Abstract

In this study protein-containing by-products of deoiling processes rich in phenolics were applied to meat to be used as potential food ingredients in developing meat products with antioxidant effect. The effect of rapeseed meal (Brassica rapa L.), camelina meal (Camelina sativa), soy meal and soy flour (from soybean, Glycene max L.), in inhibiting oxidation of lipids and proteins was tested in cooked pork meat patties. A commercial CO2 extract from rosemary (Rosmarinus officinalis) was used as a reference material alone and in combination with the other plant materials. The cooked pork meat with added plant materials was oxidized for 10 days at 5 °C under light. The oxidation was followed by measuring the formation of hexanal, pentanal and propanal by headspace gas chromatography and the formation of protein carbonyls by converting them to 2,4-dinitrophenylhydrazones (DNPH). Rapeseed meal (0.5 and 0.7 g/100 g meat) and camelina meal (0.7 g/100 g meat) as such and their combination (addition of 0.5 g/100 g) with rosemary extract (0.04 g/100 g) were effective antioxidants toward both protein and lipid oxidation while soy meal and flour were effective only in combination with rosemary extract.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oxidative reactions are a major cause of the chemical deterioration of muscle foods during cooking and storage [1]. Meat is especially prone to oxidation processes due to its complex structure including muscular extracts, myofibrillar systems, polyunsaturated fatty acids, and pro-oxidants [2]. Oxidative reactions in muscle foods are accelerated by heat processing which releases protein-bound iron, activates heme-containing proteins, disrupts cellular membrane systems, and inactivates enzymes [3, 4], and by addition of sodium chloride which increases the pro-oxidant activity of iron [5]. Quality losses in oxidized meat products are generally characterized by flavor deterioration, discolorization, destruction of nutrients, and possible formation of toxic compounds [6].

Protein and lipid interactions contribute to number of functional properties of meat and meat products [7]. In the presence of oxidizing lipids, protein oxidation is manifested by free radical chain reactions similar to those for lipid oxidation [8]. The attack of reactive oxygen species (ROS) on muscle proteins leads to destruction of amino acid residues and the generation of carbonyl compounds. Formation of carbonyls is one of the most salient changes in oxidized proteins. Therefore, the concentration of carbonyl groups is highly indicative of protein oxidation [9]. Although oxidatively modified proteins exhibit alterations in functionality as manifested in the gel-forming ability, water-binding capacity, emulsifying capacity, solubility, and viscosity [7, 10, 11], the exact mechanism underlying in the textural changes has not been elucidated [9].

In order to control the type and extent of protein modification, selection of specific antioxidants, which inhibit both lipid and protein oxidation, can be used [1, 9]. The effectiveness of plant materials such as herbs and essential oils against lipid oxidation is linked to the presence of phenolic compounds and has been proved in different types of meat products [12–15]. Thus, phenolic containing raw materials applied to meat could substantially improve the quality of meat by affecting its oxidative status and improve the nutritional value of the product, and extend the shelf life. As an application of using by-products of deoiling processes of different oilseeds, rapeseed and camelina meals, and soybean, could thus be used as rich sources of phenolic compounds, proteins and essential fatty acids [16]. Soy is already widely used by food industry as the most abundant and economical source of protein, particularly as a good balance of amino acids, and as source of lysine. The use of less refined soy materials rather than the highly refined isolates and concentrates may be also more beneficial from the antioxidant activity perspective. As shown by Wang and Murphy [17, 18], producing soy protein isolates and concentrates resulted in a significant loss of total isoflavone contents including genistein, daidzein, and glycitein during the processing steps between the raw material and refined product. In general, phenolic compounds present in plant materials are considered to be potential in reducing the risk of diseases [19, 20]. Phenolic extracts and isolated fractions of various plant phenolics have been attributed with positive properties such as antimutagenic, antimicrobial, anticarcinogenic, and anti-inflammatory effects as well as being antioxidants in different model systems including LDL, liposomes and, meat [21–25]. According to Vuorela et al. [26] most of the phenolic compounds remain in the meal when the oil is pressed from the seeds. Therefore, the meat, poultry, and fisheries industries stand to benefit from use of different co-products or by-products of food industry in the development of functional foods.

The aim of the study was to investigate the effect of protein containing by-products of deoiling processes rich in phenolics, such as rapeseed meal, camelina meal, soy meal, and soy flour, in inhibiting oxidation of lipids and proteins in cooked pork meat patties. Rosemary extract, commercially used as an antioxidant in meat, was used as a reference material both alone and in combination with the other plant materials.

Materials and methods

Materials

The rapeseed (Brassica rapa L.) meal used was the residue of rapeseed deoiling process in which the oil was expelled from the seeds at elevated temperature by Mildola Ltd (Finland). Camelina (Camelina sativa) meal was obtained from Raisio Ltd (Finland). Soy flour (from soybean Glycene max L.) (Soyolk) was from Cereform Ltd (Northampton, England), and soy meal (SoyUp) was from Eco Food Factory Ltd (Finland). Rosemary extract (Stabiloton WS®) used was the supercritical extract from Rosmarinus officinalis L. by RAPS Ltd (Germany). Meat and fat from pork were obtained from local butcher shop. Quersetin was from Sigma, chlorogenic acid and genistein were from Extrasynthèse (Genay, France). Hexanal was from Aldrich (Germany). All solvents were HPLC grade and purchased from Rathburn Chemicals Ltd (Walkerburn, Scotland). MilliQ water purification system was used (Millipore, Bedford, Mass.). The sodiumphosphate buffer with 6-M guanidine hydrochloride (Aldrich) was made of disodiumhydrogenphosphate (NaHPO4·12H2O) (J.T. Baker, Deventer, Holland) and sodiumdihydrogenphosphate (NaH2PO4·H2O) (Merck, Darmstadt, Germany) adjusted to pH 6.5. Trichloroacetic acid and potassiumchloride were obtained from Merck (Darmstadt, Germany). 2,4-Dinitrophenylhydrazine was purchased from Fluka. Chemicals used were of analytical purity.

Characterization of plant materials

Extraction of plant phenolics

The extraction of rapeseed, camelina and soy meal, soy flour and rosemary extract phenolics was performed according to method of Vuorela et al. [23] with some modifications. One to two grams of plant material and 20 ml 80% methanol was put in a centrifuge tube and was shaken in a water bath (75°C) for 60 min. The clear phenolic extract was collected after centrifugation (6000 rpm, 15 min).

Phenolic content

The amount of total polyphenols was measured colorimetrically according to the Folin-Ciocalteau procedure [27]. Phenolic extract (0.2 ml) was evaporated to dryness. After that 0.2 ml of methanol/water (1:2) 1 ml Folin-Ciocalteau reagent (1:10) and 0.8 ml sodium dicarbonate solution (7.5%) were added. After 30 min the total phenolic content was measured at 765 nm by Perkin-Elmer λ25 UV-Vis spectrophotometer, Norwalk, CT [26]. Gallic acid was used as standard compound. The results were expressed as gallic acid equivalents (GAE), in milligram of plant material. The HPLC analysis of phenolics was performed according to the method outlined by Koski et al. [28] for phenolic acids and their derivatives, and by Kähkönen et al. [29] for other phenolic compounds. Catechin, gallic acid, chlorogenic acid, sinapic acid and rutin were used as standard compounds. Isoflavones and lignans were analyzed in soy meal and flour according to the methods by Nurmi et al. [30] and Nurmi et al. [31], respectively. Also the content of tocopherols in the pressed cakes of camelina and rapeseed, soy meal, soy flour, and rosemary extract were analyzed [32].

Protein concentration of plant phenolics

The protein concentration was measured by determination of nitrogen according to the Kjehldahl procedure [33], and calculated with a 6.25 nitrogen conversion factor.

Total fat and fatty acid composition

The total fat of plant materials was determined by using a Soxtec Avanti 2050 automatic extraction system. The fatty acid composition was measured after hydrolyzing and methylating the fat extracts by gas chromatography. Nonadecanoic acid (C 19:0 fatty acid) was used as an internal standard. A commercial methyl ester mixture (Nu Chek Prep, GLC-63A) was used as a standard. The results were expressed as methyl ester equivalents of fatty acids.

Preparation of pork meat patties

The meat model system was performed according to the method of Vuorela et al. [23]. Red meat from longissimus dorsi muscle of pork, and fat from pork back (2:1) water (10%) and salt (1.4%) were homogenized in a Tecator 1094 cutter for 3–4 min. The mass was then divided in portions, and to each portion the tested antioxidants were added by blending by hand. Rapeseed meal, camelina meal, soy meal, and soy flour were tested at levels of 0.3, 0.5, and 0.7 g/100 g meat. In addition, these plant materials were tested at level of 0.5 g/100 g meat in combination with rosemary extract of addition level of 0.04 g/100 g meat. Rosemary extract was tested at levels 0.04 g and 0.08 g/100 g meat, which were the recommended usage levels (0.4–0.8 g/kg) by manufacturer. Standard compounds, quersetin, chlorogenic acid, and genistein, were tested at levels of 0.01 g/100 g meat. Samples were then vacuum-packed and heated in a water bath (80 °C, 10 min). After heating, the bags were opened, and the samples were transferred to decanter flasks, covered with plastic wrapper, and kept at 5 °C under light. Oxidation was followed by measuring the lipid and protein oxidation at the day 0, at the day 3, at the day 6, and at the day 10. The oxidation experiments were performed in triplicate.

Analysis of oxidation products

Lipid oxidation

Lipid oxidation was followed by measuring the formation of volatile aldehydes, hexanal, pentanal and propanal, by headspace gas chromatography. A sample (2 g) was put in a headspace vial, and the formation of hexanal, pentanal and propanal was measured by headspace gas chromatography equipped with a capillary column (Nordibond NB-54, 25 m, 0.32 mm), and a flame ionization detector. Samples were injected with automatic sampler (Perkin Elmer HS 40XL). Vials were thermostated for 20 min at 80°C. Oven temperature was held constant at 60°C. The inhibition of plant phenolics against formation of different aldehydes was calculated at day 6: (A 0−A 1)/A 0×100, where A 0 is the area of aldehyde in control sample and A 1 is the area of aldehyde in tested sample. The inhibitions were expressed as percentages.

Protein oxidation

Protein oxidation was followed by measuring the formation of protein carbonyls by converting them to 2, 4-dinitrophenylhydrazones (DNPH) and measured by spectrophotometer according to method outlined in Oliver et al. [34]. Concentration (nM) of carbonyls was calculated as [Abs370nm/21.0mM−1cm−1)×1000], where 21.0mM−1 cm−1 is the molar extinction coefficient of carbonyls. For protein quantification a standard solution of bovine serum albumin (BSA) in 20 mM sodiumphosphate buffer with 6 M guanidine hydrochloride (pH 6.5) was prepared and the protein concentrations were determined according to a standard curve. The inhibition of plant materials against formation of protein carbonyls was calculated: (C 0−C 1)/C 0×100, where C 0 is the concentration (nM) of protein carbonyls per mg of protein in a control sample and C 1 is the concentration (nM) of protein carbonyls per mg of protein in a tested sample. The inhibitions were expressed as percentages.

Statistical analysis

Statistical analysis was performed using Statgraphics Plus (STCC Inc., Rockville, ML, USA) one-way ANOVA.

Results and discussion

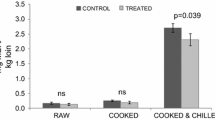

The lipid and protein oxidation curves during 10 days of oxidation in the presence of standard compound quersetin, and camelina meal are shown in Fig. 1. The effect of the plant materials toward oxidation are presented as inhibition values at day 6 of oxidation (Table 1) since there were no changes in the inhibition of lipid oxidation between the 6th and 10th day (Fig. 1). The initial level of protein oxidation was approximately 0.4 nmol/mg of protein. The content of protein carbonyls increased during the first 6 days of oxidation to reach a maximum level which was approximately sixfold the initial level in the control sample. In other studies, basal level of carbonyl groups has been reported in fresh beef meat to be approximately 3 nmol/mg protein [35, 36]. Also the decrease of carbonyl groups after a long incubation has already been observed with different oxidation systems [36, 37], which is in accordance with our results (Fig. 1). Thus, for comparison results for protein and lipid oxidation, the inhibition values at day 6 of oxidation are presented (Table 1) as the formation of protein carbonyls is not decreasing. Aroma has an important influence on the final consumer acceptance of the commodity. Although sensory evaluation was not performed during the oxidation, odour of the meat patties with added plant phenolics was mild and acceptable, and no visible changes in texture was observed.

Rapeseed meal at a concentration of 0.7 g/100 g meat as well as both rapeseed meal and camelina meal in combination with rosemary extract were excellent antioxidants toward lipid oxidation in inhibiting hexanal formation (≥95% inhibition). Rapeseed meal at a lower concentration (0.5 g/100 g meat) and camelina meal (0.7 g/100 g meat) as such showed good antioxidant activity toward hexanal formation (≥80% inhibition). These phenolic rich plant materials were also effective in inhibiting formation of pentanal. Methanolic extracts of both camelina and rapeseed meals have been reported to show remarkable radical scavenging activity (DPPH test, electron spin resonance (ESR) test), and antioxidant activity in β-carotene/linoleic acid system [38]. The amount of total phenolics of rapeseed is 5,100 μg/g with the hydroxycinnamic acids dominating (3,100 μg/g, Table 2). According to Vuorela et al. [23, 26] the main hydroxycinnamic acid derivatives in rapeseed meal contributing to antioxidant effect are sinapine (2,400—2,900 μg/g) and sinapic acid (280 μg/g). The effect of sinapic acid (23.5 mg/100 g meat) in inhibiting the formation of hexanal in meat was 89.0±10.3% [23]. However, also much smaller amounts of rapeseed phenolics are effective toward oxidation of meat. The antioxidant effect of rapeseed meal (0.3 g of meal containing 1.5 mg phenolics/100 g meat) in inhibiting the formation of hexanal in meat was 66.4±6.7% (Table 1), which is accordance with our earlier findings [23]. The combination of rapeseed meal (0.5 g/100 g meat) with the commercial CO2 extract of rosemary (0.04 g/100 g meat) was excellent toward oxidation of meat lipids. Although the amount of phenolic compounds (3.6 mg) present in 0.7 g of rapeseed meal was lower compared to 0.7 g camelina meal (4.3 mg phenolics), rapeseed meal showed higher antioxidant activity toward lipid oxidation. This difference in the efficacy of rapeseed and camelina phenolics toward oxidation of meat lipids is in part explained by the more than two times higher content of sinapine in rapeseed meal. The oilseed by-products contained tocopherols with the highest amount of α-tocopherol (52 μg/g) found in rapeseed meal compared to that (24 μg/g) in camelina meal (Table 2). However, camelina meal was rich in γ-tocopherol (177 μg/g). Tocopherols are well known to be important natural antioxidants for the oxidative stability of vegetable oils [39, 40].

In camelina meal there are several phenolic compounds present, which may be responsible for the antioxidant activity. The phenolic composition in camelina meal was predominated by flavonols, hydroxycinnamic acids, flavanols and, tocopherols (Table 2). Our results are comparable to the levels of sinapine (1.7–4.2 mg/g), sinapic acid (56.5 mg/g), and flavanoids (142.79 mg/g) reported earlier [38, 41]. According to Matthäus and Zubr [41] Camelina sativa oilseed cakes contain also other bioactive substances such as condensed tannins (1.0–2.4 mg/g) and glucosinolates (14.5–23.4 μmol/g). In the present study, camelina meal had the highest total fat level (24%) whereas rapeseed meal contained 11% of fat. The fatty acid composition of rapeseed meal and camelina meal were in accordance with the profiles of rapeseed and camelina oils [42, 43]. As camelina meal contains a high amount of α-linolenic acid (Table 3), it is the most susceptible to oxidation compared to the other by-products of oilseed processing. Most likely sinapine, the choline ester of sinapic acid, and sinapic acid are responsible for the antioxidant effect of camelina meal (Table 2). In addition to tocopherols, partly flavonols, such as quercetin glycosides, also contribute to the antioxidant activity of camelina meal as the amount of flavonols predominated that of hydroxycinnamic acids.

Inhibition of protein oxidation compared to lipid oxidation is only moderate. This may be due to the reason that inhibition of lipid oxidation is the primary target for antioxidants, and protein oxidation the secondary. Rapeseed and camelina meal contained 32% protein (Table 3) contributing to ca. 0.7–1.6% of the meat proteins. Camelina meal phenolics were more potent in inhibiting the oxidation of proteins than rapeseed phenolics. Camelina meal as such (0.7 g/100 g meat) as well as rapeseed meal and camelina meal in combination with rosemary extract were the best antioxidants against protein oxidation with inhibition levels between 76.2 and 70.0%. Lower concentrations were also effective as camelina meal (0.5 g/100 g meat), soy meal in combination with rosemary extract, and rapeseed meal (0.3 g and 0.5 g/100 g meat) were also potent in inhibiting the formation of protein carbonyls. In addition to sinapic acid and its derivative, sinapine, also other phenolic compounds, such as quercetin glycosides are likely to contribute to the antioxidant effect toward protein oxidation. Compared to the effect of sinapic acid with 59.7% inhibition for addition of 23.5 mg/100 g meat [23], quercetin was superior with 76.8% inhibition (Table 1) toward formation of protein carbonyls. Camelina meal exhibited higher antioxidant activity toward protein oxidation than rapeseed meal. This difference in the antioxidant activity of camelina and rapeseed toward oxidation of proteins may partly be explained by the difference in the tocopherol content. In contrast, the amount of tocopherols (201 μg) present in 0.7 g of soy flour was higher than in camelina meal (174 μg) but the antioxidant effect was much weaker. Dietary vitamin E is known to reduce lipid oxidation in the precooked meat products made from pork, beef and poultry [44, 21]. The addition of α-tocopherol to meat products, however, is not considered to be effective toward lipid oxidation [45], although dietary vitamin E reduces lipid oxidation in meat products.

In comparison to the antioxidant activity of rapeseed and camelina meal, soy meal and soy flour were potent in inhibiting lipid oxidation only in combination with rosemary extract (Table 1). Rosemary is known to exhibit the most effective activity among herbs as spice and flavoring agent. Rosemary extract has been shown to act as an effective antioxidant in combination with a chelator such as phosphates in meat [20], in combination with α-tocopherol in frozen-crushed fish meat models [46], in combination of BHA or BHT with citric acid in turkey breakfast sausages [47], in combination with sodium tripolyphosphate in restructured chicken nuggets [48], in pre-cooked roast beef slices [49], and in addition of tertiary butylhydroxyquinone (TBHQ) in restructed beef steaks [50]. In addition, Nassu et al. [51] demonstrated that fermented goat meat containing 0.05% rosemary showed the best characteristics in relation to oxidative stability and to sensory acceptance, when compared with a sample containing 0.025% rosemary. The addition of rosemary essential oil (0.6 g/kg) in refrigerated frankfurters inhibited protein oxidation by 22.8% [52]. The phenolic diterpenes, carnosic acid and carnosol, account for over 90% of antioxidant activity of rosemary [20]. However, in the present study rosemary extract added to the meat in amounts relevant to food use (0.04%), showed poor antioxidant activity (Table 1). It may be assumed that the antioxidant activity of rosemary extract in combination with soy meal or soy flour is due to synergism, since addition of rosemary significantly improved the antioxidant protection of the by-products of soy processing. However, there were no synergistic effects of antioxidant activity with rapeseed and camelina meal in combination with rosemary extract.

In soy meal and soy flour isoflavones and lignans were the predominant phenolic compounds present. Soy meal contained higher amount of total phenolics (2,600 μg/g) than soy flour (1,800 μg/g). However, soy flour contained more isoflavones and lignans than soy meal (Table 2). There were also differences in the content of macromolecules, as soy meal contained 53% protein and only 1% fat compared to 41% protein and 23% fat in soy flour (Table 3). The total isoflavone content of soy flour is reported to range from 1000 to 1650 μg/g, and also the amounts of genistein (460–940 μg/g), daidzein (440–710 μg/g), and glycitein (70–140 μg/g) [53, 54] are in accordance with our findings. The secoisolariciresinol content in soy flour is reported to be 1.3 μg/g [52]. While the amount of total phenolics (1.8 mg) in 0.7 g of soy meal was approximately the same as in 0.3 g of camelina meal (1.9 mg), soy meal contained significantly less tocopherols thus partly explaining why the inhibition of both lipid and protein oxidation was weaker in soy meal. In addition, 0.5 g of soy meal, 0.7 g of soy flour, and 0.08 g of rosemary extract, with total phenolics (1.3 mg) showed poor antioxidant effect compared to 0.3 g of rapeseed meal with approximately the same amount of total phenolics (1.5 mg). Similar findings of antioxidant effects on lipid oxidation were presented with soy protein hydrolysates (2%), which inhibited the formation of conjugated dienes by 46% and the amount of thiobarbituric acid-reactive substances (TBARS) by 32% in cooked pork patties [55]. In frozen pork patties, rosemary (0.1%) and soy protein (0.01%) inhibited the TBARS by 50 and 38%, respectively [56], indicating a less than moderate antioxidant effect. Conflicting results have been reported regarding the antioxidant activity of genistein, daidzein, and glycitein. As genistein exerted antioxidant activity in lipid/aqueous solution, in contrast it possessed very little antioxidant effect on soybean oil [57]. Genistein also lacked antioxidant activity toward oxidation of lipids in emulsions [58], which relates to our findings as genistein showed pro-oxidant activity (Table 1). Osborn-Barnes and Akoh also [58] reported the ability of daidzein to exhibit pro-oxidant activity in structured lipid-based emulsions. Lignans have been suggested to exert antioxidant activity, which is supported by the radical scavenging property of secoisolariciresinol diglucoside [59]. On the other hand, according to Rawel et al. [60] interactions of different phenolic acids such as gallic acid, chlorogenic acid, quersetin, myricetin, caffeic acid and kaempferol, cause a reduction in lysine, cysteine and tryptophan residues in soy proteins. Thus, it is clear that the mode of antioxidant action of isofavones and lignans, as well as that of other phenolic compounds, toward oxidation is affected by the environment. The structure of food and interactions with the other food constituents may alter the antioxidant efficacy.

In conclusion, rapeseed meal was an excellent antioxidant toward oxidation of meat lipids. Both rapeseed and camelina meals as well as their combination with rosemary extract were effective in protecting cooked pork meat patties toward lipid and protein oxidation. Sinapic acid and its derivative, sinapine, were partly responsible for the antioxidant activity of rapeseed and camelina meal. Also tocopherols present in the oilseed by-products may contribute to the antioxidant effect. The antioxidant properties of camelina meal were enhanced by flavonols. In contrast to rapeseed and camelina meal, soy meal and soy flour were effective only in combination with rosemary extract due to their synergistic interactions. The results indicate that residues of deoiling processes containing various bioactive substances could be exploited for example as potential food ingredients in developing functional meat products.

References

Frankel EN (1996) Food Chem 57:51–55

Monahan FJ (2000) . In: Decker EA, Faustman C, Lopez-Bote CJ (eds), Antioxidants in muscle foods. Nutritional strategies to improve quality. Wiley, New York, pp 3–23

Mielche MM, Bertelsen G (1994) Trends Food Sci Technol 5:322–327

Mei LY, Crum AD, Decker EA (1994) J Food Lipids 1:273

Kanner J, Harel S, Jaffe R (1991) J Agric Food Chem 39:1017–1021

Kanner J (1994) Meat Sci 36:169–189

Zayas JF (1997) Functionality of proteins in food. Springer, Berlin Heidelberg New York

Schaich KM (1980) CRC Crit Rev Food Sci Nutr 13:189–244

Xiong YL (2000) . In: Decker EA, Faustman C, Lopez-Bote CJ (eds) Antioxidants in muscle foods. Wiley, New York, pp 85–111

Pokorny J, Davidek J, Chocholata V, Panek J, Bulantova H, Janitz W, Valentova H, Vierecklova M (1990) Nahrung 34:159–169

Howell NK, Herman H, Li-Chan ECY (2001) J Agric Food Chem 49:1529–1533

McCarthy TL, Kerry JP, Kerry JF, Lynch PB, Buckley DJ (2001) Meat Sci 57:45–52

Formanek Z, Kerry JP, Higgins FM, Buckley DJ, Morrissey PA, Farkas J (2001) Meat Sci 58:337–341

Estévez M, Ventanas S, Ramírez MR, Cava R (2004) J Agric Food Chem 52:5168–5174

Sebranek JG, Sewalt VJH, Robbins KL, Houser TA (2005) Meat Sci 69:289–296

Zubr J, Matthäus B (2002) Ind Crops Prod 15:155–162

Wang H-J, Murphy PA (1994) J Agric Food Chem 42:1666–1673

Wang H-J, Murphy PA (1996) J Agric Food Chem 44:2377–2383

Rice-Evans CA, Packer L (ed) (1998) Flavonoids in health and disease. Marcel Dekker, New York

Shahidi F (ed) (1997) Natural antioxidants: Chemistry, health effects, and applications. AOCS Press, Champaign, Illinois

Mercier Y, Gatellier P, Viau M, Remignon H, Renerre M (1998) Meat Sci 48:301–318

Viljanen K, Kylli P, Kivikari R, Heinonen M (2004) J Agric Food Chem 52:7419–7424

Vuorela S, Salminen H, Mäkelä M, Kivikari R, Heinonen M (2005) J Agric Food Chem 53:8492–8497

Vuorela S, Kreander K, Karonen M, Nieminen R, Hämäläinen M, Galkin A, Laitinen L, Salminen J-P, Moilanen E, Pihlaja K, Vuorela H, Vuorela P, Heinonen M (2005) J Agric Food Chem 53:5922–5931

Clifford MN (2000) J Sci Food Agric 80:1033–1043

Vuorela S, Meyer AS, Heinonen M (2004) J Agric Food Chem 52:8202–8207

Singleton VL, Rossi JA (1965) Am J Enol Vitic 16:144–158

Koski A, Pekkarinen S, Hopia A, Wähälä K, Heinonen M (2003) Eur Food Res Technol 217:110–114

Kähkönen MP, Hopia AI, Heinonen M (2001) J Agric Food Chem 49:4076–4082

Nurmi T, Mazur W, Heinonen S, Kokkonen J, Adlercreutz H (2002) J Pharm Biomed Anal 28:1–11

Nurmi T, Voutilainen S, Nyyssönen K, Adlercreutz H, Salonen JT (2003) J Chromatogr B 797:101–110

Ryynänen M, Lampi A-M, Salo-Väänänen P, Ollilainen V, Piironen V (2004) J Food Composition and Analysis 17:749–765

AOAC International (1995) Official methods of Analysis. AOAC International, Arlington, VA

Oliver CN, Ahn B-W, Moerman EJ, Goldstein S, Stadtman ER (1987) J Biol Chem 262:5488–5491

Martinaud A, Mercier Y, Marinova P, Tassy C, Gatellier P, Renerre M (1997) J Agric Food Chem 45:2481–2487

Mercier Y, Gatellier P, Renerre M (2004) Meat Sci 66:567–473

Batifoulier F, Mercier Y, Gatellier P, Renerre M (2002) Meat Sci 61:389–395

Matthäus B (2002) J Agric Food Chem 50:3444–3452

Pekkarinen S, Hopia A, Heinonen M (1998) Fett/Lipid 3:69–74

Mäkinen M (2002) Lipid hydroperoxides: Effects of tocopherols and ascorbic acid on their formation and decomposition. Academic dissertation, University of Helsinki, Finland, EKT series 1253

Matthäus B, Zubr J (2000) Ind Crops Prod 12:9–18

Zubr J (1998) False flax as oil-seed crop for sustainable agriculture. Sustainable agriculture for food, energy and industry. James and James (Science publishers) Ltd, pp 682–686

Leonard EC (1998) Inform 9:830–838

Bertelsen G, Jensen C, Skibsted LH (2000). In: Decker EA, Faustman C, Lopez-Bote CJ (eds), Antioxidants in muscle foods. Wiley, New York, pp 367–394

Rhee KS (1987) . In: St Angelo AJ, Bailey ME (eds) Warmed-over flavour of meat. Academic Press Inc Orlando, Florida, pp 267–289

Wada S, Fang X (1992) J Food Process Preserv 16:263–274

Barbut S, Josephson DB, Maurer J (1985) J Food Sci 50:1356–1363

Lai S-H, Gray JI, Smith DM, Booren AM, Crackel RL, Buckley DJ (1991) J Food Sci 56:616–620

Murphy A, Kerry JE, Buckley DJ, Gray JI (1998) J Sci Food Agric 77:235–243

Stoick SM, Gray JI, Booren AM, Buckley DJ (1991) J Food Sci 56:597–600

Nassu RT, Goncalves G, da Silva MA, Beserra FJ (2003) Meat Sci 63:43–49

Estévez M, Ventanas S, Cava R (2005) J Food Sci C:427–432

Umphress ST, Murphy SP, Franke AA, Custer LJ, Blitz CL (2005) J Food Compos Anal 18:533–550

Pillow PC, Duphorne CM, Chang S, Contois JS, Strom SS, Spitz MR, Hurstings SD (1999) Nutr Cancer 33:3–19

Pena-Ramos EA, Xiong YL (2003) Meat Sci 64:259–263

McCarthy TL, Kerry JP, Kerry JF, Lynch PB, Buckley DJ (2001) Meat Sci 57:177–184

Esaki H, Onozaki H, Kawakishi S, Osawa T (1996) J Agric Food Chem 44:696–700

Osborn-Barnes H, Akoh CC (2003) J Agric Food Chem 51:6856–6860

Prasad K (1997) Mol Cell Biochem 168:117–123

Rawel HM, Czajka D, Rohn S, Kroll J (2002) Int J Biol Macromol 30:137–150

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salminen, H., Estévez, M., Kivikari, R. et al. Inhibition of protein and lipid oxidation by rapeseed, camelina and soy meal in cooked pork meat patties. Eur Food Res Technol 223, 461–468 (2006). https://doi.org/10.1007/s00217-005-0225-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-005-0225-5