Abstract

To investigate the effects of lignin on the discoloration of Black locust (Robinia pseudoacacia) wood during heat treatment, chromatic indexes of the extractive-free wood samples are examined at different moisture contents (MC) under oxygen and nitrogen environment, respectively. The organic acids are produced during heat treatment, resulting in pH decrease in the samples. Components absorbing visible light are formed during heat treatment, and oxygen and moisture contents have obvious effects on the decrease in L*, increase in a* value, yellowness (b*) and total color difference (ΔE) of the samples. It is found that the β-5, C α C β unsaturated bond, the conjugated carbonyl group, quinones structures, α, β-unsaturated ketone and α-C = O in lignin increased after heat treatment. The formation of condensation products, the low-molecular-weight phenolic substances and the oxidation products in lignin result in the increment of the light absorption within the entire visible region.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Discoloration of the wood during heat treatment is mainly due to chemical changes of the components (Sundqvist and Morén 2002). Generally, the effect of heating on wood color depends on the temperature, moisture content, exposure to oxygen as well as pH value of the wood (Sandermann and Rothkamm 1959; Koch et al. 2002). The discoloration reactions during wood drying may involve not only the components in the lignified cell walls of the wood, but also the compounds in lumen (Bauch 1984; Koch and Bauch 2000).

Colored products formed from extractives and hemicelluloses degradation have been considered as a significant reason for wood discoloration (Sehistedt-Persson 2003; Sundqvist 2004). Organic acids released from hemicelluloses degradation act as a catalyst to the decomposition of polysaccharide (Tjeerdsma et al. 1998; Sivonen et al. 2002). The cleavage of β-O-4 linkage and reduction of methoxyl content in lignin result in the more condensed structure (Wikberg and Maunu 2004; Tjeerdsma et al. 1998). The formation of oxidation products, such as quinones, is also referred to as an important reason for color change (Mitsui et al. 2001; Bekhta and Niemz 2003).

Black locust (Robinia pseudoacacia) is a fast-growing wood species, which can be applied to the manufacture of furniture, floor material, and many other outdoor and indoor applications due to its hardness and durable properties. However, its readily discoloration during wood drying process limits its application. In an earlier work, it was found that the structure alteration of the polar extractives in wood is the main reason for the wood discoloration in wood drying process. In fact, the lignin is subjected to heat treatment, and the conjugated structures can be formed, which will also contribute to the optical absorption and color formation (Windeisen and Wegener 2008; Yamauchi et al. 2005).

The objective of this study is to investigate the effects of lignin on the discoloration of Black locust (Robinia pseudoacacia) wood during heat treatment. Since lignin structure is subject to chemical changes in the isolation process, the in situ lignin, presented in the extractive-free wood samples, is employed in this work. The effects of humidity and oxidation on wood discoloration are studied by measurement of chromatic parameters, UV–Vis and FTIR-ATR of extractive-free samples after heat treatment.

Materials and methods

Black locust (Robinia pseudoacacia) wood was cut from Heilongjiang province, northeast China. After being stabilized in ambient conditions for 3 months at room temperature, the wood was minced into 40–60 mesh and kept in a dry and dark place in a PE bag.

Extraction of wood meal

The first extraction was performed with 75% ethanol, 50% ethanol to obtain the flavone and derivatives for another study purpose. Immediately after that, the second extractions were carried out with absolute ethanol, benzene, acetone and ether successively. To ensure the extractives were removed as completely as possible from the samples, the following extractions will not continue until the reflux extractant in the flask turned colorless. Finally, the extracted wood meal was dried in vacuum followed by sealed storage.

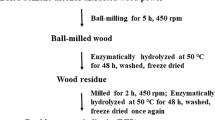

Heat treatment

Extractive-free wood meals were conditioned with boiled distilled water at moisture content of 0, 10, 30, 50, 70% and stabilized before heated in an autoclave.

The wood meals were heated in parallel in a sealed stainless steel autoclave at 120°C for 24 h, and then they were vacuum dried at room temperature in the dark prior to color measurement and spectroscopy analysis.

Determination of pH value

After heat treatment at different moisture contents, the extractive-free wood meals were immersed in distilled water for 48 h at room temperature and the pH values were determined with an E-201-C acidometer.

Measurement of color parameters

The wood meals were pressed into pellets with a die of 30 mm in diameter, and the color parameters were recorded with DF110 colorimeter using a D65 standard illuminant and 10° standard observer. The aperture is 18 mm in diameter. The color parameters L*, a* and b* were determined with the CIELAB system, with lightness (L*) from 0% (black) to 100% (white), a* from green (−a) to red (+a) and b* from blue (−b) to yellow (+b). The ΔL*, Δa*, Δb*and C* were calculated using the unheated extractive-free sample as a reference (e.g., ΔL* = L* treated —L* ref ), and their corresponding total color differences (ΔE) were calculated using the following formula:

UV–Vis diffuse reflectance spectra and FTIR-ATR spectra

The diffuse reflectance spectra were recorded over the wavelength range 240–800 nm on a UV-3100 UV–Vis near-IR spectrophotometer.

ATR spectra were performed on the Tensor27 spectrophotometer (BRUKER) with an ATR-unit using the Bruker OPUS software. All the spectra were measured at a resolution of 2 cm−1 and 32 scans. The FTIR-ATR spectra were baseline-corrected and normalized at the maximum absorption band at 1,050 cm−1 as the internal standard (Windeisen and Wegener 2008).

Results and discussion

The pH variation of the extractive-free wood after heat treatment

The data in Table 1 shows the pH values obtained after heat treatment under different conditions. Before heat treatment, the pH value of the extractive-free wood meal is in fact the pH value of water. The pH values of the samples are found decreased after being heated in both oxygen and nitrogen environment, which indicates a production of organic acids, especially the acetic acid (Nuopponen et al. 2004). The presence of oxygen and the moisture contents enhanced the acid production. The formation of acetic acid should be caused by the thermal cleavage of acyl groups in hemicelluloses, mainly by the degradation of hemicelluloses glucuronoxylan, where acetyl groups (at carbon 2 or 3 of the glucuronoxylan backbone) are split off (Theander and Nelson 1988). It has been reported that the formic acid and acetic acid can be formed after heat treatment of wood at high temperatures (Tjeerdsma et al. 1998; Alén et al. 1985). The other organic acids, such as 4-O-methylglucuronic and galacturonic acids, can also be produced as a result of the hydrolysis of wood, which may also contribute to the pH decrease (Windeisen et al. 2007).

Variation of color parameters before and after heat treatments

The CIELAB parameters L*, a*, b* and c* and ΔE values of the extractive-free wood meals after being heated at 120°C and difference moisture contents are shown in Table 2.

As shown in Table 2, the lightness indices (L*) of all the samples decrease after heat treatment and oxygen has a greater effect on the decrease in L*, which indicates that more components absorbing visible light are formed during heat treatment.

The a* values of the samples increase after heat treatment, and they increase much more in oxygen than in nitrogen. It is implied that the formation of condensation products and degradation and/or oxidation products, such as the quinone-like substances, absorb the complementary light of reddish color. The increases of a* values of the samples heated are due, at least in most part, to the chemical changes of lignin, because the extractive-free samples are used in this study, and an important role should be played by the in situ lignin.

After heat treatment, the yellowness (b*) and C* show a similar trend to the values of a*. The increase in yellowness (b*) values of the heated samples could be partly caused by the low-molecular-weight phenolic substances, which are pale yellow (Hiltunen et al. 2006) and formed during heat treatment. The phenol resource of the sample should be mainly from lignin in wood since the other phenolic substances have been basically removed in the extraction process.

The total color differences (ΔE) of the heat-treated samples increase obviously, and the existence of water plays a very important part in the chemical changes of lignin when exposed to heat.

It can be seen from Table 2 that ΔE values of the samples change much more when heated in oxygen than in nitrogen, which indicates that oxygen has a big influence on the formation of color substances during heat treatment. The changes of L*, b* and ΔE at different humidity show that the moisture content doubtlessly has an effect on the discoloration. It can be figured out that water acts as the medium to carry the oxygen and organic acids to participate in the discoloration reactions. The discoloration of the extractive-free wood samples should be mostly due to the formation of new chromophoric units in the lignin of wood because of the unstable characteristics to the oxidation and condensation. Although the degradation and oxidation of saccharide (e.g., hemicelluloses) can be another factor for the formation of color substances (Sehistedt-Persson 2003; Sundqvist 2004), they are comparatively stable to heat treatment at such a low temperature due to the saturated structure. Therefore, the effect of degradation of hemicelluloses on discoloration is limited to a small extent.

UV–Vis diffuse reflectance spectra analysis

Figure 1 shows the UV–Vis diffuse reflectance spectra obtained from the extractive-free samples heated in the presence of oxygen and nitrogen at different moisture contents. It can be found that the absorptions within the whole visible region (380–780 nm) of all the samples obviously increased after heat treatment, which suggests some kind of coloring reactions in lignin during heat treatment. The absorption of the samples heated in oxygen is greater than that in nitrogen, which implies the oxidation reactions during heat treatment. There is no obvious difference in the absorptions within the two treatments for wavelengths above 400 nm at high moisture contents above 30%.

It can be found that the absorption at 280 nm increases after heat treatment at the condition of water, which indicates the augmentation of β-5, unsaturated C α C β bond and β-C = O structure in lignin (Polcin and Rapson 1969). The intensified peak at about 330–350 nm can be attributed to the conjugated structures, such as double bonds and the conjugated carbonyl group in side chains in lignin (Coniferyl aldehyde, for example) (Polcin and Rapson 1969). The attachment of these groups to other unsaturated structures will lead to further absorption in the visible region. Quinoids structures, which result from the oxidation of the aromatic hydroxyl groups of lignin during heat treatment, can also contribute to the absorption in the visible region as the subtle shoulders in 400–500 nm. These would make up the potential reason of the increase in a* and b* values.

The increase in the absorptions signifies the oxidation and condensation reactions in lignin during heat treatment, since the saturated polysaccharides can scarcely be changed by heating below 120°C. This will influence the absorption spectra in the visible region. It is a good explanation for the increase in optical absorption and the variation of color parameters.

FTIR(ATR) spectra analysis

Figure 2 shows the FTIR-ATR spectra (normalized at 1,050 cm−1) of the extractive-free samples treated in the presence of oxygen and nitrogen at different moisture contents.

It can be found that the absorptions in the band of 1,100–1,800 cm−1 tend to increase after heat treatment. The high intensity of the aromatic skeletal vibration at 1,604 and 1,505 cm−1 and the shift of 1,505–1,510 cm−1 after being heated should be caused by the splitting of aliphatic side chains in lignin (Ucar et al. 2005) and/or the condensation reactions (Faix 1992). After heat treatment, the peak at 1,321 cm−1 is obviously increased, which characterizes the existence of condensing reactions in lignin structures according to Faix (1992). The intensified peak at 1,425 cm−1 signifies new conjugated double bond formation during heat treatment, which could be one of the important reasons for the increase in a* and b* values after heat treatment.

The increment of acid structure (1,736 and 1,235 and 900 cm−1) at 0% moisture content in both nitrogen and oxygen suggests the production of acetic acid by the degradation of acetyl groups in hemicelluloses. The increase in acids can also catalyze the condensation reactions of lignin (1,509, 1,425, 1,321 cm−1).

The increases of absorption at 1,648 and 1,321 cm−1 when heated at 0% moisture content implies the formation of the structure of α, β-unsaturated ketone and α-C = O in lignin structure. These will contribute to the darkness of the samples and the increase in the chrominance parameters.

The peak at 1,668 cm−1 after heated in oxygen at 30% moisture can be attributed to the quinone structure (Shi and Sun 1988). The formation of quinone structure is well consistent with the increase in chromaticity parameter a*. It can be found that, after being heated, the samples with moisture contents contain more esterified structure (1,716 and 1,104 cm−1) when compared with that under dry condition. These changes indicate that the presence of water facilitates the degradation of acetyl groups, which is also a good explanation for pH decrement of the samples heated at 30% moisture content.

It can also be found in Fig. 2 that the -OH stretching band at 3,400 cm−1 is decreased and the peak at 2,850–2,950 cm−1 is intensified after heat treatment, which should be explained as the dehydration or esterification reactions in wood during heat treatment.

Conclusion

The pH values of the samples decrease after treatment both in oxygen and in nitrogen environment due to the production of organic acids. Components absorbing visible light are formed during heat treatment. Oxygen and moisture contents have greater effects on the decrease in L*, increase in a* value, yellowness (b*) and total color difference (ΔE) of the samples. The formation of condensation products, low-molecular-weight phenolic substances and oxidation products such as the quinone-like substances from lignin are found by measurement of UV–Vis and FTIR-ATR spectra. The β-5, C α, C β unsaturated bond and the conjugated carbonyl group, quinoids structures and α-C = O in lignin are increased. Splitting of aliphatic side chains in lignin and the condensation reactions are found after heat treatment.

References

Alén R, Lahtela M, Niemelä K, Sjöström E (1985) Formation of hydroxy carboxylic acids from softwood polysaccharides during alkaline pulping. Holzforschung 39:235–238

Bauch J (1984) Discolouration in the wood of living and cut trees. IAWA Bull, New Series 5:92–98

Bekhta P, Niemz P (2003) Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57:539–546

Faix O (1992) Fourier Transform infrared spectroscopy. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, Berlin Heidelberg, pp 83–109

Hiltunen E, Pakkanen TT, Alvila L (2006) Phenolic compounds in silver birch (Betula pendula Roth) wood. Holzforschung 60:519–527

Koch G, Bauch J (2000) Discolouration in European beechwood (Fagus sylvatica L.) during storage and drying. In: Tamásy-Bánó M (ed) Proceedings of the 2nd COST E15—workshop ‘Quality drying of hardwoods’. University of West Hungary, Sopron, 5 pp, 11–13 Sept 2000

Koch G, Bauch J, Puls J, Welling J (2002) Ursachen und wirtschaftliche Bedeutung von Holzverfärbungen. AFZ Der Wald 57:315–318

Mitsui K, Takada H, Sugiyama M, Hasegawa R (2001) Changes in the properties of light-irradiated wood with heat treatment: part 1 Effect of treatment conditions on the change in colour. Holzforschung 55:601–605

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2004) Thermal modifications in softwood studied by FT-IR and UV resonance Raman spectroscopies. J Wood Chem Technol 24:13–26

Polcin J, Rapson WH (1969) The interpretation of UV and visible spectrum of lignin, 55th annual meeting of the technical section. Canadian Pulp and Paper Association, Montreal, pp 28–31

Sandermann W, Rothkamm M (1959) Über die Bestimmung der pH-Werte von Handelshölzern und deren Bedeutung für die Praxis. Holz Roh-Werkst 17:433–440

Sehistedt-Persson M (2003) Colour responses to heat treatment of extractives and sap from pine and spruce. In: 8th International IUFRO Wood Drying Conference. Brasov, Romania, pp 459–464

Sivonen H, Maunu S, Sundholm F, Jämsä S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56:648–654

Shi Y, Sun X (1988.10) Identification of spectra and chemical of organic compounds. Jiangsu science and technology publishing house, P. R. China, p 107

Sundqvist, B (2004) Colour changes and acid formation in wood during heating. Doctoral Thesis, Lulea University of Technology, p 10

Sundqvist B, Morén T (2002) The influence of wood polymers and extractives on wood colour induced by hydrothermal treatment. Holz Roh-Werkst 60:375–376

Theander O, Nelson D (1988) Aqueous, high-temperature transformation of carbohydrates relative to utilization of biomass. In: Tipson RS, Horton D (eds) Advances in carbohydrate chemistry and biochemistry. Academic. Harcourt Brace Jovanovich Publishers, San Diego, pp 273–326

Tjeerdsma B, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh-Werkst 56:149–153

Ucar G, Meier D, Faix O, Wegener G (2005) Analytical pyrolysis and FTIR spectroscopy of fossil Sequoiadendron giganteum (Lindl.) wood and MWLs isolated hereof. Holz Roh Werkst 63:57–63

Wikberg H, Maunu S (2004) Characterisation of thermally modified hard- and softwoods by 13C CPMAS NMR. Carbohydr Polym 58:461–466

Windeisen E, Wegener G (2008) Behaviour of lignin during thermal treatments of wood. Ind Crops Prod 27:57–62

Windeisen E, Strobel C, Wegener G (2007) Chemical changes during the production of thermo-treated beech wood. Wood Sci Technol 41(6):523–536

Yamauchi S, Iijima Y, Doi S (2005) Spectrochemical characterization by FT-Raman spectroscopy of wood heat-treated at low temperatures: Japanese larch and beech. J Wood Sci 51:498–506

Acknowledgments

Thanks are owed to the financial support from National Natural Science Foundation of China for this research. (Series number of the project: 30671633).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, C., Yongming, F., Jianmin, G. et al. Coloring characteristics of in situ lignin during heat treatment. Wood Sci Technol 46, 33–40 (2012). https://doi.org/10.1007/s00226-010-0388-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-010-0388-5