with increasing moisture content (Table 2).

A strain sweep (0.1–10%) was used to determine the limit of viscoelastic behaviour of imitation cheese. Stress was proportional to strain when strain values were less than 1%, which is in agreement with the findings of Mounsey and O’Riordan [14]. G’ decreased with increasing temperature from 22 to 95 °C for each imitation cheese (Fig. 1). The G’ values for the 46MC cheese at 22 °C were greater (P<0.001) than those for the higher moisture content imitation cheeses. The TPA results also indicated that the 46MC cheese was harder than the other imitation cheeses at room temperature and in this regard there was a good quadratic relationship between hardness (x) and G’ values at 22 °C (y) where \( y = 0.0012x^{2} - 0.388 + 51.202 \) (r2=0.99). G’ values at 22 °C decreased linearly with increasing moisture content (r2=0.93).

The G” values (Fig. 2) also decreased with increasing temperature. The G” values for the 46MC imitation cheese at 22 °C were greater (P<0.05) than those for the higher moisture cheeses. Additionally the higher the moisture content of the cheese the lower the G’ and G” values over the entire temperature range, although these differences were not significant at temperatures above 65 °C (Figs. 1, 2, inset). As the temperature increased from 22 to 95 °C, the tanδ values for all imitation cheeses increased (Fig. 3), consistent with a weakening and ultimately melting of the matrix, the increase was most pronounced for the 52MC and 54MC cheeses. Tanδ values increased (P<0.05) with increasing moisture content throughout the temperature range.

Electron micrographs were prepared in an attempt to relate microstructure to texture and rheology. SEM images showed that all of the imitation cheese had fat globules with diameters ranging from approximately 2 to 12 μm, distributed within the protein matrix (Fig. 4). The 46MC and 50MC cheeses had numerous fat globules, with diameters of approximately 7 μm. The 52MC and 54MC cheeses had fewer but larger fat globules with diameters of approximately 12 μm. The number of fat globules seemed to decrease, and their size increase, with increasing moisture content. Electron micrographs also show the development of a “honeycomb” or “lacelike” structure as the moisture content increased, which was particularly evident in the case of the 52MC and 54MC cheeses (Fig. 4c and d, respectively).

Discussion

It has been well recognised that the chemical composition of processed cheese type products affects their functional properties in product applications, particularly in relation to textural and melting characteristics [16]. Water plays an important role in such products, particularly via its interaction with protein. The hydration, disaggregation, network establishment and limited solubilisation of protein occur in the saline aqueous phase of what is essentially an oil-in-water emulsion [8]. Hence, an understanding of the effect of increasing moisture contents is important not only from an economic but also from a functional application perspective.

In the design of this experiment the effective concentrations of fat, protein and ash in the cheeses decreased as the moisture content was increased. However the relative ratios of protein to fat and protein to emulsifying salts were maintained. Maintenance of the latter was considered particularly important as the concentration of emulsifying salts plays a critical role in the solubilisation of rennet casein and ultimately the functionality of the imitation cheese [8].

The highest level of moisture that could be consistently and reproducibly incorporated was 54 g/100 g. Although a 56 g/100 g cheese appeared homogeneous on discharge from the cooker, pockets of free water were visible when the cheese was subsequently examined post cooling. In the case of cheeses with moisture contents above 56 g/100 g, free water was evident even at the cooking stage. Prolonging the cooking/shearing time did not contribute to increased incorporation of water as assessed visually. The cheeses with moisture contents of 54 g/100 g or less exhibited uniformity in terms of (1) results of moisture analysis and (2) visual appearance. However, examination of the scanning electron micrographs does suggest the presence of microscopic pools of “free” or ‘“unbound” water in the 52MC and 54MC cheeses that are not evident in the lower moisture cheeses.

The protein matrix of the higher moisture cheeses were characterised by a honeycombed or lacelike appearance, which was not evident in the 46MC and 50MC cheeses. Furthermore, such features in the protein matrix had not been previously observed in cheeses with moisture contents of 50 g/100 g, manufactured at our laboratory with equivalent formulations and processing regimes [15, 17]. It is likely that the honeycomb appearance may have resulted from evaporation of pools of free water during preparation of the samples for microscopy. The SEM images of the 52MC and 54MC cheeses were further differentiated from those of the lower moisture cheeses by the presence of fewer and larger fat globules. This suggests less efficient emulsification in the higher moisture cheeses, which is consistent with the lower concentration of both protein and emulsifying salts in the aqueous phase. Furthermore it may reflect a greater tendency for coalescence of the dispersed fat phase compared with the lower moisture cheeses. The apparent inability of the casein to “bind” all of the water present and the less effective emulsification of fat at the higher moisture levels assist in the explanation of many of the textural, rheological and melt properties observed in this study.

The observed decreases in hardness with increasing moisture level are most likely due to increased hydration of the protein matrix. Such increased hydration is likely to attenuate protein–protein interactions thus plasticising the matrix, resulting in decreased hardness. The plasticising effect of increased hydration is also evident in the decreases in G’ and G” values with increasing moisture content. Similar observations have been made by others on the effects of increasing moisture content on the hardness of Mozzarella [5] and other natural cheeses [18]. At moisture levels above 52 g/100 g further increases in moisture appear to lead to increasing levels of free water rather than increased hydration per se. However, the presence of such free water is also likely to contribute to reduced hardness and lower G’ and G” values. Additionally, in the case of the 52MC and 54MC products there is also an apparent increase in fat globule size and this has previously been reported [19] to have a softening effect on cheese texture. From the foregoing discussion one might reasonably expect to see a decrease in cohesiveness with increasing moisture content, particularly at the lower end of the range examined; however, no such decrease was observed in the present study.

The melting of imitation cheese is arguably its most important functional characteristic. In the present study the effect of moisture content on this behaviour was investigated using both an empirical test and dynamic rheology. While meltability did increase with increase in moisture content this was only markedly so at the higher moisture levels, i.e. the biggest incremental increase in meltability occurred when the moisture content was increased from 52 to 54 g/100 g. This suggests that the free water evident in the 52MC and 54MC cheeses is more effective in increasing meltability than the water that is more completely adsorbed as water of hydration in the 46MC and 50MC cheeses.

This contention is further supported by the dynamic rheology results, particularly in the temperature range 60–80 °C, i.e. temperatures similar to those experienced by the cheese in the melt test. In this range one can clearly see that both the elastic and the viscous moduli of the molten 52MC and 54MC cheeses are lower than those of the 46MC and 50MC products. Clearly, if the melted 52MC and 54MC cheeses are less viscous than the 46MC and 50MC cheeses then they will flow further in the melt test. Furthermore, the maximum tanδ values observed for the 52MC and 54MC cheeses (approximately 6) were substantially greater than those for the 46MC and 50MC cheeses (2.5±0.6 and 2.6±0.8, respectively) and were also greater than values previously observed in this laboratory [14, 15].

The crossover temperature also decreased with increasing moisture content. It may be that in the 52MC and 54MC cheeses the pools of free moisture behave as discontinuities in the protein matrix, weakening it and the weaker matrix would require less energy to melt. Additionally and similarly the larger fat globules in the 52MC and 54MC cheeses present greater discontinuity in the protein matrix and may also contribute to the reduced crossover temperature. The trends in melting behaviour observed in the present study are consistent with those reported by other workers [20, 21].

Conclusions

The softening and increased meltability of imitation cheeses with increased moisture contents may be attributed to the combined effects of an increase in free water, larger fat globules and decreased protein–protein interactions. A model of moisture behaviour in imitation cheese consistent with the observations reported here is that at moisture contents up to around 50 g/100 g the moisture is almost entirely bound by the casein network as water of hydration. At moisture contents of 52 g/100 g or greater, the hydration capacity of the network is exceeded and further increases in moisture will result in increasing quantities of free moisture within the product. So long as this free water is finely distributed, a visually homogeneous cheese can be produced but at moisture contents above 54 g/100 g this becomes increasingly difficult owing to coalescence of free water, and the appearance of visible “loose moisture” within the cheese becomes unavoidable. While the present study suggests that the “limiting” moisture content achievable in imitation cheese seems to be 54 g/100 g, it should be remembered that this limit refers only to the formulation system used in this study. The precise position of this limit will also critically depend on the hydration characteristics of the rennet casein from which the cheese was made and it is acknowledged that others have established that these can be highly variable [7].

References

McMahon DJ, Oberg CJ (1998) Aust J Dairy Tech 53:98–101

Marshall RJ (1990) J Sci Food Agric 50:237–252

Templeton HL, Sommer HH (1932) J Dairy Sci 15:29–41

Flanagen JF, Thompson DP, Brower DP, Gyuricsek DM (1987) Cultured Dairy Prod J 13:24–30

McMahon DJ, Alleyne MC, Fife RL, Oberg CJ (1996) J Dairy Sci 70:1911–1921

Drake MA, Swanson BG (1995) Trends Food Sci Tech 6:366–368

Ennis MP, Mulvihill DM (1999) Food Hydrocolloids 13:325–337

Ennis MP, O’Sullivan MM, Mulvihill DM (1998) Food Hydrocolloids 12:451–457

Ennis MP, Mulvihill DM (2001) Int J Dairy Tech 54:23–28

IDF (1958) International Dairy Federation, Brussels (Standard 4)

IDF (1993) International Dairy Federation, Brussels (Standard 20B)

Anon (1955) National Standards Authority of Ireland, Dublin (I.S. 96)

AOAC (2002) Official method 935.42, Chapter 33, p.71

Mounsey JS, O’Riordan ED (1999) J Food Sci 64:701–703

Mounsey JS, O’Riordan ED (2001). J Food Sci 66:586–591

Shimp LA (1985). Food Tech 39:63–70

Murphy KJ (1999) MAgrSc Thesis, National University of Ireland, Dublin

Chen AH, Larkin JW, Clark CJ, Irwin WE (1979) J Dairy Sci 62:901–907

Lobato-Calleros C, Vernon-Carter EJ, Hornelas-Uribe Y (1998) J Texture Studies 29:569–586

Savello PA, Ernstrom CA, Kalab M (1989) J Dairy Sci 72:1–11

Guinee TP, Auty MAE, Mullins C (1999) Austr J Dairy Tech 54:84–89

Acknowledgements

Funding for this research was granted under the Food Institutional Research Measure administered by the Irish Department of Agriculture, Food and Rural Development, and is gratefully acknowledged. The assistance of D. Cottell and B. Cregg of the Electron Microscopy Unit, University College Dublin, in preparation and interpretation of SEM images is also appreciated

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hennelly, P.J., Dunne, P.G., O’Sullivan, M. et al. Increasing the moisture content of imitation cheese: effects on texture, rheology and microstructure. Eur Food Res Technol 220, 415–420 (2005). https://doi.org/10.1007/s00217-004-1097-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-1097-9