Abstract

The quantification of microplastics (MP) in environmental samples is currently a challenging task. To enable low quantification limits, an analytical method has been developed combining pressurized liquid extraction (PLE) and pyrolysis GC-MS. The automated extraction includes a pre-extraction step via methanol followed by a subsequent PLE using tetrahydrofuran. For the most frequently used synthetic polymers polyethylene (PE), polypropylene (PP), and polystyrene (PS), limits of quantification were achieved down to 0.007 mg/g. Recoveries above 80% were attained for solid matrices such as soil and sediments. The developed method was applied for MP quantification in environmental samples such as sediment, suspended matter, soil, and sewage sludge. In all these matrices, PE and PP were detected with concentrations ranging from 0.03 to 3.3 mg/g. In sewage sludge samples, all three polymers were present with concentration levels ranging between 0.08 ± 0.02 mg/g (PP) and 3.3 ± 0.3 mg/g (PE). However, especially for solid samples, the analysis of triplicates revealed elevated statistical uncertainties due to the inhomogeneous distribution of MP particles. Thus, care has to be taken when milling and homogenizing the samples due to the formation of agglomerates.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plastic particles with a size smaller than 5 mm, widely referred to as microplastics (MP), stand in the focus of recent environmental studies worldwide [1,2,3,4,5,6,7,8,9,10]. However, in environment samples, the quantification of MP is still a major challenge. Due to their special properties (very high molecular weights, poor solubility in most solvents), MPs cannot be analyzed by classical analytical methods such as GC-MS or LC-tandem MS. Basically, two different analytical strategies have been discussed in recent publications [11,12,13,14]. The first one is based on isolation of MP particles by density separation and spectroscopic (FTIR, Raman) identification [15,16,17]. These methods deliver information about polymer species, particle numbers, and size distribution [18]. These are important parameters to estimate the toxicological potential. However, for MP monitoring, evaluation of sources and sinks, as well as MP distribution in environmental systems, mass concentrations are more suitable than particle numbers. Using spectroscopic methods, only a rough estimation of the MP quantities can be attained [19]. The second strategy is based upon thermal decomposition coupled to mass spectrometry, which is more suitable for MP quantification [20]. Unice et al. developed a quantification method for polymers of tires using pyrolysis-gas chromatography mass spectrometry (pyr-GC-MS). Quantification was based upon specific pyrolysis products and deuterated internal standards. The method needed only a minor sample preparation and yielded a limit of detection of 14 μg/g of tire tread in soil and sediments [21]. For the quantification of thermoplastics, Duemichen et al. described a combination of thermal extraction with thermogravimetric analysis and a subsequent analysis with thermal desorption gas chromatography mass spectrometry (TDS-GC-MS). After pyrolysis at 600 °C and enrichment of the degradation products on solid-phase absorbers, plastic species were quantified by GC-MS analysis detecting polymer-specific decomposition products [22]. This method enables the quantification of various plastics species such as polyethylene (PE), polypropylene (PP), and polystyrene (PS) in different environmental matrices such as soils, water, and mussels. However, the achieved limits of detection (LOD) of 5 g/kg are relatively high, due to a high signal background in GC-MS analysis caused by the formation of decomposition products of natural matrix ingredients. Another crucial issue is the inhomogeneous distribution of the MP particles in the sample matrix. As a consequence, the sample in-weights have to be sufficiently high to obtain representative aliquots. However, the required elevated in-weights are frequently not feasible for most of the used analysis systems, especially when analyzing MP > 100 μm. Several approaches have been reported to minimize matrix effects and to reduce the LOD. For instance, Fischer and Scholz-Böttcher used a rather time-intensive enzymatic and chemical digestion as well as a density separation for the treatment of fish samples prior to pyr-GC-MS analysis [23]. Fuller and Gautam described an alternative extraction procedure for MP using pressurized liquid extraction (PLE) [24]. In a first extraction step, sample matrices were reduced by liquid extraction with methanol using elevated temperatures and pressures. Extraction of polymers was enabled with dichloromethane (DCM) at 180 °C and 100 bar. Under those extreme conditions, even polymers such as PE and PP are soluble in DCM. Fuller and Gautam used infrared spectroscopy for a qualitative analysis of relatively high quantities (several milligrams) of polymers. However, there is a need for a quantification of MP below 1 mg/g to enable a reliable determination in environmental samples.

In this paper, we present a combination of PLE and pyr-GC-MS for the quantification of MP in environmental samples. The described method has been designed for a high throughput analysis of the most frequently found plastic sorts PE, PP, and PS present at low concentrations in complex matrices such as sediments, soil, and sewage sludge.

Material and methods

Chemicals

PE and PS were purchased from PSS Polymer (Mainz, Germany). PP, sea sand, and tetrahydrofuran (THF) (unstabilized) were obtained from Sigma-Aldrich (Schnelldorf, Germany). Methanol (LC-MS grade) was obtained from Merck (Darmstadt, Germany). The internal standard polystyrene-d5 was purchased from Polymer Source (Montreal, Canada). Glass fiber extraction thimbles and silica gel 60 (70–270 mesh) were received from Macherey-Nagel (Düren, Germany).

Calibration

For calibration, different amounts of the polymers were diluted in calcined sea sand (600 °C, 2 h) as inert matrix. The polymers were ground in a cryo mill from Retsch (Haan, Germany) to a fine powder. Two hundred fifty milligram of each polymer was weighed in and the mixture of polymers was then mixed with calcined sea sand to obtain 10 g of polymer/sand mixture. This mixture was homogenized for 20 min in a planet mill (Fritsch, Idar-Oberstein, Germany). To obtain calibration curves, the stock mixture was serially diluted in sand by mixing 1–2 g mixture with an adequate amount of sand to reach the desired polymer concentrations for each calibration point. The mixture was homogenized in a planet mill after each dilution step. Calibration ranged from 0.005 to 10 mg/g. Calibration samples were extracted and analyzed in the same way as the environmental samples. Calibration curves were fitted by the MassHunter Quantitative Analysis tool (Agilent, Santa Clara, CA, USA) using 1/x weighting.

Pressurized liquid extraction

Approximately 1 g sample was weighed into 10-mL stainless steel extraction cells (Dionex, Sunnyvale, CA, USA) and extracted using an ASE-350 (Dionex, Sunnyvale, CA, USA) with the parameters listed in Table 1. In a first step, a pre-extraction with methanol was performed to reduce disturbing matrix effects. MP extraction was enabled by using THF at 185 °C and 100 bar. Extracts were collected in 60-mL vials containing 200 mg calcined silica gel (600 °C, 2 h). After extraction, 10 μL of polystyrene-d5 (270 μg/mL in dichloromethane) was spiked as internal standard and the solvent was subsequently evaporated, while precipitating polymers were captured on the silica gel. MP adhered to vial walls were rinsed off with DCM for at least three times. For homogenization, the silica gel was subsequently ground for 5 min by means of a planet mill.

pyr-GC-MS

For pyr-GC-MS analysis, 20 mg of milled silica gel were weighed into a 80-μL pyrolysis cup (Eco-Cup LF, Frontier Laboratories, Saikon, Japan) and pyrolyzed at 600 °C. Measurements were performed with a Multi-Shot Pyrolyzer EGA/PY-3030D (Frontier Laboratories, Saikon, Japan) and an Auto-Shot Sampler AS-1020E (Frontier Laboratories, Saikon, Japan). The pyrolyzer was attached to an Agilent 7890B gas chromatograph (Santa Clara, CA, USA) equipped with an Ultra ALLOY® UA-5(MS/HT) metal capillary separation column (Frontier Laboratories, Saikon, Japan). Column dimensions were 30 m length, 0.25 mm inner diameter, and 0.25 μm film thicknesses. Chromatographic separation was performed by the following temperature program: hold at 40 °C for 2 min, increase at 20 °C min−1 to 320 °C and hold for 13 min. For detection, an Agilent MSD 5977B (Santa Clara, CA, USA) in scheduled selected ion monitoring (SIM) mode was used.

Figure 1 depicts the different steps of the whole analytical process.

Quantification

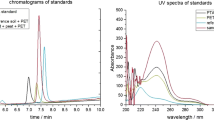

For quantification of the polymers, characteristic pyrolysis products were monitored. These indicator compounds were specific for the certain polymers (Table 2 and Fig. 2).

Background contamination and spiking experiments

To estimate the extent of cross-contamination of the samples, procedural blanks using calcined sea sand were carried out during each sample series. To evaluate the risks of a sample contamination during sample preparation, glass fiber filters (1.6 g, 176 cm2) were placed in the fume hood and on the lab bench where samples were prepared. After 26 days, the filters were extracted and analyzed as well.

Validation

To determine the selectivity of the developed method, natural matrices were mixed with sea sand (3 wt%) and 1 g of this mixture was extracted by PLE as described above. Wood from a cherry tree (Prunus avium), leafs from evening primrose (Oenothera sp.), and yew needles (Taxus baccata) were collected in a domestic garden in the area of Bingen (Germany) by the owner. Carp filet (Cyprinus carpio) and crayfish (Gammarus sp.) were collected from the river Rhine in Germany and freeze-dried and milled. Motor oil based on mineral oil and cellulose filters was taken from laboratory stock. Humic acids (~ 30–40%) were purchased from Carl Roth (Karlsruhe, Germany).

To evaluate the influence of MP particle sizes on reproducibility and to determine minimum sample mass for representative aliquots, mixtures of sand and different sized PE particles (fraction 10–50 and 200–400 μm) were analyzed. Exactly 20 mg PE was mixed with calcined sea sand to a total weight of 2 g and intensively homogenized in a hand mortar. This mixture (10 mg/g) was diluted by mixing 400 mg with calcined sea sand to obtain a total weight of 4 g and a concentration of 1 mg/g. After intensive homogenization of the samples in a hand mortar, the detection was performed either by direct in-weighing of 20 mg into the pyrolysis cup or after an extraction of 200 mg or 1 g by PLE as described above.

Recovery experiments were carried out by analyzing 1 g sand containing 3 wt% of humic acids spiked with 0.05 and 0.75 mg/g MP (PE, PP, PS). Reproducibility of the method was determined by extracting five environmental samples six to seven times and a subsequent detection by pyr-GC-MS.

Environmental samples

To evaluate the appropriateness of the developed analytical method for environmental samples, a variety of matrices were collected and air dried. To reduce the risk of contamination, any contact of the samples to plastic tools and vessels was avoided during sampling and storage. Stainless steel spades were used for sampling of sediments, soils, and sewage sludge which where thereafter transported/stored either in glass or aluminum vessels. Not less than 500 g was collected for each sample. Sediments taken at the shore of an island in the river Rhine (Niederwerth, Koblenz, Germany) were fractionated (630, 200, 63 μm) by wet-sieving and subsequently ground and homogenized in a planet mill (Fritsch, Idar-Oberstein, Germany). All other samples were also ground and homogenized in a planet mill, but were not sieved. Suspended matter of the rivers Rhine (km 590.3) and Moselle (km 2.1) were collected by means of continuous flow centrifugation in the area of Koblenz. Road side soils were collected on an arterial road (approx. 9000 vehicles per day) in Cologne (Germany) directly at the kerb. Sewage sludge was taken from two wastewater treatment plants (WWTPs) in Bavaria (Germany) with population equivalents of 70,000 and 170,000, respectively. Furthermore, a potting soil was bought in a local store in Koblenz, Germany. For solvent extraction, 0.3 to 1 g of the samples was weighed in. Extractions and analyses were always carried out at least in triplicate as described above.

Results and discussion

MP inhomogeneity of the samples is a big challenge in MP quantification. To get representative aliquots of the samples, especially when analyzing MP particles > 100 μm, relatively high sample in-weights are needed. Typical in-weights in thermo analytical methods for MP determination lie in the range of 10–50 mg [21, 25, 26]. To evaluate the minimum sample in-weight, we analyzed mixtures of sand and PE particles of two different size fractions (10–50 μm and 200–400 μm) at two different spiked concentrations (1 mg/g and 10 mg/g). Direct analyses of 20 mg, the maximum manageable sample in-weight using 80-μL pyrolysis cups, by pyr-GC-MS indicated large statistical uncertainties with relative standard deviations (RSD) of up to 50% (ref. Table 3). Therefore, higher in-weights were applied up to 1000 mg for PLE with THF. RSDs below 10% were achieved for the 10–50 μm fractions using an in-weight of 200 mg, while for the 200–400 μm fractions, even an in-weight of 1000 mg still indicated larger variations with a RSD of 21%. It can be concluded that samples with large MP particles (> 200 μm) should be ground in a cryo mill prior to PLE to ensure a homogeneous distribution of the particles in the sample matrix.

Extraction of polymers

We developed an extraction procedure optimized for the quantification of small MP concentrations (< 1 mg/g). Due to the poor solubility of PE and PP in most solvents, extraction of these plastics is impossible under conditions applied for organic emerging contaminants [27, 28]. However, at 180 °C, the polymers PE, PP, and PS can be dissolved and extracted with DCM with elevated recoveries [24]. The use of DCM has two main disadvantages: (i) high toxicological potential for humans and (ii) a precipitation of the extracted polymers in the capillaries of the PLE, leading to cross-contaminations and sometimes even to clogging of the whole tubing system during method development. For these reasons, the less toxic and less volatile THF was tested as substitute. THF yielded quantitative extraction recoveries for PE, PP, and PS in sediments and soils when using an extraction temperature of 185 °C at 100 bar for 9 min. This increased temperature also prevents the clogging of the 100 μm frit in the static valve [24]. In order to identify the optimum conditions and cycle numbers for extraction via PLE, 1 mg of PE and PP was weighted into an extraction cell and were extracted with THF at 185 °C as described above. Each extraction cycle was analyzed separately for PE and PP. Since particle size is a crucial parameter with regard to solvation behavior, relatively large particles of PE (ca. 2 mm) and PP (> 200 μm) were added to the extraction cells. During the first three cycles, more than 80% of PE and PP was recovered (ref. Table 4). A quantitative extraction of PE and PP was reached after four and six cycles, respectively. Even relatively large particles could be extracted under the selected conditions. To ensure a complete extraction and to prevent cross-contaminations, seven extraction cycles were applied for the extraction of environmental solid samples. PS was not included in this experiment as it was not in our target list at that time. However, it can be safely assumed that 7 extraction cycles are also sufficient for PS, since it is readily soluble in THF even at room temperature [29].

Under the chosen conditions, not only polymers but also natural organic matter (NOM) was extracted when analyzing sediments and soil. For that reason, a pre-extraction via methanol was applied, enabling a separation of an appreciable amount of the NOM and, thus, improving the recoveries and statistical variations of the polymers in pyr-GC-MS analysis due to reduced matrix effects disturbing the measurements (ref. chapter “Matrix interferences”).

During the cooling of the extract, PP and PE precipitate in the vials, while PS remains dissolved. Considering the very low amounts of plastics in the samples (5 μg), adhesion of a precipitated polymer film to the glass surface of the extraction vial would render the recovery of the analyte impossible. In order to avoid this and to enable the transfer of the extracted analytes into the pyrolysis cups, two strategies were tested: (i) insertion of glass fiber extraction thimbles into the vials and (ii) covering of the vial bottom with silica gel prior to extraction, inducing a sorption of the polymers on these materials instead of the glass surface. As the glass fiber thimbles were unstable and fragmented during extraction, only the silica gel was appropriate for usage. In order to cover the whole bottom of a 60-mL vial, 200 mg of silica gel was added. After solvent evaporation, the silica gel with the sorbed extraction residues was removed from the vial, homogenized, and weighed into the pyrolysis cups. Considering a sample in-weight of 1 g, an enrichment factor of 5 can be realized by the extraction step described above.

pyr-GC-MS

For the quantification of PE, PP, and PS via pyr-GC-MS, specific indicator substances formed during pyrolysis were used as previously reported [22, 23]. The trimer 2,4-dimethylhept-1-ene and the monomer styrene were chosen for PP and PS, respectively. Styrene is not a particularly specific indicator substance for PS, since it can be formed from other synthetic polymers such as acrylonitrile butadiene styrene (ABS) or styrene-butadiene rubber (SBR) during thermolysis. The styrene trimer is more specific, but the sensitivity and the reproducibility are significantly reduced. Therefore, we used the monomer, taking into account that the results do not represent PS concentrations, but a sum parameter of styrene containing synthetic polymers. For PE, two indicator substances were monitored: the alkene 1-pentadecene and the alkadiene 1,14-pentadecadiene. The latter was more selective (ref. chapter validation), while the former was more sensitive (ref. chapter calibration). To maximize sensitivity, the selected ion fragments of each indicator substance were measured in SIM mode.

Calibration

The preparation of different calibration concentrations from a stock solution by serial dilution was impossible, due to the poor solubility of PE and PP in most solvents. Direct weighing of certain quantities of the polymers was also an unsuitable method due to uncertainties of weighing of small quantities when preparing the lower calibration levels. Therefore, as an alternative, a serial dilution of the stock mixture with an inert matrix (calcined sea sand) was carried out. Calibration points were generated by analyzing known concentrations of mixtures of the three polymers (PE, PP, PS) diluted in sand. After extraction, polystyrene-d5 was added as internal standard. Relative peak areas were calculated with regard to polystyrene-d5 to prepare the calibration curves. For all three polymers, linear calibration curves down to 0.005 mg/g were achieved (ref. Table 5 and Fig. 3). For PP and PS, linear responses were obtained up to 1 mg/g, while for PE, a linear response even up to 10 mg/g was achieved.

Limits of quantification

Due to ubiquitous occurrence of plastics in labs, false-positive detection of MP is a crucial issue. Therefore, the quantification is not limited by the sensitivity of the detection system, but by background concentrations. Thus, LOQs were defined as the concentration at which 95% of blank samples show a lower signal. To estimate background concentrations, blank samples containing only sand were extracted and analyzed. From the average relative responses of 11 blank samples, the blank polymer concentrations with the one-sided confidence interval (t(p = 0.95;n-1 = 10) = 1.812) were calculated and assumed as limits of quantification (LOQ). The obtained LOQs are shown in Table 6.

Matrix interferences

Quantification of MP by pyr-GC-MS is based on the indirect determination of the polymers by their thermal degradation products (pyrolysis products). These products could, however, also be formed from matrix ingredients present in environmental samples. Therefore, the selectivity of the indicator compounds was tested by analyzing organic materials which were not contaminated by plastic species. Each of the chosen organic materials represents a typical ingredient of environmental matrices such as proteins, fats, or polysaccharides. Table 7 provides bias for the different polymers induced by mixtures of 30 mg organic material in 1 g sea sand. The tested matrices led to no noteworthy bias for PP. For PS, only wood (lignin) caused an increased background of 0.042 mg/g. No bias was caused by protein-rich matrices such as crayfish or fish meal. Proteins and more precisely the incorporated amino acid phenylalanine are well-known precursors for styrene during pyrolysis [23]. Proteins were eliminated during the pre-extraction step and thus not extracted by THF. Thus, it is very likely that the quantification of PP and PS in environmental samples is not strongly biased by the presence of naturally occurring substances as long as no high portions of wood are present.

Interferences were indeed found for PE. The highest bias was obtained with engine oil, since 30 mg engine oil generated similar signals as 1.1 mg PE. However, this might only be a problem for environmental samples highly contaminated by oil or gasoline spills. In those cases, the use of the alkadiene as indicator substance gave better results. This was also found for fish filet. This matrix contains relatively high amounts of fatty acids which release n-alkanes and n-alkenes during thermolysis [30]. With increasing carbon number and number of double bounds (0, 1, or 2), these interferences decrease strongly [23, 31]. The used indicator compound 1,14-pentadecadiene was not formed by the thermolysis of fatty acids.

For the other tested matrices such as wood or leaf, the matrix-induced bias was in the same range, independent of whether 1,14-pentadecadiene or 1-pentadecene was used for quantification. However, the much higher sensitivity and lower LOQ for the alkene compared with the alkadiene has to be taken into account. The high specificity of the analytical method is caused by the pre-extraction with methanol, solvent extraction with THF, and the selected indicator compounds for quantification. Interfering matrix compounds were either not extracted or were washed out in a pre-extraction step. The developed method was suitable for MP quantification even in matrices containing high quantities of organic compounds.

Contamination during sample preparation

To detect sample contaminations caused by atmospheric deposition [32], glass fiber filters were displayed at different sites (fume hood and lab bench) in the lab for 26 days. None of the filters showed MP concentrations above the LOQ. Thus, contaminations of the samples during sample preparation can be neglected.

Recoveries and reproducibility

To check whether different matrices have effects on the extraction efficiency and reproducibility, spiking experiments were performed in a synthetic matrix (3% humic acids in sea sand) at two different concentration levels (0.05 and 0.75 mg/g). Recoveries for PP and PS (Table 8) indicate that matrix effects are not dominant when considering statistical uncertainties of around ± 20%. For PE at both spiking levels, all recoveries laid above 100%. This might be an indication for a slight over-determination between 15 and 31%. However, since the statistical uncertainties were in a similar range, this cannot be finally concluded. Recoveries for other organic material (fish filet, crayfish, leaf, fir needle) lay in the same range (data not shown).

To check the reproducibility of the analytical method, five different environmental matrices (soil and sewage sludge) were analyzed in six to seven replicates over the whole analytical method (ref. Table 9). Relative standard deviations were about 10% or lower, highlighting a high reproducibility and reliability of the method.

Environmental samples

Sediments, suspended particulate matter, soils (roadside and potting soil), and sewage sludge were analyzed with regard to their contamination with PP, PE, and PS MP. Table 10 summarizes the quantitative results and confidence intervals (95%).

In sediment from the river Rhine, PP and PE were detected with concentrations of 0.032 ± 0.001 and 0.028 ± 0.006 mg/g, respectively, independent of the grain size (> 63 μm or > 200 μm), while PS was not present at all above the LOQ (0.008 mg/g). However, PE and PP were detected in the suspended matter of Rhine (km 590.3) and Moselle (km 2.1) in concentrations up to 0.98 ± 0.02 and 0.055 ± 0.010 mg/g, respectively. In the sewage sludge, all three polymers were detected with concentrations ranging from 0.08 ± 0.02 mg/g (PP) up to 3.3 ± 0.3 mg/g (PE). The sewage sludges were sampled at two different WWTPs with 70,000 and 170,000 population equivalents, respectively. The analyzed potting soil contained PE in similar concentration as in sewage sludge, but only traces of PP were detected and PS was not detected at all. In contrast, in the soils taken at the kerb of a road with about 9000 vehicles per day in Cologne (Germany), all three polymers were found with concentrations up to 0.85 ± 0.07 mg/g (PE). The relatively low PS concentrations compared with sewage sludge are quite surprising, since styrene, the used indicator, can also be released during pyrolysis of SBR, a polymer in tire tread. Thus, high contents of SBR could pretend elevated PS concentrations not present in reality.

However, the extraction rates of SBR by PLE and the extent of styrene released during SBR pyrolysis were not evaluated in this study, but will be investigated in future studies. In any case, these results confirm that the developed analytical method is appropriate to detect MP of PE, PP, and PS in several kinds of matrices.

Conclusion and outlook

MP quantification in solid environmental samples is still a challenge. For detecting small quantities of MP in sediments and soils, an extraction step is necessary. Due to the particular manner of the polymers and inhomogeneous distribution especially of particles > 100 μm in the sample, an in-weight of at least 1 g sample is required to get a representative aliquot of the sample. Often-used density separation is very time-consuming and difficult to automate. The same is true for the subsequent removal of the organic matrix by enzymatic, oxidative, or acidic/basic digestion. The presented MP extraction in combination with pyr-GC-MS enables a quantification of MP in sediments, soils, and sewage sludge in less than 7 h. The described solvent extraction offers matrix removal and MP enrichment in one fully automated step. Disturbance by matrix components, which are known to appear in thermo analytical methods [25], could be reduced to a minimum. The method was successfully validated for the quantification of PE, PP, and PS at low concentrations in the presence of different organic matrix compounds demonstrating the selectivity of the extraction method and the used indicator compounds. In all analyzed environmental samples, MP was detected pointing out the ubiquitous occurrence of MP in the environment and the need for analytical methods for comprehensive monitoring campaigns. The method will be expanded by further plastic types (e.g., tire polymers and polyethylene terephthalate). In future studies, the method will be used for MP monitoring in soil and sediment of freshwater systems. The method is not able to determine the number and the size of the particles, and thus, it can be seen as a complementary method to those using the density separation and spectroscopic methods such as Raman and μ-FTIR. A possible application is as a fast screening method before a detailed analysis of selected samples by more time-consuming spectroscopic methods.

References

Mani T, Hauk A, Walter U, Burkhardt-Holm P. Microplastics profile along the Rhine River. Sci Rep. 2015;5:17988. https://doi.org/10.1038/srep17988.

Blettler MCM, Ulla MA, Rabuffetti AP, Garello N. Plastic pollution in freshwater ecosystems: macro-, meso-, and microplastic debris in a floodplain lake. Environ Monit Assess. 2017;189(11):581. https://doi.org/10.1007/s10661-017-6305-8.

Chae Y, An Y-J. Current research trends on plastic pollution and ecological impacts on the soil ecosystem: a review. Environ Pollut. 2018;240:387–95. https://doi.org/10.1016/j.envpol.2018.05.008.

Dekiff JH, Remy D, Klasmeier J, Fries E. Occurrence and spatial distribution of microplastics in sediments from Norderney. Environ Pollut. 2014;186. https://doi.org/10.1016/j.envpol.2013.11.019.

Imhof HK, Laforsch C, Wiesheu AC, Schmid J, Anger PM, Niessner R, et al. Pigments and plastic in limnetic ecosystems: a qualitative and quantitative study on microparticles of different size classes. Water Res. 2016;98:64–74. https://doi.org/10.1016/j.watres.2016.03.015.

Peters CA, Hendrickson E, Minor EC, Schreiner K, Halbur J, Bratton SP. Pyr-GC/MS analysis of microplastics extracted from the stomach content of benthivore fish from the Texas Gulf Coast. Mar Pollut Bull. 2018;137:91–5. https://doi.org/10.1016/j.marpolbul.2018.09.049.

Vidyasakar A, Neelavannan K, Krishnakumar S, Prabaharan G, Sathiyabama Alias Priyanka T, Magesh NS, et al. Macrodebris and microplastic distribution in the beaches of Rameswaram Coral Island, Gulf of Mannar, Southeast coast of India: a first report. Mar Pollut Bull. 2018;137:610–6. https://doi.org/10.1016/j.marpolbul.2018.11.007.

Piehl S, Leibner A, Löder MGJ, Dris R, Bogner C, Laforsch C. Identification and quantification of macro- and microplastics on an agricultural farmland. Sci Rep. 2018;8(1):17950. https://doi.org/10.1038/s41598-018-36172-y.

Haave M, Lorenz C, Primpke S, Gerdts G. Different stories told by small and large microplastics in sediment - first report of microplastic concentrations in an urban recipient in Norway. Mar Pollut Bull. 2019;141:501–13. https://doi.org/10.1016/j.marpolbul.2019.02.015.

Mani T, Primpke S, Lorenz C, Gerdts G, Burkhardt-Holm P. Microplastic pollution in benthic midstream sediments of the Rhine River. Environ Sci Technol. 2019. https://doi.org/10.1021/acs.est.9b01363.

Elert AM, Becker R, Duemichen E, Eisentraut P, Falkenhagen J, Sturm H, et al. Comparison of different methods for MP detection: what can we learn from them, and why asking the right question before measurements matters? Environ Pollut. 2017;231(Part 2):1256–64. https://doi.org/10.1016/j.envpol.2017.08.074.

Renner G, Schmidt TC, Schram J. Analytical methodologies for monitoring micro(nano)plastics: which are fit for purpose? Curr Opin Environ Sci Health. 2018;1:55–61. https://doi.org/10.1016/j.coesh.2017.11.001.

Huppertsberg S, Knepper TP. Instrumental analysis of microplastics—benefits and challenges. Anal Bioanal Chem. 2018. https://doi.org/10.1007/s00216-018-1210-8.

Zarfl C. Promising techniques and open challenges for microplastic identification and quantification in environmental matrices. Anal Bioanal Chem. 2019. https://doi.org/10.1007/s00216-019-01763-9.

Käppler A, Fischer D, Oberbeckmann S, Schernewski G, Labrenz M, Eichhorn K-J, et al. Analysis of environmental microplastics by vibrational microspectroscopy: FTIR, Raman or both? Anal Bioanal Chem. 2016;408(29):8377–91. https://doi.org/10.1007/s00216-016-9956-3.

Tagg AS, Sapp M, Harrison JP, Ojeda JJ. Identification and quantification of microplastics in wastewater using focal plane array-based reflectance micro-FT-IR imaging. Anal Chem. 2015;87(12):6032–40. https://doi.org/10.1021/acs.analchem.5b00495.

Primpke S, Lorenz C, Rascher-Friesenhausen R, Gerdts G. An automated approach for microplastics analysis using focal plane array (FPA) FTIR microscopy and image analysis. Anal Methods. 2017;9(9):1499–511. https://doi.org/10.1039/C6AY02476A.

Araujo CF, Nolasco MM, Ribeiro AMP, Ribeiro-Claro PJA. Identification of microplastics using Raman spectroscopy: latest developments and future prospects. Water Res. 2018;142:426–40. https://doi.org/10.1016/j.watres.2018.05.060.

Simon M, van Alst N, Vollertsen J. Quantification of microplastic mass and removal rates at wastewater treatment plants applying focal plane array (FPA)-based Fourier transform infrared (FT-IR) imaging. Water Res. 2018;142:1–9. https://doi.org/10.1016/j.watres.2018.05.019.

Mai L, Bao L-J, Shi L, Wong CS, Zeng EY. A review of methods for measuring microplastics in aquatic environments. Environ Sci Pollut Res. 2018;25(12):11319–32. https://doi.org/10.1007/s11356-018-1692-0.

Unice KM, Kreider ML, Panko JM. Use of a deuterated internal standard with pyrolysis-GC/MS dimeric marker analysis to quantify tire tread particles in the environment. Int J Environ Res Public Health. 2012;9(11):4033–55. https://doi.org/10.3390/ijerph9114033.

Duemichen E, Braun U, Senz R, Fabian G, Sturm H. Assessment of a new method for the analysis of decomposition gases of polymers by a combining thermogravimetric solid-phase extraction and thermal desorption gas chromatography mass spectrometry. J Chromatogr A. 2014;1354:117–28. https://doi.org/10.1016/j.chroma.2014.05.057.

Fischer M, Scholz-Böttcher BM. Simultaneous trace identification and quantification of common types of microplastics in environmental samples by pyrolysis-gas chromatography–mass spectrometry. Environ Sci Technol. 2017;51(9):5052–60. https://doi.org/10.1021/acs.est.6b06362.

Fuller S, Gautam A. A procedure for measuring microplastics using pressurized fluid extraction. Environ Sci Technol. 2016. https://doi.org/10.1021/acs.est.6b00816.

Eisentraut P, Dümichen E, Ruhl AS, Jekel M, Albrecht M, Gehde M, et al. Two birds with one stone—fast and simultaneous analysis of microplastics: microparticles derived from thermoplastics and tire wear. Environ Sci Technol Lett. 2018;5(10):608–13. https://doi.org/10.1021/acs.estlett.8b00446.

David J, Steinmetz Z, Kučerík J, Schaumann GE. Quantitative analysis of poly(ethylene terephthalate) microplastics in soil via thermogravimetry–mass spectrometry. Anal Chem. 2018. https://doi.org/10.1021/acs.analchem.8b00355.

Brand S, Schlüsener MP, Albrecht D, Kunkel U, Strobel C, Grummt T, et al. Quaternary (triphenyl-) phosphonium compounds: environmental behavior and toxicity. Water Res. 2018;136:207–19. https://doi.org/10.1016/j.watres.2018.02.032.

Wick A, Jacobs B, Kunkel U, Heininger P, Ternes TA. Benzotriazole UV stabilizers in sediments, suspended particulate matter and fish of German rivers: new insights into occurrence, time trends and persistency. Environ Pollut. 2016;212:401–12. https://doi.org/10.1016/j.envpol.2016.01.024.

García MT, Gracia I, Duque G, Lucas A, Rodríguez JF. Study of the solubility and stability of polystyrene wastes in a dissolution recycling process. Waste Manag. 2009;29(6):1814–8. https://doi.org/10.1016/j.wasman.2009.01.001.

Scholz-Böttcher BM, Nissenbaum A, Rullkötter J. An 18th century medication “Mumia vera aegyptica” – fake or authentic? Org Geochem. 2013;65:1–18. https://doi.org/10.1016/j.orggeochem.2013.09.011.

Dümichen E, Barthel A-K, Braun U, Bannick CG, Brand K, Jekel M, et al. Analysis of polyethylene microplastics in environmental samples, using a thermal decomposition method. Water Res. 2015;85:451–7. https://doi.org/10.1016/j.watres.2015.09.002.

Bergmann M, Wirzberger V, Krumpen T, Lorenz C, Primpke S, Tekman MB, et al. High quantities of microplastic in Arctic deep-sea sediments from the HAUSGARTEN observatory. Environ Sci Technol. 2017;51(19):11000–10. https://doi.org/10.1021/acs.est.7b03331.

Acknowledgments

This work was part of the FONA project “Microplastics in Inland Waters - Investigation and Modeling of Entries and whereabouts in the Danube Area as a Basis for Action Planning (MicBin)” funded by the German Federal Ministry of Education and Research (BMBF).

Funding

Funding by the Federal Ministry of Transport and Digital Infrastructure (BMVI) is acknowledged. Tim Lauschke is thankful for financial support by University of Koblenz.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dierkes, G., Lauschke, T., Becher, S. et al. Quantification of microplastics in environmental samples via pressurized liquid extraction and pyrolysis-gas chromatography. Anal Bioanal Chem 411, 6959–6968 (2019). https://doi.org/10.1007/s00216-019-02066-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-019-02066-9