Abstract

A facile and convenient approach for the preparation of interconnected multiwalled carbon nanotube (MWCNT) monolithic sorbents in recycled plastic caps has been developed. The method, which was based on the photopolymerization of the individual MWCNTs via the formation of a W/O medium internal phase emulsion (40/60 w/w%), provides control over the size of pores, rigidity, and the mechanical stability of the final solid. Pluronic L121 was used as a surfactant containing the water phase inside it and, consequently, the organic and non-polar phase, in which the MWCNTs and the cross-linker were trapped, remained on the outside of the droplets. Optical microscopy and scanning electron microscopy (SEM) were employed to characterize the morphology of both the emulsions and the final solids, respectively. In addition, nitrogen intrusion porosimetry was performed in order to study how the specific surface area of the final monolithic solid changed (from 19.6 to 372.2 m2 g−1) with the variables involved in the polymerization step. To exemplify the great sorbent potential of the synthesized material, a colorimetric assay based on the retention of methylene blue within the interconnected MWCNT monolithic structure was carried out. Finally, following the positive results, the carbon nanotube-monolithic stirred caps were applied for the determination of chlorophenols in a biological matrix such as human urine, obtaining excellent recovery values (91–98%) and good precision (5.4–9.1%) under optimized extraction conditions.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbon nanotubes (CNTs) are currently one of the most prominent materials because of their large specific surface area, extreme lightness, high mechanical stability, and exceptional electronic and thermal properties [1, 2]. For all these reasons, they are used in a wide variety of applications and different areas among which its use as sorbents stands out [3, 4]. Due to their graphitic nature, the interactions with the target compounds are mainly hydrogen bonding, electrostatic forces, van der Waals forces, π-π stacking, and hydrophobic interactions. Concretely in dispersive μSPE, the high tendency to aggregation of carbon nanostructures as well as the additional step required for the separation of nanoparticles once the extraction has finished may limit their widespread use as sorbents. Thus, retaining the nanoparticles on solid supports or preferably assembling or linking CNTs to form interconnected porous macrostructures, which show both the unique properties of the nanoscale and the easy to handle of the macroscopic monolithic polymers, is highly desirable [5, 6]. In this context, although several carbon nanotube-based composite monolithic solids have been prepared from dispersions of the nanotubes and gelators, fabricating monoliths exclusively formed by nanoparticles is still challenging with only a few successful examples [7,8,9].

Part of the difficulty in preparing the pure nanoparticle-based monoliths is that CNTs interact between them by π-π stacking and van der Walls forces, which leads to fragile and unstable final solids [6, 9, 10]. Additionally, the fabrication and attachment of this kind of materials to the inner walls of an extraction support or device (e.g., tubes, tips, and stir-cakes) without breaking the solid is limited by the characteristic and high contraction of the monolith that occur during the synthesis process, especially in those supports with diameters of the order of millimeters [11, 12]. Therefore, the development of new synthetic routes to obtain monoliths based only on nanoparticles inside extraction devices holds the key to extend their applications.

Over the past years, monolithic polymeric materials have been prepared in several polypropylene devices such as stir-cake units [13,14,15], which are based on a sorbent placed in a holder with an ironware in order to integrate the stirring. The sorption process in addition to being strongly influenced by the properties of the nanomaterial [16, 17] is also affected by the conditions and format used in the extraction [18]. This configuration avoids the direct contact of the solid with the sample vessel, and consequently, high stirring rates can be used during the extraction procedure increasing its reusability. Another important advantage is that the unit can be easily recovered from the sample [19].

In this work, carbon nanotube-based monolithic solids have been prepared from a W/O emulsion under UV light. For this purpose, multiwalled carbon nanotubes (MWCNTs) were dispersed in the organic phase (external and continuous phase) while aqueous phase was trapped in the droplets formed by the surfactant. The polymerization procedure was carried out in plastic bottle caps previously modified with UV energy to ensure the attachment of the solid to their inner walls improving the mechanical stability of the system. In addition, an ironware was integrated in the plastic cap in order to incorporate stirring to the extraction unit. Finally, the monolithic stirred caps were successfully applied to the extraction of chlorophenols from urine samples since these compounds are highly toxic and carcinogenic at low levels [20]. Therefore, they have been classified as priority pollutants by the US Environmental Protection Agency (EPA). Thus, urine has been selected as biological matrix because they approximately 80% of the amount ingested are excreted rapidly by the kidneys [21]. Moreover, urine is one of the most widely biological matrices analyzed due to its high availability and non-invasive collection in comparison with blood, serum, amniotic fluids, or gastric contents among others.

Experimental section

Reagents, materials, and samples

All reagents were of analytical grade or better. The analytes (methylene blue, 4-chlorophenol, 2,6-dichlorophenol, 2,3-dichlorophenol, 3,4-dichlorophenol, 2,4,5-trichlorophenol) were obtained from Sigma-Aldrich (Madrid, Spain; http://www.sigmaaldrich.com). Standard solutions of each analyte were prepared in methanol (Sigma-Aldrich) at a concentration of 1 g L−1 and stored at 4 °C. Working standard solutions were prepared on a daily basis by rigorous dilution of the stocks in ultrapure Milli-Q water. Hexane was used for elution.

Reagents used in the preparation of the monolithic phase, viz., ethylene dimethacrylate (EDMA), lauroyl peroxide (LPO), chloroform, and Pluronic L121, were purchased from Sigma-Aldrich. Benzophenone (BP) was also purchased from Sigma-Aldrich. Methanol was obtained from Scharlab, Spain (http://scharlab.com/). Multiwalled carbon nanotubes (> 90% carbon basis, D × L 110–170 nm × 5–9 nm) and carboxylated multiwalled carbon nanotubes (c-MWCNTs, > 95 wt% purity, D × L < 8 nm × 10–30 μm, 3.86 wt% functional content) were obtained from Sigma-Aldrich. Amino-carbon nanotubes (> 95% purity, D × L 15 nm × 5–20 μm) were purchased from Nanolab (http://www.nano-lab.com/).

Blank urine samples were collected from healthy adult volunteers and stored in polytetrafluoroethylene (PTFE) flasks at − 20 °C until analysis. For confidentiality and non-disclosure purposes, these samples were provided without any information from the donors and discarded after being analyzed. The spiked samples were prepared by adding the analytes at a concentration of 500 μg L−1, and then they were left to stand for 24 h until the analysis.

Instrumentation

Photopolymerization and photografting processes were performed into an UV crosslinker (Bio link crosslinker) from LABOLAN, S.L. (Spain), equipped with UV lamps (5 × 8 W, 254 nm). SEM micrographs of polymeric materials were obtained with a scanning electron microscope (JEOL JSM 6300).

GC/MS analyses were performed in an Agilent Technologies (Palo Alto, CA, USA) HP6890 gas chromatograph equipped with a HP5973 mass spectrometric detector based on a quadrupole analyzer and an electron multiplier detector. System control and data acquisition were achieved with a HP1701CA MS ChemStation software.

A splitless mode was selected for injection, using helium (6.0 grade, Air liquid, Seville, Spain) at a flow rate of 1 mL min−1 as carrier gas. Chromatographic separations were performed on a fused silica HP-5MS capillary column, 30 m × 0.25 mm i.d. coated with 5% diphenyl, 95% dimethylpolysiloxane (film thickness 0.25 μm) from Agilent. The column temperature program was as follows: 2.5 min at 40 °C, raised up to 100 °C at 25 °C min−1, then immediately ramped at 4 °C min−1 up to 180 °C and raised up to 300 °C at 40 °C min−1, and kept finally at this temperature for 3 min. The quadrupole mass spectrometer detector was operated in selected ion monitoring mode, recording the following fragment ions: m/z 128 (from 6.0 to 12.0 min), m/z 162 (from 12.0 to 16.5 min), and m/z 196 (from 16.50 to 30.90 min). Electron impact ionization (70 eV) was used for analyte ionization/fragmentation. The injector, MS source, and quadrupole temperatures were kept at 250 °C, 230 °C, and 150 °C, respectively. The injection volume was 2 μL. The peak areas were used for quantification of individual analytes. The transfer line and ionization source were maintained at 280 °C and 250 °C, respectively.

Preparation of the chemically interconnected carbon nanotube monolithic sorbents

As it can be seen in the Fig. S1A (see Electronic Supplementary Material, ESM), the monolithic solid was prepared into a plastic bottle cap as a holder with an ironware which allows the stirring of the system. The inner walls of the plastic cap were modified before the polymerization in order to anchor a thin layer of a polymer (EDMA) which ensures the subsequent linking of the synthesized solid to the plastic holder [22, 23]. In brief, the cap was filled with a 5% w/v methanolic benzophenone solution and irradiated with UV light for 30 min. Next, the cap was modified with a 15% v/v methanolic EDMA solution and irradiated again for 30 min. Once photografting has finished, the cap was abundantly washed with methanol and water.

The preparation of the monolithic phase was carried out via photopolymerization approach using the pretreated plastic cap (ESM Fig. S1B). For this purpose, the aqueous phase (water) and organic phase containing chloroform, EDMA, and the MWCNTs with a W/O ratio of 40/60 w/w% were mixed. LPO was used as radical initiator and 3 wt% was added to the organic phase. Thus, a surfactant (L121) was used to achieve the homogeneous and stable mixture of both phases generating droplets with the polar part inwards (Fig. 1). Then, the cap was filled with the emulsion and it was placed under irradiation for 3 h. Finally, the resulting carbon nanotube monolith was washed in methanol in order to remove the water from the droplets generating voids and pores in the solid structure as shown in Fig. 1.

Microextraction procedure

The MWCNT monolith was used for the extraction of the target chlorophenols from aqueous standards and urine samples. The microextraction procedure consisted of the following steps: firstly, monolithic stirred unit was placed in a vessel containing 25 mL of aqueous standard/urine sample with the analytes derivatized following a previously described procedure [24] and then it was stirred at 300 rpm for 180 min. Once finalized this step, the monolithic extraction unit was withdrawn from the liquid phase by means of an external magnet and washed with Milli-Q water (5 mL) at 300 rpm for 5 min. To elute the analytes, the stirred unit was introduced in hexane (1.5 mL) and stirred at 300 rpm for 15 min as well. Finally, the organic extract was filtered and analyzed by GC/MS. Before reusing the unit, it was washed sequentially with acetone and water without showing degradation effects of the monolithic structure or losses in the extraction efficiency, which was thanks to its affinity both organic and aqueous solvents.

Results and discussion

Preparation and characterization of the chemically interconnected carbon nanotube monolithic sorbents

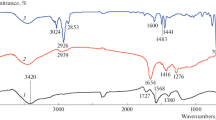

In this study, a series of MWCNT emulsions were systematically evaluated by variation of several parameters including polymerization time, chloroform/EDMA ratio, and the amount of surfactant as well as the percentage of MWCNTs present in the mixture. Additionally, functionalized carbon nanotubes with carboxyl and amine groups were also tested in order to clarify the role and importance of semi-polar (functionalized MWCNTs) or nonpolar (non-functionalized MWCNTs) nature of the nanoparticles during the polymerization. The initial synthesis conditions were taken from a previous work in which carbon nanohorns (dahlia-like structure) were used as main monomers in the polymerization [25]. Thus, the polymerization mixture consisted of 60 wt% external organic phase (20 wt% EDMA (cross-linker) and 40 wt% chloroform) and 40 wt% aqueous phase (Milli-Q water). Both phases were prepared separately. Then, 2 wt% of MWCNTs and 2 wt% LPO (free-radical initiator), respectively, were added to the organic phase. Polymerization was accomplished by irradiation for 1 h. The optimum amount of Pluronic L121 to achieve a stable emulsion with an acceptable size of droplets was fixed at 18 wt%.

Firstly, emulsions with MWCNTs, c-MWCNTs, and amino-MWCNTs were prepared and their stability with the time was visually studied. The emulsion containing MWCNTs resulted totally homogeneous during 24 h (Fig. 2a). However, emulsions with carboxylated- and amino-MWCNTs gave rise to unstable mixtures even freshly prepared (Fig. 2b, c). This fact is probably due to functionalized MWCNTs that pass through from organic phase to water because of their increased hydrophilic character associated with the surface groups. This behavior was observed in the microscope images of emulsions: while Fig. 2a shows a homogeneous distribution of the individual nanotubes throughout the mixture, Fig. 2b, c notices the formation of large aggregates of the nanotubes some of which presented a circular shape, corroborating the hypothesis that nanotubes modified with carboxylated- and amino-groups had more affinity for the polar phase. Consequently, non-functionalized MWCNTs were used in further emulsions.

The next variable to study was the polymerization time. For that, emulsions containing MWCNTs were placed under UV energy during 1, 2, 3, and 4 h. As it can be seen in the Fig. 3, larger polymerization times produced a denser EDMA-polymer coating of the MWCNTs which promoted the cross-linked of the nanoparticles generating more robust final solids. In this way, although solids were formed with 1 and 2 h of irradiation, they were not stable enough to withstand the stirring, breaking, and falling off the holder. On the other hand, monoliths polymerized during 3 and 4 h showed good stability during the stirring.

Another crucial variable that directly affects to the linking of MWCNTs between them to form a continuous structure is the amount of EDMA in the emulsions. Therefore, organic phases containing 10, 20, and 30 wt% of EDMA were prepared (ESM Table S1). Figure 4 corresponds to the SEM characterization of the solids prepared with these percentages. Micrographs at high magnifications showed denser EDMA polymer coatings on MWCNTs which correspond to the increased amount of EDMA in the emulsion. This demonstrates the copolymerization of the EDMA with the MWCNTs in the organic or external phase of the emulsion, and thus, solids with a more cross-linked and more rigid monolithic structures were generated. These results were complemented with those obtained by nitrogen intrusion porosimetry (ESM Table S1) where the average pore diameter remained practically constant despite the chloroform/EDMA ratio used. This fact confirms that the pore size of the final solid is only influenced by the amount of surfactant and the W/O ratio in the emulsion. On the other hand, when the percentage of EDMA was increased, the specific surface area increased due to the formation of the polymeric coating on the MWCNTs, which presented protuberances and globules, giving rise to a more porous structure and therefore with a high specific surface. Nevertheless, the polymeric EDMA coatings on the MWCNTs could lead to a slight worsening of the extraction performance as the graphitic surface of the MWCNTs could not interact directly with the analytes via π-stacking.

Finally, the effect of the amount of MWCNTs in the polymerization was evaluated preparing emulsions which contain percentages of MWCNTs between 0 and 3 wt%. As can be noted from the Fig. 5a, the monolithic solid was not obtain in the absence of MWCNTs. Hence, this provides a real demonstration that MWCNTs are the principal monomers in the polymerization reaction, and therefore, they are responsible for generating the three-dimensional monolithic structure. In this context, EDMA acts only as a cross-linker monomer reinforcing the monolithic structure of MWCNTs. In addition, in Fig. 5b, it is shown the great morphological difference between the solid obtained without MWCNTs and MWCNT monoliths (Fig. 6), showing a typical globular structure of methacrylate polymers. However, when MWCNTs were added to the emulsion, the monolithic structure was obtained for all percentages (from 1 to 3 wt%) of MWCNTs. Figure 7 shows the micrographs for the monoliths with 1 and 3 wt% in which the greater wall thickness and quantity of MWCNTs per nanometer obtained with high percentages is especially highlighted.

In view of the above, emulsion with 50/10 (w/w%) of chloroform/EDMA and 3 wt% of MWCNTs was selected as optimum emulsion in order to prepare stable monolithic units with high specific surface areas (372.2 m2 g−1). Micrographs at different magnifications were acquired to characterize its morphology and porous structure. Low magnifications (Fig. 6a, b) confirmed successful three-dimensional network formation between individual nanotubes and the pores formed by the surfactant and the aqueous phase during the polymerization step. Large pores showed average sizes of 20 μm with cylindrical shapes. Moreover, micrographs at higher magnifications (Fig. 6c, d) depicted that the tubes were welded together under the influence of UV irradiation and the crosslinking at their contact region. Micrometer-sized walls were obtained as a result of the linked MWCNTs (indicating their corresponding junction points by yellow circles). Another advantage of this final solid is that the EDMA coating is thinner which facilitates the π-interactions between the analytes and the graphitic carbon surface of the nanoparticles. As proof of its versatility, the final monolithic solid prepared in several plastic caps with different shapes, diameters, and heights is shown in Fig. 8. It should be noted the high stability of all units prepared as well as the possibility of reusing plastic caps by making a simple pre-modification of its internal wall.

Application to the extraction and preconcentration of chlorophenols from human urine samples

The monolithic sorbent was employed for the extraction of the five chlorophenols (4-chlorophenol, 2,6-dichlorophenol, 2,3-dichlorophenol, 3,4-dichlorophenol, 2,4,5-trichlorophenol) from human urine samples following the extraction procedure described in the “Experimental section.” All the variables involved in the extraction procedure were studied following a univariable methodology, in order to isolate the effect of each variable on the new proposed method (discussion and related figures are shown in the ESM). The optimal conditions were (a) sample volume of 25 mL, (b) stirring rate of 500 rpm, (c) 100 g L−1 NaCl, and (d) extraction time of 180 min.

The method was validated in terms of sensitivity, linearity, and precision. Thus, the corresponding calibration graphs were constructed by extracting in duplicate nine working aqueous standards containing the five analytes at different concentrations (10–10,000 μg L−1). For all the analytes, a good linearity (R > 0.99) was observed. The limits of detection (LODs) and limits of quantification (LOQs), which were calculated by using a signal-to-noise of 3 and 10, respectively, are shown in Table 1. Moreover, the reproducibility (expressed as relative standard deviation, RSD) in both the synthesis (inter-units from different syntheses) and the extraction procedure (intra-units) was tested and also given in Table 1.

Finally, the accuracy of the method was evaluated through a recovery study. Three different blank urine samples were fortified with the target chlorophenols at a concentration of 500 μg L−1, and they were left to stand refrigerated for 24 h prior to analysis. The urine samples enriched with the analytes were extracted with independent extraction units. The recovery values (n = 3) were calculated dividing the concentration found by the concentration added and expressed in percentage. The results obtained are listed in Table 1, which varied between 91 and 98%, demonstrating that there are no inferences of the matrix with the analytes. Although a worse precision of the data was obtained in comparison with the values obtained with aqueous standards, the method efficiently extracts chlorophenols from human urine.

Conclusions

Monolithic solids consisting of interconnected MWCNTs were prepared in recycled plastic caps. Firstly, organic phase containing the MWCNTs was mixed with an aqueous phase by using a surfactant. Once the mixture was homogeneous, the caps, which were pre-treated in order to link the solid to their inner walls, were filled and placed under UV light for 3 h. The UV energy gave rise to the polymerization reaction getting to crosslink the MWCNTs between them until forming a three-dimensional and macroscopic monolithic structure. This structure presented pores with an average size of 20 μm, which were generated by removing the internal aqueous phase and the surfactant.

Although this methodology to obtain monolithic solids formed only by carbon nanoparticles via the formation of a medium internal phase emulsion using UV energy to initiate the polymerization is based on our previous work [25], several differences can be highlighted. First, carbon nanohorns instead of carbon nanotubes were employed in that approach to form the monolithic structure. In this context, the differences found in the optimization of the both syntheses, including amount of cross-linker and nanoparticles as well as the irradiation time required to complete the polymerization and consequently achieve a stable and robust monolithic structure, are associated with the type of carbon nanostructure (carbon nanohorns or carbon nanotubes) selected and the system/support which the polymerization and extraction is carried out (pipette tips or stirred caps).

It should be noted that this approach allowed to reuse plastic caps from used bottles as well as to obtain porous and mechanically stable solids composed mainly of MWCNTs inside the caps. Consequently, the developed monolithic extraction units withstood high agitation speeds without breaking or losing part of the solid. In addition, solids with a great variety of diameters and heights were prepared, thus opening the range of possibilities in terms of sorbents. A proof-of-concept study demonstrated both methylene blue and chlorophenols were retained and subsequently pre-concentrated from water and biological samples.

References

Intrchom W, Mitra S. Analytical sample preparation, preconcentration and chromatographic separation on carbon nanotubes. Curr Opin Chem Eng. 2017;16:102–14.

Harris PJ. Carbon nanotubes and related structures: new materials for the twenty-first century. AAPT. 2004.

Herrera-Herrera AV, González-Curbelo MÁ, Hernández-Borges J, Rodríguez-Delgado MÁ. Carbon nanotubes applications in separation science: a review. Anal Chim Acta. 2012;734:1–30.

Speltini A, Merli D, Profumo A. Analytical application of carbon nanotubes, fullerenes and nanodiamonds in nanomaterials-based chromatographic stationary phases: a review. Anal Chim Acta. 2013;783:1–16.

Liu L, Ma W, Zhang Z. Macroscopic carbon nanotube assemblies: preparation, properties, and potential applications. Small. 2011;7:1504–20.

Du R, Zhao Q, Zhang N, Zhang J. Macroscopic carbon nanotube-based 3D monoliths. Small. 2015;11:3263–89.

De Marco M, Markoulidis F, Menzel R, Bawaked SM, Mokhtar M, Al-Thabaiti SA, et al. Cross-linked single-walled carbon nanotube aerogel electrodes via reductive coupling chemistry. J Mater Chem A. 2016;4:5385–9.

Schütt F, Signetti S, Krüger H, Röder S, Smazna D, Kaps S, et al. Hierarchical self-entangled carbon nanotube tube networks. Nat Commun. 2017;8:1215.

Zou J, Liu J, Karakoti AS, Kumar A, Joung D, Li Q, et al. Ultralight multiwalled carbon nanotube aerogel. ACS Nano. 2010;4:7293–302.

Lalwani G, Kwaczala AT, Kanakia S, Patel SC, Judex S, Sitharaman B. Fabrication and characterization of three-dimensional macroscopic all-carbon scaffolds. Carbon. 2013;53:90–100.

Fresco-Cala B, Cárdenas S. Potential of nanoparticle-based hybrid monoliths as sorbents in microextraction techniques. Anal Chim Acta. 2018.

Iacono M, Connolly D, Heise A. Fabrication of a GMA-co-EDMA monolith in a 2.0 mm id polypropylene housing. Materials. 2016;9:263.

Huang X, Chen L, Lin F, Yuan D. Novel extraction approach for liquid samples: stir cake sorptive extraction using monolith. J Sep Sci. 2011;34:2145–51.

Huang X, Wang Y, Yuan D, Li X, Nong S. New monolithic stir-cake-sorptive extraction for the determination of polar phenols by HPLC. Anal Bioanal Chem. 2013;405:2185–93.

Lin F, Nong S, Huang X, Yuan D. Sensitive determination of organic acid preservatives in juices and soft drinks treated by monolith-based stir cake sorptive extraction and liquid chromatography analysis. Anal Bioanal Chem. 2013;405:2077–81.

Lucena R, Simonet B, Cárdenas S, Valcárcel M. Potential of nanoparticles in sample preparation. J Chromatogr A. 2011;1218:620–37.

Jiménez-Soto JM, Lucena R, Cárdenas S, Valcárcel M. Solid phase (micro) extraction tools based on carbon nanotubes and related nanostructures. 2010.

Cárdenas S, Lucena R. Recent advances in extraction and stirring integrated techniques. Separations. 2017;4:6.

Lucena R. Extraction and stirring integrated techniques: examples and recent advances. Anal Bioanal Chem. 2012;403:2213–23.

Ahlborg UG, Thunberg TM, Spencer HC. Chlorinated phenols: occurrence, toxicity, metabolism, and environmental impact. CRC Crit Rev Toxicol. 1980;7:1–35.

Honda M, Kannan K. Biomonitoring of chlorophenols in human urine from several Asian countries, Greece and the United States. Environ Pollut. 2018;232:487–93.

Fresco-Cala B, Cárdenas S, Herrero-Martínez JM. Preparation of porous methacrylate monoliths with oxidized single-walled carbon nanohorns for the extraction of nonsteroidal anti-inflammatory drugs from urine samples. Microchim Acta. 2017;6:1863–71.

Fresco-Cala B, Mompó-Roselló O, Simó-Alfonso EF, Cárdenas S, Herrero-Martínez JM. Carbon nanotube-modified monolithic polymethacrylate pipette tips for (micro)solid-phase extraction of antidepressants from urine samples. Microchim Acta. 2018;185:127.

Garcia-Valverde MT, Lucena R, Cardenas S, Valcarcel M. In-syringe dispersive micro-solid phase extraction using carbon fibres for the determination of chlorophenols in human urine by gas chromatography/mass spectrometry. J Chromatogr A. 2016;1464:42–9.

Fresco-Cala B, Cárdenas S. Preparation of macroscopic carbon nanohorn-based monoliths in polypropylene tips by medium internal phase emulsion for the determination of parabens in urine samples. Talanta. 2019;198:295–301.

Acknowledgments

The authors would like to thank the Central Service for Research Support (SCAI) of the University of Córdoba for the service provided to obtain the micrographs.

Funding

Financial support from the Spanish Ministry of Science and Innovation (CTQ2017-83175R) is gratefully recognized.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Informed consent was obtained from all individual participants involved in the study. The study has been approved by the appropriate ethics committee (Comité de Ética de la Investigación de Córdoba) and has been performed in accordance with the ethical standards.

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 333 kb)

Rights and permissions

About this article

Cite this article

Oliva-Lamarca, Y., Fresco-Cala, B. & Cárdenas, S. Synthesis, characterization, and application of chemically interconnected carbon nanotube monolithic sorbents by photopolymerization in polypropylene caps. Anal Bioanal Chem 411, 3291–3299 (2019). https://doi.org/10.1007/s00216-019-01795-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-019-01795-1