Abstract

This paper presents a thermal characterization of hardwoods of Hungarian origin. The study covers the wood of the following tree species: sessile oak (Quercus petraea), beech (Fagus sylvatica), hornbeam (Carpinus betulus), black locust (Robinia pseudoacacia), lime (Tilia platyphyllos), ash (Fraxinus ornus), maple (Acer campestre), alder (Alnus glutinosa), and aspen (Populus tremula). Wood samples were subjected to differential scanning calorimetry and thermogravimetry in an air atmosphere at different heating rates of 10, 20, and 40 °C·min−1. The activation energy was calculated using the Flynn–Wall–Ozawa method. Thermogravimetric analysis revealed that tree species differed considerably in the mass loss and the temperature of the maximum mass loss rate related to the thermal degradation of the main wood components and the oxidation of char mainly derived from lignin. Beech, hornbeam and ash were characterized by a high mass loss attributed to decomposition of hemicelluloses. The mass loss assigned to the thermal degradation of cellulose varied from 35.41% (ash wood) to 53.65% (alder wood). Sessile oak wood showed the greatest mass loss and the highest temperature of thermoxidation of residual lignin and char. Calorimetrically measured values of the exothermic effect of the wood thermal degradation were in the range 7.93–9.65 kJ g−1. The average values of activation energy for the thermal degradation of carbohydrates and the thermoxidation of residual lignin and char were found to be 176.0 ÷ 197.3 kJ mol−1and 196.4 ÷ 319.5 kJ mol−1, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With rising environmental problems, wood remains a unique renewable and environmentally friendly natural resource produced in significant amounts worldwide. The physical and mechanical properties of wood, its aesthetically pleasing characteristics, and its low cost are reasons for a growing interest in the use of wood for construction, building, decoration, and furniture (Tomak et al. 2012; Jiang et al. 2015) as well as for heating (Narron et al. 2020; Korshunov et. al. 2020). The properties of wood very often need to be modified in order to work with the material that is most suitable for a particular application. Thermo-hydro and thermo-hydro-mechanical modifications of wood are common, for example drying, steaming, and heat treatment (Sandberg et al. 2013). It is practically important to understand the thermal behavior of wood before it can be used as a building material, as reinforcement in polymer composites or as fuel (Yao et al. 2008; Poletto et al. 2012a; Poletto 2016b; TranVan et al. 2014; Todaro et al. 2018).

The methods of thermal analysis such as thermogravimetry (TG) and differential scanning calorimetry (DSC) are widely applied to study the thermal behavior of wood and lignocellulosic materials in inert and oxidative atmospheres. It is known that the thermal degradation of wood is determined by the thermal decomposition of its main components, i.e. hemicelluloses, cellulose, and lignin (Grønli et al. 2002; Poletto et al. 2010; Sebio-Puñal et al. 2012). The proportions of these components in wood vary among species. In general, hardwoods have a higher content of hemicelluloses (25–35%) and less lignin (18–30%) as compared to softwoods (hemicelluloses 20–25%, lignin 26–34%). Cellulose content ranges between 35 and 50% for both hardwoods and softwoods. In hardwoods, pentosans are the main hemicelluloses, whereas hexosans are prevalent in softwoods (Azarov et al. 2010; Rowell et al. 2012). Wood shows different degradation profiles depending on the variation of chemical composition (Sebio-Puñal et al. 2012). TG and DSC allow to distinguish the temperature intervals of the thermal degradation of wood components and provide information about mass loss, the maximum mass loss rate, and reaction heat.

Among wood components, hemicelluloses have the lowest thermal stability. These polysaccharides are easily hydrolyzed in the temperature range of 225–325 °C due to the presence of acetyl groups. Cellulose decomposes in the temperature range of 305–375 °C (Shen et al. 2009; Poletto et al. 2010; Sebio-Puñal et al. 2012). Lignin decomposes slowly in a wide temperature range because various oxygen functional groups in its structure have different thermal stability, their cleavage occurs at different temperatures. The decomposition of the polymer structure in lignin starts at 200–275 °C but the main process occurs around 400 °C (Bartkowiak and Zakrzewski 2004; Brebu and Vasile 2010). Thus, the intervals of thermal degradation of wood components partly overlap (Órfão et al. 1999; Safi et al. 2004).

Numerous studies have focused on the pyrolysis of wood and lignocellulosic fibers, and the thermal decomposition kinetics under an inert atmosphere due to pyrolysis plays a major role in the production of fuels, wood-based carbonized materials, and polymer composite processing (Ota and Mozammel 2003; Grioui et al. 2006; D’Almeida et al. 2008; Yao et al. 2008; Poletto et al. 2010, 2012b; Slopiecka et al. 2012; Monteiro et al. 2012; Zakikhani et al. 2016; Sharma and Mohanty 2021). Analysis of wood degradation under oxidative conditions is related to the design and development of combustion and gasification systems (Branca and Blasi 2004). Combustion of lignocellulosic materials involves solid pyrolysis and combustion of pyrolysis products (Janković et al. 2020). It is known that the presence of oxygen enhances the thermal degradation of the materials at low temperatures, causes the appearance of gas-phase reactions between the volatile released and oxygen, and promotes the combustion of the char generated in the early stages of the solid degradation (Bilbao et al. 1997). Analysis of the literature shows that either the wood thermal degradation of various deciduous species in an oxidative atmosphere or kinetics of wood combustion has been described in several studies (Fang et al. 2006; Franceschi et al. 2008; Brostow et al. 2009; Budrugeac and Emandi 2010; Emandi et al. 2011; Garcia-Maraver et al. 2013; TranVan et al. 2014; Loskutov et al. 2015). It was demonstrated that the methods of thermal analysis can be applied to the assessment of wood composition and the holocellulose/lignin ratio as well as to the evaluation of the combustion properties in terms of the amount of energy released and the thermal stability of wood. Brostow et al. (2009) stated that the species of the wood had an effect on the combustibility of the sample, but no connection was found between the wood density and the parameters characterizing the burning process. Fang et al. (2006) studied the influence of oxygen concentration on kinetics of wood combustion. It was found that the activation energy increased linearly with concentration of oxygen at the first stage. At the second stage of combustion, the activation energy varied linearly only when the concentration of oxygen was below 65%. So far, as we know, only a few studies provide both the thermal degradation characteristics of wood and the kinetic parameters of combustion process simultaneously for some hardwoods (Liu et al. 2002; Shen et al. 2009; Maryandyshev et al. 2015). Therefore, in the present work, the experiments on the wood samples were carried out in an air atmosphere. The objective was to study the wood thermoxidative degradation and its kinetics of nine deciduous species used in the timber industry in Europe. The data obtained from the thermal analysis of wood of the given species in an oxidative atmosphere will enhance our knowledge of wood heat resistance and contribute to the development of different combustion applications.

2 Materials and methods

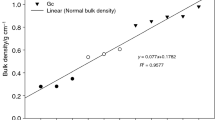

The samples from nine hardwood species were studied, namely sessile oak (Quercus petraea) (1), beech (Fagus sylvatica) (2), hornbeam (Carpinus betulus) (3), black locust (Robinia pseudoacacia) (4), lime (Tilia platyphyllos) (5), ash (Fraxinus ornus) (6), maple (Acer campestre) (7), alder (Alnus glutinosa) (8), and aspen (Populus tremula) (9) of West Hungarian origin. These tree species have been widely used in the European wood industry. Wood samples were collected from the forests or the sawmills of Sopron region. A full disk (20 mm thick) was cut from the tree at breast height. The wood disks were stored for two months in a normal climate room to reach homogenous moisture content on the full cross section. The disks were sawn carefully with a fine-tooth metal saw on the diameter line of the disk to represent the full cross section of the tree (Fig. 1). The fine sawdust was used for the thermal analysis. The particle size was 50 ÷ 80 meshes.

Thermogravimetry was carried out on a TG 209 F1 thermal analyzer (Netzsch, Germany) in an air atmosphere with 20 cm3/min flow, from 25 up to 700 °C. Approximately 10 mg of powdered samples were placed into Al2O3 crucible and heated at different rates of 10, 20, 40 °C/min. Differential scanning calorimetry was performed on a DSC 204 F1 thermal analyzer (Netzsch, Germany) in an air atmosphere with 40 cm3/min flow, from 25 up to 600 °C. Approximately 1 mg of powder was placed in an alumina crucible with a pierced lid and heated at a rate of 10 °C/min. The DSC measurement was repeated in triplicates for each specimen.

The activation energy (Ea) is one of the important kinetic parameters for a reaction. The activation energy of the thermal decomposition of wood was calculated based on thermogravimetric data using the isoconversional method of Flynn–Wall–Ozawa (FWO). According to the FWO theory, an equation for calculating Ea looks like (Mamleev et al. 2004):

where α is the degree of conversion:\(\alpha = \frac{{m_{0} - m}}{{m_{{}} - m_{f} }}\); m0 is the initial sample mass in the TG experiment; m is the current sample mass at temperature T; mf is the final sample mass after thermal degradation; β is the heating rate; R is the gas constant; A is the pre-exponential factor; F(a) is the function of mathematical representation of the FWO kinetic model.

The FWO method is based on the assumption that the reaction rate for a constant degree of conversion depends only on the temperature. The activation energy of the thermal decomposition of a sample is determined by the value of the angle of the straight line slope constructed in coordinates \(\mathrm{ln}\beta -\frac{1}{T}\) for a number of α values. Knowledge of the reaction mechanism (order) is not required.

3 Results and discussion

The TG/DTG profiles obtained from the thermal degradation of hardwoods in an air atmosphere are shown in Fig. 2. During thermal degradation in air, mass loss occurs continuously until the mass becomes almost constant and the DTG peaks give a clear indication of the number of mass loss stages (Safi et al. 2004).

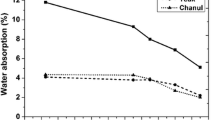

The mass loss in the TG curves below 180 °C (not shown in Fig. 2) attributed to the evaporation of water and volatile compounds of wood (Kumar et al. 2008) varied from 3.5% (lime) to 6.8% (aspen). In the range 180–700 °C, deciduous species revealed three peaks (shoulders) in the DTG (derivative thermogravimetric) curves related to three consistent stages of mass loss which represent the thermal degradation of the main wood components and char combustion (Liu et al. 2002; Gao et al. 2004a, b; Safi et al. 2004; Fang et al. 2006; Shen et al. 2009; Lόpez-González et al. 2013; Protásio et al. 2017; Janković et al. 2020). Analyzing the TG and DTG curves, it can be noticed that the thermal degradation of wood completely finished at 500 °C for all tree species studied.

The first stage is assigned to decomposition or dehydration of hemicelluloses in the range 185–303 °C (Gao et al. 2004a) and can be seen as a peak or shoulder in the DTG curves for all deciduous species studied. Up to 300 °C, the material does not undergo significant oxidation, and reactions typical for pyrolysis occur (Órfão et al. 1999). The peak at 283–289 °C was observed for beech, hornbeam, and ash. For other tree species, the decomposition of hemicelluloses was identified only as a shoulder. This can be explained by different amounts of hemicelluloses. The tree species namely beech, hornbeam, and ash had the high loss of mass (33.91–35.94%) at this stage. Alder, aspen, black locust, and sessile oak showed only 20.23–24.33% (Table 1). The rest revealed intermediate values. The present findings are consistent with the literature data. Shen et al. (2009) reported a shoulder-peak at around 280 °C attributed to thermal decomposition of hemicelluloses of deciduous species (aspen, oak, birch) in an oxidative atmosphere. Emandi et al. (2011) investigated the wood composition by thermogravimetry in static air and observed the maximum mass loss rate of hemicelluloses at a temperature of 288–297 °C for lime, hornbeam, maple, beech, and poplar.

The second stage is due to the dehydration and combustion of cellulose up to 380 °C. At this stage, the less-stable aliphatic groups are mainly broken down through hemolytic cleavage of C–C and C-H bonds, resulting in a highly condensed and cross-linked carbonaceous material (Gao et al. 2004a). The degradation of cellulose was observed as a well defined peak in DTG curves for all tree species studied. Sessile oak had the lowest temperature of the DTG peak, while lime, alder, and aspen showed the highest one. By defining the thermal stability as the DTG peak temperature it is suggested that cellulose component of sessile oak wood is the least thermally stable among hardwoods. The mass loss at this stage varied from 35.41% (ash) to 53.65% (alder). The maximum mass loss rate was significantly higher (18.68–19.65% min−1) for lime, alder, and aspen which had a greater mass loss of cellulose and the least (9.28% min−1) for ash. The difference in the thermal stability of cellulose in wood of the tree species studied may be related to its crystallinity index, crystallite size and degree of polymerization (Poletto et al. 2012a). The cellulose thermal stability may also be influenced by extractives. It was demonstrated that a higher content of extractives accelerates the degradation process and promotes an increase in the conversion values at lower temperatures reducing the wood thermal stability (Poletto 2016a).

In general, the deciduous species showed a total mass loss of carbohydrates (hemicelluloses and cellulose) from 67.72% (sessile oak) to 75.88% (lime). The present results are similar to those obtained by thermogravimetry in air for maple, beech, hornbeam of Romanian origin (Emandi et al. 2011).

The third stage is due to degradation of residual lignin and oxidation of char formed previously. Lignin is the main contributor at this stage. Lignin is responsible for the formation of char due to its higher thermal stability compared to cellulose and hemicelluloses (Protásio et al. 2017). According to Órfão et al. (1999) and Yang et al. (2007), char yield was 37–46% for lignin, 20% for hemicelluloses and 5% for cellulose. A very narrow peak in the DTG curves and a high mass loss rate reflect a rapid combustion of char. Sessile oak showed the highest mass loss (25.69%), aspen and lime the lowest ones (17.54 and 17.69%, respectively). The DTG peak temperature was the highest (462 °C) for sessile oak indicating the greatest lignin thermal stability, followed by alder, black locust and aspen, lime, maple, beech, hornbeam, and ash. The maximum mass loss rate was the lowest for sessile oak and the highest for alder. It indicates that more thermally stable lignin of sessile oak wood decomposes more slowly as compared to other hardwoods studied. Shen et al. (2009) also observed that oak had the highest temperature of DTG peak (450 °C) compared to other deciduous species at a heating rate of 10 K/min in an oxidative atmosphere. Emandi et al. (2011) reported the temperature of the DTG peak assigned to lignin thermoxidation at 473.8 °C for oak (Quercus robur).

The amount of residual at 700 °C (ash) reflects the inorganic content and varied from 1.27% (sessile oak) to 3.35% (beech). The present results are consistent with literature data. Brostow et al. (2009) studied combustion properties of woods and reported ash content of 0.6–2.7% obtained in TGA experiments. Liu et al. (2002) found that the ash yield at 750 °C from wood degradation was in the range 1.0–6.3%.

The DSC curves show the heat flow during thermal degradation of wood samples (Fig. 3). Below 150 °C, an endoderm at 49–63 °C mainly due to the removal of moisture was observed for all wood samples studied (not shown in Fig. 3). With increasing temperature above 150 °C, the processes become exothermic with energy release from the devolatilization and combustion (Maryandyshev et al. 2015). The DSC curves of tree species exhibited two exothermic peaks (exotherms) at 333.6–341.6 °C and 447.8–481.9 °C, which can be attributed to thermal degradation of cellulose and thermoxidation of residual lignin and char, respectively. The present findings related to the temperatures of two exotherms are in accordance with literature data reported for the combustion of woods (Tsujiyama and Miyamori 2000; Maryandyshev et al. 2015). Besides the first exothermic peak of cellulose degradation, there is a slight shoulder located at the lower temperature region in the DSC curves, which may be assigned to the decomposition of hemicelluloses. DSC peaks correspond to two main peaks in DTG curves of wood samples but occur at higher temperatures due to differences in processes of the heat and mass transfer. Two sharp and closely spaced exothermic peaks indicate a large rate of heat release during the oxidative degradation of wood (Gao et al. 2004b).

The tree species revealed some differences in peak intensities in the DSC curves. According to the literature, the height and area of DSC peaks reflect the various content and nature of cellulose and lignin in woods (Reh et al. 1986; Franceschi et al. 2008). It can be noticed that the temperature of the second exothermic peak varied significantly among hardwoods. The sessile oak wood was characterized by the highest peak temperature at which heat release occurred during the thermoxidation of residual lignin and char formed previously. This fact confirms the thermogravimetry data.

The values of exothermic effect of wood thermal degradation obtained by DSC are given in Table 2. The amount of heat released was the highest (9.65 kJ g−1) for sessile oak and the lowest (7.93 kJ g−1) for aspen. The present results are similar to the reported values of 8.60 kJ g−1obtained for maple (Acer saccharum) but higher than 6.83 kJ g−1 found for oak (Quercus rubra) by Brostow et al. (2009). A positive correlation was found between the value of the exothermic effect and the mass loss of samples at the third stage assigned to thermoxidation of lignin and char (r = 0.95 at p < 0.05).

The FWO method is the most suitable method to determine the kinetics of the thermal decomposition of wood and other materials (Mamleev et al. 2004; Muralidhara and Sreenivasan 2010; Slopiecka et al. 2012; Baroni et al. 2016; Abdelouahed et al. 2017; Sharma and Diwan 2017; Sobek and Werle 2020; Janković et al. 2020). The mechanisms and kinetics of thermal decomposition of wood in non-isothermal conditions have been described in detail by Poletto et al. (2012b).

Figures 4 and 5 show the building FWO graphs for the thermal degradation of ash wood (as an example) and the dependence of activation energy on the conversion rate of wood substance for all tree species studied.

Curves of activation energy (Ea) versus conversion degree (α) obtained by FWO method: sessile oak (1), beech (2), hornbeam (3), black locust (4), lime (5), ash (6), maple(7), alder (8), aspen (9); X-axis is the conversion degree (α); Y-axis is the activation energy (Ea, kJ mol−1); black circle: predominant change in the degree of holocellulose conversion, black triangle: change in the degree of residual lignin and formed char conversion

The average value of activation energy of thermal decomposition of holocellulose (hemicelluloses, cellulose) for all tree species at 0.05 ≤ α < 0.50 was 186.90 kJ mol−1, the standard deviation was 7.55 kJ mol−1. The coefficient of variation was 4.04% (Fig. 6). The values Ea obtained in this study are in agreement with results of López et al. (2013) and Maryandyshev et al. (2015) who applied FOW isoconversional model to evaluate kinetic parameters for the combustion of lignocellulosic biomass and woods.

According to the differences between the minimum and the maximum of Ea at 0.05 ≤ α < 0.50, tree species can be divided into two groups: (1) poplar, oak, beech, lime, hornbeam, and alder (29 ÷ 44 kJ mol−1); (2) black locust, ash, maple (60 ÷ 127 kJ mol−1) (Fig. 5). It indicates that black locust, ash, maple have more heterogeneous composition and structure of carbohydrate complex of wood.

At the stage of residual lignin and char thermoxidation (Ea(average) 231.17 kJ mol−1, standard deviation 40.71 kJ mol−1; 0.45 < α ≤ 0.85), the coefficient of variation of the average activation energy among all tree species was significantly higher (17.61%) than the one for the thermal degradation of holocellulose. It can be noticed from Fig. 5 that value of activation energy has tendency to increase at the end of thermoxidation. It was found that Ea correlated well with the degree of conversion in this range of the thermal degradation for some wood specimens (lime, ash, maple, alder, and aspen). This can be explained by the increasing density of molecular packing of the decomposing sample residue.

4 Conclusion

In this study, thermogravimetry and differential scanning calorimetry were used to determine the parameters and kinetics of the thermal degradation of nine hardwoods in an oxidative (air) atmosphere. The results showed that the differences found in the temperature of DTG/DSC peaks, the mass loss, and the maximum mass loss rate of main wood components (hemicelluloses, cellulose, lignin) as well as the values of exothermic effect and activation energy allow to differentiate tree species in terms of wood thermal stability. The obtained results can be used to develop modes of wood drying, thermal modification, and pellet manufacturing.

References

Abdelouahed L, Leveneur S, Vernieres-Hassimi L, Balland L, Taouk B (2017) Comparative investigation for the determination of kinetic parameters for biomass pyrolysis by thermogravimetric analysis. J Therm Anal Calorim 2:1201–1213. https://doi.org/10.1007/s10973-017-6212-9

Azarov VI, Burov AV, Obolenskaya AV (2010) Xимия дpeвecины и cинтeтичecкиx пoлимepoв (Chemistry of wood and synthetic polymers). Saint-Peterburg (in Russian) Lan’ Publ., 624 p.

Baroni ÉG, Tannous K, Rueda-Ordόñez YJ, Tinoco-Navarro LK (2016) The applicability of isoconversional models in estimating the kinetic parameters of biomass pyrolysis. J Therm Anal Calorim 123:909–917. https://doi.org/10.1007/s10973-015-4707-9

Bartkowiak M, Zakrzewski R (2004) Thermal degradation of lignins isolated from wood. J Therm Anal Calorim 77:295–304. https://doi.org/10.1023/B:JTAN.0000033214.95457.fe

Bilbao R, Mastral JF, Aldea ME, Ceamanos J (1997) Kinetic study for the thermal decomposition of cellulose and pine sawdust in an air atmosphere. J Anal Appl Pyrolysis 37(1):53–64. https://doi.org/10.1016/S0165-2370(96)00957-6

Branca C, Blasi CD (2004) Global interinsic kinetics of wood oxidation. Fuel 83(1):81–87. https://doi.org/10.1016/S0016-2361(03)00220-5

Brebu M, Vasile C (2010) Thermal degradation of lignin—a review. Cellul Chem Technol 44(9):353–363

Brostow W, Menard KP, Menard N (2009) Combustion properties of several species of wood. Chem Chem Technol 3(3):173–176

Budrugeac P, Emandi A (2010) The use of thermal analysis methods for conservation state determination of historical and/or cultural objects manufactured from lime tree wood. J Therm Anal Calorim 101:881–886. https://doi.org/10.1007/s10973-009-0671-6

D’Almeida LFS, Barreto DW, Calado V, D’Almeida JRM (2008) Thermal analysis of less common lignocellulose fibers. J Therm Anal Calorim 91(2):405–408

Emandi A, Vasiliu CI, Budrugeac P, Stamatin I (2011) Quantitative investigation of wood composition by integrated FT-IR and thermogravimetric methods. Cellul Chem Technol 45(9–10):579–584

Fang MX, Shen DK, Li YX, Yu CJ, Luo ZY, Cen KF (2006) Kinetic study on pyrolysis and combustion of wood under different oxygen concentrations by using TG-FTIR analysis. J Anal Appl Pyrolysis 77:22–27. https://doi.org/10.1016/j.jaap.2005.12.010

Franceschi E, Cascone I, Nole D (2008) Thermal, XRD and spectrophotometric study on artificially degraded woods. J Therm Anal Calorim 91(1):119–125

Gao M, Li S, Sun C (2004a) Thermal degradation of wood in air and nitrogen treated with basic nitrogen compounds and phosphoric acid. Combust Sci Technol 176:2057–2070. https://doi.org/10.1080/00102200490514840

Gao M, Sun C, Zhu K (2004b) Thermal degradation of wood treated with guanidine compounds in air. J Therm Anal Calorim 75:221–232

Garcia-Maraver A, Salvachúa D, Martínez MJ, Diaz LF, Zamorano M (2013) Analysis of the relation between the cellulose, hemicellulose and lignin content and the thermal behavior of residual biomass from olive trees. Waste Manag 33(11):2245–2249. https://doi.org/10.1016/j.wasman.2013.07.010

Grioui N, Halouani K, Zoulalian A, Halouani F (2006) Thermogravimetric analysis and kinetics modeling of isothermal carbonization of olive wood in inert atmosphere. Thermochim Acta 440:23–30. https://doi.org/10.1016/j.tca.2005.09.018

Grønli MG, Várhegyi G, Blasi CD (2002) Thermogravimetric analysis and devolatilization kinetics of wood. Ind Eng Chem Res 41(17):4201–4208. https://doi.org/10.1021/ie0201157

Janković B, Manić N, Dodevski V, Radojević M, Stojiljković D (2020) Kinetic study of oxy-combustion of plane tree (Platanus orientalis) seeds (PTS) in O2/Ar atmosphere. J Therm Anal Calorim 142:953–976. https://doi.org/10.1007/s10973-019-09154-z

Jiang J, Li J, Gao Q (2015) Effect of flame retardant treatment on dimensional stability and thermal degradation of wood. Constr Build Mater 75:74–81. https://doi.org/10.1016/j.conbuildmat.2014.10.037

Korshunov A, Kichatov B, Sudakov V, Kolobov A, Gubernov V, Kiverin A (2020) Torrefaction of wood in a quiescent layer of talc. Energy Fuels 34(4):4660–4669. https://doi.org/10.1021/acs.energyfuels.9b04478

Kumar A, Wang L, Dzenis YA, Jones DD, Hanna MA (2008) Thermogravimetric characterization of corn stover as gasification and pyrolysis feedstock. Biomass Bioenergy 32:460–467. https://doi.org/10.1016/j.biombioe.2007.11.004

Liu NA, Fan W, Dobashi R, Huang L (2002) Kinetic modeling of thermal decomposition of natural cellulosic materials in air atmosphere. J Anal Appl Pyrol 63:303–325. https://doi.org/10.1016/S0165-2370(01)00161-9

Lόpez R, Fernández C, Gόmez X, Martínez O, Sánchez ME (2013) Thermogravimetric analysis of lignocellulosic and microalgae biomasses and their blends during combustion. J Therm Anal Calorim 114:295–305. https://doi.org/10.1007/s10973-012-2843-z

López-González D, Fernandez-Lopez M, Valverde JL, Sanchez-Silva L (2013) Thermogravimetric-mass spectrometric analysis on combustion of lignocellulosic biomass. Bioresour Technol 143:562–574. https://doi.org/10.1016/j.biortech.2013.06.052

Loskutov SR, Shapchenkova OA, Aniskina AA (2015) Thermal analysis of wood of the main tree species of Central Siberia. Siberian Journal of Forest Science 6:17–30. https://doi.org/10.15372/SJFS20150602

Mamleev V, Dourbigot S, Le Bras M, Lefebvre J (2004) Three model-free methods for calculation of activation energy in TG. J Therm Anal Calorim 78(3):1009–1027. https://doi.org/10.1007/s10973-004-0467-7

Maryandyshev P, Chernov A, Lyubov V, Trouve´ G, Brillard A, Brilhac J-F (2015) Investigation of thermal degradation of different wood-based biofuels of the northwest region of the Russian Federation. J Therm Anal Calorim. https://doi.org/10.1007/s10973-015-4798-3

Monteiro SN, Calado V, Margem FM, Rodriguez RJS (2012) Thermogravimetric stability behavior of less common lignocellulosic fibers—a review. J Mater Res Technol 1(3):189–199. https://doi.org/10.1016/S2238-7854(12)70032-7

Muralidhara KS, Sreenivasan S (2010) Thermal degradation kinetic data of polyester, cotton and polyester-cotton blended textile material. World Appl Sci J 11(2):184–189

Narron RH, Winowiski T, Gargulak J, Hendricks K (2020) Fiber-first approach to isothermal calorimetry for quantification of self-heating reduction by antioxidants for the wood pelleting industry. Fuel 274:117788. https://doi.org/10.1016/j.fuel.2020

Órfão JJM, Antunes FJA, Figueiredo JL (1999) Pyrolysis kinetics of lignocellulosic materials-three independent reactions model. Fuel 78:349–358. https://doi.org/10.1016/S0016-2361(98)00156-2

Ota M, Mozammel HM (2003) Chemical kinetics of Japanese cedar, cypress, fir, and spruce and characterization of charcoal. J Wood Sci 49:248–254

Poletto M (2016a) Effect of extractive content on the thermal stability of two wood species from Brazil. Maderas Cienc Tecnol 18(3):435–442. https://doi.org/10.4067/S0718-221X2016005000039

Poletto M (2016b) Thermal degradation and morphological aspects of four wood species used in lumber industry. Rev Árvore 40(5):941–948. https://doi.org/10.1590/0100-67622016000500018

Poletto M, Dettenborn J, Pistor V, Zeni M, Zattera AJ (2010) Materials produced from plant biomass. Part I: evaluation of thermal stability and pyrolysis of wood. Mater Res 13(3):375–379. https://doi.org/10.1590/S1516-14392010000300016

Poletto M, Zattera AJ, Forte MMC, Santana RMC (2012a) Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour Technol 109:148–153. https://doi.org/10.1016/j.biortech.2011.11.122

Poletto M, Zattera AJ, Santana RMC (2012b) Thermal decomposition of wood: kinetics and degradation mechanisms. Bioresour Technol 126:7–12. https://doi.org/10.1016/j.biortech.2012.08.133

Protásio TP, Junior MG, Mirmehdi S, Trugilho PF, Napoli A, Knovack KM (2017) Combustion of biomass and charcoal made from babassu nutshell. Cerne 23(1):1–10. https://doi.org/10.1590/01047760201723012202

Reh U, Kraepelin G, Lamprecht I (1986) Use of differential scanning calorimetry for structural analysis of fungally degraded wood. Appl Environ Microbiol 52(5):1101–1106. https://doi.org/10.1128/aem.52.5.1101-1106.1986

Rowell RM, Pettersen R, Tshabalala MA (2012) Cell wall chemistry from: handbook of wood chemistry and wood composites. CRC Press, Florida

Safi MJ, Mishra IM, Prasad B (2004) Global degradation kinetics of pine needles in air. Thermochim Acta 412(1–2):155–162. https://doi.org/10.1016/j.tca.2003.09.017

Sandberg D, Haller P, Navi P (2013) Thermo-hydro and thermohydro-mechanical wood processing: an opportunity for future environmentally friendly wood products. Wood Mater Sci Eng 8(1):64–88. https://doi.org/10.1080/17480272.2012.751935

Sebio-Puñal T, Naya S, Lόpez-Beceiro J, Tarrío-Saaverda J, Artiaga R (2012) Thermogravimetric analysis of wood, holocellulose, and lignin from five wood species. J Therm Anal Calorim 109:1163–1167. https://doi.org/10.1007/s10973-011-2133-1

Sharma P, Diwan PK (2017) Study of thermal decomposition process and the reaction mechanism of the eucalyptus wood. Wood Sci Technol 51:1081–1094. https://doi.org/10.1007/s00226-017-0924-7

Sharma A, Mohanty B (2021) Thermal degradation of mango (Mangifera indica) wood sawdust in a nitrogen environment: characterization, kinetics, reaction mechanism, and thermodynamic analysis. RSC Adv 11:13396–13408. https://doi.org/10.1016/j.biortech.2012.08.133

Shen DK, Gua S, Luo KH, Bridgwater AV, Fang MX (2009) Kinetic study on thermal decomposition of woods in oxidative environment. Fuel 88:1024–1030. https://doi.org/10.1016/j.fuel.2008.10.034

Slopiecka K, Bartocci P, Fantozzi F (2012) Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl Energy 97:491–497. https://doi.org/10.1016/j.apenergy.2011.12.056

Sobek S, Werle S (2020) Kinetic modelling of waste wood devolatilization during pyrolysis based on thermogravimetric data and solar pyrolysis reactor performance. Fuel 261(1):116459. https://doi.org/10.1016/j.fuel.2019.116459

Todaro L, Rita A, Pucciariello R, Mecca M, Hiziroglu S (2018) Influence of thermo-vacuum treatment on thermal degradation of various wood species. Eur J Wood Prod 76:541–547. https://doi.org/10.1007/s00107-017-1230-7

Tomak ED, Baysal E, Peker H (2012) The effect of some wood preservatives on the thermal degradation of Scots pine. Thermochim Acta 547:76–82. https://doi.org/10.1016/j.tca.2012.08.007

TranVan L, Legrand V, Jacquemin F (2014) Thermal decomposition kinetics of balsa wood: kinetics and degradation mechanisms comparison between dry and moisturized materials. Polym Degrad Stab 110:208–215. https://doi.org/10.1016/j.polymdegradstab.2014.09.004

Tsujiyama S, Miyamori A (2000) Assignment of DSC thermograms of wood and its components. Thermochim Acta 351(1–2):177–181. https://doi.org/10.1016/S0040-6031(00)00429-9

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Yao F, Wu Q, Lei Y, Guo W, Xu Y (2008) Thermal decomposition kinetics of natural fibers: activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab 93:90–98. https://doi.org/10.1016/j.polymdegradstab.2007.10.012

Zakikhani P, Zahari R, Sultan MTH, Majid DL (2016) Thermal degradation of four bamboo species. BioResources 11(1):414–425. https://doi.org/10.15376/biores.11.1.414-425

Acknowledgements

The work was carried out as part of GINOP-2.3.3-15-2016-00038, "Further processing of wood and wood products based on green chemistry and technology, through creating modern research infrastructure" in the framework of the Széchenyi 2020 Program. The implementation of this project is supported by the European Union, co-financed by the European Regional Development Fund.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shapchenkova, O., Loskutov, S., Aniskina, A. et al. Thermal characterization of wood of nine European tree species: thermogravimetry and differential scanning calorimetry in an air atmosphere. Eur. J. Wood Prod. 80, 409–417 (2022). https://doi.org/10.1007/s00107-021-01763-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01763-6