Abstract

In the product development process, structural optimization plays vital role because it deals with size, shape and topology of the structures. However, structural performance greatly depends on its geometric shape and hence structural shape optimization has remained one of the most active research areas since early 1970s. Conventional parametric shape optimization technique employs grid-based numerical tools like FEM and BEM for structural analysis, which experiences some innate limitations like mesh distortion and frequent remeshing, element locking and poor approximation while dealing with large shape changes during the optimization process. Meshless Methods (MMs) can alleviate these issues when used as a structural analysis tool in shape optimization. In last two decades, MMs have been explored for structural shape optimization along with various deterministic and stochastic optimization algorithms. The objective of present work is twofold, first is to review advanced parametric shape optimization techniques which are based on MMs like Element Free Galerkin (EFG) method and Reproducing Kernel Particle Method (RKPM) for linear elastic, thermoelastic, hyperelastic, frictional contact and structure dynamics optimization problems and second is to emphasize benefits of meshless techniques in shape optimization. Based on the review, the article presents some critical observations including Design Sensitivity Analysis (DSA) in meshless environment, numerical integration techniques in MMs and benefits of coupled FEM-MM approach in shape optimization. At the end, promising future research directions in shape optimization field based on MMs are presented along with concluding remarks.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

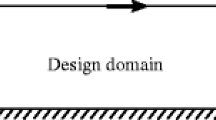

Structural optimization deals with determination of optimum layout of the structure which includes information on its size, shape and topology (Fig. 1). Conceptually, these problems deal with different aspects, for instance, sizing problem determines optimal thickness/cross-sectional area for minimizing weight, shape optimization finds best geometric shape under prescribed constraints while topology optimization decides location and size of cavities in the domain (Bendsøe and Sigmund 2002). As widely accepted reference, modern structural optimization has its root in 1960 when Schmit (1960) proposed a ‘Structural Synthesis’ technique by combining FEM with nonlinear numerical optimization method for a simple three-bar truss structure. It is worth to mention that majority of the early research dealt with sizing optimization. The development in shape optimization somewhat lagged behind because of its inbuilt nonlinearities. For comprehensive details on historical development of structural optimization field, review articles of Arora (1990) and Vanderplaats (1993) may be referred.

Shape optimization is a post processing tool used in product design process to optimize the product configuration obtained after topology optimization by modifying internal and external boundaries. Accordingly, shape optimization decides final geometric shape of the structure which can improve structural performance; hence shape optimization has remained an active research area from early 1970s to till date. The technique is comprised of three phases, i.e. geometry description & modification (design model), structural analysis (analysis model) and optimization algorithm (optimization model). For an efficient shape optimization technique, strong interaction between these models is crucial. The design model defines the problem domain under consideration with the geometric elements which subsequently gets converted into the analysis model compatible for numerical analysis for computing structural response and finally an appropriate optimization algorithm is adopted for obtaining optimum configuration through iterative process (Wall et al. 2008). In this iterative process of shape optimization, structural analysis techniques play vital role because it highly influences quality of solutions and computational time of the process. Grid-based numerical techniques like FEM and BEM have become standard tools for structural analysis in shape optimization since early 1970s. The earliest work in shape optimization with FEM was presented by Zienkiewicz and Campbell (1973) followed by Bhavikatti and Ramakrishnan in shape optimization of fillets in flat and round tension bars (1977), shoulder fillets in tension bars and T-heads (1979) and rotating disks (1980), Schnack in shape optimization for stress concentration (1979), Dems and Dems and Morz in multiparameter shape optimization of elastic bars under torsion (1978, 1980), Queau and Trompette in shape optimal design of two dimensional structures e.g. polygonal plate, fillet and spherical vessel (1980) and optimal shape design of turbine blades (1983), Bennett and Botkin in shape optimization of automotive structures (1981) and two dimensional structures with adaptive mesh refinement e.g. torque arm and bracket (1983, 1985), Imam in shape optimization of three dimensional structures (1982), Braibant et al. (1983) and Braibant and Fleury (1984, 1986) in shape optimization with CAD concepts and B-splines’ and Botkin and Bennett in three dimension folded plate structures (1985). Over a period of time, some limitations of FEM became apparent in shape optimization, like, accuracy of initial mesh for continuously changing geometry needing subsequent remeshing and inaccurate boundary stresses impairing design sensitivities, which promoted use of BEM in shape optimization around mid 1980s. Because BEM formulates the problem with boundary integral equations (BIEs) which describes the problem with known and unknown boundary states, the dimension of problem is reduced which reduces quantum of input data and computational efforts compared to FEM. Mota Soares et al. (1984a, b) were the first to employ BEM in optimizing geometry of shafts followed by Mota Soares et al. (1984a, 1984b) for minimizing compliance of two dimensional linear elastic structures, Sandgren and Wu (1988) in plane stress, plane strain and three dimensional elasticity problems, Xu and Yu (1990) in problems of minimizing stress concentrations, Yang (1990) in two-dimensional linear elastic structures e.g. an infinite plate with elliptical hole and fillet, Lee and Kwak (1991) in two dimensional thermoelastic structures, Tafreshi and Fenner (1991) in two dimensional elastic structures e.g. plate with a hole and connecting rod, Zhang et al. (1992) in shape design sensitivities for materially and geometrically non-linear problems and Yamazaki et al. (1993) in two dimensional plate with hole shapes.

1.1 MMs in shape optimization

Owing to the rapid development in computational mechanics and computer speed in last three decades, several numerical shape optimization techniques have been proposed which are broadly classified as: Parametric and Free-form techniques. The parametric technique (Fig. 1) is based on the ‘design element’ concept given in the early work by Imam (1982), Braibant et al. (1983) and Braibant and Fluery (1984). The technique is based on selection of meaningful geometrical design parameters governing the shape of the structure and considered as an extension of parametric CAD wherein the optimum configuration is located within the search space covered by design variables with externally defined objective function (Chen et al. 2007). Every change made in design variable brings change in the design domain which needs evaluation of structural performance through structural analysis by numerical simulation techniques like FEM and BEM. However, there exist numerous limitations with conventional grid-based techniques in shape optimization problems, like,

-

1)

Remeshing: Grid-based techniques need frequent remeshing to avoid distorted elements with deteriorated aspect ratios which may result in poor accuracy in a new shape design during the optimization process (Bennett and Botkin 1985).

-

2)

Mesh topology: In a gradient-based shape optimization technique, from view point of accurate sensitivities and stable optimization process, it is devisable to maintain same mesh topology for initial and perturbed geometry, during the optimization process (Kim and Choi 2005; Lacroix and Bouillard 2003; Grindeanu et al. 1999)

-

3)

Grid optimization: Conventional grid-based techniques are sensitive to node distribution in the domain which require grid optimization i.e. r-refinement (number of nodal points remain same but are repositioned) for minimizing the computational errors (Diaz et al. 1983; Ingber and Mitra 1986).

-

4)

Element locking: Conventional displacement-based FEM suffers from locking i.e. element formulation is incapable of capturing appropriate displacements in case of hyperelastic and nearly incompressible materials (whose poission’s ratio approaches 0.5 and volumetric strain 0) which results in significant loss of accuracy (Babuska and Suri 1992; Grindeanu et al. 1999; Kim et al. 2001a, b). In FEM framework, mixed interpolation i.e. displacement/pressure (u/p) is a popular approach for handling this issue wherein displacements and pressure are interpolated separately (Bathe 1996).

-

5)

Poor Accuracy: Conventional displacement -based FEM (with linear shape functions) gives discontinuous secondary field variables e.g. stress across element boundaries leading to another mathematical difficulty in imposing point stress constraints during the shape optimization process (Bobaru and Mukherjee 2001). Within FEM framework, mixed formulation based on extended variational principles e.g. Hu-Washizu functional may be used for obtaining smooth stress variation wherein displacements and stresses are treated as independent variables (Bathe 1996). Alternatively, techniques like superconvergent patch recovery and posteriori error estimates as proposed by Zienkiewicz and Zhu may be used (1987; 1992). However, at material interface, geometrical interface or loading interface, discontinuity in stresses can be captured by FEM with nodes positioned at those interfaces.

To conquer aforementioned issues related to conventional parametric shape optimization techniques based on FEM, various alternative techniques have been proposed from different perspectives:

-

a)

Isogeometric analysis (IGA): IGA as proposed by Hughes et al. (2005) has emerged as an efficient shape optimization technique in last one decade because it unifies geometric description of design and analysis model through discretization based on Non-Uniform Rational B-Spline (NURBS) elements which eliminate error-prone and time consuming conversion of geometric information from design model to analysis model at each iterative step of FEM based shape optimization.

-

b)

XFEM with level sets: Though eXtended FEM (XFEM) was mainly proposed (Moes et al. 1999; Belytschko et al. 2003a, b) to improve classical FEM in dealing with moving boundaries and discontinuities in the problem but use of XFEM along with level set description in structural optimization was firstly demonstrated by Belytschko et al. (2003a, b). Here, XFEM enables working with fixed mesh while level sets can construct and track smooth geometry in fixed grid without explicit parameterization which will be quite useful in shape optimization.

-

c)

MMs: MMs have also gained much attention by broader research community in last two decades and proved quite promising in shape optimization because they do not employ elements/mesh to construct shape function for field variable approximation in the domain; instead a set of nodes and their associated support domain are used. Thus, MMs eliminate mesh related issues of conventional shape optimization techniques.

Although main theme of this paper is shape optimization techniques based on MMs, Section 1.2 presents brief introduction and review of IGA and XFEM based shape optimization techniques for comparison.

To provide bird’s eye view of the literature on ‘parametric shape optimization techniques based on MMs’, found in the database of ‘Google Scholar’ and ‘Scopus’ (English language publications), Table 1 summarizes the basic information while detailed review, its analysis and critical observations are presented in section 3.

Though parametric approach has been extensively explored, the downside of this approach is its suitability to only those problems which are formulated with well defined design parameters e.g. distances or radii. Thus, there exist evident limitations of parametric approach in terms of its inability to support large topological changes in the structures and need of re-evaluation of the boundary representation associated with every change made in design variables. In contrast, some recent techniques in shape and topology optimization are based on free form implicit representation of design shape, which supports boundary deformation and large topological changes with ease. In the free-form approach, the shape is defined by its boundaries without any prior explicit dimensional parameterization. It searches the space of free-form shapes by incremental local motion of the free-form boundaries (Chen et al. 2007). Level set methods (LSMs) are the most frequently employed free-form shape optimization technique wherein shape is represented as a level set of a higher-dimensional surface and the problem is formulated and solved on this higher-dimensional surface. The method was proposed by Osher and Sethian (1988) to compute and analyze motion of interfaces in two and three dimensions under prescribed velocity field.

1.2 Shape optimization with IGA and XFEM

Conventional shape optimization techniques based on FEM use different geometric descriptions for design and analysis model i.e. modern CAD tools rely on Computer Aided Geometric Design (CAGD) elements like Bezier, B-Spline and NURBS curves and surfaces for geometry description while currently used FEM software packages employ piecewise linear approximation of geometry. With different geometric descriptions used in design and analysis model, the FEM based shape optimization becomes inefficient and inaccurate due to repetitive conversions required for geometric information of design model to the analysis model (Schramm and Pilkey 1993; Wang and Turtelautb 2015). In contrast, IGA unifies the design and analysis model by discretization based on Non-Uniform Rational B-Spline (NURBS) three dimensional solid elements. Once the initial mesh is constructed for defining the exact geometry with NURBS elements, subsequent refinement doesn’t need any further communication with CAD model, thus eliminates error-prone conversion of geometric description between design model and analysis model in shape optimization. Hughes et al. (2005) anticipated IGA based shape optimization as a promising future research area and accordingly in a set of recent articles IGA has been successfully implemented in shape optimization. For instance, Wall et al. (2008) proposed a shape optimization technique for two-dimensional elastic continuum structures e.g. a cantilever beam, a plate with a hole and an open spanner based on IGA and gradient-based method of moving asymptotes (MMA). Later, Cho and Ha (2009) emphasized the advantages offered by NURBS based isogeometric shape design optimization and isogeometric sensitivity over conventional FE sensitivity and shape optimization for linear elastic problems e.g. L-shape stiffener and connecting rod geometry. A variant of IGA i.e. T-spline (a generalization of non-uniform B-spline, which permits T-junctions) based IGA was proposed by Ha et al. (2010) for shape optimization of 2D linear elastic structures which reduces number of degrees of freedom and yields same optimal shape more efficiently. NURBS based geometries are affected by both, location and weights of its control points. In spite of this fact, most of the research work considers only locations of control points as design variables and evaluates analytical sensitivities with respect to control point only, which is termed as partial sensitivities (Qian 2010). However, Nagy et al. (2010) developed sizing and shape design optimization technique for curved beam structures using IGA with design variables taken as location and corresponding weights of control points. Full sensitivity formula for computing sensitivities for both control point locations and weights with numerical implementation in linear elastic 2D shape optimization problems e.g. a plate with a hole, a cantilever beam and an open spanner was proposed by Qian (2010). In a recent development, Fubeder et al. (2015) proposed equivalence of two approaches in IGA framework, i.e., discretize first–optimize then vs. optimize first–discretize then with gradient-based shape optimization technique and it has been shown that both these schemes yield same discrete systems. Wang and Turtelautb (2015) proposed a shape optimization technique for quasi-static processes within IGA framework with adjoint sensitivity analysis, wherein problem formulation was extended to include time dependent loads and responses. Another recent development demonstrated development of generalized isogeometric shape sensitivity formulation in curvilinear coordinate system by Ha (2015), which was then applied to derive shape sensitivity analysis of geometrically exact shell model and its shape optimization. Conventional IGA in shape optimization of trimmed or topologically complex shell structures pose many difficulties which include dividing the complex shell structure in multiple NURBS patches and need of special techniques for attaching them for analysis. Kang and Youn (2016) proposed IGA based shape optimization technique with gradientbased algorithm for trimmed shell structures using two dimensional Trimmed Surface Analysis (TSA) with a single patch extended throughout. While in another recent development, Herrema et al. (2017) proposes a first of its kind computational framework, utilizing Rhinoceros (typically abbreviated as Rhino – a commercial CAD software based on NURBS) and its graphical algorithmic editor, Grasshopper, which is capable of performing IGA-based parametric design optimization of realistic engineering structures which are generated through complex geometric operations of CAD.

Despite of aforementioned promising benefits offered by IGA in shape optimization, there exist some shortcomings in its original form which includes domain parameterization i.e. how to parameterize a volumetric domain from its boundary. This is due to the fact that a CAD model provides boundary information only while numerical analysis in general requires parameterizations of the interior of the domain (Lian et al. 2017, Li and Qian 2011). This issue can be effectively dealt with boundary integral based isogeometric analysis i.e. isogeometric boundary element method (IGABEM) wherein analysis problem is formulated with boundary integral form and the design boundary representation and approximation of physical fields is carried out with NURBS (Li and Qian 2011). The concept was proposed by Simpson et al. (2012) by realizing the fact that NURBS based boundary representation and BEM deals with quantities entirely based on problem boundary. Owing to the tight integration achieved between CAD and analysis, IGABEM offers immediate advantages in shape optimization and hence employed in some of the recent articles (Lian et al. 2017, Lian et al. 2016, Kostas et al. 2015, Li and Qian 2011). Thus, IGA (both FEM and BEM based) has triggered a renewed interest in the field of shape optimization.

XFEM was mainly developed with the objective of handling crack propagation problems without remeshing, but the potential use of XFEM with level sets for structural topology optimization was initially identified by Belytschko et al. (2003a, b). Later, Duysinx et al. (2006) proposed generalized shape optimization approach for a benchmark problem of the plate with a hole, using XFEM and LSMs, which results in smooth boundary description and allows topological modifications, too. Miegroet and Duysinx (2007) also proposed 2D fillet shape optimization for minimizing stress concentration using XFEM and level set description with sequential convex programming. In these techniques, XFEM enables working with fixed mesh while level set features help in smooth shape description and defining design variables.

1.3 Layout of the present review

MMs have become popular alternative numerical techniques to conventional grid-based techniques in diverse fields of engineering research, including structural shape optimization, in last two decades. These techniques eliminate innate limitations of FEM in structural shape optimization. Accordingly, the objective of present work is to review shape optimization techniques based on MMs and to emphasize their benefits.

The field of shape optimization is almost five decades old now. Several review articles have been presented in this field during this tenure. Brief details on the development in this field can be referred from following reviews/bibliography:

-

1)

A survey by Haftka and Grandhi (1986) on shape optimization for automated mesh generation and refinement techniques in FEA, selection of design variables with techniques for sensitivity calculation, solution techniques and applications.

-

2)

A literature review by Ding (1986) on typical procedural steps involved in shape optimization including FE mesh generation and refinement, sensitivity analysis and solution methods.

-

3)

A survey on structural shape optimization by Hsu (1994), covering developments from 1987 to 1993, with emphasize on techniques of geometry representation, structural analysis, sensitivity analysis, optimization, difficulties encountered in extending two dimensional to three dimensional shape optimization and significance of zero-order optimization algorithms in shape optimization.

-

4)

A bibliography by Mackerle (2003) on topology and shape optimization of structures using FEM and BEM, covering research papers, conference proceedings and thesis/dissertation presented during 1999 to 2001 in this field.

-

5)

A survey on structural optimization in mechanical product development by Saitou et al. (2005) with major research focus on geometry parameterizations, approximation methods, optimization techniques and integration with non-structural issues like cost, manufacturing and assembly aspects.

The layout of present review is as follows:

-

Section 2 presents comparison of different grid-based analysis techniques and MMs for their capabilities and limitations in shape optimization followed by essential numerical aspects of MMs like meshless shape functions and their properties, technique to impose EBCs and numerical integration which assist further discussion on MMs application in shape optimization.

-

Section 3 covers review of EFG and RKPM based shape optimization techniques for diverse engineering field problems.

-

Section 4 presents critical observations of the present review including DSA in meshless environment, numerical integration techniques in MMs and benefits of coupled FEM-MM approach in shape optimization.

-

Section 5 presents promising future research directions in the field of shape optimization with emphasize on role of MMs.

-

Section 6, finally, presents conclusion of the present review article.

2 Structural analysis techniques

Success of shape optimization process greatly depends on structural analysis technique used because it greatly influences solution accuracy and computational time of the process. The major concerns for selection of analysis technique in shape optimization include amount of input data required i.e. converting geometric information of design model into the analysis model, versatility of analysis technique and solution accuracy achieved. Various grid-based techniques and MMs are discussed here in terms of their usefulness and limitations in shape optimization and are shown on timeline in Fig. 2.

2.1 Grid-based techniques

Before the development of numerical techniques for structure mechanics problems in 1950s, analytical methods were used for structural analysis. However, it was not possible to model and analyze large and complex structures with analytical methods. In mid 1950s, major development of FEM for structural analysis began in aerospace industries and by 1970s it was developed as a practical analysis tool to model complex problems of diverse engineering fields. With its versatility in dealing with various types of loading, boundary conditions and nonlinearities, FEM became a standard technique for obtaining structural response in shape optimization and today almost all modern commercial software packages use FEM for structural optimization e.g. Genesis, MSC.Nastran, OptiStruct etc. However, there exist some computational drawbacks with FEM which become severe in shape optimization problems, like, continuously changing geometry in shape optimization problems need frequent remeshing to avoid distorted elements which may impair solution accuracy. Here, mesh refinement techniques, both manual and automated become extremely important to maintain certain level of solution accuracy. Sophisticated adaptive mesh refinement techniques, eliminating user intervention, including h and p refinement have been studied extensively in the literature (Mohite and Upadhyay 2015; Schleupen et al. 2000; Bennett and Botkin 1985). Another major concern related to FEM in gradient-based shape optimization is the condition of maintaining same topology of mesh for initial and perturbed geometry for accurate computation of design sensitivities and stable optimization process. To achieve this, one must ensure mesh updates to follow the direction of design velocity field in DSA (Kim and Choi 2005). Moreover, discontinuous approximation of secondary field variables like stresses across element boundaries due to linear shape functions in displacement-based FEM also impairs solution accuracy. To alleviate these evident limitations of FEM in shape optimization, BEM gained much attention as an alternative numerical technique by mid 1980s. Being boundary oriented technique, BEM formulates boundary value problems (BVP) with BIEs which describe problems with known and unknown boundary states, thus reducing dimension of problem by one degree which requires discretization of the surface rather than the volume. Consequently, meshing time reduces considerably and design changes can be incorporated with ease. Degree of accuracy for the field variables at boundary of the domain will also remain high with BEM, which makes it suitable for stress concentrated shape optimization applications. Thus, BEM offers several advantages over FEM in shape optimization problems like lesser input data, smaller computational efforts and higher accuracy in boundary stress approximation (Xu and Yu 1990). However, BEM is not efficient in dealing with problems involving inhomogeneity and nonlinearities. Non-banded and non-sparse system matrices become another computational drawback of BEM.

Numerical methods based on Lagrangian grid, like FEM, the grid is attached to the material during the entire computation process and hence it deforms with material under external loading which leads to mesh distortion issue in classical FEM based shape optimization techniques. The problem can be resolved effectively by adopting Fixed Grid (FG)/Eulerian grid approach in which the grid of finite elements (in background) remains fixed throughout the design optimization process while the geometric model is allowed to move across it to accommodate shape variation. Subsequently, the shape density concept, quite similar to homogenization in topology optimization, for identifying finite elements inside, outside or on the boundary is adopted for shape optimization However, it must be noticed that the total design space occupied by the fixed grid must include all possible design combinations based on upper and lower bounds of design parameters (Najafia et al. 2015; Kim and Chang 2005; Gracia and Gonzalez 2004; Garcia-Ruiz and Steven 1999).

2.2 MMs: Alternative numerical techniques

A new class of numerical techniques has emerged in last two decades wherein novel techniques for shape function construction allow field variable approximation globally with a set of nodes and their associated support domains only, without defining elements/mesh. MMs provide accurate and stable numerical solution for governing PDEs with all possible boundary conditions and are expected to be superior to conventional grid-based techniques. Numerous meshless techniques have been developed by employing novel techniques of shape function construction like moving least square (MLS) approximants, reproducing kernel approximation, partition of unity (PU) and so forth. Some of the well-known MMs include Smoothed Particle Hydrodynamics (SPH) by Lucy (1977), Element Free Galerkin (EFG) method by Belytschko et al. (1994), Reproducing Kernal Particle Method (RKPM) by Liu et al. (1995), Meshless Local Petrov Galerkin (MLPG) method by Atluri and Zhu (1998), Point Interpolation Method (PIM) by Liu and Gu (1999, 2001) and so forth. It is worth to notice that, based on their computational framework; these techniques may need background mesh for numerical integration purpose which is not related to the approximation of field functions and does not weaken the meshless characteristics and its associated benefits.

Although MMs were mainly developed to solve some specific class of problems, like fracture mechanics with moving material discontinuities, large deformations and simulation of manufacturing process e.g. metal forming where conventional grid-based techniques struggle to provide accurate solutions even after successive remeshing, some features of these techniques make them much suitable analysis technique in structural optimization problems e.g. shape optimization. Different meshless techniques may employ different shape functions for approximating field variables but they share a common useful feature of lifting the stringent requirement of meshing as posed by FEM which is extremely beneficial in shape optimization problems and provide much needed flexibility. Moreover, meshless shape functions produce continuous approximation of field variables i.e. displacement and stress which will improve design sensitivities and overall solution accuracy in shape optimization process. Past literature shows enthusiastic results of MMs i.e. EFG and RKPM in shape optimization problems of various fields (Table 1). To discuss significance of various numerical aspects of MMs in shape optimization, it is essential to present those aspects here including their shape functions and its properties, techniques to impose EBCs and numerical integration.

2.3 Meshless shape functions

MMs may be classified based on various criteria, for instance, method of deriving discrete system equations, method of constructing shape functions etc. Accordingly, MLS approximants are employed to construct shape functions of desired order continuity in EFG, MLPG and HP-cloud method. The MLS approximant, u h (x) of the field function u(x) defined over the domain Ω is given by,

where, pT(x) are monomial basis functions of order m and a(x) are vector coefficients which are functions of space coordinates x. They are determined at any point x by minimizing weighted discrete L2 norm defined as follows,

where, n is the number of nodes in neighborhood of x for which weight function wi(x-xi) can’t be zero and ui is the nodal value of u at x = xi. The neighborhood of x is termed as domain of influence or support domain.

Weight functions in MLS approximants play two important roles i.e. providing suitable weightings to the residuals for different nodes in the influence domain based on their position from the point of interest and ensuring compatibility condition of shape functions i.e. continuity of field function over the domain. Some of the frequently used weight functions are exponential and spline functions of different orders (Liu 2010).

In order to minimize weighted residual (2) at any arbitrary point x within the domain,

On further simplification, approximation uh(x) can be written as,

where, ϕ i (x) is called the MLS shape functions in EFG and it is given by,

MLS shape functions (5) are complex and computationally more expensive, as it needs matrix inversions, compared to polynomial like shape functions of FEM. Again, it is essential that moment matrix, A(x) must remain invertible for obviating singularity issues in the formulation. While from accuracy viewpoint, MLS shape functions provide exemplary approximation i.e. smoother stress, strain fields in the solution even with low order monomial basis function that is owing to higher order weight functions. But they do not possess Kronecker delta property, which means u h (x i ) ≠ u i , and hence imposition of EBCs become more complex than conventional FEM. Kronecker delta property of shape function is defined in the following way:

Numerous techniques have been developed for imposing EBCs in MMs, which includes Lagrange multiplier, penalty approach, modified variational principle, coupling with FEM, transformation method, Nitsche’s method and D’Almbert’s principle (Belytschko et al. 1994; Dolbow and Belytschko 1998; Lu et al. 1994; Krongauz and Belytschko 1996; Gunther and Liu 1998; Hoai 2009; Chen et al. 1996; Griebel and Schweitzer 2002). Among these techniques, penalty approach is more convenient in implementation because it results in positive definite and banded system matrices without increasing its size. However, it is crucial to select appropriate value of penalty parameter, α for desired solution accuracy.

On the other hand, SPH (Lucy 1977; Gingold and Monaghan 1977) and RKPM (Liu et al. 1995) fall under the same category of MMs wherein shape functions are constructed using integral representation methods. In SPH, the approximation of field variable u(x), u h (x) is given in the following way,

where, \( \overset{\frown }{W}\left( x-\xi, h\right) \) is the kernel function and h is termed as smoothing length in SPH which is often termed as compact support domain or influence domain. The kernel function provides continuity and the locality of the approximation with compact support and commonly used kernel functions are Gaussian or spline functions of different orders.

On the basis of theory of wavelets and some desirable features of SPH, DEM and EFG methods, Liu et al. proposed RKPM approach. Shape function in RKPM is derived by introducing correction function, C(x, ξ) in (7), which improves SPH approximation near boundary. Thus, approximation in RKPM is given by,

Upon discretizing the domain Ωs by a set of particles [x 1 , x 2 ,..,x n] and using trapezoidal rule, (8) can be rewritten as,

The correction function C(x, x-x i ) is constructed by monomial basis as follows,

where, H(x - x i ) and q(x) are basis function and coefficient vectors respectively. To get shape functions, (10) is substituted in (9),

where, ϕ i (x) is termed as RKPM shape functions and it is given by,

Again, RKPM shape functions do not possess Kronecker delta property (6); hence, EBCs are imposed with special techniques mentioned earlier.

2.4 Numerical integration in MMs

Numerical integration is the approximation of continuous integral over a domain Ω by a discrete sum, in the following way:

where, n q is number of quadrature points, ξ l is the coordinate of point l and W l is the corresponding weight (Beissel and Belytschko 1996). Overall performance and accuracy of MMs depend on accurate and efficient numerical integration schemes. Several techniques have been proposed for numerical integration of discrete equations in MMs, which includes classical Gauss quadrature technique (utilizing back ground cell structure/mesh), direct nodal integration (Beissel and Belytschko 1996), stabilized confirming nodal integration (SCNI) (Chen et al. 2001) and partition of unity quadrature technique (PUQ), moving least square quadrature (MLSQ) (Carpinteri et al. 2002; Duflot and Hung 2002). Classical Gauss quadrature technique has been found much useful in practical applications but the need of background integration cells makes these techniques ‘pseudo meshless’. However, the background mesh (for numerical integration) is not related to the approximation of field functions and does not weaken the meshless characteristics and its associated benefits (Chen et al. 2001). Dolbow and Belytschko (1999) studied sources of errors associated with Gauss quadrature numerical integration schemes in MMs. The misalignment between local support domain of shape functions and integration cells results in significant error in MMs and affects convergence rate. Hence, it was highly desirable to derive completely meshless formulation. Accordingly, Beissel and Belytschko (1996) proposed nodal integration to develop truly meshless technique. However, the proposed nodal integration was suffering from spatial instability initially, which was dealt by adding a stabilization term consisting of the square of the residual of the equilibrium equation to the potential energy functional. Another stabilized nodal integration technique was proposed by Chen et al. (2001) by strain smoothing technique in RKPM framework, which avoids evaluation of shape function derivatives at nodes and thus eliminates spurious modes while Carpinteri et al. (2002) and Duflot and Hung (2002) proposed a new integration technique (14) based on partition of unity property of meshless shape functions which does not require background mesh/cells since the quadrature cells are determined by the weight supports of meshless shape function and thus resulting technique will be truly meshless.

where, H(x) is given by,

3 Shape optimization with MMs

The present section reviews shape optimization techniques based on EFG and RKPM in problems of diverse engineering fields and emphasizes major gain obtained through meshless implementation instead of conventional grid-based techniques.

3.1 Linear elastic problems

EFG based shape DSA and shape optimization technique was firstly developed by Bobaru and Mukherjee (2001) wherein sensitivities were derived through material derivative approach, using Direct Differentiation Method (DDM) and particular approximation for displacement sensitivities, thus avoiding differentiation of meshless shape functions with respect to design variables. The proposed technique was applied to optimize two dimensional fillet shape geometry for minimizing area which provided lower value of objective function compared to earlier solutions obtained by Phan et al. (1998) using Boundary Contour Method (BCM) and Zhao (1991) using BEM and optimum shape without any remeshing. Later, Grindeanu et al. (2002) proposed CAD-based shape optimization by integrating a CAD tool i.e. Pro/Engineer with RKPM for shape optimization of two dimensional hyperelastic structure and three dimensional linear elastic structure. Their work was inspired from earlier work by Hardee et al. (1999) for CAD based shape DSA and shape optimization with FEM. They proposed a new hierarchical boundary displacement method to maintain consistency between the discrete and CAD model throughout the shape optimization process and sensitivities were computed by hybrid finite difference and boundary displacement procedure. The capability of proposed technique was demonstrated by solving a three dimensional elastic beam structure with uniform loading without any mesh distortion. Another RKPM based shape optimization technique was proposed by Kim et al. (2003) for two dimensional and three dimensional linear elastic structures with the objective of demonstrating meshless shape DSA and its numerical implementation. They derived sensitivities through material derivative of variational equation and considered design derivatives of meshless shape functions (unlike Bobaru and Mukherjee 2001) which proved more consistent approach for meshless DSA. The proposed RKPM based shape optimization technique was insensitive to regularity of the particle distribution and generated optimum shapes of bracket, torque arm and road arm geometry without mesh distortion and any remeshing as compared to the earlier study by Bennett and Botkin (1985) using FEM for the same problems. Moreover, the proposed technique showed improved convergence rate of design optimization process through accurate computation of sensitivities with RKPM. On the other hand, Zou et al. (2007) proposed numerical shape optimization technique based on ‘truly meshless’ RKPM formulation with PU based numerical integration (see (14) (15)) using Shephard function, as follows:

They computed sensitivities by FDM for convenience and the technique was applied to optimize fillet geometry for minimizing area which generated lower objective function value than the earlier solutions obtained by Bobaru and Mukherjee (2001) using EFG and Zhao (1991) using BEM for the same problem. In majority of research, MMs were coupled with conventional deterministic optimization techniques for achieving optimum shapes, but Zhang et al. (2005) proposed a novel approach of shape optimization by combining RKPM with Multi Family Genetic Algorithm (MFGA) to eliminate computational burden of sensitivity computation. They employed PUQ technique for numerical integration (see (14) and (15)) in RKPM framework which avoided background cells/mesh and results in truly meshless formulation. The technique employed in optimizing complex connecting rod geometry for minimizing area and outperformed the earlier solution obtained with FEM and GA by Annicchiarico and Cerrolaza (1999). Moreover, it was observed that MFGA showed high convergence rate and ease of implementation in the proposed technique.

3.1.1 Coupled FEM-MM approach

It was observed in Bobaru and Mukherjee (2001) and Kim et al. (2003) that DSA based on MMs produces more accurate sensitivity information due to higher order differentiability of displacements and stresses obtained with MMs. However, increased computational efforts of MMs owing to its complex shape functions involving matrix inversions (e.g. (5)) and higher order numerical integration schemes remain challenging. Thus, more rational and beneficial approach in shape optimization is to couple MMs with FEM in which MMs are used only in a part of domain where better approximation is required. Another major gain with the coupled approach will be the ease of imposing EBCs with coupled technique itself, thus avoiding any other special technique for imposing EBCs. Accordingly, Lacroix and Bouillard (2003) proposed coupling of FEM with EFG to improve sensitivity analysis for structural optimization problems for alleviating evident difficulties associated with geometry perturbation and updating mesh in classical FEM. The coupling of two techniques was accomplished by introducing interface elements between FE and EFG domains, where hybrid displacement approximation was defined using ramp functions, as follows:

where, R(x) is the ramp function defined using FE shape functions in following way,

The technique eliminated mesh distortion and issue of imposing EBCs with EFG. Much later, Gong et al. (2009) also proposed coupled FE-EFG approach, based on isoparametric quadrangle interface element, for shape optimization of 2D linear elastic structures in which sensitivities were computed through DDM of discretized equilibrium equation of interface elements. The proposed coupled technique was successfully employed to optimize fillet shape geometry for minimizing area and offered several advantages including mesh distortion eliminated completely, ease of imposing EBCs and improved computational performance.

3.2 Thermoelastic problems

EFG based shape optimization techniques for thermoelastic problems was firstly proposed by Bobaru and Mukherjee (2002) wherein sensitivities were computed by FDM for convenience and SQP algorithm was used for optimization. The proposed technique employed in optimizing the triangular thermal fin geometry for maximizing heat transfer and produced ‘finger-type’ shape design without any remeshing, which was missed in earlier solution with FEM by Hou et al. (1992). Again, the proposed technique surpassed the FEM solution (Hou et al. 1992) in fixed-fixed beam under thermo mechanical load for minimizing deviation of deformed top boundary from the straight line. Later, Bobaru and Rachakonda (2004a) identified the ill-posed problem condition for the triangular thermal fin shape optimization in Bobaru and Mukherjee (2002) which indicated the ‘optimal’ fin structure with an infinite number of fins of infinitesimal thickness closely packed together. To resolve this issue, authors proposed an additional constraint in terms of non-overlapping thermal boundary layer outside the fin’s convective boundary to make problem well posed and find optimal shape of fin geometry. EFG based shape optimization technique was developed to solve the non-linear constrained optimization problem with sensitivity computed through FDM and optimization through SQP. The optimum fin shape design was obtained without any remeshing. The work was further extended by the same authors (Bobaru and Rachakonda 2004b) to examine the effect of fin materials with different conductivity parameters i.e. high conductivity materials like aluminium and copper and low conductivity material like titanium on optimal shape profiles of fins which produced sharp pointed thin fin shapes for highly conducting materials while thicker, rounded fin shapes for low conductivity materials without any remeshing.

Though EFG implementation found much beneficial in aforementioned thermoelastic problems, Bobaru and Rachakonda (2006) identified limitation of the existing technique in terms of its ability to support extremely large shape changes which may result in the problem regions with very low node density or material overlapping due to node movements. To alleviate this issue, they proposed fixed-grid shape optimization technique based on EFG and referred it as E(FG)2, wherein physical domain was projected over a fictitious domain and shape changes occurred over a fixed-grid covering the fictitious domain. The proposed technique was tested in previously studied fin geometry shape optimization problems (Bobaru and Mukherjee 2002; Bobaru and Rachakonda 2004a, b) and it was observed that the proposed technique was insensitive to biased grid, thus eliminating the issue of special node arrangement required in (Bobaru and Rachakonda 2004a, b) and permitted to enlarge the bounds on the design variables.

3.3 Hyperelastic problems

Numerical simulation and successive shape optimization of hyperelastic e.g. rubber structures and near incompressible conditions i.e. Poission’s ratio approaching 0.5 and volumetric strain nearly 0 present many difficulties owing to its large deformations which leads to locking issues in conventional displacement based FEM. In FEM framework, mixed formulations, considering pressure and displacement as unknowns, are popular in these conditions (Bathe 1996). Alternatively, MMs are more suitable in these problems as they are free from mesh distortion and element locking issues. Accordingly, Grindeanu et al. (1998) and Grindeanu et al. (1999) proposed continuum based DSA and shape optimization of hyperelastic structures based on RKPM for the first time. Both, material and shape design variables were considered with direct differentiation and adjoint variable method in DSA which was further extended by using a pressure projection method for avoiding volumetric locking in nearly incompressible materials. The proposed technique employed to optimize geometry of the engine mount for minimizing mass using modified feasible design method available in the Design Optimization Tool (DOT) (Vanderplaats 1997).

3.4 Frictional contact problems

Contact problems, both frictional and frictionless, are of great significance in many industrial applications, ranging from gears and bearings to metal forming processes like stamping and deep drawing, rubber sealing, crash tests performed in cars and biomechanics problems to name a few. Frictionless contact problems with perfectly smooth elastic bodies experiencing small deformations are relatively simple to deal with. Conversely, frictional-contact problems are path dependent and highly non-linear because contact area and contact-force intensities are unknown and vary during the loading time. Many research articles proposed DSA in linear and non-linear contact problems for path-dependent and path-independent problems (Spivey and Tortorelli 1994; Antunez and Kleiber 1996), however Kim et al. (2000a, b) were the first to propose RKPM based continuum shape DSA for contact problems of nearly incompressible hyperelastic material with a rigid body with the objective of eliminating mesh distortion issue. They derived sensitivities by taking material derivative of structural variational form and external load form. The proposed technique employed to optimize the door seal geometry and the rigid door for minimizing the gap opening with SQP algorithm of commercial optimization tool DOT (Vanderplaats 1997). The proposed work was further extended for 3D shape DSA and optimization for a metal punch problem and die design modification in solid extrusion problem (Kim et al. 2002). The sensitivities were computed by differentiating a penalty-regularized contact variational equation with respect to the shape design parameter. The technique employed to optimize two dimensional geometry of engine rubber gasket for minimizing the gap opening and die design modifications in solid extrusion process for minimizing process work without mesh distortion. In another article, Kim et al. (2001a, b) proposed continuum based shape DSA and optimization of hyperelastic structure with multibody frictional contact using RKPM to obviate mesh distortion issues with conventional FEM. Shape DSA for hyperelastic material was developed using material derivative of the variational equation while shape DSA for multibody frictional contact was developed with penalty method and modified Coulomb friction model. A numerical case study of windshield wiper blade geometry and glass was optimized for minimizing area.

Elastoplastic material behavior is often observed in many industrial applications including aerospace, automotive and metal forming processes which need attention to design and analyze components for those practical applications. Many literature explained DSA for elastoplasticity material behavior using FEM (Lee and Arora 1995; Park and Choi 1996). However, Kim et al. (2000a, b) proposed continuum based shape DSA using DDM and optimization for elastoplasticity with frictional-contact condition using RKPM to alleviate mesh distortion issue associated with FEM. The technique successfully employed to derive shape DSA in metal punch problem in forming processes and to optimize metal ring geometry compressed between two rigid walls for minimizing area using SQP algorithm in DOT. Another RKPM based shape DSA and optimization approach was developed by Kim et al. (2001a, b) for metal forming process i.e. a sheet metal stamping process wherein die shape DSA and optimization was performed to obtain desired shape of the workpiece by minimize spring-back effect. They derived design sensitivities by combining sizing DSA for a structural problem including a large deformation elastoplasticity and die shape DSA by taking the derivative of the contact constraint with respect to the die shape. The die shape optimization was successfully performed without any remeshing using SQP in DOT to minimize the normal distance between the final shape of the workpiece and the desired shape.

3.5 Structure dynamics problems

Dynamic response of structural system becomes significant when there are time varying loads and/or boundary conditions. The dynamic response of structural systems is obtained by direct numerical integration of dynamic equilibrium equations using explicit or implicit integration schemes. Several research articles proposed sizing, shape and material parameter DSA and optimization in nonlinear transient dynamics using discrete, semi-discrete or continuum equations with DDM and adjoint methods with numerical implementation through nonlinear FEM (Stupkiewicz 2001; Choi and Cho 1998; Arora and Dutta 1997; Cardoso and Arora 1992; Kulkarni and Noor 1995). However, meshless based continuum shape DSA and optimization of structural transient dynamics for the finite deformation elastoplastic materials under impact with a rigid surface was firstly proposed by Kim and Choi (2001). They used RKPM for nonlinear analysis and implicit Newmark method for integration in the time domain. Sensitivities were derived by material derivative approach with DDM and the vehicle bumper geometry was optimized for minimizing its area using SQP in DOT. Much later, Zhang et al. (2008) also proposed discreteness based DSA using DDM for deriving natural frequency and dynamic response sensitivities in structural dynamic shape optimization using RKPM to circumvent issues like mesh distortion and successive remeshing with traditional FEM. They considered design derivative of RKPM shape functions for accurately computing sensitivities. The proposed technique successfully employed in dynamic shape design optimization of the arc geometry and the fillet geometry for minimizing area.

4 Critical observations

The objective of present section is to emphasize some critical observations of the present review on meshless implementation in shape optimization which includes some major benefits and some significant numerical aspects.

-

a)

DSA in meshless environment

DSA plays crucial role in gradient-based optimization techniques as it computes the rate of performance measure change e.g. displacement, stress with respect to design variable alterations by differentiating the structural expression with respect to design variables. Accurate information of sensitivities improve convergence rate of gradient-based optimization techniques.

DSA needs careful considerations when performed in meshless environment. Research on DSA in MMs for static and dynamic problems can be found in (Zhang et al. 2008; Zou et al. 2007; Kim et al. 2003; Bobaru and Mukherjee 2001; Grindeanu et al. 1998). In the aforementioned literatures, two apparently different techniques are adopted for approximating design sensitivities in MMs. These techniques are discussed here separately:

-

1)

Considering design derivative of meshless shape functions ϕ (x) and its spatial derivatives ϕ, x (x) with respect to design variable: The fundamental difference between FEM and MMs lies in the way shape functions are constructed. Unlike FEM, where shape functions are generated locally with the aid of natural (local) co-ordinates, meshless shape functions are developed with global co-ordinates of nodes which are related to shape design variables in DSA which leads to the additional requirement of shape function differentiation with respect to design variables. Thus, design derivative of the meshless shape functions and its spatial derivatives are required to compute sensitivities in MMs.

For instance, shape DSA in RKPM framework, \( {\dot{u}}^h(x) \) can be computed by differentiating (11) with respect to design variable,

This formulation is much different from FEA wherein shape functions are independent from design. In (19) the first term includes displacement sensitivity \( {\dot{u}}_i \), while the second term \( {\dot{\phi}}_i(x) \) represents shape function dependence on design which is explicit in design velocity V(x). Design derivative of RKPM shape function \( {\dot{\phi}}_i(x) \) can be computed by numerical procedure which results in the following form of expression,

Similar approach can be adopted for deriving design derivative of spatial derivatives ϕ, x (x) of shape functions. Zhang et al. (2008) derived dynamic sensitivities for natural frequency and dynamic response, Kim et al. (2003) derived stress sensitivities in linear elastic problems and Grindeanu et al. (1998) derived stiffness and pressure sensitivities in hyperelastic problems considering design derivatives of shape functions.

-

2)

Approximation through meshless shape functions: An alternative technique for approximating shape design sensitivities in MMs is through direct approximation using meshless shape function, as (21), quite like any other continuous unknown.

It must be noticed that \( \widehat{\dot{u}} \) in (21) is an approximation of nodal values of displacement sensitivities found from discretized governing equation. Bobaru and Mukherjee (2001) and Zou et al. (2007) adopted this approach for deriving sensitivities in linear elastic problems.

Comparing two techniques i.e. (19) with (21), it appears that second approach is more convenient in its implementation as it avoids differentiation of shape functions with respect to design variables, while the first approach yields more consistent numerical results.

-

b)

Improved sensitivities, reduced computational efforts and ease of imposing EBCs with coupled FEM-MM:

As sensitivities are derivatives of structural measures, higher order continuity of displacement and stress fields in meshless techniques provide more accurate sensitivities which will improve the convergence rate of structural optimization process. It was observed that sensitivities calculated with EFG were more accurate than FEM (Lacroix and Bouillard 2003). However, MMs have proved computationally expensive due to complex shape functions involving matrix inversions (5), special techniques to impose EBCs and higher order numerical integration schemes for reducing integration errors. Hence, it is highly desirable to use a coupled approach i.e. FEM-MM to retain advantages of both the techniques and suppress their drawbacks in structural optimization problems. The coupled approach reduces computational effort and time because MM is employed only over a part of domain where better approximation is needed and the rest of the domain is modeled with FEM. This approach also alleviates issue of imposing EBCs in MM and improves computational performance of the technique. Lacroix and Bouillard (2003) and Gong et al. (2009) employed coupled FE-EFG approach for DSA and shape optimization of two dimensional linear elastic structures.

-

c)

Numerical integration with background cells/mesh:

In MMs, unlike FEM, field variable approximation and domain integration are independent from each other. Meshless shape functions are developed entirely on a set of nodes scattered in the domain, while integration is usually performed by classical Gauss quadrature with background mesh/cells. Here, approximation being independent from integration, distortion of integration cells and their deteriorated aspect ratios do not affect the solution accuracy in MMs as distorted mesh does in FEM solutions. However, integration cells in MMs have to be convex and their jacobian must remain positive for successful Gaussian integration by avoiding singularities.

During shape optimization based on MMs, the boundary nodes are allowed to move along with interior nodes for accommodating shape variations which leads to distortion of integration cells in MMs. Such conditions are acceptable in MMs, as discussed above, and don’t impair the solution accuracy (Bobaru and Mukherjee 2002; Bobaru and Rachakonda 2004a, b).

-

d)

Numerical integration with PUQ: An alternative numerical integration technique based on PUQ in MMs (see (14) and (15)) avoids use of background cells and results in truly meshless formulation since it uses partition of unity property of meshless shape functions and its support domains as quadrature cells. The technique suits to shape optimization problems because PUQ patches generated from the support domains of meshless shape functions would be able to adjust automatically with continuously changing geometry and corresponding node positions during shape optimization process and thus provides adaptivity feature. Zhang et al. (2005) and Zou et al. (2007) employed truly meshless approach with PUQ integration technique for solving two dimensional linear elastic shape optimization problems.

-

e)

Mesh topology: One of the major concern with FEM as a structural analysis tool in gradient-based shape optimization is the requirement of maintaining the same mesh topology for initial and perturbed geometry for computing design sensitivities and stable optimization process. MMs have proved much useful in those cases due to absence of mesh geometry modifications and high degree of continuity in the results obtained for displacement and stress fields (Lacroix and Bouillard 2003; Grindeanu et al. 1999)

-

f)

Effect of node distribution: As mentioned earlier, conventional grid-based techniques need type ‘r’ refinement for minimizing computational errors of structural analysis. In contrast, solution accuracy in MMs is rather insensitive to node distribution within the domain. Kim et al. (2003) compared RKPM based shape optimization results for regular and irregular node distribution and found them similar.

-

g)

Better solutions in terms of geometry and accuracy: In shape optimization techniques based on MMs, node movements to accommodate shape variations are not restricted to maintain some specific aspect ratios of integration cells as in case of classical FEM based shape optimization techniques. Distorted integration cells (with positive Jacobian) in MMs do not impair the solution accuracy while distorted mesh in FEM results in poor solution accuracy. This flexibility in MMs results in better shape designs at the end of shape optimization process which are much different from the original shape and possibly missed by FEM (Bobaru and Mukherjee 2002; Bobaru and Rachakonda 2004a, b)

Improved solution accuracy in terms of higher order continuity of displacement and stress field due to globally continuous meshless shape functions is another major gain of MMs which avoids costly and not always accurate post processing techniques. The continuous stress field obtained with MMs overcomes the difficulty of imposing point stress constraints in shape optimization as observed with conventional FEM. (Bobaru and Mukherjee 2001).

-

h)

Mesh distortion and remeshing: Solution accuracy in classical FEM is highly influenced by quality mesh i.e. quality of elements. Aspect ratio, Jacobian ratio, maximum and minimum edge and face angle are some of the important parameters for judging quality of elements in mesh. In FEM based shape optimization, though the initial mesh quality is good enough but successive shape variations may not be accommodated without distorting the initial mesh which will impair the solution accuracy if successive remeshing is not performed. Thus, remeshing becomes unavoidable in grid-based techniques in shape optimization. In contrast, MMs do not use elements for approximating field variables and hence they eliminate mesh distortion and remeshing issues completely in shape optimization process.

5 Future research:

This section attempts to provide promising future research directions in the field of shape optimization with the emphasis on role of MMs.

5.1 Coupled approach and parallel implementation

It has been noticed that meshless implementation yields competitive results in different areas of engineering research, including structural shape optimization, but the major barrier is their higher computational cost. Again, shape optimization needs repetitive structural analysis; hence, it is highly desirable to reduce the computational cost of meshless analysis by various means. Use of coupled technique i.e. FEM-MM has attracted much attention by researchers to retain potential benefits of both these techniques and to remove their drawbacks. In shape optimization, coupled approach improves accuracy of design sensitivities and reduces computational efforts and time, eliminates mesh distortion and alleviates the issue of imposing EBCs in MMs (Lacroix and Bouillard 2003; Gong et al. 2009). Accordingly; coupled approach would be more rational in shape optimization and there exists ample opportunities for future research in this area. Conversely, many researchers have proposed parallel implementation of MMs to improve its computational efficiency in solving real and large scale engineering problems (Karatarakis et al. 2013; Singh 2004; Danielson et al. 2000). However, to the best of our knowledge, for shape optimization application, parallel implementation of MMs has remained unexplored.

5.2 Three dimensional structures with ‘truly meshless’ formulation

Most of the research in shape optimization field with MMs deals with two dimensional structural shape optimization and employs background cells/mesh for numerical integration wherein positive Jacobians are essential for successful Gaussian integration. For three dimensional structural optimization problems, construction of integration zones/mesh will become more lengthy and tedious task in meshfree analysis. In this case, it is highly desirable to develop completely meshless formulation by adopting nodal integration techniques like SCNI or PUQ based technique which will eliminate background integration zones/mesh. In this context, Grindeanu et al. (2002) employed a CAD tool i.e. Pro/Engineer for defining integration zones in linear elastic three dimensional problem of elastic beam while Kim et al. (2003) developed ‘truly meshless’ RKPM based shape optimization technique with nodal integration for optimizing linear elastic three dimensional road arm geometry. It will be of great practical significance to develop ‘truly meshless’ formulation based shape DSA and optimization technique for three dimensional problems involving dynamic conditions and non-linear behavior.

6 Conclusion

The field of structural shape optimization is fairly broad, which makes it infeasible to discuss many other appealing areas of this field at the same time. The scope of the present review article is kept restricted to parametric shape optimization techniques based on MMs, their associated numerical aspects and their benefits in shape optimization. As the article emphasizes role of structural analysis technique in shape optimization, different grid-based techniques i.e. FEM, BEM, FG FEM and Eulerian grid and MMs were discussed for their usefulness in shape optimization process followed by review of EFG and RKPM based shape optimization techniques in problems of diverse fields. Moreover, the article presents some critical observations based on the review of meshless implementation in shape optimization which include meshless shape DSA, numerical integration with background cells and PUQ technique and benefits of coupled FEM-MM approach in shape optimization.

This review brings to light the potential benefits of MMs in structural shape optimization field which are as follows:

-

a)

Mesh distortion and remeshing eliminated completely even in large shape changes during the optimization process

-

b)

Higher order continuity of field variable approximation in MMs yield improved sensitivity analysis and higher convergence rate of the optimization process

-

c)

Solution accuracy in MMs is much less sensitive to node positions in the domain which eliminates type-r refinement for minimizing computational errors

-

d)

MMs do not exhibit any locking while dealing with near incompressible material model

-

e)

MMs produce better solution accuracy than FEM for similar number of degrees of freedom in the problem domain

-

f)

Due to inbuilt flexibility and versatility, MMs generate optimum shapes even through much simple initial geometries or poor guesses.

In spite of the increased computational burden with meshless implementation, aforementioned benefits may attract researchers’ attention for future work in the field of shape optimization using MMs.

References

Annicchiarico W, Cerrolaza M (1999) Finite elements, genetic algorithms and b-splines: a combined technique for shape optimization. Finite Elem Anal Des 33:125–141

Antunez HJ, Kleiber M (1996) Sensitivity analysis of metal forming process involving frictional contact in steady state. Materials Proc Tech 60:485–491

Arora JS (1990) Computational design optimization: a review and future directions. Struct safety 7:131–148

Arora JS, Dutta A (1997) Explicit and implicit methods for design sensitivity analysis of nonlinear structures under dynamic loads. Appl Mech Rev Trans ASME 50:S11–S19

Atluri SN, Zhu TL (1998) A new meshless local Petrov-Galerkin (MLPG) approach in computational mechanics. Comp Mech 22(2):117–127

Babuska I, Suri M (1992) Locking effects in the finite element approximation of elasticity problems. Numer Math 62:439–463

Bathe KJ (1996) Finite Element Procedures. Prentice Hall, Englewood Cliffs

Beissel S, Belytschko T (1996) Nodal integration of the element-free Galerkin method. Comput Methods Appl Mech Eng 139:49–71

Belytschko TY, Lu YY, Gu L (1994) Element-free Galerkin methods. Int J for Numer Methods Eng 37(2):229–256

Belytschko T, Parimi C, Moes N, Sukumar N, Usui S (2003a) Structured extended finite element methods for solids defined by implicit surfaces. Int J Num Methods Eng 56:609–635

Belytschko T, Xiao S, Parimi C (2003b) Topology optimization with implicit functions and regularization. Int J Numer Methods Eng 57:1177–1196

Bendsøe MP, Sigmund O (2002) Topology optimization: theory, methods, and applications, 2nd edn. Springer, New York

Bennett JA, Botkin ME (1981) Automated design for automotive structures. In: Mayne RW, Ragsdell KM (eds) progress in engineering optimization. ASME design engineering technical conference, Hartford CT:73-80

Bennett JA, Botkin ME (1983) Shape optimization of two-dimensional structures with geometric problem description and adaptive mesh refinement, AIAAIASMEIASCEIAHS 24th structures, structural dynamics and materials conference, AIAA-83-0941. Lake Tahoe, NV

Bennett JA, Botkin ME (1985) Structural shape optimization with geometric description and adaptive mesh refinement. AIAA J 23(3):458–464

Bhavikatti SS, Ramakrishnan CV (1977) Optimum design of fillets in flat and round tension bars. ASME paper 77-DET-45, design engineering technical conference, Chicago, IL

Bhavikatti SS, Ramakrishnan CV (1979) Optimum shape design of shoulder fillets in tension bars and T-heads. Int J Mech Sci 21:29–39

Bhavikatti SS, Ramakrishnan CV (1980) Optimum shape design of rotating disks. Comput Struct 11:397–401

Bobaru F, Mukherjee S (2001) Shape sensitivity analysis and shape optimization in planar using the element-free Galerkin method. Comput Methods Appl Mech Eng 190:4319–4937

Bobaru F, Mukherjee S (2002) Meshless approach to shape optimization of linear thermoelastic solids. Int J Numer Methods Eng 53:765–796

Bobaru F, Rachakonda S (2004a) Boundary layer in shape optimization of convective fins using a meshless approach. Int J Numer Methods Eng 60(7):1215–1236

Bobaru F, Rachakonda S (2004b) Optimal shape profiles for cooling fins of high and low conductivity. Int J Heat Mass Transf 47(23):4953–4966

Bobaru F, Rachakonda S (2006) E(FG)2: a new fixed-grid shape optimization method based on the element-free Galerkin mesh-free analysis: taking large steps in shape optimization. Struct and Multidiscip Optim 32:215–228

Botkin ME, Bennett JA (1985) Shape optimization of three-dimensional folded plate structures. AIAA J 23(11):1804–1810

Braibant V, Fleury C (1984) Shape optimal design using B-splines. Comput Methods in Appl Mech Eng 44:247–267

Braibant V, Fleury C (1986) Shape optimal design-a CAD oriented formulation. Eng with Comput 1:193–204

Braibant V, Fleury C, Beckers P (1983) Shape optimal design: an approach matching C.A.D. and optimization concepts. Report SA-109. Aerospace Laboratory of the University of Liege, Belgium

Cardoso JB, Arora JS (1992) Design sensitivity analysis of nonlinear dynamic response of structural and mechanical systems. Struct Optim 4:37–46

Carpinteri A, Ferro G, Ventura G (2002) The partition of unity quadrature in meshless methods. Int J Numer Methods Eng 54:987–1006

Chen JS, Pan C, Wu CT, Liu WK (1996) Reproducing kernel particle methods for large deformation analysis of non-linear structures. Comput Methods Appl Mech Eng 139:195–227

Chen JS, Wu CT, Yoon S, You Y (2001) A stabilized conforming nodal integration for Galerkin mesh-free methods. Int J Numer Methods Eng 50:435–466

Chen J, Shapiro V, Suresh K, Tsukanov I (2007) Shape optimization with topological changes and parametric control. Int J Numer Methods Eng 71:313–346

Cho S, Ha SH (2009) Isogeometric shape design optimization: exact geometry and enhanced sensitivity. Struct Multidisc Optim 38:53–70

Choi KK, Cho S (1998) Design sensitivity analysis and optimization of non-linear structural dynamics using DYNA3D. Seventh AIAA/USAF/NASA/ISSMO symposium on multidisciplinary analysis and optimization, AIAA, St. Louis, MOIEW AR

Danielson KT, Hao S, Liu WK, Uras RA, Li S (2000) Parallel computation of meshless methods for explicit dynamic analysis. Int J Numer Methods Engrg 47:1323–1341

Dems K (1980) Multiparameter shape optimization of elastic bars in torsion. Int J Numer Methods Eng 15:1517–1539

Dems K, Mroz Z (1978) Multiparameter structural shape optimization by the finite element method. Int J Numer Methods Eng 13:247–263

Diaz AR, Kikuchi N, Taylor JE (1983) A method of grid optimization for finite element methods. Comp Methods in Appl Mech and Eng 41:29–45

Ding Y (1986) Shape optimization of structures: a literature survey. Comput Struct 24(6):985–1004

Dolbow J, Belytschko T (1998) An introduction to programming the meshless element free Galerkin method. Archives Comput Methods Eng 5(3):207–241

Dolbow JE, Belytschko T (1999) Numerical integration of the Galerkin weak form in meshless methods. Comput Mech 23:219–230

Duflot M, Hung ND (2002) A truly meshless Galerkin method based on a moving least squares quadrature. Commun Numer Methods Eng 18:441–449

Duysinx P, Van Miegroet L, Jacobs T, Fleury C (2006) Generalized shape optimization using X-FEM and level set methods. In: Bendsøe MP, Olhoff N, Sigmund O (eds) IUTAM symposium on topological design optimization of structures, machines and materials. Solid Mechanics and its Applications 137:23–32

Fubeder D, Simeon B, Vuong AV (2015) Fundamental aspects of shape optimization in the context of isogeometric analysis. Comput Methods Appl Mech Eng 286:313–331

Garcia-Ruiz MJ, Steven GP (1999) Fixed grid finite element in elasticity optimization. Eng Comput 16(2):145–164

Gingold RA, Monaghan JJ (1977) Smoothed particle hydrodynamics: theory and allocation to non-spherical stars. Monthly Notices Royal Astron Soc 181:375–389

Gong SG, Xie GL, Zhang JP, Nie SH, Li YM (2009) Sensitivity analysis and shape optimization based on FE–EFG coupled method. Res Eng Des 20:117–128

Gracia MJ, Gonzalez CA (2004) Shape optimization of continuum structures via evolution strategies and fixed grid finite element analysis. Struct Multidisc Optim 26:92–98

Griebel M, Schweitzer MA (2002) A particle-partition of unity method. Part V: boundary conditions. In: Hildebrandt S, Karcher H (eds) Geometric analysis and nonlinear partial differential equations. Springer-Verlag, Berlin, pp 517–540

Grindeanu I, Choi KK, Chen JS, Chnag KH (1998) Design sensitivity analysis of Hyperelastic structures using a Meshless method. AIAA J 36(4):61–628

Grindeanu I, Choi KK, Chen JS, Chnag KH (1999) Shape design optimization of Hyperelastic structures using a Meshless method. AIAA J 37(8):990–997

Grindeanu I, Kim NH, Choi KK, Chen JS (2002) CAD-based shape optimization using a Meshless method. Concurrent Eng: Res and Appl 10(1):55–66

Gunther FC, Liu WK (1998) Implementation of boundary conditions for meshless methods. Comput Methods Appl Mech Eng 163(1–4):205–230

Ha YD (2015) Generalized isogeometric shape sensitivity analysis in curvilinear coordinate system and shape optimization of shell structures. Struct Multidisc Optim 52:1069–1088

Ha SH, Choi KK, Cho S (2010) Numerical method for shape optimization using T-spline based isogeometric method. Struct Multidisc Optim 42:417–428

Haftka RT, Grandhi RV (1986) Structural shape optimization: a survey. Comput Methods Appl Mech Eng 57(1):91–106

Hardee E, Chang KH, Tu J, Choi KK, Grindeanu I, Yu X (1999) A CAD-based design parameterization of elastic solids. Advances in Eng Softw 30:185–199

Herrema AJ, Wiese NM, Darling CN, Ganapathsubramanian B, Krishnamurthy A, Hsu MC (2017) A framework for parametric design optimization using isogeometric analysis. Comput Methods Appl Mech Engrg 316:944–965

Hoai SN (2009) An enforced essential boundary condition by penalty method in the element-free galerkin (EFG) methods. Vietnam J Mech 31(2):122–132

Hou JW, Sheen JS, Chuang CH (1992) Shape-sensitivity analysis and design optimization of linear, thermoelastic solids. AIAA J 30(2):528–537

Hsu YL (1994) A review of structural shape optimization. Comput in Industry 26:3–13

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194:4135–4195

Imam MH (1982) Three-dimensional shape optimization. Int J Numer Methods Eng 18:661–673

Ingber MS, Mitra AK (1986) Grid optimization for the boundary element method. Int J for Num Methods in Eng 23:2121–2136

Kang P, Youn SK (2016) Isogeometric shape optimization of trimmed shell structures. Struct Multidisc Optim 53:825–845

Karatarakis A, Metsis P, Papadrakakis M (2013) GPU-acceleration of stiffness matrix calculation and efficient initialization of EFG meshless methods. Comput Methods Appl Mech Eng 258:63–80

Kim NH, Chang Y (2005) Eulerian shape design sensitivity analysis and optimization with a fixed grid. Comput Methods Appl Mech Eng 194:3291–3314

Kim NH, Choi KK (2001) Design sensitivity analysis and optimization of nonlinear transient dynamics. Mech Struct Mach 29:351–371

Kim NH, Choi KK (2005) Structural sensitivity analysis and optimization 1: linear systems. Springer, New York