Abstract

The effect on baked muffins of progressively replacing wheat flour with resistant starch (RS) (26/0, 21/5, 16/10, 11/15 and 6/20) was studied. In this study, texture profile analysis (TPA) and the elastic recovery test were used to evaluate the effects of RS on the textural properties of fresh and stored muffins (from 0 to 16 days). Textural parameter values decreased with the increase of RS; springiness and cohesiveness reflected better than the textural differences for fresh muffins. Changes in the textural parameter values with storage time were smaller at higher RS levels. Survival analysis methodology was used to estimate the changes in muffin shelf life. Shelf life time of control muffin is higher than 20% RS muffin for 25% consumer rejection but this behaviour is the opposite for 50% consumer rejection.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Resistant starch (RS) became available commercially some years ago as a food ingredient with a nutritional label listing as dietary fibre (DF). There is no globally agreed definition of DF. One of the latest definitions is: “DF is the edible parts of plants that are resistant to digestion and absorption in the human small intestine with complete or partial fermentation in the large intestine” [1]. RS has been defined as the sum of starch and the products of starch degradation not absorbed in the small intestine of healthy individuals [2].

It is well-known and documented that the physiological effects of RS include reducing the glycemic response, acting as a functional prebiotic for some probiotic microoorganisms and increasing the production of short chain fatty acids in the large intestine, but RS is also important in the diet because of its interactions with other dietary components, including not only macronutrients such as fats and protein but also micronutrients such as minerals [3–6]. Also, as a functional food ingredient, its low water-holding capacity provides good handling properties during processing [7]. RS appears to possess a unique combination of physiological and functional properties compared to traditional types of fibre, which are generally associated with a coarser texture.

The mean DF intake in Europe is 20 g/day and the mean RS intake in Europe is likely to be low, about 4.1 g/day [3]. One way to ensure that the general population receives adequate amounts of fibre in the diet is to fortify food that would not normally be associated with fibre fortification but is often eaten as snacks, or muffins or cakes that would normally be consumed for breakfast.

Several dietary fibres have been employed to produce high fibre content muffins and cakes. Peach dietary fibre (0–10%) has been added to muffins [8]; Polizzoto et al. [9] and Shafer and Zabik [10] studied the effect of different dietary fibre sources (α-cellulose, corn bran, oat hulls, rice bran, soy bran, wheat bran and oat bran) in muffins and layer cakes, respectively; isolated fibres from wheat, pineapple and field beans seed hull have been included (5% w/w) in a sponge cake and its sensory and physical properties evaluated [11]; while Chen et al. [12] compared apple fibre with wheat and oat bran to evaluate the chemical and physical properties and their effects on muffins.

Texture is one of the main characteristics of bakery products that can be affected by the addition of DF; it can be determined by instrumental or sensory methods. Instrumental methods offer some advantage over sensory analysis because they are rapid and objective. Baeva et al. [13] made a study of texture (sensory and instrumental) to compare normal and energy reduced sponge cakes; Sahi and Alava [14] studied the crumb structure of sponge cakes to evaluate the effect of different emulsifiers; texture profile analysis of cake crumb was performed by Singh Gujral et al. [15] to study the effect of sodium lauryl sulphate; and Kamel and Rasper [16] investigated the effect on cake crumb firmness of preparing reduced-calorie cakes with sorbitol or polydextrose to replace sugar.

Storage stability or the shelf life of baked products could be defined as maintenance the sensory and physical characteristics associated with freshness such as crumb tenderness, compressibility and moistness by preventing alteration associated with staling during storage [17, 18].

However, sensory methods are the only ones that make it possible to assess consumer acceptance. Consumers expect a product with a soft, spongy, tender crumb, but also a certain degree of resistance, not crumbling easily; these characteristics worsen with storage time and, in general, consumer rejection of the product occurs before any microbiological spoilage makes it unsuitable for human consumption [19]. Different methods may be used to determine the sensory shelf life of a food product using consumer data. In the failure cut-off point method, shelf life is determined as the time when the first significant change in overall acceptability is detected. At this time, consumers detect a change in the sensory characteristics of the product with respect to the fresh product. However, this does not mean that consumers would refuse to consume the product [20]. In order to estimate sensory shelf life based on consumer rejection of a food product, survival analysis can be applied. This methodology focuses on the shelf life risk of the consumer’s rejecting the product. Survival analysis has been used to estimate the shelf life of some baked products [21, 22].

The objectives of this study are to compare the influence of replacing increasing proportions of wheat flour with four different levels of RS on the textural properties of the muffins, freshly baked and stored for two weeks, and to assess the sensory shelf life of the muffins containing resistant starch.

Materials and methods

Batter and muffin preparation

Five formulations were prepared using the same quantity of all the ingredients except the flour and RS, which were 26/0, 21/5, 16/10, 11/15 and 6/20 percent respectively. The batter formulation (expressed as a percentage of weight) consisted of wheat flour (Harinera Vilafranquina, S.A., Teruel, Spain) (composition according to the miller: 14.5% moisture, 10.1% protein); resistant starch (HI-MAIZE 260, National Starch Food Innovation, Manchester, United Kingdom) (composition data provided by the supplier: 12% moisture, 63.9% dietary fibre), sugar (26%) (Azucarera Ebro, Madrid, Spain); liquid pasteurized egg white (14%) and liquid pasteurized yolk (7%) (Ovocity, Llombay, Spain); full-fat milk (13%) (Puleva Food, Granada, Spain); refined sunflower oil (12%) (local supermarket), sodium bicarbonate (1.03%), citric acid (0.79%) and grated lemon peel (0.18%). The egg white was whipped in a mixer (Kenwood Major Classic, UK) for 2 min at speed 7 (maximum). Sugar was then added and mixed in for 30 s at speed 7. Egg yolk, citric acid and half of the milk were added and mixed in at speed 3 for 1 min. Wheat flour RS, sodium bicarbonate and grated lemon peel were added and mixed in at speed 3 for 1 min. Oil and the rest of the milk were added and mixed in at speed 4 for 3 min. The batter was placed in an automatic dosing unit (positive displacement pumps, output shaft speed = 109 rpm, output shaft torque = 7.6 Nm) (Edhard Corp., Hackettstown, USA), and each paper muffin cup (50 mm diameter) was filled with 40.5 g of batter. The muffins were baked in a conventional oven for 6 min at 225 °C and for a further 6 min at 175 °C. The oven and oven trays were always the same, the trays were placed at the same level in the oven and the number of muffins baked was always the same. The muffins from each formulation and for each storage time were prepared twice, on different days, with 24 muffins in each batch.

After cooling, the muffins were packed in polyethylene bags that were heat-sealed and stored in an environmental chamber at room temperature (20 ± 2 °C). The muffin samples were evaluated on days 0, 2, 4, 7, 9, 11, 14 and 16.

Measurement of colour

The instrumental measurement of the muffin colour was carried out with a Hunter Labscan II colorimeter, and the results were expressed in accordance with the CIELAB system with reference to illuminant D65 and a visual angle of 10°. The measurements were performed through a 6.4 mm diameter diaphragm containing an optical glass. The parameters determined were L* (L* = 0 [black] and L* = 100 [white]), a* (–a* = greenness and +a* = redness), b* (–b* = blueness and +b* = yellowness), C* chroma (saturation) and H* hue, as defined by the following equations:

The total colour difference (ΔE*) between the control muffin and the muffins with RS was calculated as follows:

The values used to determine if the total colour difference was visually obvious were the following [23].

-

ΔE* < 1 colour differences are not obvious for the human eye

-

1 < ΔE* < 3 colour differences are not appreciative by the human eye

-

ΔE* > 3 colour differences are obvious for the human eye.

Three muffins of each formulation were measured on day 0. Each muffin was cut in two halves to measure the crumb colour, and measurements were made in each muffin. All the measurements were made by placing the sample directly on the colorimeter diaphragm.

Instrumental texture measurements

Instrumental parameters were measured with a TA-XT.plus Texture Analyzer using the Texture Exponent software (version 2.0.7.0. Stable Microsystems, Godalming, UK). Six muffins per formulation and storage time were studied in each textural test. All formulations were measured in duplicate (two different preparations in different days).

Texture profile analysis (TPA)

Muffin crumbs (2.5 cm sided cubes) were evaluated after removing the upper and lower ends. The test speed was 1 mm s−1 with a strain of 50% of the original cube height and a 5 s interval between compression cycles. A trigger force of 5 g was selected. The compression was performed using a 75 mm diameter aluminium plate (P/75). The cubes were compressed twice to give a TPA from which the three primary textural parameters [24] were obtained: hardness (the peak force during the first compression cycle), springiness (the height that the food recovers during the time that elapses between the end of the first bite and the start of the second bite) and cohesiveness (the ratio of the positive force area during the second compression portion to the positive force area during the first compression), as well as resilience (area during the withdrawal of the first compression divided by the area of the first compression.

Elastic recovery test

Elastic recovery was measured according to the Standard Procedure for Muffin Firmness and Elasticity (a relaxation test derivative of the Novo Nordisk modified version of the AACC method 74-09) [25]. The percentage of recovery or elastic recovery was measured by compressing a 2.5 cm thick, 2.5 cm diameter cylinder of muffin crumb with the upper and lower ends removed at a test speed of 7.5 mm s−1 and a strain of 50% of the original height for 10 s, after which the probe was removed at a speed of 10 mm s−1. The compression was performed using a 75 mm diameter aluminium plate (P/75). The elastic recovery was measured as:

where F max is the maximum force and F10 is the force after 10 s.

Sensory analysis

Testing was carried out in a sensory laboratory equipped with individual booths [26]. Consumers were recruited among workers from the Instituto de Agroquímica y Tecnología de Alimentos, Valencia, Spain. Forty persons, 22–60 years old, approximately half female, half male, who consumed muffins frequently, were used for the study. The testing was carried out in two sessions. At each session the consumers received a muffin from each of the different storage times of two types of muffin (control and 20% RS).

For each sample, the consumers answered yes or no to the question “Would you normally consume this product?” [19, 20]. The answers (yes or no) were used to calculate the sensory shelf life of the muffins using survival analysis methodology.

Data acquisition and analysis was performed using Compusense® five release 4.6 software (Compusense Inc., Guelph, ON, Canada).

Statistical analysis

Survival analysis methodology was used to estimate shelf life, using the results obtained from consumers when asked if they would normally consume the samples, a method recently introduced by Hough et al. [19]. Its key concept is to focus the shelf-life hazard on the consumer rejecting the product rather than on the deterioration. A random variable T is defined as the storage time at which the consumer rejects the sample; the survival function S(t) can be defined as the probability of a consumer accepting a product beyond time t, so S(t) = P(T > t). Alternatively, the cumulative distribution function, F(t) = 1 − S(t), can be defined as the probability of a consumer rejecting a product before time t, that is F(t) = P(T ≤ t). Usually, survival times are not normally distributed and models such as Weibull distribution for T are chosen. The survival function is given by:

where μ and σ are the model’s parameters. The probability of a consumer rejecting a product, F(t) = P(T ≤ t), must be chosen. 25 and 50% rejection probabilities were chosen. These percentages have been used to estimate the shelf life of several foods [21, 27–29]. The SPLIDA software package for S-PLUS (Insightful Corporation, Seattle, USA) was used to calculate the survival curves.

An analysis of variance (ANOVA) was performed to study the effect of the increasing replacement of wheat flour by different levels of RS. Least significant differences were calculated by Fisher’s test. These analyses were performed using SPSS for Windows Version 12 (SPSS Inc., USA).

Results and discussion

Influence of resistant starch

Colour analysis

The variation in the colour parameters (L*, a*, b*, C*, H*) and ΔE* due to addition of RS is shown in Table 1. The higher the concentration of RS, the redness, the yellowness and consequently the chroma of muffins decreased. The “white” colour of the RS incorporated acted as diluting the pigmented elements of the formulation. For the same reason, the brightness and the hue values increased with the RS concentration.

In order to study the total colour differences between muffins in relation to RS concentration, the values of ΔE* were calculated. The reference taken in each case was the colour of the control muffin (day 0). The value of ΔE* (Table 1) increased as the concentration of RS increased. At 5 and 10% RS the colour differences were not appreciative by the human eye (1 < ΔE* < 3). At 15 and 20% RS the colour differences are obvious for the human eye: the samples were less yellowish and less colourfulness.

Texture profile analysis

A prior study was performed to determine the compression percentage that would discriminate adequately between the differences among the samples. TPA was carried out at 50% of compression; this value has been used in other studies [8, 15, 30, 31], although other compression values such as 30% have been reported [32], 35% [14], 40% [33] or 60% [34], indicating that there is not a clear criterion for this experimental condition. Although chewiness was calculated, the data are not shown because its behaviour was the same as for hardness. The TPA curves are shown in Fig. 1.

The “hardness” values (Fig. 2) of the muffins with RS were significantly lower (P < 0.05) than those of the control muffins and although the decrease in hardness was not linear with wheat replacement, the lowest hardness value was for the highest concentration of RS (20%).

The “springiness” value is shown in Fig. 2. Springiness decreased as RS rose; this decrease was clear and significant from 15% of RS. At lower concentrations of RS (5 and 10%) there were no significant differences compared to the control.

The “cohesiveness” parameter (Fig. 2) decreased with the addition of RS; at 5 and 10% the decrease in this parameter was so slight that there were no significant differences compared to the control muffin, at higher concentrations of RS (15 and 20%) the cohesiveness value decreased significantly but there were no differences between these two formulations. The lower cohesiveness values would indicate that less energy was required for the second compression.

The addition of RS produced a very slight decrease in the “resilience” parameter (Fig. 2) at 5 and 10% RS, but the decrease was not significant (P < 0.05). At greater RS concentrations (15 and 20%) the resilience value decreased significantly. The pattern of behaviour was the same as for the springiness parameter.

These results did not agree with the study by Grigelmo-Miguel et al. [8], who reported that adding peach dietary fibre to muffins increased their hardness although their springiness and cohesiveness did not differ from those of muffins without dietary fibre.

A possible explanation of the decrease in resilience and springiness with the addition of RS is that the product matrix becomes denser. At the higher RS level the number and area of the gas cells [35] and the height of the final baked muffins decreased (4.70 cm for control; 4.50 cm for 10% RS and 3.84 cm for 20% RS), and therefore, the samples were less able to recover after deformation. In fact, a volume reduction in bread with β-glucan addition was reported attributable to gluten dilution, resulting in an underdeveloped gluten network; this would limit the extend of dough inflation and gas cell stability during proving, with a reduced loaf volume [36]. Similar results were found by Tudorica et al. [37] in dietary fibre enriched pasta: significantly reduced firmness and elasticity values were obtained with fibre addition; this reduction was related to the disruptive behaviour of the fibre on the protein–starch binding during pasta matrix formation.

Elastic recovery

The elastic recovery was calculated from the relaxation curves shown in Fig. 3.

The elastic recovery results on day 0 are shown in Table 2. The values at 5 and 10% RS were the same as for the control muffins, but at higher concentration of RS this value decreased significantly. The results are in agreement with Singh et al. [38], who studied the relaxation behaviour of some foods. They reported that angel cakes and pound cakes showed a % recovery in the range of 50–40 and reported that this may be due to the cross-linked protein structure formed during the baking process. The elastic recovery value indicates the elastic and the viscous component, which are correlated with the gliadin and glutenin fractions present in wheat gluten protein.

Similar studies were carried out by Kamel and Rasper [16] to examine the effect of emulsifiers on the texture of reduced-calorie cakes, which showed that the elastic recovery values consistently fell when higher concentrations of emulsifiers were applied, and by Shearer and Davies [39] to evaluate changes of freshly baked muffins with flaxseed oil or full-fat flaxseed meal. Freshly baked muffins prepared with flaxseed meal were less elastic (ability of a muffin to relax while compressed) than the control muffins.

The results of elastic recovery were in agreement of TPA data: muffins containing higher RS concentration showed a less cohesive and elastic structure.

Textural properties during storage

The textural properties of the muffins were evaluated over a 16-day storage period. This study reflects the textural changes in the samples prepared with different RS levels that took place during storage.

As can be observed in Fig.4a, the value for the “hardness” parameter of the control muffin tripled over 16 days of storage. The muffins with 5, 10 and 15% RS behaved in the same way. The muffins with 20% RS were softer than the control muffins on day 0 and the evolution of their textural parameters over the storage time was different. Muffins with 20% RS were always softer than the other muffins, as their hardness value doubled over the 16 days of storage. In this case, 20% RS proved effective for obtaining softer muffins than the control samples and, as can be observed in Fig. 4a, it diminished the hardening of the muffins during storage. These results are in agreement with Yue and Waring [40] who have shown that muffins formulated with 40% TDF (total dietary fibre) resistant starch remained softer than the control during a 2-week storage period.

The “springiness” parameter did not provide information, as can be observed in Fig. 4b. Non-significant differences with storage time were found, although the values were lower in the presence of RS.

The “cohesiveness” showed a significant fall over the storage period (Fig. 4c), although this decrease was lower for 15% and 20% RS samples. Consequently, higher concentrations of RS were effective in preventing a sharper drop in this parameter.

The same tendency was shown by the “resilience” (Fig. 4d) and confirmed by “elastic recovery” values (Table 1).

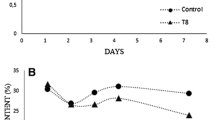

Sensory analysis

Percentage rejection versus storage time was then plotted (Fig. 5) using the Weibull distribution. The shapes of the curves were different for the two different levels of RS chosen (control and 20%) as can be observed in Fig. 5. During the early days of storage the percentage rejection was lower for the control muffins than for the 20% RS muffins, probably because the controls reminded the consumers more of a typical muffin. As time went on, however, the reverse was found, as the percentage rejection was higher for the control muffins than for the 20% RS muffins. This could be because, as mentioned above, the texture of the 20% RS muffins changed less over time.

Conclusions

The addition of RS in muffins produced a softer texture: the samples were less hard, elastic and cohesive reflecting a more tender structure; these effects were more evident at higher concentrations of RS. During a storage period of 16 days the samples with RS remained softer than control samples. These results were confirmed by sensory shelf-life analysis: after 23 days of storage the predicted percentage rejection by consumers for the RS-containing muffins was lower than the control sample.

References

De Vries JW (2003) Proc Nutr Soc 62:37–43

Asp NG, Björck I (1992) Trends Food Sci Technol 3(5):111–114

Asp NG, Van Amelsvoort JMM, Hauvast JGAJ (1996) Nutr Res Rev 9:1–31

Brown IL (2004) J AOAC Int 87(3):727–732

Kendall CWC, Emam A, Augustin LSA, Jenkins DJA (2004) J AOAC Int 7(3):769–774

Nugent AP (2005) Nutr Bull 30:27–54

Sajilata MG, Singhai RS, Kulkarni PR (2006) Compr Rev Food Sci Food Saf 5:1–17

Grigelmo-Miguel N, Carreras-Boladeras E, Martín-Belloso O (2001) Food Sci Technol Int 7(5):425–431

Polizzoto LM, Tinsley AM, Weber CW, Berry JW (1983) J Food Sci 48:111–118

Shafer MAM, Zabik ME (1978) J Food Sci 43:375–379

Sreenath HK, Sudarshanakrishna KR, Prasad NN, Santhanam K (1996) Starch/Stärke 48(2):72–76

Chen H, Rubenthaler GL, Leung HK, Baranowski JD (1988) Cereal Chem 65(3):244–247

Baeva MR, Panchev IN, Terzieva VV (2000) Nahrung 44(4):242–246

Sahi SS, Alava JM (2003) J Sci Food Agr 83:1419–1429

Singh Gujral H, Rosell CM, Sharma S, Singh S (2003) Food Sci Technol Int 9(2):89–93

Kamel BS, Rasper VF (1988) J Texture Stud 19:307–320

Paeschke T (1997) Cereal Foods World 42(5):391–395

Guy RCE (1983) J Sci Food Agric 34:477–491

Hough G, Langohr K, Gómez G, Curia A (2003) J Food Sci 68:359–362

Giménez A, Varela P, Salvador A, Ares G, Fiszman S, Garitta L (2007) Food Qual Prefer 18(2):196–204

Gámbaro A, Fiszman S, Giménez A, Varela P, Salvador A (2004) J Food Sci 69(9):401–405

Gámbaro A, Jiménez A, Varela P (2005) J Sens Stud 19:500–509

Francis FJ, Clydesdale FM (1975). Food Colorimetry: theory and applications. The AVI Publishing Company Inc., Westport

Pons M, Fiszman SM (1996) J Texture Stud 27:597–624

American Association of Cereal Chemists (2000) Approved methods of the AACC, (10th ed). Method 74–09. AACC, St. Paul, MN: the Association

ISO (1988) Sensory analysis. General guidance for design of test rooms. Standard no. 8589. Geneva, Switzerland

Gacula MC, Singh J (1984) Statistical methods in food and consumer research. Academic, New York, 505 pp

Cardelli C, Labuza TP (2001) LWT–Food Sci Technol 34:273–278

Varela P, Salvador A, Fiszman S (2005) Postharvest Biol Technol 38(1):18–24

Kim HYL, Yeom HW, Lim HS, Lim ST (2001) Cereal Chem 78(3):267–271

Lee S, Kim S, Inglett GE (2005) Cereal Chem 82(2):120–124

Khouryied HA, Aramouni FM, Herald TJ (2005) J Food Qual 28:439–451

Baik OD, Marcotte M, Castaigne F (2000) Food Res Int 33:599–607

Arunepanlop B, Morr CV, Karleskind D, Laye I (1996) J Food Sci 61(5):1085–1093

Baixauli R, Sanz T, Salvador A, Fiszman SM (2006) CONGRESS: bubbles in food 2: novelty, health and luxury

Symons LJ, Brennan CS (2004) J Food Sci 69(6):463–467

Tudorica CM, Kuri V, Brennan CS (2002) J Agric Food Chem 50:347–356

Singh H, Rockall A, Martin CR, Chung OK, Lookhart GL (2006) J Texture Stud 37:383–392

Shearer AEH, Davies CGA (2005) J Food Qual 28:137–153

Yue P, Waring S (1998) Food Aust 50(12):615–621

Acknowledgments

The authors are indebted to the Comisión Interministerial de Ciencia y Tecnología (Project AGL 2003-09208-C03-02) for the grant awarded to author R. Baixauli. The authors are also grateful to National Starch Food Innovation for supplying the resistant starch.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baixauli, R., Salvador, A. & Fiszman, S.M. Textural and colour changes during storage and sensory shelf life of muffins containing resistant starch. Eur Food Res Technol 226, 523–530 (2008). https://doi.org/10.1007/s00217-007-0565-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-007-0565-4