Abstract

Effect of short-term thermo-mechanical (STTM) densification temperature and pressure on the surface colour of veneer of four wood species—alder (Alnus glutinosa Gaertn.), beech (Fagus sylvatica L.), birch (Betula verrucosa Ehrh.), and pine (Pinus sylvestris L.) as well as possible correlations among all determined colour parameters (L*, a*, b*, h, C* and ∆E) were investigated. Veneer sheets were densified at temperatures of 100, 150 or 200 °C and pressures of 4, 8 or 12 MPa for 4 min. The results were compared with those of non-densified veneers. The colour change of the samples was evaluated by CIEL*a*b* and L*h*C* colour co-ordinate systems. The results indicated: the temperature and pressure of densification affected to a big extent the colour of the veneer samples, with the effect of densification temperature being more evident than that of pressure. After the densification process, the veneers darkened. Colour changes are most pronounced at the highest densification temperature of 200 °C and very small at the lower temperatures of 100 and 150 °C for all investigated wood species. The change in a* is more pronounced than the change in L* or b*. In general, alder and birch veneer samples are characterized by the highest values of total colour difference followed by pine and beech samples among the four species. The quadratic models can be used for the prediction of surface colour in the densification process. The results of this study indicate that it is possible to govern surface colouration of wood veneers during densification process on an industrial basis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

During the last decades, the thermo-mechanical (TM) and thermo-hydro-mechanical (THM) densification of wood (Navi and Sandberg 2012; Welzbacher et al. 2008) has been considered as an effective method to improve the properties of wood (particularly low-density species), such as modulus of elasticity, surface hardness, strength, dimensional stability, etc. In addition, TM/THM densification can also change the surface characteristics of wood (colour, roughness, wettability and surface chemistry) (Gerardin et al. 2007; Gonzalez-Pena and Hale 2009a; Inari et al. 2006; Jennings et al. 2006; Petrissans et al. 2003). On the other hand, the impact of high temperatures may contribute to the inactivation of wood surfaces, which can cause problems regarding adhesion (Aydin 2004; Inari et al. 2007; Sernek et al. 2004).

Most studies of TM/THM densification considered solid wood specimens (Navi and Sandberg 2012), and a very few studies have investigated the TM/THM densification of veneer (Bekhta et al. 2009, 2012; Bekhta and Marutzky 2007; Diouf et al. 2011). Recently, it was proposed to introduce additional operations to the production of plywood or LVL, which are based on the prior thermo-mechanical densification of veneer sheets before applying adhesive on its surface (Bekhta et al. 2009, 2012; Bekhta and Marutzky 2007). It was shown that the thermo-mechanical densification of veneers prior to glue application reduces adhesive consumption without worsening of the mechanical properties of plywood. This is achieved by reducing the surface roughness of veneers. However, during densification of veneers not only the surface roughness decreases but also the colour of veneers changes significantly. Veneer can be used not only for the manufacture of plywood or LVL, but also as overlaying material for lamination of particleboard and MDF in furniture manufacturing, where the surface colour is important both in terms of aesthetic properties and economic indicators affecting the pricing of the finished product. By changing the parameters of densification, conditions can be customized when less decorative wood, could get the colour and texture similar to exotic wood species.

The changes in colour of wood surfaces have been investigated in several previous studies (Akgul and Korkut 2012; Aydin and Colakoglu 2005; Bekhta and Niemz 2003; Bourgois et al. 1991; Burtin et al. 1998; Charrier et al. 2002; Chen et al. 2012; Chow 1971; Diouf et al. 2011; Gonzalez-Pena and Hale 2009a, b; Grekin 2007; Klumpers et al. 1993; Mononen et al. 2002; Sundqvist 2002; Sundqvist et al. 2006; Temiz et al. 2005). Colour changes of wood are interesting not only in terms of aesthetic qualities, but also in view of the fact that they imply alteration of wood components, which could affect wood properties such as strength (Bekhta and Niemz 2003; Gonzalez-Pena and Hale 2009b; Johansson and Morén 2006). Therefore, it is desirable to control the changes in colour during the execution of certain operations of wood treatment (Sundqvist 2002).

The reason for the differences in colour between different wood species may be due to differences in the chemical composition of different species (deciduous and coniferous), in particular because of variation in the extractive content of each species (Grekin 2007; Persze and Tolvaj 2012; Temiz et al. 2005). The natural colour of wood depends on the tree age and wood age (number of annual rings from the pith) (Klumpers et al. 1993). The fresh wood colour depends on the felling season (Mononen et al. 2002). Significant changes in colour of wood were also observed during storage and drying (Grekin 2007; Navi and Sandberg 2012), and steaming (Charrier et al. 2002). Some genetic factors, environmental conditions or treatment conditions, such as exposure to light, heat, moisture, alkali or acids during steaming, drying or finishing (Burtin et al. 1998) and some phenomena, such as inactivation (Aydin and Colakoglu 2005; Back 1998; Sernek 2001) and weathering (Temiz et al. 2005; Yildiz et al. 2011; Zhang et al. 2009) change the aesthetic properties of wood surfaces by changing the surface colour.

The colour of wood is suggested to be an indicator of the degree of its modification (Bekhta and Niemz 2003; Bourgois et al. 1991; Sundqvist et al. 2006), and changes in wood colour are a direct indication of chemical or biological changes (Yildiz et al. 2011), and colour measurement can be used for quantifying wood surface inactivation (Aydin and Colakoglu 2005; Chow 1971; Sernek 2001). CIEL*a*b* measurements have been used to determine the correlation between wood colour and the chemical content of heat-treated wood (Bourgois et al. 1991; Gonzalez-Pena and Hale 2009a) and wood strength (Bekhta and Niemz 2003; Gonzalez-Pena and Hale 2009b; Johansson and Morén 2006).

However, thermal modification or thermo-hydro-mechanical densification of solid wood is usually a fairly long process. In the manufacture of plywood or LVL it is not appropriate to handle thin veneer for hours. A few minutes are enough to achieve the desired results.

In the literature, there is enough information on the influence of thermo-mechanical treatment on the changes in colour of densified solid wood specimens. But most of these studies were performed on solid wood samples during long time treatment. There is no information on how densification process applied to wood/veneer for a short period of time would affect its surface quality, particularly colour changes. Therefore, the purpose of this work was to study the effect of short-term thermo-mechanical (STTM) densification temperature and pressure on the surface colour of veneers of various wood species. Possible correlations among all determined colour parameters were also investigated.

2 Materials and methods

2.1 Materials

Rotary cut veneer sheets of alder (Alnus glutinosa Gaertn.), beech (Fagus sylvatica L.), birch (Betula verrucosa Ehrh.), and pine (Pinus sylvestris L.) with dimensions of 300 by 300 by 1.5 mm3 and moisture content of 5 % were chosen for the experiments. Birch, alder and beech are common species for the manufacture of plywood and for decorative and furniture applications in Ukraine. Pine is used in large quantities especially for construction purposes. Tangential sheets of veneer have been cut into 140 by 100 mm2 rectangular pieces for thermo-mechanical densification process and subsequent measurements. Veneer sheets without visible defects were selected. Prior to thermo-mechanical densification, all test specimens were equilibrated at relative humidity of 65 % and temperature of 20 °C.

2.2 Thermo-mechanical densification technique

Each veneer specimen was thermo-mechanically densified between smooth and carefully cleaned heated plates of a laboratory press at temperatures of 100, 150 or 200 °C and pressures of 4, 8 or 12 MPa. The densification time was 4 min. The changes of densified surface veneer properties were evaluated by colour measurements.

2.3 Colour measurement

Colour measurements of all specimens were recorded on the surface of the veneer specimens before and after thermo-mechanical densification with a colorimeter Minolta Croma-Meter CR-300. The sensor head was 6 mm in diameter. Measurements were made using a D65 illuminant and 10° standard observer. Percentage of reflectance, collected at 10 nm intervals over the visible spectrum (from 400 to 700 nm) was converted into the CIEL*a*b* colour system, where L* describes the lightness, a* and b* describe the chromatic coordinates on the green–red and blue–yellow axis, respectively. From the L*a*b* values the colour difference was calculated as difference of the lightness (∆L*) and chromaticity parameters (∆a* and ∆b*) between densified and non-densified veneer samples using the following formulae:

where “d” refers to densified and “c” to non-densified samples.

In addition, hue angle (h), saturation (C*) and total colour difference (∆E) were calculated as

On the hue circle, h = 0° denotes redness and h = 90° denotes yellowness. Saturation C*, corresponding to the distance between the colour and the centre of the chromaticity plane, is a measure of colour intensity. For each specimen, ten random measurements of surface colour were taken.

2.4 Statistical analysis

For each species, a one-way analysis of variance (ANOVA) was conducted to study the effect of densification temperature and pressure on the surface colour of the densified veneer at the 0.05 significance level. Duncan’s tests were conducted for multiple comparisons of the means of the colour parameters at the different temperatures and pressures for each wood species.

3 Results and discussion

3.1 Visual observation

Figure 1 shows the comparison of colour changes in alder, beech, birch, and pine surfaces of non-densified veneer and veneer densified at different temperatures and pressures during thermo-mechanical densification process. The surface colour of densified veneer samples varied appreciably from lighter to darker with increasing temperature and pressure, but at different rates. However, it is difficult to analyse the colour in samples based only on their visual observation. Detailed analysis of the colour changes was performed using CIEL*a*b* and L*h*C* systems and is presented below.

3.2 Colour changes

The ANOVA showed that wood species, temperature and pressure levels applied to densification as well as the interactions between these variables affected the surface colour (p < 0.05). Results of L*a*b* measurements indicate that the temperature of densification is the most influencing factor on surface colour followed by wood species and pressure of densification. Since the differences among the colour parameters values of the non-densified (control) specimens and those densified at 100 °C and pressure of 4 MPa were not significant, it was found that the densification temperature of 100 °C almost did not change colour at the 4 MPa pressure level.

Table 1 shows colour values of L*, a*, b*, h and C* of non-densified and densified veneers of four investigated wood species. The average colour values, standard deviations, and 95 % confidence intervals (0.05 significance level), based on t-distribution, were calculated assuming a normal distribution. Darkening of the veneer surface (this can even be seen by visual observation) can be observed due to the thermo-mechanical densification process. The value of L* decreases due to the thermo-mechanical densification for the four investigated wood species, which means that the samples lost lightness. The decrease in lightness between 150 and 200 °C was larger than that between 100 and 150 °C. In other words, the lightness L* practically does not change at lower temperatures between 100 and 150 °C regardless of the pressure applied. The change is more significant for all investigated wood species, when the temperature reaches up to 200 °C. The combination of high temperature 200 °C and pressure of 4, 8 and 12 MPa reinforces these changes. The change trends of lightness L* values are similar for all investigated wood species; in particular, L* = 54.27 − 56.47 at the maximum temperature and pressure of densification for all investigated species. Pressure has little effect in comparison with temperature on the discolouration of investigated wood species. Exceptions are the pressures at high temperature densification (200 °C), for which there are slight colour changes. In particular, slight darkening of birch, alder and pine surfaces can be observed with increasing pressure from 4 to 12 MPa at a temperature of 200 °C. No colour changes were observed at the same densification parameters for beech veneer.

Previous studies have also reported a darkening of the wood surface as a result of heat treatment as a function of treatment temperature and the kind of wood (Bekhta and Niemz 2003). Hemicelluloses of thermally heated wood degrade and thus the lignin content of heat-treated wood increases proportionally. Thus, changes in wood lightness during heat treatment are observed mainly due to the degradation of hemicelluloses and wood colour becomes darker from the beginning of heat treatment. Degradation of hemicelluloses is enhanced by increase of heat treatment temperature (Huang et al. 2012). To better understand the background of the colour changes during thermo-mechanical densification process, a chemical and extractive analysis might be helpful (Sundqvist 2002).

Three wood veneers (beech, birch, and pine) show tendency to become redder, while alder veneer shows tendency to become greener during the thermo-mechanical densification process. Green colour tone of alder is explained by the slightly decreasing value of colour saturation and slightly increasing tonality component in a colour (see Fig. 8). Beech, birch and pine have red colour due to the reduction of a tonality component in colour and slightly increasing colour saturation (only for beech and pine). The red hue of wood is commonly associated with the extractive content of wood; accordingly, correlations between the redness values and the extractive contents of wood have been reported both for deciduous (Yazaki et al. 1994) and conifer (Gierlinger et al. 2004) trees. There is a directly proportional relationship between increasing a* values for beech, birch and pine veneers and decreasing a* values for alder veneer with rising densification temperature. Maximum (for beech, birch and pine veneers) or minimum (for alder veneer) values of a* were achieved at a temperature of 200 °C but at different pressures (at 4 MPa for alder, at 4 MPa for beech, at 12 MPa for birch and at 8 MPa for pine).

The b* values of beech and pine veneers increased with rising densification temperature and pressure, describing the trend to become yellower due to increasing colour saturation (see Fig. 9). The yellow tones of wood are primarily governed by the photochemistry of the essential wood components, particularly lignin (Nimz 1973; Yazaki et al. 1994). According to Hon and Glasser (1979), substances causing yellowing were generated by lignin and lignin derivatives, such as quinones, quinone methides, and stilbenes. The b* values of birch and alder veneers decreased with rising temperature and pressure, describing the trend of the surface to become bluer, which is explained by the reduction of a tonality component in colour and a slight decreasing value of colour saturation (see Fig. 9).

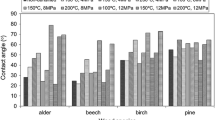

The h value, compared to the non-densified veneer, decreased for all investigated wood species with increasing temperature and pressure (Fig. 2). Especially these changes are visible at high densification temperature (200 °C). The minimum values of hue (h) were reached at the temperature of 200 °C. The h values decreased with rising temperature from 100 to 200 °C (for pressure 12 MPa) for pine, beech, alder and birch veneer by 10.9, 10.6, 8.5, and 20.4 %, respectively.

The colour saturation C* variation was different for all investigated wood species. Saturation C* of densified veneers slightly increased at the highest densification temperature of 200 °C and pressure of 12 MPa compared with non-densified pine, beech and birch veneers by 4.1, 4.1 and 6.0 % respectively; and, in contrast, the saturation C* of densified alder veneer reduced by 42.8 %. As can be seen (Fig. 3), the largest changes in colour saturation are observed for alder veneer.

The lightness difference ∆L* depended on the variation in thermo-mechanical densification conditions. For all investigated wood species, the trend of value ∆L* increased with rising densification temperature and pressure (Fig. 4). The largest changes in lightness difference (∆L*) were observed at the high densification temperature of 200 °C for densified birch, followed by alder, pine and beech veneers (∆L* = 20.31 − 29.28, ∆L* = 12.80 − 28.40, ∆L* = 16.23 − 26.50, and ∆L* = 19.65 − 20.80, respectively).

The red–green chromatic difference ∆a* variation indicates that redness of surface colour of beech, birch, and pine densified veneer surfaces were observed, while alder veneer became greener (Fig. 5).

But the redness of birch, beech, and pine veneers (∆a* = 7.48, ∆a* = 4.78, and ∆a* = 4.01, respectively) was much stronger than the greening of alder veneer (∆a* = −1.97). In addition, if significant redness for beech and pine veneers is observed only at the highest densification temperature (200 °C), then for birch veneer more redness can be observed even at the lower temperatures (100 and 150 °C).

The yellow–blue chromatic difference ∆b* variation indicates that alder veneer surface colour changes towards bluish (Fig. 6), and the largest changes in ∆b* can be observed at the temperature of 200 °C (∆b* = −13.91). While ∆b* value changes of birch and beech veneer are small and irregular (∆b* = −3.33 and 2.91 for birch, ∆b* = −1.37 and 1.75 for beech) (bluish and yellowing) compared to those of alder veneer. Pine veneer surface colour changes towards slight yellowing (∆b* = −1.25 and 2.20). However, the change in ∆b* is much more pronounced for alder than for other wood species.

Total colour difference (∆E) of veneer surfaces of all investigated wood species, which were thermo-mechanically densified at different temperatures and pressures, are shown in Fig. 7. The ∆E of beech, birch, and pine densified veneers increases slightly from 100 to 150 °C, while it changes significantly from 150 to 200 °C. Variation in total colour difference occurred at a similar rate for these three wood species. Significant changes of ∆E for densified alder veneers can already be observed even at lower temperatures (100 and 150 °C). The absolute value of ∆E for alder veneer was the highest among the wood species investigated.

The largest changes in total colour difference (∆E) were observed (Fig. 7) at the high densification temperature of 200 °C for densified alder, followed by birch, pine and beech veneers (∆E = 17.47 − 31.60, ∆E = 21.67 − 30.44, ∆E = 16.66 − 26.80, and ∆E = 19.89 − 21.22, respectively).

Variation in chromatic (colour) difference ∆E was similar to the lightness difference (∆L*), but ∆E value was slightly higher than the ∆L* value. Values of ∆E and ∆L* increased for all investigated wood species with rising densification temperature and pressure. In addition, as can be seen from Figs. 4 and 7 significant changes both of ∆L* and ∆E of alder already started even at the lower temperatures (100 and 150 °C). Significant changes of ∆E and ∆L* for other wood species were observed only at the high densification temperature (200 °C).

3.3 Correlation among colour parameters

Possible correlations among all the determined colour parameters (L*, a*, b*, h, C* and ∆E) were also investigated. Some of these correlations are presented in Figs. 8 and 9 for all investigated wood species. The regression equations and the coefficients of determination (R2) are presented in Table 2. The high values of the coefficients of determination show good linear correlation between the hue angle (h), chromatic coordinate (a*), total colour difference (∆E) and the lightness (L*) as well as between the saturation (C) and yellow–blue chromatic coordinate (b*), hue (h) and red–green chromatic coordinate (a*) for all wood species, with the exception of alder for which no correlation was found between a* and L* (R2 = 0.03), h and a* (R2 = 0.13). Poor linear correlations were found between C and a* for beech and pine (R2 = 0.55 and 0.38, respectively), and between h and b* for alder and birch (R2 = 0.46 and 0.35, respectively), and virtually no linear correlations were found between C and a* for alder and birch (R2 = 0.16 and 0.01, respectively) and between h and b* for beech and pine (R2 = 0.06 and 0.07, respectively). The best linear correlation was found between total colour difference ∆E and lightness L* for all wood species with coefficients of determination 0.90–1.00. The above presented linear correlation suggests the possibility of evaluating the colour changes during thermo-mechanical densification process by only measuring the lightness. Tolvaj and Mitsui (2010) also found a good linear correlation between hue angle and lightness of light irradiated wood, and they indicated that measuring of lightness is enough for estimating colour changes during photodegradation of wood.

Parabolic correlations were found between the lightness L* and saturation C* and chroma coordinate b* for beech, birch and pine veneers. The coefficients of determination (R2) are higher for birch and pine veneer (R2 between 0.51 and 0.73) than for beech veneer (R2 between 0.39 and 0.54). While exponential correlations between lightness L* and saturation C* and chroma coordinate b* were found for alder veneer with the coefficients of determination between 0.58 and 0.64.

3.4 Models for predicting discolouration of densified veneer

A goal of the regression analysis was to determine the dependency of surface colour parameters (L*, a*, b*, C*, h, ∆E) on selected densification parameters such as temperature and pressure. In addition to the main effects of these variables, effects of their interactions were included in the analysis.

The non-linear regression analysis technique using least squares estimation was applied to compute the coefficients of the model for colour parameters; the following model for determining the colour parameters is given:

where, T is the temperature (°C), P is the pressure (MPa), k0, k1, k2, k3, k4, k5 are constants.

For L*, a*, b*, h, C* and ∆E the modelling was successful for all wood species, except for a* response of alder with R2 = 0.38. The coefficients of the model for each investigated wood species are presented in Table 3. These models have a coefficient of determination (R2) between 0.71 and 1.00 which indicates a strong relationship between the factors and response.

Actual and predicted lightness and total colour difference are illustrated in Fig. 10. It can be seen that most of the points lie very close to the line for strong prediction. Hence, these models provide reliable prediction. Similar results were obtained for a*, b*, h and C*.

4 Conclusion

According to the above presented experimental results, the short-term thermo-mechanical densification temperature and pressure had an impact on the surface colour of veneer, and the effect of temperature was more evident than that of pressure. After thermo-mechanical densification process, the colour changes of alder and birch wood were found to be the highest among the four species and those of beech were the lowest. Generally, densified veneers of pine and birch are lighter (higher lightness) than alder and beech; densified veneers of pine and birch are more saturated (higher chroma) than alder and beech; densified veneers of pine and alder are more yellowish (higher hue) than beech and birch. From the obtained results it follows that densified veneer of all investigated wood species retains its colour only at a temperature of 100 °C and pressure of 4 MPa, but begins to lose this colour when the temperature increases to 150–200 °C as well as the pressure rises to 8–12 MPa. The largest changes in discolouration were observed at the highest densification temperature of 200 °C for all four wood species. The results of this study indicate that much of the colour changes already occur during densification process for a short period of time but at high temperatures. Good correlation was practically found between most of the investigated colour parameters. The best linear correlation was found between total colour difference and lightness for all wood species. The regression models were created for the prediction of surface colour of densified wood veneer.

References

Akgul M, Korkut S (2012) The effect of heat treatment on some chemical properties and colour in Scots pine and Uludag fir wood. Int J Phys Sci 7(21):2854–2859

Aydin I (2004) Activation of wood surfaces for glue bonds by mechanical pretreatment and its effects on some properties of veneer surfaces and plywood panels. Appl Surf Sci 233:268–274

Aydin I, Colakoglu G (2005) Effects of surface inactivation, high temperature drying and preservative treatment on surface roughness and colour of alder and beech wood. Appl Surf Sci 252:430–440

Back EL (1998) Oxidative activation of wood surfaces for glue bonding. For Prod J 41(2):30–36

Bekhta PA, Marutzky R (2007) Reduction of glue consumption in the plywood production by using previously compressed veneer. Holz Roh-Werkst 65:87–88

Bekhta P, Niemz P (2003) Effect of high temperature on the change in colour, dimensional stability and mechanical properties of spruce wood. Holzforschung 57:539–546

Bekhta PA, Hiziroglu S, Shepelyuk O (2009) Properties of plywood manufactured from compressed veneer as building material. Mater Des 30:947–953

Bekhta PA, Niemz P, Sedliacik J (2012) Effect of pre-pressing of veneer on the glueability and properties of veneer-based products. Eur J Wood Prod 70:99–106

Bourgois PJ, Janin G, Guyonnet R (1991) The color measurement: a fast method to study and to optimize the chemical transformations undergone in the thermically treated wood. Holzforschung 45:377–382

Burtin P, Allemand CJ, Charpentier JP, Janin F (1998) Natural wood colouring process in Juglans sp. (J. nigra, J. regia and Hybrid J. nigra 23 x J. regia) depends on native phenolic compounds accumulated in transition zone between sapwood and heartwood. Trees 12:258–264

Charrier B, Charrier F, Janin G, Kamdem DP, Irmouli M, Goncalez J (2002) Study of industrial boiling process on walnut colour: experimental study under industrial conditions. Holz Roh-Werkst 60:259–264

Chen Y, Fan Y, Gao J (2012) Coloring characteristics of in situ lignin during heat treatment. Wood Sci Technol 46:33–40

Chow SZ (1971) Determining veneer surface inactivation by a reflectance colorimeter. For Prod J 21(2):19–24

Diouf PN, Stevanovic T, Cloutier A, Fang C-H, Blanchet P, Koubaa A, Mariotti N (2011) Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl Surf Sci 257:3558–3564

Gerardin P, Petric M, Petrissans M, Lambert J, Ehrhrardt JJ (2007) Evolution of wood surface free energy after heat treatment. Polym Degrad Stabil 92:653–657

Gierlinger N, Jacques D, Grabner M, Wimmer R, Schwanninger M, Rozenberg P, Paques LE (2004) Colour of larch heartwood and relationships to extractives and brown-rot decay resistance. Trees 18(1):102–108

Gonzalez-Pena MM, Hale MDC (2009a) Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 1: colour evolution and colour changes. Holzforschung 63:385–393

Gonzalez-Pena MM, Hale MDC (2009b) Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 2: property prediction from colour changes. Holzforschung 63:394–401

Grekin M (2007) Color and color uniformity variation of Scots pine wood in the air-dry condition. Wood Fiber Sci 39(2):279–290

Hon DNS, Glasser W (1979) On possible chromophoric structures in wood and pulps. Polym Plast Technol 12:159–179

Huang X, Kocaefe D, Kocaefe Y, Boluk Y, Pichette A (2012) A spectrocolorimetric and chemical study on color modification of heat-treated wood during artificial weathering. Appl Surf Sci 258:5360–5369

Inari GN, Petrissans M, Lambert J, Ehrhardt JJ, Gerardin P (2006) XPS characterization of wood chemical composition after heat-treatment. Surf Interface Anal 38:1336–1342

Inari GN, Petrissans M, Gerardin P (2007) Chemical reactivity of heat-treated wood. Wood Sci Technol 41:157–168

Jennings JD, Zink-Sharp A, Frazier CE, Kamke FA (2006) Properties of compression densified wood: Part II. Surface energy. J Adhes Sci Technol 20:335–344

Johansson D, Morén T (2006) The potential of colour measurement for strength prediction of thermally treated wood. Holz Roh-Werkst 64:104–110

Klumpers J, Janin G, Becker M, Lévy G (1993) The influence of age, extractive content soil water on wood color in oak: the possible genetic determination of wood color. Ann Sci For 50(1):403–409

Mononen K, Alvila L, Pakkanen TT (2002) CIEL*a*b* measurements to determine the role of felling season, log storage and kiln drying on coloration of silver birch wood. Scand J For Res 17:179–191

Navi P, Sandberg D (2012) Thermo-hydro-mechanical processing of wood. EPEL Press, Switzerland

Nimz HH (1973) Chemistry of potential chromophoric groups in beech lignin. Tappi J 56(5):124–126

Persze L, Tolvaj L (2012) Photodegradation of wood at elevated temperature: colour change. J Photochem Photobiol B 108:44–47

Petrissans M, Gerardin P, El Bakali I, Serraj M (2003) Wettability of heat-treated wood. Holzforschung 57:301–307

Sernek M (2001) Inactivation of wood surfaces: a literature review. Virginia Tech. University, Wood-Based Composites Center, Technical Report No. 103, p 14

Sernek M, Kamke FA, Glasser WG (2004) Comparative analysis of inactivated wood surfaces. Holzforschung 58:22–31

Sundqvist B (2002) Color response of Scots pine (Pinus sylvestris), Norway spruce (Picea abies) and birch (Betula pubescens) subjected to heat treatment in capillary phase. Holz Roh-Werkst 60(2):106–114

Sundqvist B, Karlsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40:549–561

Temiz A, Yildiz UC, Aydin I, Eikenes M, Alfredsen G, Colakoglu G (2005) Surface roughness and color characteristics of wood treated with preservatives after accelerated weathering test. Appl Surf Sci 250:35–42

Tolvaj L, Mitsui K (2010) Correlation between hue angle and lightness of light irradiated wood. Polym Degrad Stab 95:638–642

Welzbacher CR, Wehsener J, Rapp AO, Haller P (2008) Thermo-mechanical densification combined with thermal modification of Norway spruce (Picea abies Karst) in industrial scale—dimensional stability and durability aspects. Holz Roh-Werkst 66:39–49

Yazaki Y, Collins PJ, Mccombe B (1994) Variations in hot water extractives content and density of commercial wood veneers from blackbutt (Eucalyptus pilularis). Holzforschung 48:107–111

Yildiz S, Yildiz UC, Tomak ED (2011) The effects of natural weathering on the properties of heat-treated alder wood. BioResources 6(3):2504–2521

Zhang J, Kamdem DP, Temiz A (2009) Weathering of copper–amine treated wood. Appl Surf Sci 256:842–846

Acknowledgments

The authors would like to thank the COST Action FP 1006 “Bringing new functions to wood through surface modification” for financial support within the frame of Short Term Scientific Mission (STSM).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bekhta, P., Proszyk, S. & Krystofiak, T. Colour in short-term thermo-mechanically densified veneer of various wood species. Eur. J. Wood Prod. 72, 785–797 (2014). https://doi.org/10.1007/s00107-014-0837-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0837-1