Abstract

The TG, DTG and DSC methods were used for investigation of the thermo-oxidative degradation in static air atmosphere and oxygen flow of some sorts of lime tree wood (recent lime tree woods with different preparations, old lime tree woods extracted from some Romanian historical and/or cultural objects). At the progressive heating in the mentioned atmospheres, all the investigated materials exhibit three successive processes, associated with dehydration and two complex thermo-oxidative processes. Each analyzed material has a characteristic thermogram (TG, DTG and/or DSC curve) that can be considered a material “fingerprint”. It was pointed out that the following non-isothermal parameters can be used for distinction between a new and old lime tree wood: mass loss in the first process of thermo-oxidation, ratio between the mass losses in the first and the second processes of thermo-oxidation, the maximum rate of the first process of thermo-oxidation. Consequently, the certification of a patrimonial object manufactured from lime tree wood could be performed by applying the thermal analysis methods.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Among the problems of museum custodians, private collectors or antiquaries’ one may specify: (a) the authentication of the cultural or historical object (author, period in which the object was manufactured, etc.); (b) selection of the treatments for preservation and restoration. As it is noticeable from literature, there is ≈150 years history of the analytical procedures for the identification of heritage objects and the assessment of their damage as a result of the environmental conditions. Improvement of these procedures was accomplished by the development of non-destructive and micro-destructive analytical methods, providing information about physical and chemical properties of a material. Among these techniques, the thermal analysis methods (TG, DTG, DTA, DSC, TMA, DMA, thermo-microscopy, micro hot table (MHT) method, etc.) were applied to characterize some material samples from heritage objects [1–39]. From the mentioned studies, Refs. [34–39] are devoted to the degradation of historical or cultural objects manufactured from different sorts of wood.

Tomassetti et al. [34–36] and Wiedemann [37, 38] pointed out that thermogravimetry (TG) enables a rapid and accurate moisture, cellulose, lignin contents and % ashes residues determination in the fresh and old wood samples. In comparison with the fresh wood samples, the ancient wood samples (archaeological waterlogged wood of a Roman vessel from the first century AD, wood from portals of churches from the thirteenth and eighteenth centuries, 2 million year fossil wood) content a scarcely amount of cellulose and the corresponding relative increase of lignin as a consequence of microbial degradation [34–36].

Sandu et al. [39] use thermogravimetric method for investigation of the non-isothermal thermo-oxidative degradation of some samples of soft lime tree wood from the structure of the supports of old painting (mobile icons and iconostasis) 100–200 years old. It was obtained that the characteristic parameters of TG and DTG curves as well as global kinetic parameters of the thermo-oxidations of wood samples depend on their deterioration degree. However, the relative high mass of analyzed samples (50 mg) did not allow an accuracy determination of the ratio between the mass losses in the two processes of thermo-oxidation put in evidence in TG and DTG curves. On the other hand, the correlations were made only TG and DTG results obtained for 10 samples: a new lime tree wood, eight samples of old lime tree wood from which three samples exhibit a very good preservation state, a carbonized wood.

The large use of lime tree (Tillia cordata Mill) wood as support for icons as well as for manufactured iconostasis from Romanian churches and monasteries is the reason for which the comparison between thermal behaviour of new and old samples of this wood sort was the objective of this article. The results obtained by thermal analysis methods (TG, DTG, DSC) for new and old lime tree woods are correlated with the damage of old woods as well as for advancing some criteria for distinction between the original artifacts and bootlegs.

Experimental

Materials

Our experiments were carried out for the new and old lime tree woods listed in Table 1. In this table, there are succinctly mentioned the preparation procedure of new woods as well as the sources and approximate ages of old woods.

Thermal analysis

TG/DTG and DSC plots were simultaneously recorded with Netzsch 409 PC apparatus from 25 to 600 °C, at 10 K min−1 heating rate. Measurements were performed in static air atmosphere as well as in high purity (99.999%) oxygen flow (30 mL min−1), using Pt–Rh crucible. The sample masses were in the range 0.72–2.60 mg.

DSC measurements were also performed with high sensitivity Netzsch DSC 204 F1 Phoenix apparatus in the following conditions: aluminum pans with drilled lids, temperature range 5–550 °C; high purity (99.999%) oxygen flow (20 mL min−1); sample mass in the range 1.00–2.18 mg.

Results and discussion

Simultaneous TG/DTG and DSC analysis

Figures 1 and 2 show the TG, DTG and DSC curves for some new and old lime tree woods analyzed in static air atmosphere and oxygen flow; similar plots have been obtained for all analyzed samples. They are qualitatively in agreement with the results previously reported for some sorts of woods [34–42].

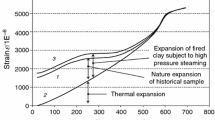

The inspection of curves given in Figs. 1 and 2 shows that the non-isothermal degradation in static air atmosphere or oxygen flow occurs through three successive processes accompanied by mass losses. In the first endothermic process, denoted by I, the water was completely loss. The next two processes, denoted by II and III, are exothermal ones and consist in the pyrolytic decomposition and thermo-oxidation of the wood. These last processes occur in the following temperature ranges: ≈250–380 °C for process II, and ≈400–500 °C for process III. According to Tomassetti et al. [34–36] and Wiedemann [37–40], the processes II and III correspond, respectively, to the cellulose and lignin thermo-oxidations. Consequently, the percentage contents of the main components of wood can be evaluated from the TG curves recorded in air static atmosphere or oxygen flow. The complexity of the global processes II and III results from the shapes of DTG and DSC curves, e.g. the shoulder of DTG curve corresponding to the process II shows that this consists in at least two successive steps. For all new lime tree woods, \( T_{\min }^{\text{DTG}} ({\text{II)}} \) (temperature corresponding to minimum of DTG curve characteristic for process II) does not depend practically on the wood sort (for analyses performed in static air atmosphere: \( \overline{{T_{\min }^{\text{DTG}} }} ({\text{II}}) \) = 328.7 ± 3.7 °C; for analyses performed in oxygen flow: \( \overline{{T_{\min }^{\text{DTG}} }} ({\text{II}}) \) = 313.0 ± 1.0 °C), while \( T_{\min }^{\text{DTG}} ({\text{II}}) \) for old woods exhibits a relative high standard deviation (for analyses performed in static air atmosphere: \( T_{\min }^{\text{DTG}} ({\text{II}}) \) = 307.8 ± 26.7 °C; for analyses performed in oxygen flow: \( T_{\min }^{\text{DTG}} ({\text{II}}) \) = 303.0 ± 15.0 °C). Similar observation was made for temperature corresponding to minimum of DTG curve characteristic for process III (\( T_{\min }^{\text{DTG}} ({\text{III}}) \)), e.g. for analyses performed in static air atmosphere and new woods \( T_{\min }^{\text{DTG}} ({\text{III}}) \) = 446.1 ± 6.7 °C, while for the same atmosphere and old woods \( T_{\min }^{\text{DTG}} ({\text{III}}) \) = 460.5 ± 22.0 °C. The main differences between the thermal behaviour of new and old woods were put in evidence by comparison of the following parameters: maximum rate of process II (\( - {\text{d}}\% \Updelta m/{\text{d}}t \)), ratio between the mass losses in processes II and III (\( \Updelta m_{\text{II}} /\Updelta m_{\text{III}} \)) that is practically equal with the ration between the cellulose and lignin contents of the wood [34–36], the percentage mass loss in process II (\( \% \Updelta m_{\text{II}} \)). According to the results presented in Fig. 3, for both atmospheres in which the analyses were performed, each of these parameters for the old woods has a lower value than that corresponding for new woods.

The comparison between the average values of the following parameter corresponding to new and old woods: maximum rate of process II (\( - {\text{d}}\% \Updelta m/{\text{d}}t \)), ration between the mass losses in processes II and III (\( \Updelta m_{\text{II}} /\Updelta m_{\text{III}} \)), and the percentage mass loss in process II (\( \% \Updelta m_{\text{II}} \)). a Analyses performed in static air atmosphere and b analyses performed in oxygen flow

The relative lower values of \( \% \Updelta m_{\text{II}} \) and \( \Updelta m_{\text{II}} /\Updelta m_{\text{III}} \) corresponding to old woods are due to the cellulose degradation as a result of natural degradation consisting in hydrolysis, decomposition, oxidation, light (especially UV) irradiation and/or biodegradation. These results are in agreement with those obtained by Tomassetti et al. [35] according to which the ancient wood samples (fir, larch, spruce) from portal of churches from thirteenth and eighteenth centuries and to 2 million-years-old fossil wood exhibited high content of carbon due to relative decrease of cellulose as a consequence of cellulose degradation and the corresponding relative increase of lignin. The relative high values of rate of process II corresponding to new woods could be due to relative high cross-linking degree of cellulose chains. Similarly, the oxidation rate of polymeric materials increases with the increased degree of substitution of carbon atoms obtained by cross-linking [43, 44]. The differences among the thermo-oxidation rates of some collagen-based materials (new and old leathers, parchment and pure collagen) were also explained [27–30] by the differences in cross-linking degree of these materials. In conclusion, according to results given in Fig. 3, the breaking of cross-linking bonds and thermo-oxidation of cellulose component of wood is one of processes that occur during the natural ageing of lime tree wood. In addition, the changes of DTG and DSC curves shapes suggest some alterations of lignin composition and structure as a result of natural aging of wood, too.

The damage degree of wood is influenced by different wood preparation procedures and by conditions of stocking and exposure. Therefore, from practical point of view, the above presented results show that differences between TG and DTG curves recorded in air or oxygen atmosphere could be used only as qualitative criteria for distinguish between a new lime tree wood and a naturally aged lime tree wood (patrimonial lime tree wood), and not for evaluation of the age of the patrimonial lime tree wood.

DSC analysis in oxygen flow

Figure 4a–c show DSC curves for some new and old lime tree woods analyzed in oxygen flow using high sensitivity Netzsch DSC 204 F1 Phoenix apparatus; similar plots have been obtained for all analyzed samples. They are qualitatively in agreement with the results previously reported for some woods [34, 36, 40–42, 45–47] as well as with our above presented results that were obtained by TG/DTG + DSC simultaneous analyses.

In all the DSC curves, a first endothermic peak (denoted by I) is observed, due to the water desorbtion, which is followed by two exothermic peaks (denoted by II and III). The first exothermic peak was considered [34, 36, 40–42, 45–47] to be due to polysaccharides (mainly cellulose) oxidation. Reh et al. [46], Wiedemann [40] and Campanella et al. [34] assigned the process III to the thermo-oxidation of lignin. The comparison of DSC curves obtained in static air atmosphere for wood, cellulose, hemicellulose and lignin performed by Tsujiyama and Miyamori [47] leads to conclusion that the process III consists in the oxidation of a mixture of lignin and polysaccharides, in which the lignin is closely combined and complexed with the polysaccharides.

The analysis of DSC results has revealed the following:

-

(a)

the temperature ranges in which the processes I and II occur are practically the same for the investigated new and old woods;

-

(b)

there are some differences among the ranges in which process III occurs for new and old woods;

-

(c)

the height of peak II that is proportional with the reaction rate is higher for new woods (see Fig. 4d);

-

(d)

the rate of process III is substantially higher for the old woods than that corresponding to new woods.

These results show that the natural aging of lime tree wood leads to chemical and structural changes of all wood components. The statement (c) could be correlated with the decrease of cross-linking degree of cellulose component of wood as a result of natural aging. From practical point of view, this statement could be also used for a qualitative distinction between a new lime tree wood and a naturally aged one.

Conclusions

The thermal analysis (TG, DTG, DSC) of some recent sorts of lime tree wood and some patrimonial lime tree wood samples extracted from Romanian historical and/or cultural objects were performed in static air atmosphere and oxygen flow.

The comparison of the recorded TG, DTG and DSC curves shows that the following parameters decrease as a result of natural aging: mass loss in the first process of thermo-oxidation; ratio between the mass losses in the first and the second processes of thermo-oxidation; the maximum rate of the first process of thermo-oxidation. These statements could be used as criteria for distinction an original artifact and a bootleg, but not for precise evaluation of the wood age, because the damage degree of a patrimonial object manufactured from wood depends on the conditions of its storage and exposure.

Work is in progress to extend these results to other wood sorts as well as to understand the thermo-oxidative destruction processes of wood for better supporting the proposal criteria.

References

Chahine C, Rottier C. European—environmental leather project, Research report, Copenhagen, 1996.

Larsen R. Experiments and observations in the study of environmental impact on historical vegetable tanned leathers. Thermochim Acta. 2000;365:85–99.

Chahine C. Change in hydrothermal stability of leather and parchments with deterioration: a DSC study. Thermochim Acta. 2000;365:101–10.

Cohen NS, Odlyha M, Foster G. Measurement of shrinkage behaviour in leather and parchment by dynamic mechanical analysis. Thermochim Acta. 2000;365:111–7.

Wess TJ, Orgel JP. Changes of collagen structure by drying dehydrothermal treatment and relation to long term deterioration. Thermochim Acta. 2000;365:119–28.

Fessas D, Schiraldi A, Tenni R, Zuccarello LV, Bairate A, Facchini A. Calorimetric, biochemical and morphological investigations to validate a restoration method of fire injured ancient parchment. Thermochim Acta. 2000;348:129–37.

Odlyha M, Cohen NS, Foster GM, Aliev A, Verdonck E, Grady D. Dynamic mechanical analysis (DMA), 13Csolid state NMR and micro-thermomechanical studies of historical parchment. J Therm Anal Calorim. 2003;71:939–51.

Della Gatta G, Badea E, Ceccarelli R, Usacheva T, Masic A, Collucia S. Assessment of damage in old parchment by DSC and SEM. J Therm Anal Calorim. 2005;82:637–49.

Roduit B, Odlyha M. Prediction of thermal stability of fresh and aged parchment. J Therm Anal Calorim. 2006;85:157–64.

Marcolli C, Wiedemann HG. Distinction of original and forged lithographs by means of thermogravimetry and Raman spectroscopy. J Therm Anal Calorim. 2001;64:987–1000.

Odlyha M, Cohen NS, Campara R, Foster GM. Environmental research for art conservation and assessment of indoor conditions surrounding cultural objects. J Therm Anal Calorim. 1999;56:1219–32.

Prati S, Chiavari G, Cam D. DSC application in the conservation field. J Therm Anal Calorim. 2001;76:315–27.

Knappe S, Mohler H, Opfermann J, Walter H. Thermal analysis for paints. Germany: Netzsch-Geratebau GmbH; 2001.

Wiedemann HG, Arpagaus E, Muller D, Marcolli C, Weigel S, Reller A. Pigments of the bust of Nefertiti compared with those of Karnak Talatats. Thermochim Acta. 2002;382:239–47.

Genestar C, Cifre J. Thermal analysis for the characterization of grounds used in works of art: preliminary results. Thermochim Acta. 2002;385:117–26.

Foster GM, Ritchie S, Lowe C. Controlled temperature and relative humidity dynamic mechanical analysis of paint films. J Therm Anal Calorim. 2003;73:119–26.

White RE, Thomas PS, Phillips MR, Wuhre R. A DSC study of the effect of lead pigments on the during of cold pressed linseed oil. J Therm Anal Calorim. 2005;80:237–9.

Heide K, Hartmann E, Gent K, Wiedemann HG. MS-TGA of ancient glasses: an attempt to determine the manufacturing conditions (I). Thermochim Acta. 2000;365:147–56.

Campanella L, Favero G, Flamini P, Tomassetti M. Prehistoric terracottas from the Libyan Tadrart Acasus. J Therm Anal Calorim. 2003;73:127–42.

Drebuschchak VA, Mylnikova LN, Drebushchak TS, Boldyrev VV. The investigation of ancient pottery. Application of thermal analysis. J Therm Anal Calorim. 2005;82:617–26.

Shoval S, Beck P. Thermo-FTIR spectroscopy analysis as a method of characterizing ancient ceramic technology. J Therm Anal Calorim. 2005;80:609–16.

Wang Q, Odlyha M, Cohen NS. Thermal analysis of selected soil samples from the tombs at the Tianma-Qucun site, Shanxi, China. Thermochim Acta. 2000;365:189–95.

Anastasiou H, Hasapis Th, Zorba T, Pavlidou K, Chrissafis E, Paraskevopoulos KM. TG-DTA and FTIR analyses of plasters from Byzantine monuments in Balkan region. J Therm Anal Calorim. 2006;84:27–32.

Silva DA, Wenk HR, Monteiro PJM. Comparative investigation of mortars from Roman Colosseum and cistern. Thermochim Acta. 2005;438:35–40.

Odlyha M, Wang Q, Foster GM, de Groot J, Horton M, Bozek L. Thermal analysis of model and historic tapestries. J Therm Anal Calorim. 2005;82:627–36.

Friolo KH, Ray AS, Stuart BH, Thomas PS. Thermal analysis of heritage stones. J Therm Anal Calorim. 2005;80:559–63.

Budrugeac P, Miu L, Bocu V, Wortmann FL, Popescu C. The use of thermal analysis methods in investigation of the thermal degradation of collagen-based materials that are supports of cultural and historic objects. J Therm Anal Calorim. 2003;72:1057–64.

Budrugeac P, Miu L, Popescu C, Wortmann FJ. Identification of collagen-based materials that are supports of cultural and historical objects. J Therm Anal Calorim. 2004;79:975–85.

Popescu C, Budrugeac P, Miu L, Idiţoiu C, Wortmann FJ. Thermal analysis of patrimonial leather objects. 30-th Aachen textile conference, Aachen, Germany, 2003.

Budrugeac P, Miu L, Souckova M. Use of thermal analyses methods and scanning electron microscopy to asses the damage in the patrimonial books from Romanian libraries. J Therm Anal Calorim. 2007;88:693–8.

Badea E, Miu L, Budrugeac P, Giurginca M, Mašić A, Badea N, et al. Study of deterioration of historical parchments by various thermal analysis techniques completed by SEM, FTIR, UV-VIS-NIR and unilateral investigations. J Therm Anal Calorim. 2008;91:17–27.

Popescu C, Budrugeac P, Wortmann FJ, Miu L, Demco DE, Baias M. Assessment of collagen-based materials which are supports of cultural and historical objects. Polym Degrad Stab. 2008;93:976–82.

Budrugeac P, Miu L. The suitability of DSC method for damage assessment and certification of historical leathers and parchments. J Cult Herit. 2008;9:146–53.

Campanella L, Tomassetti M, Tomellini R. Thermoanalysis of ancient, fresh and waterlogged woods. J Therm Anal Calorim. 1991;37:1923–32.

Tomassetti M, Campanella L, Tomellini R, Meuci C. Thermogravimetric analysis of fresh and archeological waterlogged woods. Thermochim Acta. 1987;117:297–315.

Tomassetti M, Campanella L, Tomellini R. Thermogravimetric analysis of ancient and fresh woods. Thermochim Acta. 1990;170:51–65.

Wiedemann HG. Thermoanalytische untersuchung von baumaterialien ägyptischer mumiensärge. J Therm Anal. 1998;52:93–107.

Wiedemann HG, Wood LI. Wood. In: Kemp RB, editor. Handbook of thermal analysis and calorimetry. Vol 4, Chap 14. Amsterdam: Elsevier; 1999.

Sandu ICA, Brebu M, Luca C, Sandu I, Vasile C. Thermogravimetric study on the ageing of lime wood supports of old paintings. Polym Degrad Stab. 2003;80:83–91.

Wiedemann HG. Thermal analysis of the wood components in relation to growth period of tree. Thermochim Acta. 1993;229:215–28.

Gao M, Sun C, Zhu K. Thermal degradation of wood treated with guanidine compounds in air. Flammability study. J Therm Anal Calorim. 2004;75:221–32.

Franceschi E, Cascone I, Nole D. Thermal, XRD and spectrophotometric study on artificially degraded woods. J Therm Anal Calorim. 2008;91:119–25.

Slusarski L. Thermal stability of elastomers. J Therm Anal. 1984;29:905–12.

Vasile C. Degradation and decomposition. In: Vasile C, editor. Handbook of polyolefins. 2nd ed, Chap 17. New York: Dekker; 2000.

Reh U, Krapelin G, Lamprecht I. Differential scanning calorimetry as a complementary tool in wood biodegradation studies. Thermochim Acta. 1987;119:143–50.

Reh U, Krapelin G. Characterization of wood for musical instruments by DSC analysis. Thermochim Acta. 1993;151:91–7.

Dr Sho-IchiTsujiyama, Miyamori A. Assignment of DSC thermograms of wood and its components. Thermochim Acta. 2000;351:177–81.

Acknowledgements

This work was performed within project PN II nr. 91_003/2/2007, financially supported by Romanian Ministry of Education and Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Budrugeac, P., Emandi, A. The use of thermal analysis methods for conservation state determination of historical and/or cultural objects manufactured from lime tree wood. J Therm Anal Calorim 101, 881–886 (2010). https://doi.org/10.1007/s10973-009-0671-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0671-6