Abstract

An experimental series is performed to study the response of unsaturated silt compacted on the dry and wet side of optimum water content due to change in drainage conditions during the triaxial test process. Soil samples were compacted at water content of 15% and 25% maintaining degree of compaction at 85%. The drainage conditions for pore air and pore water pressure was changed for isotropic consolidation, monotonic shear and water infiltration processes. The isotropic consolidation was performed by keeping pore air pressure drained and pore water pressure undrained. During monotonic shear both pore air and water pressures were undrained, whereas, the water infiltration was carried in fully drained conditions. The water infiltration was carried by keeping deviatoric stress and axial strain constant on the specimen. It was observed that the drainage conditions affect the deformation behavior of soil and results in a rapid decrease in specimen volume. Moreover, the stress paths for the specimens with constant deviatoric stress moved towards the failure line whereas the stress paths for the specimens with constant axial strain moved along the reference failure line.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Most soil slopes and embankments are constructed with compacted unsaturated soils. The pore water pressure in an unsaturated soil is generally negative with respect to the atmospheric pressure whereas the pore air pressure can either be atmospheric or have a positive magnitude above atmospheric conditions (Yoshikawa et al. 2015; Zhang et al. 2014). The construction of embankments results in variations in the pore pressures within the compacted soil. As the embankment is constructed, the lower layers are compacted by the placement of overlying layers of soil/silty clay. Pore pressure changes during construction are commonly assumed to take place under undrained conditions over a rapid construction period. In practice, most of the experimental investigations performed on unsaturated soil are carried out under constant air pressure. Oka et al. (2010) and Toyota and Takada (2012) discussed the importance of air pressure on the mechanical behavior of unsaturated silty clay by conducting triaxial tests in fully undrained conditions. In reality, it is difficult to achieve drained conditions for water and air, for example, during rainfall the air trapped in some parts of embankment during seepage process increases air pressure. Similarly, when a methane hydrate is dissociated under the seabed, the ground becomes unsaturated with high gas pressure (Shimizu et al. 2006). Therefore, unsaturated soil behavior is important to investigate in drained and undrained conditions for pore air pressure and pore water pressure during triaxial compression tests. Reduced soil matric suction due to precipitation infiltration causes decrease within the effective stress acting on the failure plane (Brand 1981). Reduction in effective stress decreases soil shear strength as a result slope failure may occur. The actual field conditions and field stress path can be replicated and failure mechanism of slope can be studied in laboratory by testing unsaturated soil sample and infiltrating water into the specimen sheared in constant stress conditions (Farooq et al. 2004). The influence of water infiltration on shear stress transformation was studied by Gui and Wu (2014). They observed that unnecessary volume deformations and subsequent softening of soil samples were due to change in shear stress state. The water infiltration was found to be the main reason of change in shear stress state. Irfan and Uchimura (2015) performed experimental study under constant stress conditions and infiltrated water in unsaturated soil specimens to replicate the field stress path. They propose that infiltrated water can be equally distributed in the soil specimen by wrapping it with filter paper of helix shape. The infiltrated water was found uniformly distributed by using this technique. It was also found that slope failure mechanism can be replicated in laboratory by using this method. Karami et al. (2015) studied the wetting of compacted unsaturated soil under anisotropic stress state and concluded that wetting depends mainly on the initial suction and the stress state in which wetting occur. A state-of-the-art collapse casing mechanism of collapsible soils upon wetting was provided by Li et al. (2016). It was suggested that behavior of collapsible soils can be studied with the parameter obtained from the conventional tests based on soil mechanics approaches. In a study conducted by Lin et al. (2018), the results of unconfined compression test were combined with the pressure plate tests to obtain the unconfined compression strength and matric suction of the samples. Soil samples were first compacted at designated water content and then subjected to the wetting process for saturation and subsequent dry process to its target suction. The correlation among the matric suction, the unconfined compression strength and the total cohesion was studied. The calculated results compare reasonably with the unsaturated triaxial test results.

In the current study, silty soil prepared with two percentages of water contents was tested under different drainage conditions during the triaxial test process. The consolidation was performed in constant water content conditions in which controlled pressure was pore air; whereas, pore water pressure was undrained and measured accurately. The shearing was performed in fully undrained condition. In undrained conditions pore air and pore water pressures were not permitted to flow out from the soil and were accurately measured. After shearing, water was infiltrated in fully drained conditions from the bottom of the specimen. First two tests were performed by keeping axial strain constant then further tests were carried out by keeping deviatoric stress constant. Figure 1 shows the schematic representation of tentative movement of stress paths when the water was infiltrated during the test process. In Fig. 1a, AB shows the stress paths when the soil specimens were sheared to maximum deviatoric stress in undrained conditions. BC shows the movement of stress paths along the failure line when the water was infiltrated by keeping axial stress constant in fully drained conditions. In Fig. 1b, DE shows the stress path when the soil specimens was sheared in undrained conditions. Stress path (i), (ii) and (iii) shows the level of deviatoric stress up to which shearing was carried out. EF shows the movement of stress path towards the failure line when the water was infiltrated by keeping the deviatoric stress constant in fully drained conditions.

2 Test Setup and Methodology

2.1 Test Setup

Triaxial tests on unsaturated soils cannot be performed on conventional triaxial apparatus used for fully saturated soils (Fredlund and Rahardjo 1993). The occurrence of air in unsaturated soils made testing procedure and the technique more complex. The most important and difficult part of the testing of unsaturated soil is independently measuring pore air and water pressure. Considering the requirements of unsaturated soil testing, this study has been performed on a modern triaxial test device. The graphical illustration of triaxial test apparatus is shown in Fig. 2. The lucid acrylic cell has been used to observe the specimen behavior from cell outside. The vertical load on the soil specimen was applied with a servo motor having loading speed of 1500 cycles/h. The load was measured by the inner load cell which is installed between the loading rod and top cap. Cell pressure was supplied by regulating air pressure. It was measured by cell pressure transducer with a maximum capacity of 1 MPa and controlled by an external pressure gauge. The axial displacement was measured by local vertical deformation transducer (LVDT) arranged outside the triaxial cell chamber. The total volume change of the soil specimen was measured with Low Capacity Differential Pressure Transducer (LCDPT). The procedure of measuring specimen volume change with LCDPT has been described in Japanese Geotechnical Society standard JGS0527-2009. Pressure on the inner side and the outer side of the inner cell are the same as it is open end, therefore, volumetric correction is not needed. Before starting the test, water level in inner cell is kept higher than the water level in outer cell. The water level in outer cell is kept fixed and taken as reference. When the specimen contracts the level of water in inner cell moves upwards and when soil specimen dilates the water level moves downwards. The change in water level is recorded by a computer software which is then calculated as total volume change of specimen as per relations given in Japanese Geotechnical Society standard JGS0527-2009.

Triaxial cell used in current study is illustrated in Fig. 3. The top cap of 6 cm diameter has a solenoid valve to control drained/undrained air and a pore air pressure transducer. A polytetrafluoroethylene, known as Teflon (PTFE) sheet and a membrane filter has been used to isolate the paths for measurement and control of both pore pressures (i.e. air and water). The PTFE sheet allows the flow of air and resists the follow of water and pasted at the bottom of the top cap. Membrane type “Supor 450” from Pall Corporation is used in study. The membrane filter has pore size of 0.45 µm, thickness of 140 µm and provided air entry value of 250 kPa (Habasimbi and Nishimura 2019; Nishimura 2014). The membrane filter allows the flow of water and resists the flow of air and placed on the bottom pedestal. The pore water pressure was measured by pore water pressure transducer having a maximum capacity of 1 MPa.

Various tests performed on unsaturated soils are, fully drained, undrained and constant water content tests (Leong et al. 2013). In fully drained tests, the drainage valves are kept open for both air and water so that no excess pore pressure is developed. Tests in fully undrained conditions are performed such that air or water is not allowed to flow out of the specimen i.e. drainage valve for both pressures is kept closed. Excess pore air and water pressure developed due to loading in undrained conditions, as a result, the specimen volume might not remain constant and changed due to air compression. It is important to measure the pore air pressure inside the specimen during the test process. The pore air pressure passing through the PTFE sheet was measured from the specimen top by a pore air pressure transducer installed in top cap of the triaxial chamber. The pore air pressure was controlled with air regulator which was also used to ensure the continuous supply of air throughout the test. A solenoid valve, to open and close supply for drained and undrained air, is also fitted in the top cap with air drainage line.

2.2 Soil Physical Properties

The material used comprises of DL Clay(commercial name). Which is a fine grained material without plasticity. The appearance of freshly and freely deposited DL clay looks yellowish brown. Powdered DL clay is composed of Kaolinite (40%), silica (30%) and pyrophyllite (30%) which are also used as agricultural chemicals. The DL clay is artificially made by Showa KDE Co., Ltd. It is classified as non-plastic silt (ML in Japanese unified soil classification system 2003) with 0.1% sand, 90.4% silt and 9.5% clay contents. The physical properties and grain size accumulation curve of DL Clay are summarized in Table 1 and Fig. 4 respectively.

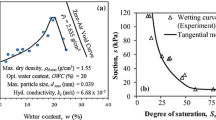

The optimum water content of soil is 20% and the maximum dry density of soil is 1.55 g/cm3 obtained from the standard proctor compaction test. The compaction curve of DL clay is shown in Fig. 5.

2.3 Specimen Preparation

The soil was compacted at two different water contents to prepare specimens by using static compacted method. The compacted specimens were prepared using a compaction steel mold meant especially for static compaction because the material behaves poorly under standard compaction method. Before compaction, the dried DL clay was mixed with water to prepare specimens with water content (w) of 15% and 25%. Specimens with 15% w i.e. on dry side of the optimum water content, were termed as Dry “D” specimens, and 25% w i.e. on wet side of the optimum water content were termed as Wet “W” specimens. The wet DL clay was compressed statically in a special cylinder-shaped mold having a 5 cm diameter. In order to obtain the best possible standard homogeneity, the samples were prepared in five layers of 2 cm height using static compaction technique (Rasool and Kuwano 2018). All specimens prepared were 5 cm in diameter and 10 cm in height. Table 2 shows the properties of specimens used in this study.

2.4 Test Procedure

After compaction and measuring initial suction, the cell and pore air pressure was increased with the axis translation technique (ATT). The pore water pressure was undrained and pore air pressure was drained throughout this process. At start of the isotropic consolidation process, the cell pressure was increased to achieve the net confining stress of 100 kPa in fully undrained conditions which took approximately 10 min. After reaching the desired net confining stress the consolidation was carried out under constant water content conditions for about 20 h. The shearing process was carried out in fully undrained conditions. After shearing, the water absorption procedure, which can also be called as “infiltration process” was executed in fully drained conditions by opening the valve of pore water and air. The specimens tested in the current study are classified as D, D100, D200, D275, and W, W100, W200. The specimens “D” and “W” were first sheared to the maximum axial strain of 15% after which specimens were allowed to drain/absorb water by keeping axial strain constant. The specimens D100, D200, D275, W100, and W200 were first sheared to the deviatoric stress of 100, 200 and 275 kPa after which specimens were allowed to drain/absorb water by keeping deviatoric stress constant.

3 Experimental Results

3.1 Measurement of Initial Suction

Previous researches also showed that the soil behavior in unsaturated conditions is influenced by initial suction. However, distribution of pore water in soil and the degree of saturation are factors influencing the initial suction (Karube and Kawai 2001; Yang et al. 2012). Figure 6 shows the initial soil suction values plotted against degree of saturation. Because of similar degree of saturation, initial suction of all the dry and wet samples were almost same. Specimens with a lower degree of saturation showed higher initial suction due to the presence of less water content inside specimen and vice versa. The measured initial suction become stable in 20 min after placement of samples on a pedestal. The curves of dry samples converged to an initial suction of about − 28 to − 30 kPa and for wet samples about − 13 to − 15 kPa. The membrane filter placed on the bottom pedestal helped in stabilizing of initial suction rapidly.

3.2 Consolidation Process

After the measurement of initial suction and application of the axis translation technique when pore water pressure became 0 kPa, the samples were moved to isotropic consolidation. The cell pressure was increased to net confining stress of 100 kPa in fully undrained conditions. On reaching 100 kPa, an isotropic consolidation was carried out in constant water content conditions, in which water was not drained whereas air was drained. The time-dependent changes in the cell, pore air and pore water pressure are shown in Fig. 7a, b. As pore air and pore water pressure was undrained during the increase of cell pressure, therefore, we can see slight increase in both pore air and pore water pressure. Since pore air pressure was set to drained condition 2 min after reaching net confining stress of 100 kPa, therefore the pore air pressure came back to its original value along with pore water pressure while keeping suction constant. In the consolidation stage, the pore air pressure was controlled during drained conditions to keep its value constant, whereas pore water pressure was uncontrolled during undrained conditions. The pore water pressure in wet specimens remained approximately 0 kPa throughout the consolidation process as shown in Fig. 7b, whereas, in the case of dry specimens increase in pore water pressure was observed towards the end of the consolidation process as shown in Fig. 7a. In most of the cases, the value of pore water pressure increased to a value close to the value of pore air pressure. The possible reason can be attributed to a gap formed between the specimen and the pedestal with the lapse of time and gradually became influenced by the pore air pressure.

The relationship between axial, lateral, volumetric strains and net confining stress is shown in Fig. 8a, b. The positive value of strains in graphs indicates shrinkage which showed a decrease in volume of specimens with an increase in net confining stress. The process of increasing cell pressure was carried in fully undrained conditions. The equation of state of gas explains that volume decreases as the pressure of gas increases (Carman 1956; Fredlund and Rahardjo 1993). The increase in pore air pressure during the process of increasing cell pressure can also be seen in Fig. 7a, b therefore, the volume change in the specimen is due to compression of air. Furthermore, since during isotropic consolidation it was expected that axial strain should be equal to lateral strain resulting in an isotropic change in volume but the graphs shows that axial strain was not equal to lateral strain and specimens show anisotropic behavior. The anisotropic behavior of specimens was due to static compaction technique used during sample preparation in which the specimens were compacted axially. The greater axial stress during preparation stage can be considered as one of the key factor for anisotropic behavior of specimens during consolidation. The effect of greater past pressure caused the specimens to deform more latterly. Overall it was observed that volume changes were more in wet specimens than in dry specimens, this is because of compaction stress applied to wet specimens was approximately half that on dry specimens during sample preparation.

3.3 Shear Behaviour

The deviatoric stress and axial strain relationship during shear for dry and wet specimens is shown in Fig. 9. The specimens were sheared at a rate of 0.05 mm/min in fully undrained conditions. The fully undrained conditions simulated the rapid construction period and then water was allowed to infiltrate (i.e. drained conditions) to study the instability problems after the construction. Specimens D and W were sheared to 15% axial strain according to the Japanese Geotechnical Society standard JGS0527-2009. Increase in soil suction due to decrease in water content affects the shear behavior of unsaturated soils, but there is a limit beyond which, further increase in suction will not result in any significant change in the behavior (Estabragh and Javadi 2012). The maximum value of deviatoric stress achieved for specimen D was about 275 kPa, after getting this value other dry specimens D100, D200 and D275 were sheared to deviatoric stress value of 100, 200 and 275 kPa. We can see that up to 2% axial strain deviatoric stress is increasing linearly. Specimen D275 showed some decrease in deviatoric stress after getting peak value, this was due to the limitation of controlling the software and loading machine. It was not possible to perform water infiltration by keeping deviatoric stress constant at 275 kPa, therefore the value was reduced to 250 kPa and the water infiltration process was performed. Similarly, maximum deviatoric stress value for W specimen at 15% axial strain was 200 kPa and specimen W100 and W200 were sheared to deviatoric stress value of 100 and 200 kPa. Increase in pore water pressure during shearing process is shown in Fig. 10. The wet specimens showed more increase in pore water pressure as compared to dry specimens. The figure also shows that the increase in pore water pressure is also affected by the level of deviatoric stress.

The relation between volumetric strain versus axial strain during shear process is presented in Fig. 11a, b. Since the unsaturated soil contains air, it shows some volume change when sheared even in fully undrained condition due to the volume change of the pore air. The dilative behavior is shown by the specimens because of high degree of compaction during the shear process which can be seen in Fig. 11a. At the end of shearing the specimens bulged in the radial direction due to increase in volume. The effect of high degree of compaction was not pronounced on wet specimens. The volume change of wet specimens is shown in Fig. 11b, specimen W showed dilation at initial shear, it then contracted and dilated again at the end of shearing. W100 was slightly inflated whereas W200 first expanded and then showed subsequent contraction. As the same test procedure was applied, shear was stopped in the middle of test for specimens D100, D200, D275, W100 and W200 as those specimens displayed similar behavior as D and W if shear was continued.

3.4 Water Infiltration Process

The water infiltration is related to the phenomena when the excess pore air (and water) pressure induced in the construction process go back to the atmospheric pressure with time. Increase in the pore water pressure may take place when river water level rises. The water infiltration process in this series is performed after the end of shearing. The axial strain was kept constant for specimen D and W, and deviatoric stress was kept constant for other specimens. The matric suction was decreased in order to start water infiltration process. To decrease suction, first, the pore air pressure was decreased to atmospheric pressure, if still water infiltration process could not start, the pore water pressure was increased in steps to start water infiltration. The time-dependent changes in pore air/water pressure and the amount of infiltrated water is shown in Fig. 12a, b. In the case of dry specimens, pore air pressure was first decreased in steps of 5 kPa at 1 h interval till it became equal to atmospheric pressure. When the water infiltration did not start after 1 h, the pore water pressure was increased in steps of 5 kPa at 1 h interval till water infiltration started and specimen reached a degree of saturation of 86%. From Fig. 12a we can see that dry specimens started absorbing water at higher pore water pressure. In the case of wet specimens, the water infiltration process started as soon as the pore air pressure was decreased. For wet specimens, as compared to dry specimens, higher pore air/water pressure was developed during shear, therefore it took more time to decrease pore air pressure and the complete infiltration process. The water infiltration process of wet specimens was also continued until they reached the degree of saturation at 86%. Another possible reason of delayed water infiltration in dry specimens is that the water infiltration initiated quickly in the specimen with a higher degree of saturation as compared to those with a lower degree of saturation (Farooq et al. 2004). As wet specimens have a higher degree of saturation as compared to dry specimens, therefore, water infiltration process started quickly. During water infiltration process the pores in the soil may be occluded. Occluded air bubbles commonly occur in unsaturated soils having a degree of saturation greater than 90% (Fredlund and Rahardjo 1993). However, in this study, the maximum degree of saturation achieved was 86%, thus, the occluded stage might not occur.

Figures 13 and 14 shows a change in volume of the dry–wet specimens during water infiltration process with time in form of volumetric strain. In the case of dry specimens, the trend Ⓐ shows the decrease in volume is only due to net confining stress before water infiltration. The trend Ⓑ shows a small decrease in volume of specimens due to water infiltration except for D275. For D275 there was a small decrease in volume up to 60% degree of saturation after that volume decreased suddenly due to the collapse, as seen in the trend Ⓒ. The collapse occurred due to water infiltration by increasing pore water pressure at higher constant deviatoric stress. The collapse behavior was also observed in specimen D but due to constant axial strain volume change did not occur rapidly. The wet specimen showed a decrease in volume with a decrease in net stress and an increase in the degree of saturation. The volume decrease for W and W200 was greater as compared to W100 due to the collapse. The collapse of W occurred at the start of infiltration process at 78% degree of saturation and for W200 it occurred at 83% degree of saturation after which sudden decrease in volume can be observed. From the above observations, it can be concluded that collapse occurrence depends on the state of loading on the specimen. In case of monotonic loading it occurred near maximum deviatoric stress for dry specimens. Whereas, by keeping axial strain or deviatoric stress constant during water infiltration it occurred for wet specimens.

The change in stress path due to water infiltration is shown in Fig. 15, whereas full stress path due to both shear and water infiltration is shown in Fig. 16. Figure 15a shows that deviatoric stress of dry specimens was kept constant except for D. There was no change in deviatoric stress of D100 and D200, however, some decrease in the deviatoric stress of D250 was observed due to collapse behavior. The decrease in the deviatoric stress of D was due to constant axial strain. By looking at the mean effective stress on the horizontal axis, it first moved towards the right side then to the left. At the start of water infiltration process, the pore air pressure was first decreased resulting in a decrease in suction stress. Since mean effective stress is the sum of the mean net and suction stress, therefore, decrease in pore air pressure result in an increase of mean effective stress and stress path moved to right side. After decreasing pore air to atmospheric pressure, pore water pressure was increased resulting in a negative value of suction stress keeping mean net stress same; hence, stress path again moved to left side. Although with start of water infiltration, degree of saturation and suction stress increased but negative suction caused decreases in mean effective stress. It was observed that stress paths moved towards the failure line due to water infiltration without application of further deviatoric stress. In Fig. 15b we can see a decrease in the deviatoric stress of W100 and W200 due to collapse behavior, whereas, a decrease in the deviatoric stress of W was due to constant axial strain. Thus, we can say that the collapse behavior was related to deviatoric stress, it has no effect on the mean effective stress of soil. It was also observed that the mean effective stress of wet specimens did not change much during water infiltration process because the water infiltration started with a decrease in pore air pressure. The water infiltration results in an increase in the degree of saturation hence in suction stress. The decrease in mean net stress and an increase in suction stress cancel the effect of each other, therefore mean effective stress remained unchanged. A reference failure line is drawn in Fig. 16 connecting stress path of D and W specimens. It can be seen from the graph that the stress path for the specimens with constant deviatoric stress moved to the left whereas stress path for the specimens with constant axial strain moved along the reference failure line as it was assumed in the beginning showing that water infiltration affects the stress paths of unsaturated soil.

4 Conclusions

A series of triaxial tests have been conducted to study the influence of drainage conditions and water infiltration on the mechanical behavior of soil in unsaturated conditions. Followings are the main conclusions obtained from study:

The soil initial suction is affected by water content. It increases with decrease in the degree of saturation.

The results of constant water content conditions during isotropic consolidation showed lesser decrease in volume of the specimen after a long time because of drained pore air pressure. Higher compaction effort during specimen preparation also results in lesser decrease in volume during the isotropic consolidation process.

Shearing under fully undrained conditions showed that the deviatoric stress of dry soil was higher than the wet soil. Moreover, the soil specimens exhibited dilative behavior due to higher degree of compaction.

During water infiltration under fully drained conditions, change in pore water pressure caused the collapse deformation. The wet soil showed more collapse deformation as compared to dry soil. In addition, water infiltration caused movement of stress paths towards failure line without further increase in deviatoric stress.

Finally, the dry soil showed better performance as compared to wet soil under same conditions used in this testing program. It showed high initial suction, less volume deformation during consolidation, dilative behavior and high shear strength during shearing. It also required more decrease in suction to start water infiltration and showed lesser collapse deformation. This suggested that soil should be compacted on the dry side of optimum moisture content to get better performance during the service life of a soil slope or embankment.

References

Brand EW (1981) Some thoughts on rain-induced slope failures. In: Proceedings of 10th international conference on soil mechanics and foundation engineering, pp 373–376

Carman P (1956) Flow of gases through porous media. Academic Press, New York

Estabragh AR, Javadi AA (2012) Effect of suction on volume change and shear behaviour of an overconsolidated unsaturated silty soil. Geomech Eng 4(1):55–65. https://doi.org/10.12989/gae.2012.4.1.055

Farooq K, Rolando O, Ikuo T (2004) Response of unsaturated sandy soils under constant shear stress drained condition. Soils Found 44(2):1–13. https://doi.org/10.3208/sandf.44.2_1

Fourth Committee for Soil Classification and Nomenclature. Japanese Society of Pedology (2003) Unified soil classification system of Japan (2nd approximation). Hakuyuusha, Tokyo (in Japanese)

Fredlund DG, Rahardjo H (1993) Soil mechanics for unsaturated soils. https://doi.org/10.1016/0267-7261(93)90011-F

Gui MW, Wu YM (2014) Failure of soil under water infiltration condition. Eng Geol 181:124–141. https://doi.org/10.1016/j.enggeo.2014.07.005

Habasimbi P, Nishimura T (2019) Soil water characteristic curve of an unsaturated soil under low matric suction ranges and different stress conditions. Int J Geosci 10:39–56. https://doi.org/10.4236/ijg.2019.101004

Irfan M, Uchimura T (2015) Helical filter paper technique for uniform distribution of injected moisture in unsaturated triaxial specimens. Soils Found 55(4):749–760. https://doi.org/10.1016/j.sandf.2015.06.008

JGS 0527-2009. Method for triaxial compression test on unsaturated soils (standards of Japanese geotechnical society)

Karami Q, Maleki M, Makarchian M, Karijani MS (2015) Factors affecting mechanical behavior of unsaturated silty sand on wetting path. J GeoEng 10(2):45–51. https://doi.org/10.6310/jog.2015.10(2).2

Karube D, Kawai K (2001) The role of pore water in the mechanical behavior of unsaturated soils. Geotech Geol Eng 19(3–4):211–241. https://doi.org/10.1023/A:1013188200053

Leong EC, Nyunt TT, Rahardjo H (2013) Triaxial testing of unsaturated soils. In: Multiphysical testing of soils and shales, pp 33–44. https://doi.org/10.1007/978-3-642-32492-5_3

Li P, Vanapalli S, Li T (2016) Review of collapse triggering mechanism of collapsible soils due to wetting. J Rock Mech Geotech Eng 8(2):256–274. https://doi.org/10.1016/j.jrmge.2015.12.002

Lin HA, Wang CC, Wang XH (2018) A simplified method to estimate the total cohesion of unsaturated soil using an UC test. Geomech Eng 16(6):599–608. https://doi.org/10.12989/gae.2018.16.6.599

Nishimura T (2014) Influence of seepage event on cyclic triaxial behavior of a compacted unsaturated soil. In: Proceedings 6th international conference on unsaturated soils, sydney, pp 791–796

Oka F, Kodaka T, Suzuki H, Kim YS, Nishimatsu N, Kimoto S (2010) Experimental study on the behavior of unsaturated compacted silt under triaxial compression. Soils Found 50(1):27–44. https://doi.org/10.3208/sandf.50.27

Rasool AM, Kuwano J (2018) Influence of matric suction on instability of unsaturated silty soil in unconfined conditions. Int J GEOMATE 14(42):1–7. https://doi.org/10.21660/2018.42.7115

Shimizu M, Sakamoto S, Nishioka T (2006) Effects of drainage conditions on the shear strength of unsaturated soil. In: 4th international conference on unsaturated soils, pp 1223–1234. https://doi.org/10.1061/40802(189)100

Toyota H, Takada S (2012) Technique for undrained triaxial tests on unsaturated soils using active control of pore-air pressure. Geotech Test J 35(3):480–489. https://doi.org/10.1520/GTJ104065

Yang S-R, Lin H-D, Huang W-H (2012) Variation of initial soil suction with compaction conditions for clayey soils. J Mech 28(3):431–437. https://doi.org/10.1017/jmech.2012.52

Yoshikawa T, Noda T, Kodaka T (2015) Effects of air coupling on triaxial shearing behavior of unsaturated silty specimens under constant confining pressure and various drained and exhausted conditions. Soils Found 55(6):1372–1387. https://doi.org/10.1016/j.sandf.2015.10.004

Zhang LL, Fredlund DG, Fredlund MD, Wilson GW (2014) Modeling the unsaturated soil zone in slope stability analysis. Can Geotech J 51(12):1384–1398. https://doi.org/10.1139/cgj-2013-0394

Acknowledgements

The Japanese Ministry of Education, Culture, Sports, Science and Technology (MEXT) and Department of Civil and Environmental Engineering, Saitama University, Japan are gratefully acknowledged for providing research facilities and financial assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rasool, A.M., Kuwano, J. & Tachibana, S. Experimental Study on the Response of Unsaturated Silt Due to Change in Drainage Conditions During the Triaxial Test Process. Geotech Geol Eng 38, 1707–1719 (2020). https://doi.org/10.1007/s10706-019-01125-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-01125-3