Abstract

The release and antimicrobial activity of potassium sorbate (KS) supported in tapioca starch–glycerol edible films prepared by different gelatinization/drying techniques against Zygosaccharomyces bailii was studied. Antimicrobial release in liquid media of different pHs (3.0–6.0) could be approximated to a pseudo first-order kinetic model and was almost accomplished after 30 min. Filmmaking method involving slow gelatinization and drying rate resulted in the highest fraction of KS released at equilibrium. Rate constant was higher when pH of the receiving media was 4.5 and fast gelatinization/fast drying had been used. The effectiveness of the preservative released for controlling the microbial growth depended on the pH of the receiving media, being higher at pH 3.0. No effect of filmmaking method was observed. In relation to film effectiveness as a barrier to contamination, it was observed that the preservative was available to prevent an external Z. bailii contamination and also to control yeast growth in an acidified (pH 4.5) high water activity (a w = 0.980) semisolid product.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Edible films and coatings are proposed to be used for food product protection, improving quality and shelf life without impairing consumer acceptability [1–4]

Edible films are not designed for totally replacing traditional packaging. They might be used as a stress factor to help to assure a long and adequate shelf life. They can control moisture, gases, lipid migration and can also be carriers of additives and nutrients. Hydrocolloids such as cellulose, gums, starch and proteins have been used to formulate edible films, and plasticizers are usually employed (i.e., glycerol, sorbitol, polyethylene glycol) to enhance their mechanical properties [5–7].

Edible antimicrobial films and coatings have shown to be an efficient alternative in controlling food contamination. Durango et al. [8] reported that the growth of both deteriorating and pathogenic microorganisms may be prevented through the incorporation of antimicrobial agents into edible films. In the last years, research has been performed concerning the use of edible films for surface application of natamycin, benzoate, and potassium sorbate [9, 10] and for slow release of lysozime, nisine [11–13], and propylparaben [14].

According to legislation and labeling in the USA, edible coatings and films are considered a part of the food; as a consequence, their ingredients must comply with the CFR and be declared on the label under the Federal Food, Drug, and Cosmetic Act [15]. The European Union (EU) considers that an edible film is a special active part of the food and from a legal point of view, it is to be regarded as a foodstuff, along with the food packed in the film, having to fulfill the general requirements for food [16]. However, each country has clear regulations regarding the addition of preservatives to food, which often include purity requirements, analytical methodology, labeling, and maximum allowed levels. Therefore, at the moment, the application of edible films containing preservatives must be ruled under such legislation.

Different authors [17–24] reported that composition, film-forming method and drying process conditions influence the physicochemical properties, when films are based on proteins, chitosan, or hydroxypropyl starch. Rindlav et al. [25] reported that the crystallinity degree of potato starch edible films is dependent on the temperature, the air humidity, and the time that elapses during drying from gel to film. These changes of crystallinity affected film mechanical properties but did not influence its oxygen and water vapor permeabilities according to Rindlav-Westling et al. [26]. As a consequence, the study of edible film performance in relation to its composition and processing is a subject of importance due to the need of a complete characterization of the film to evaluate advantages and disadvantages of its application in relation to food shelf life.

Tapioca starch is produced in Latin America, Asia, and Southern Africa. In Latin America it is popularly used as a meal, as animal fodder, or cooked and eaten as a vegetable. A part of its production is exported. It has been seen that tapioca starch is used to a much lesser extent than other starches, such as corn, in food industry. Anyhow, its importance as a source of starch is growing rapidly, especially because its price in the world market is low as compared to starches from other sources [27]. A potential use of tapioca starch as a matrix for the development of edible films has been also considered [28].

Sorbic acid and its potassium salt (sorbates) are considered GRAS additives and are active against yeast, molds, and many bacteria [29]. These preservatives are unstable in aqueous solution and can suffer an oxidative degradation or can be metabolized by microorganisms under certain conditions of storage [29, 30]. Addition of sorbates to edible films has been proposed as a way of minimizing surface microbial contamination [9, 31, 32]. To accomplish this objective, a certain concentration of the preservative must be present at the surface of the product. Reduction of the surface level due to diffusion into the food or due to degradation of the preservative must be taken into account when designing an antimicrobial film [33–36].

The objective of this research was to study the kinetics of release and the antimicrobial action of sorbates contained in tapioca starch edible films obtained by different methods, in order to evaluate their potential use as a stress factor for controlling microbial growth and lengthening the shelf life of preserved food products.

Materials and methods

Preparation of films

Mixtures of tapioca starch, glycerol, and water (5.0:2.5:92.5 in weight) or of starch, glycerol, potassium sorbate (KS), and water (5.0:2.5:0.3:92.2 in weight) were prepared.

Tapioca starch was provided by Industrias del Maíz S.A. (Argentina). Glycerol (Mallickrodt, Argentina) and KS (Sigma, St Louis, Missouri) used were of analytical grade.

Preparation of films was accomplished through the following methods:

-

1.

Method 1: Heating of 300 g film forming solution on a magnetic stirrer with a hot plate at an initial rate of 1.6°C/min for approximately 25 min, moment at which the system entered in the gelatinization step (gelatinization temperature about 70 °C). Afterwards, heating was maintained at a lower rate (around 0.3 °C/min) for an additional period of 40 min. After gelatinization, films were casted over glass plates and dried at 50 °C (R.H. 22%), for 2 h. Drying was completed in a controlled temperature chamber (Velp, Italy) at 25 °C and R.H., 80–90% during a week.

-

2.

Method 2: Heating of 300 g film forming solution on a magnetic stirrer with hot plate at a constant rate of 1.8°C/min for approximately 30 min. In this case, it could be visually appreciated that gelatinization began around 70°C. After gelatinization, films were casted over glass plates and dried at 50°C (R.H. 22%) for 2 h. Drying was completed in a chamber (Velp, Italy) at 25°C and R.H. 80–90% during a week.

-

3.

Method 3: Heating of 300 g film forming solution on a magnetic stirrer with hot plate at a constant rate of 1.8°C/min for approximately 30 min. After gelatinization, films were casted over glass plates and dried at 50°C (R.H. 22%) for 2 h. Drying was completed over CaCl2 (R.H. 0%) at 25°C during 2 days.

For both the gelatinization techniques assayed, sample final temperature was 82°C and vacuum was applied to remove air from the systems before casting.

Once constituted, the films were peeled off from the glass plates and before evaluating the film properties, samples were conditioned at 25°C over a saturated solution of NaBr (water activity, a W=0.576) for 7 days. Sample thickness was measured to the nearest 0.01 mm, using an optical microscope (Nikon AFX II, Japan) at three different locations in each specimen. The thickness of the cast films resulted to be in the range 0.31–0.36 mm.

Kinetics of preservative release in a liquid medium

In order to evaluate the performance of films made through different methods, kinetics of preservative release in a liquid medium at pH 3.0 or 4.5 was evaluated. In the case of filmmaking method 3, release was also evaluated at pH 6.0.

Twenty-two discs (1.3–1.4 cm diameter) of each type of edible film, weighing approximately 1.3×10−3 kg, were introduced in 250 ml glass flasks containing 100 ml of Saboureaud broth (Biokar Diagnostics, Beauvais, France) with the pH being adjusted to 3.0, 4.5, or 6.0 with citric acid (5.2 mol/l) and inoculated with 3–5×106 CFU/ml of Z. bailii. Flasks were shaken at 150 rpm by means of an orbital shaker (Shaker Pro, Vicking S.A., Buenos Aires, Argentina) for 7 days at 25°C. In order to study the kinetics of preservative release, aliquots of broth were extracted at selected times along 120 h, which comprised very short intervals (0.5, 1.5, 3, 5, 10, 20, 30, 45, 60, 120, 240, and 360 min) at the beginning of the assay and larger intervals from 24 h and beyond (24, 48, 72, 120 h). Samples were centrifuged to remove yeast and the KS concentration was evaluated. A control assay using a non-inoculated broth was also performed to rule out if yeast growth influenced sorbate release.

Kinetics of preservative release in a semisolid medium

To study the diffusion of the preservative in a semisolid food model, two film discs (1 cm diameter) were applied on the surface of 20 ml Saboureaud agar (Biokar Diagnostics, Beauvais, France) contained in plates (diameter 9 cm) and with a w depressed to 0.980 by addition of glucose and pH adjusted to 4.5 with citric acid (5.2 mol/l). Plates were incubated at 25°C for 48 h.

At selected times (0, 4, 8, 12, 16, 20, and 24 h), agar circles of 3 cm of diameter were cut with the help of a cork borer and their KS contents were determined. The area of agar cut included the agar area where the film discs have been deposited and also a safety zone evaluated in previous assays as exceeding the maximum area where sorbate diffusion occurred, under experimental conditions.

Antimicrobial activity

For the purpose of comparing the performance of sorbates supported in films obtained through the different methods assayed, the effectiveness of the antimicrobial released in a liquid medium or acting as a barrier to yeast contamination of high a w products was studied.

Antimicrobial activity of the films was evaluated using as indicator Z. bailii, a spoilage yeast known due to its resistance to several stress factors commonly used in food elaboration such as decreasing pH, incorporation of high levels of sugar, pasteurization and, especially, addition of lipophilic preservatives [37]. These particular characteristics of Z. bailii make it very important to study the conditions to minimize its growth in order to ensure the proper quality of foods.

Inoculum preparation

Z. bailii NRRL 7256 inoculum was prepared in Saboureaud broth at 25°C until early stationary phase was achieved (24 h).

Effectiveness for controlling microbial growth of preservative released in a liquid medium

The procedure applied was similar to the one described for the study of the kinetics of preservative release in a liquid medium. Samples were incubated at 25°C and at selected times (0, 5, 10, 22, 26, 30, 48, 54, 72, 96, 144, and 168 h) they were collected and the microbial growth was evaluated. Analogous assays were performed using films free of preservative to test the effects of other components of the film on the microbial growth.

To compare the effect on microbial growth of sorbate gradually released from film throughout storage with the effect of direct addition of the preservative to the medium, the amount of sorbates released at equilibrium conditions was determined for each film studied and this quantity was added, as KS, at time zero, to an inoculated Saboureaud broth.

Systems were incubated as previously mentioned and, at selected times, aliquots of broths were removed in duplicate for enumerating Z. bailii populations.

Effectiveness of potassium sorbate containing films as barriers to yeast contamination

The ability of potassium sorbate containing films in preventing external contamination was studied. For this purpose, discs of diameter 1 cm were aseptically cut from the films (with and without potassium sorbate) and were applied to a sterile glass surface (petridish of 9 cm of diameter). Then, the discs were seeded with 10 μl of an inoculum of Z. bailii containing approximately 5×106 CFU/ml and incubation of the systems was performed at 25°C for 24 h.

In order to study the performance of the films to prevent microbial contamination of a high water activity (a w) product, Saboureaud agar with a w depressed to 0.980 by addition of glucose and pH adjusted to 4.5 with citric acid (5.2 mol/l) was formulated to resemble that kind of products. Discs of 1 cm diameter were cut from films with or without KS and applied on the surface of the agar. Then, 10 μl of a culture of Z. bailii containing approximately 3–5×106 UFC/ml were seeded on the film discs. Samples were incubated at 25°C for 48 h.

Sampling for both assays was performed at selected times (0, 4, 8, 12, 16, 20, and 24 h or 0, 4, 8, 12, 16, 20, 24, 30, and 48 h) by taking two discs, each one being suspended in 1 ml of peptone water (Biokar Diagnostics, Beauvais, France) contained into a short glass tube (16 mm×100 mm). Samples were shaken for 2 min at 2500 rpm with a vortex (MS 1 Minishaker, IKA-Works Inc., USA), prior to enumerating Z. bailii populations.

Enumeration of Z. bailii

For all assays performed, Z. bailii population was enumerated by surface plating on Saboureaud agar and incubation at 25°C for 5 days prior to counting.

Potassium sorbate content

KS content was measured according to the AOAC [38] oxidation method which includes steam distillation followed by oxidation to malonaldehyde and measurement at 532 nm of the pigment formed between malonaldehyde and thiobarbituric acid. Determinations were performed in duplicate.

Fourier transform infrared spectrometry (FT-IR)

Fourier transform infrared spectrometry was employed to determine the possible interactions between starch and sorbate in the films studied. The transmittance, between 400 and 4000 cm−1, of KS, tapioca starch film, or tapioca starch-sorbate film (without glycerol to exclude potential interferences) was measured using a FT-IR spectrophotometer (Nicolet 510 P, Thermo Electro Corporation, Waltham, MA). The measurement was performed at 25°C and 50% relative humidity. KS powder was dispersed in KBr (pellet procedure) and film samples were measured by attenuated total reflection technique (ATR) on ZnSe crystal at 45°C.

Mathematical data treatment and statistical analysis

Microbiological results are reported on the basis of their average and standard deviation (n=3).

Nonlinear regression analysis was applied to model kinetics of release. Kinetic parameters obtained were analyzed through analysis of variance (ANOVA, α 0.05) and the Tukey post test [39] was applied to establish significant differences between the parameters.

Nonlinear regression and statistical analysis were performed using the Statgraphics Plus program for Windows, version 3.0, 1997 (Manugistics, Inc., Rockville, Maryland, U.S.A).

Results and discussion

Kinetics of preservative release in a liquid medium

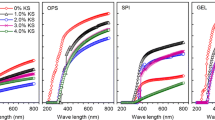

Figure 1 (panel A, B, and C) shows the release of KS from tapioca starch edible films obtained by different filmmaking techniques to Saboureaud broths inoculated with Z. bailii and with pH 6.0, 4.5, or 3.0. In order to appreciate curves in details, only first points are shown (until 300 min). From the assay of broths which were not inoculated, it was observed that the kinetics was not affected by the presence of microorganisms (data not shown).

Release of sorbates from tapioca starch edible film. Panel A: Method 1 film. (▴) pH 4.5; (•) pH 3.0. Panel B: method 2 film. (▴) pH 4.5; (•) pH 3.0; Panel C: method 3 film. (□) pH 6.0; (▴) pH 4.5; (•) pH 3.0. M KS,t : amount of potassium sorbate released at time t; M KS,T: total amount of potassium sorbate contained in the film at time zero

The amount of KS released at time t (M KS,t ) divided by the total amount of KS contained in the film at time zero (M KS,T) was higher than 0.8, independent of the broth pH, after 30 min of contact. Moreover, after 5 min of exposure more than 50% of the preservative had been liberated, in general, from the films assayed to the broth, showing a rapid release. The same trend was reported for the release of KS from κ-carrageenan films [40]. Such a high rate might, in turn, reduce the antimicrobial effect of the film for long-term storage. Buonocore et al. [12, 13] reported that control of antimicrobial agent release into water is possible through modifications of the crosslinking of polyvinylalcohol. Changes in film composition can also help to control release of the preservative [41].

The amount of KS released form tapioca starch film increased with time until an asymptotic value was reached. KS release data could be approximated by a pseudo first order kinetic:

where \(Q_t = M_{{\rm KS},t} /M_{{\rm KS,T}}\) is the fraction of KS released at time t, \(Q_{{\rm inf}} = M_{{\rm KS,}\,{\rm inf}} /M_{{\rm KS,T}}\) is the fraction of KS released when equilibrium was achieved, M KS,inf is the amount of preservative released at the end of the experience and, k is the first order kinetic constant.

Qinf and k values were obtained, for the different films studied, by nonlinear regression analysis and results are shown in Table 1. ANOVA showed that method applied to prepare films affected significantly (α=0.5), the kinetic of KS release. It can be observed that film obtained by Method 1 have the highest Qinf values. On the other hand, films obtained by methods 2 and 3 released a similar fraction of KS (Qinf) at pH 4.5 and these fractions were lower than that released by film made through method 1. For pH 3.0, Qinf values obtained followed the order method 1>method 2>method 3.

According to results previously reported [42] films made from tapioca starch and containing sorbates showed crystallinity that decreased in the order method 1>method 2>method 3. The greater crystallinity observed when method 1 was used is, probably, a consequence of longer heating and drying times [18, 43]. As a consequence, most OH-groups of starch became involved in intramolecular H-bonding and therefore were less available for other interactions [44]. Under such conditions, sorbates could have fewer possibilities of forming complexes through hydrogen bonding with polar groups of starch and, could be more ready for release. The increase in amorphous characteristics due to the shorter time of gelatinization procedure involved in methods 2 and 3 and, to the fast drying process involved in method 3, might explain the increased release of sorbates for these filmmaking methods. According to Arvanitoyannis et al. [17, 18] a lower level of organization of polymer chains is attained when faster gelatinization and/or evaporation rate is used for casting hydroxypropyl starch and gelatin.

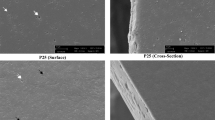

Sorbic acid can form complexes with starch, their nature depending on the type of starch as well as on the concentration and the chemical characteristics of the preservative [45]. Mentioned complexes might modify some properties of the preservative like its solubility, diffusivity, partition coefficient and the ability to penetrate into a biological membrane, decreasing the antimicrobial activity [46]. Ofman et al. [47] reported that potassium sorbate interacts with tapioca starch affecting sorptional behavior, bulk density, cohesiveness and initial Young modulus. In this work, we have confirmed that interaction, through IR, for films made through method 2. As can be observed in Fig. 2, in the starch-KS films (trace B), the -- COO_ asymmetrical stretching signal of sorbate (trace C), suffered a displacement from 1559 to 1537 cm−1; probably, this is determined by hydrogen bonding of starch and sorbates.

It can be observed in Table 1 that, in the range 3.0–4.5, broth pH did not exert a significant (α: 0.05) effect on Q inf. Anyhow, as can be seen in Fig. 1 panel C, antimicrobial concentration in the broth, at pH 4.5 and 3.0, suffered a restrained increase between 10 and 90 min for method 3 and this behavior resulted in significantly lower values of Q inf than the ones obtained for pH 6.0.

Analysis of rate constants (k) showed that filmmaking technique and broth pH exerted a significant influence on the release of sorbates (Table 1). It can be seen that the k values were significantly higher at pH 4.5 for methods 1 and 2 films. Probably, after immersion in broth, the film swelled as a result of the diffusion of water molecules into the film, affecting its pH. As a consequence, a different relation between dissociate and non-dissociate form of the preservative was achieved in each case. At pH 3.0, the non-dissociated form prevailed (sorbic acid) and this form is less soluble in aqueous systems than the sorbate charged form [29]. However, k values obtained for films made through method 3 and assayed in the 3.0–6.0 pH range, were the highest, in general, and did not show significant differences for the different pHs assayed. This latter trend may be related with the amorphous character of this film which might facilitate water interaction with film matrix, producing an increased loosening and higher values of k (Table 1). It was reported for methylcellulose-chitosan films containing KS that rates of preservative release at pH 3.0 and 6.0 were not significantly different [9]. Moreover, no effect of pH (3.8–7.0) of the solution adjacent to the film in the diffusion of KS supported in a κ-carrageenan film was observed by Choi et al. [40]. On the contrary, other researchers [48] observed a longer surface retention of sorbic acid contained in a methylcellulose-palmitic acid film as the pH of a water-glycerol receiving solution was increased from 3.0 to 7.0. The different trends mentioned in relation to the effect of the pH of the solution on the release of the preservative suggest that the type of polymer used to make the film plays an important role.

When filmmaking influence on preservative release was evaluated at pH 3.0 or 4.5, it was observed that lower values of the rate constant were obtained, in general, for films made through method 1 or method 2. As a consequence, we can conclude that a lower rate of drying determined a crystalline degree and/or a greater structural order of film matrix which restricted matrix-water interaction producing lower rate constants for release than those observed for film made through method 3. Anyhow, the amorphous conditions of this last film enhanced not only water-starch interaction but also antimicrobial-starch interaction. This last effect seems to have prevailed for longer immersion times determining a lower Q inf for method 3 than for method 1.

Kinetic of preservative release to a semisolid medium

The antimicrobial release to a semisolid medium was studied for films made through method 3. Diffusion increased with time until an asymptotic value was reached after 4 h of storage. The kinetic constant of release (k=0.037±0.06 min−1) and the asymptotic value (Q inf=0.605±0.018) were lower than the ones obtained for the liquid medium and results are in accordance with trends reported by Guilbert et al. [49], who stated that diffusion of sorbic acid was restricted due to the presence of a gel structure. As the a w of the agar used was higher than the one of the films (0.980 vs 0.576), swelling of the film was observed: disk diameter increased from an initial value of 1 cm to a value of ≈1.3 cm at the end of the experiment, due to the absorption of free water by starch matrix.

Antimicrobial activity

Effectiveness for controlling microbial growth of preservative released to a liquid medium

Figure 3 compares the ability for inhibiting the growth of Z. bailii, of a broth containing sorbate released from a tapioca starch film, in relation to the direct addition at the beginning of the incubation period, of the amount of preservative found at equilibrium conditions of release. As different filmmaking methods did not influence the antimicrobial activity of sorbate, results shown are those obtained for films made through method 3.

Z. bailii growth in Saboureaud broth adjusted to different pH values. CFU/mL: colony forming units per milliliter. Panel A: pH 6.0; Panel B: pH 4.5; Panel C: pH 3.0. Broth with film containing potassium sorbate (◆). Broth containing a free potassium sorbate film (Δ). Broth with direct addition of the amount of potassium sorbate liberated from films at equilibrium conditions (▴). Vertical bars represent standard deviation of the mean (n=3)

When the receiving pH broth was 6.0, sorbates released from the film or its direct addition to the medium did not affect yeast growth. As can be seen (Fig. 3, panel A) yeast reached the stationary phase, approximately, after 48 h of incubation. This lack of inhibitory action is probably due to the presence of the preservative in the dissociated form, being the non-dissociated form the one which mainly possess antimicrobial activity [29, 50, 51].

As it can be seen in Fig. 3, panel B, when the receiving pH broth was 4.5, in the presence of sorbate released from the film, yeast lag phase was extended to 20 h and then, growth took place at a rate lower than the one observed for the control system (broth containing a preservative free film). However, the population level at the stationary phase was similar for both systems. Direct addition of KS to the broth showed the same effect on the microorganism than the one exerted by sorbate released from the film. In summary, sorbates released from the film or added at the beginning of the incubation, extended lag phase, decreased yeast growth rate and had no effect on stationary population. This behavior is related to the fact that for a pH of 4.5, at equilibrium conditions, sorbate present in the media ranged from 0.418 to 0.464 g/kg (expressed as KS) for different filmmaking methods, being this amount, probably, below the minimum inhibitory concentration (MIC) at this pH [48, 49]. It must be mentioned that the MIC for Z. bailii at pH 5.0 is 1.005 g/kg (expressed as KS) according to Praphailong et al. [52] and, that Castro et al. [53] stated that at pH 3.5 and, in Saboureaud broth acidified with citric, the MIC for this microorganism, is 0.400 g/kg (expressed as KS).

When the receiving pH broth was 3.0, sorbates released from the film or directly added to the medium, extended the lag phase to 20 h. Then, the population decreased reaching a reduction of 2log cycles after 72 h (Fig. 3, panel C). Results obtained are as expected taking into account that the amount of sorbates released from films at equilibrium condition ranged from 0.387 to 0.481 g/kg (expressed as KS) for different filmmaking methods, and that at pH 3.0, the MIC for inhibiting the growth of Z. bailii in Saboureaud broth is 0.300 g/kg (expressed as KS) according to Gliemmo et al. [36].

Films free of preservative and immersed in broth adjusted at pH 4.5 or 6.0 did not modify yeast growth pattern suggesting that neither depression of pH nor the release of any component of the film matrix exerted any inhibitory effect on growth. But, when pH of the receiving solution was depressed to 3.0, yeast lag phase was extended to 15 h, growth rate decreased, and a lower level of population in the stationary phase was observed. This behavior confirmed that pH depression to 3.0 exerted per se an inhibitory effect on yeast growth as it was reported previously by other researchers [52, 53].

It must be highlighted that sorbate equilibrium concentration in the broth remained constant throughout the incubation period demonstrating that the preservative neither was used by the yeast cells nor was destroyed by an oxidative mechanism.

It can be concluded that effectiveness of KS does not depend on the form of KS addition probably due to the high rate of sorbate release from films (Table 1). At pH 4.5 and, at the beginning of the incubation period, release from the film was as effective in controlling growth as direct addition and at pH 3.0; both forms of addition showed the same efficacy, probably as a result of having a preservative level above the MIC needed to inhibit Z. bailii.

According to Chung et al. [14], slow release of propyl paraben is not as effective as direct addition of the antimicrobial when the initial concentration of the S. cereviseae is rather high. Anyhow, a major advantage of slow release over direct addition might be the continuous microbial inhibition if slow delivery to food is attained during an extended period fact that can help to reduce cross contamination during food use and storage rather than during preservation. In our case, we observed a high initial release of preservative when studies were conducted without the restriction generated by a semisolid matrix, generally present in food products. This high initial release could inhibit the microbial growth at the early stage of storage. However it might also result in an increase of the antimicrobial concentration at the food surface and hence increase its diffusion rate from the surface into the foodstuff due to the high concentration gradient.

Effectiveness of potassium sorbate containing films as barriers to yeast contamination

Figure 4 (panel A) shows the effect of KS incorporated in tapioca starch films obtained by method 3 on inhibition of Z. bailii inoculated at the surface of film discs. Films containing KS promoted a yeast population decrease that was one log cycle higher than the one determined by free preservative films after 24 h of incubation. This assay demonstrated that sorbates contained in the films are available to act as a barrier for external yeast contamination.

Films as barriers to external contamination by Z. bailii. CFU/g t: colony forming units per gram at time t. CFU/g i: colony forming units per gram at time zero. Panel A: Growth of Z. bailii in the surface of the film. Panel B: Growth of Z. bailii in the surface of a film in contact with a semisolid media of a w 0.98 and pH 4.5. (▴) method 1 (M1) film with potassium sorbate; (◆) method 2 (M2) film with potassium sorbate; (▪) method 3 (M3) film with potassium sorbate; (▵) M1 film without potassium sorbate; (⋄) M2 film without potassium sorbate, (□) M3 film without potassium sorbate. Vertical bars represent standard deviation of the mean (n=3)

On the other hand, when the film stayed in contact with an acidified high water activity (a w) product (Saboureaud agar with a w depressed to 0.98 by addition of glucose and pH adjusted to 4.5 with citric acid. Fig. 4, panel B), it was observed that Z. bailii population remained at the lag phase for systems covered with films carrying KS. No differences were observed for different casting techniques assayed. On the contrary, the semisolid food model covered with free-preservative films suffered a 3log cycle increase of the yeast counts after 48 h of storage.

Conclusions

Sorbates contained in tapioca starch—glycerol edible films were released with a pseudo first order kinetic to liquid media of pH 3.0–6.0. Rate constant (k) was affected by gelatinization/drying technique applied: higher rate of gelatinization and drying of films (method 3) determined a faster liberation of the preservative until equilibrium conditions. This fact could be a consequence of the higher amorphous degree of starch matrix. Liquid media pH, also affected k values for filmmaking methods 1 and 2: higher pH determined higher k probably due to the increase with pH of the solubility of sorbates in aqueous systems.

Fraction of preservative released (Q inf) was affected by filmmaking method: slow gelatinization and drying determined the highest values, probably due to the increase in crystalline degree fact that involved a lower availability of OH groups to interact with sorbates. It is important to remark that for all filmmaking techniques assayed, sorbates were almost completely released after 30 min of immersion in a liquid media.

Antimicrobial effectiveness of sorbates released to a liquid medium was not affected by mode of addition: at pH 4.5, direct addition of the preservative was as effective in delaying yeast growth as sorbates released from the film. At pH 3.0, preservative released from the film or directly added, decreased yeast population reaching a reduction of 2log cycle after 72 h.

In relation to film effectiveness as a barrier to contamination, it was observed that the preservative is available to prevent an external Z. bailii contamination and also to control yeast growth in an acidified (pH 4.5) high water activity (a w=0.98) semisolid product. Diffusion of sorbates contained in the film to the food model increased with time until an asymptotic value was reached after 4 h of storage and it corresponded to a 61% of total KS content of the film. The rate of release and the asymptotic value achieved were lower than the ones observed for the liquid medium.

Edible coatings and films are considered part of the food. There are clear regulations regarding the addition of preservatives to food for each country, which include the maximum levels of preservatives that are allowed. As a consequence, it is important to remark that the edible film formulation proposed must be adapted in order to ensure a content of potassium sorbate in the food that is in accordance with maximum values of sorbate allowed by food legislation of the country of application.

References

Baker R, Baldwin E, Nisperos-Carriedo M (1994) In: Krochta JM, Baldwin EA, Nisperos-Carriedo MO (eds) Edible coatings and films to improve food quality, 1st edn. Technomic Publishing, Lancaster, PA, pp 89–104

García M, Martino M, Zaritzky N (1998) J Sci Food Agric 76:411–420

Del-Valle V, Hernández-Muñoz P, Guarda A, Galotto MJ (2004) Food Chem 91:751–756

Baeva M, Panchev I (2004) Food Chem 92:343–348

Romero-Bastida CA, Bello-Perez LA, García MA, Martino MN, Solorza-Feria J, Zaritzky NE (2005) Carbohydr Polym 60:235–244

Lazaridou A, Biliaderis CG (2002) Carbohydr Polym 48:179–190

Yang L, Paulson AT (2000) Food Res Int 33:563–570

Durango AM, Soares NFF, Andrade NJ (2006) Food Control 17(5):336–341

Chen MH, Yeh GHCh, Chiang BH (1996) J Food Process Preserv 20:379–390

Franssen LR, Rumsey TR, Krochta JM (2004) J Food Sci 69(5):347–353

Park SI, Daeschel M, Zhao Y (2004) J Food Sci 69(8):215–221

Buonocore GG, Nobile MA, Panizza A, Bove S, Battaglia G, Nicolais L (2003) J Food Sci 68(4):1365–1370

Buonocore GG, Nobile MA, Panizza A, Corbo MR, Nicolais L (2003) J Control Release 90:97–107

Chung D, Chikindas M, Yan K (2001) J Food Protect 64(9):1420–1424

Franssen LR, Krochta JM (2003) In: Roller S (ed) Naturals antimicrobials for the minimal processing of foods. CRC Press, Boca Ratón, FL

Fabec B, Hellstrom T, Henrysdotter G, Hjulmand-Lassen M, Nilsson J, Rüdinger L, Sipiläinen-Malm T, Solli E, Svensson K, Thorkelsson A, Tuomala V (2000) Active and intelligent food packaging. A Nordic report on the legislative aspects. Nordic co-operation, pp 21–22, http://www.norden.org/pub/ebook/2000-584.pdf

Arvanitoyannis SI, Nakayama A, Aiba S (1998) Carbohydr Polym 37:371–382

Arvanitoyannis SI, Nakayama A, Aiba S (1998) Carbohydr Polym 36:105–119

Cha DS, Cooksey K, Chinnan MS, Park HJ (2003) Lebensm Wiss Technol 36:209–213

Dawson PL, Hirt DE, Rieck JR, Acton JC, Sotthibandhu A (2003) Food Res Int 36:959–968

Jangchud A, Chinnan MS (1999) J Food Sci 64(1):153–157

Le Tien C, Letendre M, Ispas-Szabo P, Mateescu MA, Delmas-Petterson G, Yu HL, Lacroix M (2000) J Agr Food Chem 48:5566–5575

Menegalli F, Sobral P, Roques M, Laurent S (1999) Dry Technol 17:1697–1706

Roy S, Welle CL, Gennadios A, Zeece MG, Testin RF (1999) J Food Sci 64(1):57–60

Rindlav Å, Hulleman SHD, Gatenholm P (1997) Carbohydr polym 34:25–30

Rindlav-Westling Å, Stading M, Hermansson AM, Gatenholm P (1998) Carbohydr Polym 36:217–224

FAO (2004) Global cassava market study business opportunities for the use of cassava. In: Proceedings of the validation forum on the global cassava development strategy, vol. 6. International fund for agricultural development, Rome

Famá L, Rojas AM, Goyanes S, Gerschenson L (2005) Lebensm Wiss Technol 38:631–639

Sofos JN (1989) Sorbate food preservatives. CRC Press, Boca Raton, FL

Gerschenson LN, Campos CA (1995) In: Barbosa Canovas G, Welti Chanes J (eds) Food preservation by moisture control. Fundamentals and applications. Technomic Publishing, Lancaster, PA, pp 761–790

Cagri A, Ustunoi Z, Ryser ET (2001) J Food Sci 66(6):865–870

Han JH, Floros JD (1997) J Plast Film Sheet 13:287–298

Vodjani F, Torres JA (1989) J Food Process Eng 58:33–48

Vodjani F, Torres JA (1989) J Food Process Preserv 13:417–430

Vodjani F, Torres JA (1990) J Food Sci 55:841–846

Gliemmo MF, Campos CA, Gerschenson LN (2004) J Food Sci 69(2):39–44.

Warth AD (1977) J Appl Bacteriol 43:215–230

AOAC (1990) Official methods of analysis, 13th edn. Association of Official Analytical Chemists, Washington, DC.

Sokal RR, Rohlf JB (2000) Biometry. The principles and practice of statistics in biological research. W. H. Freeman, San Francisco, CA

Choi JH, Choi WY, Chinnan MJ, Park HJ, Lee DS, Park JM (2005) Lebensm Wiss Technol 38:417–423

Ozdemir M, Floros JD (2001) J Food Eng 47:149–155

Flores S, Famá L, Rojas AM, Goyanes S, Gerschenson LN (2006) Food Res Int, accepted for publication

Biliaredis CG (1994) In: Alexander RJ, Zobel HF (eds) Developments in carbohydrate chemistry. The American Association of Cereal Chemists, St Paul, MN, pp 87–135

Dumoulin Y, Serge A, Szabo P, Cartilier L, Mateescu MA (1998) Carbohydr Polym 37:361–370

Duckova K, Mandak M (1981) Pharmazie 36(H9):634–635

Kurup TRR, Wan LS, Chan LW (1995) Pharm Acta Helvetica 70:187–193

Ofman M, Campos C, Gerschenson L (2004) Lebensm Wiss Technol 37(3):355–361

Rico-Peña DC, Torres JA (1991) J Food Sci 56:497–499

Guilbert S, Giannakopoulus A, Cheftel JC (1986) In: Simatos D, Multon JL (eds) Properties of water in foods. Martinus Nijhoff Publishers, Dordrecht, The Netherlands, pp 343–355

Pethybridge AD, Ison RW, Harrigan WF (1983) J Food Technol 18:789–796

Eklund T (1983) J Appl Bacteriol 54:383–389

Praphailong W, Fleet GH (1997) Food Microbiol 14:459–468

Castro MP, Garro O, Campos CA, Gerschenson LN (2002) Food Sci Technol Int 8(1):33–39

Acknowledgements

We acknowledge the financial support from Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT), Universidad de Buenos Aires (UBA), Consejo Nacional de Investigaciones Científicas y Técnicas de la República Argentina (CONICET) and Fundación Antorchas.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Flores, S., Haedo, A.S., Campos, C. et al. Antimicrobial performance of potassium sorbate supported in tapioca starch edible films. Eur Food Res Technol 225, 375–384 (2007). https://doi.org/10.1007/s00217-006-0427-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-006-0427-5