Abstract

Advancement in technology and changing lifestyle demand reduction in baking time with good quality product. One of the ways to reduce the baking time is by introducing rapid heating modes such as microwave, infrared and jet impingement heating. However, use of such heating modes during the baking process may alter the final product quality such as surface colour, moisture content, crumb hardness and porosity. Energy efficiency and product quality are the prime factors for any process industry and combining two or more heating modes (hybrid heating) can yield the desired quality of baked product. Therefore, hybrid heating oven shows promise of providing energy and time efficient baking process. Use of hybrid heating requires a thorough knowledge of baking process along with biochemical and physical transformation. This review contents scientific papers published in the last 15 years mainly, dealing with various ovens and its hybrid heating modes used for the baking process are summarized along with the merits and limitations of these approaches.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Success and growth of any industry depend on the quality of products and energy efficient processes. Food processes like baking, frying, roasting, boiling etc. are some of the most energy intensive unit operations (Fluch et al. 2017; Mukherjee et al. 2017). The demand for baked products increased significantly with over 94 million tonnes of bread was consumed each year (Khatir et al. 2015). Baking is one of the most heat sensitive processes in which the heating has a significant influence on quality (chemical, physical and sensory qualities) and cost of the final product (Khatir et al. 2015). The process of baking involves several operations like mixing, proving, baking, cooling, etc. These processes play specific role in the final product quality (Cauvain and Young 2003). As an illustration, the operating conditions during baking have an influence on key quality parameters of bread (texture, moisture content, surface colour and geometry of bread). However, major bread quality parameters were temperature dependent and therefore, can be controlled through the optimization of oven temperature (Therdthai and Zhou 2003).

Baking is a complex and irreversible process. At the end of this process, the dough changes in two different parts i.e. crumb and crust, both of which have their distinct texture. The golden brown colour of bread surface forms due to the non-enzymatic browning reaction initiated as a result of high surface temperature (> 120 °C) and low moisture content (< 0.05%) of bread surface (Chhanwal et al. 2012; Vanin et al. 2009; Weibiao Zhou and Hui 2014). The crumb is a result of starch gelatinization and protein coagulation. The crust has less moisture content as compared to crumb and crumb moisture remains almost constant throughout the baking process (Lucas 2014; Vanin et al. 2009).

The heat transfer during the baking in an oven generally occurs in all the three modes i.e. convection, conduction and radiation. The velocity of the heating medium, heating temperature, nature of food product and heating time are the major factors affecting the heat transfer and in turn the quality of the baked products. Optimization of various oven parameters is the most important aspect in baking industries for obtaining a good quality product as the temperature uniformity, heating efficiency, baking time and humidity level in oven affects the final product quality (Zhou and Therdthai 2007). The baking of bread is a process of simultaneous heat and mass transfer (SHMT). Evaporation-condensation mechanism dominates this SHMT, and has a major role in the formation of crust and crumb. Details about the evaporation-condensation mechanism can be found in the literature (Chhanwal et al. 2011; Chhanwal and Anandharamakrishnan 2014; Tank et al. 2014; Therdthai and Zhou 2003; Thorvaldsson and Janestad 1999).

The heating mode has a significant role in the final baked product characteristics (crumb and crust formation, browning and flavour development). The baking industry looks forward to the use of a non-conventional heating oven to accelerate the process, increase yield while enhancing product quality with a reduction in processing cost. Decock and Cappelle (2005) reviewed various technologies and new market trends in the bread baking process. Many non-conventional heating techniques were used for a baking process such as microwave, infrared, jet impingement etc. (Li et al. 2013) (Tables 1 and 2). Apart from the above techniques, some researchers also worked on the combination of different techniques such as microwave-infrared (Datta and Ni 2002; Keskin et al. 2004; Gulum Sumnu et al. 2005) and microwave-jet impingement (Li and Walker 1996; Gülüm Sumnu et al. 2007).

Hybrid heating techniques help to improve the energy efficiency of the process with optimum product quality. Therefore, one can say that the hybrid heating is a promising technology for the baking process. However, there is a lack of knowledge and complete understanding of the baking process in hybrid heating modes. Datta and Rakesh (2013) emphasize that the control over the quality of the product can be achieved on automation of the oven with better predictability and programmability of the parameters and using different heating modes simultaneously. Moreover, a review comprehending the glimpse of the recent development in this area is not available. Therefore, this review article discusses scientific papers published mainly in the last 15 years dealing with various ovens and its hybrid heating modes used in the baking process along with highlighting their merits, demerits and effect on the final product characteristics. Additionally, different heating modes affect the quality of the product by entirely different ways and the use of hybrid modes makes it more complex. Therefore, understanding of the effect of different heating mode on product quality also requires special attention. This review briefly discusses these phenomena, mainly focusing on microwave, infrared and jet impingement heating during the baking process. In this approach, we excluded the use of hybrid heating for drying or dehydration and only focused on the baking ovens and the major baked products like bread and cake. Additionally, hybrid heating ovens used in paint industries were also excluded due to intended end use.

Microwave Ovens

In the recent years, microwave heating is gaining importance in the food industry for various operations such as baking, thawing, heating, cooking, and drying due to its instant and rapid heating with precise process control (Campañone and Zaritzky 2005; Campañone et al. 2012; Campañone and Zaritzky 2010; Cha-um et al. 2011; Chavan and Chavan 2010; Datta and Rakesh 2013; Datta and Anantheswaran 2001; Sakiyan et al. 2011; Turabi et al. 2008a). The changing lifestyle and demand for ready to eat food are major driving force behind the popularity of the microwave oven. It is now one of the essential home appliances of the household. Though, the microwave had done well with the major food processing operations; it fails to excel in baking operations. This was due to the complex nature of the bread baking process. Major quality parameters such as browning of bread surface, starch gelatinization and volume expansion were affected during microwave heating. Along with these defects, dense or gummy texture, hard crumb; insufficient gelatinization, more weight loss, rapid staling, non-uniform heating and development of hot and cold spots are also the major concerns during microwave baking (Rakesh et al. 2009; Sumnu 2001). According to Sakiyan et al. (2011), level of gelatinization increases with the increase in baking time and the microwave oven failed to carry out complete gelatinisation due to short baking time. Microwave oven provides poor physicochemical changes and improper interactions of the major ingredients as compared to convection oven (Ozmutlu et al. 2001). Yin and Walker (1995) also stated that one of the reasons for the poor quality of the baked product is insufficient starch gelatinization is due to the quick heating in a microwave oven.

Baking is simultaneous heat and mass transfer process. During conventional baking, heat is transferred to the product by radiation (hot metal parts such as oven wall), convection (from the hot air) and conduction (product surface to the core) mode. Water evaporates from the product surface in the initial stage of the baking process and crust forms which further restricts evaporation of water from the core region as the heat penetrates (Chhanwal et al. 2012; Purlis and Salvadori 2010). However, in microwave heating, heat is generated due to ionic polarization and dipole rotation. In ionic polarization, an electric field accelerates the pace of ions which results in a collision between the ions. This collision converts moving ions kinetic energy into thermal energy and increases the temperature of food. In dipole rotation, the polar molecules (water) tries to align themselves to the polarity of the field that rapidly changes in the microwave (2450 million times). Heat is generated inside the food samples and transferred by conduction throughout the product (Singh and Heldman 2009; Gülüm Sumnu 2001). Therefore, the heating pattern of the microwave is volumetric compared to conventional surface heating that changes the baked product characteristics.

Dielectric properties (dielectric constant and dielectric loss factor) of the material majorly influence the interaction of food and the microwaves. This depends on the frequency, composition, physical structure, temperature, moisture content and density (Sakiyan et al. 2007). Dielectric constant represents the ability of the material to store the electric energy, whereas dielectric loss factor defines the ability to dissipate microwave energy into heat. Physical properties (temperature, porosity, specific volume, thermal conductivity, dielectric properties, etc.) of the bread baked using different heating modes such as microwave-infrared, microwave-jet impingement and jet impingement alone were analysed by Sumnu et al. (2007). Figure 1 shows the porosity and thermal conductivity of bread during the baking process using different heating modes. Bread baked in jet impingement oven shows higher porosity and specific volume compared to the bread obtained in other two ovens. During the baking process, the dielectric properties and thermal conductivity of bread baked in all three modes decreased sharply for an initial 2–3 min and then remained constant. A sharp decrease of dielectric properties and thermal conductivity for an initial period was due to the rapid increase in porosity and rapid moisture loss as moisture content and porosity mainly influence dielectric properties during baking. Gülüm Sumnu et al. 2007 also found that dielectric properties of the crust portion of the bread were higher than the crumb portion. Porosity, cake formulation (fat content, fat replacer, etc.) and temperature affect the dielectric properties of cake baked in the microwave and microwave-infrared combination oven (Ozge et al. 2006). Increase in fat content showed increase in dielectric properties whereas an increase in temperature shows a negative impact (i.e. decrease) on them. Further, Sakiyan et al. (2007) found that the cake with fat replacer containing whey protein baked in the microwave and microwave-infrared combination oven was firmer than cake containing fat.

Porosity and thermal conductivity of breads during baking in different heating modes (Sumnu et al. 2007)

During microwave baking, due to the rapid heat generation, there may be insufficient time for starch gelatinization, volume expansion, crumb structure formation and flavour development. During the microwave baking, soggy food product is obtained due to the surface moisture accumulation (Datta and Ni 2002). The temperature and moisture content play a major role in the surface browning of the baked product (Decareau 1992; Therdthai and Zhou 2003). Maillard browning and caramelization reactions are mainly responsible for producing flavoured and coloured compounds during baking. During microwave heating, heat is generated inside the product and cool ambient temperature fails to induce surface browning (Maillard browning and caramelization reactions) in the baked product (Gülüm Sumnu 2001). Aromatic compounds responsible for flavour development in cakes are absent in cake baked in a microwave oven (Whorton and Reineccius 1990). Therefore, the speed and mechanism of microwave heating hamper the final baked product quality (Ozmutlu et al. 2001). Product geometry (volume and shape), dielectric properties (Datta and Anantheswaran 2001), oven size, its geometry (Geedipalli et al. 2008; Geedipalli et al. 2007) and position of product inside the oven (Rakesh et al. 2010) also affect the final product quality.

Many researchers have tried to overcome these defects and utilize the full potential of the microwave oven. Some researchers tried to modify the ingredient, whereas several tried to use shields and susceptors for packaging, combined heating with the infrared, conventional or jet impingement. Flavour loss in the microwave baked product is due to the absence of the crust and this loss can be minimized by using oil phase or increasing oil concentration in the formulation (Yaylayan and Roberts 2001). The increase in yeast level and proofing time can yield the same quality baked product with the microwave-conventional oven as that of convection oven (Willyard 1998). Sánchez-Pardo et al. (2008) suggested that changes and improvement in the product formulation are necessary to obtain the best quality product in a microwave oven comparable to the convection oven product.

Demirekler et al. (2004) studied microwave and halogen-lamp combination oven, and they concluded that halogen-lamp power and baking time have a significant role in the colour development of the baked product. Comparable quality product in terms of colour, textural, specific volume, and porosity was obtained. As compared to the halogen lamp power, microwave power was found to be more responsible for weight loss of product (Demirekler et al. 2004; Sevimli et al. 2005). This was due to the higher penetration depth and quick volumetric heating of product by microwave, compared to surface heating by halogen lamps. It is possible to obtain the microwave baked product, having a brown and crisp crust when microwave heating was combined with jet impingement heating (Walker and Li 1993). Microwave-jet impingement oven can reduce the baking time significantly. However, it yields a product with the lowest volume and the firmest texture (Li and Walker 1996). Bread firmness was a function of microwave power and pressure when baked in the microwave-pressure oven (Ovadia and Walker 1996). İçöz et al. (2004) used susceptor in microwave baking to overcome surface browning problems. However, an increase in microwave power resulted in a darker product and showed a negative impact on the quality of bread in terms of hardness. Keskin et al. (2004) used halogen lamp-microwave combination oven to overcome crust colour problem associated with microwave baked bread. They obtained a product with specific volume and crust colour comparable to conventionally baked bread. However, it fails in providing similar firmness and weight loss as conventional baked bread. Moreover, firmness can be controlled by, providing the required humidity in the halogen lamp-microwave oven (Sevimli et al. 2005). Geedipalli et al. (2008) reported that different improvements in process conditions, formulation and use of other heating techniques failed to provide satisfactory final product quality, and major issues remain as it is with the quality of food baked in a microwave oven. Sánchez-Pardo et al. (2012) compared the heating in the microwave for two cycles with conventional oven and concluded that product baked in a convection oven has good quality than a microwave oven. According to the Ozkoc et al. (2009), bread baked in a microwave oven has higher firmness due to their lower moisture content and leaching out of starch from the granules. During storage of microwave baked bread, they found B-type crystal structure (consist of 36 water molecules) more dominant with high crystallinity due to the staling of bread.

Microwave heating is rapid heating technique which is unable to provide desired quality characteristics in the baked products due to altered heat and mass transfer. Changes occur while baking were studied by the various researchers and it underlines that the rapid and volumetric heating changes baked product characteristics. Therefore, combining microwave heating with other rapid surface heating mode such as infrared, jet impingement would yield the desired quality product.

Infrared Radiating Ovens

Infrared radiation heating is a well-known technology in the food industry from the last few decades. Recently, its use in different food processing operations has increased due to its rapid surface heating capability. It has shown wide application in dehydration of vegetables, fish, pasta, and rice; frying meat; roasting cereals, coffee and cocoa; baking biscuits and bread; grilling; reheating; broiling; and cooking (Krishnamurthy et al. 2008; Kumar et al. 2009; Wang and Sheng 2004). Infrared is electromagnetic radiation with wavelength range between visible light and microwaves i.e. 0.78–1000 μm. Infrared waves are classified on the basis of their wavelength in three different types, i.e. near-infrared (0.78 to 1.4 μm), mid-infrared (1.4 to 3.0 μm), and far-infrared (3.0 to 1000 μm). Far-infrared waves are more suitable for food heating as most of the food components absorb energy from this wavelength range (Krishnamurthy et al. 2008; Nowak and Lewicki 2004; Sakai and Hanzawa 1994; Sandu 1986). Infrared heating offers many advantages over conventional heating. These include shorter start up time, efficient and uniform heating, less processing time and less energy cost (Krishnamurthy et al. 2008). However, infrared heating has some disadvantages such as low penetration power, prolonged exposure to biological materials may cause fracturing, insensitive to reflective properties of coatings. Infrared heating is largely influenced by the penetration depth of radiation and product surface characteristics (Datta and Rakesh 2013; Krishnamurthy et al. 2008).

Basic Laws Pertaining to Infrared Radiation

Plank’s Law

The Plank’s law gives the spectral blackbody emissive power distribution at a given temperature. It is useful to determine the total radiative heat flux when the specific surface temperature of the heating source is known. It is expressed as,

Where, k is the Boltzmann’s constant (1.3806 × 10−23 J/K), n is the refractive index of the medium, λ is the wavelength (μm), T is the source temperature (K), c0is the speed of light (km/s), and h is Plank’s constant (6.626 × 10−34 J.s).

Wien’s Displacement Law

The Wien’s displacement law gives the peak wavelength at which radiation spectral distribution emitted by blackbody achieve maximum emissive power. Infrared source temperature to obtain the desired spectral distribution is given by the equation,

Where λmax is the peak wavelength (μm) and T is the source temperature (K).

Stefan-Boltzmann’s Law

The Stefan-Boltzmann law gives the total power radiated by an infrared source at a specific temperature.

Where, σ is Stefan-Boltzmann’s constant (5.670 × 10−8 W/m2 K4).

Beer’s Law

The Beer’s law gives the transmitted spectral irradiance in the non-homogenous system. It states that the amount of light absorbed by the solution varies exponentially with the length of the light path in solution and concentration of the solution. It is expressed as,

Where \( {\sigma}_{\lambda}^{\ast } \) is the spectral extinction coefficient (m2/kg), Hλ0 is incident spectral irradiance (W/m2∙μm), Hλis transmitted spectral irradiance (W/m2∙μm), and u is mass absorbing medium per unit area (kg/m2).

The mechanism of radiation heating is based on absorption of radiations by the product, and it solely depends on the wavelength of radiation. Electronic, vibrational, and rotational changes in the state of an atom or molecule, respectively, occur at wavelength ranges of 0.2–0.7 μm, 2.5–100 μm and 100 μm (Decareau 1985). During far-infrared heating (FIR), the food absorbs energy by a mechanism of change in molecular vibration state and cause heating. The main components of food that absorb the far-infrared energy of wavelength > 2.5 μm are water and organic components (Krishnamurthy et al. 2008; Sakai and Hanzawa 1994). The penetration ability of a short wavelength is ten times that of long wavelength infrared radiations. A shorter wavelength penetrates deeper while long wavelength results in surface heating (Skjöldebrand 2001). Shorter wavelength yields wet crust, and longer wavelength resulted in a dry crust in infrared bread baking (Levinson 1992). During infrared bread baking, crust and crumb forms simultaneously, whereas in case of conventional baking crust forms first followed by crumb (Skjöldebrand 2001). It was reported that baking in only infrared heating mode produces bread with a thick crust, low specific volume and higher firmness than conventionally baked ones (S. G. Sumnu and Ozkoc 2010). The reflectance and penetration depth influence the infrared heating. In their study on the determination of optical properties of food during infrared heating, Almeida et al. (2006) observed that reflectance increases as moisture content increases and varies with the wavelength of infrared radiation. The increase in reflectance decreases the fraction of the incident energy available for the food to absorb. Further, they also reported that the penetration depth of the near-infrared is lower than that of microwaves and underlines surface heating characteristics. The penetration depth varies with the wavelength and is mostly influenced by the moisture content (Almeida et al. 2006).

Researchers have attempted using infrared radiations for the baking process alone or combined with microwave and conventional heating due to its advantages over the conventional baking oven. Wade (1987) reported the use of a quartz-tungsten tube (emit near-infrared radiation) for biscuit baking with 40–50% reduction in baking time and a comparable product quality. Even though, the moisture content of biscuits baked using infrared radiation was higher; it did not show any spontaneous breakage (checking) as shown by biscuits with higher moisture content baked in conventional oven. This characteristic was due to the forced air cooling during the post-baking period and even moisture distribution throughout the biscuits baked in an infrared oven. Skjöldebrand and Andersson (1989) compared crust characteristics (colour and thickness) of bread baked in an infrared and conventional oven. They observed thinner crust and softer crumb with short baking time for bread baked in the infrared oven. According to Skjöldebrand et al. (1988) wavelengths, longer than 2 μm are responsible for developing of crust colour. Skjöldebrand (2001) suggested the use of shortwave infrared radiation along with convection for rapid baking. Baking time depends upon the thickness of product and 25 to 30% reduction in baking time was achieved with the infrared heating (Skjöldebrand 2001). Halogen lamp-microwave combination oven provides cakes with satisfactory specific volume and colour (Sevimli et al. 2005). Martínez-Bustos et al. (1999) used infrared heating for baking of wheat flour tortillas producing optimum product quality. The rate of colour development in white bread was higher with far-infrared radiations compared to near-infrared radiations, due to surface heating characteristics of far-infrared radiations (Sato et al. 1991). Shyu et al. (2008) compared qualities of four bakery products (bun bread, toast, pound cake, and sponge cake) baked in the far-infrared oven with a conventional oven. The softer sponge cake was obtained with far-infrared oven compared to a conventional oven. Moreover, other quality parameters such as volume, water activity and sensory quality were similar for both baking methods. The sensory analysis of baked products however showed significantly higher mean scores for convection oven than the far-infrared oven for physical quality characteristics. Keskin et al. (2004) reported inferior quality of the product during infrared baking with very thick crust, low specific volume, firm texture and high moisture loss. Halogen-lamp power and the baking time have significantly affected the colour formation of the baked cakes (Keskin et al. 2004). Recently, Ploteau et al. (2015) used infrared emitters for French bread baking at low oven temperature. Recently, Najib et al. (2015) used computational fluid dynamics modeling approach to study the air flow and temperature profile in an infrared oven.

From the above reports, it is clear that the only infrared heating may be not sufficient to achieve the best quality product even though in some studies near-comparable product is obtained. Only surface heating and low penetration depth are the major drawbacks of the infrared heating. However, these drawbacks can be used positively when combined with the other heating modes such as microwave or jet impingement heating.

Jet Impingement Oven

Jet impinging is a process in which a jet of fluid impinges on the surface of the product, for a purpose of rapid heat and mass transfer (Datta and Rakesh 2013). It is a special type of forced convection heating using high velocity (5–50 m/s) hot air used (Kocer et al. 2007). High-speed jets are used for heating and cooling process in several industries such as in textile industries for cooling of textiles, in glass industries for the tempering of glass plates, in metal industries for annealing of metal. The impinging jet technique was first used for food product cooking by Smith 1975 (U.S. patent 3884213). They created a forced convection oven using impingement jet, to improve product quality and minimize cooking time. On an industrial basis, the impinging jet was first used for pizza industries, and then applied to many other foods products such as bread baking, flaky pastries, and cookies (Li and Walker 1996). Jet impingement ovens are widely used in meat processing and standard oven for pizza cooking (Geedipalli et al. 2008). These days, the impinging jet is used for different food application like cooking, baking, toasting, roasting, etc. due to their rapid and uniform heat transfer rates. The high velocity of jets reduce the boundary layer between the heating surface and heating medium as well as provide a uniform and high heat transfer rate (Jambunathan et al. 1992).

Jet impingement baking is more superior to conventional baking due to its high heat transfer rate, higher efficiency, shorter baking time, rapid moisture removal, uniform heating, lower oven temperatures, reduced moisture loss and comparable quality parameters (Li and Walker 1996; Ovadia and Walker 1998; Sarkar and Singh 2004). Wählby et al. (2000) studied the effect of jet impingement oven on cooking time and quality of food. They reported that jet impingement oven requires 25 °C less air temperature than reference oven for the baking bun in the same time. It has been reported that almost 12% energy can be saved using jet impingement (Li et al. 2013) as the efficiency of jet impingement ovens (65%) is higher than gas-fired ovens (35%) (Geedipalli et al. 2008). Impingement jet oven flow pattern was studied by Sarkar et al. (2006) and Nitin et al. (2006). Due to faster heating of the impinging jet oven, the heat transfer rates increase four times and baking time reduces by half than convection ovens (Li and Walker 1996; Ovadia and Walker 1998). Banooni et al. (2008) studied baking of flatbread in the impinging jet oven and concluded that its high velocity and pressure do not have any undesirable effects on the final quality parameters of products. Datta et al. (2007) reported that product baked in jet impingement mode had the highest total porosity followed by microwave-jet impingement and microwave-infrared modes. Higher moisture content and a higher level of compressibility were observed in food products cooked by jet impingement heating (Walker 1991). Olsson et al. (2005) compared impinging jet oven, convection oven and infrared oven for bread baking. They observed that during impinging jet oven early crust formation causes high moisture retention in the crumb. Rapid colour development can be achieved by combining infrared with jet impingement heating and thus reducing baking time. Although, the moisture loss was increased during combination heating. However, the reduced baking time ensures retention of enough moisture inside the product. Higher colour development of the crust was observed in case of infrared heating compared to jet impingement due to the thinner crust formed during infrared heating, even though rapid surface temperature rise was observed in jet impingement (Olsson et al. 2005). Heat transfer between cookie-shaped object and jet impinged hot air was studied by Nitin and Karwe (2006). They observed that the heat transfer coefficient value is a function of the jet air velocity and nozzle to plate spacing. It increases with increasing velocity and decrease in nozzle-to-plate spacing. Apart from the above studies, some researchers focused on modelling of the jet impingement oven (Sarkar et al. 2006; Wählby et al. 2000), flow pattern (Marcroft et al. 1999; Marcroft and Karwe 1999; Sarkar and Singh 2004), and estimation of heat transfer coefficient (Anderson and Singh 2006; Nitin et al. 2006; Nitin and Karwe 2001, 2006; Sarkar et al. 2006; Zuckerman and Lior 2006) during jet impingement heating.

Jet impingement heating has several advantages such as higher heat transfer rate, higher moisture retention and high porosity product. Although jet impingement heating looks as a promising technology, however, not much research work in baking is reported using it. Combining jet impingement with infrared heating helps in achieving the best quality product with a reduction in process time.

Moreover, combining all the above-discussed heating modes i.e. microwave, infrared and jet impingement heating, to achieve a reduction in baking time along with the best quality product is a major challenge for the researchers. An overview of the research carried out in the baking process using hybrid heating mode is discussed in the subsequent section.

Electric Resistance Oven (ERO)

In 1939, Baker developed an electric resistance oven in which heat was generated internally based on the electrical resistance offered by the product. This oven works on the principles of Joule’s first law and Ohm’s law, in which heating occurs due to the electrical resistance generated during passage of an electrical current through a material (Derde et al. 2014; He and Hoseney 1991). Major problem with the ERO was uneven moisture distribution in baked product and no crust formation (He and Hoseney 1991; Martin et al. 1991). Derde et al. (2014) observed that moisture content of ERO baked bread is different than the bread baked in conventional ovens. Wang and Sastry (1997) studied the effect of sodium chloride addition in formulation observed that the presence of sodium chloride reduces the rate of electrical conductivity during gelatinization. Moreover, some studies were conducted using ERO to find relation of cake baking and its viscosity (Shelke et al. 1990), gas generation during baking and firmness of product (He and Hoseney 1991; Martin et al. 1991). Gally et al. (2016) studied the baking in ERO by both experimental and modelling basis. They observed that the conductivity of yeasted dough decreases with its porosity, and presence of salt significantly influence the heating rate.

Hybrid Heating Ovens

Hybrid heating or combination of two or more modes of heating is additive in nature and thus reduces the processing time (Datta and Rakesh 2013). Sumnu et al. (2005) reported a 75% reduction in baking time when combination heating of microwave-infrared was used for cake baking. Demirekler et al. (2004) reported a 60% reduction in bread baking time using halogen-microwave heating compared to convention heating with a comparable product quality. Starch gelatinization and browning are the major parameters for deciding bread quality and used as baking index. Ozkahraman et al. (2016) also reported that the use of microwave-infrared combination oven help in reducing baking time of legume cakes with improved textural properties and surface colour than those baked in the conventional oven. Ozkoc and Seyhun (2015) also stated that the optimized gluten-free bread formulation (addition of the guar gum and 5% flaxseed) gives the good quality product in terms of texture, higher volume, and colour when baked in the microwave-infrared oven. The effect of microwave-infrared combination oven on the wheat cake and gluten-free rice cake quality was studied by Sumnu et al. (2005) and Turabi et al. (2008a, b), respectively. Patel et al. (2005) used conventional, jet-impingement and microwave jet-impingement heating for bread baking process. Figure 2 shows the temperature profile of bread geometric centre during baking in different ovens. Microwave jet-impingement heating showed very high heating rate (16.7 °C/min) compared to jet-impingement (6.5 °C/min) and conventional heating (6 °C/min), for large size bread. They further observed that the enthalpy of amylopectin recrystallization, bread firmness rate and soluble amylose level were lower at a low heating rate and in turn affect the starch gelatinization and crumb structure. Keskin et al. (2005) reported that combining microwave and infrared heating increases starch gelatinization in cookies compared to only microwave heating. Sakiyan et al. (2011) however reported that degree of starch gelatinization of cake varies with different types of heating ovens such as microwave-infrared, microwave and conventional ovens due to the dielectric nature of fat. Convection ovens have better results for weight loss and firmness of the product than halogen lamp-microwave combination oven (Keskin et al. 2004). Datta and Rakesh (2013) stated that, in order to obtain a crisp food product, the low level of microwave heating needs to be combined with high surface temperature heating such as infrared or jet impingement heating.

Temperature profile of breadcrumb centre during baking in different ovens and heating rate (Patel et al. 2005)

Ozkoc et al. (2009) reported that the infrared-microwave combination heating gave lower hardness of bread and was partially able to solve the problem of microwave baking. Keskin et al. (2004) used halogen lamp-microwave combination oven for bread baking and were able to get similar specific volume and crust colour quality of bread as in conventionally baked bread. However, weight loss and firmness of the product was higher compared to conventional bread. Tireki et al. (2006) studied bread crumb formation using infrared, microwave and infrared-assisted microwave heating. Ozkoc et al. (2009) observed that comparable quality bread can be obtained using infrared-microwave combination oven as obtained in a conventional oven. The product obtained will have lower hardness, higher moisture content and reduced staling compared to microwave oven baked bread. Apart from that, FTIR analysis and retrogradation enthalpy were similar in case of bread baked in conventional and infrared-microwave combination oven. Bread baked in microwave oven shows more crystalline structure due to swelling, hydration and starch gelatinization (Ozkoc et al. 2009). Further, they studied the effect of gum addition on the microstructure of bread baked in conventional and infrared-microwave combined oven (Ozkoc et al. 2009) and reported more distorted starch granules in conventionally baked bread containing gums compared to those baked in infrared-microwave combined oven. From the reported (Ozkoc et al. 2009) microstructure analysis, it was clear that the effect of the heating mechanism plays a significant role on microstructure compared to the batter formulation. In this study, they found that the pores of bread baked in infrared-microwave combination oven form channel due to coalescence as they are packed closely and lose their spherical shape while pores in the conventional bread remain spherical without the coalescence. Bread baked in the conventional oven has 63% of the pores having a size more than 1000 μm compared to 75% in infrared-microwave combination. However, on the addition of xanthan-guar gum blend, the pore fraction was reduced. Granular residues with continuous starch structure were observed in the case of infrared-microwave combination compared to continues sheet of gelatinized starch in case of conventional bread (Ozkoc et al. 2009). Demirkesen et al. (2013a, b) used infrared-microwave combination oven to obtain gluten-free bread with uniform structure and moisture content. Keskin et al. (2006) studied the effects of different gums such as xanthan, guar, xanthan-guar blend, and kappa-carrageenan on the dielectric properties and quality of bread baked in infrared-microwave combination oven. They reported that the dielectric properties of bread samples formulated with kappa-carrageenan found to be the highest among all the gum types with higher dielectric loss factor that resulted in a rapid temperature increase of dough/bread and resulted in low porosity and hardened bread structure. Use of kappa-carrageenan shows undesirable final bread quality. The addition of xanthan-guar gum blend resulted in improved bread quality in terms of low hardness values, high specific volume, and porosity. Olsson et al. (2005) stated that a combination of near-infrared radiation and jet impingement, increased the rate of crust colour development and shortened the pre-heating time in comparison with pre-heating in a conventional household oven. Also, infrared heating gives a thinner crust comparatively to convection one. Sumnu et al. (2005) reported that the use of a microwave oven alone in the case of baking of cakes did not result in a good quality product. They reported that a microwave-infrared combination heating resulted in a good quality product with optimum surface colour development, reduced weight loss, as well as firmness and increased volume. It took only 5 min to bake a cake with 70% halogen lamp and at 50% microwave power levels.

Hybrid heating ovens also reported for gluten-free bakery products recently. Demand for gluten-free bakery product increased in the individuals having gluten intolerance which cause genetic celiac disease that is responsible for the small intestine inflammation and leads to nutrient malabsorption. Torres et al. (2017) stressed gluten-free bakery product with antioxidant activity for the celiac disease patient. Demirkesen et al. (2011) optimized the formulation for gluten-free bread containing chestnut-rice flour using response surface methodology (RSM) for the hybrid heating oven. Comparable quality bread in terms of firmness, specific volume, weight loss and colour changes was obtained with 46.5% chestnut flour with 40% infrared and 30% microwave power during 9 min baking process. The proportion of the chestnut flour and infrared power were the significant factors influencing all the quality parameters of gluten-free bread moreover, microwave power and baking time affect the bread firmness, specific volume and weight loss of product. In another study by Demirkesen et al. (2013a), bread baked in infrared-microwave combination oven shows lower degrees of starch gelatinization (84–88%) than those in conventionally baked gluten-free bread (92–94%). The flour proportions of tigernut and rice along with the oven type influence bread quality. A 20:80 tigernut/rice flour gives bread comparable to conventional bread. However, the addition of tigernut flour reduces the degree of starch gelatinization in both the oven due to the higher gelatinization temperature of tigernut flour. Further, image analysis of gluten-free bread baked in infrared-microwave combined oven shows that there are homogenous pore distributions with an increase in a number of pores and pore area fraction compared to gluten-free bread baked in a conventional oven (Demirkesen et al. 2013b). Apart from that, starch granules in these breads do not disintegrate completely due to shorter processing time that affect swelling and gelatinization (Demirkesen et al. 2013b). Retrogradation enthalpies and total crystallinity values of gluten-free bread prepared with rice and chestnut flour along with the addition of xanthan-guar gum blend-DATEM mixture in formulations did not show significant differences with different baking oven and significantly delayed staling characteristics by decreasing moisture loss, hardness (Demirkesen et al. 2014).

The use of hybrid heating modes gives an optimum quality baked product with low staling characteristics. Microwave-jet impingement heating shows the higher heating rate while microwave-infrared heating shows higher starch gelatinization and low stalling of bread during storage. Bread baked by conventional and hybrid heating modes show different pore size and pore structure while retrogradation enthalpy was alike. In the combined heating also, microwave power is the most influencing factor for product quality. Microwave-infrared heating give the best quality bread in terms of firmness, volume and weight loss while reducing baking time drastically. Gluten-free bread formulated using rice flour along with chestnut or tigernut flour also shown similar trends when studied using different hybrid heating modes.

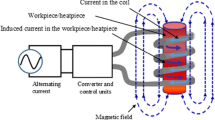

Future Trends in Non-conventional Heating Ovens

Emergence of new heating and processing technologies for energy efficiency, thrust for green technology, and superior quality product demands will increase the demand of non-conventional heating ovens. Many heating methods tried and tested for the food dehydration may find ways in food processing sector as non-conventional heating oven. Newer technologies such as induction heating, radiofrequency heating, and microwave combined with hydrodiffusion (López-Hortas et al. 2018) may be introduced in future as non-conventional heating ovens. Emergence of 3d food printing technology demands customized ovens for the printed food. Major challenge for the food scientist and technologist is to scale-up the non-conventional heating ovens at industrial level while obtaining the best quality product. Moreover, addition of new product recipes due to consumer demands such as gluten-free, sugar-free, reduced fat will also pose major hurdles to design the future customized ovens.

Conclusion

Baking is an irreversible process which involves various physicochemical transformation and changing heating mode affects the product quality significantly. Baking using non-conventional heating is a promising technology to achieve energy efficient process while reducing the processing time. Despite the fact that many home appliance companies are introducing various hybrid heating ovens for domestic consumers, such ovens are yet to be used at the industry level. Research on these non-conventional heating was going on since last two decades. However, its industrial implementation is yet to be carried out due to the lack of thorough understanding of impact of these heating modes on product quality, shelf life and most importantly consumer acceptance. It is important to bridge the gap between research and industrial applications. Though, jet impingement heating shown promise of efficient heating but combination with the microwave or infrared was not yet reported and hence can be studied in future. ERO oven was unable to produce the quality baked product. With the current available data, this review concludes that the infrared-microwave combination heating dominates hybrid heating domain due to the comparable quality product obtained with significant baking time reduction. The use of infrared heating along with the microwave heating provides good quality, stable baked product compared to other non-conventional heating. Apart from that, these heating modes are also compatible with the gluten-free bakery products.

References

Almeida, M., Torrance, K. E., & Datta, A. K. (2006). Measurement of optical properties of foods in near- and mid-infrared radiation. International Journal of Food Properties, 9(4), 651–664. https://doi.org/10.1080/10942910600853667.

Anderson, B. A., & Singh, R. P. (2006). Effective heat transfer coefficient measurement during air impingement thawing using an inverse method. International Journal of Refrigeration, 29(2), 281–293. https://doi.org/10.1016/J.IJREFRIG.2005.05.016.

Banooni, S., Hosseinalipour, S. M., Mujumdar, A. S., Taheran, E., Bahiraei, M., & Taherkhani, P. (2008). Baking of flat bread in an impingement oven: An experimental study of heat transfer and quality aspects. Drying Technology, 26(7), 902–909. https://doi.org/10.1080/07373930802142614.

Bilgen, S., Coşkuner, Y., & Karababa, E. (2004). Effects of baking parameters on the white layer cake quality by combined use of conventional and microwave ovens. Journal of Food Processing and Preservation, 28(2), 89–102. https://doi.org/10.1111/j.1745-4549.2004.tb00813.x.

Campañone, L. A., & Zaritzky, N. E. (2005). Mathematical analysis of microwave heating process. Journal of Food Engineering, 69(3), 359–368. https://doi.org/10.1016/J.JFOODENG.2004.08.027.

Campañone, L. A., & Zaritzky, N. E. (2010). Mathematical modeling and simulation of microwave thawing of large solid foods under different operating conditions. Food and Bioprocess Technology, 3(6), 813–825. https://doi.org/10.1007/s11947-009-0249-0.

Campañone, L. A., Paola, C. A., & Mascheroni, R. H. (2012). Modeling and simulation of microwave heating of foods under different process schedules. Food and Bioprocess Technology, 5(2), 738–749. https://doi.org/10.1007/s11947-010-0378-5.

Cauvain, S. P., & Young, L. S. (2003). Water control in baking, în Bread making: Improving quality, ed. Cauvain, SP. Woodhead Publishing Limited, Cambridge.

Cha-um, W., Rattanadecho, P., & Pakdee, W. (2011). Experimental and numerical analysis of microwave heating of water and oil using a rectangular wave guide: Influence of sample sizes, positions, and microwave power. Food and Bioprocess Technology, 4(4), 544–558. https://doi.org/10.1007/s11947-009-0187-x.

Chavan, R. S., & Chavan, S. R. (2010). Microwave baking in food industry: A review. International Journal of Dairy Science, 5(3), 113–127.

Chhanwal, N., & Anandharamakrishnan, C. (2014). Temperature- and moisture-based modeling for prediction of starch gelatinization and crumb softness during bread-baking process. Journal of Texture Studies, 45(6), 462–476. https://doi.org/10.1111/jtxs.12097.

Chhanwal, N., Indrani, D., Raghavarao, K. S. M. S., & Anandharamakrishnan, C. (2011). Computational fluid dynamics modeling of bread baking process. Food Research International, 44(4), 978–983. https://doi.org/10.1016/J.FOODRES.2011.02.037.

Chhanwal, N., Tank, A., Raghavarao, K. S. M. S., & Anandharamakrishnan, C. (2012). Computational fluid dynamics (CFD) modeling for bread baking process—A review. Food and Bioprocess Technology, 5(4), 1157–1172. https://doi.org/10.1007/s11947-012-0804-y.

Chhanwal, N., Ezhilarasi, P. N., Indrani, D., Anandharamakrishnan, C. (2015). Influence of electrical and hybrid heating on bread quality during baking. Journal of Food Science & Technology, 52, 4467–4474. https://doi.org/10.1007/s13197-014-1478-4.

Datta, A. K., & Anantheswaran, R. C. (2001). Handbook of microwave technology for food applications. M. Dekker.

Datta, A. K., & Ni, H. (2002). Infrared and hot-air-assisted microwave heating of foods for control of surface moisture. Journal of Food Engineering, 51(4), 355–364. https://doi.org/10.1016/S0260-8774(01)00079-6.

Datta, A. K., & Rakesh, V. (2013). Principles of microwave combination heating. Comprehensive Reviews in Food Science and Food Safety, 12(1), 24–39. https://doi.org/10.1111/j.1541-4337.2012.00211.x.

Datta, A. K., Sahin, S., Sumnu, G., & Ozge Keskin, S. (2007). Porous media characterization of breads baked using novel heating modes. Journal of Food Engineering, 79(1), 106–116. https://doi.org/10.1016/J.JFOODENG.2006.01.046.

Decareau, R. V. (1985). Microwaves in food processing industry. USA: Academic Press.

Decareau RV (1992) Microwave foods: New product development. Food & Nutrition Press.

Decock, P., & Cappelle, S. (2005). Bread technology and sourdough technology. Trends in Food Science & Technology, 16(1–3), 113–120. https://doi.org/10.1016/J.TIFS.2004.04.012.

Demirekler, P., Sumnu, G., & Sahin, S. (2004). Optimization of bread baking in a halogen lamp?microwave combination oven by response surface methodology. European Food Research and Technology, 219(4), 341–347. https://doi.org/10.1007/s00217-004-0969-3.

Demirkesen, I., Sumnu, G., Sahin, S., & Uysal, N. (2011). Optimisation of formulations and infrared-microwave combination baking conditions of chestnut-rice breads. International Journal of Food Science & Technology, 46(9), 1809–1815. https://doi.org/10.1111/j.1365-2621.2011.02682.x.

Demirkesen, I., Sumnu, G., & Sahin, S. (2013a). Image analysis of gluten-free breads prepared with chestnut and rice flour and baked in different ovens. Food and Bioprocess Technology, 6(7), 1749–1758. https://doi.org/10.1007/s11947-012-0850-5.

Demirkesen, I., Sumnu, G., & Sahin, S. (2013b). Quality of gluten-free bread formulations baked in different ovens. Food and Bioprocess Technology, 6(3), 746–753. https://doi.org/10.1007/s11947-011-0712-6.

Demirkesen, I., Campanella, O. H., Sumnu, G., Sahin, S., & Hamaker, B. R. (2014). A study on staling characteristics of gluten-free breads prepared with chestnut and rice flours. Food and Bioprocess Technology, 7(3), 806–820. https://doi.org/10.1007/s11947-013-1099-3.

Derde, L. J., Gomand, S. V., Courtin, C. M., & Delcour, J. A. (2014). Moisture distribution during conventional or electrical resistance oven baking of bread dough and subsequent storage. Journal of Agricultural and Food Chemistry, 62(27), 6445–6453.

Fluch, J., Brunner, C., & Grubbauer, A. (2017). Potential for energy efficiency measures and integration of renewable energy in the European food and beverage industry based on the results of implemented projects. Energy Procedia, 123, 148–155. https://doi.org/10.1016/J.EGYPRO.2017.07.243.

Gally, T., Rouaud, O., Jury, V., & Le-Bail, A. (2016). Bread baking using ohmic heating technology; a comprehensive study based on experiments and modelling. Journal of Food Engineering, 190, 176–184. https://doi.org/10.1016/J.JFOODENG.2016.06.029.

Geedipalli, S. S. R., Rakesh, V., & Datta, A. K. (2007). Modeling the heating uniformity contributed by a rotating turntable in microwave ovens. Journal of Food Engineering, 82(3), 359–368. https://doi.org/10.1016/J.JFOODENG.2007.02.050.

Geedipalli, S., Datta, A. K., & Rakesh, V. (2008). Heat transfer in a combination microwave–jet impingement oven. Food and Bioproducts Processing, 86(1), 53–63. https://doi.org/10.1016/J.FBP.2007.10.016.

He, H., & Hoseney, R. C. (1991). A critical look at the electric resistance oven. Cereal Chemistry, 68(2), 151–155.

İçöz, D., Sumnu, G., & Sahin, S. (2004). Color and texture development during microwave and conventional baking of breads. International Journal of Food Properties, 7(2), 201–213. https://doi.org/10.1081/JFP-120025396.

Jambunathan, K., Lai, E., Moss, M. A., & Button, B. L. (1992). A review of heat transfer data for single circular jet impingement. International Journal of Heat and Fluid Flow, 13(2), 106–115. https://doi.org/10.1016/0142-727X(92)90017-4.

Keskin, S., Sumnu, G., & Sahin, S. (2004). Usage of enzymes in a novel baking process. Nahrung/Food, 48(2), 156–160. https://doi.org/10.1002/food.200300412.

Keskin, S. O., Oztürk, S., Sahin, S., Koksel, H., & Sumnu, G. (2005). Halogen lamp–microwave combination baking of cookies. European Food Research and Technology, 220(5–6), 546–551. https://doi.org/10.1007/s00217-005-1131-6.

Keskin, S. O., Sumnu, G., & Sahin, S. (2006). A study on the effects of different gums on dielectric properties and quality of breads baked in infrared-microwave combination oven. European Food Research and Technology, 224(3), 329–334. https://doi.org/10.1007/s00217-006-0334-9.

Keskin, S. O., Sumnu, G., & Sahin, S. (2007). A study on the effects of different gums on dielectric properties and quality of breads baked in infrared-microwave combination oven. European Food Research and Technology, 224(3), 329–334. https://doi.org/10.1007/s00217-006-0334-9.

Khatir, Z., Taherkhani, A. R., Paton, J., Thompson, H., Kapur, N., & Toropov, V. (2015). Energy thermal management in commercial bread-baking using a multi-objective optimisation framework. Applied Thermal Engineering, 80, 141–149. https://doi.org/10.1016/J.APPLTHERMALENG.2015.01.042.

Kocer, D., Nitin, N., & Karwe, M. (2007). Application of CFD in jet impingement oven. In D. W. Sun (Ed.), Computational fluid dynamics in food processing (pp. 469–487). Boca Raton: CRC Press.

Krishnamurthy, K., Khurana, H. K., Soojin, J., Irudayaraj, J., & Demirci, A. (2008). Infrared heating in food processing: An overview. Comprehensive Reviews in Food Science and Food Safety, 7(1), 2–13. https://doi.org/10.1111/j.1541-4337.2007.00024.x.

Kumar, C. M., Appu Rao, A. G., & Singh, S. A. (2009). Effect of infrared heating on the formation of sesamol and quality of defatted flours from Sesamum indicum L. Journal of Food Science, 74(4), H105–H111.

Levinson, M.L. (1992). Two stage process for cooking/browning/crusting food by microwave energy and infrared energy. US5094865.

Li, A., & Walker, C. E. (1996). Cake baking in conventional, impingement and hybrid ovens. Journal of Food Science, 61(1), 188–191. https://doi.org/10.1111/j.1365-2621.1996.tb14756.x.

Li, X.-D., Alamir, M., Witrant, E., Della-Valle, G., Rouaud, O., Boillereaux, L., & Josset, C. (2013). Further investigations on energy saving by jet impingement in bread baking process. IFAC Proceedings, 46(2), 701–706. https://doi.org/10.3182/20130204-3-FR-2033.00017.

López-Hortas, L., Gannon, L., Moreira, R., Chenlo, F., Domínguez, H., & Torres, M. D. (2018). Microwave hydrodiffusion and gravity (MHG) processing of Laminaria ochroleuca brown seaweed. Journal of Cleaner Production, 197, 1108–1116. https://doi.org/10.1016/J.JCLEPRO.2018.06.274.

Lucas, T. (2014). Baking, bakery products science and technology. Chichester: John Wiley & Sons.

Marcroft, H. E., & Karwe, M. V. (1999). Flow field in a hot air jet impingement oven—Part I: A single impinging jet. Journal of Food Processing and Preservation, 23(3), 217–233. https://doi.org/10.1111/j.1745-4549.1999.tb00381.x.

Marcroft, H. E., Chandrasekaran, M., & Karwe, M. V. (1999). Flow field in a hot air jet impingement oven ? Part 11: Multiple impingement jets. Journal of Food Processing and Preservation, 23(3), 235–248. https://doi.org/10.1111/j.1745-4549.1999.tb00382.x.

Martin, M. L., Zeleznak, K. J., & Hoseney, R. C. (1991). A mechanism of bread firming. I. Role of starch swelling. Cereal Chemistry, 68, 498–503.

Martínez-Bustos, F., Morales, S. E., Chang, Y. K., Herrera-Gómez, A., Martínez, M. J. L., Baños, L., Rodríguez, M. E., & Flores, M. H. E. (1999). Effect of infrared baking on wheat flour tortilla characteristics. Cereal Chemistry Journal, 76(4), 491–495. https://doi.org/10.1094/CCHEM.1999.76.4.491.

Mukherjee, S., Asthana, A., Howarth, M., & Mcniell, R. (2017). Waste heat recovery from industrial baking ovens. Energy Procedia, 123, 321–328. https://doi.org/10.1016/J.EGYPRO.2017.07.259.

Najib, A. M., Abdullah, M. Z., Khor, C. Y., & Saad, A. A. (2015). Experimental and numerical investigation of 3D gas flow temperature field in infrared heating reflow oven with circulating fan. International Journal of Heat and Mass Transfer, 87, 49–58. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2015.03.075.

Nitin, N., & Karwe, M. V. (2001). Heat transfer coefficient for cookie shaped objects in a hot air jet impingement oven. Journal of Food Process Engineering, 24(1), 51–69. https://doi.org/10.1111/j.1745-4530.2001.tb00531.x.

Nitin, N., & Karwe, M. V. (2006). Numerical simulation and experimental investigation of conjugate heat transfer between a turbulent hot air jet impinging on a cookie-shaped object. Journal of Food Science, 69(2), fep59–fep65. https://doi.org/10.1111/j.1365-2621.2004.tb15510.x.

Nitin, N., Gadiraju, R. P., & Karwe, M. V. (2006). Conjugate heat transfer associated with a turbulent hot air jet impinging on a cylindrical object. Journal of Food Process Engineering, 29(4), 386–399. https://doi.org/10.1111/j.1745-4530.2006.00072.x.

Nowak, D., & Lewicki, P. P. (2004). Infrared drying of apple slices. Innovative Food Science & Emerging Technologies, 5(3), 353–360. https://doi.org/10.1016/J.IFSET.2004.03.003.

Olsson, E. E. M., Trägårdh, A. C., & Ahrné, L. M. (2005). Effect of near-infrared radiation and jet impingement heat transfer on crust formation of bread. Journal of Food Science, 70(8), e484–e491. https://doi.org/10.1111/j.1365-2621.2005.tb11519.x.

Ovadia, D. Z., & Walker, C. E. (1996). Re-examination of the bread firming curve. Starch-Starke, 48(4), 137–144. https://doi.org/10.1002/star.19960480404.

Ovadia, D. Z., & Walker, C. E. (1998). Impingement in food processing. Food Technology (USA), 52(4), 46–50.

Ozge Ozkoc, S., Sumnu, G., & Sahin, S. (2009). The effects of gums on macro and micro-structure of breads baked in different ovens. Food Hydrocolloids, 23(8), 2182–2189.

Ozge, S., Sumnu, G., & Meda, V. (2006). The effect of different formulations on physical properties of cakes baked with microwave and near infrared-microwave combinations. Journal of Microwave Power and Electromagnetic Energy, 41(1), 20–26. https://doi.org/10.1080/08327823.2006.11688551.

Ozkahraman, B. C., Sumnu, G., & Sahin, S. (2016). Effect of different flours on quality of legume cakes to be baked in microwave-infrared combination oven and conventional oven. Journal of Food Science and Technology, 53(3), 1567–1575. https://doi.org/10.1007/s13197-015-2101-z.

Ozkoc, S. O., & Seyhun, N. (2015). Effect of gum type and flaxseed concentration on quality of gluten-free breads made from frozen dough baked in infrared-microwave combination oven. Food and Bioprocess Technology, 8(12), 2500–2506. https://doi.org/10.1007/s11947-015-1615-8.

Ozkoc, S. O., Sumnu, G., Sahin, S., & Turabi, E. (2009). Investigation of physicochemical properties of breads baked in microwave and infrared-microwave combination ovens during storage. European Food Research and Technology, 228(6), 883–893. https://doi.org/10.1007/s00217-008-1001-0.

Ozmutlu, O., Sumnu, G., & Sahin, S. (2001). Assessment of proofing of bread dough in the microwave oven. European Food Research and Technology, 212(4), 487–490. https://doi.org/10.1007/s002170000276.

Patel, B. K., Waniska, R. D., & Seetharaman, K. (2005). Impact of different baking processes on bread firmness and starch properties in breadcrumb. Journal of Cereal Science, 42(2), 173–184. https://doi.org/10.1016/J.JCS.2005.04.007.

Ploteau, J. P., Glouannec, P., Nicolas, V., & Magueresse, A. (2015). Experimental investigation of French bread baking under conventional conditions or short infrared emitters. Applied Thermal Engineering, 75, 461–467. https://doi.org/10.1016/J.APPLTHERMALENG.2014.09.034.

Purlis, E. (2014). Optimal design of bread baking: Numerical investigation on combined convective and infrared heating. Journal of Food Engineering, 137, 39–50. https://doi.org/10.1016/j.jfoodeng.2014.03.033.

Purlis, E., & Salvadori, V. O. (2010). A moving boundary problem in a food material undergoing volume change—Simulation of bread baking. Food Research International, 43(4), 949–958. https://doi.org/10.1016/J.FOODRES.2010.01.004.

Rakesh, V., Datta, A. K., Amin, M. H. G., & Hall, L. D. (2009). Heating uniformity and rates in a domestic microwave combination oven. Journal of Food Process Engineering, 32(3), 398–424. https://doi.org/10.1111/j.1745-4530.2007.00224.x.

Rakesh, V., Seo, Y., Datta, A. K., McCarthy, K. L., & McCarthy, M. J. (2010). Heat transfer during microwave combination heating: Computational modeling and MRI experiments. AICHE Journal, 56(9), 2468–2478. https://doi.org/10.1002/aic.12162.

Sakai, N., & Hanzawa, T. (1994). Applications and advances in far-infrared heating in Japan. Trends in Food Science & Technology, 5(11), 357–362. https://doi.org/10.1016/0924-2244(94)90213-5.

Sakiyan, O. (2015). Optimization of formulation of soy-cakes baked in infrared-microwave combination oven by response surface methodology. Journal of Food Science and Technology, 52, 2910–2917. https://doi.org/10.1007/s13197-014-1342-6.

Sakiyan, O., Sumnu, G., Sahin, S., & Meda, V. (2007). Investigation of dielectric properties of different cake formulations during microwave and infrared?microwave combination baking. Journal of Food Science, 72(4), E205–E213. https://doi.org/10.1111/j.1750-3841.2007.00325.x.

Sakiyan, O., Sumnu, G., Sahin, S., Meda, V., Koksel, H., & Chang, P. (2011). A study on degree of starch gelatinization in cakes baked in three different ovens. Food and Bioprocess Technology, 4(7), 1237–1244. https://doi.org/10.1007/s11947-009-0210-2.

Sánchez-Pardo, M. E., Ortiz-Moreno, A., Mora-Escobedo, R., Chanona-Pérez, J. J., & Necoechea-Mondragón, H. (2008). Comparison of crumb microstructure from pound cakes baked in a microwave or conventional oven. LWT - Food Science and Technology, 41(4), 620–627. https://doi.org/10.1016/J.LWT.2007.05.003.

Sánchez-Pardo, M. E., Ortiz-Moreno, A., García-Zaragoza, F. J., Necoechea-Mondragón, H., & Chanona-Pérez, J. J. (2012). Comparison of pound cake baked in a two cycle microwave-toaster oven and in conventional oven. LWT - Food Science and Technology, 46(1), 356–362. https://doi.org/10.1016/J.LWT.2011.08.013.

Sandu, C. (1986). Infrared radiative drying in food engineering: A process analysis. Biotechnology Progress, 2(3), 109–119. https://doi.org/10.1002/btpr.5420020305.

Sarkar, A., & Singh, R. P. (2004). Air impingement technology for food processing: Visualization studies. LWT - Food Science and Technology, 37(8), 873–879. https://doi.org/10.1016/J.LWT.2004.04.005.

Sarkar, A., Nitin, N., Karwe, M. V., & Singh, R. P. (2006). Fluid flow and heat transfer in air jet impingement in food processing. Journal of Food Science, 69(4), CRH113–CRH122. https://doi.org/10.1111/j.1365-2621.2004.tb06315.x.

Sato, N., Sato, M., & Nagashima, A. (1991). Bread improver and method of producing bread. European Patent Application, 91306669(2).

Sevimli, K. M., Sumnu, G., & Sahin, S. (2005). Optimization of halogen lamp–microwave combination baking of cakes: A response surface methodology study. European Food Research and Technology, 221(1–2), 61–68. https://doi.org/10.1007/s00217-004-1128-6.

Shelke, K., Faubion, J. M., & Hoseney, R. C. (1990). The dynamics of cake baking as studied by a combination of viscometry and electrical resistance oven heating. Cereal Chemistry, 67(6), 575–580.

Shyu, Y. S., Sung, W. C., Chang, M. H., & Hwang, J. Y. (2008). Effect of far-infrared oven on the qualities of bakery products. Journal of Culinary Science & Technology, 6(2–3), 105–118. https://doi.org/10.1080/15428050802336955.

Singh, R. P. & Heldman. (2009). Indroduction to Food Engineering. Academic Press.

Skjoldebrand, C., 2001. Infrared heating. In: P. Richardson (Ed.), Thermal technologies in food processing (pp. 208–228). Elsevier.

Skjöldebrand, C., & Andersson, C. (1989). A comparison of infrared bread baking and conventional baking. Journal of Microwave Power and Electromagnetic Energy, 24(2), 91–101. https://doi.org/10.1080/08327823.1989.11688080.

Skjöldebrand, C., Ellbjär, C., Andersson, C. G., & Eriksson, T. S. (1988). Optical properties of bread in the near-infrared range. Journal of Food Engineering, 8(2), 129–139. https://doi.org/10.1016/0260-8774(88)90059-3.

Sumnu, G. (2001). A review on microwave baking of foods. International Journal of Food Science & Technology, 36(2), 117–127. https://doi.org/10.1046/j.1365-2621.2001.00479.x.

Sumnu, S. G., & Ozkoc, S. O. (2010). Infrared baking and roasting. In Z. Pan & G. Atungulu (Eds.), Infrared heating for food and agriculture processing (pp. 203–224). Boca Raton: CRC Press.

Sumnu, G., Sahin, S., & Sevimli, M. (2005). Microwave, infrared and infrared-microwave combination baking of cakes. Journal of Food Engineering, 71(2), 150–155. https://doi.org/10.1016/J.JFOODENG.2004.10.027.

Sumnu, G., Datta, A. K., Sahin, S., Keskin, S. O., & Rakesh, V. (2007). Transport and related properties of breads baked using various heating modes. Journal of Food Engineering, 78(4), 1382–1387. https://doi.org/10.1016/J.JFOODENG.2006.01.010.

Tank, A., Chhanwal, N., Indrani, D., & Anandharamakrishnan, C. (2014). Computational fluid dynamics modeling of bun baking process under different oven load conditions. Journal of Food Science and Technology, 51(9), 2030–2037. https://doi.org/10.1007/s13197-012-0736-6.

Therdthai, N., & Zhou, W. (2003). Recent advances in the studies of bread baking process and their impacts on the bread baking technology. Food Science and Technology Research, 9(3), 219–226. https://doi.org/10.3136/fstr.9.219.

Thorvaldsson, K., & Janestad, H. (1999). A model for simultaneous heat, water and vapour diffusion. Journal of Food Engineering, 40(3), 167–172. https://doi.org/10.1016/S0260-8774(99)00052-7.

Tireki, S., Sumnu, G., & Esin, A. (2006). Effect of microwave, infrared and infrared-assisted microwave heating on the drying rate of bread dough. American Journal of Food Technology, 1(2), 82–93.

Torres, M. D., Arufe, S., Chenlo, F., & Moreira, R. (2017). Coeliacs cannot live by gluten-free bread alone—every once in awhile they need antioxidants. International Journal of Food Science & Technology, 52(1), 81–90. https://doi.org/10.1111/ijfs.13287.

Turabi, E., Sumnu, G., & Sahin, S. (2008a). Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food and Bioprocess Technology, 1(1), 64–73. https://doi.org/10.1007/s11947-007-0003-4.

Turabi, E., Sumnu, G., & Sahin, S. (2008b). Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocolloids, 22(2), 305–312. https://doi.org/10.1016/J.FOODHYD.2006.11.016.

Turabi, E., Sumnu, G., & Sahin, S. (2010). Quantitative analysis of macro and micro-structure of gluten-free rice cakes containing different types of gums baked in different ovens. Food Hydrocolloids, 24(8), 755–762. https://doi.org/10.1016/j.foodhyd.2010.04.001.

Vanin, F. M., Lucas, T., & Trystram, G. (2009). Crust formation and its role during bread baking. Trends in Food Science & Technology, 20(8), 333–343. https://doi.org/10.1016/J.TIFS.2009.04.001.

Wade, P. (1987). Biscuit baking by near-infrared radiation. Journal of Food Engineering, 6(3), 165–175. https://doi.org/10.1016/0260-8774(87)90022-7.

Wählby, U., Skjöldebrand, C., & Junker, E. (2000). Impact of impingement on cooking time and food quality. Journal of Food Engineering, 43(3), 179–187. https://doi.org/10.1016/S0260-8774(99)00149-1.

Walker, C. E. (1991). Air-impingement drying and toasting of ready-to-eat cereals. Cereal Foods World, 36(10), 871–877.

Walker, C. E., & Li, A. (1993). Impingement oven technology. Part III: Combining impingement with microwave. American Institute of Baking Technology Bulletin, 15(9), 1–6.

Wang, W.-C., & Sastry, S. K. (1997). Starch gelatinization in ohmic heating. Journal of Food Engineering, 34(3), 225–242. https://doi.org/10.1016/S0260-8774(97)00085-X.

Wang, J., & Sheng, K. C. (2004). Modeling of muti-layer far-infrared dryer. Drying Technology, 22(4), 809–820. https://doi.org/10.1081/DRT-120034264.

Whorton, C., & Reineccius, G. (1990). Current developments in microwave flavors. Cereal Foods World (USA), 35, 553–559.

Willyard, M. R. (1998). Conventional browning and microwave baking of yeast raised dough. Cereal Foods World (USA), 43, 131–138.

Xue, J., & Walker, C. E. (2003). Humidity change and its effects on baking in an electrically heated air jet impingement oven. Food Research International, 36(6), 561–569. https://doi.org/10.1016/S0963-9969(02)00221-1.

Yaylayan, V. A., & Roberts, D. D. (2001). Generation and release of food aromas under microwave heating. New York: Marcel Dekker.

Yin, Y., & Walker, C. E. (1995). A quality comparison of breads baked by conventional versus nonconventional ovens: A review. Journal of the Science of Food and Agriculture, 67(3), 283–291. https://doi.org/10.1002/jsfa.2740670302.

Zhou, W., & Hui, Y. H. (2014). Bakery Products Science and Technology. West Sussex: John Wiley & Sons.

Zhou, W., & Therdthai, N. (2007). Three-dimensional modeling of a continuous industrial baking process. In D. W. Sun (Ed.), Computational fluid dynamics in food processing (pp. 287–312). Boca Raton: CRC Press.

Zuckerman, N., & Lior, N. (2006). Jet impingement heat transfer: Physics, correlations, and numerical modeling. Advances in Heat Transfer, 39, 565–631. https://doi.org/10.1016/S0065-2717(06)39006-5.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chhanwal, N., Bhushette, P.R. & Anandharamakrishnan, C. Current Perspectives on Non-conventional Heating Ovens for Baking Process—a Review. Food Bioprocess Technol 12, 1–15 (2019). https://doi.org/10.1007/s11947-018-2198-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2198-y