Abstract

Textile industries are one of the largest generator of wastewater as large amount of water is used in coloring and finishing processes. The effluents released from textile industries contain biodegradable and non-biodegradable chemicals such as dyes, dispersants, leveling agents etc. These effluents are released into water bodies which can modify the physical, chemical and biological nature of the receiving water bodies. Azo dyes are largely utilized in textile industry as coloring agent. During the processing of textile, a lot of dyestuff specifically lost to the wastewater due to inefficiency in dyeing processes which may causes serious health and environmental problems. Therefore, removal of dyes from textile wastewater is necessary prior to their disposal. Several physico-chemical techniques have been utilized for the treatment of wastewater containing dyes, but execution of these strategies have the distinctive limitations of being expensive, unable to the complete removal of dyes from wastewater, and producing noteworthy amounts of sludge that may cause auxiliary pollution issues. The application of microorganisms (bacteria, fungi and algae) and plants for the removal of azo dyes from textile wastewater is an attractive option over the physico-chemical methods. Biological methods are environment friendly, produce less sludge, and inexpensive. Water recycling is the reuse of treated wastewater for valuable purposes such as agricultural irrigation and industrial processes etc. Recycling of textile wastewater is important for restricting the amount of wastewater and expenses of production, and recommended for the protection of environment.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

Water is, without a doubt, the most precious natural resource that exists on our planet. It is a basic need for sustenance of all forms of life and life on earth would be non-existent without water. In spite of the fact that we as humans know about this reality, day to day the water pollution issues are far worse around the world, because of human activity and rapid industrialization (Gupta et al. 2015). Industrial wastewaters are the significant contributor to water pollution by polluting rivers, lakes and oceans. These wastewaters are released by different industries such as textile, dyestuffs, paper and pulp, distillery, tannery, oil mill and metal industries. Textile industries are one of the largest generator of wastewater due to extensive volume of water is utilized in dyeing and finishing processes (Saratale et al. 2011). The pollution issues because of textile industries wastewater have expanded as a result of the way that over the most recent couple of decades, there has been rapid advancement in the dye and dyeing industries due to increased demand for textile products. The discharge of wastewater from textile industries has introduced various toxic organic compounds into different components of the environment, making it the major sources of serious pollution issues around the world. Wastewater discharged from textile industries contains biodegradable and non-biodegradable chemicals such as wide variety of dyes, dispersants, leveling agents, heavy metals, dissolved inorganics, acids and alkali that make the environmental challenge for textile industry (Olukanni et al. 2006). The textile wastewater can change the physical, chemical and biological nature of the receiving water bodies by increasing the biochemical oxygen demand (BOD), chemical oxygen demand (COD), total dissolved solids (TDS), total suspended solids (TSS) as well as alters the pH and gives the intense colorations to water bodies (Singh et al. 2017a). The textile waste water contains diverse chemicals, and among the different chemicals, dyes are accounted as imperative pollutants. The occurrence of very low concentrations of dyes (less than 1 ppm for some dyes) in water is exceptionally noticeable. It influences the aesthetic value, water clarity and solubility of gases in lakes, rivers and other water bodies, decreases photosynthetic activity by hindering light penetration into more profound layers and in addition delineates toxic impacts on aquatic organisms (Rana et al. 2013). Dyes are colored unsaturated organic complex compound having capacity to absorb light in the visible region. They are utilized as a part of expansive amounts in various industries including textile, paper, printing, leather, food, plastic, etc. as coloring material. There are more than 8000 chemical products related with the coloring procedures recorded in the Color Index whereas over 100,000 economically accessible dyes exist with an annual production of 7 × 105 metric tons (Zollinger 1987; Singh et al. 2015a). Dyes comprise a wide range of various chemical structures which is based on substituted aromatic and heterocyclic groups, for example, aromatic amine, phenyl and naphthyl. Among the various chemical classes of dyes, azo dyes (~60 to 70%) are the largest class with considerable diversity of colors. Anthraquinone dyes are the second largest class (~15%) followed by triphenylmethanes (~3%) dyes (Fig. 8.1). These dyes are widely utilized in textile industries and are the major well-known synthetic dyes discharged into the environment (Zhao and Hardin 2007).

During the processing of textile, huge amounts of dyestuffs are specifically lost to the wastewater due to inefficiency in dyeing processes which at last finds its way into the environment (Singh et al. 2015a). The amount of dye lost in the wastewater relies upon the applied chemical class of dye, varying from 2% loss (basic dyes) to about 50% loss (in certain reactive dyes). This residual amount of dye is responsible for the coloration and high BOD and COD of the textile wastewater. Release of dye containing wastewater from textile industries into the environment causes serious health and environmental problems. These dyes cannot be degraded easily and some of them are hazardous to humans and other living forms. Moreover, some dyes and/or their degraded intermediate might be either toxic or mutagenic and carcinogenic (Singh et al. 2014). The salts and heavy metals from highly colored wastewater are also toxic to aquatic life. Therefore, wastewater discharged from textile industries has critical ecological concern and removal of dyes from wastewater is necessary prior to their reuse or disposal in order to ensure our water be safe for the future generation.

Conventional treatment processes like adsorption, oxidation, chemical reduction, precipitation, irradiation, membrane filtration, coagulation/flocculation and ion exchange have been utilized in removing various toxic chemicals of general wellbeing and ecological concern. These traditional techniques have their own limitations at large scale (Singh et al. 2014). These methods are not able to completely remove the recalcitrant dyes and their organic metabolites as well as they produce a lot of sludge and secondary waste which need additional treatment and safe disposal (Saratale et al. 2011). Other advance methods, for example, ozonation, electrochemical destruction, treatment using Fenton’s reagent and photocatalysis may also used for the treatment of textile wastewater. However, these technologies typically include complicated approach and are very costly. The biological treatment methods can overcome these limitations because it is cost competitive, produces less amount of sludge and eco-friendly alternative to conventional physico-chemical treatment. Biological dye removal strategies with the help of microbes and plants may exhibit a relatively cost effective and environment friendly approach (Singh and Singh 2017). The adaptability of microbial systems makes them able to degrade wide variety of dyes. These methods are generally based on the microbial biotransformation of dyes. The microbes used for the decolorization of dyes are bacteria, fungi, yeast and algae. Over the most recent couple of years, new procedures for the treatment of textile wastewater have been developed. Among them, biological methods are able to remove the dyes with less ecological effect and without the utilization of harmful chemical compounds in mild pH and temperature conditions (Robinson et al. 2001). Together with the environmental and health concerns, textile industries require large volume of fresh water in production process of the textile products. The wastewater volume varies from mill to mill. Due to the large volumes of potable water utilized by the textile industries, the management of wastage of consumable water with recycling and reusing advancements are getting to be imperative for restricting the measure of wastewater and expenses of generation, and recommended for the protection of environment (Dos Santos et al. 2006). Water recycling is the reuse of treated wastewater for useful purposes, for example, agricultural irrigation and industrial processes etc.

8.2 Environmental Concern

Due to rapid urbanization and industrialization, huge amount of chemicals including dyes are produced and are being employed in daily life. Synthetic dyes are extensively used in various industries for example in textile, leather, paper, food, cosmetics and pharmaceuticals etc. About 100,000 synthetic dyes are produced including several varieties of dyes such as reactive, basic, acidic, azo, diazo, anthraquinone dyes with a yearly production of over 7 × 105 metric tons for commercial purposes. Due to inefficient dyeing process 10–50% of the dye used are not bind with the textile fabric and entering the wastewater directly (Pandey et al. 2007). Textile industries produces large amount of colored wastewater because it requires high volumes of water for their processing. Large amounts of chemically different dyes used by the textile industries are poured to the ecosystem and they become a major concern for living organisms as most of the synthetic dyes have complex aromatic structure which is largely toxic, mutagenic, carcinogenic and recalcitrant in nature (Grassi et al. 2011). Dyes in wastewater causes incidence of bladder tumors and it has been reported that dye industry workers are more prone to common population for such incidence. In addition, they reduce the esthetic nature of water and photosynthetic activity of aquatic lives by diminished light penetration valuable for photosynthesis. Several reports are available about the harmful effect of colored wastewater on animals, plants and microorganisms. Because of their stability to temperature, light and microbial attack, they are recalcitrant organic compounds. High suspended solids, acidity, heat, color and many other substances largely contribute to the pollution of textile wastewater. Process of color removal from textile wastewater and dyestuff manufacturing industry’s wastewater is a difficult task. Several impurities discharged with untreated wastewater leads to change in dissolved oxygen, biological oxygen demand, chemical oxygen demand and color etc. when accumulated in natural or artificial water ecosystem (Saratale et al. 2013).

These impurities are not only the source of mortality for living organisms but also results in sub lethal stress and have profound effect on growth rate, reproductive success and their ability to compete with other species in the ecosystem. Therefore, their removal from textile wastewater is vital before discharge into the ecosystem water bodies.

8.3 Characteristics of Wastewater from Textile Industry

With the expanded need of textile products, the textile industry and its wastewater have been expanding relatively, making it one of the significant wellsprings of serious pollution issues around the world. The characteristics of wastewater from textile industries are highly variable, depending on the type of dye, type of fabric and the concentration of the added agents. These effluents are complexes of many constituents, including a broad category of dyes, natural polluting influences extricated from the fibers and different products, for example, acids, alkalis, salts and heavy metals (Ashfaq and Khatoon 2014). The wastewater discharged from textile industry is immensely colored having high biological oxygen demand (BOD), chemical oxygen demand (COD), high conductivity and alkaline nature (Singh et al. 2017a). The textile coloring industry utilizes vast volume of water and generates huge quantities of wastewater from various steps in the dyeing and finishing processes (Babu et al. 2007). A large portion of wastewater produced by textile industries is during the wet processing stages which include sizing, desizing, scouring, bleaching, mercerization, dyeing, printing, finishing and ultimately washing (EPA 1997).

-

Sizing: It is the first preparative step, in which sizing agents are added which provide strength to the fibres and limit breakage. The sizing agents utilized in this step is starch, polyvinyl alcohol (PVA) and carboxymethyl cellulose.

-

Desizing: In this approach, the sizing materials are removed from the grey fabric prior to weaving. This step is necessary because the presence of sizing agents on the fabric hinders the penetration of other chemicals in the subsequent stages.

-

Scouring: This procedure is utilized to remove impurities, for example, waxes, natural oils, surfactants and fatty acids from the fibres by using an alkali solution.

-

Bleaching: In this step unwanted color from the fibres is removed with the help of chemicals such as hydrogen peroxide and sodium hypochlorite.

-

Mercerising: It is a continuous chemical procedure which is utilized to enhance dye intake capacity of the fabric, lustre, tensile strength and fibre appearance. This process is accomplished by concentrated alkaline solution.

-

Dyeing: The main purpose of this process is adding dyestuff molecules (color) to the textile fibres. This procedure typically requires extensive volumes of water in the dye bath as well as during the rinsing step.

-

Printing: This process produces colored patterns on the fabric by using print containing dyestuff, pigments and other auxiliary chemicals.

-

Finishing: This step includes the final operations necessary for making the textile presentable and attractive such as drying, providing dimensional stability, calendaring, softening etc.

During each step diverse kind of chemicals are utilized, for example, strong acids, strong alkalis, inorganic chlorinated compounds, hypochlorite of sodium, organic compound such as dyestuff, bleaching agent, finishing chemicals, starch, thickening agent, surface active chemicals, wetting and dispersing agents and salts of metals. Different dyes (mostly azo dyes) are utilized during coloring stage for shading purpose and multicolor are utilized to enhance excellence of products. Depending on the coloring procedure of textile, various chemicals like metals, salts, surfactants, organic processing assistants, sulfide and formaldehyde, might be added to enhance the adsorption of dye onto the fibres (Ashfaq and Khatoon 2014). Because of the nature of different chemical processing of textiles, huge amount of wastewater consisting of diverse potential pollutants are released from cotton processing operations (Table 8.1).

The wastewater generated during textile wet processing stages are marked by high variations in various parameters such as COD, BOD, TS, TDS, pH, color and water usage. Much of the times BOD/COD ratio of the textile wastewater is around 0.25 that infers that the wastewater having huge measures of organic matter which is non-biodegradable. The composition of textile wastewater will rely upon various types of organic-based compounds, chemicals and variety of dyes utilized in the dry and wet-processing steps of textile industry (Dos Santos et al. 2006). The wastewater released by textile industries is highly colored having huge quantity of various types of dyes mainly azo dyes. These dyes are important sources of environmental pollution pose hazardous effect on aquatic life because of its strong color, high COD, BOD and low biodegradability. Inspite of the dyes, textile effluent additionally contains variable pH and ionic strength, and high salts concentration too.

8.4 Conventional Methods of Treatment of Wastewater from Textile Industry

Textile industries consume huge amount of water and chemicals for wet processing of textiles. Number of coloring agents such as dyes, tannins, lignin and inorganic pigments etc. are used to impart color in textile fibers. Among the textile wastewater various types of coloring agents are present especially dye wastes are predominant. Massive amount of complex compounds with high concentrations are present in the textile wastewater. Nigam et al. (2000) revealed that very low concentrations of dyes in wastewater are highly visible and undesirable. The release of unprocessed wastewater from textile industry is the primary and the most polluting phenomenon of the globe. The conventional methods used to treat the wastewater are physico-chemical and biological methods. The physico-chemical methods include coagulation, flocculation and ozonation etc. whereas biological methods are used for the removal of nitrogen, phosphorous, organics and metal traces. In the last few decades, many techniques or methods have been developed which offers economic and competent means to treat the textile wastewater. The existing literature proves that large number of conventional methods including physico-chemical, biological processes and some new emerging techniques like microbial fuel cells, genetic engineering, biofilms, nanotechnology etc are effective in decolorization of textile wastewater. Robinson et al. (2001) suggested that when two or three methods have to be combined then maximum color removal achieved.

There are various types of physico-chemical methods utilized in the treatment of textile wastewater.

8.4.1 Adsorption

Out of several physico-chemical methods, adsorption is believed as one of the most successful method applied in textile wastewater treatment. Adsorption techniques have gained attention recently due to their great efficiency in the removal of pollutants. It produces a high quality product, and is a process which is economically feasible. In this method, porous material or filter are used to adsorb and remove the pollutants present in wastewater. Activated carbon, kaolin and silicon polymers are commonly used adsorbents having selective adsorption capacity for dyes but activated carbon is gained preference over other popular adsorbents.

The activated carbon has specific characteristic to adsorb dyes, it can efficiently remove the water soluble dyes in wastewater, such as reactive dyes, basic dyes and azo dyes, but on the other hand it can’t absorb the suspended solids and insoluble dyes. Many factors such as temperature, pH, dye-sorbent interaction, sorbent surface area, particle size and contact time have largely influence the adsorption process (Kumar et al. 1998). Amino nitrogen based adsorbent like chitin possesses significant amount of adsorption capacity for acid dyes.

8.4.2 Membrane Separation Process

This method is basically based on separation of certain substances present in wastewater by the use of microporous membrane with selective permeability. Presently reverse osmosis, nanofiltration, ultrafiltration and microfiltration are the membrane pressure based separation processes which are used for treatment of dyeing wastewater. Reverse osmosis offers decolorization and removal of all mineral salts, hydrolyzed reactive dyes, and chemical compounds present in dye wastewater in a single step. Nanofiltration, another membrane based separation process used to treat colored wastewater having several nanometers aperture with 80–1000 Da molecular weights of retention capacity. Recently combination of nanofiltration and adsorption exploited for the treatment of dye wastewater in which adsorption step utilized before nanofiltration to increases the process output. The nanofiltration mediated treatment of dyeing wastewater, treatment of solutions with high concentration and complex nature is proved to be very efficient in recent days (Babu et al. 2007).

8.4.3 Ion Exchange

Ion exchange method is not extensively utilized for treatment of textile wastewater as it cannot apply to remove a wide range of dyes (Slokar and Le Marechal 1997). In this method ion exchange resin is used and colored wastewater allows passing over it until the available exchange sites are saturated. This method offers removal of both anionic and cationic dyes from wastewater with some advantages such as no loss of adsorbent, recovery of solvent after use and the removal of soluble dyes. The high operation cost of this method limits its application for the treatment of textile wastewater.

8.4.4 Fentons Reagent

Fentons reagent is a chemical method suitable for the treatment of wastewater which are resistant to biological treatment or toxic to live biomass (Slokar and Le Marechal 1997). It is based on the sorption or bonding process for removal of dissolved dyes from wastewater and also has potential in decolorizing both soluble and insoluble textile dyes. Usually this method is used as pre treatment at higher temperature than ambient however, in large scale treatment plant ambient temperature is use with excess of iron as well as hydrogen peroxide. Hydrogen peroxide is strong oxidizing agent and activated to form hydroxyl radicals which are potent decolorizer of wide range of dyes present in textile wastewater.

8.4.5 Ozonation

Ozone is known to be very good oxidizing agent because it posses high instability (oxidation potential, 2.07) compared to other oxidizing agent like chlorine (1.36) and H2O2 (1.78). It is very promising in decolorization of dyes as it can easily reduce the double bond present in the several textile dyes. This method oxidizes a significant portion of COD by inhibiting or destroying the foaming properties of surfactants and useful for the treatment of wastewater containing toxic and high fraction of non-biodegradable components.

8.4.6 Photochemical

This method is used to degrade dye molecules by UV treatment in the presence of water. Hydroxyl radicals which are generated in high concentration are sole source of color removal. H2O2 is activated by the use of UV light to generate hydroxyl radical for the efficient removal of dyes. In this method other factors such as intensity of the UV radiation, pH, dye structure and the dye bath composition are largely contribute in treatment process. Some additional by-products like organic aldehydes, metals, halides, inorganic acids and organic acids are also produced during treatment of textile wastewater.

There are advantages of using photochemical treatment over other available methods that it offers no sludge production and foul odors during treatment of wastewater.

8.4.7 Cucurbituril

It is a cyclic polymer of glycoluril and formaldehyde. Cucurbituril so named due to its structure which is in shaped like a pumpkin, and urea (uril) monomer is its important integral part. It has extraordinary sorption capacity to remove various types of textile dyes. The polymer has potential to remove almost all the dye classes such as reactive, acid, basic and disperse etc to achieve complete decolorization.

8.5 Biological Treatment of Wastewater from Textile Industry

The wastewater released from textile industries are complexes of many constituents. The major pollutant of textile wastewater is dyes especially azo dyes. Azo dyes are complex aromatic compounds with one or more azo (–N=N–) groups. These dyes are recalcitrant in nature and not degraded easily (Singh et al. 2015b). Therefore, removal of these dyes is essential before their release into the ecological systems. The removal of dyes from textile wastewater is constantly associated with the decolorization treatment utilized for textile wastewater. As dyes are intended to be chemically stable and durable colorants, they are generally not degraded easily and effectively. The processes based on biological systems have immense ability to degrade the textile dyes and resolve the issue of superfluous pollutants and high BOD/COD of the textile industries effluents. Different taxonomic category of microorganisms (bacteria, fungi, algae) and plants have the potential to remove dyes from textile wastewater (Fig. 8.2). Moreover, treatment of textile wastewater with biological system is environment friendly and inexpensive as contrast with other treatment processes.

8.5.1 Treatment of Wastewater from Textile Industry by Using Bacteria

Different trophic categories of bacteria are often used for removal of dyes present in textile wastewater. These bacteria are easily cultivated, propagate rapidly and suited fine for decolorization, degradation and mineralization of textile dyes under suitable conditions (Singh and Singh 2017; Singh et al. 2015a). The process of removal of dye by bacterial system might be anaerobic, aerobic or include a combination of both anaerobic and aerobic conditions. However, physiology of bacteria propagated in aerobic and anaerobic conditions is significantly different (Stolz 2001).

8.5.1.1 Under Anaerobic Conditions

Under anaerobic conditions, the bacterial removal of azo dyes from textile effluent is simple, non-specific and more viable process. It involves the reduction of azo linkage in the dye molecule by a variety of cytoplasmic azoreductases. These azoreductases are soluble and having low-substrate specificity. The reductive cleavage of azo linkage produces colorless aromatic amines which are generally impervious to anaerobic mineralization and might be hazardous or mutagenic to living beings (Saratale et al. 2011). Removal of dyes under anaerobic conditions necessitate complex organic carbon or energy source. The rate of dye removal is reliant on the supplemented carbon source and in addition the structure of dye (Bromley-Challenor et al. 2000). Extensive studies have been accomplished utilizing different species of bacteria like Citrobacter sp., Pseudomonas putida, Clostridium bifermentans, Pseudomonas luteola, Staphylococcus hominis for removal of azo dye under anoxic/anaerobic condition (Singh et al. 2017b). Inspite of the fact that large numbers of these bacteria were capable to propagate aerobically but removal of dyes was accomplished just under anaerobic conditions. Different bacterial species such as species of Bacillus, Pseudomonas, Micrococcus, Proteus, Aeromonas and purple non-sulfur photosynthetic bacteria were observed to be efficient in the removal of a number of azo dyes under anaerobic condition. In addition, various studies have been accounted for the decolorization of azo dyes mediated by bacterial culture under anoxic/anaerobic condition (Table 8.2).

8.5.1.2 Under Aerobic Conditions

The dyes present in textile wastewater as a major pollutant are not readily metabolized under aerobic environment because reduction of azo linkage is generally hindered in the presence of oxygen (Ola et al. 2010). However, some bacteria have ability to metabolize azo dyes by reductive mechanisms under aerobic condition. These bacteria are generally specific towards their substrate and produce an oxygen-insensitive azoreductase which exhibit great specificity towards the structure of dyes and utilizes NADH as cofactors for the activity. The oxygen-insensitive azoreductases reductively cleave the azo linkage of specific azo compound and produce aromatic amines under aerobic condition (Stolz 2001). Different bacterial species and their strains have been reported for removal of azo dyes under aerobic condition (Table 8.3). A large number of these species remove the dyes (azo compounds) in aerobic condition only in the presence of additional carbon sources as they cannot use dye as the substrate for their growth and energy (Padmavathy et al. 2003). A small number of bacteria are capable to grow on azo compounds by utilizing the azo compounds as their sole carbon source. These bacteria catalyze the reductive cleavage of azo (–N=N–) bonds and use the resulting amines for their growth as carbon and energy source. The bacterial strains Xenophilus azovorans KF 46 and Pigmentiphaga kullae K24 can utilize the Carboxy-Orange I and Carboxy-Orange II dye, respectively for their growth under aerobic condition (Kulla et al. 1983). However, these bacterial strains could not utilize the structurally resembling sulfonated dyes like Acid Orange 20 (Orange I) and Acid Orange 7 (AO7).

8.5.1.3 Using Bacterial Consortium/Mixed Cultures

The removal of dye from textile wastewater by bacteria is proficient and quick, yet individual bacterial strains more often cannot completely mineralize the azo dyes (Joshi et al. 2008). Moreover, these bacteria are generally specific towards a sort of textile dye, and because of the chemical unpredictability of textile wastewater, it is important to elaborate more effective microbial dye removal process. Subsequently, wastewater treatment systems containing mixed microbial populations/bacterial consortia accomplish a more advanced level of biodegradation and mineralization due to the synergistic or co-metabolic action of the microbial groups (Khehra et al. 2005). Several researchers have used the mixed cultures and bacterial consortia for removal of textile azo dyes (Table 8.4). The uses of mixed cultures/bacterial consortia for decolorization of dye have extensive preferences over the utilization of pure single bacterial cultures (Saratale et al. 2010). A noteworthy benefit of consortia over the utilization of pure/individual bacterial strains in the removal of azo dyes is that, the diverse bacterial strains in consortia may attack at various positions of the dye molecule or can utilize the metabolic intermediates produced by the co-existing bacterial strains for assist the decomposition, and in some cases accomplishing the mineralization of azo dyes (Jadhav et al. 2010).

8.5.1.4 Mechanism of Removal of Azo Dyes by Bacteria

The removal of azo dyes by the bacterial system can take place through two mechanisms: biosorption and enzymatic degradation.

8.5.1.4.1 Biosorption

Biosorption procedures have picked up an extensive significance because of their effectiveness in the elimination of pollutants (dyes), found to be more stable for conventional methods (Aksu 2005). Biosorption is the straightforward process of color removal by entire bacterial cells via adsorption of the dye molecule onto the bacterial biomass by means of different functional groups of heteropolysaccharide and lipid constituents of the cell wall. Removal of dye based on biosorption process includes the interaction of dye to a solid organic or inorganic matrix. The interaction of dye to the matrix depends on matrix composition and dye structure. Different sorts of interactions, like electrostatic, ionic exchange, Van der Waals forces, complexation or chelation involve in the interaction of dye to the matrix.

The remediation of dye by biosorption is impacted by different determinant, for example, surface area of sorbent, particle size, pH, temperature, contact time, presence of salts, surfactants and metals (Robinson et al. 2001). It must be highlighted that the sorption procedures only change the phase of pollutants from one phase to another and subsequently generate sludge which need to be safe disposal or recovered by some different procedure. The bacterial species such as Pseudomonas luteola and Aeromonas sp. are capable to remove the Reactive Blue 5, Reactive Red 22, Reactive Violet 2, Reactive Yellow 2 dyes by biosorption (Hu 1994).

8.5.1.4.2 Enzymatic Mechanism

The initial step in bacterial removal of azo dyes is reductive cleavage of azo linkage (chromophore) with the help of soluble cytoplasmic azoreductases. This azoreductase mediated cleavage involves the sequential transfer of four electrons to the azo bond (–N=N–) of dye in the presence of reducing equivalent (NADH) in two successive steps. In each step, two electrons are transferred to the azo bond of dye resulting in the cleavage of azo linkage via a Hydrazo intermediate. This reaction leads to the formation of colorless aromatic amines which may be additionally degraded to simpler or non toxic form under aerobic conditions (Pandey et al. 2007) (Fig. 8.3).

As majority of azo dyes are high molecular weight compounds having sulfonate substituent groups, they are improbable to move across the cell membranes. Thus, reduction of these sulfonated azo dyes occurs through a mechanism that is not reliant on their intracellular uptake (Russ et al. 2000). In this mechanism a link is established by means of redox mediator between intracellular electron transport system of bacteria and the extracellular azo dye (high molecular weight compounds) (Myers and Myers 1992) (Fig. 8.4). The redox mediator compounds having low molecular weight act as electron shuttles between the extracellular azo dye and azoreductase enzyme which is present in the outer membrane of the bacterial cell (Gingell and Walker 1971).

8.5.1.5 Removal of Triphenylmethane and Anthraquinone Dyes by Bacteria

Triphenylmethane and anthraquinone based dyes are the groups of dyes which are usually utilized in textile industries after the azo dyes (Singh et al. 2017a). Triphenylmethane dyes are synthetic dyes with triphenylmethane (C6H5)3CH as their backbones. On the other hand, anthraquinone dyes are characterized by their chromophore group (═C═O), forming an anthraquinone complex. Triphenylmethane and anthraquinone-based dyes are more resistant to degradation because of their synthetic origins and complex aromatic structures. Removal of these dyes from textile wastewater may take place either by biosorption or biodegradation. Biodegradation of these dyes may involve enzymes such as laccase, lignin peroxidase (LiP), tyrosinase, manganese peroxidase (MnP) and DCIP reductase. These enzymes help in removal of triphenylmethane and anthraquinone dyes by depolymerisation, demethoxylation, decarboxylation, hydroxylation and aromatic ring opening reactions (Singh et al. 2015a). Many bacterial species have been reported for the degradation of triphenylmethane and anthraquinone dyes (Table 8.5).

8.5.2 Treatment of Wastewater from Textile Industry by Using Fungi

Among industrial wastewater, textile wastewater requires vigorous treatment processes due to their complex nature. Number of microorganisms has been reported for efficient dye decolorization and degradation from wastewater; these microorganisms include bacteria, algae or fungi. The processes they employ are aerobic, anaerobic or combination of both. Treatment process is principally relying on the structure of dye and nature of microorganisms (Keharia and Madamvar 2003). Application of biological organisms leads to partial or complete mineralization of wastewater dyes to CO2 and H2O (Mohan et al. 2002). Fungi has been considered as an important living organism for the treatment of textile wastewater and in degradation of dyes. Several species of fungi are known which can biosorb or decolorize various dyes. These living microorganisms encodes enzymes such as laccase, manganese peroxidase (MnP) and lignin peroxidase (LiP) which are nonspecific in nature and involved in biodegradation of dyes. The extracellular nature of these enzymes proved to be beneficial in tolerating high concentrations of the harmful dyes. The dead cell biomass of fungi exhibit biosorption process which rely on several physico-chemical interactions such as adsorption, deposition and ion exchange.

8.5.2.1 Pure Cultures of Phanerochaete chrysosporium

The pure culture of P. chrysosporium is most frequently used for the removal of textile dyes because of their capacity to produce high concentration of enzyme. The dye removal extent is largely based on the dye-microorganism compatibility and composition of medium. It was observed that many extracellular enzymes such as LiP and MnP and laccase may facilitate the process of decolorization. Enayatizamir et al. (2011) observed degradation of dye Azo Black Reactive 5 when treated with P. chrysosporium and achieved 92% decolorization rate after 3 days. It is also a well known fact that to achieve maximum dye decolorization careful selection of fungal strain and appropriate culture condition is required. Chagas and Durrant (2001) identified the role of enzymes Mn-peroxidase, h-glucosidase and laccase produced by P. chrysosporium and Pleurotus sajor-caju when tested and compared biodegradation of dyes Amaranth, Tartrazine, New Coccine and Orange G. Couto et al. (2000) proved that on addition of activators such as tween 80, manganese (IV) oxide, veratryl alcohol the production rate of lignolytic enzymes by P. chrysosporium is enhance and increased Poly R-478 dye decolorization achieved.

8.5.2.2 Pure Cultures of Other Important Fungi

Several other fungi have been employed for the treatment of textile wastewater containing diverse group of dyes. Many genera of fungi have been used either in living or inactivated structure. Yesiladali et al. (2006) stated that Trichophyton rubrum LSK-27 is a promising isolate for dye removal processes and can be a potent culture for treatment of textile wastewater under aerobic conditions for non toxic degradation of dye molecule. Wesenberg et al. (2002) reported the decolorization of wastewater from a textile dye producing industry by the agaric white-rot fungus Clitocybula dusenii and observed that on optimal conditions up to 87% of the dyes of a fourfold diluted wastewater were decolorized after 20 days of incubation. In last decades decolorization of dyes such as Magenta, Pararosaniline, Malachite Green, Brilliant Green and Crystal Violet by Kurthia sp. has been extensively studied. Ganoderma lucidum was used for treatment of textile wastewater in a batch reactor under optimized conditions, a maximum decolorization of 81.40% and a COD reduction of 90.30% were achieved.

The white rot fungi Ganoderma sp. En3, Trametes versicolor and Irpex lacteus was highly effective in treatment of textile wastewater and remove more than 90%, 60% and 93% color, respectively. Several pure and mixed fungal cultures are given in Table 8.6 which shows potential for treatment of textile wastewater. Amaral et al. (2004) studied the decolorization of wastewater from a textile industry by T. versicolor and reported that for a sevenfold diluted wastewater a decolorization percentage reached to 40% which was much lower than that found for a synthetic wastewater having same color (300 mg/l) whereas a higher decolorization percentage (92%) was obtained with a 42-fold diluted wastewater (dye concentration 50 mg/l). Different fungal cultures have been used for treatment of number of different dyes from many classes successfully.

8.5.3 Treatment of Wastewater from Textile Industry by Using Algae

Algae are photosynthetic, minute organisms, which typically inhabit aquatic environments (pond, lake and sea etc.), soil and other appropriate area. Microalgae degrade and utilized dyes as a nitrogen source (Table 8.7), contribute their role to overcome eutrophication in the aquatic system (Ruiz et al. 2011) and also they are key scavenger of CO2 which is a major global warming gas (Mata et al. 2011). Microalgae show tremendous scavenging potential towards heavy metals (Table 8.7). They are used in biofuel production and considered as promising source of renewable energy (Ferrell and Sarisky-Reed 2008). Recently, algae have been used in bioremediation and to cleanup wastewater due to their high efficiency in absorbing both inorganic and organic pollutants, including heavy metals, pesticides, toxic compounds, dissolved nutrients and even radioactive materials (Mata et al. 2011). Microalgae produce around 50% of the oxygen present in the atmosphere by the process of photosynthesis which vital for life on our planet. Microalgae are necessary for the life of ocean and lakes as they are placed bottom of food chain and contribute their role in the stability of aquatic ecosystem.

The treatment cost of textile wastewater is high because of their very high concentrations of total Nitrogen and Phosphorous and toxic metal (Gasperi et al. 2008). The textile wastewater is also rich in both organic and inorganic compounds and useful for algal biomass as a sustainable growth medium (Green et al. 1995). Microalgae grow and accumulate nutrient from wastewater by making them sustainable and suitable for low cost wastewater treatment (de-Bashan et al. 2010). The species such as Chlorella vulgaris accumulate higher lipid content (42%) when grown in wastewaters (Feng et al. 2011). It is beneficial to design the wastewater High Rate Algal Ponds (HRAPs) setup in the vicinity of textile industries to trap sustainable and renewable source of energy. Presently wastewater treatments HRAPs are the only environment friendly and economic system to produce biofuels (Park et al. 2011).

8.5.3.1 Methods and Mechanism of Algal Textile Wastewater Treatment

Microalgae are known to remove textile effluents by bioadsorption and biotransformation.

8.5.3.1.1 Bioadsorption

It is an energy independent process and no requirement of input of synthetic chemical. Operation cost of this method is very low as it is carried out effectively in situ at the contaminated site. Removal of dyes and metal ion from textile wastewater by using plant material as adsorbents is attractive feature of this prominent technology (Mohammad et al. 2012). High affinity between adsorbent and adsorbate species (toxic substances) plays a major role in this process. The process will be continues till the establishment of equilibrium between the solid bound adsorbate species and its reminants in the solution. Mango peel, tree barks, tea leaf powder, coconut bunch waste, banana peel, wheat husk etc. are the several sorbent which were already tested for their adsorption capacity (Nevine 2008).

8.5.3.1.2 Biotranformation (Biodegradation)

Chemical conversion of a substance into a desired product may be done with the aid of whole microbial cell, containing the necessary enzyme(s) or isolated enzyme. Enzymes and whole cell biocatalysts possess many useful properties, which determine preferential use of catalysts for organic synthesis. These catalysts have some characteristic features such as require mild reaction conditions, high chemo and stereo selectivity, usually performed in an aqueous environment but can also be efficient in solvent mixtures for example vinyl acetate, an organic solvents used for esterification by enzymes esterases and lipases (Schmid et al. 2001).

8.5.3.2 Factors Affecting the Algal Growth

-

(a)

Abiotic, physical and chemical: light, nutrient concentration, O2, CO2, pH, salinity, toxic chemicals

-

(b)

Biotic factors: pathogens like bacteria, fungi, viruses

-

(c)

Operational factors: mixing, dilution rate, depth, addition of bicarbonate, harvesting frequency

8.5.3.3 Advantages of Algal Textile Wastewater Treatment

-

(a)

Use of microalgae can sort out the problems of global warming by fixing large amount of CO2 in the atmosphere. It was estimated that 1 kg of CO2 is required for production of 1 kg algal biomass which is a better option to overcome the problem of global warming.

-

(b)

It is superior in remediation processes as a wide range of dyes, heavy metals, toxic chemicals and other wastes can be treated with algae and they are non pathogenic in nature.

-

(c)

Use of microalgae is environment friendly and not associated with secondary pollution problems.

-

(d)

Recently microalgae are used as biofuel and considered as alternative to conventional fuel that is diminishing very fast.

-

(e)

Microalgae have excellent heavy metal scavenging properties.

-

(f)

Blue-green algae are the suitable organism which performs dual role of wastewater treatment and simultaneously biomass production.

-

(g)

To decrease the space and land requirement in treatment of wastewater by microalgae a hyper concentrated algal culture known as ‘activated algae’ is utilized which removes nitrogen and phosphorous in less than 1 h.

-

(h)

Microalgae remove N and P nutrients from wastewater in very short period of time as they utilized it for the synthesis of protein, phospholipid and nucleic acid.

Thus algal growth can keep the water clean and make natural waters more suitable for human consumption.

8.5.3.4 Limitation of Algal Textile Wastewater Treatment

-

(a)

Fresh water algae normally start with a small population but by utilization of large amount of sunlight and required nutrients, they slowly develop in large population. They also produce scums and facilitate the removal of water color. When left untreated, these algae could suffocate aquatic flora and fauna.

-

(b)

Lagoon systems want more land space than other treatment process.

-

(c)

Cold climate have adverse effect so they need additional land or longer detention times in these areas.

-

(d)

Odor produced during algal blooms or with anaerobic lagoons limits its use.

-

(e)

Mosquitoes and other insects use unmanaged algal lagoons as site for breeding.

-

(f)

They are as much efficient in removal of heavy metals from wastewater as plants.

-

(g)

Sometimes additional treatment requires for wastewater from lagoons.

8.5.4 Treatment of Wastewater from Textile Industry by Using Plants

Phytoremediation is a green innovation that utilizes plant frameworks for remediation and rebuilding of the polluted destinations. Plants have inbuilt enzymatic apparatus equipped for removing the complex structures of pollutants and can be utilized for cleaning the polluted destinations. It is a naturally stable and maintainable recovery system for bringing contaminated locales into beneficial purpose however, is still in exploratory stage; hence it needs more consideration and logical overview (APHA 2005). Phytoremediation has been appeared to be cost competitive in different aquatic systems. This technique utilizes special plants known as hyperaccumulators to purify heavy metal contaminated sites (Table 8.8). In hyperaccumulation, heavy metal pollutants are absorbed by the roots of the plants and are concentrated in the plant tissues or decomposed to less harmful forms. Plants that can assimilate and tolerate high amounts of heavy metals are considered as potent candidates of phytoremediation. The importance of phytoremediation is the low capital costs, aesthetic advantages, reduction in leaching of pollutants and stabilization of soil. It includes principally fertilization and watering for keeping up plant development. In case of heavy metals remediation, extra operational expenses will likewise incorporate in harvesting, disposal of contaminated plant mass and repeating the plant development cycle.

Floating aquatic macrophytes are characterized as plants that buoy on the water surface with submerged roots. Many aquatic macrophytes are potent candidates of phytoremediation as they exhibit solid abilities to retain unnecessary heavy metals and accumulate them in plant tissues (Salt et al. 1995). Additionally, the rapid proliferation and direct contact of aquatic macrophytes with the polluted environment encourages the decontamination procedure and guarantees the sanitation of contaminated water bodies. The most widely recognized aquatic macrophytes being utilized in wastewater treatment are water hyacinth (Eichhornia crassipes), penny wort (Centella asiatica), water lettuce (Pistia stratiotes), and water ferns (Azolla filiculoides). E. crassipes is potent growers known to twofold their populace in 2 weeks. The plant has high degree of tolerance and high limit for the take-up of heavy metals including cadmium, chromium, cobalt, nickel, lead and mercury, which could make it reasonable for the biocleaning of textile wastewater. E. crassipes can remediate different toxic pollutants, for example, cyanide, which is ecologically valuable in territories that have experienced gold mining activities.

8.5.4.1 Properties of Hyperaccumulators

-

(a)

The plant must have the capacity to tolerate abnormal amounts of the element in root and shoot cells. The hypertolerance property is the key which ensure the hyperaccumulation.

-

(b)

In addition to tolerance, the hyperaccumulation properties should be stable. Further, the plant should have the capacity to accumulate several metals.

-

(c)

The plant should be competent to translocate an element from roots to shoots at high rates. Normally, the concentrations of Zn, Cd or Ni in root are at least ten times higher than shoot; but in case of hyperaccumulators, the concentrations of metal in shoot can surpass the root levels.

-

(d)

There must be a quick take-up rate for the element at levels which happen in soil arrangement along with fast growth of the plant and increased biomass production.

-

(e)

The plant must have the ability to grow outside of their area of collection.

-

(f)

The species should be of economic interest.

-

(g)

The plant should be resistant to disease and pests.

-

(h)

Unattractive to animals minimizing the risk of biomagnification.

8.5.4.2 Methods and Mechanism for Plant Textile Wastewater Treatment

Depending on the underlying procedures, relevance and contaminant type, phytoremediation can be done by various techniques and systems.

8.5.4.2.1 Phytoremediation to Treat Organic Contaminants

Phytotransformation (Phytodegradation)

Phytotransformation, is the breakdown of pollutants taken up by plants via metabolic process inside the plant, or the breakdown of pollutants encompassing the plant with the help of enzymes produced by the plants (Schnoor 1997). Complex organic contaminants are degraded into simpler or less toxic forms which are utilized by the plant tissues to enable the plant to become fast grower. Plants contain enzymes that catalyze and enhance the chemical reactions. Some enzymes degrade and change the ammunition wastes while others breakdown the chlorinated solvents and herbicides.

Phytostimulation (Rhizodegradation)

Phytostimulation is the removal of pollutants in the rhizosphere by microbial action that is increased by the nearness of plant roots. It is a much slower process as compare to phytotransformation. Sugars, alcohols and acids are the natural substances produced by the plant roots that give nourishment to soil microorganisms and the extra supplements increase their action. Certain microorganisms can digest fuels or organic solvents that are harmful to humans and breakdown those into innocuous products in a process known as biodegradation. Biodegradation is likewise supported by the way plants loosen the soil and transport water to the territory.

Phytovolatilisation

Phytovolatilisation is the process in which uptake and transpiration of a pollutant takes place by the plant resulting in release of the altered form of pollutant in the climate. Phytovolatilisation happens as growing trees and different plants take up water and the organic pollutants. Poplar trees at one specific investigation site have been appeared to volatilize more than 90% of the trichloroethanol (TCE) they take up (James et al. 2009).

8.5.4.2.2 Phytoremediation for Treatment of Metal Contaminants

Phytoaccumulation (Phytoextraction)

In the process of phytoaccumulation, the uptake of metals from soil takes place by plant roots into over the ground portions of plants. After that plants have been permitted to grow and after some time they are harvested for recycling of the metals through incineration or composting (Irshad et al. 2015). This procedure might be repeated as important to bring soil contaminant levels down as far as possible. In case of incineration, the ash must be dispose safely in a hazardous waste landfill; however, the volume of ash will be under 10% of the volume that would be created.

Rhizofiltration

Rhizofiltration is the adsorption or precipitation of contaminants onto the plant roots that are in solution encompassing the root zone. Rhizofiltration is like phytoextraction, yet the plants are utilized to clean up contaminated groundwater instead of soil. The plants to be utilized for cleanup are grown in greenhouses with their roots in water. As the roots become saturated with pollutants, they are harvested. For example, sunflowers were effectively utilized to remove radioactive pollutants from wastewater (Rahman et al. 2013).

Phytostabilisation

Phytostabilisation is the process in which certain plant species is used to immobilize the pollutants in the soil and groundwater via absorption and accumulation by roots inside the root zone. This method decreases the mobility of the pollutants and avoids their movement to the groundwater or air, and furthermore lessens the bioavailability for entry into the food chain. This method can be utilized to restore a vegetative cover at sites where characteristic vegetation is missing because of high contaminants in surface soils. Hyperaccumulators can be utilized to reestablish vegetation to the destinations, in this way diminishing the potential movement of pollutants through breeze and transport of uncovered surface soils as well as reduces the leaching of soil contamination to groundwater.

8.5.4.2.3 Phytoremediation for Hydraulic Control of Contaminants

Riparian Corridors

Riparian passageways (the bank of a river) or buffer strips are specific employments of phytoremediation that may likewise consolidate parts of phytodegradation, phytovolatilisation and rhizodegradation to control, intercept or remediate pollutants entering in a river or groundwater plume (Hill 1996). In a riparian corridor, plants might be applied along with the water stream, whereas buffer strips might be applied around the border of landfills. The uses of these frameworks prevent pollution from spreading into surface water and additionally groundwater.

Vegetative Cover

Vegetative cover/cap is a self-managing cap made out of soil and plants growing in or over waste in a landfill. This sort of cap is an alternative option to composite clay or plastic layer caps. Plants control erosion and limit drainage of water that could somehow permeate via the landfill and form polluted leachates. Moreover, a vegetative cap can be outlined, not exclusively to control erosion and drainage of water, yet additionally to improve the degradation of underlying materials in the landfill.

8.5.4.3 Advantages of Phytoremediation

-

(a)

Cost competitive: cheaper than other remedial approaches.

-

(b)

Applicability: applicable to moderately multi-contaminated sites of large extension.

-

(c)

Favorable public perception: enhanced aesthetics, decreased noise and bad smell.

-

(d)

Greenhouse effect reduction: CO2 sequestration into biomass.

-

(e)

Removable energy production: energy can be recovered from the controlled combustion of the harvested biomass.

8.5.4.4 Limitation of Phytoremediation

-

(a)

Root depth: some efficient phytoextractors’ roots are situated in depth.

-

(b)

Applicability: For the most part, the utilization of phytoremediation is restricted to sites with low to medium pollutant concentrations, top soil contaminant localization, bioavailability of contaminants.

-

(c)

Treatment rate: Relatively slow in comparison to bioremediation technologies.

-

(d)

Seasonal dependence: Efficiency is strongly reduced during the winters.

-

(e)

Potential contamination of food chain: Probability of entry of pollutants into the food chain via consumption of plant biomass by animals.

8.6 Factors Affecting the Treatment of Wastewater from Textile Industry

Ecosystems are active entity with unpredictable abiotic circumstances such as pH, salts, temperature and O2 etc. Microorganisms are very sensitive towards dyes, high salinity, change in pH and heavy metals. The best suited microorganisms for bio-treatment of textile wastewater are isolated from textile industry contaminated background, including soil, wastewater and sludge and further allow growing in adverse condition. Various researches have concluded that the operational parameters must be optimum for the success of biological treatment systems. Thus the effects of these parameters are vital for assessing the potential of a variety of microorganisms for bioremediation of xenobiotics. Maximum rate of dye decolorization are achieved when the various parameter like temperature, pH, aeration and redox potential of the reaction system must be optimized. The composition of textile wastewater varies greatly and may contain nutrients, organics, salts, sulfur derivatives and toxicants as well as the color.

The effect of each of the factors indicated above on the treatment process must be precisely examined prior to use of biological or other methods for the treatment of textile wastewater.

8.6.1 pH

The medium pH is an important parameter for the optimal physiological activity of microbial cultures and decolorization of textile wastewater. It plays a significant role for movement of nutrients through the cell membrane, affects the microbial cell growth and various biochemical, enzymatic processes. It was estimated that the suitable pH for color removal from wastewater is 6–10. Bacteria shows superior decolorization and biodegradation activity at neutral or basic pH while fungi and yeast at acidic or neutral pH. The decolorization potential of anaerobic and aerobic microorganisms is directly affected by the pH of the wastewater. Adaptation of biological organisms to varying pH improves the process of wastewater treatment.

8.6.2 Temperature

It is an important abiotic environmental factor and the remediation potential of microorganisms is largely influenced by the changes in temperature. An optimum temperature is needed for the growth and reproduction of the decolorizers (typically soil bacteria and fungi). Beyond the defined optimum temperature, the process of decolorization reduces due to slow growth and multiplication. The microbial cells countered temperature change by adaptation through biochemical or enzymatic means. Such changes in temperature lead to a rapid alteration of the activation energy in the microbial physiology (Chang and Kuo 2000). The extent of color removal increases with increasing initial temperature.

8.6.3 Dye Structure

Diverse groups of synthetic dyes are present such as acidic, reactive, azo, diazo, anthraquinone, basic, disperse and metal-complex dyes (Banat et al. 1996). These dyes differ in their chemical composition such as either they hold special functional groups or they are isomers. These differences notably influenced the decolorization potential of the microorganisms. Simplicity and molecular weight of dyes present in wastewater have direct correlation with decolorization mechanism. Dyes with simple structures and low molecular weights show faster decolorization, whereas the decolorization of complex and high molecular weight dyes is slow.

8.6.4 Dye Concentration

The decolorization of dye in wastewater largely depends on the initial dye concentration. Rate of color removal decreases step by step with rise in concentration of dye due to dye mediated toxic effect on microbial degrader or the masking the active sites of effectors enzymes by dye molecule with alternative structures (Sponza and Isik 2004). The dye concentration can affect the success of dye removal via combination of factors such as toxicity of dye, higher concentration of co-contaminants and capacity of enzyme to recognize their substrate at very low concentration in target wastewater.

8.6.5 Salts

The textile wastewater contains number of impurities such as salts or metal ions acids and alkalis etc. Wastewaters from dyeing plants and textile processing industries contain considerable amounts of salts in addition to azo dyes. Dyestuff industry wastewaters contain salt concentrations up to 15–20%. Thus, using microbial cultures capable of tolerating salt stress is preferable for treating such wastewaters. The capacity of Shewanella putrefaciens strain AS96 in removing four azo dyes with different structure at variable concentrations of NaCl was analyzed. The azo dyes Direct Red 81, Reactive Black 5, Acid Red 88 and Disperse Orange 3 decolorized upto 100% when NaCl concentration was 0–40 g/l. Time for decolorization increased with increase in NaCl concentration (60 g/l) and decolorization extent also decreased drastically (Khalid et al. 2008).

8.6.6 Agitation

Enormous literature is available which correlate the effect of agitation and static condition with microbial decolorization of synthetic dyes containing wastewater. Microorganisms accelerate decolorization under both shaking and static conditions. Higher rate of color removal is found under shaking condition due to better oxygen transfer and distribution of nutrients as compared to stationary cultures but exceptionally agitated cultures of Pseudomonas sp. SUK1 and some other cultures showed less decolorization than static conditions.

8.6.7 Nutrients

Nutrients also play a significant role in dye decolorization process. Suitable amount of nutrients have significant effect on the growth of microorganism and enhance the degradation of dyes in wastewaters. Pseudomonas sp. BSP-4 isolated from azo dye contaminated soil was capable to decolorize azo dye Black E by utilizing it as nitrogen source upto 300 ppm in 36 h (Sudhakar et al. 2002). Nutrients, such as nitrogen, carbon and sulfur etc. have noticeable effect on wastewater treatment.

8.7 Recycling of Wastewater from Textile Industry

Recycling has turned into a fundamental procedure in the treatment of wastewater and play a role in control the pollution. The significant wastes produced by textile industries are mainly fibers, beaming wastes, dyes and various chemicals. These procedures utilize around 200 l of water/kg of fiber and generate large volume of wastewater (Babu et al. 2007). Textile industry utilizes a number of processes during the production of textile, for example, washing, weaving, dyeing, printing, finishing, quality and process control and warehousing, in addition to garment making. These processes contribute the different type of pollutants in textile wastewater.

A recycled product is the materials which have been recovered or modified from wastes either from the manufacturing process or after usage. There are distinctive strategies for recycling of textile wastewater; physical (mechanical), biological, chemical and thermal recovery. Considering the variability of textile wastewater, various strategies of wastewater recycling must work in a coordinated manner so as to accomplish a notable impact on recycling.

8.7.1 Methods of Textile Wastewater Recycling

The mechanical or physical methods for treatment of wastewater include under primary treatment while use of biological methods for further treatment is part of secondary treatment. The advanced secondary treatment process involved in combined use of chemical and biological system for example disinfection of the water by injecting chlorine. The tertiary treatment is expensive, used to remove traces of chemicals and dissolved solids.

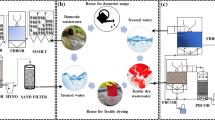

8.7.1.1 Physical Recovery

This is the first step in the recycling process of textile wastewater. In this process the raw waste is passed through the metallic bar screens for the separation of large stuffs like sticks and rags from the water. Water moves through bar screens and reaches into grit chamber (Fig. 8.5) in which the influent water flow is slows for setting down of gravel and sand into the bottom of chamber. Primary clarifiers mediate further slowing of influent water flow so that settleable organics deposit in the bottom whereas greases, oils and fat float to the top. This process useful in removal of almost 50% of the contaminants present in wastewater (Jefferson et al. 1999).

8.7.1.2 Biological Recovery

In this process water runs into aeration tank where oxygen is mixed with it and microorganisms use organic material as food which leads to removal of remaining contaminants, decrease in BOD level. Wastewater biosolids are the end product after the conversion of non-settleable solids into settleable solids of wastewater by microorganisms. Several operators of wastewater recycling plants consider themselves “bug farmers”, because they are in the business of growing and harvesting a healthy population of microorganisms (Vineta 2014). Chemical or substance present in wastewater is harmful to microorganism which can interfere with the biological operation of a water recycling plant. When the water recycling plant is not adequately operating because of chemicals which kill the microorganisms, water reuse programs are threatened and the quality of water discharged to receiving streams is poor.

8.7.1.3 Chemical Recovery

After the bugs (pathogenic microorganism) complete its role, chemical such as chlorine are used to kill the remaining pathogens as a final clarifiers. The residual chlorine must be must be removed from system before discharge into lakes and rivers by using sulfur dioxide (SO2). Chlorine gas have risks on using and storing as it is highly toxic, so use of ultraviolet radiation as an alternative to chlorine provides final disinfection of water.

8.7.1.4 Thermal Recovery

It is useful in the waste recycling technology where higher temperatures are required for the processing of the waste feedstock. This recovery system is believed to be thermal entity and include number of process such as cement kiln, mechanical heat treatment, pyrolysis, gasification, incineration, thermal depolymerization and waste autoclaves.

8.7.2 Advantages of Textile Wastewater Recycling

Enhancing the management of wastewater recycling can be beneficial for business and the environment by:

-

(a)

Reducing expense of acquiring materials and augmenting the proficiency of material use.

-

(b)

Increasing productivity and profitability.

-

(c)

Reducing the expenses of wastewater treatments and disposal.

-

(d)

Reducing the ecological effects by lessening utilization of crude materials and delivering less waste.

-

(e)

Enhancing the public image and employee satisfaction by promoting an ecofriendly image and giving a more secure working environment.

8.7.3 Limitation of Textile Wastewater Recycling

-

(a)

In spite of the fact that the environmental attention to the overall population has expanded in the recent years, their eagerness to effectively take an interest in reducing the waste is still needed to be improved.

-

(b)

There is no economic motivation for waste producers to diminish the waste.

-

(c)

Low qualities, high transportation cost or absence of market interest for recovered or recycled materials.

-

(d)

The majority of small and medium recovery and recycling ventures demoralizes the interest in waste recycling technologies.

8.7.4 Future Scope of Textile Recycling Work

Clothing and textile recycling process reduces the need for landfill spaces, pressure on virgin resources, demand for dyes and fixing agents, saves energy and reduces pollution. As textile mill sludge contains organic matter, it can be turned into sludge ash by igniting it to 800 °C for 2 h. This sludge ash can be used in concrete.

8.8 Factors Affecting the Recycling of Wastewater from Textile Industry

Factors influencing recycling of wastewater performance can be listed down as below:

8.8.1 User Opinions and Satisfaction

Water recycling process is indirectly associated with user opinion and satisfaction because user is always aware with the quality of water. Water Supply Corporation (WSC) of the particular area is responsible to ensure the quality of the water, track record of all operation and maintenance done. Thus, indirectly the complaints from the user have direct bearing on the performance of the water treatment plant.

8.8.2 Community Management

The community management is responsible to ensure that the wastewater recycling plant is well managed, under control and efficiently operated to produce high quality water. The water recycling plants requires vigorous monitoring by operator because it is based on machine and automatic run. The operator must be full time working for controlling and operating the wastewater recycling machine.

8.8.3 Level of Service

Water quality is defined in terms of its chemical, physical, and biological characteristics. The level at which wastewater recycling is performed is an important factor for recycling.

8.8.4 Materials and Equipment

The machinery and equipment involved in processing the wastewater must be highly efficient, so that it can be used for drinking, farming and industrial purposes. The machinery must be for a long term use and blended with new technology to give a better performance towards water recycling.

8.8.5 Financial Status

The water recycling processes needs lots of expenditure on the machinery, building, workers, dams and chemical treatment. The cost of recycling is very high to make it operative. Because of this reason, the government has allocated a lot of money to enable the water recycling function well. Thus, the user will get the benefit from this investment and can use the water safely.

8.8.6 Personnel

One of the important factors which influence the wastewater recycling process is the technician or staff availability and training because clean water is essential for good health, fisheries, wildlife and industries. Water recycling plant operators recycle wastewater upto an extent where it is safe for drinking. A skilled operator will have much influence on to the performance of the water recycling system.

8.8.7 Working conditions

The operators working in wastewater recycling plant works from both indoors and outdoors, and might be exposed to noise from machinery and nasty smells of wastewater. They should give careful consideration to security methods because they may face hazardous conditions, such as slippery walkways, risky gases and malfunctioning equipment. Treatment plants generally operates 24 h every day, 7 days a week, hence, working conditions largely influence the water treatment performance.

References

Agarry SE, Ayobami OA (2011) Evaluation of microbial systems for biotreatment of textile waste effluents in Nigeria: biodecolorization and biodegradation of textile dye. J Appl Sci Environ Manag 15:79–86

Aksu Z (2005) Application of biosorption for the removal of organic pollutants: a review. Process Biochem 40:997–1026

Al-Fawwaz AT, Abdullah M (2016) Decolorization of Methylene Blue and Malachite Green by immobilized Desmodesmus sp. isolated from North Jordan. Int J Environ Sci Dev 7:95–99

AL-Rajhia S, Raut N, AL-Qasmi F et al (2012) Treatments of industrials wastewater by using microalgae. 2012 International Conference on Environmental, Biomedical and Biotechnology IPCBEE 41, IACSIT Press, Singapore

Amaral PFF, Fernandes DLA, Tavares APM et al (2004) Decolorization of dyes from textile wastewater by Trametes versicolor. Environ Technol 25:1313–1320

Anastasi A, Parato B, Spina F et al (2011) Decolorization and detoxification in the fungal treatment of textile wastewaters from dyeing processes. New Biotechnol 29:38–45

Anjaneya O, Souche SY, Santoshkumar M et al (2011) Decolorization of sulfonated azo dye Metanil Yellow by newly isolated bacterial strains: Bacillus sp. strain AK1 and Lysinibacillus sp. strain AK2. J Hazard Mater 190:351–358

APHA (2005) Standard methods for the examination of water and wastewater, 21st edn. APHA, AWWA and WEF, Washington, DC

Arulazhagan P (2016) A study on microbial decolorization of reactive red M88 by Bacillus subtilis isolated from dye contaminated soil samples. Int J Curr Res Biol Med 1:1–13

Asgher M, Jamil F, Iqbal HMN (2012) Bioremediation potential of mixed white rot culture of Pleurotus ostreatus IBL-02 and Coriolus versicolor IBL-04 for textile industry wastewater. J Bioremediation Biodegrad S1:007

Ashfaq A, Khatoon A (2014) Waste management of textiles: a solution to the environmental pollution. Int J Curr Microbiol App Sci 3(7):780–787

Ayed L, Mahdhi A, Cheref A et al (2011) Decolorization and degradation of azo dye Methyl Red by an isolated Sphingomonas paucimobilis: biotoxicity and metabolites characterization. Desalination 274:272–277

Azarpira H, Behdarv P, Dhumal K et al (2014) Potential use of cyanobacteria species in phycoremediation of municipal wastewater. Int J Biosci 4:105–111

Babu BR, Parande AK, Raghu S et al (2007) Cotton textile processing: waste generation and effluent treatment. J Cotton Sci 11:141–153

Baker AJM, Brooks RR (1989) Terrestrial higher plants which hyperaccumulate metallic elements: a review of their distribution. Ecol Phytochem Biorecovery 1:81–126

Baker AJ, Walker PI (1990) Ecophysiology of metal uptake by tolerant plants. In: Shaw AJ (ed) Heavy metal tolerance in plants evolutionary aspects. CRC Press, Boca Raton, pp 155–178

Banasova V, Horak O (2008) Heavy metal content in Thalspi caerulescens J. et C. Presl growing on metalliferous and non-metalliferous soils in Central Slovakia. Int J Environ Pollut 33:133–145

Banat IM, Nigam P, Singh D, Marchant R (1996) Microbial decolorization of textile dye-containing effluents: a review. Bioresour Technol 58(3):217–227

Barry SAS, Clark SC (1978) Problems of interpreting the relationship between the amounts of lead and zinc in plants and soil on metalliferous wastes. New Phytol 81:773–783

Barzanti R, Colzi I, Arnetoli M et al (2011) Cadmium phytoextraction potential of different Alyssum species. J Hazard Mater 196:66–72

Baumann A (1885) Das Verhalten von Zinksatzen gegen Pflanzen und im Boden. Landwirtsch Vers Statn 31:1–53

Blaylock MJ, Salt DE, Dushenkov S et al (1997) Enhanced accumulation of Pb in Indian mustard by soil-applied chelating agents. Environ Sci Technol 31:860–865

Boyd RS, Jaffré T, Odom JW (1999) Variation in nickel content in the nickel-hyperaccumulating shrub Psychofria douarrei (Rubiaceae) from New Caledonia. Blotroplca 31:403–410

Brahmbhatt NH, Jasrai RT (2015) Biodegradation of reactive dyes by two microalgal species. Int J Sci Res 4:1697–1702

Brahmbhatt NH, Jasrai RT (2016) The role of algae in bioremediation of textile effluent. Int J Eng Res Gen Sci 4:443–453

Bromley-Challenor KCA, Knapp JS, Zhang Z et al (2000) Decolorization of an azo dye by unacclimated activated sludge under anaerobic conditions. Water Res 34:4410–4418

Brooks V (1998) Phytochemistry of hyperaccumulators plants that hyperaccumulate heavy metals. CAB International, Wallingford, pp 15–54

Burnell JN (1981) Selenium metabolism in Neptunia amplexicaulis. Plant Physiol 67:316–324

Chagas EP, Durrant LR (2001) Decolorization of azo dyes by Phanerochaete chrysosporium and Pleurotus sajor-caju. Enzym Microb Technol 29:473–477

Chan GF, Rashid NAA, Koay LL et al (2011) Identification and optimization of novel NAR-1 bacterial consortium for the biodegradation of orange II. Insight Biotechnol 1:7–16

Chan GF, Rashid NAA, Chua LS et al (2012) Communal microaerophilic-aerobic biodegradation of Amaranth by novel NAR-2 bacterial consortium. Bioresour Technol 105:48–59

Chang JS, Kuo TS (2000) Kinetics of bacterial decolorization of azo dye with Escherichia coli NO3. Bioresour Technol 75:107–111

Cheriaa J, Khaireddine M, Rouabhia M et al (2012) Removal of triphenylmethane dyes by bacterial consortium. Sci World J 2012:512454

Chitra MJ, Das A, Goel M et al (2013) Microalgae application for treatment of textile effluents. Res J Pharm Biol Chem Sci 4:1602–1606

Cosio C, Martinoia E, Keller C (2004) Hyperaccumulation of cadmium and zinc in Thlaspi caerulescens and Arabidopsis halleri at the leaf cellular level. Plant Physiol 134:716–725

Couto SR, Rivela I, Munoz MR et al (2000) Stimulation of lignolytic enzyme production and the ability to decolorize Poly R-448 in semisolid-state cultures of Phanerochaete chrysosporium. Bioresour Technol 74:159–164

Das A, Mishra S, Verma VK (2015) Enhanced biodecolorization of textile dye remazol navy blue using an isolated bacterial strain Bacillus pumilus HKG212 under improved culture conditions. J Biochem Technol 6:962–969

de-Bashan LE, Hernandez JP, Nelson KN et al (2010) Growth of quailbush in acidic, metalliferous desert mine tailings: effect of Azospirillum brasilense Sp6 on biomass production and rhizosphere community structure. Microb Ecol 60:915–927

Deng D, Guo J, Zeng G et al (2008) Decolorization of anthraquinone, triphenylmethane and azo dyes by a new isolated Bacillus cereus strain DC11. Int Biodeterior Biodegrad 62(3):263–269

Deram A, Patit D, Robinson B et al (2000) Natural and induced heavy metal accumulation by Arrhenatherum elatius: implications for phytoremediation. Commun Soil Sci Plant Anal 31:413–421

Dos Santos AB, Bisschops IAE, Cervantes FJ (2006) Closing process water cycles and product recovery in textile industry: perspective for biological treatment. In: Cervantes FJ, Van Haandel AC, Pavlostathis SG (eds) Advanced biological treatment processes for industrial wastewaters, vol 1. International Water Association, London, pp 298–320

El-Kassas HY, Mohamed LA (2014) Bioremediation of the textile waste effluent by Chlorella vulgaris. Egypt J Aquat Res 40:301–308

Enayatizamir N, Tabandeh F, Rodriguez-Couto (2011) Biodegradation pathway and detoxification of the diazo dye Reactive Black 5 by Phanerochaete chrysosporium. Bioresour Technol 102(22):10359–10362

EPA (1997) Profile of the Textile Industry Environmental Protection Agency. EPA, Washington DC

Evangelista-Barreto NS, Albuquerque CD, Vieira RHSF et al (2009) Co-metabolic decolorization of the reactive azo dye Orange II by Geobacillus stearothermophilus UCP 986. Text Res J 79:1266–1273

Feng Y1, Li C, Zhang D (2011) Lipid production of Chlorella vulgaris cultured in artificial wastewater medium. Bioresour Technol 102:101–105