Abstract

In the present work, an artificial neural network (ANN) model was developed for predicting the effects of some production factors such as adhesive ratio, press pressure and time, and wood density and moisture content on some physical properties of oriented strand board (OSB) such as moisture absorption, thickness swelling and thermal conductivity. The MATLAB Neural Network Toolbox was used for the training and optimization of the artificial neural network. The ANN model having the best prediction performance was determined by means of statistical and graphical comparisons. The results show that the prediction model is a useful, reliable and quite effective tool for predicting some physical properties of the OSB produced under different manufacturing conditions. Thus, this study has presented a novel and alternative approach to the literature to optimize process parameters in OSB manufacturing process.

Zusammenfassung

In dieser Studie wurde ein künstliches neuronales Netz (ANN) entwickelt, um den Einfluss einiger Produktionsfaktoren, wie zum Beispiel Klebstoffmenge, Pressdruck, Pressdauer, Holzdichte und Holzfeuchte, auf die physikalischen Eigenschaften von OSB, wie Wasseraufnahme, Dickenquellung und Wärmeleitfähigkeit zu ermitteln. Für die Trainingsphase und Optimierung des künstlichen neuronalen Netzes wurde die MATLAB Neural Network Toolbox verwendet. Anhand statistischer und graphischer Vergleiche wurde das ANN Modell mit der besten Vorhersageleistung bestimmt. Die Ergebnisse zeigen, dass dieses Modell ein nützliches, zuverlässiges und effektives Werkzeug zur Vorhersage verschiedener physikalischer Eigenschaften von unter verschiedenen Bedingungen hergestelltem OSB ist. Somit wird in dieser Studie ein neuer und alternativer Ansatz für die Optimierung von Prozessparametern bei der OSB-Herstellung vorgestellt.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Oriented strand board (OSB) is a multi-layered panel made from strands of wood of a predetermined shape (typically, 15–25 mm wide, 75–150 mm long, and 0.3–0.7 mm thick) bonded together with a binder (often water resistant) under pressure and heat. At the same time, OSB is a performance—rated structural panel engineered for uniformity, strength, versatility, and workability (Thoemen et al. 2010).

The physical and mechanical properties of OSB make it suitable for a wide range of structural and non-structural applications, such as packaging and building construction. About 100 OSB production lines with a capacity of over 40 million m3/year have been installed around the world. North America is the largest producer of OSB; 85 % of the world’s production is concentrated in USA and Canada. Europe operates 15 factories with a total capacity of 4 million m3/year (Thoemen et al. 2010).

There are many factors affecting the OSB properties. Factors related to strand geometry and adhesive ratio, press pressure and time, board density and moisture content are some of these factors and interact with each other. OSB is a porous and strongly hygroscopic material and the moisture absorption (MA) and thickness swelling (TS) characteristics of OSB negatively affect the use of OSB. Therefore, determination of the effects of the manufacturing factors on characteristics of OSB is very important (Wu 1999; Wu and Piao 1999; Moya et al. 2009).

In order to optimize process parameters in OSB manufacturing, all parameters and variables of OSB production should be considered and tested. However, artificial neural network modeling can be used to determine optimum process parameters in OSB manufacturing without spending much time, energy and costs. ANNs are suitable for modeling various manufacturing functions.

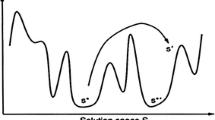

ANNs are an advanced data modeling tool used for modeling complex, undefined and nonlinear relationships between inputs and outputs without any prior assumptions or any existing mathematical relationships between them. It is inspired by the structural, functional, and computational aspect of a biological neural network (Choudhury et al. 2012). ANNs, as one of the most attractive branches in artificial intelligence, are now being used for a wide variety of engineering applications such as prediction, optimization, classification, pattern recognition and data processing (Canakci et al. 2012). Recently, ANN modeling technique has been developed as powerful modeling tool in comparison to the statistical or numerical methods (Ceylan 2008).

Collection of data, determination of input/output parameters and analysis, and pre-processing of the data are the initial phase in ANN modeling. Training of ANN and testing of trained ANN are the central phase. In the training process, error function of ANN is decreased by iteratively adjusting the values of weights and biases. The adjusting operation is repeated until the network performance function is minimized or an acceptable value is reached. Then the performance and the generalization capability of constructed and trained ANN model is tested using an unseen data sample. If the network performance is high, the weights and the biases of the network are stored. Once the network is trained/learned, it can be used to predict the outcomes of different input sets (Yildirim et al. 2011).

A typical ANN consists of a sequence of layers with full connections between successive layers. The layers consist of a number of small individually interconnected processing units (nodes), usually called neuron. No connection exists between neurons of the same layer. An ANN model generally contains one input layer, one or more hidden layers, and one output layer. The input layer receives the data, the output layer shows the results of the network, and the hidden layer or layers process the data.

The neurons are interconnected using weight factors (w ij ). A neuron (j) in a given layer receives information (x i ) from all the neurons in the preceding layer (Fig. 1). It sums up information (net j ) weighted by factors corresponding to the connection and the bias of the layer (θ j ), and transmits output values (y j ) computed through applying a mathematical function (f(.)) to net j , to all neurons of the next layer. This process is summarized in Eqs. (1) and (2), and illustrated in Fig. 1 (Ozsahin 2012).

The number of neurons in the input layer depends on the number of entry variables, while the number of neurons in the output layer depends on the number of desired outputs (Esteban et al. 2009a). The numbers of hidden layers and neurons in the hidden layers are also problem—specific and obtained by a process of trial and error. The influence of the number of neurons in the hidden layer on the performance of the network is quite complicated. If the architecture of ANN model is too simple, the trained network does not have sufficient ability to obtain the relationship of inputs and outputs. Whereas, if the architecture is too complex, the training of the network will be over fitted or the model will not converge to the goal error. There is currently no explicit rule to determine the number of neurons in the hidden layer or layers (Ozsahin 2012; Ma et al. 2012).

ANNs play an important role in engineering applications and have aroused much interest in recent years. Also ANNs have been widely used in the field of wood science, such as the recognition of the wood species (Tou et al. 2007; Esteban et al. 2009b; Khalid et al. 2008), drying process of wood (Ceylan 2008; Wu and Avramidis 2006; Zhang et al. 2006a), the prediction of some mechanical properties in particleboard, plywood and wood (Cook and Chiu 1997; Fernández et al. 2008, 2012; Esteban et al. 2011; Mansfield et al. 2007), the optimization of process parameter in wood products manufacturing process (Cook et al. 1991, 2000; Cook and Whittaker 1992, 1993), classifying of wood veneer defects (Drake and Packianather 1998; Pham and Sagiroglu 2000; Packianather et al. 2008; Castellani and Rowlands 2008; Packianather and Drake 2000, 2004, 2005; Packianather 1997), the calculation of wood thermal conductivity (Avramidis and Iliadis 2005a; Xu et al. 2007), analysis of moisture in wood (Avramidis and Iliadis 2005b; Avramidis and Wu 2007; Zhang et al. 2006b), predicting fracture toughness of wood (Samarasinghe et al. 2007), statistical process control in the manufacture of particleboard (Esteban et al. 2009c), the prediction of wood dielectric loss factor (Avramidis et al. 2006), the detection of structural damage in medium density fiberboard panels (Long and Rice 2008), the classification of wood defects (Nordmark 2002; Kurdthongmee 2008; Rojas and Ortiz 2010), analysis based on non-destructive testing of wood—based composite materials (Esteban et al. 2009a; Zhu et al. 2009).

The aim of this study was to determine and optimize some physical properties of OSB such as the moisture absorption (MA), thickness swelling (TS) and thermal conductivity (TC) characteristics based on variation of certain process parameters such as adhesive ratio, press pressure, pressing time, density and moisture content values by designing and using an artificial neural network model.

2 Experimental

2.1 Material

Data used in this study were provided from a previous study by Yapici (2008). OSB manufacturing was reported by Yapici (2008) in accordance with the following characteristics: made of Scots pine (Pinus sylvestris L.) wood with strands dimensions approximately 80 mm long, 20 mm wide and 0.7 mm thick. The strands were dried to 3 % moisture content before adhesion. Then, adhesive material without wax, solid content of 47 % liquid phenol–formaldehyde resin, was applied as 3, 4.5 and 6 % based on the weight of oven dry wood strands. Press time and pressure were kept as 3, 5 and 7 min. at 35, 40, 45 kg/cm2, respectively. The shelling ratio was 40 % for core layer and 60 % for face layer, and density of the boards was aimed at 0.70 g/cm3. A total of 27 OSB panels, dimensioned 56 × 56 × 1.2 cm³, were made for the experiments. Hand formed mats were pressed in a hydraulic press. These panels were labeled from 1 to 27. All mats were pressed under automatically controlled conditions at 182 ± 3 °C. After pressing, the boards were conditioned to constant weight at 65 ± 5 % relative humidity and a temperature of 20 ± 2 °C until they reached stable weight according to TS 642/ISO 554 (1997). Afterwards, the density and moisture content values of OSBs were determined according to the related standards TS–EN 323 (1999) and TS–EN 322 (1999). The thermal conductivity test was performed based on ASTM C 1113–99 (2004) hotwire method.

In the present work, adhesive ratio, press pressure, pressing time, density and moisture content were defined as the input variables, while the moisture absorption (MA), thickness swelling (TS) and thermal conductivity (TC) were used as the output variables.

2.2 ANN analysis

The MATLAB Neural Network Toolbox was used for the training and optimization of ANNs. The data used in building networks were obtained from experimental works (Yapici 2008). Total data set was randomly divided into two groups. 18 data sets were used for the training of ANNs and the remaining nine data sets were selected for testing of ANNs performances. The data sets are shown in Tables 1 and 2. In order to determine the optimum network architecture and parameters such as the number of layers, number of neurons in each layer, transfer functions, learning rule, number of learning cycles, initialization of the weights and the biases etc., the trial and error method was applied. Several different ANN structures and parameters were tested until the error between the experimental and the predicted outputs was minimized. The mean square error (MSE) was used as the performance function for ANN models. MSE was computed according to the following equation.

where t i and td i are the targeted and predicted values of data i, respectively; and N represents the total number of measurements.

Prior to training of the network the data sets must be normalized to equalize the importance of variables. Therefore, training and testing data sets were normalized using their minimum and maximum values within the range of −1 to 1 due to the use of the hyperbolic tangent sigmoid function in the models. The outputs were finally converted back to the original scale, with a reverse normalizing process to evaluate the results. The normalization operations were carried out using Eq. (4).

where, X norm is the normalized value of a variable X (real value of the variable), and X max and X min are the maximum and minimum values of X, respectively.

The prediction performance of each model was evaluated and compared for each case using statistical and graphical comparisons. To assess the prediction performance of the ANN models, the root mean square error (RMSE), the mean absolute percentage error (MAPE) and coefficients of determination (R2) were used. The RMSE, MAPE and R2 values were calculated using Eqs. (5), (6) and (7), respectively. The lower RMSE and MAPE values represent the more accurate estimation results. The higher r2 values represent the greater similarities between targeted and predicted outputs.

where \( \overline{t} \) is the average of predicted values.

The developed ANN model consists of five input nodes in the input layer namely adhesive ratio, pressing time, press pressure, density and moisture content. The three nodes in the output layer represent the three output parameters namely moisture absorption (MA), thickness swelling (TS) and thermal conductivity (TC). The best performance of the ANNs model in terms of the RMSE, MAPE and r2 values were obtained for the configuration characterized by 3–4 neurons in the hidden layers. Fig. 2 illustrates the schematic structure (architecture) for the proposed ANN prediction model.

In this study, feed forward and back propagation multilayer ANN was used due to its robustness and generalization capacity. This type of neural network is undoubtedly the most popular neural network structure used in engineering applications. In the proposed network model, hyperbolic tangent sigmoid transfer function in the hidden layers and linear transfer function in the output layer as the activation function were preferred. The Levenberg–Marquardt algorithm (trainlm) was used as the training algorithm. The gradient descent with a momentum back propagation algorithm (traingdm) was used as the learning rule.

3 Results and discussion

The training of the ANN was stopped after 50 epochs because the targeted MSE value (0.005) was reached. Evolution of the error during the iterative process for the best network architecture is shown in Fig. 3. The goal is the targeted MSE value and best achieved MSE value in Fig. 3. According to Fig. 3, goal and best MSE values overlap.

Statistical and graphical comparisons were used to evaluate the performance of the proposed ANN model. It was confirmed that the ANN model was generated satisfactory and consistent results when likened with the experimental measurements.

The predicted (calculated) values, measured values, percentage error ratio, and the RMSE and MAPE values for the moisture absorption (MA), thickness swelling (TS) and thermal conductivity (TC) properties are given in Tables 1 and 2. When the tables are examined, the values calculated by utilizing the ANN prediction model seem to be very close to the real data.

Figs. 4 and 5 show the relationship between the real values and the predicted values. The comparative plots of outcomes of the ANN prediction model and the experimental results for the MA, TS and TC properties are shown in Figs. 6 and 7.

The mean absolute percentage errors were 2.37, 2.50 and 2.94 % for the moisture absorption (MA), thickness swelling (TS) and thermal conductivity (TC), respectively in the testing phase. For tested data, the maximum absolute percentage error for predicted values did not exceed 4.6 % for MA, 8.0 % for TS and 7.2 % for TS. These values and comparisons demonstrate that the network effectively generates sensitive results and has a sufficient accuracy and reliability rate for the modeling of the MA, TS and TC characteristics of the OSB.

In this optimization study, adhesive ratio, density and moisture content are fixed as 5.25 %, 0.725 g/cm3 and 7.25 %, respectively. The intermediate values not obtained from the experimental study were predicted from the proposed ANN model. The optimum MA, TS and TC values determined by the ANN prediction model for different pressing time (minute), press pressure (kg/cm2) are given in Table 3. As shown in Table 3, OSB manufacturing capacity will be increased with less pressing time and higher press pressure limits for almost the same MA, TS and TC properties of OSB.

4 Conclusion

Considering the complexity of the relationship between the inputs and outputs, the results obtained are highly encouraging and satisfactory by the ANN prediction model.

Figs. 4 and 5 show the scattered diagram of the experimental values and the predicted values of the ANN model for the moisture absorption (MA), thickness swelling (TS) and thermal conductivity (TC) characteristics. The results show that the ANN model has a very high coefficient of determination (R2) between the predicted and measured physical properties of OSB. The R2 has been determined for the MA, TS and TC characteristics of the OSB as 0.973, 0.983 and 0.853, respectively in the testing phase. These values support the applicability of the proposed ANN prediction model.

In the study, the well-trained ANN model has been proved to be a sufficient and successful tool for modeling the MA, TS and TC characteristics of OSB. The results of the research indicated that the ANN modeling can be used to optimize process parameters in OSB manufacturing process without the need for experimental studies that require much time and high testing costs.

References

ASTM C 1113–99 (2004) Standard test method for thermal conductivity of refractories by hot wire (platinum resistance thermometer technique). ASTM, USA

Avramidis S, Iliadis L (2005a) Predicting wood thermal conductivity using artificial neural networks. Wood Fiber Sci 37(4):682–690

Avramidis S, Iliadis L (2005b) Wood–water sorption isotherm prediction with artificial neural networks: a preliminary study. Holzforschung 59(3):336–341

Avramidis S, Wu H (2007) Artificial neural network and mathematical modeling comparative analysis of nonisothermal diffusion of moisture in wood. Holz Roh—Werkst 65:89–93

Avramidis S, Iliadis L, Mansfield SD (2006) Wood dielectric loss factor prediction with artificial neural networks. Wood Sci Technol 40:563–574

Canakci A, Ozsahin S, Varol T et al (2012) Modeling the influence of a process control agent on the properties of metal matrix composite powders using artificial neural networks. Powder Technol 228:26–35

Castellani M, Rowlands H (2008) Evolutionary feature selection applied to artificial neural networks for wood veneer classification. Int J Prod Res 46(11):3085–3105

Ceylan I (2008) Determination of drying characteristics of timber by using artificial neural networks and mathematical models. Drying Technol 26(12):1469–1476

Choudhury TA, Hosseinzadeh N, Berndt CC (2012) Improving the generalization ability of an artificial neural network in predicting in-flight particle characteristics of an atmospheric plasma spray process. J Therm Spray Technol 21(5):935–949

Cook DF, Chiu CC (1997) Predicting the internal bond strength of particleboard, utilizing a radial basis function neural network. Eng Appl Artif Intell 10(2):171–177

Cook DF, Whittaker AD (1993) Neural network process modeling of a continuous manufacturing operation. Eng Appl Artif Intell 6:559–564

Cook DF, Massey JG, Shannon RE (1991) A neural network to predict particleboard manufacturing process parameters. Forest Sci 37(5):1463–1478

Cook DF, Ragsdale CT, Major RL (2000) Combining a neural network with a genetic algorithm for process parameter optimization. Eng Appl Artif Intell 13:391–396

Drake PR, Packianather MS (1998) A decision tree of neural networks for classifying images of wood veneer. Int Adv Manuf Technol 14:280–285

Esteban LG, Fernández FG, de Palacios P (2009a) MOE prediction in Abies pinsapo Boiss. timber: application of an artificial neural network using non–destructive testing. Comput Struct 87:1360–1365

Esteban LG, Fernández FG, de Palacios P, Conde M (2009b) Artificial neural networks in variable process control: application in particleboard manufacture. Invest Agrar Sist Recur For 18(1):92–100

Esteban LG, Fernández FG, de Palacios P, Romero RM, Cano NN (2009c) Artificial neural networks in wood identification: the case of two juniperus species from The Canary Islands. IAWA J 30(1):87–94

Esteban LG, Fernández FG, de Palacios P (2011) Prediction of plywood bonding quality using an artificial neural network. Holzforschung 65:209–214

Fernández FG, Esteban LG, de Palacios P, Navarro N, Conde M (2008) Prediction of standard particleboard mechanical properties utilizing an artificial neural network and subsequent comparison with a multivariate regression model. Invest Agrar Sist Recur For 17(2):178–187

Fernández FG, de Palacios P, Esteban LG, Garcia–Iruela A, Rodrigo BG, Menasalvas E et al (2012) Prediction of MOR and MOE of structural plywood board using an artificial neural network and comparison with a multivariate regression model. Compos B 43:3528–3533

Khalid M, Lee ELY, Yusof R, Nadaraj M (2008) Design of an intelligent wood species recognition system. Int J Simul: Syst Sci Technol 9(3):9–19

Kurdthongmee W (2008) Colour classification of rubberwood boards for fingerjoint manufacturing using a SOM neural network and image processing. Comput Electron Agric 64:85–92

Long W, Rice RW (2008) Detection of structural damage in medium density fiberboard panels using neural network method. J Compos Mater 42:1133–1145

Ma X, Zeng W, Tian F, Sun Y, Zhou Y (2012) Modeling constitutive relationship of BT25 titanium alloy during hot deformation by artificial neural network. J Mater Eng Perform 21(8):1591–1597

Mansfield SD, Iliadis L, Avramidis S (2007) Neural network prediction of bending strength and stiffness in western hemlock (Tsuga heterophylla Raf.). Holzforschung 61(6):707–716

Moya L, Tze WTZ, Winandy JE et al (2009) The effect of cyclic relative humidity changes on moisture content and thickness swelling behavior of oriented strand board. Wood Fiber Sci 41(4):447–460

Nordmark U (2002) Knot identification from CT images of young Pinus sylvestris sawlogs using artificial neural networks. Scand J Forest Res 17:72–78

Ozsahin S (2012) The use of an artificial neural network for modeling the moisture absorption and thickness swelling of oriented strand board. BioResources 7(1):1053–1067

Packianather MS (1997) Design and optimization of neural network classifiers for automatic visual inspection of wood veneer. Ph. D. Thesis, University of Wales

Packianather MS, Drake PR (2000) Neural networks for classifying images of wood veneer. Part 2: Int. J Adv Manuf Technol 16:424–433

Packianather MS, Drake PR (2004) Modelling neural network performance through response surface methodology for classifying wood veneer defects. Proc Inst Mech Eng Part B: J Eng Manuf 218(4):459–466

Packianather MS, Drake PR (2005) Comparison of neural and minimum distance classifiers in wood veneer defect identification. Proc Inst Mech Eng Part B: J Eng Manuf 219(11):831–841

Packianather MS, Drake PR, Pham DT (2008) Feature selection method for neural network for the classification of wood veneer defects. In: Proceedings of the World Automation Congress, Waikoloa, September 28–October 2 (1–3):790–795

Pham DT, Sagiroglu S (2000) Neural network classification of defects in veneer boards. Proc Inst Mech Eng Part B: J Eng Manuf 214(3):255–258

Rojas G, Ortiz O (2010) Identification of knotty core in pinus radiata logs from computed tomography images using artificial neural network. Maderas, Ciencia y Tecnologia 12(3):229–239

Samarasinghe S, Kularisi D, Jamieson T (2007) Neural networks for predicting fracture toughness of individual wood samples. Silva Fennica 41(1):105–122

Thoemen H, Irle M, Sernek M (2010) Wood–Based Panels: An Introduction for Specialists. Brunel University Press, London

Tou JY, Lau PY, Tay YH (2007) Computer vision–based wood recognition system. In: Proceedings of International Workshop on Advanced Image Technology (IWAIT). Bangkok, Thailand, p 197–202

TS 642/ISO 554 (1997) Standart atmospheres and/or testing; Specifications

TS–EN 322 (1999) Wood–Based panels, determination of moisture content. TSE, Ankara

TS–EN 323 (1999) Wood–Based panels, determination of density. TSE, Ankara

Wu Q (1999) In–plane dimensional stability of oriented strand panel: effect of processing variables. Wood Fiber Sci 31(1):28–40

Wu H, Avramidis S (2006) Prediction of timber kiln drying rates by neural networks. Drying Technol 24(12):1541–1545

Wu Q, Piao C (1999) Thickness swelling and its relationship to internal bond strength loss of commercial oriented strand board. Forest Prod J 49(7/8):50–55

Xu X, Yu ZT, Hu YC, Fan LW, Tian T, Cen KF (2007) Nonlinear fitting calculation of wood thermal conductivity using neural Networks. Zhejiang University Press 41(7):1201–1204

Cook DF, Whittaker AD (1992) Neural network models for prediction of process parameters in wood products manufacturing. In: proceeding of first Industrial Engineering Research Conference. Chicago, 20–21 May, p. 209–211

Yapici F (2008) The Effect of Some Production Factors on The Properties of OSB Made from Scotch Pine (Pinus sylvestris L.) Wood. Ph. D. Thesis, Zonguldak Karaelmas University

Yildirim I, Ozsahin S, Akyuz KC (2011) Prediction of the financial return of the paper sector with artificial neural networks. BioResources 6(4):4076–4091

Zhang D, Sun L, Cao J (2006a) Modeling of temperature–humidity for wood drying based on time–delay neural network. J For Res 17(2):141–144

Zhang J, Cao J, Zhang D (2006b) ANN–based data fusion for lumber moisture content sensors. Trans Inst Meas Control 28(1):69–79

Zhu XD, Cao J, Wang FH, Sun JP, Liu Y (2009) Wood defect identification based on artificial neural network. Comput Intell Intell Syst 51:207–214

Acknowledgments

The author is thankful to Dr. Fatih Yapici, Department of Furniture and Decoration, Technical Education Faculty, Karabuk University, Karabuk, Turkey, for providing the database used in the paper and for many fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozsahin, S. Optimization of process parameters in oriented strand board manufacturing with artificial neural network analysis. Eur. J. Wood Prod. 71, 769–777 (2013). https://doi.org/10.1007/s00107-013-0737-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0737-9