Abstract

In this paper, a triticale-based edible film coating on muffins is presented and its potential use in retarding the staling process has been studied. Edible film effects were established by measuring weight, height, volume, density, color, texture and image analysis of control and coated muffins during storage. A discriminative sensory test was also carried out. Triticale coating diminished the hardness values of the muffins during storage. The kinetics of staling was faster for control muffins than for coated ones. Descriptive parameters of shape and size in the crumb`s structure shown that storage time increased significantly the percent of small pores and decrease solidity values of pores of control muffins, while no significant difference was found in coated muffins. Our results indicate that the triticale film coating is able to compensate the staling and preserves an appearance associated with freshness in muffins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The appearance of baked products is an important quality attribute that influences the visual perceptions of consumers and hence, the potential purchase of the product. Characteristics of bakery products have been studied [1–3]. The industry has been trying to solve problems and defects with innovations in the manufacturing process in attempt to maintain market value.

In recent years, food packaging research has focused more on biodegradable films, including films made from plant sources. The use of edible films cannot replace the use of traditional packaging materials, but it is necessary to take into account their functional characteristics and the possible advantages in certain applications [4]. An edible coating or film has been defined as a thin, continuous layer of biopolymer that can be consumed and is usually applied onto a surface of a food product by spraying, dipping or brushing [5]. Spraying is a technique that offers uniform coating and the possibility of successive applications which does not contaminate the coating solution. The performances of edible coatings not only depend on the methods employed, but also the properties of the coating materials. Many natural materials have the potential to make well performing edible coatings, including proteins, polysaccharides, and lipids [6]. Triticale (x Triticosecale Wittmack) is the hybrid between wheat (Triticum ssp) and rye (Secale ssp). This cereal may be suitable for grain production, forage, energy, bioethanol production [7–9] and film formation [10–12].

Muffins are sweet, baked products which are highly appreciated by consumers due to their good taste and soft texture. This product is characterized by a typical porous structure and high specific volume, which confers a spongy texture [13]. Muffins are widely used as snacks among consumers, so that bakery and snack food industries continuously compete to be first in the market by improving quality and merchandising factors such as the cost, packaging and shelf life of the products [3].

Staling is one of the most important attributes in bakery products quality. Staling is a complex process that includes changes in mouth texture, loss of tenderness, humidity redistribution and partial dryness. All these changes contribute to reduce consumer acceptability [14]. The stability during storage or shelf life can be defined as the maintenance of the physical and sensorial characteristics associated with freshness, such as tenderness, compressibility and humidity and the minimization of the alterations associated with staling [15]. Several works have analyzed how to minimize the textural changes in cakes and muffins during storage with edible films that cover the product [16, 17].

In the coating process, one or more liquid layers are deposited on a solid substrate and subsequently dried to form solid films, which possess specific functions. Application of edible coatings to bakery products requires the formation of films directly on food surfaces. Spraying was chosen as the most suitable technique for our purpose because it produces uniform coating. Deposition by spraying requires droplet–droplet contact and aggregation, which is a critical step for homogeneous film structure. The application of spraying to real products could be an attractive option as the technique offers the major advantage (over dipping) of a more uniform coating, especially on non-regular surfaces [18].

The objectives of this work were to coat muffins with edible films of triticale flour produced by spraying and evaluate the ability of this coating to retard staling and to increase the shelf life of a bakery product.

Materials and methods

Materials

Wheat flour, fresh whole eggs, sunflower oil, sugar, powder milk and whole milk were purchased in the local market. Triticale (variety Buck TK 205) flour (moisture content, 13.25 ± 0.02 g 100 g−1, protein content, 8.88 ± 0.02 g 100 g−1, ash content, 0.61 ± 0.02 g 100 g−1, particle size: pass through a US Standard Sieve No 100) was donated by Campeloni Semillas S.A. (Córdoba, Argentina). All chemical reagents used in this research were purchased from Sigma-Aldrich Chemie Gmbh (Munich, Germany) and were of analytical grade.

Preparation of muffins

The muffins were prepared using the following formula based on flour weight: 6.7 % baking powder, 2.2 % salt, 49 % sugar, 106 % milk, 27 % liquid whole eggs and 38 % butter. A single-bowl mixing procedure was used. After baking of 40.0 ± 0.3 g batter in paper cups for 30 min at 180 °C in a convection oven (Pauna, Buenos Aires, Argentina) the muffins were allowed to cool at room temperature. Muffins were prepared on three different days using the same materials and equipment. Each day represents a true replicate (n = 3).

Film-forming solution preparation

Triticale flour was used as film-forming component. Edible film-forming solutions were obtained by dispersion of triticale flour (4 % w/v) in water for 15 min (pH 10.7). Glycerol (30/100 g flour) was added and the resulting dispersion was then magnetically stirred for 15 at 75 °C. The film-forming solution was then allowed to cool at room temperature. This concentration was chosen based on previous studies [19], where it was found that an adequate plasticizing effect cannot be obtained below this critical concentration.

Coating application

Coated muffins (CM) were obtained by spraying the film-forming solution over muffins at a pressure of 2 bar and at room temperature. An in-house spray facility developed at the University of Córdoba with a hydraulic spray nozzle was used. Spray conditions (film-forming solution volume, distance between the nozzle and the muffins) were standardized. The application of 4 mL of film-forming solution per muffin was at a fixed distance between the nozzle and muffin of 40 cm. The upper surface of the muffins was coated and dried at 40 °C for 40 min. Uncoated muffins were used as control.

Storage of muffins and shelf-life analysis

All the samples (uncoated control and coated muffins) were stored at room temperature for 7 days for evaluation (the limiting hardness value was obtained from muffins stored for 10 days). The storage duration was selected according other investigations [16, 20] and standard requirements for fresh bakery products. An analysis of muffin quality and properties was carried out. All tests were conducted in triplicate unless noted otherwise.

Muffins evaluation

Muffin weight was determined with the aid of a precision scale (Mettler Instrument, Switzerland). Muffin height was measured with a calliper from the highest point of the muffin to the bottom of the paper. Volume of muffins was determined by rape-seed displacement test. Density of muffins was calculated by dividing weight by volume. Measurements were made in triplicate.

Color measurement

A Konica Minolta 508d spectrocolorimeter was used to measure the color of the muffins. Results were expressed in accordance with the CIELAB system. The color of the crust and crumb of three muffins from each batch was measured five times at random sites on each of three different muffins.

Texture of the muffins

Muffins crumb texture was evaluated using a TA-XT2 texture analyzer (Stable Microsystems, Surrey, U.K.). Measurements were performed on the central crumb slices (20 mm thick) from two muffins in each batch, recording the mean of the six measurements. A texture profile analysis (TPA) was performed using the software “Texture Expert” and the probe P/25 (25 mm diameter Aluminum cylinder). The TPA (double compression test) used a compression of 50 % of the initial height, a speed of 1 mm/s, and a 10 s waiting time between the two cycles. The parameters obtained from the curves were hardness (the peak force during the first compression cycle), springiness (the height that the food recovered between the end of the first compression and the start of the second compression) and resilience (area during the withdrawal of the first compression divided by the area of the first compression).

Avrami model

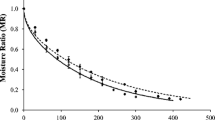

Hardness was fitted to the Avrami equation:

where θ is the fraction of total change in the crumb hardness at time t, H0, Ht and H∞ are experimental values of hardness at time zero, t (0, 3, 5 and 7 days), and infinity (or limiting value at 10 days of storage), k is the rate constant and n is the Avrami exponent. The reciprocal of the rate constant (1/k) is termed time constant. All the parameters were obtaining to Kim and D’Appolonia [21].

Scanning of muffins and image analysis

Muffins were cut vertically and placed over the glass of a scanner (HP Scanjet G3010). Scanning was performed with a resolution of 300 dpi. The scanned images were analyzed with the software Image J (http://rsbweb.nih.gov/ij/) [22] that uses the contrast between two phases (pores and solid part) of the image. The scanned color image was first converted to gray scale. Using bars of known lengths, pixel values were converted into distance units. A rectangular cross-section of the images was cropped. The area of these cropped images, on which this analysis was performed, was 2 × 2 cm for each image. Shape descriptors (circularity, aspect ratio, roundness and solidity), Feret diameter, minimum Feret diameter and pore area distribution were calculated (Table 1).

Sensory evaluation

In order to evaluate the sensory changes of the muffins with film coating, students and staff at University of Córdoba, Argentina, performed sensory analysis. During test sessions twenty-five panelists worked in individual booths evaluating the muffins (control and film-coated). A discriminative triangle test was performed [23]. The judges were requested to evaluate two attributes: outer surface color and overall impression (aroma and flavor, freshness in mouth, softness). Muffins were identified by a three digit random number and offered to the judges on a dish. Panelists were given room-temperature water to cleanse the palate before presentation of samples. Paper ballots were used. Comments about the samples were allowed. Roessler table was used in determining significance in triangle (one-tailed) tests.

Statistical analysis of the results

Analysis of variance (ANOVA) was carried out to test mean differences (p < 0.05). Once differences were detected, a Tukey’s multiple comparison test was used to find out which means were statistically and significantly different (p < 0.05). The InfoStat Statistical Software (version 2013e) was used for statistical analysis [24].

Results and discussion

Muffin properties: Weight, height and density

Weight, height and density values of muffins (control and coated) throughout storage time are shown in Table 2. The weight of control muffins decreased significantly during storage time. Nevertheless, storage time did not significantly influence the weight of triticale film coated muffins. The water losses produced during storage in these muffins was negligible in relation to the total weight of the muffins, and consequently this parameter did not change. The density of control muffins increased at day 7. Besbes et al. [25] explained similar results in bread by the redistribution of water at the molecular scale between protein and starch, to possible changes in volume or may be because of crumb contraction. This contraction is probably a result of the reorganization of the biopolymers contained in the crumb, which undergo biochemical and physical changes. However, there was no significant difference in density for CM during storage.

Color measurement

Color is one of the most important appearance characteristic because it affects directly consumer preference for the food product. Color in baked goods could come from different sources: intrinsic color imparted by individual ingredients [26], developed color resulting from the interaction of ingredients [27], like Maillard or caramelization reactions, besides processing changes associated to chemical or enzymatic reactions. During storage, moisture is lower, affecting the crust color, which becomes more flat color. A discoloration occurs during the storage period and often the consumers recognized this as a sign of poor quality of the muffins. The colors attributes obtained for each kind of muffins are presented in Table 2. The lightness values L* of the crust of uncoated muffins remained fairly constant during storage. CM shown the highest values of L* after storage indicating a significantly brighter color than in control muffins.

All the muffins crust were, as expected, darker than the muffin crumbs. It was observed a decrease in the lightness (L*) and an increase in the yellowness (b*) values of the crumb of uncoated muffins during storage. That is to say, the crumb of control muffins acquired a more saturated yellowish color. No significant differences were observed in the L* and b* values of the crumb of coated muffins.

Textural properties

The efficiency of triticale flour edible coating in controlling the staling of muffins can be evaluated by texture parameters. Texture is one of the main characteristics of bakery products. A loss of the desired texture results in shorter shelf-life. According to Gómez et al. [28] the study of texture of cakes could be reduced to the study of hardness, resilience and springiness.

This study reflects the textural changes in the samples (control and coated muffins) that took place during storage. Changes in the textural parameter values with storage time are shown in Figs. 1 and 2. The firmness or hardness of the final product is most often measured because of the strong correlation between crumb firmness and consumer perception of bread freshness [29]. The hardness values of control muffins increased during the storage time (Fig. 1), possibly because of water loss from the surface. These results are in accordance with previous studies [20]. Triticale film coating proved effective for obtaining softer muffins than the control samples during storage. As can be observed in Fig. 1, triticale coating diminished the hardening of the muffins during storage. However, Fig. 2 shows that there were no statistically significant differences for springiness during storage. Similar results were obtained by Grigelmo-Miguel et al. [20]. The same tendency was shown by the resilience (Fig. 2). Baixauli et al. [30] also found the same for the springiness parameter.

Springiness and resilience values of control (black square) and triticale film-coated muffins (white square) initially (0) and at 7 days of storage (7). Bars represent the standard deviation of six determinations. Same letter indicates not significant differences (Turkey’s adjusted analysis of variance p < 0.05)

The rate of firming or hardness of muffins (control and coated) could be quantitatively analyzed by the Avrami equation. Hardness data were modeled using the Avrami equation and the parameters are shown in Table 3. The Avrami exponent (n) values obtained in this study for control and CM (1.51 and 1.70 respectively) reflected similar morphology of the process of staling. Analysis of Avrami equations from different formulations [31] showed that an increment in n indicate small increments in crumb firmness in the first storage period (0–3 days). Higher n values were often associated with lower k values. The estimated Avrami coefficient k for crumb hardness of CM decreased by 24 % compared to the control. According to Armero et al. [31], a decrease in k value led to slower crumb firming kinetics. The time constant is the time for any given fraction of material to be converted into the stale form [21]. The higher time constant is, the slower the staling kinetics is. The time constant value obtained for CM was higher (31 %) than the control. Crumb firming kinetics depend on changes in material resistance with time and also on material distribution, the later mostly determining crumb hardness kinetics [31]. Triticale film coating was effective in retarding the staling process and this resulted in softer fresh muffins.

Image analysis of muffins

Image analysis is a technology that allows measurements from digitalized images. These measurements provide objective evaluations of the morpho-colorimetric features of samples. This method is more quantitative and less biased than the common method of visual perception, which is prone to variation due to the personal opinions of inspectors [32]. Many studies have demonstrated the utility of image analysis for the study of morphometric characteristics in fruits and vegetables [33] and bakery products [3, 34]. In this study, some of the descriptive parameters of shape and size in the structure of crumbs were measured as this quantitative analysis can be related to the stage of ageing of the muffins. Figure 3a shows the sample graph of a crumb image. The binarised image that was obtained by the Image J software can be seen in Fig. 3b. Binarised images were used for quantitative analysis of pores. Pore area distribution of crumb muffins is shown in Fig. 4. According to our results, storage time increased significantly the percentage of pores of area 0.1–0.99 mm2 and increased the percent of pores of area 5–9.9 mm2 in control muffins. Meanwhile, in triticale film coated muffins, storage time only affected the percent of pores of area 5–9.9 mm2 but not the percent of pores of area 0.1–0.99 mm2.

Circularity is a measure of the particle’s shape relative to a perfect circle. A perfect circle has a circularity of 1, while an irregular object has a circularity value closer to 0. Storage time produced a significant decrease of circularity of pores in crumb of control muffins, while no significant difference was found in terms of circularity for CM (Fig. 5). AR (elongation) is the aspect ratio of the particle’s fitted ellipse. The AR values of pores of crumb are shown in Fig. 5. No significant difference between control and CM was found during the storage time. The roundness factor describes the degree of deformation of the sample. The roundness values of the pores of crumb are shown in Fig. 5. No significant differences between control and CM were found during the storage time. The roundness values in this study were found between 0.53 and 0.59. A value greater than 0.6 indicates high roundness, between 0.4 and 0.6 indicates medium roundness, and less than 0.4, low roundness. Solidity (convexity) is the ratio of area of the 2-dimensional projection of the aggregate particle to the convex area. The convex area can be defined as the area enclosed by an imaginary “string” wrapped around the object. Solidity has values in the range 0–1. A low solidity towards 0 indicates a rough particle edge. A high solidity of 1 indicates a smooth particle edge. Storage time produced a significant decrease of solidity of pores in crumb of control muffins, while no significant difference was found in terms of solidity for CM (Fig. 5). Feret diameter is not a diameter in its actual sense but the common basis of a group of diameters derived from the distance of two tangents to the contour of the particle in a well-defined orientation. Feret’s diameter is the greatest distance between any two points along the boundary of the object. The minimum caliper diameter is MinFeret. The results of Feret diameters are shown in Fig. 5. No statistically significant differences in Feret Diameter and MinFeret between control and CM were found during the storage time. If a particle has an irregular shape, the Feret diameter usually varies much more than with regularly shaped particles. The examination of internal pore structure changes can be related to hardness values. Muffins with the higher hardness values possessed the higher percent of small air pores and lower solidity values.

Effect of triticale film coating on circularity (a), aspect ratio (b), roundness (c), solidity (d) and Feret and MinFeret values (e) of pores of crumb of control and triticale film-coated muffins, initially (0) and at 7 days of storage (7). Bars represent the standard deviation from triplicate determinations. Different letters (a–c) indicate significant differences (Turkey’s adjusted analysis of variance p < 0.05)

Sensory evaluation

In order to know the acceptability of the muffins, a sensory analysis was carried out. The statistical interpretation of the test is based on the binomial law with p = 1/3 (null hypothesis: no differences between the two tested products; alternative hypothesis: samples have significant differences between each other). When the number of correct answers of a triangle test equals or exceeds the critical value compatible at a given probability level with a binomial distribution with parameter 1/3 (52 %, p < 0.05), the null hypothesis is rejected and significant differences between samples are concluded [35]. Our results showed that the triticale film coating did not change significantly the visual aspect of the muffins (48 % of panelists gave correct answers). Overall impression (aroma and flavor, freshness in mouth, softness) of CM came out significantly different (72 % of panelists gave the correct answers) from the control muffins (p < 0.05).

Conclusions

During a storage period of 10 days the muffins coated with triticale flour edible film remained softer than uncoated control samples. After the process of spraying, the particles of film-forming solution impact the surface of muffin and form bonds with it, resulting in a coating with high bonding strength. Storage time did not significantly influence the weight, but triticale film coating diminished the hardening of the muffins during storage and was effective in retarding the staling process due to a decrease in k value and slower crumb firming kinetics. Also, the time constant value obtained for CM was higher (31 %) than the control. Storage produced a significant decrease of circularity of pores in crumb of control muffins, while no significant difference was found for coated muffins. Triticale film coating was effective in retarding staling process and this resulted in softer fresh muffins.

References

Z.M. Abdullah, A.S. Aziz, A.M. Dos-Mohamed, Quality inspection of bakery products using a color-based machine vision system. J. Food Qual. 23, 39–50 (2000)

A. Angioloni, C. Collar, Bread crumb quality assessment: a plural physical approach. Eur. Food Res. Tech. 229, 21–30 (2009)

O. Grillo, V. Rizzo, R. Saccone, B. Fallico, A. Mazzaglia, G. Venora, G. Muratore, Use of image analysis to evaluate the shelf life of bakery products. Food Res. Int. 62, 514–522 (2014)

S. Saucedo-Pompa, R. Rojas-Molina, A.F. Aguilera-Carbó, A. Saenz-Galindo, H. de La Garza, D. Jasso-Cantú, C. Aguilar, Edible film based on candelilla wax to improve the shelf life and quality of avocado. Food Res. Int. 42, 511–515 (2009)

T. Bourtoom, Edible films and coatings: characteristics and properties. Int. Food Res. J. 15, 237–248 (2008)

Y. Zhong, G. Cavender, Y. Zhao, Investigation of different coating application methods on the performance of edible coatings on Mozzarella cheese. LWT Food Sci. Technol. 56, 1–8 (2014)

J.R. Jørgensen, L.C. Deleuran, B. Wollenweber, Prospects of whole grain crops of wheat, rye and triticale under different fertilizer regimes for energy production. Biomass Bioenergy 31, 308–317 (2007)

D. Pejin, L.J. Mojovic, V. Vucurovic, J. Pejin, S. Dencic, M. Rakin, Fermentation of wheat and triticale hydrolysates: a comparative study. Fuel 88, 1625–1628 (2009)

M. Marković, S. Markov, O. Grujić, L. Mojović, S. Kocić-Tanackov, M. Vukašinović, J. Pejin, Microwave as a pre-treatment of triticale for bioethanol fermentation and utilization of the stillage for lactic acid fermentation. Biochem. Eng. J. 85, 132–138 (2014)

A. Aguirre, R. Borneo, A. León, Properties of triticale flour protein based films. LWT Food Sci. Tech. 44, 1853–1858 (2011)

A. Aguirre, R. Borneo, A. León, Properties of triticale protein films and their relation to plasticizing–antiplasticizing effects of glycerol and sorbitol. Ind. Crops Prod. 50, 297–303 (2013)

A. Aguirre, R. Borneo, A. León, Antimicrobial, mechanical and barrier properties of triticale protein films incorporated with oregano essential oil. Food Biosci. 1, 2–9 (2013)

M. Matos, T. Sanz, C. Rosell, Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll. 35, 150–158 (2014)

M. Gómez, B. Oliete, V. Pando, F. Ronda, P.A. Caballero, Effect of fermentation conditions on bread staling kinetics. Eur. Food Res. Tech. 226, 1379–1387 (2008)

T. Paeschke, Shelf life extension of reduced-fat baked goods using fruit powders. Cereal Foods World 42, 391–395 (1997)

M. Baeva, I. Panchev, Investigation of the retaining effect of a pectin-containing edible film upon the crumb ageing of dietetic sucrose free sponge cake. Food Chem. 92, 343–348 (2005)

I.N. Panchev, M.R. Baeva, S.I. Lambov, Influence of edible films upon the moisture loss and microstructure of dietetic sucrose-free sponge cakes during storage. Dry. Tech 23, 925–940 (2005)

B. Bravin, D. Peressini, A. Sensidoni, Development and application of polysaccharide–lipid edible coating to extend shelf-life of dry bakery products. J. Food Eng. 76, 280–290 (2006)

J. Bartolozzo, R. Borneo, A. Aguirre, Efecto del recubrimiento con películas de harina de triticale sobre el envejecimiento de muffins.; XIV Congreso Argentino de Ciencia y Tecnología de los Alimentos –CYTAL, Rosario, Argentina (2013)

N. Grijelmo-Miguel, E. Carreras-Boladeras, O. Martín-Belloso, Development of high-fruit-dietary-fibre muffins. Eur. Food Res. Tech. 210, 123–128 (1999)

S.K. Kim, B.L. D’Appolonia, Bread staling studies. I. Effect of protein content on staling rate and bread crumb pasting properties. Cereal Chem. 54, 207–215 (1997)

M.D. Abramoff, P.J. Magalhaes, S.J. Ram, Image processing with image. J. Biophotonics Int. 11, 36–42 (2004)

M. Meilgaard, G.V. Civille, B.T. Carr, Sensory evaluation techniques, 3rd edn. (CRC Press, Boca Raton, 1999)

J.A. Di Rienzo, F. Casanoves, M. Balzarini, L. Gonzalez, M. Tablada, C.W. Robledo, InfoStat. Grupo InfoStat, Facultad de Ciencias Agropecuarias, Universidad Nacional de Córdoba, Argentina, (2013), http://www.infostat.com.ar

E. Besbes, V. Jury, J.-Y. Monteau, A. Le Bail, Effect of baking conditions and storage with crust on the moisture profile, local textural properties and staling kinetics of pan bread. LWT Food Sci. Tech. 58, 1–9 (2014)

M.A. Gularte, E. de la Hera, M. Gomez, C Rosell (2012) Effect of different fibers on batter and gluten-free layer cake properties. LWT Food Sci. Tech. 48, 209–214 (2012)

K. Acosta, G. Cavender, W.L. Kerr, Sensory and physical properties of muffins made with waxy whole wheat flour. J. Food Qual. 34, 343–351 (2011)

M. Gómez, E. Ruiz-Paris, B. Oliete, V. Pando, Modeling of texture evolution of cakes during storage. J Texture Stud. 41, 17–33 (2010)

L.G. Carr, M.A.B. Rodas, J.C.M. Della Torre, C.C. Tadini, Physical, textural and sensory characteristics of 7-day frozen part-baked French bread. LWT Food Sci. Tech. 39, 540–547 (2006)

R. Baixauli, A. Salvador, S.M. Fiszman, Textural and colour changes during storage and sensory shelf life of muffins containing resistant starch. Eur. Food Res. Tech. 226, 523–530 (2008)

E. Armero, C. Collar, Crumb firming kinetics of wheat breads with anti-staling additives. J. Cereal Sci. 28, 165–174 (1998)

M. Sonka, V. Hlavac, R. Boyle, Image processing, analysis, and machine vision, 3rd edn. (Thomson Learning, Toronto, 2008)

F. Lopez-Garcia, G. Andreu-Garcia, J. Blasco, N. Aleixos, J.M. Valiente, Automatic detection of skin defects in citrus fruits using a multivariate image analysis approach. Comput. Electron. Agric. 71, 189–197 (2010)

E. Turabi, G. Sumnu, S. Sahin, Quantitative analysis of macro and micro-structure of gluten-free rice cakes containing different types of gums baked in different ovens. Food Hydrocoll. 24, 755–762 (2010)

J. Bi, Sensory discrimination tests and measurements (Blackwell Publishing, Iowa, 2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bartolozzo, J., Borneo, R. & Aguirre, A. Effect of triticale-based edible coating on muffin quality maintenance during storage. Food Measure 10, 88–95 (2016). https://doi.org/10.1007/s11694-015-9280-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-015-9280-1