Abstract

In this research, the costs as well as flexural and tensile strength of bamboo reinforced concrete material were predicted and optimized using artificial neural network (ANN) and non-dominated sorting genetic algorithm-II (NSGA-II). The inputs to the ANN were curing days and percentage bamboo content in the bamboo reinforced concrete material, while the outputs were cost, flexural and tensile strength. The ANN predicted the experimentally determined values of the tensile strength, flexural strength and costs of the bamboo reinforced concrete material excellently with correlation coefficients of 0.99635, 0.99739 and 1, respectively. Subsequently, the ANN was used as the fitness function for NSGA-II for multi-objective optimization of the cost, flexural and tensile strength of bamboo reinforced concrete material. The Pareto optimal solution obtained could serve as a design guide for engineers for optimal design of structures using cost, flexural and tensile strength of bamboo reinforced concrete material.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Ideally, the engineer would like concrete to reach the required strength at minimum time, thereby reducing construction time and saving costs. However, to achieve this, the use of higher quality materials is often required, which is usually costly. Hence, there must be a trade-off between concrete strength and the cost of achieving the strength. This is amenable to multi objective optimization where the conflicting objectives of cost and strength need to be optimized.

The use of bamboo as building material has been established in the literature. Research by Moroz et al. (2014) showed that bamboo reinforcement in concrete presents a potential alternative to steel reinforcement for low-cost housing application. Agarwal et al. (2014) performed several tests to show the behaviour of bamboo reinforced concrete members under loading. The test results suggest that bamboo with proper treatment has potential to substitute steel as reinforcement. Javadian et al. (2016) stated in their research that bamboo is potentially superior to timber and to construction steel in terms of its weight to strength ratio. Their research equally showed that the new bamboo-composite reinforcement they developed could replace steel reinforcement in concretes.

Having established that bamboo is a good building material, there is the need to model and predict its mechanical properties, which would be of great importance to engineers. Accurate modelling and prediction of mechanical properties of concrete is invaluable to engineers (Nwobi-Okoye and Umeonyiagu 2013, 2015; Nwobi-Okoye et al. 2013; Umeonyiagu and Nwobi-Okoye, 2013, 2015a, b). In modern times, due to advances in computer technology and artificial intelligence, soft computing techniques, such as artificial neural network (ANN), fuzzy logic, adaptive neuro-fuzzy inference system (ANFIS), genetic algorithm (GA), simulated annealing etc., are widely used in modelling and prediction of mechanical properties of engineering materials (Atuanya et al. 2014; Nwobi-Okoye and Umeonyiagu 2013, 2015, 2016; Nwobi-Okoye et al. 2013; Umeonyiagu and Nwobi-Okoye, 2013, 2015a, b).

Khademi et al. (2016) used ANN, ANFIS, and multiple linear regression (MLR) to predict the 28-day compressive strength of recycled aggregate concrete (RAC). They used 14 different input parameters for the study. The study results concluded that prediction of 28-day compressive strength of RAC was better by ANN and ANFIS in comparison to MLR. Douma et al. (2017) used ANN to predict the properties of self-compacting concrete (SCC) containing fly ash (FA) as cement replacement. They used six input parameters, namely total binder content, FA replacement percentage, water–binder ratio, fine aggregates, coarse aggregates and super-plasticizer to predict the four output parameters slump flow, L-box ratio, V-funnel time and compressive strength at 28 days of SCC. The study result shows that ANN could be used effectively for predicting accurately the properties of SCC containing FA. Qi et al. (2018) used ANN and particle swarm optimization (PSO) for predicting the unconfined compressive strength (UCS) of cemented paste backfill (CPB). The ANN was used for modeling the non-linear relationship between the input and output variables, while PSO was used for optimizing the architecture of the ANN. The ANN inputs were tailings type, cement-tailings ratio, solids content, and curing time. The results obtained showed that PSO was effective in optimizing the architecture of the ANN. The results equally showed that ANN model was very accurate in predicting CPB strength based on a comparison of the predicted UCS values with experimental values. Naderpour et al. (2018) used ANN to predict the compressive strength of RAC. The input parameters to the ANN were water cement ratio, water absorption, fine aggregate, natural coarse aggregate, recycled coarse aggregate, and water-total material ratio. The results obtained showed that the ANN is an effective tool for predicting the compressive strength of RAC, which is comprised of different types and sources of recycled aggregates. Ahmadi et al. (2017) used ANN to predict the steel-confined compressive strength of concrete in circular concrete filled steel tube (CCFT) columns under axial loading. Their findings showed the precision and efficiency of ANN model for predicting the capacity of CCFT columns. Cascardi et al. (2017) used ANN to predict the strength of FRP-confined concrete. The results showed that the proposed model could effectively be used for the design of FRP-confined concrete and guarantees an improved accuracy with respect to the available competitors. Eskandari-Naddaf and Kazemi (2017) used ANN to predict the compressive strength (Fc) of mortar mixtures containing different cement strength classes of CME 32.5, 42.5, and 52.5 MPa. The inputs to the ANN were six water/cement ratios (W/C) (0.25, 0.3, 0.35, 0.4, 0.45, and 0.5) and three sand/cement ratios (S/C) (2.5, 2.75, and 3) along with the three types of cement strength classes mentioned above. Based on the inputs they prepared 54 different experimental samples. The experimental samples were subsequently used to train, validate and test the network. The results they obtained showed that in comparison with two other existing models, the developed ANN model had precise and accurate predictions and performed better than the other two models in predicting the compressive strength of the mortar. Kellouche et al. (2019) used ANN for predicting the carbonation of fly-ash concrete taking into account the most influential parameters, including mixture proportions and exposure conditions. They considered six input parameters namely, binder and fly-ash content, water-to-binder ratio, CO2 concentration, relative humidity, and time of exposure; one output is carbonation depth for developing the ANN model. Their findings showed a high correlation between the experimental and the ANN predicted values of the carbonation depth. Rebouh et al. (2017) used an ANN model optimized by GA for the prediction of the compressive strength of concrete containing natural pozzolan. They used more than 400 experimental data collected from past studies in building this model. They compared hybrid ANN-GA model with ANN model using the same architecture and found that the ANN-GA model performed better than the non-optimized ANN. The hybrid ANN-GA model predicted effectively the compressive strength of concrete containing natural pozzolan with a correlation coefficient of 0.93. Boga et al. (2013) studied the effects of using ground-granulated blast furnace slag (GGBFS) and calcium nitrite-based corrosion inhibitor (CNI) on the mechanical and durability properties of concrete (compressive strength, splitting tensile strength, chloride ion permeability) using ANN and ANFIS. The results of the study showed that experimental data can be predicted with a very high degree of accuracy by the ANN and ANFIS models. Duan et al. (2013) used ANN model to predict the compressive strength of the RAC. The results of the research show that ANN could be used effectively as a tool for predicting the compressive strength of RAC prepared with varying types and sources of recycled aggregates. Three different models of MLR model, ANN, and ANFIS were trained, tested and used by Khademi et al. (2017) for predicting the 28-day compressive strength of concrete with 173 different mix designs. A comparison of the three models showed that ANN and ANFIS performed better in predicting the compressive strength than MLR, which performed poorly. Mashhadban et al. (2016) used ANN and particle swarm optimization algorithm (PSOA) to generate a polynomial model for predicting SCC properties. The obtained results showed that the mechanical properties can be significantly improved by fiber reinforcement, and workability of the SCC decreases with increasing fiber content. In addition, the research findings showed that PSOA integrated with the ANN is a flexible and accurate method for prediction of mechanical properties of fiber reinforced SCC properties. Mashrei et al. (2013) proposed a back-propagation neural network (BPNN) model for predicting the bond strength of FRP-to-concrete joints. They used a database of one hundred and fifty experimental data points from several sources for training and testing the BPNN. The results of the research showed that the BPNN is a very good alternative method for predicting the bond strength of FRP-to-concrete joints when compared to experimental results and those from existing analytical models. A parametric regression model (RM), neural network (ANN) and an adaptive network-based fuzzy inference system (ANFIS) model were developed by Sadrmomtazi et al. (2013) for predicting the compressive strength of EPS concrete for possible use in mix-design framework. The results showed that the elite ANN model constructed with two hidden layers and comprised of three neurons in each layer could be used effectively for prediction. In addition, the ANN model performed better than the ANFIS model, which also gave good predictions, but the RM was found to be poor in the compressive strength predictions. Wang et al. (2015) used RM, ANN and fuzzy inference system model (FIS) for predicting the free expansion strain of SSC under wet curing conditions. They used 730 experimental data to develop the model. A comparison of the results showed that the values predicted by the RM, the ANN and FIS models are close to the experimental results, but the RM was found to be less accurate than the ANN method and the FIS method. An ANN was used by Yaprak et al. (2013) to predict the compressive strength of concrete. They used a data set containing a total of 72 concrete samples for the research. The input parameters consisted of two distinct W/C ratios, three different types of cements, three different cure conditions and four different curing periods. The study results showed that ANN provides a good alternative to the existing compressive strength prediction methods.

A very important use of modelling in civil engineering is for multi-objective optimization. According to Zavala et al. (2014), in civil and industrial engineering, structural design optimization problems are usually characterized by the presence of multiple conflicting objectives, as to get the minimum investment cost and the maximum safety of the final design. One of the interesting findings of Zavala et al. (2014) is that non-dominated sorting genetic algorithm-II (NSGA-II) and strength Pareto evolutionary algorithm 2 (SPEA2) are still the most commonly used multi-objective metaheuristics in the literature on structural optimization. Güneyisi et al. (2014) carried out a multi-objective optimization analysis on the strength and permeability related properties of high performance concretes made with binary and ternary cementitious blends of FA and metakaolin (MK). They used statistical-based RMs and the response surface method with the backward stepwise techniques in the multi-objective optimization analysis by maximizing compressive strength while minimizing chloride permeability, water sorptivity, and water absorption. The research results showed that the ternary use of FA and MK with the approximate cement replacement values of 13.3% and 10%, respectively provided the best results for the testing age of 90 days, when the optimized strength and permeability based durability properties of the concretes are concerned.

The aim of this study was to carry out a multi-objective optimization of bamboo reinforced concrete material in order to optimize tensile strength and cost, as well as flexural strength and cost. The study used ANN and NSGA-II to achieve these objectives.

2 Materials and methods

2.1 Bamboo acquisition

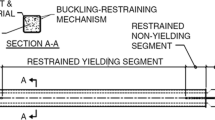

The species of bamboo used was Bambusa vulgaris. Bamboo showing pronounced brown colour was used. The brownish coloration signified maturity. The longest diameters of the culm were selected for large splint. It was known from literature that the longest length of bamboo splint was approximately 19 mm—providing the maximum area with the least amount of curvature (Janseen 1988). The bamboo was not cut in the rainy season or early dry season. This is because culms are generally weaker due to increased fibre content in the rainy season. The bamboo was allowed to dry and was seasoned after cutting. The culms were split into splints approximately 19 mm wide using a circular saw machine. The seasoned bamboo received a waterproof coating to reduce swelling when in contact with concrete. Bitumen with grade S125 was used in this experimental work as coating material. A thin coat of bitumen was applied on the bamboo splint using a paint brush. Immediately after the application of the bitumen coat, fine sand was applied on the coated bamboo to increase the bonding strength. Next, the bamboo splints were left for 24 h to dry prior to being handled.

The tests carried out on the bamboo showed a density of the dried specimen of 589 kg/m3, average tensile strength of 105.6 MPa (N/mm2), average flexural strength of 122.4 MPa (N/mm2), and average compressive strength of 53.4 MPa (N/mm2). The modulus of elasticity in tension was 3593 MPa (N/mm2), while the modulus of elasticity in compression was 10,404.2 MPa (N/mm2).

2.2 Preparation, curing and testing of concrete beam samples

In general, the technique used in conventional reinforced concrete has not been changed, when bamboo was used as the reinforcement. The materials for concrete production were dried in the laboratory for at least 2 weeks prior to the commencement of the project. Ordinary Portland cement was used; river sand (sharp sand) as the fine aggregate and locally sourced coarse aggregate or gravel (with a maximum size of 25 mm) were also used.

A reinforced concrete mix design of 1:2:4 with a water–cement ratio of 0.54 was used. The weight of the different materials per rectangular beam (150 × 150 × 600)mm and per cylindrical beam (150 × 300) mm are given in Table 1. The water used in preparing the concrete samples satisfied the conditions prescribed in BS 3148 (1980). The required concrete specimens were made in threes in accordance with the method specified in BS 188: Part 109 (1983) and cured in accordance with BS 1881: Part 111 (1983). The beams were tested in accordance with BS 1881: Part 118 (1983) using the flexural testing machine.

2.3 Determination of costs of concrete and bamboo

The costs of the reinforced concrete were determined with the following formula:

3 Soft computing techniques for modelling material properties

Soft computing techniques are computational and artificial intelligence techniques used in modelling and optimization of processes and systems. Soft computing techniques used in prediction of material properties such as ANN, fuzzy logic, ANFIS etc. are often easier to develop than mathematical models, and most of the time more accurate than mathematical models. Soft computing tools used in optimization include GA, simulated annealing, ant colony optimization, particle swarm optimization etc.

With the cheap costs and easy accessibility of cheap powerful computing tools, soft computing tools used for optimization are increasingly used in everyday engineering application.

3.1 Artificial neural networks (ANNs)

Artificial neural network is one of the soft computing tools inspired by nature. ANN simulates the working principles of neurons in the brain and nervous system to solve real life computational problems. ANN consists of layers namely: input, hidden and output layers. These layers are made up of artificial neurons that are linked together to form a network. Most ANNs are feedforward multilayer perceptron networks. Feed forward networks use backward propagation algorithms for learning. Some learning algorithms used by ANN include gradient descent algorithm, Levenberg–Marquardt algorithm, GA or other natural optimisation algorithms (Russell and Norvig 2003; Haupt and Haupt 2004).

The basic unit of the ANN is the artificial neuron. ANNs mimic the way neurons operate in the nervous systems of living organisms. The structure of the neuron is shown in Fig. 1. An ANN as shown in Fig. 1 consists of nodes or units connected by links. Consider a node i linked by node j where \(a_{j}\) is the activation from node j to node i. Each link has a numeric weight \(W_{j,i}\) assigned to it, which is the determining factor of the strength and sign of the connection.

Each unit or node i first computes a weighted sum of its inputs:

\(input_{i}\) is used as the variable to an activation or transfer function g(x) to obtain the activation \(a_{i}\) at node i such that:

The transfer function is typically a threshold transfer function such as a sin function, a sigmoid function, hyperbolic tangent function etc. Higher preference is given to transfer functions that are differentiable. Similarly, nonlinear transfer functions, such as the sigmoid function, perform better than linear transfer functions. A typical transfer function, the sigmoid activation function, is given by the equation:

Based on the mathematical and computational foundations of ANN, stated above, consider an ANN shown in Fig. 2. The ANN consists of two input units, two hidden units and one output unit. Given an input vector \(X = (x_{1} ,x_{2} , \ldots x_{n} )\), the activations of the input units are set to \((a_{1} ,a_{2} , \ldots a_{n} ) = (x_{1} ,x_{2} , \ldots x_{n} )\). The computational working of the network for two inputs is stated in Eqs. (4) and (5):

The sum of squares error is used by the network to compare actual and computed values. The objective function of the network learning is therefore to minimize the sum of squares error. The ANN learning process uses optimisation algorithms such as Levenberg–Marquardt algorithm, gradient descent algorithm, GA or other natural optimisation algorithms (Russell and Norvig 2003; Haupt and Haupt 2004). The learning process is called training. Training the network could be supervised or unsupervised training. In supervised training, the network is provided with the inputs and appropriate outputs; hence, the network is trained with a data set consisting of actual/experimental input parameters and the responses. In unsupervised/adaptive learning, the network is provided with inputs but not the outputs. In this present application, the supervised learning was used; hence, the appropriate network architecture is the feed-forward architecture as shown in Fig. 2. Generally, developing ANN models consists of three steps, namely training, validation and testing. A certain percentage of the experimental data, usually 70%, is used to train the network. After training the performance of the network is validated by another data set, usually 15% of the experimental data. After training and validation, the ANN model is tested by the remaining data set.

Consider a training example with input x and output y. The network error E is given by:

Here

y = the true/experimental value,

\(h_{W} (x)\) is the output of the perceptron.

Assuming the gradient descent algorithm is used as the learning algorithm, the following is obtained:

In gradient descent algorithm where the objective is to reduce the weight, the weight update is given by:

To compare the performance of any network configuration, a statistical measure known as the coefficient of correlation (R2) between the predicted output and the experimental responses is the most commonly used criterion, where (R2) is given by (Khademi and Jamal 2016):

ANNs are used for prediction, clustering, classification, pattern recognition etc. ANNs can predict complex input–output relationships without using any mathematical model to do so. The inputs to ANN used in this research are number of days for curing and the percentage bamboo content in reinforced concrete, while the outputs are flexural strength and tensile strength of the reinforced concrete material. Predicting the process parameter accurately is absolutely necessary in many engineering applications as the quality, economics and optimal performance of the process depend on this. Development of a good ANN model is very crucial to achieving this objective. The developed ANN model could be an excellent fitness function for a GA used for multi objective optimization of the bamboo reinforced concrete.

3.2 Genetic algorithm

Genetic algorithm is one of the most widely used soft computing techniques for optimization. The algorithm used to develop GA is based on the theory of evolution (Piuleac et al. 2013). The algorithm is based on the fact that cross breeding and mutations are used in nature to obtain the fittest organisms that survive from generation to generation. GA starts with an initial population called the starting population (Igboanugo and Nwobi-Okoye 2011; Okiy et al. 2017). A fitness function is used to select the fittest among the population that will move to the next generation. Usually, half of the initial population is selected for the next generation (Igboanugo and Nwobi-Okoye 2011; Okiy et al. 2017). The selected population undergoes cross breeding and mutation in the next generation to reach the size of the initial population before selection. Theoretically, the optimum is reached when the fitness of a population member in a certain generation cannot be improved in subsequent generations (Igboanugo and Nwobi-Okoye 2011; Okiy et al. 2017). Sometimes, the optimum may be a local optimum, which would ultimately give a wrong result, but modern sophisticated GA software often give results that are global optima or close to it.

3.3 ANN-NSGA-II procedure

The non-dominated sorting genetic algorithm (NSGA-II) was used in this study. NSGA is a variant of the classical GA used for multi-objective optimization. The algorithm as shown in Fig. 3a uses the evolutionary procedure of selection, crossover and mutations to obtain the optimal values of a multi-objective function on the Pareto front. In NSGA II, based on the ordering of Pareto dominance, the population is sorted into a hierarchy of subpopulations. An assessment of how similar members of each sub group are is done on the Pareto front, and the resulting groups and measures of group similarity are used to promote a diverse front of non-dominated solutions.

Evaluation of the fitness of the population members in NSGA-II algorithm shown in Fig. 3a is done using a fitness function. Usually, a mathematical function relating the input parameters to the outputs is used. However, in this study, no mathematical function was used. Instead, ANN was used as the fitness function.

Figure 3b shows the conceptual model of the procedure developed for the multi-objective optimization of bamboo reinforced concrete beams using ANN and NSGA-II algorithm.

It is important to note that in most experiments in materials science and engineering, the exact mathematical relationship between the input parameters and responses are unknown. Hence, the exact mathematical model of the black box is often impossible to find, giving rise to development of mathematical or computational models to approximate the behaviour of the black box. Often, computational models using soft computing tools such as ANN and ANFIS perform better than mathematical models as earlier noted. This necessitated the use of ANN as a fitness function in NSGA-II models used in this study.

In the conceptual model shown in Fig. 3b, the first step during the development of the ANN-NSGA-II procedure is the acquisition of experimental data of the variation of reinforcement cost with percentage bamboo content (bamboo%) and curing days as well as the variation of tensile and flexural strength with percentage bamboo content (bamboo%) and curing days. Then, an ANN function named NET1 was trained with the experimentally obtained reinforcement cost data. Another ANN function named NET2 was trained and developed with experimentally obtained tensile and flexural strength data obtained. Subsequently a multi output function (multiObjective function) was developed with MATLAB with the outputs being cost and tensile/flexural strength and the inputs being curing time (days) and bamboo (%) in reinforcement using NET1 and NET2. The operating characteristics of an NSGA-II algorithm described in Fig. 3a was set with objective function being the multi objective function earlier developed. After setting the upper and lower limits of the inputs (curing time (days) and bamboo (%)), the GA program was run and the Pareto optimal solution was obtained as the output.

4 Results and discussion

4.1 ANN modeling and results

The feedforward backward propagation neural network was used for the modelling. For tensile and flexural strength predictions, the number of hidden neurons, which gave optimum performance, was 20. The training algorithm used for all the ANNs was Levenberg–Marquardt, which performed better than others. One hundred and twenty (120) experimental inputs and responses were used for ANN training, testing and validation. Seventy percent (70%) of the data (84) were used for training, while fifteen percent (15%) each (18) were used for testing and validation, respectively.

The network architecture consists of two input units, twenty (20) hidden units and one output unit, as shown in Fig. 4. This structure performed better than other configurations tested. The inputs consist of percentage bamboo content and ageing time in days, while the outputs consist of the tensile strength and flexural strength values.

For the tensile strength prediction, the optimum network performance was reached at an epoch of 71. The epoch was set at 1000 to ensure that the network was well-trained. Figure 5 shows the training state of the ANN for tensile strength prediction. The errors were repeated 6 times after epoch 65 and the test was stopped at epoch 71. This error repeats starting at epoch 11 show over-fitting of the data. Hence, the epoch 10 is taken as the base and its weights taken as the final weights. It is important to note that the validation check is equal to 6 due to the fact that the errors are repeated 6 times before stopping the process.

Figure 6 shows the performance of the ANN for tensile strength prediction during training, validation and testing as well as the mean squared error (MSE) of the network. As shown in Fig. 6, the error started at high value during training, validation and testing but gradually reduced as the number of epochs increased. The training process continues until the validation error increased for six iterations. Hence, the training stopped at epoch 71 to avoid overfitting the data sets. As Fig. 6 shows, the best validation performance occurred at epoch 65, and after 6 error iterations, the process stopped at epoch 71. The results shown in Fig. 6 are similar to those in Fig. 5. For tensile strength predictions, the MSE of the network during training, validation and testing was 9.9467 × 10−7, 9.48917 × 10−6 and 6.90235 × 10−6, respectively, as shown in Fig. 6.

Figure 7 shows the error histogram of the ANN for tensile strength prediction. As the error histogram shows, most of the errors fall between 0.0025 and − 0.0025. The zero error is in a vertical line parallel to the ordinate with 33 instances during training.

The regression coefficient of correlation between the experimentally obtained tensile strength and the ANN predicted tensile strength during training, validation and testing is shown in Fig. 8a–c with values of 0.99926, 0.99099 and 0.98921, respectively. The regression coefficient of the network (training, testing and validation) was 0.99742, as shown in Fig. 8d.

For the flexural strength prediction, the optimum network performance was reached at an epoch of 22. The epoch was set at 1000 to ensure that the network was well-trained. Figure 9 shows the training state of the ANN for flexural strength prediction. The errors were repeated 6 times after epoch 16, and the test was stopped at epoch 22.

Figure 6 shows the performance of the ANN for flexural strength prediction during training, validation and testing as well as the MSE of the network. For flexural strength predictions, the MSE of the network during training, validation and testing was 1.60710 × 10−2, 3.09230 × 10−1 and 1.41846 × 10−1, respectively as shown in Fig. 10.

Figure 11 shows the error histogram of the ANN for flexural strength prediction. As the error histogram shows, most of the errors fall between 0.3500 and − 0.3500. The zero error is in a vertical line parallel to the ordinate with 33 instances during training.

The regression coefficient of correlation between the experimentally obtained flexural strength and the ANN predicted flexural strength during training, validation and testing is shown in Fig. 12a–c with values of 0.99949, 0.99177 and 0.99204, respectively. The regression coefficient of the network (training, testing and validation) was 0.99733 as shown in Fig. 12d.

For the cost predictions, a network with three hidden neurons was enough to predict the variations of the age hardening cost with process parameters. As in the network for tensile strength and flexural strength predictions, one hundred and twenty (120) experimental inputs and responses were used for ANN training, testing and validation. Seventy percent (70%) of the data (84) were used for training, while fifteen percent (15%) each (18) were used for testing and validation, respectively.

Figure 13 shows the training state of the ANN for cost prediction. The errors were repeated 0 times after epoch 9 and the test was stopped at epoch 9.

Figure 14 shows the performance of the ANN for cost prediction during training, validation and testing as well as the MSE of the network. The MSE of the network for cost prediction during training, validation and testing was 5.64326 × 10−21, 3.62883 × 10−21 and 1.76017 × 10−20, respectively as shown in Fig. 14.

Figure 15 shows the error histogram of the ANN for flexural strength prediction. As the error histogram shows, most of the errors fall between 9.1 × 10−12and − 9.1 × 10−12. The zero error is in a vertical line parallel to the ordinate with 68 instances during training.

The regression coefficients of correlation between the experimentally obtained flexural strength and the ANN predicted flexural strength during training, validation and testing were all 1 and are shown in Fig. 16a–c. The regression coefficient of the network (training, testing and validation) was 1 as shown in Fig. 16d.

Tables 2 and 3 show some ANN predictions of the experimental responses for tensile and flexural strengths, respectively. Table 2 is used to draw Fig. 8, while Table 3 is used to draw Fig. 12.

4.2 Result of process multi-objective optimization using NSGA-II algorithm

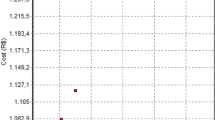

The results of execution of the algorithm described in Sect. 3.3 using the ANNs developed in Sect. 4.1 are stated here. A MATLAB function, which is a well-trained ANN as previously described, was used as the fitness function for a multi objective GA to carry out the optimization of the concrete reinforcement process. The upper and lower limits of the experimental variables were used as the upper and lower bounds of the optimization algorithm as described in Sect. 3.3. For tensile strength optimization, the negative values of the tensile strength were used during the optimization because the objective of the GA is to minimize the objective function. The population size used by the NSGA-II algorithm was 50 while the crossover and mutation rates were 0.8 and 0.1, respectively. The optimized Pareto front achieved after 107 iterations is shown in Fig. 17. The inputs (days and percentage bamboo content) corresponding to the obtained tensile strength and cost values on the optimized Pareto front are shown in Table 4. The maximum and minimum values of tensile strength returned by the multi objective optimization algorithm were 0.169 and 0.105, respectively, as shown in Table 4. The difference between the reinforcement cost for the minimum and maximum tensile strength values in the Pareto front was 1.24.

For flexural strength optimization, the negative values of the flexural strength were used during the optimization for the same reason as stated above. The population size used by the NSGA-II algorithm was 50 while the crossover and mutation rates were 0.8 and 0.1, respectively. The optimized Pareto front achieved after 145 iterations is shown in Fig. 18. The inputs (days and percentage bamboo content) corresponding to the obtained flexural strength and cost values on the optimized Pareto front are shown in Table 5. The maximum and minimum values of tensile strength returned by the multi objective optimization algorithm were 18.827 and 10.685, respectively, as shown in Table 5. The difference between the reinforcement cost for the minimum and maximum tensile strength values in the Pareto front was 0.73.

5 Conclusion

The following conclusions are drawn from this research:

-

1.

It was discovered that as the percentage of bamboo in the concrete increases, the tensile strength increases until a certain percentage content when the strength starts decreasing. Equally, the tensile strength increases as the ageing days increase.

-

2.

As the percentage of bamboo in the concrete increases, the flexural strength increases until a certain percentage content when the strength starts decreasing. Equally, the flexural strength increases as the ageing days increase.

-

3.

The Pareto optimal values can serve as a design guide for structural engineers in designing structures optimally with the material compositions and curing period.

-

4.

GA with ANN as fitness function (GA-NN system) is an excellent tool for multi-objective optimization of bamboo reinforced concrete structures.

References

Agarwal A, Nanda B, Maity D (2014) Experimental investigation on chemically treated bamboo reinforced concrete beams and columns. Constr Build Mater 71:610–617

Ahmadi M, Naderpour H, Kheyroddin A (2017) ANN model for predicting the compressive strength of circular steel-confined concrete. Int J Civ Eng 15(2):213–221

Atuanya CU, Government MR, Nwobi-Okoye CC, Onukwuli OD (2014) Predicting the mechanical properties of date palm wood fibre-recycled low density polyethylene composite using artificial neural network. Int J Mech Mater Eng 7(1):1–20

Boğa AR, Öztürk M, Topçu İB (2013) Using ANN and ANFIS to predict the mechanical and chloride permeability properties of concrete containing GGBFS and CNI. Compos B Eng 45(1):688–696

British Standard 1881: Part 109 (1983) Method for making test beams from fresh concrete. British Standards Institution Publication, London

British Standard 1881: Part 111 (1983) Method of normal curing of test specimens (20°C. British Standards Institution Publication, London

British Standard 1881: Part 118 (1983) Method for determination of flexural strength. British Standards Institution Publication, London

BS 3148 (1980) Tests for water for making concrete. British Standards Institution Publication, London, p 1980

Cascardi A, Micelli F, Aiello MA (2017) An artificial neural networks model for the prediction of the compressive strength of FRP-confined concrete circular columns. Eng Struct 140:199–208

Douma OB, Boukhatem B, Ghrici M, Tagnit-Hamou A (2017) Prediction of properties of self-compacting concrete containing fly ash using artificial neural network. Neural Comput Appl 28(1):707–718

Duan ZH, Kou SC, Poon CS (2013) Prediction of compressive strength of recycled aggregate concrete using artificial neural networks. Constr Build Mater 40:1200–1206

Eskandari-Naddaf H, Kazemi R (2017) ANN prediction of cement mortar compressive strength, influence of cement strength class. Constr Build Mater 138:1–11

Güneyisi E, Gesoğlu M, Algın Z, Mermerdaş K (2014) Optimization of concrete mixture with hybrid blends of metakaolin and fly ash using response surface method. Compos B Eng 60:707–715

Haupt RL, Haupt SE (2004) Practical genetic algorithms. Wiley, Hoboken

Igboanugo AC, Nwobi-Okoye CC (2011) Optimisation of transfer function models using genetic algorithms. J Niger Assoc Math Phys 19:439–452

Janseen JA (1988) The importance of bamboo as a building material. International Bamboo Workshop, Kerala Forest Research Institute, India, pp 235–241

Javadian A, Wielopolski M, Smith IF, Hebel DE (2016) Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr Build Mater 122:110–117

Kellouche Y, Boukhatem B, Ghrici M, Tagnit-Hamou A (2019) Exploring the major factors affecting fly-ash concrete carbonation using artificial neural network. Neural Comput Appl 31(2):969–988

Khademi F, Jamal SM (2016) Predicting the 28 days compressive strength of concrete using artificial neural network. I Manag J Civ Eng 6(2):1

Khademi F, Jamal SM, Deshpande N, Londhe S (2016) Predicting strength of recycled aggregate concrete using artificial neural network, adaptive neuro-fuzzy inference system and multiple linear regression. Int J Sustain Built Environ 5(2):355–369

Khademi F, Akbari M, Jamal SM, Nikoo M (2017) Multiple linear regression, artificial neural network, and fuzzy logic prediction of 28 days compressive strength of concrete. Front Struct Civ Eng 11(1):90–99

Mashhadban H, Kutanaei SS, Sayarinejad MA (2016) Prediction and modeling of mechanical properties in fiber reinforced self-compacting concrete using particle swarm optimization algorithm and artificial neural network. Constr Build Mater 119:277–287

Mashrei MA, Seracino R, Rahman MS (2013) Application of artificial neural networks to predict the bond strength of FRP-to-concrete joints. Constr Build Mater 40:812–821

Moroz JG, Lissel SL, Hagel MD (2014) Performance of bamboo reinforced concrete masonry shear walls. Constr Build Mater 61:125–137

Naderpour H, Rafiean AH, Fakharian P (2018) Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J Build Eng 16:213–219

Nwobi-Okoye CC, Umeonyiagu IE (2013) Predicting the compressive strength of concretes made with unwashed gravel from eastern Nigeria using artificial neural networks. Niger J Technol Res 8(2):22–29

Nwobi-Okoye CC, Umeonyiagu IE (2015) Predicting the flexural strength of concretes made with granite from eastern Nigeria using multi-layer perceptron networks. J Niger Assoc Math Phys 29(2015):55–64

Nwobi-Okoye CC, Umeonyiagu IE (2016) Modelling the effects of petroleum product contaminated sand on the compressive strength of concretes using fuzzy logic and artificial neural networks. Afr J Sci Technol Innov Dev 8(3):264–274

Nwobi-Okoye CC, Umeonyiagu IE, Nwankwo CG (2013) Predicting the compressive strength of concretes made with granite from eastern Nigeria using artificial neural networks. Niger J Technol (NIJOTECH) 32(1):13–21

Okiy S, Oreko BU, Nwobi-Okoye CC, Igboanugo AC (2017) Optimisation of multi input single output transfer function models using genetic algorithms. J Niger Assoc Math Phys 40:459–466

Piuleac CG, Curteanu S, Rodrigo MA, Sáez C, Fernández FJ (2013) Optimization methodology based on neural networks and genetic algorithms applied to electro-coagulation processes. Cent Eur J Chem 11(7):1213–1224

Qi C, Fourie A, Chen Q (2018) Neural network and particle swarm optimization for predicting the unconfined compressive strength of cemented paste backfill. Constr Build Mater 159:473–478

Rebouh R, Boukhatem B, Ghrici M, Tagnit-Hamou A (2017) A practical hybrid NNGA system for predicting the compressive strength of concrete containing natural pozzolan using an evolutionary structure. Constr Build Mater 149:778–789

Russell SJ, Norvig P (2003) Artificial intelligence: a modern approach. Pearson Educational Inc., Upper Saddle River

Sadrmomtazi A, Sobhani J, Mirgozar MA (2013) Modeling compressive strength of EPS lightweight concrete using regression, neural network and ANFIS. Constr Build Mater 42:205–216

Umeonyiagu IE, Nwobi-Okoye CC (2013) Predicting the compressive strength of concretes made with washed gravel from eastern Nigeria using artificial neural networks. J Niger Assoc Math Phys 23:558–559

Umeonyiagu IE, Nwobi-Okoye CC (2015a) Predicting flexural strength of concretes incorporating river gravel using multi multi-layer perceptron networks: a case study of eastern Nigeria. Niger J Technol (NIJOTECH) 34(1):12–20

Umeonyiagu IE, Nwobi-Okoye CC (2015b) Modelling compressive strength of concretes incorporating termite mound soil using multi-layer perceptron networks: a case study of eastern Nigeria. Int J Res Rev Appl Sci 24(1):19–30

Wang B, Man T, Jin H (2015) Prediction of expansion behavior of self-stressing concrete by artificial neural networks and fuzzy inference systems. Constr Build Mater 84:184–191

Yaprak H, Karacı A, Demir I (2013) Prediction of the effect of varying cure conditions and w/c ratio on the compressive strength of concrete using artificial neural networks. Neural Comput Appl 22(1):133–141

Zavala GR, Nebro AJ, Luna F, Coello CAC (2014) A survey of multi-objective metaheuristics applied to structural optimization. Struct Multidiscip Optim 49(4):537–558

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

I, on behalf of my co-author declare that we do not have any conflict of interest with respect to this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Umeonyiagu, I.E., Nwobi-Okoye, C.C. Modelling and multi objective optimization of bamboo reinforced concrete beams using ANN and genetic algorithms. Eur. J. Wood Prod. 77, 931–947 (2019). https://doi.org/10.1007/s00107-019-01418-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01418-7