Abstract

To reduce and mitigate rainfall-induced problems, there is a need to improve understanding of the failure mechanism of unsaturated soil due to changes in water content in the soil body. Natural slopes, man-made slopes and embankments are generally made of unsaturated soils. In this regard, the objective of this study is to investigate the behavior of unsaturated silty soil due to change in water content and suction. The change in the water content of the sample represents the effect of rainfall. Moreover, this study aimed at understanding the effect of the degree of compaction on the strength and deformation characteristics of unsaturated silty soil. In the experiments, two series of laboratory element tests on double-cell triaxial machine carried out on DL clay (silty soil) in which water content varied from dry to wet of optimum moisture content, and the degree of compaction varied to study the effect at diverse overburden pressures. The test series is conducted in constant water content condition, and the measurements are closely monitored throughout the test course (initial suction to shear) to observe the changes in effective stress. The observed changes in the parameters are also presented in three dimensions to show the behavior of soil under the influence of more than two parameters. From this research, it is examined that with the increase in degree of compaction, volume change behavior transformed from compressive to dilative. Moreover, the strength of the silty soil increased with the increase in suction, i.e., due to decrease in water content, and vice versa.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

A firm and stable subgrade is essential for the pavement structure’s long-term bearing performance under vehicle loading. Some of the common problems of subgrade that affect the pavement stability are subgrade subsidence, subgrade slope collapse and ruts. These problems occurred due to insufficient bearing capacity of subgrade. The shear strength properties of the subgrade (compacted clayey soil) are affected by soil type, water content, degree of compaction and state of stress. The water content and degree of compaction are the main factors that affect the shear strength of a specific subgrade compacted soil [1]. In the case of compacted clayey soil, the suction and internal friction angle decreased with the increase in compaction and water content, and the cohesion peak appeared around the optimum moisture content [2]. In unsaturated soils, the cohesion and internal friction angle linearly decreased with the increase in water content. The decrease in cohesion due to water content is more evident than the internal friction angle [3]. The generation of pore water pressure during loading may cause geotechnical problems like slope failure [4]. The behavior of soil with a known initial state, a boundary condition and type of loading (due to any mechanical process) can be studied experimentally via the triaxial test [5, 6].

Melinda [7] investigated the shear strength and deformation characteristics of the residual soil during water infiltration that leads to failure. Rasool et al. [8] studied the behavior of unsaturated silty soil under constant shear stress and matric suction plane. The results indicated that with the increase of confinement (confining pressure), the water infiltration decreased due to the reduction in void ratio. The results also showed that a failure surface is a unique plane which is not affected much by drainage conditions.

Natural slopes, man-made slopes and embankments are generally made of unsaturated soils. In case of unsaturated soils, the important state variables are mean effective stress (p′), shear stress (q), void ratio (e) and one more variable among the following: suction (s), water content (w) and degree of saturation (Sr). In the above-mentioned studies, the research focused on the shear phase only to investigate the effect of various stress paths, water content variations during the constant net stress/shear stress/matric suction planes and variation of water content in the sample on the shear strength of unsaturated soils. The present study investigates the effect of water content and suction on the behavior of unsaturated silty soil (DL clay) in all the phases, i.e., initial suction, axis translation, consolidation and shear. The effect of degree of compaction on the behavior of unsaturated silty soil is also investigated. Finally, different stress variables are plotted in three dimensions (3D) to explain the behavior of unsaturated soil in all the phases of the experiment under the influence of more than two parameters.

2 Experimental Setup

Double-cell triaxial test apparatus having a strain control loading system was used in this research, as shown in Fig. 1. The advantage of using double-cell triaxial test apparatus is in its precise measurement of volume change [9] which is complex in unsaturated soils due to the presence of pore water pressure and pore air pressure. Pore water pressure was controlled and monitored from the bottom of the pedestal, whereas pore air pressure was controlled and monitored at the top cap. A membrane filter of high air entry value 420 kPa is used at the pedestal which does not allow the flow of air, while polytetrafluoroethylene (PTFE) sheet is used in the top cap, which does not allow the flow of pore water. A low-capacity differential pressure transducer (LCDPT) is used to measure the volume change behavior. Linear variable differential transducer (LVDT) was used to measure the axial deformation. The data/signals were acquired by all the transducers and then shifted to the amplifier, which minimizes the noise and increases the signal voltage. These analog signals were converted into digital signals by A/D board, and finally, a software (Digit Basic) was used, which presents the data in the form of physical values. The schematic diagram of the equipment is shown in Fig. 1.

3 Material and Methodology

To study the behavior of unsaturated silty soil, DL clay (commercial name of soil) is used in this study, because its suction value stabilizes in a shorter interval of time so that each test could be performed in a stipulated time frame. According to Japanese Geotechnical Society (JGS), it is classified as having medium–low compressibility (ML) and composed of 90% silt and 10% clay which shows that its grain size is larger than average clay. This silty soil has a relatively uniform grain size distribution with a mean grain size D50 approximately 0.03 mm. The optimum moisture content of the soil was 20%, the maximum particle size was 0.039 mm, and maximum dry density was 1.55 g/cm3. The appearance of freshly and freely deposited DL clay looks yellowish brown. The physical properties of DL clay are summarized in Table 1.

3.1 Sample Preparation and Test Phases

In this research, the samples (5 cm × 10 cm) were prepared with different initial water content (having the same dry density). Each sample was compacted in five layers by static compaction to achieve the uniform density (in element test; a slight change in the sample properties affects the test results). Two series of tests were performed in this study. In the first series of tests (Test Series # 1), three samples of DL clay were prepared. The water content was varied from dry to wet side of optimum moisture content. Moreover, two more samples were prepared for the second series of tests (Test Series # 2) with a higher degree of compaction to check the behavior of unsaturated silty soil at higher overburden pressure. The sample properties are shown in Table 2.

In this study, the tests were carried out in four phases, i.e., PI, PII, PIII, PIV, under constant water condition which replicates the situation in which excess pore air pressure dissipates rapidly, while pore water pressure dissipates with time [10] at confining stress of 100 kPa (see Fig. 2). High confinement was considered because, at this confinement, the top cap fully rests on the sample without any gap so that the clear behavior of sample can be studied. In phase I (PI), the initial suction was measured by placing the sample on the pedestal. It was observed that suction value increased and then stabilized at a specific value and time for different water contents (see Fig. 3). It was also observed that the sample at higher water content has taken less time to reach the stabilized value of suction. In phase II (PII), as shown in Fig. 2, the axis translation technique (ATT) was applied to keep the pore water pressure positive so that no voids were developed inside the pedestal, which affects the reading of pore water pressure. The important thing that should be monitored during axis translation is that the pore air and cell pressures should be increased simultaneously, and it must be equivalent to the decreasing amount of pore water pressure. Otherwise, the effective stresses will increase and may affect the stresses inside the sample. In phase III (PIII), isotropic consolidation was carried out until the observed volume change from low-capacity differential pressure transducer (LCDPT) becomes constant. The consolidation process will occur after the application of the confining pressure if the pore fluids are allowed to drain. On the other hand, the consolidation process will not occur if the pore fluids are not allowed to drain (maintained in undrained condition) [10]. In phase IV (PIV), the sample was sheared up to 15% of axial strain, at the strain rate of 0.05%/min as per JGS standard [11]. All the phases are presented in Fig. 2.

Figure 4 showed the behavior of deviatoric stress (q), mean effective stress (p′) and suction (s). This figure shows the result of Test 1 of the first series (Test Series # 1) having a dry density of 1.26 g/cm3, the water content of 15%, and the suction against 15% water content is 25 kPa, while maximum deviatoric stress achieved is 272 kPa and mean effective stress is 202 kPa.

Mean effective stress is given by,

Effective axial stress is given by,

Effective radial stress is given by,

where p′ is mean effective stress, σa′ is effective axial stress, σr′ is effective radial stress, p is mean stress, ua is pore air pressure, s is suction, Sr is degree of saturation, σanet is net axial stress, σa is axial stress, σrnet is net radial stress, σr is radial stress, and q is deviatoric stress.

In PI and PII phases (see Fig. 4), during the initial suction measurement and axis translation, no axial and radial stresses were applied, while mean effective stresses are due to degree of saturation and suction. However, during isotropic consolidation, an equal amount of desired confining stress and axial stress is applied, which resulted in zero deviatoric stress (q), while mean effective stress is increased. During the shear, confinement is kept constant while axial stresses are increased as a result of which deviatoric stress and mean effective stress are increased as shown in Fig. 4 (PIV). For clear understanding/behavior of important parameters like deviatoric stress (q), mean effective stress (p′) and suction (s) are also plotted in three dimensions as shown in Fig. 5.

4 Results

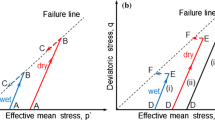

During the Test Series # 1 (degree of compaction, 81%) and Test Series # 2 (degree of compaction, 88%) on unsaturated silty soil (DL clay), the strength and deformation characteristics are emphasized. The shearing phase of the test is used to describe the mechanical properties of the material. In Test Series # 1, during the shearing, it is observed that deviatoric stress is more toward the dry side of optimum moisture content (OMC, 20%), while it is less on the wet side of OMC (see Fig. 6). This is because on dry side of optimum moisture content, the matric suction is more while matric suction is less on the wet side as shown in Fig. 7. Similar trend is observed in Test Series # 2, i.e., higher deviatoric stress is observed at lower water content. Moreover, the deviatoric stress is more in Test Series # 2 than in Test Series # 1 due to higher degree of compaction.

The test results indicated that the sample at the degree of compaction of 81% (Test Series # 1) showed compressive behavior during shearing phase, while at the degree of compaction of 88% (Test Series # 2), it showed dilative behavior during shearing phase as shown in Fig. 8. The experimental result (Test Series # 1) further showed that with the increase of water content, the sample showed more compression and void ratio is decreased accordingly, while the degree of saturation is increased due to reduction in the void ratio as shown in Figs. 8 and 9, whereas on dilation side (Test Series # 2), with the increase in water content, the sample showed less dilation and degree of saturation is decreased slightly due to dilative behavior as shown in Figs. 8 and 9.

The change in void ratio (e), suction (s), and deviatoric stress (q) in all the phases, i.e., PI to PIV, under Test Series # 1 and Test Series # 2 with the initial water content of 15% is plotted in three dimensions (3D) as shown in Fig. 10. The 3D representation indicates the compressive and dilative behavior of the sample (during shearing) prepared at the degree of compaction of 81% (Test Series #1) and 88% (Test Series # 2). The void ratio (e) at the end of consolidation phase (PIII) is quite close in both the test series, but it is completely opposite at the end of shearing phase (PIV) as shown in Fig. 10. The change in volumetric strain and void ratio through all the testing phases for Test Series # 1 is presented in Figs. 11 and 12. During the shearing phase (PIV), the volumetric strain increases, and void ratio decreases from the initial value. The change in volumetric strain and void ratio through all the testing phases for Test Series # 2 is presented in Figs. 13 and 14. During the shearing phase (PIV), the volumetric strain decreases, and void ratio increases from the initial value. It is also observed that after the consolidation phase (PIII), the void ratio in test series # 1 (1.019) is close to test series # 2 (0.985) but during shearing phase, the sample showed compressive behavior in test series # 1 and dilative behavior in test series # 2 as shown in Figs. 12 and 14. This indicates the influence of the initial state (particles arrangement) of the soil.

5 Conclusion

From this research, it is observed that during the axis translation phase if the increase in the pore air pressure and cell pressure is not synchronized, then the suction and effective stresses will increase, and it will affect the later phases (consolidation, shear) of the test.

It is concluded that with the increase of degree of compaction, strength increases, and volume change behavior clearly changed from compressive to dilative. On the compression side, with the increase of water content, the sample showed more compression, and the degree of saturation is increased with the decrease in void ratio. On dilation side, with increase in water content, the sample showed dilation, and the degree of saturation is slightly decreased with the increase in void ratio. The samples which are prepared at same initial water content (15%) for both the test series showed quite a close void ratio after the end of consolidation phase (PIII), but during shearing phase, the sample showed compressive behavior in test series # 1 and dilative behavior in test series # 2. This indicates the influence of the initial state (particles arrangement) of the soil.

The results also indicated that with the increase in suction of the sample, the strength increases and vice versa. It would be the primary reason that the increase in water content in the slopes of unsaturated soil results in the non-stability of the slopes.

References

Huzhu, Z., Hanbing, L., Jing, W., Weizhi, D.: Investigation of the effect of water and degree of compaction on the shear strength of clay soil material. Funct. Mater. 24(2), 290–297 (2017)

Cokca, E., Erol, O., Armangil, F.: Effects of compaction moisture content on the shear strength of an unsaturated clay. Geotech. Geol. Eng. 22, 285–297 (2004)

Shen, C.N., Fang, X., Wang, H.W., Sun, S.G., Guo, J.F.: Effect of suction, moisture content and dry density on shear strength of remolded unsaturated soils. Rock Soil Mech. 30(5), 1347–1351 (2009)

Thu, M.T., Rahardjo, H., Leong, E.C.: Critical state behavior of a compacted silt specimen. Soils Found. 47(4), 749–755 (2007)

Terzaghi, K., Peck, R.B.: Soil Mechanics in Engineering Practice, 2nd edn. Wiley, New York (1967)

Bishop, A.W., Henkel, D.J.: The Measurement of Soil Properties in the Triaxial Test, 2nd edn. Edward Arnold Publishers Ltd., Michigan (1964)

Melinda, F., Rahardjo, H., Han, K.K., Leong, E.C.: Shear strength of compacted soil under infiltration condition. J. Geotech. Geo-Environ. Eng. 130(8), 807–817 (2004)

Rasool, AM., Kuwano, J., Tachibana, S.: Behavior of compacted unsaturated soil in isotropic compression, cyclic and monotonic shear loading sequences in undrained condition. In: 6th International Symposium on Deformation Characteristics of Geomaterials, pp. 267–274. IOS Press, Buenos Aires (2015)

Mendes, J., Toll, D.G., Evans, F.: A double cell triaxial system for unsaturated soils testing. In: Mancuso, C., Jommi, C., D’Onza, F. (eds.) Unsaturated Soils: Research and Applications, pp. 5–10. Springer, Heidelberg (2012)

Fredlund, D.G., Rahardjo, H.: Soil Mechanics for Unsaturated Soils. Wiley, New York (1993)

Japan Geotechnical Society Standards (vol. 2), 5.5 c& e, 527-2009

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ahmed, I., Kuwano, J., Malik, A.A., Shrestha, D.R. (2021). Behavior of Unsaturated Silty Soil Due to Change in Water Content and Suction. In: Hazarika, H., Madabhushi, G.S.P., Yasuhara, K., Bergado, D.T. (eds) Advances in Sustainable Construction and Resource Management. Lecture Notes in Civil Engineering, vol 144. Springer, Singapore. https://doi.org/10.1007/978-981-16-0077-7_35

Download citation

DOI: https://doi.org/10.1007/978-981-16-0077-7_35

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0076-0

Online ISBN: 978-981-16-0077-7

eBook Packages: EngineeringEngineering (R0)