Abstract

A novel porous monolith has been prepared and used as a sorbent in stir-cake-sorptive extraction (SCSE). The monolithic material was prepared by in-situ copolymerization of allyl thiourea (AT) and divinylbenzene (DB) in the presence of dimethylformamide as a porogen solvent. To optimize the polymerization conditions, different monoliths with different ratios of functional monomer to porogenic solvent were prepared, and their extraction efficiency was investigated in detail. The monolith was characterized by elemental analysis, scanning electron microscopy, mercury intrusion porosimetry, and infrared spectroscopy. Analysis of polar phenols in environmental water samples by a combination of ATDB-SCSE and HPLC with diode-array detection was selected as a model for the practical application of the new sorbent. Several extraction conditions, including extraction and desorption time, pH, and ionic strength of the sample matrix were optimized. The results showed that the new monolith had high affinity for polar phenols and could be used to extract them effectively. Under the optimum conditions, low detection (S/N = 3) and quantification (S/N = 10) limits were achieved for the phenols, within the ranges 0.18–0.90 and 0.59–2.97 μg L−1, respectively. The linearity of the method was good, and the method enabled simple, practical, and low-cost extraction of these analytes. The distribution coefficients between ATDB and water (K ATDB/W) were calculated for the phenolic compounds and compared with K O/W. Finally, the proposed method was successfully applied to the determination of the compounds in three environmental water samples, with acceptable recovery and satisfactory repeatability.

HPLC chromatograms of real water sample treated with ATDB-SCSE (a) and spiked water sample treated with ATDB-SCSE (b)

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Porous monoliths were first introduced by Hjerten et al. in 1989 [1] and subsequently developed by other research groups [2–5]. Preparation of monoliths is very simple—polymerization of a monomer mixture with a porogen solvent in a suitable container to form a porous polymer bed. Monoliths have many advantages, for example, ease of preparation, high reproducibility, versatile surface chemistry, and rapid mass transport. Because of these outstanding characteristics, monoliths have been widely used as stationary phases in HPLC [6, 7], capillary HPLC [8], and capillary electrochromatography (CEC) [9, 10]. Recently, porous monoliths have also been used as adsorbents in extraction techniques, for example, SPE [11, 12], in-tube SPE [13, 14], solid-phase microextraction [15], and SBSE [16, 17].

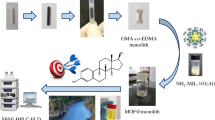

Among the different extraction formats, stir extraction is interesting because of operational simplicity. There are several formats of stir extraction with monoliths as sorbents, for example, stir-bar-sorptive extraction (SBSE) [16], stir-rod-sorptive extraction (SRSE) [18], and stir-cake-sorptive extraction (SCSE) [19]. We have prepared a series of new coatings based on monoliths for SBSE (SBSEM) [16, 20–23]. The SBSEMs were successfully used to extract organic pollutants [16, 19–22] and inorganic ions [23] from all kinds of matrix. However, the coatings were damaged during the stirring process because the stir bar was in direct contact with the bottom of the sample vessel. As a result, the SBSE could be re-used only 20–60 times (80–200 h) [19–21]. To avoid frictional loss of the monolithic polymer coatings, a new poly(2-acrylamide-2-methylpropanesulfonic acid-co-octadecyl methacrylate-co-ethylene glycol dimethacrylate) monolith as adsorbent for SRSE was prepared by Feng et al. [18]. The rod could be re-used at least 60 times, but the procedure for preparation of the coating and the operating procedure for extraction were not convenient. In our previous study, SCSE using a poly(vinylimidazole-co-divinylbenzene) (VIDB) monolith as adsorbent was developed [19]. Use of VIDB-SCSE was very simple. First, the VIDB-based monolithic cake was synthesized by in-situ polymerization; the cake was then inserted in a holder constructed from a syringe cartridge to enable magnetic stirring of the cake during the extraction process. The results showed that VIDB-SCSE enabled effective extraction of steroid hormones from milk. Because the monolithic cake did not make contact with the vessel wall during stirring and there was no frictional loss of adsorbent, its longevity was excellent and it could be re-used at least 250 times. This SCSE also had other advantages, for example simple operation and high adsorbent capacity, and was cost-effective and environmentally friendly.

Phenol and substituted phenols are strong polar compounds with very low octanol–water distribution coefficients (K O/W); log K O/W for phenol, for example, is only 1.46. Their low K O/W values indicate that phenolic compounds are strongly hydrophilic and are difficult to extract from aqueous samples [24, 25]. Several extraction procedures, for example liquid–liquid extraction (LLE) [26], solid-phase extraction (SPE) [27], solid-phase micro-extraction (SPME) [28], and SBSE [24, 25] have been developed for separation and enrichment of phenols, but these procedures have disadvantages. For LLE, large amounts of poisonous organic solvent are used [26]; variability and low recovery of SPE have been reported [27]; the adsorbent capacity of SPME is too low [28]; when PDMS-based SBSE was used to extract polar phenols, derivatization was necessary to increase extraction efficiency, and the derivatization procedure was inconvenient and harmed the coating [24, 25]. We have used SBSE based on poly(vinylpyrrolididone-co- divinylbenzene) (VPDB) monolith to enrich phenols [29]. The VPDB-SBSE can be used for direct extraction of phenols without derivatization, but the enrichment capacity was not good and the VPDB-SBSE adsorbent could be re-used only 20 times. Therefore, developing a simple and effective method for extraction of phenols is still of interest to researchers.

In this research, a novel monolithic adsorbent for SCSE was prepared from poly(allyl thiourea-co-divinylbenzene) (ATDB). The effect of preparation and extraction conditions on the performance of ATDB-SCSE for polar phenols was investigated in detail, and a new method combining ATDB-SCSE and liquid desorption, followed by HPLC with diode-array detection (ATDB-SBSE–LD–HPLC–DAD) was developed for analysis of trace phenols in environmental water samples. The results showed that the new ATDB-SCSE method could be used to extract and concentrate polar phenols effectively, and the adsorbent could be used for more than 1,200 h.

Experimental

Chemicals and reagents

Allyl thiourea (AT) (98 %) and divinylbenzene (DB) (80 %) were supplied by Alfa Aesar (Tianjin, China); azobisisobutyronitrile (AIBN) (97 %, recrystallized before use) and dimethylformamide (DMF) (97 %) were purchased from Shanghai Chemical (China); HPLC-grade acetonitrile (ACN) and methanol were purchased from Tedia (Fairfield, USA). Water used throughout the study was purified by use of a Milli-Q water-purification system (Millipore, USA). Phenol (P), bisphenol A (BPA), o-nitrophenol (o-NP), 2,4-dichlorophenol (2,4-DCP), 2,4-dimethylphenol (2,4-DMP), and 4-chloro-3-methylphenol (4-C-3-MP) of analytical grade were supplied by Alfa Aesar (Tianjin, China).

Standard solutions (1,000 mg L−1) of each phenol were prepared in methanol, and renewed monthly. A mixed standard solution of the six phenols was prepared by dissolving 10.00 mg of each compound in methanol in a 10-mL volumetric flask. The stock solutions were stored at 4 °C and diluted with ultra-pure water to the required concentration when used.

Instrumentation

The morphology of the monolith was examined by use of a model XL30 scanning electron microscope (SEM) (Philips, Eindhoven, The Netherlands). The pore size distribution of the ATDB was measured by use of a mercury intrusion porosimeter (MIP) (Porous Materials, Ithaca, NY, USA). Elemental analysis (EA) was performed with a PerkinElmer (Shelton, CT, USA) model PE 2400. FT-IR spectroscopy was performed with an Avatar-360 instrument (Thermo Nicolet, Madison, WI, USA).

HPLC analysis was performed with a Shimadzu (Japan) LC system equipped with a binary pump (LC-20AB) and a diode-array detector (DAD) (SPD-M20A). Sample injection was performed with a RE3725i manual sample injector with a 20-μL loop (Rheodyne, Cotati, CA, USA), all experiments were performed at room temperature.

Chromatographic conditions

The phenolic compounds were separated on a Supelco C18 column (5 μm particle size, 250 mm × 4.6 mm i.d.). The mobile phase was a 1:1 (v/v) mixture of ACN and water, and the flow rate was 1.0 mL min−1. The injection volume was 20 μL and the detector wavelength was set at 271 nm.

Preparation of the ATDB-SCSE unit

The ATDB-SCSE unit was prepared in three steps. The first was synthesis of ATDB monolithic cake. AIBN (1 % (w/w) of the total amount of monomer) was used as polymerization initiator in all polymerization reactions. Different monomers and porogen concentrations were used for different ATDB (Table 1). The monomer mixture and porogen (DMF) were mixed ultrasonically to form a homogeneous solution and the reactant solution was then purged with nitrogen for 3 min. Subsequently, the reactant mixture was poured into a syringe cartridge (12 mm i.d.), one side of which was blocked by plugging with a syringe. The cartridge was then sealed with septa and kept at 70 °C for 24 h. After polymerization, the ATDB monolithic cake was pushed out slowly by use of the handspike of the syringe. The cake was extracted with methanol in a Soxhlet apparatus for 24 h to remove residual monomers, porogen, uncross-linked polymers, and initiator. Finally, the ATDB was dried in air for 1 h to obtain the final monolithic cake (12 mm diameter and 2 mm thick). The polymerization equation is given in Fig. 1.

In the second step, the extraction holder for SCSE was constructed. The construction process is described in detail elsewhere [19]. Briefly, a syringe cartridge (6 mm height and 12 mm i.d.) was used as the holder; one side of the cartridge was indented by cutting so that as much of the ATDB monolithic cake as possible was in contact with the sample. On the other side, the cartridge was pierced by a laboratory-prepared, glass-protected, iron wire (1 mm diameter, 13 mm long) to enable magnetic stirring of the device. To enable sample flow through the stir cake system, six small holes (1 mm diameter) were drilled around the cartridge.

After construction of extraction holder, the ATDB monolithic cake was gently inserted into the holder to furnish the ATDB-SCSE unit.

Extraction and desorption mode

In this study, stirred extraction and stirred liquid-desorption (LD) modes were used. The samples were stirred at 300 rpm by use of the SCSE unit at room temperature. A mixed solution of BPA and o-NP (100 μg L−1 of each; 100 mL) was used to study the effect of polymerization conditions on extraction efficiency. In the study of the optimum conditions for extraction of phenolic compounds, 100 mL of a mixed solution containing the six target compounds (100 μg L−1 each) was used. After the extraction, the ATDB-SCSE unit was removed, immersed in 3.0 mL methanol, and stirred for a specific time to release the extracted analytes. The stripping desorption solution was used directly for HPLC–DAD analysis.

Calculation of the distribution coefficients of the phenols between ATDB and water (K ATDB/W)

In the same way as for calculation of K O/W [30], the distribution coefficients K ATDB/W for phenolic compounds were calculated by use of Eq. (1):

where K ATDB/W is defined as the ratio, at equilibrium, of the concentration of a solute in the ATDB phase (C ATDB) to the concentration of the solute in water (C W). This ratio is equal to the ratio of the mass of the solute in the ATDB phase (m ATDB) to that in the aqueous phase (m W) multiplied by β (where β = V W/V ATDB, and V W and V ATDB are the volumes of water and monolith, respectively). In this study, the β value was 442.5.

Results and discussion

Preparation and characterization of the ATDB-SCSE unit

To obtain the best extraction performance in ATDB-SCSE, the effect of monomer and porogen content on extraction efficiency was studied in detail. BPA and o-NP were selected to investigate the effect of monomer and porogen concentrations on extraction efficiency (Table 1). The results showed that the amounts of monomer and porogen had an important effect on the extraction performance of ATDB-SCSE. Considering the extraction performance and useful longevity, the optimized conditions for preparation of the ATDB monolithic cake were: proportion of AT in the monomer mixture 40 %, and the ratio of monomer mixture to porogen 45–55 % (w/w) (Table 1, ATDB-8). Good cake to cake reproducibility was observed in ATDB-SCSE . The RSD (n = 4) of enrichment factors for BPA and o-NP were 5.75 % and 3.48 %, respectively.

The new ATDB monolithic cake prepared under the optimum conditions (cake 8) was characterized by EA, IR, MIP, and SEM. EA of the ATDB revealed its C, N, and S content were 61.2 % (w/w), 6.85 % (w/w), and 8.82 % (w/w), respectively, indicating that AT and DB were successfully incorporated into the monolith during the polymerization process. FT-IR analysis (Electronic Supplementary Material; Fig. S1) of the structure of the final monolith further confirmed the polymerization of AT and DB. The spectrum contains a strong peak at approximately 2,925.8 cm−1, which can be attributed to the CH3 and CH2 groups. A weak band at 1,018.8 cm−1 indicates the presence of C = S groups. The adsorption peaks observed at 1,625.9, 1,602.6, and 1,509.2 cm−1 are those of phenyl groups. The medium bands at 3,015.4, 1,485.8, 1,443.0 cm−1 indicate the presence of C–N and NH2 in the ATDB monolith. Figure 2a shows the SEM image of the ATDB monolith at 20,000× magnification. The interconnected skeleton and the pores in the texture of the monolithic material are clearly apparent. The skeleton and pores are evenly distributed throughout the monolith. They are also interwoven together, leading to the formation of an interpenetrating network. Figure 2b shows the pore-size distribution plot. Two types of pore were present in the monoliths—large, with pore size approximately 550 nm, and mesopores, with pore size approximately 120 nm. This result is in good accord with the SEM. The presence of large pores ensures the monolith has very good permeability, enabling favorable mass transfer in extraction applications. The total surface area of the material, calculated from the Brunauer–Emmett–Teller (BET) plot, is 13.8 m2 g−1. The relatively large surface area ensures the extraction capacity of the new ATDB-SCSE method is high.

Optimization of ATDB-SCSE for polar phenols

To investigate the extractive ability of ATDB-SCSE for phenolic compounds, ATDB-SCSE was used to extract six phenols present at trace concentrations in water samples, without derivatization. Several important conditions, including extraction and desorption time, and the pH and ionic strength of the sample matrix, were studied in detail to optimize the extraction conditions.

Effect of extraction and desorption time

The extraction time profiles of the six phenols were monitored by varying the extraction time from 0.5 to 3.0 h (Fig. 3a). The results showed that amount extracted increased substantially when the extraction time was increased from 0.5 to 2.5 h, and did not obviously change when extraction time was further prolonged. The sharp slopes of the profiles between 0.5 to 2.5 h indicate that the ATDB monolith had remarkable extraction capacity for these analytes. The effect of liquid desorption time was also studied by varying the time from 0.25 to 2.0 h (Fig. 3b). It was found that 0.25 h was sufficient for desorption of the compounds in ATDB-SCSE when the extraction time was 2.5 h. Consequently, 2.5 and 0.25 h were adopted for the extraction and desorption procedures, respectively, in subsequent research.

Effect of pH

There are polar amino groups in the ATDB monolith, and phenols also are polar compounds, so sample pH will substantially affect extraction efficiency. Figure 4 shows the effect on extraction efficiency of matrix pH over the range 3.0–12.0. The results showed that the efficiency of extraction of all the analytes improved slowly when the pH was increased from 3.0 to 8.0, and then decreased when the pH was increased further.

This interesting trend may be explained as follows. At low pH the phenols are neutral; therefore, hydrophobic interaction between the monolith and the analytes is the main mechanism of extraction. With increasing pH, ionization of the phenols occurs. At the same time, the amino groups in monolith are activated. Thus anion-exchange interaction between the phenols and the amino groups also contributes to extraction, which leads to increased extraction efficiency. However, when the pH is increased further, the favorable anion-exchange interaction is weakened because hydroxyl groups in the samples compete with phenol groups to interact with the activated amino groups. At the same time, increasing ionization of the phenols results in a decrease in the hydrophobic interaction. Therefore, the extraction performance of ATDB-SCSE decreases at high pH. The experimental results demonstrate well that not only hydrophobic interaction but also anion-exchange interaction contribute to the extraction. According to these results, setting the matrix pH to 8.0 is recommended for extraction of polar phenols by ATDB-SCSE.

The effect of ionic strength

According to our previous research [20–22], appropriately increasing the ionic strength of the sample matrix would increase the extraction performance for polar compounds. In this study, the ionic strength of the matrix was adjusted by addition of NaCl from 0 to 30 % (w/v) (Fig. 5). Results indicated that the efficiency of extraction of the compounds was highest at 5 %. Use of NaCl above 5 % reduced extraction of phenols in ATDB-SCSE. An initial increase and then a decrease in extraction efficiency with increasing concentration of sodium chloride can be explained on the basis of two simultaneously occurring processes as described by Lord and Pawliszyn [31]. Initially, extraction efficiency was increased because of the salting out effect. In competition with this process, however, was the fact that polar molecules might participate in electrostatic interaction with the salt ions in solution, thereby reducing their ability to move into the extraction phase, which reduced the extraction efficiency. Thus, initially, the salting out effect was predominant and increased the extraction efficiency; then electrostatic interaction reduced the efficiency. On the basis of on these observations, an overall salt concentration of 5 % (w/v) was selected for further studies.

From these experimental results, the optimized conditions for extraction of polar phenols by ATDB-SCSE were: extraction and desorption time 2.5 and 0.25 h, respectively; matrix pH 8.0; and overall salt concentration in the matrix 5 %.

Calculation of K ATDB/W

Six phenolic compounds spiked at 50 μg L−1 were analyzed by ATDB-SCSE–LD–HPLC–DAD under the above optimized conditions. A typical chromatogram is shown in Fig. 6b. Compared with direct injection (Fig. 6a), the peak heights obtained for the six phenols obviously increase after enrichment. Table 2 shows K ATDB/W and K O/W for the phenolic compounds. According to Ref. [30], distribution coefficients (K) give a good indication of whether and how well a given solute can be extracted by a sorbent. It can be seen from the table that the values of K ATDB/W for all the phenols are higher than their corresponding K O/W, which means the ATDB monolith has high affinity for the phenols. The reason is that there are activated urea groups in the ATDB monolith; it can, therefore, be used for effective extraction of phenols by hydrophobic interaction and anion exchange. Because of the high extraction capacity of ATDB-SCSE, substantial enhancement of the peak height can be achieved, which indicates that a lower detection limit could be achieved by ATDB-SCSE.

HPLC chromatograms of six phenols in spiked Milli-Q water sample. (a) Direct injection of spiked water sample with each analyte at 50 μg L−1; (b) spiked water sample with each analyte at 50 μg L−1 and treated with ATDB-SCSE. Conditions: extraction and desorption time were 2.5 h and 0.25 h, respectively; pH was 8.0; overall salt concentration of matrix was set at 5 %

Validation of the ATDB-SCSE–LD–HPLC–DAD method

Blank water samples were spiked with the phenols and analyzed to evaluate the developed method. Linear dynamic range, correlation coefficients, recovery, limits of detection (LODs), limits of quantification (LOQs), and reproducibility for the phenols under the optimized experimental conditions are listed in Table 3. It is apparent the performance of this method is good. The linear dynamic range for a 100-mL sample was 2.0–200.0 μg L−1 for P, BPA, 2,4-DMP, 4-C-3-MP, and 2,4-DCP and 1.0–200.0 μg L−1 for o-NP, all with good linearity (R 2 > 0.99). The LODs and LOQs were determined as the concentrations for which signal-to-noise ratios were 3 and 10, respectively; these were in the ranges 0.18–0.90 and 0.61–2.98 μg L−1, respectively. The LODs and LOQs were low enough for analysis of trace levels of phenol residues in water samples. The precision of the method was evaluated by determination of within and between-day repeatability, calculated as RSD; all RSDs were <8 %. These results show that the precision and accuracy of the method are acceptable for routine monitoring purposes. ATDB-SCSE also has excellent longevity. Compared with SBSE, the extractive medium in SCSE does not make contact with the wall of the vessel during stirring, therefore, there is no frictional loss of sorbent. When ATDB-SCSE was used continuously for more than 1,200 h there was no obvious change in extraction performance. The RSD (n = 6) values of peak area during the investigation of stability for P, BPA, o-NP, 2,4-DMP, 4-C-3-MP, and 2,4-DCP were 5.82 %, 8.84 %, 9.33 %, 8.18 %, 6.58 %, and 9.21 %, respectively (peak-area details are given in the Electronic Supplementary Material, Table S1). The excellent longevity of ATDB-SCSE indicates that the running cost can be reduced in practical application.

Our method was compared with other reported sample-preparation procedures; the results are presented in Table 4. LODs were lower in this method than in other methods with the same kind of detector. Typically, lower LODs can be obtained by GC–MS than by HPLC–DAD in the determination of phenols. However, for determination of all six phenols, the proposed method had lower LOD values than SPE–GC–MS. It was also found that the LODs of all the phenols studied by use of this method were lower than in our previous research.

Analysis of water samples

When water samples were analyzed by use of this method, low concentrations of 2,4-DMP were detected in Furong lake and in the reservoir at Xiamen University (Table 5). To validate the feasibility of the method, extraction recovery was assessed after spiking real samples with mixed standard solutions at 10 and 100 μg L−1. Typical chromatograms obtained from un-spiked and spiked water samples by use of this method are shown in Fig. 7. Acceptable recovery and reproducibility were obtained; recovery varied from 63.4 % to 115 % and RSD for reproducibility was less than 9 % for all the analytes in all the samples (Table 5), demonstrating good method feasibility.

HPLC chromatograms of Furong lake water in Xiamen university treated with ATDB-SCSE. (a) water sample directly treated with ATDB-SCSE (b) spiked water sample with each analyte at 100 μg L−1 and treated with ATDB-SCSE. The conditions were the same as in Fig. 6

Conclusions

In this study, a new SCSE method based on poly(allyl thiourea–divinyl benzene) monolithic material as adsorbent was developed. Because there are abundant polar urea groups in the porous ATDB monolith, it had high affinity for polar phenols. The hyphenated method ATDB-SCSE–LD–HPLC–DAD was successfully applied to direct determination of six strongly polar phenols at trace levels in water samples without derivatization. In comparison with existing extraction methods for determination of phenols, the proposed method was simple, sensitive, cost-effective, stable, and environmentally friendly. We therefore hope it can become a useful and practical method for monitoring phenols in water samples or other matrices.

References

Hjerten S, Liao JL, Zhang R (1989) J Chromatogr 473:273–278

Svec F (2012) J Chromatogr A 1228:250–262

Hara T, Kobayashi H, Ikegami T, Nakanishi K, Tanaka N (2006) Anal Chem 78:7632–7642

Lin H, Ou JJ, Zhang ZB, Dong J, Wu MH, Zou HF (2012) Anal Chem 84:2721–2728

Hoth DC, Rivera JG, Colon LA (2005) J Chromatogr A 1079:1–2

Yang GL, Yan CH, Bai LG, Li J, Duan YH (2012) Anal Meth 4:1098–1104

Brice RW, Zhang X, Colon LA (2009) J Sep Sci 32:15–16

Huang XJ, Wang QQ, Yan H, Huang Y, Huang BL (2005) J Chromatogr A 1062:183–188

Lei W, Zhang LY, Wan L, Shi BF, Wang YQ, Zhang WB (2012) J Chromatogr A 1239:64–71

Liang Y, Zhu GJ, Wang TT, Zhang XD, Liang Z, Zhang LH, Zhang YK (2011) Electrophoresis 32:2911–2914

Nema T, Chan ECY, Ho PC (2010) Talanta 82:488–494

Bravo JC, Garcinuño RM, Fernández P, Durand JS (2007) Anal Bioanal Chem 388:1039–1045

Zheng MM, Ruan GD, Feng YQ (2010) J Chromatogr A 1216:7510–7519

Thabano JRE, Breadmore MC, Hutchinson JP, Johns C, Haddad PR (2007) J Chromatogr A 1175:117–126

Qiu LJ, Liu W, Huang M, Zhang L (2010) J Chromatogr A 1217:7461–7470

Huang XJ, Qiu NN, Yuan DX (2008) J Chromatogr A 1194:134–138

Bratkowska D, Marcé RM, Cormack PAG, Borrull F, Fontanals N (2011) Anal Chim Acta 706:135–142

Liu YB, Ma Q, Feng YQ (2010) J Chromatogr A 1217:3583–3589

Huang XJ, Chen LL, Lin FH, Yuan DX (2011) J Sep Sci 34:2145–2151

Huang XJ, Yuan DX (2007) J Chromatogr A 1154:152–157

Huang XJ, Qiu NN, Yuan DX, Lin QM (2010) J Chromatogr A 1217:2667–2673

Huang XJ, Yuan DX, Huang BL (2008) Talanta 75:172–177

Huang XJ, Lin JB, Yuan DX (2010) J Chromatogr A 1217:4898–4903

Kawaguchi M, Ishii Y, Sakui N, Okanouchi N, Ito R, Saito K, Nakazawa H (2005) Anal Chim Acta 533:57–65

Kawaguchi M, Inoue K, Yoshimura M, Sakui N, Okanouchi N, Ito R, Yoshimura Y, Nakazawa H (2004) J Chromatogr A 1041:19–27

Jeannot R, Sabik H, Sauvard E, Dagnac T, Dohrendorf K (2002) J Chromatogr A 974:143–159

Braun P, Moeder M, Schrade S, Popp P, Kuschk P, Engewald W (2003) J Chromatogr A 988:41–51

Sirvent G, Hidalgo M, Salvad V (2004) J Sep Sci 27:613–618

Huang XJ, Qiu NN, Yuan DX (2009) J Sep Sci 32:1407–1414

Poole SK, Poole CF (1995) Analyst 120:1733–1738

Lord H, Pawliszyn J (2000) J Chromatogr A 902:17–63

Cladera A, Miró M, Estela JM, Cerdà V (2000) Anal Chim Acta 421:155–166

Wu YL, Hu B, Hou YL (2008) J Sep Sci 31:3772–3781

Simoes NG, Cardoso VV, Ferreira E, Benoliel MJ, Almeida CMM (2007) Chemosphere 68:501–510

Helaleh MIH, Takabayashi FS, Korenag T (2001) Anal Chim Acta 428:227–234

Schilling R, Clarkson PJ, Cooke M (1998) Fresenius J Anal Chem 360:90–94

Acknowledgements

Dr XJ Huang is grateful for support from the National Natural Science Foundation of China (grant 21077085), the Scientific Research Foundation for Returned Overseas Chinese Scholars, the State Education Ministry, the New Century Excellent Talents in Fujian Province University, and Fundamental Research Funds for Central Universities (no. CXB2011037). Dr XJ Li is grateful for support from the Fujian Provincial Key Program of Science and Technology (no. 2011Y0001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the topical collection Monolithic Columns in Liquid Phase Separations with guest editor Luis A. Colon.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 213 kb)

Rights and permissions

About this article

Cite this article

Huang, X., Wang, Y., Yuan, D. et al. New monolithic stir-cake-sorptive extraction for the determination of polar phenols by HPLC. Anal Bioanal Chem 405, 2185–2193 (2013). https://doi.org/10.1007/s00216-012-6301-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-012-6301-3