Abstract

The entomovector technology (Hokkanen and Menzler-Hokkanen 2007; Mommaerts and Smagghe 2011) utilizes insects as vectors of biological control agents for targeted precision biocontrol towards plant pests and diseases, providing an intriguing example of multitrophic interactions. As the insect vector normally is a pollinator of the crop plant, it adds a further dimension to these interactions. The technology depends on bee management, manipulation of bee behaviour, components of the cropping system, and on the plant-pathogen-vector-antagonist-system. We investigate in this chapter how to exploit and support the natural ecological functions of biocontrol and pollination, and enhance these via innovative management. Recent systematic developments of the entomovector technology are described, with focus on the component technologies such as the dispensers and carrier substances (see Mommaerts and Smagghe 2011; Mommaerts et al. 2011; Hokkanen et al. 2012). With functioning dispensers and improved, new microbiological control agents (MCA) available, excellent results have been obtained, and will be described in two case studies. The first involves open field studies conducted in Finland with honey bees (Apis mellifera Linnaeus (Hymenoptera: Apidae)) as the vector of “Prestop-Mix”, containing Gliocladium catenulatum J1446 (Hypocreales, Bionectriaceae), to control Botrytis cinerea Pers.: Fr. (Helotiales: Sclerotiniaceae) in strawberries, and the second describes the efficiency of bumble bees (Bombus terrestris Linnaeus (Hymenoptera: Apidae)) to vector the commercial product “Prestop-Mix” to control B. cinerea in strawberries in the greenhouse.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

5.1 Introduction

The entomovector technology (Hokkanen and Menzler-Hokkanen 2007; Mommaerts and Smagghe 2011) utilizes insects as vectors of biological control agents for targeted precision biocontrol of plant pests and diseases, providing an intriguing example of multitrophic interactions. As the insect vector normally is a pollinator of the crop plant, it adds a further dimension to these interactions. The technology depends on bee management, manipulation of bee behaviour, components of the cropping system, and on the plant-pathogen-vector-antagonist-system. We investigate in this chapter how to exploit and support the natural ecological functions of biocontrol and pollination, and enhance these via innovative management. Recent systematic developments of the entomovector technology are described, with focus on the component technologies such as the dispensers and carrier substances (see Mommaerts and Smagghe 2011; Mommaerts et al. 2011; Hokkanen et al. 2012). With functioning dispensers and improved, new microbiological control agents (MCA) available, excellent results have been obtained, and will be described in two case studies. The first involves open field studies conducted in Finland with honey bees (Apis mellifera Linnaeus (Hymenoptera: Apidae)) as the vector of “Prestop-Mix”, containing Gliocladium catenulatum J1446 (Hypocreales, Bionectriaceae), to control Botrytis cinerea Pers.: Fr. (Helotiales: Sclerotiniaceae) in strawberries, and the second describes the efficiency of bumble bees (Bombus terrestris Linnaeus (Hymenoptera: Apidae)) to vector the commercial product “Prestop-Mix” to control B. cinerea in strawberries in the greenhouse.

In this chapter the key components of the entomovector technology are described in detail. We also give space to the different dispenser types and their capacity to load the insect vector (also called as acquisition), the selection criteria for the carrier materials with respect to MCA stability (Hjeljord et al. 2000), and vector safety (Israel and Boland 1993; Pettis et al. 2004). The acquisition of a powdery MCA product is not only affected by the formulation type, but also by the insect body characteristics and behaviour of the insect and by the dispenser type. The already 20-years of entomovectoring studies resulted in the development of two dispenser types: namely the one-way type and the two-way type. For honey bees it was shown that the use of two-way dispensers resulted in a higher loading of the bees (Bilu et al. 2004). Similarly, Mommaerts et al. (2010) developed a new two-way dispenser for B. terrestris, realizing a 10-fold higher loading of bumble bees compared to earlier dispensers, and also without affecting the foraging intensity of the workers. Important criteria crucial to the success of the entomovector approach are that an optimal dispenser should (a) load the vector with a sufficient amount of the powdery product, (b) not interfere with the foraging behaviour, and that (c) the dispenser should have long refilling intervals (>1 day) (Kevan et al. 2008; Mommaerts and Smagghe 2011).

The choice of the most efficient pollinator species as vector is crucial for maximizing pollination and disease control at the same time. Due to their availability, three pollinators have been used as vectors: honey bees, bumble bees, and mason bees. For instance, Maccagnani et al. (2005, 2006) worked with solitary bees (Osmia cornuta Latreille (Hymenoptera: Megachilidae)) and honey bees in delivering MCA for the control of fire blight, an important apple and pear disease caused by Erwinia amylovora (Burrill) Winslow (Enterobacteriales: Enterobacteriaceae).

The successful control of a disease or pest by the entomovector technology, either in the greenhouse or in the open field, depends on a web of criteria, ranging from the dispenser design, the selection of the vector, and the transport of the control agent, to the safety of the control agent to the environment and humans. The chapter deals with the complex interactions and provides the reader at the end with a future perspective.

5.1.1 Biological Control in Modern Horticulture

The adoption of biological control in horticulture is driven by the lack of suitable chemical pesticide options in many countries, failures in controlling pests and diseases with classic pesticide applications (spray and/or irrigation), as well as by consumer demand for products free of pesticide residues, and by the health risks to workers applying pesticides in enclosed structures such as greenhouses. Additional benefits to growers include that there are no phytotoxic effects on plants associated with biological control, no problems with residues, and no loss of control efficacy due to resistance in the pests with biological control agents (van Lenteren 2008).

Biological control has rapidly become an essential component of modern horticultural production systems. The use of biological control is in many cases attractive both from an environmental and economic perspective (van Lenteren 2008), and consequently, there has been recently a large increase in the uptake of biological control of vegetable pests as well as in the production of ornamental crops in Europe. Most pests and some diseases of greenhouse vegetables can now be controlled with biological control agents (van Lenteren 2008). The most striking development has taken place in Spain, where 20,000 ha of greenhouses are now routinely using biological control (Pilkington et al. 2010). Until 2006 biological control was only used on a small scale in Spain, but by the growing season of 2007–2008 already more than 75% of the 8,000 ha of sweet pepper in Almeria started to implement biological control (Van der Blom et al. 2009). The market size for biological control agents in Almeria is estimated to amount to 30 million Euros, which is more than the total market for the rest of Europe.

Currently more than 150 species of natural enemies are commercially available to growers around the world, which is already much more than the number of active ingredients for insect control by chemical pesticides (van Lenteren 2008). About 80% of the overall commercial value of biological control (excluding Bacillus thuringiensis Berliner (Bacillales: Bacillaceae) (Bt)) has been estimated to be generated by their use in greenhouses (van Lenteren 2008; Pilkington et al. 2010).

In contrast with arthropod control in the greenhouses, which has been the spearhead of commercial biological control, the control of plant diseases with biological antagonists has clearly lagged behind. Plant pathologists have discovered many suitable control agents, but their commercial development has been slow and only relatively few products are available to growers (Christensen 2006; Strømeng 2008). The difficult and expensive registration process required for MCAs is the likely explanation for this situation (Ravensberg 2011).

Biological control on outdoors horticultural crops is far less developed than that in protected crops. Also here the control of insect and mite pests by biological means is much more advanced than the biocontrol of plant diseases. The most widespread current practice in outdoor horticultural crops in Europe is the application of predatory mites against mite pests in vineyards: about 40,000 ha are treated annually (Sigsgaard 2006). Of the European orchard area, some 30,000 ha is applying biological control, with the use of predatory mites for spider mite and rust mite control being the most widespread practice. Biocontrol agents are also released against Lepidopteran and Homopteran pests. On strawberries, phytoseiid predatory mites are applied against spider mites on approximately 20,000 ha annually (Sigsgaard 2006). Biological control of some major diseases of horticultural crops, notably of the grey mould fungus (B. cinerea) on strawberries, has repeatedly been attempted with several antagonistic organisms, but with inconsistent and usually poor results (e.g., Hjeljord et al. 2000; Prokkola and Kivijärvi 2007; Strømeng 2008).

5.1.2 Efficacy of MCAs as Disease and Pest Management Agents

Efficacy of MCAs in controlling pests and diseases in practical pest management is a key component of their commercial success. For any biological control product, however, several conditions must be met at the same time in order for them to be successful (Gelernter and Lomer 2000):

-

(a)

technical efficacy: the product must control the target pest or disease satisfactorily;

-

(b)

practical efficacy: target pest control must be achieved with a high degree of predictability, and the application procedure of the MCA must be simple and should fit into the grower’s other routines;

-

(c)

commercial viability: procedures required to bring the product into the market, and the economics of its production, pricing, and returns to the producer as well as to the grower must be satisfactory, and compare favourably with competing control options;

-

(d)

sustainability: the use of the product must be economically sustainable to all parties, and it should be ecologically sustainable so that it can be applied into the foreseeable future;

-

(e)

provision of public benefit: if the use of a MCA, in addition to meeting the other criteria, also brings along tangible public benefits (such as improvement in the quality of life, improved pollination services, etc.), it will improve the likelihood of success of the product in question.

If the product fails in any of the ‘must’-criteria, it is unlikely to become a truly successful MCA. A large majority of the unsuccessful MCA product leads probably did not meet some of the above criteria, and has resulted in their far lower share than anticipated of pest and disease control markets: it still is not more than about 2%, instead of 10% or 20%, as it was predicted to be (Frost and Sullivan 2001). Indeed, far less than 5% of the initial leads developed at the universities ever result in a commercially viable biopesticide (Törmälä 1995). One simple reason most often cited for the lack of commercial success is the poor and erratic field performance of the tested products.

Encouragingly, however, there are an increasing number of examples of successful MCA. The most important family of products are the Bt-based bioinsecticides, which alone account for over one-half of all MCA sales worldwide. They are widely used against pests in high-value crops such as vegetables and fruits, but also in corn and cotton. For example, over 50% of cabbage, celery, eggplant and raspberry area in the USA are treated annually with Bt. Additionally Bt-based products are very important in forest protection, accounting for about 25% of total insecticide use in forest systems, and in mosquito control for example in Italy, France and Germany.

Over the past two decades a large number of fungal MCA have been registered for insect control, including at least five species in Europe and four in North-America, and several more fungal products for plant disease and nematode control. Among the dozens of insect virus-based MCA, worldwide, the most successful and striking example is the NPV of the velvetbean caterpillar Anticarsia gemmatalis Hübner (Lepidoptera: Noctuidae) on soybean in Brazil (Moscardi 1999). It is currently applied annually over one million hectares every year, and it gives over 80% control of the pest at a lower cost than that for chemical insecticides.

Despite some successes, an important question remains: why has the expected market potential of MCA yet to be realised? To understand this more fully, we need to consider the most important selection criteria of the MCA from the point of view of the grower. These include the:

-

Speed and degree of activity

-

Persistence of activity

-

Selectivity of activity

-

Economic performance

It is clear that a satisfactory control of the target pest or disease must be obtained. The problem for MCAs usually is that their mode of action is different from that of the chemical pesticides: the growers expect to see immediate results (e.g., dead insects after the treatment), which is hardly ever the case with MCAs. From the crop protection point of view, the speed of kill is not usually critical, because infected insects soon stop feeding, but remain on the plant and do not ‘drop dead’. Therefore they do not cause any further damage, but still appear on the plant, causing the grower to lose trust in the efficacy of the product. For MCA-bioinsecticides the Bt-based products and nematodes usually have an adequate speed of kill, while other MCA need more consideration in this respect. Developments on two fronts are needed here: (1) investigations on how to increase the speed of kill, and/or (2) abandoning the chemical pesticide paradigm requiring fast results. Approaches utilised so far to increase the speed of kill include:

-

(i)

selection, and even engineering, of more virulent strains of the MCA (e.g., viruses, nematodes);

-

(ii)

increasing the effective dose (e.g., fungi, whose degree of activity often is dose-dependent);

-

(iii)

combining the MCA with other agents or ‘enhancers’ for a synergistic action; the other agents utilized include low doses of pesticides, oils, optical brighteners, and specific proteins (e.g., ‘enhancin’) (Moscardi 1999).

In an educational process to train the growers to abandon the chemical pesticide paradigm, emphasis should be on the behaviour of the target organisms (e.g., cessation of feeding) as well as on the persistence of activity and long-term impacts. MCAs are all living organisms with their own population dynamics and interaction with the environment, usually providing a long-term control for example via secondary cycling and/or horizontal transfer of the MCA. In addition, the persistence of the MCA can be enhanced via rapidly developing and improved formulation technology, including microencapsulation of Bt-based toxin crystals, using UV-protectants, oils, substrate matrixes, etc. for extended activity of the MCA. There is much scope for improvement in this area, and rapid advances can be expected if adequate research emphasis is focused on these questions.

Cohen et al. (1999) discussed very interestingly the barriers to progress in using biocontrol agents, asking whether these are biological, engineering, economic, or cultural. They pointed out that the biological constraints have largely been solved, or are intensively being studied and can be expected to be solved soon. On the other hand, the engineering bottlenecks (e.g., automated mass-production of MCAs) have received less attention, but are equally important to success. Likely the most important obstacle is the “can’t-do-culture”, which limits the willingness to invest, and even to think along these new lines, even when it is realistic to expect that the biological and engineering bottlenecks can be solved. Many beneficial organisms could already, or in the near future, be produced and sold at a fraction of their current cost, making them very competitive and significant in overall crop protection, in practically any crop. The question still stands: what prevents this from happening?

5.2 Historical Perspective of the Entomovector Technology

The term ‘entomovector technology’ was first used by Hokkanen and Menzler-Hokkanen (2007), and the approach incorporates different ecological components such as pollinators, biocontrol agents and plant pathogens/insect pests (Kevan et al. 2008). However, its success is based on mutual and suited interactions between the appropriate components of vector, control agent, formulation and dispenser, and it needs to be safe for the environment and the human health (Fig. 5.1).

Schematic view of the multifaceted interactions within the entomovector technology. (Adapted from Kevan et al. 2008)

5.2.1 Pollinators as Vector: A Choice Determined by the Vector Species

Within the entomovector technology the selection of the pollinator vector is a crucial step towards success. To date many crops are being pollinated (see for an overview Goulson 2010), but not all used pollinators are classified as ‘good pollinators’. Thus, the main criterion to maximize MCA deposition on the target is to choose a vector which will visit the crop efficiently. Therefore it is important to explore our knowledge on vector-plant interactions, and on the influence of environmental conditions on vector activity.

Until now due to their availability, three pollinator genera have been reported to vector MCAs onto crops: honey bees (A. mellifera), bumble bees (Bombus impatiens Cresson (Hymenoptera: Apidae) and B. terrestris) and the mason bee (O. cornuta). As listed in Table 5.1, the first studies were conducted in orchards with honey bees, and more recently also with the solitary mason bee, while bumble bees disseminated MCAs under both field and greenhouse conditions. This vector choice can be explained by their behaviour: bumble bees tolerate high temperature fluctuations and are bad weather foragers (Guerra-Sanz 2008; Goulson 2010); the mason bee has so far only been used in orchard crops (see for review Bosch and Kemp 2002), and honey bees are less appropriate to pollinate greenhouse long-blooming crops (Cribb and Hand 1993; Guerra-Sanz 2008). But for the latter also the foraging behaviour was shown to be sensitive to weather conditions (temperature, cloudiness and rain) (Goulson 2010), which can affect the capacity of the bees to disseminate the MCA onto flowers (Vanneste 1996; Maccagnani et al. 1999). In addition, upon selection of a vector also their foraging ranges need to be considered, as they need to be able to transport the MCA into the flowers. Honey bees have a larger foraging range (up to 3 km) compared to both the mason bee (100–200 m) and bumble bees (for B. terrestris: 800–1500 m) (Vicens and Bosch 2000; Osborne et al. 2008; Wolf and Moritz 2008).

To transport the MCA into the flowers of the crops, vectors need to become attracted to the flowers. Studies investigating the foraging behaviour of bees identified two factors affecting crop visitation rate: the population levels of other bees in the vicinity (Vanneste 1996), and floral-related cues (innate and learned preferences which include flower size, colour, odour, temperature and reward) (Spaethe et al. 2001; Stout and Goulson 2002; Farina et al. 2007; Raine and Chittka 2007; Rands and Whitney 2008; Whitney et al. 2008; Forrest and Thomson 2009; Lunau et al. 2009; Molet et al. 2009; Gil 2010). Although these factors are difficult to control, several entomovectoring studies assured vector visitation in crops under open field conditions either by spraying a bee-attractant (Bee-Scent®) (Peng et al. 1992), by increasing the colony size up to 50,000 bees/hive (Escande et al. 2002; Shafir et al. 2006), or by using up to four plant cultivars per field plot (Yu and Sutton 1997; Kovach et al. 2000; Escande et al. 2002). In addition, and based on Ngugi et al. (2002), also the timing of vectoring was shown to be crucial and should be started before most of the flowers are open, and thus before the presence of the plant pathogen (Wilson et al. 1992; Johnson et al. 1993a, b; Wilson and Lindow 1993; Alexandrova et al. 2002).

Next to transport also deposition of the MCA on the target organ, such as the stigma of flowers, was found necessary for the successful control of the plant pathogen E. amylovora (Scherm et al. 2004). For the different vector species the successes so far obtained using the entomovectoring technology in connection with the crop considered, are summarized in Table 5.1.

5.2.2 Dissemination of MCAs into Flowers of Target Crops

The next step towards the success of the entomovector technology is to guarantee that vectors acquire a sufficient amount of MCA, which allows optimal transport to the flowers. Most of the commercial powdery MCA formulations are not developed for vectoring and thus need to be improved (see Sect. 5.2.2.2). But next to the formulation of the MCA-based product, acquisition on the vector body is also determined by the dispenser type (see Sect. 5.2.2.1).

5.2.2.1 The Loading Capacity of the Different Dispenser Types So Far Developed

Dispensers must be designed in a way that they are safe for the vector, that they load the vector with a sufficient amount of MCA, and that they have refilling intervals of >1 day. Over the 20-years of entomovectoring studies multiple dispensers have been developed (for review see Mommaerts and Smagghe 2011), representing two basic approaches: one-way dispensers and two-way dispensers (Fig. 5.2). One-way dispensers were shown less suitable, as their use resulted in low MCA acquisition on the vector, affected the foraging behaviour, and demanded a daily refill (Thomson et al. 1992; Johnson et al. 1993a; Dag et al. 2000; Bilu et al. 2004; Maccagnani et al. 2005; Mommaerts et al. 2010). There is one exception: a high loading of >104 CFU per bee, a threshold of efficiency as determined by Bilu et al. (2004), was obtained with the over-and-under one-way dispenser developed for the bumble bee B. impatiens by Yu and Sutton (1997), and its modified version (Kapongo et al. 2008b).

Schematic view of (a) one-way type dispensers where the chamber through which the bees enter or leave the dispenser is the same (or is not completely separated), and (b) two-way dispensers where the chamber (with control agent) through which bees leave the dispenser is separated from the chamber (without control agent) via which they enter the dispenser. (red arrow = outgoing bees, green arrow = incoming bees, and □ = MCA powder formulation)

Using the same over-and-under design but within a two-way dispenser system such as the Tray-, Peng-, Triwaks-, Gross- and Houle-dispenser, multiple authors reported on an increased vector loading of >105 CFU per honey bee and/or obtained good control of the targeted disease/pest (Gross et al. 1994; Jyoto et al. 1999; Kovach et al. 2000; Bilu et al. 2004; Dedej et al. 2004; Albano et al. 2009; Hokkanen et al. 2012). This suggests that the two-way type dispensers, in total six, developed for honey bees are satisfactory, and actually to date one commercial dispenser, namely the “BeeTreat”, is available on the market (Fig. 5.3) (Hokkanen et al. 2012). The latter dispenser type has not been patented, and its specifications are freely available on the internet (www.aasatek.fi).

The commercially available honey bee dispenser, the “Bee-Treat”. (a) Schematic view: 1 the dispenser; 2 detachable steering part, to be inserted into the dispenser; 3 entrance to the dispenser; 4 exit of the dispenser; 5 landing platform for the incoming bees made of transparent plexiglass; 6 entrance corridor for bees to return to the hive (crawl over the solid block 2 to access opening 3). The powder MCA is loaded in an area between 3 and 4. (b) Photograph of a “Bee-Treat” connected to a honey bee hive (Drawings and photo: Heikki Hokkanen)

Other vectors such as bumble bees and the mason bee differ in their behaviour compared to honey bees, and thus require an appropriate two-way dispenser. Nonetheless, reports on the development of two-way dispenser designs are limited to only a few studies. For bumble bees two-way dispensers comprise the overlapping-passageway-dispenser (Maccagnani et al. 2005), the Houle-dispenser (Albano et al. 2009) and the Mommaerts-dispenser (Mommaerts et al. 2010). Next to a satisfactory loading (>104 per bee) only the latter dispenser showed no adverse effects on the foraging activity and refilling intervals of >1 day (Fig. 5.4) (Mommaerts et al. 2010); this system is currently under investigation under large greenhouse conditions. Also, to date one two-way dispenser has been developed for O. cornuta showing a good average load (104–107 CFU/bee) (Maccagnani et al. 2006). Further validation in practice is needed because of observed avoidance behaviour towards the powder immediately after filling of the dispenser.

The two-way Mommaerts-dispenser. (a) Photograph from the front without cover lid, and (b) schematic drawing top view. 1 connection of the exit compartment with the bumble bee hive; 2 exit compartment with a grid at the bottom which contains the powder MCA formulation; 3 exit holes with bumble bee-in-closer; 4 entrance hole; 5 bumblebee-in-closer, connecting the entrance compartment with the bumble bee hive. Dispenser length = 20 cm

5.2.2.2 The Role of Dilutions and Formulations in MCA Acquisition and Transport by the Vector

For transport by bees, MCAs need to be formulated as a powder (Fig. 5.5). In early studies the self-prepared mixtures consisted of MCAs and pollen (Thomson et al. 1992), but thereafter entomovectoring studies added carriers such as flours to MCAs or to commercially available MCA formulations. These carriers increase the acquisition and transport efficacy by reducing loss during flight (Kevan et al. 2008; Mommaerts et al. 2011). However, carriers of MCA formulations must show MCA stability and vector safety. For example the mineral carrier talc adversely affected MCA growth (Hjeljord et al. 2000) and honey bee brood (Pettis et al. 2004), and induced honey bee grooming behaviour due to irritation (Israel and Boland 1993), while flours as carrier decreased grooming by 50% (Kevan et al. 2008). Potential carriers comprise corn flour (Peng et al. 1992; Al-mazra’awi et al. 2006b), bentonite (Kevan et al. 2008), “Maizena-Plus” (corn starch) (Mommaerts et al. 2011), and polystyrene beads (Butt et al. 1998). The latter carrier was too expensive for commercial formulations, compared with flours and meals which are inexpensive, safe and food grade qualified. Unfortunately, 20 years after the first entomovectoring study was conducted there is still inadequate information on the potential of different carriers and their role in vector acquisition. A study by Al-mazra’awi et al. (2007) found a negative correlation between honey bee loading and carrier particle size and moisture content. For example carriers with a particle diameter above 300 μm were not acquired on the honey bee body, while smaller particles in the range of 1–150 μm resulted in a good loading. This confirms the need for future studies.

Acquisition of a powder MCA formulation: (a) Honey bee disseminating “Prestop-Mix” to a strawberry flower (Photo by Heikki Hokkanen). (b) SEM picture showing the presence of conidia and the carrier corn meal of the powder formulation of G. roseum on the femoral setae of a honey bee. (Bar = 70 μm) (Picture adapted from Peng et al. (1992))

5.2.3 The Reliability of Vectored MCAs

Many of the MCAs isolated from soils, leaves or insects have been tested for their control capacity, but only a few have been registered for agricultural use. In the European Union the active substances of microbial pesticides that are included in Directive 91/414/CEE comprise 14 fungicides and 5 insecticides. Regulations require that the MCA formulation is safe for the environment and humans. However, they are not all suitable for use in the entomovector system, and to date only two microbial pesticides are registered for this purpose, namely “Binab-T-vector” that is based on a combination of two antagonistic fungi, Trichoderma atroviride P.Karst (Hypocreales, Hypocreaceae) and Hypocrea parapilulifera B.S.Lu, Druzhin & Samuels (Hypocreales, Hypocreaceae), and “Prestop-Mix” that is a preparation of G. catenultum J1446.

5.2.3.1 MCAs Against Plant Pathogens

Table 5.1 summarizes the different successes already obtained with the entomovector technology for the dissemination of MCAs against several economically important plant pathogens of orchard fruits as apple and pear, strawberry, raspberry, blueberry and sunflowers.

B. cinerea, the grey mould fungus, is a pathogen which is difficult to control because of its high genetic variability and its capacity to grow on every plant part (Mertley et al. 2002; Beever and Weeds 2004; Williamson et al. 2007). Suppression was shown after vectoring with honey bees or bumble bees of three MCAs, namely Clonostachys rosea (Link.: Fr.) Schroers, Samuels, Seifert & Gams (formerly Gliocladium roseum Bainier) (Hypocreales: Bionectriaceae), Trichoderma harzianum T39 and G. catenulatum J1446. In strawberry, the incidence of B. cinerea could be reduced in the stamens from 53% to 35%, in the petals from 18% to 15%, and also in the fruits (Peng et al. 1992; Shafir et al. 2006). Similar results were also shown for covered areas and greenhouses vectoring the same MCAs in raspberries, in strawberries, and in tomato and sweet pepper (Peng et al. 1992; Yu and Sutton 1997; Kapongo et al. 2008a; Mommaerts et al. 2011). To date, all entomovector studies reported a mean deposition of 103–104 CFU per flower, an amount shown by Elad and Freeman (2002) to be sufficient to suppress the plant pathogen B. cinerea. Moreover, based on the obtained results it can be concluded that vectoring by bumble bees suppressed B. cinerea as efficiently as when vectored by honey bees, although the colony size is only 1/60 of that of the honey bees.

Sclerotinia sclerotiorum (Lib.) de Bary (Helotiales: Sclerotiniaceae) on sunflower can not be efficiently controlled chemically because the treatment is not economically feasible. Trichoderma spp. have been recognized as suitable fungal antagonists. The control by Trichoderma spp. was also confirmed when the MCA was disseminated by a high density of honey bees, vectoring into the flowers of sunflowers, which were protected until 31 days after application of the pathogen (Escande et al. 2002).

Monilinia vaccinii-corymbosi (JM Reade) Honey (Helotiales: Sclerotiniaceae), a disease of blueberry, has two infection phases but flowers are only infected in the second phase via the gynoecial pathway (Shinners and Olson 1996; Ngugi et al. 2002). As blueberries are a crop being typically pollinated by honey bees, vectoring studies have also been conducted with this vector. So far only one study evaluated the capacity to control this plant pathogen with the entomovector technology. Dedej et al. (2004) showed that vectoring of Bacillus subtilis (Ehrenberg) Cohn (Bacillales: Bacilaceae) QRD132 significantly suppressed the infection level of this plant pathogen from 21–67% to 7–44%.

E. amylovora, a disease of mainly Rosaceae such as apple, pear and raspberry, infects host plants primarily through nectarthodes in flowers (Oh and Beer 2005). Epiphytic bacteria, such as Erwinia herbicola (Löhnis) Dye and Pseudomonas fluorescens (Trevison) Migula, have been vectored by honey bees in pear and apple orchards (Thomson et al. 1992). Analyses of the flowers showed the capacity of the bees to disseminate the MCA, but cold temperatures reduced the numbers of bacterium per flower, and did not allow to evaluate the biocontrol capacity. The early blooming of orchard crops might pose a problem for entomovector studies using honey bees, because of their sensitivity to bad weather conditions. But next to honey bees also the mason bee is a known orchard pollinator. In one study by Maccagnani et al. (2006) the mason bee was identified as a better vector to disseminate powdery MCA into pear flowers due to a higher CFU per flower (104 versus 104–107) and a higher deposition of CFU/flower up to the 6th consecutively visited flower as compared to honey bees. However, firm conclusions will be drawn in future studies when biocontrol capacity will be investigated.

In conclusion, entomovector studies conclude that the success of plant pathogen control depends on the frequency of the visits by the vector to the crop. Thus when a satisfactory level of the MCA into flowers is realized, a good control level will be achieved. Several authors reported that the suppression capacity was variable, and Shafir et al. (2006) even found a loss of control at high disease pressure. Indeed, bees will visit flower crops while foraging but some will be visited more than others and so a high variability in numbers of CFU per flower (ranging between 0 and 104 CFU/flower) is not unlikely (Thomson et al. 1992; Kovach et al. 2000; Shafir et al. 2006; Albano et al. 2009). It should be noted that there is less loss of viability of the MCA by vectoring, in comparison to a spray application (Yu and Sutton 1997; Kovach et al. 2000). Under optimal conditions these viable spores can colonize the flower giving protection towards infectious diseases (Fig. 5.6).

It is of interest that, in addition to its presence in the flowers, disseminated MCA has also been recovered on the leaves. Kapongo et al. (2008a) showed that 90% of the sampled tomato leaves and 76% of the sampled sweet pepper leaves contained C. rosea, vectored by B. impatiens. Therefore, it is likely that the entomovector technology could be of help in protecting also plant structures other than flowers, and also to control foliar diseases such as powdery mildews.

5.2.3.2 MCAs of Pest Insects

Pollinators (honey bees and bumble bees) have also been shown to be useful in the control of pest insects which feed on, or inhabit, the flowers of oil seed rape, canola, sunflowers, tomato and sweet pepper (Table 5.1). However, to date studies have been conducted in field cages or in small greenhouses, while information on open field is lacking. The first MCA disseminated in this context was Heliothis nuclear polyhedrosis virus (HNPV) which killed 74–87% of the collected Helicoverpa zea Boddy (Lepidoptera: Noctuidae) larvae from crimson clover (Gross et al. 1994). Later successes were also reported for several other entomopathogenic fungi and one bacterium: Metharizium anisopliae (Metchnikoff) Sorokin (Hypocrreales: Clavicipitaceae) against larvae/adults of Meligethes aeneus Fabricius (Coleoptera: Nitidulidae) and Ceuthorhynchus assimilis Dejean (Coleoptera: Curculionidae) (Butt et al. 1998; Carreck et al. 2007); B. thuringiensis var kurstaki against Cochylis hospes (Jyoti and Brewer 1999), and Beauveria bassiana (Balsamo) Vuillemin GHA (Hypocrreales: Cordycipitaceae) against Lygus lineolaris (Palisot de Beauvois) (Hemiptera: Miridae) (Al-mazra’awi et al. 2006a). For the latter MCA also several greenhouse pest populations (thrips, tarnished plant bug, whiteflies and aphids) were controlled when bumble bees of B. impatiens vectored 103–104 CFU of B. bassiana into the flowers (Al-mazra’awi et al. 2006b; Kapongo et al. 2008a, b). Previously B. bassiana and M. anisopliae were often inefficient due to the difficulty of suspending the conidia in water because of their hydrophobic cell walls (Noma and Strickler 2000), and the adverse effects on the viability of the conidia of a spray application (Nilsson and Gripwall 1999) but the entomovector technology opens future perspectives.

As with MCAs against plant diseases, MCAs of pest insects have also been reported on the leaves of vectored crops. For example B. bassiana GHA was recovered at high amounts on the sampled leaves: 92% for tomato, 87–92% for sweet pepper, and 70–82% for canola (Al-mazra’awi et al. 2006a; Kapongo et al. 2008b). It can therefore be concluded, as above for plant pathogens, that the entomovector technology is not limited to targeting insect pests of flowers only.

5.3 The Entomovector Technology as Tool Against an Important Plant Pathogen of Strawberries: Case Studies in Open Field and Greenhouse

This section describes an innovative approach to solve one of the most difficult disease problems in strawberry production. The EU is the biggest producer of strawberries in the world, and of the single member countries, Spain is the number two producer after the USA. Turkey is the third most important strawberry producer in the world. In total, the strawberry area in the EU was 111,801 ha in 2008 (FAO 2011). In terms of economic importance, strawberry is in Finland the 12th most valuable agricultural commodity (after a long list of top-ranking animal-based products such as meat, milk, eggs, etc.), and ranks similarly among top-20 agricultural commodities in countries like Germany (15th), Estonia (15th), and Belgium (16th) (FAO 2011). Besides, organic strawberry growing has rapidly expanded in Europe, but organic berry and fruit production suffers heavily from the lack of effective disease and pest management tools, and occasionally from inadequate insect pollination. As a consequence, the expanding demand on organic berries cannot be filled today.

Grey mould (B. cinerea) is the most important biotic threat to strawberry growing, and conventional growing uses more fungicides on strawberry than on any other crop, usually 3–8 treatments per season. The industry is concerned about the slow progress in the development of biological control methods (biofungicides) against Botrytis (AAFC 2009), as the chemical fungicides rapidly lose their ability to control the disease. Currently organic strawberry growers have no means of preventing grey mould on their crop, and consequently, they occasionally lose the harvest almost entirely. Conventional growers suffer 10–20% pre-harvest crop losses to grey mould on the average (Strømeng 2008), even up to 25–35% (IPMCenters 2011) despite the numerous fungicide treatments.

The entomovector approach represents the only significant breakthrough in sight for providing control of this problem disease, to improve the pollination of strawberry crops, and to significantly improve the yield and quality of berry production and thus, farm economics. The entomovector technology contributes to improved resource use and efficiency in production, and enhances local biodiversity unlike most other plant protection systems.

5.3.1 Open Field Studies Conducted in Finland with Honey Bees of Apis mellifera as Vector of “Prestop-Mix”, Containing G. catenulatum J1446, to Control B. cinerea in Strawberries

Comprehensive on-farm research has been carried out in Finland on the use of honey bee-disseminated, targeted biocontrol of the grey mould B. cinerea, with the antagonistic MCA G. catenulatum J1446. Research started in 2006 with three commercial farms (one of them organic) in the northern Savo region of the country, and expanded in 2007 to five farms (including two organic farms), on which intensive research and monitoring was carried out. In addition, about 20 commercial strawberry farms participated in extensive trials in different parts of Finland (Fig. 5.7). Intensive research was continued on four farms in the years 2008 and 2009, while some 20 additional farms joined annually in the extensive trials in all parts of the country. Based on the data generated during the first two study years, the method was officially approved in spring 2008 by the Finnish Food Safety Authority to be used for grey mould control by all growers. Two-way dispensers must be used and the recommended rate of the MCA is 400 g/ha (but no restrictions on the dose are set).

In the first preliminary field trials in 2005, some of the available dispenser types were tested, but they proved unreliable or not suitable for practical use under the variable Finnish weather conditions. We therefore developed our own model, namely the “Bee-Treat” dispenser (Fig. 5.3), which is now commercially produced and the only type available in Finland (also used in Estonia) (www.aasatek.fi).

During the 4 years of the intensive studies we compared : (i) bee-disseminated biocontrol with (ii) standard chemical fungicide treatments, (iii) combined treatments, and with (iv) untreated controls, all on strawberry cultivar’Polka’. The fungicide treatments varied according to the farmer’s practice and the year, but normally included 3–5 spray treatments against the grey mould; in addition, standard other pesticide treatments were carried out as usual (including insecticides and herbicides). The total number of pesticide treatments varied between 3 and 9 per season in the conventionally grown strawberry (no pesticide treatments on the organic farms).

Bee dissemination of the antagonistic MCA was started at the onset of strawberry flowering, and was continued at each site until the end of flowering (about 3 weeks). The powdery MCA product was added in the dispenser by the grower daily in the morning before flight activity of the bees (about 5–10 g product at a time), and in total about 300–500 g of the MCA product was dispensed per ha. On rainy days MCA was added only if there was a clear break in the rain, and the bees were flying out.

Two strong beehives/ha were employed in the dissemination, placed at the edge of the study field (Fig. 5.3). Very light exclusion cages with large mesh size were used to keep bees from entering the control plots, and plots with pesticide treatment only, during the flowering. The cages were removed after flowering, and in a separate assay it was determined that the cages did not have a statistically significant influence on the level of grey mould in the enclosed area.

Four replicates for each treatment were included at each study location (farm). Assessments of grey mould incidence were carried out in 2006 and in 2007 by counting 100 berries (minimum diameter 1 cm) in each replicate, and determining its health status (marketable or mouldy). In 2008 and 2009 all the ripe berries were picked at normal picking time (every 2 days) from 1 m of the strawberry row (marked in the field), divided into two baskets (marketable and mouldy), and weighed. Additionally, in 2007, an assay of storage durability was carried out with berries picked from each treatment.

Technically all the experiments worked out very well. Bees accustomed themselves rapidly to the dispensers, and after 1–2 days exited and entered the hive through the dispenser without hesitation. Bee visits on the strawberry flowers were monitored throughout the flowering season in 2007, and they were found to visit each flower on the average ten times every day, throughout the season, carrying a load of the biocontrol fungus to the flower each time.

Consistently, all control treatments were highly effective regardless the weather conditions during the four study years: overall, bee-vectored biocontrol alone decreased disease incidence on average by 50%, chemical control by 65%, and both methods together by 80%. However, when the marketable yield was measured (instead of disease incidence), biocontrol alone proved to be as effective as, or more effective than the two other methods. Remarkably the detailed results obtained in 2008 do show for chemical control a high degree of disease control, but only marginal increase in marketable yield over untreated control in the absence of enhanced pollination by bees (Fig. 5.8a). In contrast, biocontrol alone provided in 2008 the highest marketable yields, with 90% overall increase over untreated controls. Surprisingly, combining biocontrol with chemical control did not increase the total marketable yield, despite providing superior disease control (Fig. 5.8a).

Overview of the yield of marketable (healthy = red bars) and mouldy berries (= grey bars) per 1 m of strawberry row obtained in case study 1. (a) Comparison of marketable yield from the four different treatments, relative to untreated control (= 100%) [Data from 2008 (4 farms, each with 4 replicates)]. (b) Yields on an organic strawberry farm in 2008, comparing untreated controls (no active disease control, natural pollination), enhanced pollination by honey bees but without active disease control, and enhanced pollination combined with targeted honey bee disseminated biocontrol (Hokkanen et al. 2012)

The pattern displayed by treatments involving chemical fungicide sprays can only be explained by a likely impact of the sprays on the yield potential of the strawberry plants. Based on the total berry yield produced by the strawberry plants (marketable and mouldy berries together), the lowering of the yield potential by the chemical sprays was 17% in the treatments without enhanced pollination (first two columns in Fig. 5.8a), and 18% in the bee pollinated treatments (last two columns in Fig. 5.8a).

A significant part of the yield increases, as shown in Fig. 5.8a, are due to improved pollination of the flowers, inherent in the concept of using bees to vector the MCA. This was clearly demonstrated by the detailed data from an organic farm, where the pollination effect of bees was studied (Fig. 5.8b): marketable berry yield per 1 m of the strawberry row was 610 g in the untreated control, but 965 g when abundant bee pollination was provided (58% yield increase). Adding the grey mould control by C. catenulatum further increased the marketable berry yield to 1,253 g (105% yield increase over the untreated controls).

All grey mould control treatments improved significantly the shelf-life of strawberries, approximately doubling their durability. Combined use of biocontrol and fungicides extended the shelf-life of the berries more than either method alone.

In conclusion, the experiences of dozens of growers in Finland using the bee-disseminated biological control have been very positive (Hokkanen and Menzler-Hokkanen 2007, 2009). The method is technically easy to handle – not a single grower has complained that the system would be difficult to manage. Despite the frequent filling of the dispensers, the amount of work required is far less than for chemical treatments: filling a dispenser takes less than 2 min in the morning. Besides the facts that the use of biocontrol saved time, work and equipment for the growers, its main advantage may be that it saves money: while the costs of chemical control range at about 500–1,000 €/ha, biocontrol cost is only about 300 €/ha.

One berry grower – and beekeeper – who has participated in this research from its very beginning, summarises his experiences after 4 years as follows: “When I started growing strawberries 20 years ago, yield levels were typically about 5,000 kg/ha. After I started to keep bees ten years ago, the yields rose up to about 6,000-9,000 kg/ha. During the past four years, the yields never have been below 10,000 kg/ha”.

5.3.2 The Efficiency of Bumble Bees of Bombus terrestris to Vector the Commercial Product “Prestop-Mix”, Containing G. catenulatum J1446, in Greenhouse Strawberries to Control B. cinerea in Belgium

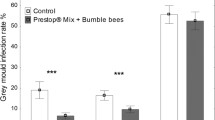

In this series of experiments, we report on the potential of B. terrestris to suppress the plant pathogen, B. cinerea under the controlled conditions of a greenhouse as greenhouse strawberries are currently pollinated by B. terrestris. As depicted in Fig. 5.9, four different treatments were investigated (Mommaerts et al. 2011):

-

T1: “control” = manual infection with B. cinerea and no pollination by bumblebees;

-

T2: “Maizena-Plus” = manual infection with B. cinerea and dissemination of “Maizena-Plus” by bumblebees via the Mommaerts-dispenser;

-

T3: “Prestop-Mix” = manual infection with B. cinerea and dissemination of “Prestop-Mix” by bumblebees via the Mommaerts-dispenser, and

-

T4: “Prestop-Mix + Maizena-Plus” = manual infection with B. cinerea and dissemination of mixture of “Prestop-Mix” and “Maizena-Plus” (1/1, w/w) by bumblebees via the Mommaerts-dispenser.

In these experiments the Mommaerts-dispenser was used as developed and described in Mommaerts et al. (2010) and presented here in Fig. 5.4.

The biocontrol efficacy was determined at two different time points, namely at picking of the red berries (pre-harvest yield), and after 2 days of incubation in the laboratory after picking (post-harvest yield). The strawberry fruits were scored according to a binary system of 0 and 1, where ‘0’ stands for fruits without symptoms of damage, and ‘1’ for infected fruit.

As depicted in Table 5.2, for the pre-harvest yield, yields were higher in the treatments including “Prestop-Mix” as compared to the treatments without MCA. This increase of control was obtained when flowers were inoculated with a mean number of 640 CFU of B. cinerea per flower, resembling a medium disease pressure. Analyses of the flowers confirmed the capacity of manual inoculation B. cinerea to grow on the petals as mycelium was found after 24 h. Also the greenhouse conditions with temperature of 18.5–20.6°C and relative humidity of 88–97% were in the optimal range for growth of the plant pathogen during the entire experimental period.

For the post-harvest yield, the same trend was observed. Strawberries were better protected in T3 and T4 (including “Presop-Mix”) because the numbers of picked berries that remained free of B. cinerea after a 2-day-incubation was higher than in T1 and T2 (without MCA) (Table 5.2).

Finally, when considering the total yield (pre-harvest yield x post-harvest yield), vectoring of “Prestop-Mix + Maizena-Plus” (T4) or “Prestop-Mix” alone (T3) resulted in the highest yield, while the total yield percentages were significantly lower (p < 0.05) for T1 and T2 (Table 5.2).

In conclusion, the total yield in the treatments including biocontrol was 2–2.5 times higher than in the controls. In addition, it is of interest that addition of the carrier “Maizena-Plus” to “Prestop-Mix” at 1:1 (w/w) resulted in a similar yield to that of “Prestop-Mix” used alone. This observation might be interesting for future studies investigating the formulation of MCA products.

Next to the biocontrol efficiency, the present study also confirmed the safety of the MCA for the vector. Over the 4-week blooming period during which bumble bees disseminated “Prestop-Mix”, the amount of worker mortality in T3 and T4 was not higher than in T2. In addition, monitoring of the foraging activity of the bumble bee workers did not show any adverse effects by the MCA.

5.4 Conclusions and Future Perspectives

Biological control in open field is a challenge. In general berry and fruit production currently suffers heavily from the lack of effective disease and pest management tools, as well as from inadequate insect pollination. The present chapter provides evidence that these limitations can be overcome via development of targeted precision biocontrol and pollination enhancement involving honey bees, bumble bees, and solitary bees. Also the case study conducted in open field strawberry farms in Finland confirmed the potential of this technology for specific applications, where classic control methods are not possible. Similar to open field, several research groups have reported promising results on plant pathogen and/or pest control under greenhouse conditions using Bombus bumble bees. Until today, research by several groups on the entomovector context have resulted in advances in:

-

(i)

the development of suitable dispensers;

-

(ii)

exploring the knowledge of pollinator efficiency;

-

(iii)

the identification of potential carriers;

-

(iv)

several commercially available MCAs.

Here it is important to mention that to date the entomovector technology is already recommended and officially approved since spring 2008 by the Finnish Food Safety Authority for practice in open field strawberries in Finland. As future perspective, we expect that the use of the entomovector technology in agriculture and horticulture would benefit from further research on aspects as follows:

-

First, in order to minimize yield loss it is crucial that MCA efficacy can be guaranteed towards growers under diverse environmental conditions. In this context it would be interesting to evaluate combinations of different MCA strains and/or mixtures of MCAs with low risk chemical pesticides. For example, case study 1 indicated a potential for the combined use of “Prestop-Mix” within the entomovector technology and the chemical control strategy currently applied by cultivators in open field strawberry.

-

Second, so far several entomovector studies reported a high loss of the MCA product during vector flight. We are therefore convinced that there is still a need to further fine-tuning of commercial MCA formulations. The final goal of these adaptations would be to optimize MCA product deposition in the flowers to improve control capacity under high disease or pest pressure. So far several potential carriers have been reported, but their usefulness within the entomovector technology will strongly depend on their safety towards the vectors. For example, case study 2 of this chapter demonstrated the efficacy of corn starch (“Maizena-Plus”) when mixed with “Prestop-Mix”, along with its safety towards bumble bees.

-

Third, the entomovector technology has confirmed to control different plant pathogens and pest insects, particularly B. cinerea in strawberries. However, it should be said that this technology can be of use in more and other crops and in the control of more and other diseases and pests. Together with this growing development, we believe it opens the search for new antagonists, and in addition for investigations into depth on antagonist-plant pathogen/pest-plant interactions.

-

Fourth, entomovector studies reported so far only reported on the use of one vector per study to disseminate the MCA product. Here we envisage that to guarantee pollination during the whole day or during the whole blooming season, it might be useful to investigate the efficiency when a combination of two or more vectors species is used. For this selection, information on the behaviour of the pollinator(s) is crucial as well as the guarantee that enough floral resources are present to avoid over-pollination and/or competition.

In summary, the entomovector technology is a “win-win” situation because the use of pollinators does not only lead to improved pollination but also to a reduction of the pest/disease pressure. We hope therefore that further research will contribute to its success and to its implementation in current IPM programs as a sustainable agriculture solution for crop protection.

References

AAFC (2009) Crop profile for strawberry in Canada. Agriculture and Agri-Food Canada. Available at http://dsp-psd.pwgsc.gc.ca/collection_2009/agr/A118-10-17-2005E.pdf. Accessed on 10 Feb 2011

Albano S, Chagon M, de Oliveira D, Houle E, Thibodeau PO, Mexia A (2009) Effectiveness of Apis mellifera and Bombus impatiens as dispensers of the Rootshield® biofungicide (Trichoderma harzianum, strain T-22) in a strawberry crop. Hell Plant Prot J 2:57–66

Alexandrova M, Bazzi C, Lameri P (2002) Bacillus subtilis strain BS-F3: colonisation of pear organs and its action as a biocontrol agent. Acta Hortic 590:291–297

Al-mazra’awi MS, Shipp JL, Broadbent AB, Kevan PG (2006a) Dissemination of Beauveria bassiana by honey bees (Hymenoptera: Apidae) for control tarnished plant bug (Hemiptera: Miridae) on canola. Biol Control 35:1569–1577

Al-mazra’awi MS, Shipp JL, Broadbent AB, Kevan PG (2006b) Biological control of Lygus lineolaris (Hemiptera: Miridae) and Frankiniella occidentalis (Thysanoptera: Thripidae) by Bombus impatiens (Hymenoptera: Apidae) vectored Beauveria bassiana in greenhouse sweet pepper. Biol Control 37:89–97

Al-mazra’awi MS, Kevan PG, Shipp L (2007) Development of Beauveria bassiana dry formulation for vectoring by honey bees Apis mellifera (Hymenoptera: Apidae) to the flowers of crops for pest control. Biocontrol Sci Technol 17:733–741

Beever RE, Weeds PL (2004) Taxonomy and genetic variation of Botrytis and Botryotinia. In: Elad Y, Williamson B, Tudzynski B, Delen N (eds) Botrytis: biology, pathology and control. Kluwer Academic Publishers, Dordrecht/Boston/London, pp 29–52

Bilu A, Dag A, Elad Y, Shafir S (2004) Honey bee dispersal of biocontrol agents: an evaluation of dispensing devices. Biocontrol Sci Technol 14:607–617

Bosch J, Kemp WP (2002) Developing and establishing bee species as crop pollinators: the example of Osmia spp. (Hymenoptera: Megachilidae) and fruit trees. Bull Entomol Res 92:3–16

Butt TM, Carreck NL, Ibrahim L, Williams IH (1998) Honey bee-mediated infection of pollen beetle (Meligethes aeneus Fab.) by the insect-pathogenic fungus, Metarhizium anisopliae. Biocontrol Sci Technol 8:533–538

Carreck NL, Butt TM, Clark SJ, Ibrahim L, Isger EA, Pell JK, Williams IH (2007) Honey bees can disseminate a microbial control agent to more than one inflorescence pest of oilseed rape. Biocontrol Sci Technol 17:179–191

Christensen L (2006) Practical use of biological control of pest and diseases in Danish glasshouses - bottlnecks and challenges. In: Hansen LS, Enkegaard A, Steenberg T, Ravnskov S, Larsen J (eds) Proceedings of the International Workshop “Implementation of Biocontrol in Practice in Temperate Regions - Present and Near Future”. DIAS report Plant Production 119:169–171

Cohen AC, Nordlund DA, Smith RA (1999) Mass rearing of entomophagous insects and predaceous mites: are the bottlenecks biological, engineering, economic, or cultural? Biocontrol News Info 20(3):85N–90N

Cribb DM, Hand DW (1993) A comparative study of the effects of using the honeybee as a pollinating agent of glasshouse tomato. J Hortic Sci 68:79–88

Dag A, Weinbaum SA, Thorp R, Eiskowitch D (2000) Evaluation of pollen dispensers (‘inserts’) effect on fruit set and yield in almond. J Apic Res 39:117–123

Dedej S, Delaplane KS, Scherm H (2004) Effectiveness of honey bees in delivering the biocontrol agent Bacillus subtilis to blueberry flowers to suppress mummy berry disease. Biol Control 31:422–427

Elad Y, Freeman S (2002) Biological control of fungal plant pathogens. In: Kempken F (ed) The Mycota, a comprehensive treatise on fungi as experimental systems for basic and applied research. Springer, Heidelberg

Escande AR, Laich FS, Pedraza MV (2002) Field testing of honeybee-dispersed Trichoderma spp. to manage sunflower head rot (Sclerotinia sclerotiorum). Plant Pathol 51:346–351

FAO (2011) FAOSTAT agricultural production statistics. Available at http://faostat.fao.org/site/567/ and at http://faostat.fao.org/site/339/. Accessed on 10 Feb 2011

Farina WM, Gruter C, Acosta L, Cabe SMC (2007) Honeybees learn floral odors while receiving nectar from foragers within the hive. Naturwissensch 94:55–60

Forrest J, Thomson JD (2009) Background complexity affects colour preference in bumblebees. Naturwissensch 96:921–925

Frost & Sullivan (2001) European biopesticides market. Available at http://www.frost.com. Accessed 15 Apr 2005

Gelernter WD, Lomer CJ (2000) Success in biological control of above-ground insects by pathogens. In: Gurr G, Wratten SD (eds) Biological control: measures of success. Kluwer Academic Publishers, Dordrecht

Gil M (2010) Reward expectations in honeybees. Commun Integr Biol 3:95–100

Goulson D (2010) Bumblebees behaviour, ecology and conservation. Oxford University Press, New York, pp 317

Gross HR, Hamm JJ, Carpenter JE (1994) Design and application of a hive-mounted device that uses honey bees (Hymenoptera: Apidae) to disseminate Heliothis nuclear polyhedrosis virus. Biol Control 23:492–501

Guerra-Sanz JM (2008) Crop pollination in greenhouses. In: James RR, Pitts-Singer T (eds) Bee pollination in agriculture ecosystems. Oxford University Press, New York

Hjeljord LG, Stensvand A, Tronsmo A (2000) Effect of temperature and nutrient stress on the capacity of commercial Trichoderma products to control Botrytis cinerea and Mucor piriformis in greenhouse strawberries. Biol Control 19:149–160

Hokkanen HMT, Menzler-Hokkanen I (2007) Use of honeybees in the biological control of plant diseases. Entomol Res 37(suppl 1):A62–A63

Hokkanen HMT, Menzler-Hokkanen I (2009) Successful use of honey bees for grey mould biocontrol on strawberries and raspberries in Finland. Apidologie 40:659

Hokkanen HMT, Menzler-Hokkanen I, Mustalahti A-M (2012) Honey bees (Apis mellifera) for precision biocontrol of grey mould (Botrytis cinerea) with Gliocladium catenulatum on strawberries and raspberries in Finland. Arthropod-Plant Interactions (submitted)

IPMCenters (2011) Crop profile for strawberries in Louisiana. Available at http://www.ipmcenters.org/cropprofiles/docs/LAstrawberries.pdf. Accessed on 10 Feb 2011

Israel MS, Boland GJ (1993) Influence of formulation on efficacy of honey bees to transmit biological controls for management of Sclerotinia stem rot of canola. Can J Plant Pathol 14:244

Johnson KB, Stockwell VO, Burgett DM, Sugar D, Loper JE (1993a) Dispersal of Erwinia amylovora and Pseudomonas fluorescens by honeybees from hives to apple and pear blossoms. Phytopathology 83:478–484

Johnson KB, Stockwell VO, Mclaughlin RJ (1993b) Effect of antagonistic bacteria on establishment of honey bee-dispersed Erwinia amylovora in pear blossoms and on fire blight control. Phytopathology 83:995–1002

Jyoti JL, Brewer GJ (1999) Honeybees (Hymenoptera: Apidae) as vector of Bacillus thuringiensis for control of branded sunflower moth (Lepidoptera: Tortricidae). Environ Entomol 28:1172–1176

Kapongo JP, Shipp L, Kevan P (2008a) Optimal concentration of Beauveria bassiana vectored by bumble bees in relation to pest and bee mortality in greenhouse tomato and sweet pepper. Biocontrol 53:797–812

Kapongo JP, Shipp L, Kevan P, Sutton JC (2008b) Co-vectoring of Beauveria bassiana and Clonostachys rosea by bumblebees (Bombus impatiens) for control of insect pests and suppression of grey mould in greenhouse tomato and sweet pepper. Biol Control 46:508–514

Kevan PG, Kapongo J-P, Al-mazra’awi M, Shipp L (2008) Honey bees, bumble bees and biocontrol. In: James RR, Pitts-Singer T (eds) Bee pollination in agriculture ecosystems. Oxford University Press, New York

Kovach J, Petzoldt R, Harman GE (2000) Use of honeybees and bumble bees to disseminate Trichoderma harzianum 1295–22 to strawberries for Botrytis control. Biol Control 18:235–242

Lunau K, Unseld K, Wolter F (2009) Visual detection of diminutive floral guides in the bumblebee Bombus terrestris and in the honeybee Apis mellifera. J Comp Physiol 195A:1121–1130

Maccagnani B, Mocioni M, Gullino ML, Ladurner E (1999) Application of Trichoderma harzianum by using Apis mellifera as a vector for the control of grey mold of strawberry: first results. IOBC Bull 22:161–164

Maccagnani B, Mocioni M, Ladurner E, Gullino ML, Maini S (2005) Investigation of hive-mounted devices for the dissemination of microbiological preparations by Bombus terrestris. Bull Insectol 58:3–8

Maccagnani BBC, Biondi E, Tesoriero D, Maini S (2006) Potential of Osmia cornuta as a carrier of antagonist bacteria in biological control of fire blight: a comparison with Apis mellifera. Acta Hort (ISHS) 704:379–386

Mertley JC, Mackenzie SJ, Legard DE (2002) Timing of fungicide applications for Botrytis cinerea based on development stage of strawberry flowers and fruit. Plant Dis 86:1019–1024

Molet M, Chittka L, Raine NE (2009) How floral odours are learned inside the bumblebee (Bombus terrestris) nest? Naturwissensch 96:213–219

Mommaerts V, Smagghe G (2011) Entomovectoring in plant protection. Arthropod-Plant Interact 5:81–95

Mommaerts V, Put K, Vandeven J, Jans K, Sterk G, Hoffmann L, Smagghe G (2010) Development of a new dispenser for bumblebees and evaluation to disseminate microbiological control agents in strawberry in the greenhouse. Pest Manag Sci 66:1199–1207

Mommaerts V, Kurt P, Smagghe G (2011) Bombus terrestris as pollinator-and-vector to suppress Botrytis cinerea in greenhouse strawberry. Pest Manag Sci 67:1069–1075

Moscardi F (1999) Assessment of the application of baculoviruses for control of Lepidoptera. Annu Rev Entomol 44:257–289

Ngugi HK, Scherm H, Lehman JS (2002) Relationship between blueberry flower age, pollination and conidal infection by Monilinia vaccinii-corymbosi. Ecol Popul Biol 92:1104–1109

Nilsson U, Gripwall E (1999) Influence of application technique on the viability of the biological control agents Verticillium lecanii and Stenernema feltiae. Crop Prot 18:53–59

Noma T, Strickler K (2000) Effects of Beauveria bassiana on Lygus hesperus (Hemiptera: Miridae) feeding and oviposition. Environ Entomol 29:394–402

Oh CS, Beer SV (2005) Molecular genetics of Erwinia amylovora involved in the development of fire blight. FEMS Microbiol Lett 253:185–192

Osborne JL, Martin AP, Carreck NL, Swain JL, Knight ME, Goulson D, Hale RJ, Sanderson RA (2008) Bumblebee flight distances in relation to the forage landscape. J Anim Ecol 77:401–415

Peng G, Sutton JC, Kevan PG (1992) Effectiveness of honeybees for applying the biocontrol agent Gliocladium rosea to strawberry flowers to suppress Botrytis cinerea. Can J Plant Pathol 14:117–129

Pettis JS, Kochansky J, Feldlaufer MF (2004) Larval Apis mellifera L. (Hymenoptera: Apidae) mortality after topical application of antibiotics and dusts. J Econ Entomol 97:171–176

Pilkington LJ, Messelink G, van Lenteren JC, Le Mottee K (2010) Protected biological control – biological pest management in the greenhouse industry. Biol Control 52:216–220

Prokkola S, Kivijärvi P (2007) Effect of biological sprays on the incidence of grey mould, fruit yield and fruit quality in organic strawberry production. Agric Food Sci 16:25–33

Raine NE, Chittka L (2007) The adaptive significance of sensory bias in a foraging context: floral colour preferences in the bumblebee Bombus terrestris. PLoS One 2(6):e556. doi:10.1371/journal.pone.0000556

Rands SA, Whitney HM (2008) Floral temperature and optimal foraging: is heat a feasible floral reward for pollinators? PLoS One 3(4):e2007. doi:10.1371/journal.pone.0002007

Ravensberg W (2011) A roadmap to the successful development and commercialization of microbial pest control products for control of arthropods, vol 10, Progress in biological control. Springer, Zoetermeer, 383 p

Scherm H, Ngugi HK, Savelle AT, Edwards JR (2004) Biological control of infection of blueberry flowers caused by Monilinia vaccinii-corymbosi. Biol Control 29:199–206

Shafir S, Dag A, Bilu A, Abu-Toamy M, Elad Y (2006) Honeybee dispersal of the biocontrol agent and Trichoderma harzianum T39: effectiveness in suppressing Botrytis cinerea on strawberry under field conditions. Eur J Plant Pathol 116:119–128

Shinners TC, Olson AR (1996) The gynoecial infection pathway of Monilinia vaccinii-corymbosi in lowbush blueberry (Vaccinium angustifolium). Can J Plant Sci 76:493–497

Sigsgaard L (2006) Biological control of arthropod pests in outdoor crops – the new challenge. DIAS report Plant Production 119, pp 153–168

Spaethe J, Tautz J, Chittka L (2001) Visual constraints in foraging bumblebees: flower size and color affect search time and flight behaviour. Proc Natl Acad Sci USA 98:3898–3903

Stout JC, Goulson D (2002) The influence of nectar secretion rates on the responses of bumblebees (Bombus spp.) to previously visited flowers. Behav Ecol Sociobiol 52:239–246

Strømeng GM (2008) Aspects of the biology of Botrytis cinerea in strawberry (Fragaria x ananassa) and alternative methods for disease control. Philosophiae Doctor (PhD) thesis 2008, pp 56

Thomson SV, Hansen DR, Flint KM, Vandenberg JD (1992) Dissemination of bacteria antagonistic to Erwinia amylovora by honey bees. Plant Dis 76:1052–1056

Törmälä T (1995) Economics of biocontrol agents: an industrial view. In: Hokkanen HMT, Lynch JM (eds) Biological control: benefits and risks. Cambridge University Press, Cambridge, pp 277–282

van der Blom J, Robledo A, Torres S, Sánchez JA (2009) Consequences of the wide scale implementation of biological control in greenhouse horticulture in Almeria. Spain. IOBC/WPRS Bull 49:9–13

van Lenteren JC (ed) (2008) Internet book of biological control, 5th edn. IOBC, Wageningen, www.IOBC-Global.org

Vanneste JL (1996) Honey bees and epiphytic bacteria to control fire blight, a bacterial disease of apple and pear. Biocont News Info 17:67N–78N

Vicens N, Bosch J (2000) Pollinating efficacy of Osmia cornuta and Apis mellifera (Hymenoptera: Megachilidae, Apidae) on ‘Red Delicious’ apple. Environ Entomol 29:235–240

Whitney HM, Dyer A, Chittka L, Rands SA, Glover BJ (2008) The interaction of temperature and sucrose concentration on foraging preferences in bumblebees. Naturwissensch 95:845–850

Williamson B, Tudzynski B, Tudzynski P, Van Kan JAL (2007) Botrytis cinerea: the cause of grey mold disease. Mol Plant Pathol 8:561–580

Wilson M, Lindow SE (1993) Interactions between the biological control agent Pseudomonas fluorescens A506 and Erwinia amylovora in pear blossoms. Phytopathology 83:117–123

Wilson M, Epton HAS, Sigee DC (1992) Interactions between Erwinia herbicola and E. amylovora on the stigma of hawthorn blossoms. Phytopathology 82:914–918

Wolf S, Moritz RFA (2008) Foraging distance in Bombus terrestris L. (Hymenoptera: Apidae). Apidologie 39:419–427

Yu H, Sutton JC (1997) Effectiveness of bumblebees and honeybees for delivering inoculum of Gliocladium roseum to raspberry flowers to control Botrytis cinerea. Biol Control 10:113–122

Acknowledgements

The authors acknowledge support for their research by the Fund for Scientific Research-Flanders (FWO-Vlaanderen), the Flemish agency for Innovation by Science and Technology (IWT-Vlaanderen), the Special Research Funds of Ghent University and of VUB, NordForsk grant 70066 (Entomovector technology), NordForsk Project no. 45941 (BICOPOLL-NET), and CORE-Organic II project “BICOPOLL” in an ERA-NET funded by the European Commission’s 7th Framework Program.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media B.V.

About this chapter

Cite this chapter

Smagghe, G., Mommaerts, V., Hokkanen, H., Menzler-Hokkanen, I. (2012). Multitrophic Interactions: The Entomovector Technology. In: Smagghe, G., Diaz, I. (eds) Arthropod-Plant Interactions. Progress in Biological Control, vol 14. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-3873-7_5

Download citation

DOI: https://doi.org/10.1007/978-94-007-3873-7_5

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-3872-0

Online ISBN: 978-94-007-3873-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)