Abstract

In this research, the constitutive relationships of BT25 titanium alloy based on regression and artificial neural network (ANN) methods were established and studied by analyzing the results of hot compression tests. The isothermal compression tests were conducted on a Gleeble 1500 thermo-mechanical simulator in the deformation temperatures ranging from 940 to 1000 °C with an interval of 20 °C and the strain rates of 0.01, 0.1, 1.0, and 10.0 s−1 with a height reduction of 60%. The average deformation activation energy of the alloy was derived as 623.26 kJ/mol at strain of 0.7 by using the non-linear regression method and assuming a hyperbolic sine equation between the stress, strain rate, and deformation temperature. On the basis of the experimental data samples, an ANN model was proposed and trained. The hot processing parameters of temperature, strain rate, and strain were used as the input variables and the flow stress as the output variable. The comparison of experimental flow stresses with predicted values by ANN model and calculated value by regression method was carried out. It was found that the predicted results by ANN are in a good agreement with the experimental values, which indicates that the predicted accuracy of the constitutive relationship established by ANN model is higher than that using the multivariable regression method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Constitutive models are a collection of representations that describe the macroscopic response of a material to applied stress under different combinations of strain, strain rate, and deformation temperature. These models are widely used in the analysis of manufacturing processes such as metal forming and machining (Ref 1–3). However, the accuracy of such analyses greatly depends on the accuracy of constitutive models used. Previously, numerous investigations (Ref 4–6) have been performed to construct the mathematical constitutive models by the regression method, which is primarily used to represent the behavior of the material at moderate ranges of temperature and strain rate. For instance, Wanjara et al. (Ref 4) have investigated the effect of process parameters on the flow stress behavior, and determined the flow stress which related to the parameters using an Arrhenius-type equation during isothermal compression of IMI834 alloy in the α and α + β phase regions. Also, the constitutive relationship of the 17-4 PH stainless steel under the hot compression test has been investigated with the three expressions of Zener-Hollomon parameter using regression method by Mirzadeh and Najafizadeh (Ref 5). However, these methods are rarely satisfactory in practical applications because of the highly non-linear and complex relationships between the flow stress and the processing parameters, which cost much time and are difficult to be established validly by using regression method.

As an alternative to the traditional approach for the development of constitutive model, there is a growing interest in artificial neural network (ANN) as a paradigm of computational knowledge representation (Ref 7–10). Generally, an ANN approach has a number of advantages compared with the traditional approaches. Although it does not need explicit assumptions or knowledge regarding the mathematical or physical properties, yet the ANN method possesses an excellent learning ability of the interrelations of large amount of data obtained from experiments and patterns in a series of input and output data. Recently, with the rapid development of ANN, many researchers have paid much attention to the solution of non-linear and complex problems in term of constitutive modeling of titanium alloys (Ref 11–15). Li et al. (Ref 11) constructed a three-layer back-propagation (BP) neural network to acquire the constitutive modeling of Ti-15-3 titanium alloy and concluded that the use of an ANN for the constitutive relationship looks very encouraging. Mulyadi et al. (Ref 13) developed an ANN constitutive model for Ti-6Sn-2Zr-4Mn-6Mo alloy, which exhibited an ANN prediction superior to a parametric constitutive model. Sun et al. (Ref 14) used a neural network tool for establishing the constitutive relationship of Ti600 alloy. Apparently, the ANN model has a strong ability to establish the constitutive relationship based on incomplete or noisy data information, and it can generalize rules from those cases for which is trained, applying these rules to new stimulations.

However, the Russian alloy BT25 is less commonly known in the west, little public knowledge has been found regarding its constitutive relationship and high temperature deformation behavior. Basically, the BT25 alloy is a martensite two-phase titanium alloy, which is designed for manufacturing compressor disks with excellent tensile strength and creep performance at least at 550 °C (Ref 16, 17). In recent years, it has received much attention in China due to its potential for manufacturing the dual-property blisk (Ref 18). The dual-property blisk consisting of lamellar microstructure in disc section and equiaxed microstructure in the blades is significantly affected by the hot processing parameters such as deformation temperature, strain, and strain rate. For the purpose of achieving the desired microstructure of the blisk, it is crucial to develop and study the constitutive relationship of the BT25 alloy with lamellar starting microstructures during hot deformation.

Therefore, the objective of this work is to study the hot deformation behavior, and establish an accurate constitutive relationship based on the ANN model, which is related to the different deformation process parameters for the BT25 titanium alloy with lamellar starting microstructure. Furthermore, the comparison of flow stress between experimental values and the data obtained by the ANN model and regression method has been carried out.

Material and Experimental Procedures

Material

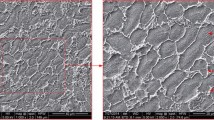

The nominal composition of BT25 titanium alloy under investigation is given in Table 1. The α + β/β phase transition temperature of the alloy is approximately 1025 °C, determined via a technique involving heat treatment followed by metallographic observations. The testing specimens from the β-forged disks with diameter of 240 mm were machined into cylinder with 8 mm in diameter and 12 mm in height according to the standard method for hot compression test. Glass lubricants were used to coat the top and bottom surfaces of specimen, in order to reduce the friction between the specimens and anvils. Specimens were heated to the test temperature, and soaked for 5 min before hot compression so as to obtain a uniform deformation temperature. The original microstructure of the samples is shown in Fig. 1. A typical lamellar microstructure can be markedly observed which consists of large beta grains about 400 μm grain size and α lamellas with a length of 20-40 μm and width of 0.5 μm. In addition, a random orientation of lamellas was observed.

In order to develop the constitutive relationship of BT25 titanium alloy, a series of isothermal compression tests were conducted on a Gleeble 1500 thermo-mechanical simulator in the deformation temperature range from 940 to 1000 °C that were all in the α + β phase field, strain rate range from 0.01 to 10 s−1 and the height reduction of 60%. The true stress-strain curves were recorded automatically in the isothermal compression process.

The Structure of Neural Networks

ANN modeling is essentially a “black box” linking input data to output data using a particular set of non-linear functions. Among the various kinds of ANN approaches that exist, the multilayer perceptron architecture-based feed-forward ANN with BP learning algorithm has become the most popular in materials modeling and materials processing control applications. It has been used in the present study since the multilayer network has greater representational power for dealing with highly non-linear, strongly coupled, multivariable system (Ref 19).

Neural networks need to be trained in a learning process before they are applied. The following matters are extremely important in the design or training of neural networks: (i) architecture of the neural network, (ii) transfer function, and (iii) training algorithm. In general, each neural network is composed of an input layer, an output layer and one or more hidden layers. First step, the architecture of the neural network refers to the number of the layers in the ANN and the number of the neurons in each layer. Thus the structure of one input, one hidden, and one output layer was used in the present model. The next important thing is to obtain the number of hidden units which can determine the complexity of neural network and precision of predicted values. As mentioned in Ref 20, if the architecture of ANN model is too simple, the model does not have sufficient ability to learn the process correctly during the training. Oppositely, when the model is too complex, it may not converge or the trained data may be over fitted. In the present model, the value of mean square error (MSE) is used to check the ability of a particular architecture. It is obviously seen in Fig. 2 that the mean square error of the network decreases to the minimum value when the number of neurons in hidden layer is 10, which indicates that the network with 10 neurons can exhibit an optimal performance.

Subsequently, each neuron has an associated transfer function which can represent how the weighted sum of its inputs is converted to the results into an output value. Hornik et al. (Ref 21) suggested that a three-layer ANN with sigmoid transfer functions can map any function of practical interest. In this investigation, the sigmoid function to calculate the neuron network was chosen as follows:

Finally, design the training algorithm which affects the accuracy and stability of the ANN model. In recent years, a number of variations of the standard algorithm have been developed (Ref 22). Particularly, the BP training usually can give the best results in terms of model performance and training time required. In the BP algorithm, the error between target and the network output is calculated and this will be back propagated using the steepest descent or gradient descent approach. The network weights are adjusted by moving a small step in the direction of negative gradient of error surface during each iteration. The iterations are repeated until a specified convergence is reached. Therefore, the neural network developed in this investigation is trained with the BP algorithm which is able to represent a better fitting and generalization of the model. A schematic architecture of the feed-forward neural network in the present study is given in Fig. 3. The deformation temperature, log strain rate and strain were determined as the input variables of the ANN model, while the output variable is flow stress. Instead of \( \dot{\upvarepsilon },\,\;\log \dot{\upvarepsilon } \) has been chosen since σ usually varies with \( \log \dot{\upvarepsilon } \) on a physical basis.

Before training the ANN model, the values usually have different dimensions and ranges. As a result, the input and output datasets should be normalized before being applied to the neural network so that they were confined between 0.1 and 0.9 according to the Eq 2.

where X i is the normalized value of a certain parameter (temperature, strain, logarithm of strain rate, or flow stress), X is the measured value for this parameter, X min and X max are the minimum and maximum values in the database for this parameter, respectively.

Results and Discussion

The True Stress-True Strain Curves

For representing the flow behavior with starting lamellar microstructure in α + β phase filed, the typical true stress-true strain curves of BT25 titanium alloy deformed in the deformation temperature range of 940-1000 °C and strain rate of 0.01-10 s−1 are given in Fig. 4(a) and (b), respectively. Similar to other titanium alloys, the flow curves exhibit a peak stress in the early stages of deformation due to the influence of work hardening, and then the flow stresses gradually decrease to a certain stress level with increasing strain. In addition, it is also found that the flow stress increases with the strain rate at a certain temperature, and decreases with an increase of the deformation temperature at a certain strain rate. Meanwhile, it is interesting to note that at strain rate of 0.01 s−1, the curves show a slightly serrated oscillation, which may be caused by lamellar globularization or dynamic recrystallization. Such phenomena reveal the fact that flow stress is closely depended on the processing parameters (strain, strain rate, and temperature). Therefore, it is meaningful and necessary to establish the constitutive relationship of BT25 titanium alloy with starting lamellar microstructure.

Constitutive Relationship by Regression Method

The constitutive relationship among flow stress, strain rate, and deformation temperature during hot deformation at a given strain can be described by the Zener-Hollomon parameter (Ref 23):

where Z is the Zener-Hollomon parameter, σ is the flow stress, \( \dot{\upvarepsilon } \) is the strain rate, T is the deformation temperature in Kelvin, A, α, and n are the material constants, Q is the apparent activation energy, and R is the universal gas constant.

The calculation of Q has been performed according to the following relationships:

where n and s are represented the average slope of the lines in the \( \ln (\dot{\upvarepsilon }) \) against \( \ln [\sinh (\upalpha \upsigma )] \) and \( \ln [\sinh (\upalpha \upsigma )] \) against 1000/T as shown in Fig. 5(a) and (b), respectively.

The average value of Q at strain of 0.7 was derived as 623.26 kJ/mol for the present alloy. Figure 6 displays the variation of Z with \( \ln [\sinh (\upalpha \upsigma )] \), indicating that a single line can be drawn through the experimental data. The values of A, α, and n were calculated as 2.1 × 1025, 0.0104, and 2.98, respectively. Substituting the value of constants in Eq 3, the constitutive equation of the alloy at strain of 0.7 is developed as follows:

Although these constants of Eq 3 depending on the material are calculated as special values, they cannot fit the whole data set to one set of equation parameters very well. In other words, it is complicated and time-consuming to capture the essence of the specific deformation characteristics using the fit of one equation or a set of equation parameters to the whole strain range. Fortunately, the ANN is an effective approach that can deal with the problems mentioned above very well.

Evaluation of Artificial Neural Network Model

ANN is a sort of more simple and accurate technique to predict the flow stress of materials. An important and primary step in using ANN is the separation of the dataset into training and testing datasets, because the better the representation of the data in the training dataset, the better its predictive capabilities within those input ranges. In the present study, the normalized data set at strain of 0.1-0.6, and 0.8 were chosen as training set and the data set at the strain of 0.7 were remained as testing set.

The generalization capability of the trained network is quantified in terms of the correlation coefficient (R) and the mean absolute relative error (MARE), based on the target output and predicted values according to the following equations:

where E is the experimental value and P is the predicted value obtained from the network model. \( \bar{E} \) and \( \bar{P} \) are the mean values of E and P, respectively. N is the total number of data employed in the investigation. The correlation coefficient is a commonly used statistic and provides information on the strength of linear relationship between experimental and predicted values. For perfect prediction, all the data points should lie on the line inclined at 45° from the horizontal.

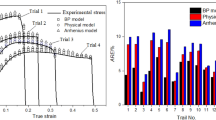

Figure 7 shows the predicted flow stress by the ANN model versus the experimental value for the total training dataset. It can be seen that the predicted results from ANN model agree well with the experimental value, as is also indicated by the correlation coefficient (R) value of 0.998. Thus, the well-trained network model has excellent accuracy in predicting the flow stress of BT25 titanium alloy. After the training procedure, the network model is tested by unused data sets for the sake of checking whether the predicted results agree with the experimental results. Figure 8 shows the plot of experimental flow stress and predicted value by ANN model at strain of 0.7. The correlation coefficient is obtained to be 0.999, indicating that a desired predicted accuracy between the predicted and experimental value has been achieved. Additionally, combined with the established constitutive equation, the performance of the ANN model trained with BP algorithm is investigated by analysis of the relative error (RE) of neural network predictions for testing data (at strain of 0.7) which was unused earlier. The comparison of relative error between the experimental, calculated data by regression method and predicted data by ANN are shown in Fig. 9. The results demonstrate that the relative error obtained from the ANN model varied from −9 to 5%. However, the relative error is in the range of −16.5 to 21.3% for the regression method. Thus, the flow stress values are fitted better in the ANN model than the regression method. For perfect comparison, the constitutive equation model is employed to predict the flow stress and compared with the experimental values as shown in Fig. 10. The correlation coefficient is 0.988, which is lower than that acquired from the ANN model. Meanwhile, the standard deviation (SD) of the results pertaining to ANN model and constitutive equation developed by regression method are 1.776 and 11.237, respectively (Fig. 8 and 10). This means that the accuracy of predicted flow stress based on the ANN model is higher than that using the regression method and a good correlation between the predicted and experimental data has been achieved by the ANN model.

In order to make a direct analysis, Fig. 11 shows the plot of experimental value of flow stress and predicted value by both ANN and regression model at strain of 0.7 and deformation temperature of 940 and 980 °C. It can be observed that the results by ANN model agree well with the experimental, while the results by regression method give a fair estimate of the flow stress under the most deformation conditions except for the large error which occurred at strain rate of 10 s−1. Additionally, Eq 7 developed using the regression model can only provide the values of flow stress at strain of 0.7, which is limited in describing the true stress-true strain curves in the whole strain range. Alternatively, the technique of ANN is more beneficial to predict the flow stress and establish the constitutive relationship of BT25 titanium alloy under the condition of various strains. Figure 12 shows the comparison of the predicted values by ANN model with experimental values in the whole range of strain. It indicates that the established network model can offer an accurate and precise evaluation of flow stress at all the deformation conditions, and the predicted data can track the feature of dynamic softening very well.

Therefore, it can be concluded that the ANN model based on the BP learning algorithm is a more effective tool to represent the dynamic deformation behavior of the BT25 titanium alloy during high temperature deformation. Also, the results imply that the developed constitutive relationship model using ANN for the BT25 titanium alloy are consistent with what is expected from fundamental theory of hot deformation, which suggests that the established network model possesses excellent capability to predict the work hardening and flow softening stages. Although the regression model can represent the flow behavior as a fit of one equation or a set of equation parameters under a certain condition, it cannot capture the essence of the specific deformation characteristics.

Conclusions

The modeling of flow behavior of BT25 titanium alloy under various hot deformation conditions was accomplished through the flow stress prediction using ANN and constitutive equation, respectively. The following conclusions can be drawn from the results:

-

1.

The flow stress curves exhibit work hardening and flow softening in BT25 titanium alloy at low to medium strains depending on the magnitudes of deformation temperature and strain rate.

-

2.

Using the non-linear regression method and assuming a hyperbolic sine equation between the stress, strain rate, and deformation temperature, the average value of deformation activation energy of the alloy was derived as 623.26 kJ/mol at strain of 0.7.

-

3.

The developed ANN model with BP neural network is able to predict the flow stress of the present alloy over the ranges of strain, strain rate, and temperature used in this study.

-

4.

The ANN model has a better prediction at the whole deformation conditions while the hyperbolic sine equation developed by regression method has a weaker prediction compared with the ANN model.

References

A. Airod, H. Vandekinderen, J. Barros, R. Colas, and Y. Houbaert, Constitutive Equations for Room Temperature Deformation of Commercial Purity Aluminum, J. Mater. Process. Technol., 2003, 134, p 398–404

P.F. Bariani, T. Dal Negro, and S. Bruschi, Testing and Modelling of Material Response to Deformation in Bulk Metal Forming, CIRP Ann. Manuf. Technol., 2004, 53, p 573–595

L. Anand, Constitutive Equations for Hot-Working of Metals, Int. J. Plast., 1985, 1, p 213–231

P. Wanjara, M. Jahazi, H. Monajati, S. Yue, and J.P. Immarigeon, Hot Working Behavior of Near-α Alloy IMI834, Mater. Sci. Eng. A, 2005, 396, p 50–60

H. Mirzadeh, A. Najafizadeh, and M. Moazeny, Flow Curve Analysis of 17-4 PH Stainless Steel under Hot Compression Test, Metall. Mater. Trans., 2009, 40A, p 2950–2958

P. Vo, M. Jahazi, S. Yue, and P. Bocher, Flow Stress Prediction During Hot Working of Near-α Titanium Alloys, Mater. Sci. Eng. A, 2007, 447, p 99–110

W.D. Zeng, Y. Shu, and Y.G. Zhou, Artificial Neural Network Model for the Prediction of Mechanical Properties of Ti-10V-2Fe-3Al Titanium Alloy, Rare Metal. Mater. Eng., 2004, 133, p 1041–1044 (in Chinese)

Y. Sun, W.D. Zeng, Y.Q. Zhao, X.M. Zhang, Y. Shu, and Y.G. Zhou, Modeling Constitutive Relationship of Ti40 Alloy Using Artificial Neural Network, Mater. Des., 2011, 32, p 1537–1541

W. Sha and K.L. Edwards, The Use of Artificial Neural Networks in Materials Science Based Research, Mater. Des, 2007, 28, p 1747–1752

A.M. Rashidi, A.R. Eivani, and A. Amadeh, Application of Artificial Neural Networks to Predict the Grain Size of Nano-crystalline Nickel Coatings, Comput. Mater. Sci., 2009, 45, p 499–504

P. Li, K.M. Xue, Y. Lu, and R.J. Tan, Neural Network Prediction of Flow Stress of Ti-15-3 Alloy Under Hot Compression, J. Mater. Process. Technol., 2004, 148, p 235–238

Y.C. Lin, J. Zhang, and J. Zhong, Application of Neural Networks to Predict the Elevated Temperature Flow Behavior of a Low Alloy Steel, Comput. Mater. Sci., 2008, 43, p 752–758

M. Mulyadi, M.A. Rist, L. Edwards, and J.W. Brooks, Parameter Optimization in Constitutive Equations for Hot Forging, J. Mater. Process. Technol., 2006, 177, p 311–314

Y. Sun, W.D. Zeng, Y.Q. Zhao, Y.L. Qi, X. Ma, and Y.F. Han, Development of Constitutive Relationship Model of Ti600 Alloy Using Artificial Neural Network, Comput. Mater. Sci., 2010, 48, p 686–691

Z.C. Sun, H. Yang, and Z. Tang, Microstructural Evolution Model of TA15 Titanium Alloy Based on BP Neural Network Method and Application in Isothermal Deformation, Comput. Mater. Sci., 2010, 50, p 308–318

V.N. Moiseyev, Titanium Alloys: Russian Aircraft and Aerospace Applications, CRC Press, Part of Taylor & Francis Group Co., New York, 2006

Y.Q. Wang, S.C. Zhou, and W.Q. Wang, The Microstructure and Properties for BT25 Titanium Alloy Bars, Rare. Metal. Mater. Eng., 2005, 35, p 251–253 (in Chinese)

K.X. Wang, W.D. Zeng, Y.Q. Zhao, Y.J. Lai, and Y.G. Zhou, Dynamic Globularization Kinetics During Hot Working of Ti17 Alloy with Initial Lamellar Microstructure, Mater. Sci. Eng. A, 2010, 527, p 2559–2566

S.C. Juang, Y.S. Tarng, and H.R. Lii, A Comparison Between the Back-Propagation and Counter-Propagation Networks in the Modeling of the TIG Welding Process, J. Mater. Process. Technol., 1998, 75, p 54–62

H.K.D.H. Bhadeshia, Neural Networks in Materials Science, ISIJ International., 1999, 39, p 966–979

H. Kurt, S. Maxwell, and W. Halberd, Multilayer Feedforward Networks Are Universal Approximators, Neural Netw., 1989, 2, p 359–366

R.Q. Fu, T.W. Xu, and Z.X. Pan, Modeling of the Adsorption of Bovine Serum Albumin on Porous Polyethylene Membrane by Back-Propagation Artificial Neural Network, J. Membr. Sci., 2005, 251, p 137–144

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta. Metall., 1966, 14, p 1136–1138

Acknowledgments

This research was sponsored by the 973 Program of China with No. 2007CB613807, the Fund of the State Key Laboratory of Solidification Processing in NWPU with No. 35-TP-2009 and Natural Science Foundation of China with No. 51075333.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, X., Zeng, W., Tian, F. et al. Modeling Constitutive Relationship of BT25 Titanium Alloy During Hot Deformation by Artificial Neural Network. J. of Materi Eng and Perform 21, 1591–1597 (2012). https://doi.org/10.1007/s11665-011-0061-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-0061-7