Abstract

The full-scale plant for recovering P from sewage sludge ash (SSA) started operation at a wastewater treatment plant in Gifu City, Japan, in April 2010. P is released from SSA using the alkaline (NaOH) leaching technology and recovered as calcium hydroxyapatite (HAP). The full-scale plant recovers approximately 30–40% Pi from SSA and supplies about 300 t/year of by-product Pi fertilizer, named Gifu-no-daichiⓇ, mainly to local farmers. The Pi fertilizer, Gifu-no-daichiⓇ, is sold through the JA-Zen-Noh (National Federation of Agricultural Cooperative Associations) in Gifu City with a favorable reputation from farmers. Gifu City has been increasing the volume of the fertilizer sales year by year and considers it is critical to make the P recovery process more efficient and stable.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Gifu is a city located in central Japan with a population of about 410,000. In 1934, Gifu started to construct the sewer system for the first time in Japan. The Central wastewater treatment plant (WWTP), which was the first plant implemented in Gifu, began operation in July 1937. Since then, the Gifu’s sewerage system has been serving citizens and protecting the environment (Fig. 9.1). Currently, Gifu also uses the prefectural intercommunity sewerage system, which began operation in April 1991, to cover the city area at the north bank of the Kiso River. Today, 6087 ha and 2669 ha (a total of 8756 ha) of the city area are covered by the city’s own and the intercommunity sewerage system, respectively. The sewer-served population of Gifu City is now 382,090, covering 92.2% of the city’s total population.

Gifu is currently operating four WWTP in the sewerage areas (Fig. 9.1). Following the Central WWTP, the North and South WWTP started to treat wastewater in July 1966 and June 1973, respectively. Finally, the Northwest WWTP commenced operation in February 2004. The city’s four WWTP generate a total of 29,000 t/a of dewatered sludge. The North and South WWTP have a mono-incinerator that is fed solely with dewatered sludge. The Central and Northwest WWTP transport dewatered sludge by road to the North WWTP, where it is incinerated in the mono-incinerator. Since the sewage sludge ash (SSA) of the South WWTP is also transported by road to the North WWTP, a total of 700 t/a of ash piles up at the North WWTP. No biogas production plants have been installed at the WWTP, mainly because of space shortages.

2 Historical Background

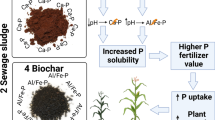

Since the mono-incineration of sewage sludge started in 1975, the cost reduction of ash disposal has been a priority challenge in the management of Gifu’s WWTP. To address this challenge, Gifu City government decided to use SSA for the manufacture of construction bricks at the North WWTP in 1994. Although bricks could be used for surfacing sidewalks and parks in the city area, the demand for bricks gradually declined year after year because of spending cuts for public works. Accordingly, Gifu decided to cease the manufacture of bricks and alternatively to use SSA as a fertilizing material. This was motivated by the price spike of phosphate (Pi) rock in 2008. Meanwhile, Gifu City has adopted bio-P processes to upgrade the activated sludge process at the WWTP to enhance Pi removal from sewage since 1998. The P content of sludge ash has increased up to 20–35% P2O5, which was nearly equivalent to that of low-grade Pi rock.

Gifu City started a collaborative research project with Metawater Co. (formerly Nihon Gaishi Co.) in 2003 to develop a technology for recovering P from SSA (see Chap. 8). Then, the city participated in a 2-year development project, called the LOTUS (Lead to Outstanding Technology for Utilization of Sludge) project, which was supported by the Ministry of Land, Infrastructure, Transport and Tourism (MLITT) in 2004 (Nakagawa 2010). The feasibility study was conducted using a test plant which was installed at the North WWTP in 2005. After MLITT’s project evaluation in 2006, Gifu City acquired a business license endorsed by Japan’s sewerage law in 2007 and applied for legislation of the by-product Pi fertilizer in 2008. The full-scale plant was constructed in the North WWTP with the cost of approximately 0.7 billion Japanese yen (c. 7 million euros) in 2009. Finally the full-scale P recovery plant started operation in April 2010 (Fig. 9.2) (Nakagawa 2011).

3 P Recovery from SSA

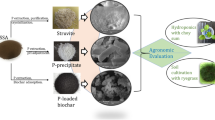

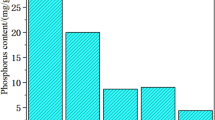

At present, the North WWTP generates approximately 200 t/a of recovered P product (i.e., calcium hydroxyapatite, HAP) using the alkaline leaching technology. Pi is released from SSA using NaOH at 50–70 °C for 1.5 h (Fig. 9.3). The residual heat of the mono-incinerator is used for heating the NaOH solution. After repeating this several times, the leachate is obtained using a membrane-type liquid-solid separator. The alkaline leaching technology was adopted because acid leaching inevitably dissolved heavy metals, thereby contaminating recovered products. After Pi is extracted (mainly from AlPO4) with NaOH, it is precipitated with Ca(OH)2 from the leachate at 20–50 °C for 9 h. The NaOH solution is returned to the head of Pi-leaching reactor for recycling, thereby saving chemical costs. The recovered HAP is washed with water, dewatered, dried, granulated into pellets, and packed in a flexible container bag. The recovered P product is a white powder having no sewage odor and contains 25–30% citrate-soluble P2O5 (Fig. 9.4). The contents of toxic heavy metals such as As and Cd were much lower than their regulatory levels for by-product Pi fertilizer in Japan. The contents of Hg, Ni, Cr, and Pb were even low compared to the strict level for calcined sludge fertilizer. The recovered P product can be used as a slow-release by-product Pi fertilizer or a component for compound fertilizers. It is also possible to use it as a raw material for some industrial applications.

The efficacy and safety of the recovered product as Pi fertilizer were confirmed by plant cultivation tests. The recovered product, which warranted product safety and quality requirements specified by the Fertilizer Regulation Act, was registered as by-product Pi fertilizer by the Ministry of Agriculture, Forestry and Fisheries of Japan in March 2009. The Pi fertilizer is now sold to local farmers under the brand of Gifu-no-daichiⓇ (The land of Gifu). This brand name, which was chosen from among names proposed by the Gifu office, implies that it would be consumed as a locally sourced fertilizer, thereby contributing to P recycling in the land of Gifu. The solid residues that are left after P recovery are subjected to weak-acid cleaning with a dilute H2SO4 solution for 5–30 min at 50–70 °C to remove heavy metals. After drying, they became brown-colored pellets having no sewage odor (Fig. 9.5). Since they meet environmental criteria for soil contamination prevention, they can be used as roadbed materials or a substitute for stone powder in asphalt filler. At present, they are also sold as a soil improver to materials companies.

4 Fertilizer Sales

When the full-scale plant began operation, no channel was available for the sale of Gifu-no-daichiⓇ. To create sales channels, Gifu City has conducted advertising campaigns, including free sample offer, briefing session for farmers, advertisement in a local magazine, and leaflet distribution. As a result, JA-Zen-Noh (National Federation of Agricultural Cooperative Associations) has launched the sales and marketing of Gifu-no-daichiⓇ. Currently, Gifu-no-daichiⓇ is sold in a 20 kg package at the JA branches in Gifu City and enjoys a good reputation from farmers (Fig. 9.6) (Ohta 2014).

Gifu City is currently making efforts to establish stable channels for the distribution and sale of recovered P products. It prioritizes the sales of Gifu-no-daichiⓇ in the Gifu area to locally recycle P from wastewater to farmland. Gifu City began the sale of Gifu-no-daichiⓇ by tons to fertilizer companies in July 2011 and has been increasing the volume of the fertilizer sales year by year. Hereafter, Gifu City gives the priority to making the P recovery from sludge ash more efficient and stable. The P recovery operation has brought some economic benefits to Gifu City, since it reduces the total operating cost compared with the manufacture of construction bricks. However, if compared with ash disposal as industrial waste, the P recovery cost is still high due to the cost of chemicals (mainly NaOH and Ca(OH)2). Further cost reduction is likely required to make P recovery from incinerated sludge ash more economically viable (Ohta 2014).

5 Conclusions

The full-scale plant for recovering P from SSA started operation at the North WWTP in Gifu City in April 2010. P is released from SSA using the alkaline (NaOH) leaching technology and recovered mainly as calcium hydroxyapatite (HAP). The full-scale plant recovers approximately 30–40% Pi from SSA and supplies about 300 t/year of by-product Pi fertilizer, named Gifu-no-daichiⓇ, mainly to local farmers. The Pi fertilizer, Gifu-no-daichiⓇ, is sold through the JA branches in Gifu City with a favorable reputation from farmers. Gifu City is increasing the volume of the fertilizer sales year by year and considers it is critical to make the P recovery process more efficient and stable.

References

Nakagawa H (2010) Phosphorus recovery project in Gifu city. J Civil Eng 51:43–46. (in Japanese)

Nakagawa H (2011) Strategy for recovering phosphorus from sewage sludge ash in Gifu city. J Jap Soc Water Environ 34:16–20. (in Japanese)

Ohta J (2014) Phosphorus recovery from sewage sludge ash. Agric Hortic 89:436–440. (in Japanese)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Nakagawa, H., Ohta, J. (2019). Phosphorus Recovery from Sewage Sludge Ash: A Case Study in Gifu, Japan. In: Ohtake, H., Tsuneda, S. (eds) Phosphorus Recovery and Recycling . Springer, Singapore. https://doi.org/10.1007/978-981-10-8031-9_9

Download citation

DOI: https://doi.org/10.1007/978-981-10-8031-9_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8030-2

Online ISBN: 978-981-10-8031-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)